ICGOO在线商城 > TPS62026DRCR

- 型号: TPS62026DRCR

- 制造商: Texas Instruments

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

TPS62026DRCR产品简介:

ICGOO电子元器件商城为您提供TPS62026DRCR由Texas Instruments设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 提供TPS62026DRCR价格参考¥4.75-¥9.64以及Texas InstrumentsTPS62026DRCR封装/规格参数等产品信息。 你可以下载TPS62026DRCR参考资料、Datasheet数据手册功能说明书, 资料中有TPS62026DRCR详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | 集成电路 (IC) |

| 描述 | IC REG BUCK SYNC 3.3V 0.6A 10SON |

| 产品分类 | |

| 品牌 | Texas Instruments |

| 数据手册 | |

| 产品图片 |

|

| 产品型号 | TPS62026DRCR |

| PWM类型 | 电压模式 |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | - |

| 产品目录页面 | |

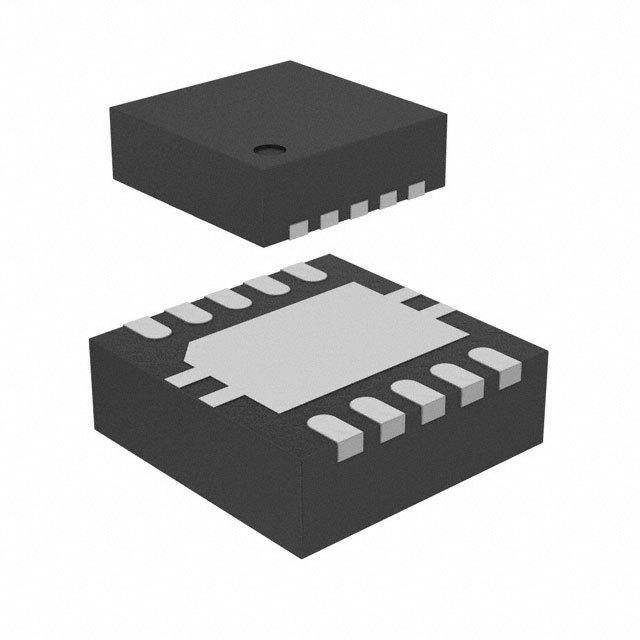

| 供应商器件封装 | 10-SON(3x3) |

| 其它名称 | 296-17694-1 |

| 包装 | 剪切带 (CT) |

| 同步整流器 | 是 |

| 安装类型 | 表面贴装 |

| 封装/外壳 | 10-VFDFN 裸露焊盘 |

| 工作温度 | -40°C ~ 85°C |

| 标准包装 | 1 |

| 电压-输入 | 2.5 V ~ 6 V |

| 电压-输出 | 3.3V |

| 电流-输出 | 600mA |

| 类型 | 降压(降压) |

| 输出数 | 1 |

| 输出类型 | 固定 |

| 频率-开关 | 1.25MHz |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 600 mA/1.25 MHz HIGH-EFFICIENCY STEP-DOWN CONVERTER FEATURES DESCRIPTION • Upto95%ConversionEfficiency The TPS6202x is a high efficiency synchronous • TypicalQuiescentCurrent:18µA step-down dc-dc converter optimized for battery pow- • LoadCurrent:600mA ered portable applications. This device is ideal for portable applications powered by a single Li-Ion • OperatingInputVoltageRange:2.5Vto6.0V battery cell or by 3-cell NiMH/NiCd batteries. With an • SwitchingFrequency:1.25MHz output voltage range from 6.0 V down to 0.7 V, the • AdjustableandFixedOutputVoltage device supports low voltage DSPs and processors in PDAs, pocket PCs, as well as notebooks and • PowerSaveModeOperationatLightload subnotebook computers. The TPS6202x operates at Currents a fixed switching frequency of 1.25 MHz and enters • Active-LowMODEpinonTPS62021 the power save mode operation at light load currents • 100%DutyCycleforLowestDropout to maintain high efficiency over the entire load current range. For low noise applications, the device can be • InternalSoftstart forced into fixed frequency PWM mode by pulling the • DynamicOutputVoltagePositioning MODE pin high. The difference between the • ThermalShutdown TPS6202x and the TPS62021 is the logic level of the MODE pin. The TPS62021 has an active-low MODE • Short-CircuitProtection pin. The TPS6202x supports up to 600-mA load • 10PinMSOPPowerPad™Package current. • 10PinQFN3X3mmPackage APPLICATIONS • PDA,PocketPCandSmartPhones • USBPoweredModems • CPUsandDSPs • PCCardsandNotebooks • xDSLApplications • Standard5-Vto3.3-VConversion Typical Application Circuit (600-mA Output Current) EFFICIENCY vs LOAD CURRENT VI TPS62020 L1 VO 100 2.5 V to 6 V 2 8 10 m H 0.7 V to VI / 600 mA 95 VO = 1.8 V 3 VIN SW 7 90 VI = 2.7 V 10 Cm F3 61 VMEINONDE PGSFNWBD 150 R1 C1 C104 m F % 8805 VI = 3.6 V 4 GND PGND 9 y − 75 VI = 5 V nc 70 cie 65 Mode = Low R2 C2 Effi 60 55 50 ModVeI == 3H.6ig Vh 45 40 0 0.01 0.10 1 10 100 1000 IL − Load Current − mA Pleasebeawarethatanimportantnoticeconcerningavailability,standardwarranty,anduseincriticalapplicationsofTexas Instrumentssemiconductorproductsanddisclaimerstheretoappearsattheendofthisdatasheet. PowerPadisatrademarkofTexasInstruments. PRODUCTIONDATAinformationiscurrentasofpublicationdate. Copyright©2003–2004,TexasInstrumentsIncorporated Products conform to specifications per the terms of the Texas Instruments standard warranty. Production processing does not necessarilyincludetestingofallparameters.

