ICGOO在线商城 > 传感器,变送器 > 光学传感器 - 环境光,IR,UV 传感器 > TMD27721

- 型号: TMD27721

- 制造商: AUSTRIAMICROSYSTEMS

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

TMD27721产品简介:

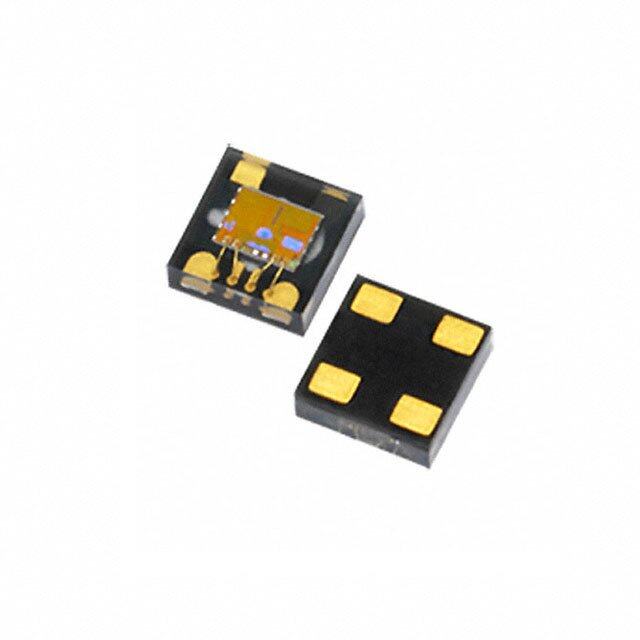

ICGOO电子元器件商城为您提供TMD27721由AUSTRIAMICROSYSTEMS设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 TMD27721价格参考。AUSTRIAMICROSYSTEMSTMD27721封装/规格:光学传感器 - 环境光,IR,UV 传感器, Optical Sensor Ambient 625nm I²C 8-SMD Module。您可以下载TMD27721参考资料、Datasheet数据手册功能说明书,资料中有TMD27721 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | IC PROXIMITY DETECTOR DGTL 8-MOD |

| 产品分类 | |

| 品牌 | AMS-TAOS USA Inc |

| 数据手册 | |

| 产品图片 | |

| 产品型号 | TMD27721 |

| PCN组件/产地 | |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | - |

| 供应商器件封装 | 8-SMD |

| 其它名称 | TMD27721TR |

| 包装 | 带卷 (TR) |

| 安装类型 | 表面贴装 |

| 封装/外壳 | 8-SMD 模块 |

| 工作温度 | -30°C ~ 85°C |

| 带接近传感器 | 是 |

| 标准包装 | 2,500 |

| 波长 | 625nm |

| 电压-电源 | 2.2 V ~ 3.6 V |

| 类型 | 环境 |

| 输出类型 | I²C |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

TMD2772/ TMD2772WA Digital ALS and Proximity Module General Description The TMD2772/TMD2772WA family of devices provides digital ambient light sensing (ALS), a complete proximity detection system, and digital interface logic in a single 8-pin surface mount module. The devices are register-set and pin-compatible with the TMD2771 family of devices and include new and improved ALS and proximity detection features and are available with 25° and 50° fields of view. The ALS enhancements include a reduced-gain mode that extends the operating range in sunlight. Proximity detection includes improved signal-to-noise performance and more accurate factory calibration. A proximity offset register allows compensation for optical system crosstalk between the IR LED and the sensor. To prevent false proximity data measurement readings, a proximity saturation indicator bit signals that the internal analog circuitry has reached saturation. The TMD2772/TMD2772WA ALS is based on the ams patented dual-diode technology that enables accurate results and approximates human eye response to light intensity under a variety of lighting conditions. The proximity detection system includes an LED driver and an IR LED, which are factory trimmed to eliminate the need for end-equipment calibration due to component variations. OrderingInformation and ContentGuide appear at end of datasheet. Key Benefits & Features The benefits and features of TMD2772/TMD2772WA, Digital ALS and Proximity Module are listed below: Figure 1: Added Value of Using TMD2772/TMD2772WA Benefits Features • Ambient light sensing, proximity detection, and IR LED • Minimizes board space requirements in a single module • Ambient light sensing (ALS) • Approximates human eye response over a • Wide variety of programmable features which wide variety of lighting conditions. Achieves enable 8,000,000:1 dynamic range with very high accurate sensing behind spectrally dark glass. sensitivity ams Datasheet Page 1 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − General Description Benefits Features • Eliminates need for customer end-product • Proximity detection calibration. • Calibrated and trimmed to provide consistent • Reduces the proximity noise reading • Control of system crosstalk and offset • Reduced proximity count variation (1) • Prevents false proximity detection in bright • Programmable offset (1) light • Selectable IR power-level without external • Saturation indicator bit (1) resistor • Programmable driver for IR LED • Enables wide operating range • 16,000:1 dynamic range • Maskable ALS and proximity interrupt • Reduces external processor burden • Programmable upper and lower thresholds with persistence filter • Power management • Programmable average power consumption • Enables dynamic power dissipation control • Programmable wait time from 2.7 ms to > 8 seconds • I²C fast mode compatible interface • Data rates up to 400 kbit/s • Industry standard two-wire interface • Input voltage levels compatible with V or 1.8V DD bus • Small foot-print module • 3.94 mm x 2.36 mm x 1.35 mm package • Available with standard 25° (TMD2772) and wide 50° • Optimize ambient light sensing angle (TMD2772WA) Note(s): 1. New or Improved feature. Applications The TMD2772 applications include: • Display Backlight Control • Cell Phone Touch Screen Disable • Mechanical Switch Replacement • Industrial Process Control • Medical Diagnostics • Printer Paper Alignment Page 2 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − General Description Block Diagram The functional blocks of this device are shown below: Figure 2: TMD2772/TMD2772WA Block Diagram LEDA LEDK LDR V DD IR LED Programmable Current Sink CH0 ADC CH0 INT Control CH1 ADC ce SCL a erf CH1 nt C I SDA I² TMD2772/TMD2772WA ams Datasheet Page 3 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Pin Assignment Pin Assignment This is a Package Module - 8 pin diagram. Package drawing is not to scale. Figure 3: Pin Diagram (Top View) TMD2772 TMD2772WA VDD 1 8 SDA VDD 1 8 SDA SCL 2 7 INT SCL 2 7 INT GND 3 6 LDR GND 3 6 LDR LEDA 4 5 LEDK LEDA 4 5 LEDK Figure 4: Pin Description Pin Number Pin Name Pin Type Description 1 V Power Supply voltage. DD I²C serial clock input terminal — clock signal for I²C 2 SCL Input serial data. Power supply ground. All voltages are referenced 3 GND Power to GND. 4 LEDA LED anode. LED cathode. Connect to LDR pin when using 5 LEDK internal LED driver circuit. LED driver input for proximity IR LED, constant 6 LDR current source LED driver. 