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 These devices have limited built-in ESD protection. The leads should be shorted together or the device placedinconductivefoamduringstorageorhandlingtopreventelectrostaticdamagetotheMOSgates. ORDERINGINFORMATION MODEPIN OUTPUT PACKAGE PACKAGEMARKING T A LOGICLEVEL VOLTAGE MSOP(1) QFN(2) MSOP QFN MODE Adjustable TPS62020DGQ TPS62020DRC BBK BBJ –40(cid:176) Cto85(cid:176) C MODE Adjustable TPS62021DGQ TPS62021DRC ASH ASJ MODE 3.3V TPS62026DGQ TPS62026DRC BKI BKJ (1) TheDGQpackageisavailableintapeandreel.AddRsuffix(DGQR)toorderquantitiesof2500partsperreel. (2) TheDRCpackageisavailableintapeandreel.AddRsuffix(DRCR)toorderquantitiesof3000partsperreel. ABSOLUTE MAXIMUM RATINGS overoperatingfree-airtemperaturerangeunlessotherwisenoted(1) UNITS SupplyvoltageVIN(2) –0.3Vto7V VoltagesonEN,MODE,FB,SW(2) –0.3VtoV +0.3V CC Continuouspowerdissipation SeeDissipationRatingTable Operatingjunctiontemperaturerange –40(cid:176) Cto150(cid:176) C Storagetemperaturerange –65(cid:176) Cto150(cid:176) C Leadtemperature(soldering,10sec) 260(cid:176) C (1) Stressesbeyondthoselistedunderabsolutemaximumratingsmaycausepermanentdamagetothedevice.Thesearestressratings only,andfunctionaloperationofthedeviceattheseoranyotherconditionsbeyondthoseindicatedunderrecommendedoperating conditionsisnotimplied.Exposuretoabsolute-maximum-ratedconditionsforextendedperiodsmayaffectdevicereliability. (2) Allvoltagevaluesarewithrespecttonetworkgroundterminal. PACKAGE DISSIPATION RATINGS T £ 25(cid:176) C T =70(cid:176) C T =85(cid:176) C PACKAGE Rq JA(1) POWAERRATING POWAERRATING POWAERRATING MSOP 60(cid:176) C/W 1.67W 917mW 667mW QFN 48.7(cid:176) C/W 2.05W 1.13W 821mW (1) Thethermalresistance,Rq JAisbasedonasolderedPowerPADusingthermalvias. RECOMMENDED OPERATING CONDITIONS MIN TYP MAX UNIT V Supplyvoltage 2.5 6.0 V I V Outputvoltagerangeforadjustableoutputvoltageversion 0.7 V V O I I Outputcurrent 600 mA O L Inductor(1) 3.3 10 µH C Inputcapacitor(1) 10 µF I CO Outputcapacitor(1) 10 µF T Operatingambienttemperature –40 85 (cid:176) C A T Operatingjunctiontemperature –40 125 (cid:176) C J (1) Refertoapplicationsectionforfurtherinformation 2

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 ELECTRICAL CHARACTERISTICS V =3.6V,V =1.8V,I =600mA,EN=VIN,T =–40(cid:176) Cto85(cid:176) C,typicalvaluesareatT =25(cid:176) C(unlessotherwisenoted)(1) I O O A A PARAMETER TESTCONDITIONS MIN TYP MAX UNIT SUPPLYCURRENT V Inputvoltagerange 2.5 6.0 V I I Operatingquiescentcurrent I =0mA,deviceisnotswitching 18 35 µA (Q) O I Shutdownsupplycurrent EN=GND 0.1 1 µA SD V Under-voltagelockoutthreshold 1.5 2.3 V UVLO ENABLEANDMODE V ENhighlevelinputvoltage 1.4 V EN V ENlowlevelinputvoltage 0.4 V EN I ENinputbiascurrent EN=GNDorVIN 0.01 1.0 µA EN V MODEhighlevelinputvoltage 1.4 V (MODE) V MODElowlevelinputvoltage 0.4 V (MODE) I MODEinputbiascurrent MODE=GNDorVIN 0.01 1.0 µA (MODE) POWERSWITCH P-channelMOSFETon-resistance V =V =3.6V 115 210 mW I GS r DS(ON) P-channelMOSFETon-resistance V =V =2.5V 145 270 mW I GS I P-channelleakagecurrent V =6.0V 1 µA lkg(P) DS N-channelMOSFETon-resistance V =V =3.6V 85 200 mW I GS r DS(ON) N-channelMOSFETon-resistance V =V =2.5V 115 280 mW I GS I N-channelleakagecurrent V =6.0V 1 µA Ikg(N) DS I P-channelcurrentlimit 2.5V<V <6.0V 0.9 1.1 1.3 A L I Thermalshutdown 150 (cid:176) C OSCILLATOR V =0.5V 1 1.25 1.5 MHz FB f Oscillatorfrequency S V =0V 625 kHz FB OUTPUT Adjustableoutput TPS62020, V 0.7 V V O voltagerange TPS62021 IN V Referencevoltage 0.5 V ref TPS62020, V =2.5Vto6.0V;I =0mA 0% 3% I O V Feedbackvoltage TPS62021 V FB Adjustable VI=2.5Vto6.0V;0mA£ IO£ 600mA –3% 3% V =3.6Vto6.0V;I =0mA 0% 3% I O V Fixedoutputvoltage TPS620263.3V V O V =3.6Vto6.0V;0mA£ I £ 600mA –3% 3% I O V =V +0.5V(min2.5V)to6.0V,I =10 Lineregulation(1) I O O 0 %/V mA Loadregulation(1) IO=10mAto600mA 0 %/mA LeakagecurrentintoSWpin V >V ,0V£ V £ V 0.1 1 µA I O SW I I Ikg(SW) ReverseleakagecurrentintopinSW V =open;EN=GND;V =6.0V 0.1 1 µA I SW f Shortcircuitswitchingfrequency V =0V 625 kHz FB (1) Thelineandloadregulationsaredigitallycontrolledtoassureanoutputvoltageaccuracyof– 3%. 3