7 INT Output Interrupt — open drain (active low). 8 SDA Input / Output I²C serial data I/O terminal — serial data I/O for I²C. Page 4 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Absolute Maximum Ratings Absolute Maximum Ratings Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings only. Functional operation of the device at these or any other conditions beyond those indicated under Recommended Operating Conditions is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability. Figure 5: Absolute Maximum Ratings Symbol Parameter Min Max Unit V (1) Supply Voltage 3.8 V DD Voltage on LDR signal with LDR = off. • T between 0° C - 70° C A 4.8 V (2) V LDR • T between -30° C - 70° C 4.6 A 4.4 • T outside of -30° C - 85° C A LED supply voltage on LEDA input • T between 0° C - 70° C A 4.8 V (3) V LEDA • T between -30° C - 70° C 4.6 A 4.4 • T outside of -30° C - 85° C A V Digital I/O Voltage except LDR -0.5 3.8 V IO I Output terminal current except LDR -1 20 mA Out T Storage temperature range -40 85 °C stg T Operating free-air temperature -30 85 °C A Input Current ISCR (latch up immunity) CLASS 1 µA JEDEC JESD78D Nov 2011 Electrostatic Discharge HBM ESD ± 2000 V HBM JS-001-2014 Electrostatic Discharge CDM ESD ± 500 V CDM JEDEC JESD22-C101F Oct 2013 Note(s): 1. All voltages are with respect to GND. 2. Maximum voltage with LDR = off. 3. Maximum 4.8V DC over 7 years lifetime. Maximum 5.0V spikes with up to 250s cumulative duration over 7 years lifetime. Maximum 5.5V spikes with up to 10s (=1000* 10ms) cumulative duration over 7 years lifetime. ams Datasheet Page 5 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Electrical Characteristics Electrical Characteristics All limits are guaranteed. The parameters with min and max values are guaranteed with production tests or SQC (Statistical Quality Control) methods. Figure 6: Recommended Operating Conditions Symbol Parameter Min Typ Max Unit V Supply voltage 2.2 3 3.6 V DD Supply voltage accuracy, V total error DD -3 3 % including transients TA Operating free-air temperature (1) -30 85 °C LED supply voltage on LEDA input VLEDA • TA between 0-70° C 2.5 4.8 V • T outside of 0-70° C 2.5 4.4 A Note(s): 1. While the device is operational across the temperature range, functionality will vary with temperature. Specifications are stated only at 25°C unless otherwise noted. Figure 7: Operating Characteristics V = 3V, T = 25°C (unless otherwise noted) DD A Symbol Parameter Conditions Min Typ Max Units Active — LDR pulse off 195 250 Wait state 90 I Supply current μA DD Sleep state — no I²C 2.2 4 activity 3 mA sink current 0 0.4 INT, SDA output low V V OL voltage 6 mA sink current 0 0.6 Leakage current, SDA, -5 5 μA SCL, INT pins I LEAK Leakage current, LDR pin -5 5 μA TMD27721, TMD27725, 0.7 V TMD27721WA DD SCL, SDA input high V V IH voltage TMD27723, TMD27727, 1.25 TMD27723WA TMD27721, TMD27725, 0.3 V TMD27721WA DD SCL, SDA input low V V IL voltage TMD27723, TMD27727, 0.54 TMD27723WA Page 6 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Electrical Characteristics Figure 8: ADC Characteristics, V = 3V, T = 25°C, AGAIN = 16x, AEN = 1 (unless otherwise noted) DD A Parameter Test Conditions Channel Min Typ Max Unit CH0 0 1 5 E = 0, AGAIN = 120×, Dark ADC count value e counts ATIME = 0xDB (100ms) CH1 0 1 5 ADC Integration time ATIME = 0xFF 2.58 2.73 2.9 ms step size ADC number of 1 256 steps integration steps ADC counts per step ATIME = 0xFF 0 1023 counts ADC count value ATIME = 0xC0 0 65535 counts ams Datasheet Page 7 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Electrical Characteristics Figure 9: ALS Characteristics, V = 3V, T = 25°C, AGAIN = 16x, AEN = 1 (unless otherwise noted) DD A Parameter Test Conditions (1), (2), (3), (4) Channel Min Typ Max Unit CH0 4000 5000 6000 λ = 625 nm, E = 46.8 μW/cm2 counts p e CH1 950 ADC count value TMD2772 (25°) CH0 4000 5000 6000 λ = 850 nm, E = 61.7 μW/cm2 counts p e CH1 2900 CH0 4000 5000 6000 λ = 625 nm, E = 129.5 μW/cm2 counts p e CH1 950 ADC count value TMD2772WA (50°) CH0 4000 5000 6000 λ = 850 nm, E = 181.2 μW/cm2 counts p e CH1 2900 λ = 625 nm 0.152 0.19 0.228 ADC count value p ratio: CH1/CH0 λ = 850 nm 0.43 0.58 0.73 p CH0 107.2 λ = 625 nm p Re Irradiance CH1 20.4 counts responsivity /(μW/ TMD2772 (25°) CH0 81.5 cm2) λ = 850 nm p CH1 47.3 CH0 38.6 λ = 625 nm p Re Irradiance CH1 7.3 counts responsivity /(μW/ TMD2772WA (50°) CH0 27.6 cm2) λ = 850 nm p CH1 16.0 AGAIN = 1× and AGL = 1 0.16 Gain scaling, AGAIN = 8× and AGL = 0 7.2 8.0 8.8 relative to 1× gain x setting AGAIN = 16× and AGL = 0 14.4 16.0 17.6 AGAIN = 120× and AGL = 0 108 120 132 Note(s): 1. Optical measurements are made using small-angle incident radiation from light-emitting diode optical sources. Red 625 nm and infrared 850 nm LEDs are used for final product testing for compatibility with high-volume production. 