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 PIN ASSIGNMENTS DGQ PACKAGE DRC PACKAGE (TOP VIEW) (TOP VIEW) EN 1 10 PGND EN 1 10 PGND VIN 2 9 PGND VIN 2 9 PGND VIN 3 8 SW VIN 3 8 SW GND 4 7 SW GND 4 7 SW FB 5 6 MODE FB 5 6 MODE NOTE: The PowerPAD must be connected to GND. TerminalFunctions TERMINAL I/O DESCRIPTION NAME NO. EN 1 I Enable.PullingENtogroundforcesthedeviceintoshutdownmode.PullingENtoV enablesthedevice.EN I shouldnotbeleftfloatingandmustbeterminated. VIN 2,3 I Supplyvoltageinput GND 4 Analogground FB 5 I Feedback.Connectanexternalresistordividertothispin. Ifafixed-output-voltagedeviceisued,connectFBdirectlytotheoutput. MODE 6 I ThedifferencebetweenTPS6202xandTPS62021isthelogicleveloftheMODEpin.TheTPS62021hasan MODE active-lowMODEpin.TheTPS6202xisforcedintofixed-frequencyPWMmodebypullingtheMODEpinhigh. PullingtheMODEpinlowenablesthePowerSaveMode,operatinginPFMmode(Pulsefrequencymodulation) atlightloadcurrent,andinfixedfrequencyPWMatmedimumtoheavyloadcurrents.Incontrast,theTPS62021 isforcedintoPWMmodebypullingtheMODEpinlow. SW 7,8 I/O ThisistheswitchpinoftheconverterandconnectedtothedrainoftheinternalpowerMOSFETs PGND 9,10 Powerground 4

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 FUNCTIONALBLOCKDIAGRAM VIN Current limit Comparator VIN Undervoltage + Lockout Bias supply − Ref EN Soft T + E Start SkipComparator nel SF − Ref n O a M V Vcomp 1.25 MHz MODE P−Ch ower I Oscillator P Comparator S Driver SW Saw Tooth +− R Control Logic ShoLootg−itchru SW Generator Comp High Comp Low Comp Low 2 T E Comp High − LoadComparator annelMOSF Gm Compensation R1 + −Chwer + R2 No P Comp Low − + Comp Low 2 − Vref = 0.5 V MODE GND FB PGND PGND (See Note A) For the Adjustable Version the FB Pin Is Directly Connected to the Gm Amplifier NOTEA: TheTPS6202xhasanactive-highMODEpin.TheTPS62021hasanactive-lowMODEpin. NOTEB: TheresistornetworkR1andR2isonlyintegratedinfixed-outputdevices. 5

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 TYPICAL CHARACTERISTICS TableofGraphs FIGURE h Efficiency vsLoadcurrent 1,2,3 h Efficiency vsInputvoltage 4 I Noloadquiescentcurrent vsInputvoltage 5,6 Q f Switchingfrequency vsInputvoltage 7 s r P-Channelswitchr vsInputvoltage 8 DS(on) DS(on) r N-Channelrectifierswitchr ) vsInputvoltage 9 DS(on) DS(on Loadtransientresponse 10 PWMoperation 11 Powersavemodeoperation 12 Start-up 13 EFFICIENCY EFFICIENCY vs vs LOADCURRENT LOADCURRENT 100 100 VO = 3.3 V VO = 1.8 V 95 95 90 90 VI = 2.7 V 85 VI = 3.6 V 85 Mode = Low VI = 3.6 V 80 80 % VI = 5 V % − 75 Mode = Low − 75 VI = 5 V y y Mode = Low nc 70 nc 70 e e Effici 65 Effici 65 60 60 55 55 VI = 3.6 V 50 50 Mode = High 45 45 40 40 0 0.01 0.10 1 10 100 1000 0 0.01 0.10 1 10 100 1000 IL − Load Current − mA IL − Load Current − mA Figure1. Figure2. 6

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 EFFICIENCY EFFICIENCY vs vs LOADCURRENT INPUTVOLTAGE 100 100 95 VO = 1.5 V VO = 1.8 V Mode = Low 90 95 VI = 2.7 V IL = 250 mA 85 80 VI = 3.6 V 90 % % IL = 500 mA y − 75 VI = 5 V y − enc 70 enc 85 IL = 1 mA Effici 65 Mode = Low Effici 60 80 55 50 75 Mode = High 45 40 70 0 0.01 0.10 1 10 100 1000 2.5 3 3.5 4 4.5 5 5.5 6 IL − Load Current − mA VI − Input Voltage − V Figure3. Figure4. QUIESCENTCURRENT QUIESCENTCURRENT vs vs INPUTVOLTAGE INPUTVOLTAGE 23 7.5 MODE = Low MODE = High 21 TA = 85°C 7 19 6.5 A TA = 25°C mA TA = 25°C mnt − 17 nt − 6 urre 15 TA = −40°C urre 5.5 C C nt nt e 13 e 5 c c e e s s Qui 11 Qui 4.5 9 4 7 3.5 5 3 2.4 2.8 3.2 3.6 4 4.4 4.8 5.2 5.6 6 2.5 3 3.5 4 4.5 5 5.5 6 VI − Input Voltage − V VI − Input Voltage − V Figure5. Figure6. 7

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 SWITCHINGFREQUENCY P-CHANNELr DS(on) vs vs INPUTVOLTAGE INPUTVOLTAGE 1.23 0.180 1.23 TA = 85°C 0.170 − MHz 11..2222 TA = 25°C Wn) − 00..115600 TA = 85°C y o enc 1.21 DS( 0.140 TA = 25°C Frequ 1.21 TA = −40°C nnel r 0.130 witching 11..2200 P−Cha 00..111200 S 1.19 f − 0.100 TA = −40°C 1.19 1.18 0.090 1.18 0.080 2.5 2.9 3.3 3.7 4.1 4.5 4.9 5.3 5.7 6 2.5 2.9 3.3 3.7 4.1 4.5 4.9 5.3 5.7 6 VI − Input Voltage − V VI − Input Voltage − V Figure7. Figure8. N-CHANNELRECTIFIERr DS(on) vs INPUTVOLTAGE LOADTRANSIENTRESPONSE 0.150 VI = 3.6 V, 0.140 VO = 1.8 V, v PWM/PFM Operation Wn) − 0.130 TA = 85°C VOmV/di S(o 0.120 00 D 0.110 TA = 25°C 1 r r e ctifi 0.100 e R el 0.090 n han 0.080 mA C 0 N- 0.070 O60 0.060 TA = −40°C I A to m 0 0.050 5 2.5 2.9 3.3 3.7 4.1 4.5 4.9 5.3 5.7 6 50 m s/div VI − Input Voltage − V Figure9. Figure10. 8

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 PWMOPERATION POWERSAVEMODEOPERATION VI = 3.6 V, VO = 1.8 V v VSW2 V/di VSW5 V/div v di OV/ v V m OV/di 20 V m 0 2 v LmA/div ILmA/di I 0 VI = 3.6 V, 00 50 VO = 1.8 V 5 500 ns/div 2.5 m s/div Figure11. Figure12. START-UP ble div VI = 3.6 V, Ena 2 V/ VIOO = = 5 14.58 mV,A v Odi V V/ 1 v di V/ Im I 0 0 2 200 m s/div Figure13. 9

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 DETAILED DESCRIPTION OPERATION The TPS6202x is a synchronous step-down converter that typically operates at a 1.25-MHz fixed frequency. At moderate to heavy load currents the device operates in pulse-width modulation (PWM), and at light load currents the device enters power-save mode operation using pulse-requency modulation (PFM). When operating in PWM mode, the typical switching frequency is 1.25MHz with a minimum switching frequency of 1 MHz. This makes thedevicesuitableforxDSLapplications,minimizingRF(radiofrequency)interference. During PWM operation the converter uses a unique fast response voltage mode controller scheme with input voltage feed-forward to achieve good line and load regulation allowing the use of small ceramic input and output capacitors. At the beginning of each clock cycle initiated by the clock signal (S) the P-channel MOSFET switch turns on and the inductor current ramps up until the comparator trips and the control logic turns off the switch. The current limit comparator also turns off the switch in case the current limit of the P-channel switch is exceeded. After the dead time preventing current shoot through, the N-channel MOSFET rectifier is turned on and the inductor current ramps down. The next cycle is initiated by the clock signal, again turning off the N-channelrectifierandturningontheP-channelswitch. The Gm amplifier as well as the input voltage determines the rise time of the saw tooth generator, and therefore, any change in input voltage or output voltage directly controls the duty cycle of the converter, giving a very good lineandloadtransientregulation. POWER SAVE MODE OPERATION As the load current decreases, the converter enters power save mode operation. During power save mode the converter operates with reduced switching frequency in PFM mode and with a minimum quiescent current maintaininghighefficiency. The converter monitors the average inductor current and the device enters power save mode when the average inductor current is below the threshold. The transition point between PWM and power save mode is given by the transitioncurrentwiththefollowingequation: V I (cid:1) I transition 18.66(cid:1) (1) During power save mode the output voltage is monitored with the comparator by the threshold's comp low and comp high. As the output voltage falls below the comp low threshold set to typically 0.8% above the nominal output voltage, the P-channel switch turns on. The P-channel switch remains on until the transition current Equation 1 is reached. Then the N-channel switch turns on completing the first cycle. The converter continues to switch with its normal duty cycle determined by the input and output voltage but with half the nominal switching frequency of 625-kHz typ. Thus the output voltage rises and, as soon as the output voltage reaches the comp high threshold of 1.6%, the converter stops switching. Depending on the load current, the converter switches for alongerorshorterperiodoftimeinordertodelivertheenergytotheoutput.Ifthe load current increases and the output voltage can not be maintained with the transition current Equation 1, the converter enters PWM again. See Figure 11 and Figure 12 under the typical graphs section and Figure 14 for power save mode operation. Among other techniques this advanced power save mode method allows high efficiency over the entire load currentrangeandasmalloutputrippleoftypically1%ofthenominaloutputvoltage. Setting the power save mode thresholds to typically 0.8% and 1.6% above the nominal output voltage at light load current results in a dynamic voltage positioning achieving lower absolute voltage drops during heavy load transient changes. This allows the converter to operate with small output capacitors like 10 µF or 22 µF and still having a low absolute voltage drop during heavy load transient. Refer to Figure 14 as well for detailed operation ofthepowersavemode. 10