2. The 625 nm irradiance E is supplied by an AlInGaP light-emitting diode with the following typical characteristics: peak wavelength e λ = 625 nm and spectral halfwidth Δ ½ = 20 nm. p λ 3. The 850 nm irradiance E is supplied by a GaAs light-emitting diode with the following typical characteristics: peak wavelength e λ = 850 nm and spectral halfwidth Δ ½ = 42 nm. p λ 4. Unless otherwise specified, measurements are taken with ATIME= 0xF6 (27 ms). Page 8 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Electrical Characteristics Figure 10: Proximity Characteristics, V = LEDA = 3V, T = 25°C, P = 1 (unless otherwise noted) DD A EN Parameter Test Conditions Min Typ Max Units I Supply current LED On 3 mA DD LED On, PDRIVE = 0 100 LED On, PDRIVE = 1 50 I LEDA current (1) mA LEDA LED On, PDRIVE = 2 25 LED On, PDRIVE = 3 12.5 PTIME ADC conversion steps 1 256 steps PTIME = 0xFF PTIME ADC conversion time 2.58 2.73 2.9 ms (= 1 conversion step) PTIME = 0xFF PTIME ADC counts per step 0 1023 counts (= 1 conversion step) PPULSE LED pulses (2) 0 255 pulses LED On LED pulse width PPULSE = 1, PDRIVE = 0 7.3 μs LED pulse period PPULSE = 2, PDRIVE = 0 16.0 μs Proximity response, no PPULSE = 8, PDRIVE = 0, 100 counts target (offset) PGAIN = 4×, (3) 73 mm × 83 mm, 90% reflective Prox count, 100mm target, Kodak Gray Card, PGAIN = 4×, 450 520 590 counts TMD2772 devices (4) PPULSE = 8, PDRIVE = 0, PTIME = 0xFF (5) 73 mm × 83 mm, 90% reflective Prox count, 100mm target, Kodak Gray Card, PGAIN = 4×, 235 275 315 counts TMD2772WA devices (4) PPULSE = 8, PDRIVE = 0, PTIME = 0xFF (5) Note(s): 1. Value is factory-adjusted to meet the Prox count specification. Considerable variation (relative to the typical value) is possible after adjustment. 2. These parameters are ensured by design and characterization and are not 100% tested. 3. Proximity offset varies with power supply characteristics and noise. 4. ILEDA is factory calibrated to achieve this specification. Offset and crosstalk directly sum with this value and is system dependent. 5. No glass or aperture above the module. Tested value is the average of 5 consecutive readings. 6. Proximity test was done using the circuit shown in Figure 12. See PCB Pad Layout for recommended application circuit. ams Datasheet Page 9 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Electrical Characteristics Figure 11: Proximity Test Circuit Figure 12: IR LED Characteristics, V = 3V, T = 25°C DD A Parameter Test Conditions Min Typ Max Unit V Forward Voltage I = 100 mA 1.5 2.2 V F F V Reverse Voltage I = 10 μA 5 V R R P Radiant Power I = 20 mA 4.5 mW O F λ Peak Wavelength I = 20 mA 850 nm p F Δ Spectral Radiation λ I = 20 mA 40 nm F Bandwidth Figure 13: Wait Characteristics, V = 3V, T = 25°C, WEN = 1 (unless otherwise noted) DD A Parameter Conditions Min Typ Max Units Wait steps 1 256 steps Wait time WTIME = 0xFF (= 1 wait step) 2.73 2.9 ms Page 10 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Timing Characteristics Timing Characteristics Figure 14: AC Electrical Characteristics, V = 3V, T = 25°C (unless otherwise noted) DD A Parameter (1) Conditions Min Max Unit f Clock frequency (I²C only) 0 400 kHz SCL t Bus free time between start and stop condition 1.3 μs BUF Hold time after (repeated) start condition. t 0.6 μs HD;STA After this period, the first clock is generated. t Repeated start condition setup time 0.6 μs SU;STA t Stop condition setup time 0.6 μs SU;STO t Data hold time 10 ns HD;DAT t Data setup time 100 ns SU;DAT t SCL clock low period 1.3 μs LOW t SCL clock high period 0.6 μs HIGH t Clock/data fall time 300 ns F t Clock/data rise time 300 ns R C Input pin capacitance 10 pF i Note(s): 1. Specified by design and characterization; not production tested. Timing Diagrams Figure 15: Parameter Measurement Information tHIGH tR tLOW tF SCL VIH VIL tHD; STA tSU; DAT tHD; DAT tSU; STA tSU; STO tBUF SDA VIH VIL STOP START START STOP ams Datasheet Page 11 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Typical Operating Characteristics Typical Operating Characteristics Figure 16: Spectral Responsivity Figure 17: Normalized I vs. V and Temperature DD DD Page 12 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Typical Operating Characteristics Figure 18: Normalized Responsivity vs. Angular Displacement for Non-WA and WA Devices Both axes for TMD2772 Both axes for TMD2772WA ams Datasheet Page 13 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Typical Operating Characteristics Figure 19: Proximity Response of TMD2772 and TMD2772WA Modules Proximity Response of TMD2772 and TMD2772WA Conditions; PPULSE =8, PDRIVE = 0, PGAIN = 4x 1200 1000 t n u 800 o C y t mi 600 xi TMD2772 o TMD2772WA r P 400 200 0 0 25 50 75 100 125 150 175 Distance in milimeters (Response to 73mm x 83mm, 90% reflective Kodak Gray card) Figure 20: Typical LDR Current vs. Voltage Page 14 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