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 DETAILED DESCRIPTION (continued) PFM Mode at Light Load 1.6% Comp High 0.8% Comp Low VO Comp Low 2 PWM Mode at Medium to Full Load Figure14.PowerSaveModeThresholdsandDynamicVoltagePositioning The converter enters the fixed frequency PWM mode as soon as the output voltage falls below the comp low 2 threshold. DYNAMIC VOLTAGE POSITIONING As described in the power save mode operation sections before and as detailed in Figure 14 the output voltage is typically 0.8% (i.e., 1% on average) above the nominal output voltage at light load currents, as the device is in power save mode. This gives additional headroom for the voltage drop during a load transient from light load to full load. In the other direction during a load transient from full load to light load the voltage overshoot is also minimizedbyturningontheN-Channelrectifierswitchtopulltheoutputvoltageactivelydown. MODE (AUTOMATIC PWM/PFM OPERATION AND FORCED PWM OPERATION) Connecting the MODE pin of the TPS6202x to GND enables the automatic PWM and power save mode operation. The converter operates in fixed frequency PWM mode at moderate to heavy loads and in the PFM modeduringlightloads,maintaininghighefficiencyoverawideloadcurrentrange. Pulling the TPS6202x MODE pin high forces the converter to operate constantly in the PWM mode even at light load currents. The advantage is the converter operates with a fixed switching frequency that allows simple filtering of the switching frequency for noise sensitive applications. In this mode, the efficiency is lower compared to the power save mode during light loads (see Figure 1 to Figure 3). For additional flexibility it is possible to switch from power save mode to forced PWM mode during operation. This allows efficient power management byadjustingtheoperationoftheTPS6202xtothespecificsystemrequirements. ThedifferencebetweentheTPS6202x and the TPS62021 is the logic level of the MODE pin. The TPS62021 has an active-low MODE pin. Pulling the TPS62021 MODE pin high enables the automatic PWM and Power Save Mode. 100% DUTY CYCLE LOW DROPOUT OPERATION The TPS6202x offers a low input to output voltage difference while still maintaining regulation with the use of the 100% duty cycle mode. In this mode, the P-Channel switch is constantly turned on. This is particularly useful in battery powered applications to achieve longest operation time by taking full advantage of the whole battery voltage range. i.e. The minimum input voltage to maintain regulation depends on the load current and output voltageandcanbecalculatedas: (cid:4) (cid:5) VImin(cid:3)VOmax(cid:2)IOmax(cid:1) rDS(on)max(cid:2)RL (2) with: • I =maximumoutputcurrentplusinductorripplecurrent O(max) • r max=maximumP-channelswitcht . DS(on) DS(on) 11

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 DETAILED DESCRIPTION (continued) • R =DCresistanceoftheinductor L • V max=nominaloutputvoltageplusmaximumoutputvoltagetolerance O SOFTSTART The TPS6202x series has an internal softstart circuit that limits the inrush current during start-up. This prevents possible voltage drops of the input voltage in case a battery or a high impedance power source is connected to theinputoftheTPS6202x. The softstart is implemented with a digital circuit increasing the switch current in steps of typically I /8, I /4, LIM LIM I /2 and then the typical switch current limit of 1.1 A as specified in the electrical parameter table. The start-up LIM timemainlydependsontheoutputcapacitorandloadcurrent,seeFigure13. SHORT-CIRCUIT PROTECTION As soon as the output voltage falls below 50% of the nominal output voltage, the converter switching frequency as well as the current limit is reduced to 50% of the nominal value. Since the short-circuit protection is enabled during start up the device does not deliver more than half of its nominal current limit until the output voltage exceeds 50% of the nominal output voltage. This needs to be considered in case a load acting as a current sink isconnectedtotheoutputoftheconverter. THERMAL SHUTDOWN As soon as the junction temperature of typically 150(cid:176) C is exceeded the device goes into thermal shutdown. In this mode, the P-Channel switch and N-Channel rectifier are turned off. The device continues its operation when thejunctiontemperaturefallsbelowtypically150(cid:176) Cagain. ENABLE Pulling the EN low forces the part into shutdown mode, with a shutdown current of typically 0.1 µA. In this mode, the P-Channel switch and N-Channel rectifier are turned off and the whole device is in shut down. If an output voltage is present during shut down, which could be an external voltage source or super cap, the reverse leakage current is specified under electrical parameter table. For proper operation the enable (EN) pin must be terminatedandshouldnotbeleftfloating. PullingENhighstartsupthedevicewiththesoftstartasdescribedunderthesectionSoftstart. UNDERVOLTAGE LOCKOUT The undervoltage lockout circuit prevents device misoperation at low input voltages. It prevents the converter fromturningontheswitchorrectifierMOSFETwithundefinedconditions. 12

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 APPLICATION INFORMATION ADJUSTABLE OUTPUT VOLTAGE VERSION When the adjustable output voltage version TPS6202x is used, the output voltage is set by the external resistor divider.SeeFigure15. Theoutputvoltageiscalculatedas: (cid:4) R1(cid:5) VO(cid:3)0.5V(cid:1) 1(cid:2)R2 (3) withR1+R2£ 1MW andinternalreferencevoltageV typical=0.5V ref R1 + R2 should not be greater than 1 MW because of stability reasons. To keep the operating quiescent current to a minimum, the feedback resistor divider should have high impedance with R1+R2£ 1 MW . Due to this and the low reference voltage of V = 0.5 V, the noise on the feedback pin (FB) needs to be minimized. Using a ref capacitive divider C1 and C2 across the feedback resistors minimizes the noise at the feedback, without degradingthelineorloadtransientperformance. C1andC2shouldbeselectedas: C1(cid:2) 1 2(cid:1)(cid:1)(cid:1)10kHz(cid:1)R1 (4) with: • R1=upperresistorofvoltagedivider • C1=uppercapacitorofvoltagedivider ForC1avalueshouldbechosenthatcomesclosesttothecalculatedresult. C2(cid:2)R1(cid:1)C1 R2 (5) with: • R2=lowerresistorofvoltagedivider • C2=lowercapacitorofvoltagedivider For C2, the selected capacitor value should always be selected larger than the calculated result. For example, in Figure15forC2100pFareselectedforacalculatedresultofC2=88.42pF. If quiescent current is not a key design parameter C1 and C2 can be omitted, and a low impedance feedback divider has to be used with R1 + R2 < 100 kW . This reduces the noise available on the feedback pin (FB) as well but increases the overall quiescent current during operation. The higher the programmed output voltage the lowerthefeedbackimpedancehastobeforbestoperationwhennotusingC1andC2. VI TPS62020 L1 VO 2.5 V to 6 V 2 8 6.2 m H 1.8 V / 600 mA VIN SW 3 7 22 Cm F3 1 VEINN SFWB 5 R1 C1 C224 m F 6 MODE PGND 10 470 kW 33 pF 4 9 GND PGND R2 180 kW C2 100 pF Figure15.AdjustableOutputVoltageVersion Inductor Selection The TPS6202x uses typically a 10-µH output inductor. Larger or smaller inductor values can be used to optimize the performance of the device for specific operation conditions. When changing inductor values, the product of the inductor value times output-capacitor value (L· C) should stay constant. For example, when reducing the 13

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 APPLICATION INFORMATION (continued) inductorvalue,increasetheoutputcapacitoraccordingly.Seethe application circuits in Figure 17, Figure 18, and Figure 19. The selected inductor has to be rated for its dc resistance and saturation current. The dc resistance of the inductance directly influences the efficiency of the converter. Therefore an inductor with the lowest dc resistanceshouldbeselectedforhighestefficiency.FormulaEquation7calculatesthemaximuminductor current under static load conditions. The saturation current of the inductor should be rated higher than the maximum inductor current as calculated with formula Equation 7. This is needed because during heavy load transient the inductorcurrentrisesabovethevaluecalculatedunderEquation7. V O 1– V I (cid:1)I (cid:2)V (cid:1) L O L(cid:1)ƒ (6) (cid:1)I I max(cid:2)I max(cid:1) L L O 2 (7) with: • 7=Switchingfrequency(1.25MHztypical) • L=Inductorvalue • D I =Peak-to-peakinductorripplecurrent L • I max=Maximuminductorcurrent L ThehighestinductorcurrentoccursatmaximumV. I Open core inductors have a soft saturation characteristic and they can usually handle higher inductor currents versus a comparable shielded inductor. A more conservative approach is to select the inductor current rating for the maximum switch current of 1.3 A for the TPS6202x. Keep in mind that core material differs from inductor to inductor, and this impacts efficiency, especially at high switching frequencies. Refer to Table 1 and the typical applicationsandinductorsselection. Table1.InductorSelection INDUCTORVALUE DIMENSIONS COMPONENTSUPPLIER 10µH 6,6mm· 4,75mm· 2,92mm CoilcraftDO1608C-103 10µH 5,0mm· 5,0mm· 3,0mm SumidaCDRH4D28-100 3.3µH 5,0mm· 5,0mm· 2,4mm SumidaCDRH4D223R3 6.8µH 5,8mm· 7,4mm· 1,5mm SumidaCMD5D136R8 Output Capacitor Selection The advanced, fast-response voltage-mode control scheme of the TPS6202x allows the use of small ceramic capacitors with a typical value of 10 µF and 22 µF without having large output voltage under and overshoots during heavy load transients. Ceramic capacitors having low ESR values have the lowest output voltage ripple and are recommended. If required, tantalum capacitors may be used as well. Refer to Table 2 for component selection. If ceramic output capacitors are used, the capacitor RMS ripple current rating always meets the applicationrequirements.JustforcompletenesstheRMSripplecurrentiscalculatedas: V O 1– V I 1 IRMSCout(cid:2)VO(cid:1) L(cid:1)ƒ (cid:1)2(cid:1)(cid:3)3 (8) At nominal load current the device operates in PWM mode and the overall output voltage ripple is the sum of the voltagespikecausedbytheoutputcapacitorESRplusthevoltageripplecausedbycharginganddischargingthe outputcapacitor: 14

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 V O 1– (cid:1)VO(cid:3)VO(cid:1) L(cid:1)VƒI (cid:1)(cid:4)8(cid:1)C1O(cid:1)ƒ(cid:2)ESR(cid:5) (9) Wherethehighestoutputvoltagerippleoccursatthehighestinputvoltage,V. I At light load currents, the device operates in power save mode and the output voltage ripple is independent of the output capacitor value. The output voltage ripple is set by the internal comparator thresholds. The typical outputvoltagerippleis1%ofthenominaloutputvoltage. Input Capacitor Selection Because of the nature of the buck converter having a pulsating input current, a low ESR input capacitor is required for best input voltage filtering and minimizing the interference with other circuits caused by high input voltagespikes.Theinputcapacitorshouldhaveaminimumvalueof10µFfortheTPS6202x.Theinput capacitor canbeincreasedwithoutanylimitforbetterinputvoltagefiltering. Table2.InputandOutputCapacitorSelection CAPACITOR CASESIZE COMPONENTSUPPLIER COMMENTS VALUE TaiyoYudenJMK212BJ106MG Ceramic 10µF 0805 TDKC12012X5ROJ106K Ceramic TaiyoYudenJMK316BJ106KL 10µF 1206 Ceramic TDKC3216X5ROJ106M 22µF 1206 TaiyoYudenJMK316BJ226ML Ceramic 22µF 1210 TaiyoYudenJMK325BJ226MM Ceramic Layout Considerations For all switching power supplies, the layout is an important step in the design especially at high peak currents and switching frequencies. If the layout is not carefully done, the regulator might show stability problems as well as EMI problems. Therefore, use wide and short traces for the main current paths as indicated in bold in Figure 16. These traces should be routed first. The input capacitor should be placed as close as possible to the IC pins as well as the inductor and output capacitor. The feedback resistor network should be routed away from the inductor and switch node to minimize noise and magnetic interference. To further minimize noise from coupling into the feedback network and feedback pin, the ground plane or ground traces should be used for shielding. A common ground plane or a star ground as shown below should be used. This becomes very importantespeciallyathighswitchingfrequenciesof1.25MHz. The Switch Node Must Be Kept as Small as Possible TPS62020 L1 VI 2 8 6.2 m H VO VIN SW 3 7 22 Cm F3 1 VEINN SFWB 5 C222 m F 6 10 MODE PGND 4 9 GND PGND Figure16.LayoutDiagram 15

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 THERMAL INFORMATION One of the most influential components on the thermal performance of a package is board design. In order to take full advantage of the heat dissipating abilities of the PowerPAD™ packages, a board should be used that acts similar to a heat sink and allows for the use of the exposed (and solderable), deep downset pad. For further information please refer to Texas Instruments application note (SLMA002) PowerPAD Thermally Enhanced Package. The PowerPAD™ of the 10-pin MSOP package has an area of 1,52 mm · 1,79 mm (– 0,05 mm) and must be soldered to the PCB to lower the thermal resistance. Thermal vias to the next layer further reduce the thermal resistance. TYPICAL APPLICATIONS Vin TPS62020 L1 Vout 3.6V to 6.0V 3.3uH 3.3V/0.6A 2 VIN SW 8 C3 3 VIN SW 7 C4 C5 10uF 1 EN FB 5 22uF 22uF C1 6 MODE PGND10 R1 22pF 4 9 620k GND PGND R2 C2 110k 150pF Figure17.Li-Ionto3.3VWithImprovedLoadTransientResponse Vin TPS62020 L1 Vout 2.5V to 6.0V 6.8uH 1.8V/0.6A 2 VIN SW 8 C3 3 VIN SW 7 C4 10uF 1 EN FB 5 22uF C1 6 MODE PGND10 R1 22pF 4 9 620k GND PGND R2 C2 240k 68pF Figure18.1.8VOutputUsing6.8µHInductor Vin TPS62020 L1 Vout 2.5V to 6.0V 10uH 1.2V/0.6A 2 VIN SW 8 C3 3 VIN SW 7 C4 10uF 1 EN FB 5 10uF C1 6 MODE PGND10 R1 33pF 4 9 470k GND PGND R2 C2 330k 68pF Figure19.1.2VOutputUsing10µHInductor 16

TPS62020 TPS62021 TPS62026 www.ti.com SLVS076C–JUNE2003–REVISEDDECEMBER2004 Vin TPS62026 L1 Vout 3.6 V to 6 V 2 8 6.8 (cid:1)H 3.3 V/0.6 A VIN SW 3 7 C1 1 VIN SW 5 C2 10 (cid:1)F EN FB 22 (cid:1)F 6 MODE PGND 10 4 9 GND PGND Figure20. TPS62026Fixed3.3VOutputUsing6.8µHinductor Vin TPS62026 L1 Vout 3.6 V to 6 V 10 (cid:1)H 3.3 V / 0.6 A 2 8 VIN SW 3 7 C1 1 VIN SW 5 C2 10 (cid:1)F EN FB 10 (cid:1)F 6 10 MODE PGND 4 9 GND PGND Figure21. TPS62026Fixed3.3VOutputUsing10µHinductor 17

PACKAGE OPTION ADDENDUM www.ti.com 6-Feb-2020 PACKAGING INFORMATION Orderable Device Status Package Type Package Pins Package Eco Plan Lead/Ball Finish MSL Peak Temp Op Temp (°C) Device Marking Samples (1) Drawing Qty (2) (6) (3) (4/5) TPS62020DGQ ACTIVE HVSSOP DGQ 10 80 Green (RoHS NIPDAUAG Level-1-260C-UNLIM -40 to 85 BBK & no Sb/Br) TPS62020DGQR ACTIVE HVSSOP DGQ 10 2500 Green (RoHS NIPDAUAG Level-1-260C-UNLIM -40 to 85 BBK & no Sb/Br) TPS62020DRCR ACTIVE VSON DRC 10 3000 Green (RoHS NIPDAU Level-2-260C-1 YEAR -40 to 85 BBJ & no Sb/Br) TPS62021DRCR ACTIVE VSON DRC 10 3000 Green (RoHS NIPDAU Level-2-260C-1 YEAR -40 to 85 ASJ & no Sb/Br) TPS62021DRCRG4 ACTIVE VSON DRC 10 3000 Green (RoHS NIPDAU Level-2-260C-1 YEAR -40 to 85 ASJ & no Sb/Br) TPS62026DGQ ACTIVE HVSSOP DGQ 10 80 Green (RoHS NIPDAUAG Level-1-260C-UNLIM -40 to 85 BKI & no Sb/Br) TPS62026DGQR ACTIVE HVSSOP DGQ 10 2500 Green (RoHS NIPDAUAG Level-1-260C-UNLIM -40 to 85 BKI & no Sb/Br) TPS62026DRCR ACTIVE VSON DRC 10 3000 Green (RoHS NIPDAU Level-2-260C-1 YEAR -40 to 85 BKJ & no Sb/Br) (1) The marketing status values are defined as follows: ACTIVE: Product device recommended for new designs. LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect. NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design. PREVIEW: Device has been announced but is not in production. Samples may or may not be available. OBSOLETE: TI has discontinued the production of the device. (2) RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may reference these types of products as "Pb-Free". RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption. Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of <=1000ppm threshold. Antimony trioxide based flame retardants must also meet the <=1000ppm threshold requirement. (3) MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature. (4) There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device. Addendum-Page 1

PACKAGE OPTION ADDENDUM www.ti.com 6-Feb-2020 (5) Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation of the previous line and the two combined represent the entire Device Marking for that device. (6) Lead/Ball Finish - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead/Ball Finish values may wrap to two lines if the finish value exceeds the maximum column width. Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release. In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis. Addendum-Page 2

PACKAGE MATERIALS INFORMATION www.ti.com 6-Sep-2019 TAPE AND REEL INFORMATION *Alldimensionsarenominal Device Package Package Pins SPQ Reel Reel A0 B0 K0 P1 W Pin1 Type Drawing Diameter Width (mm) (mm) (mm) (mm) (mm) Quadrant (mm) W1(mm) TPS62020DGQR HVSSOP DGQ 10 2500 330.0 12.4 5.3 3.4 1.4 8.0 12.0 Q1 TPS62020DRCR VSON DRC 10 3000 330.0 12.4 3.3 3.3 1.1 8.0 12.0 Q2 TPS62021DRCR VSON DRC 10 3000 330.0 12.4 3.3 3.3 1.0 8.0 12.0 Q2 TPS62021DRCR VSON DRC 10 3000 330.0 12.4 3.3 3.3 1.1 8.0 12.0 Q2 TPS62026DGQR HVSSOP DGQ 10 2500 330.0 12.4 5.3 3.4 1.4 8.0 12.0 Q1 TPS62026DRCR VSON DRC 10 3000 330.0 12.4 3.3 3.3 1.1 8.0 12.0 Q2 PackMaterials-Page1

PACKAGE MATERIALS INFORMATION www.ti.com 6-Sep-2019 *Alldimensionsarenominal Device PackageType PackageDrawing Pins SPQ Length(mm) Width(mm) Height(mm) TPS62020DGQR HVSSOP DGQ 10 2500 364.0 364.0 27.0 TPS62020DRCR VSON DRC 10 3000 367.0 367.0 35.0 TPS62021DRCR VSON DRC 10 3000 370.0 355.0 55.0 TPS62021DRCR VSON DRC 10 3000 367.0 367.0 35.0 TPS62026DGQR HVSSOP DGQ 10 2500 364.0 364.0 27.0 TPS62026DRCR VSON DRC 10 3000 367.0 367.0 35.0 PackMaterials-Page2

None

None

None

GENERIC PACKAGE VIEW DRC 10 VSON - 1 mm max height PLASTIC SMALL OUTLINE - NO LEAD Images above are just a representation of the package family, actual package may vary. Refer to the product data sheet for package details. 4204102-3/M

PACKAGE OUTLINE DRC0010J VSON - 1 mm max height SCALE 4.000 PLASTIC SMALL OUTLINE - NO LEAD 3.1 B A 2.9 PIN 1 INDEX AREA 3.1 2.9 1.0 C 0.8 SEATING PLANE 0.05 0.00 0.08 C 1.65 0.1 2X (0.5) (0.2) TYP EXPOSED 4X (0.25) THERMAL PAD 5 6 2X 11 SYMM 2 2.4 0.1 10 1 8X 0.5 0.30 10X 0.18 PIN 1 ID SYMM 0.1 C A B (OPTIONAL) 0.5 0.05 C 10X 0.3 4218878/B 07/2018 NOTES: 1. All linear dimensions are in millimeters. Any dimensions in parenthesis are for reference only. Dimensioning and tolerancing per ASME Y14.5M. 2. This drawing is subject to change without notice. 3. The package thermal pad must be soldered to the printed circuit board for optimal thermal and mechanical performance. www.ti.com

EXAMPLE BOARD LAYOUT DRC0010J VSON - 1 mm max height PLASTIC SMALL OUTLINE - NO LEAD (1.65) (0.5) 10X (0.6) 1 10 10X (0.24) 11 SYMM (2.4) (3.4) (0.95) 8X (0.5) 6 5 (R0.05) TYP ( 0.2) VIA TYP (0.25) (0.575) SYMM (2.8) LAND PATTERN EXAMPLE EXPOSED METAL SHOWN SCALE:20X 0.07 MIN 0.07 MAX EXPOSED METAL ALL AROUND ALL AROUND EXPOSED METAL SOLDER MASK METAL METAL UNDER SOLDER MASK OPENING SOLDER MASK OPENING NON SOLDER MASK SOLDER MASK DEFINED DEFINED (PREFERRED) SOLDER MASK DETAILS 4218878/B 07/2018 NOTES: (continued) 4. This package is designed to be soldered to a thermal pad on the board. For more information, see Texas Instruments literature number SLUA271 (www.ti.com/lit/slua271). 5. Vias are optional depending on application, refer to device data sheet. If any vias are implemented, refer to their locations shown on this view. It is recommended that vias under paste be filled, plugged or tented. www.ti.com

EXAMPLE STENCIL DESIGN DRC0010J VSON - 1 mm max height PLASTIC SMALL OUTLINE - NO LEAD 2X (1.5) (0.5) SYMM EXPOSED METAL 11 TYP 10X (0.6) 1 10 (1.53) 10X (0.24) 2X (1.06) SYMM (0.63) 8X (0.5) 6 5 (R0.05) TYP 4X (0.34) 4X (0.25) (2.8) SOLDER PASTE EXAMPLE BASED ON 0.125 mm THICK STENCIL EXPOSED PAD 11: 80% PRINTED SOLDER COVERAGE BY AREA SCALE:25X 4218878/B 07/2018 NOTES: (continued) 6. Laser cutting apertures with trapezoidal walls and rounded corners may offer better paste release. IPC-7525 may have alternate design recommendations. www.ti.com

IMPORTANTNOTICEANDDISCLAIMER TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS. These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources. TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products. Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265 Copyright © 2020, Texas Instruments Incorporated

Datasheet下载

Datasheet下载