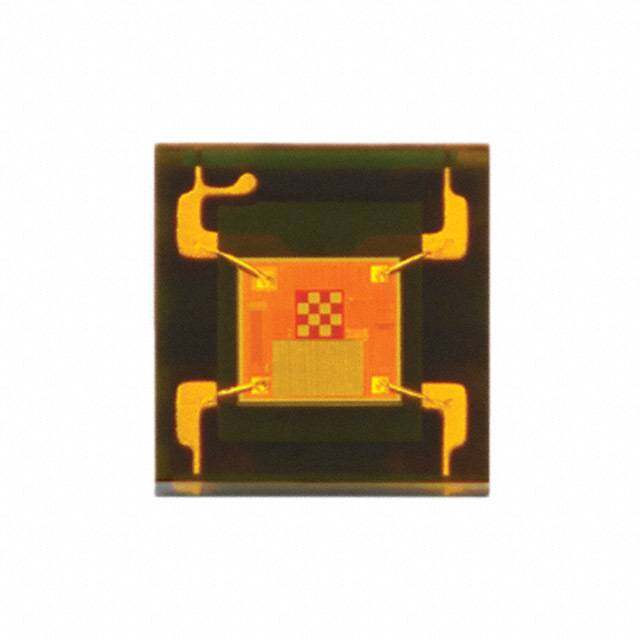

TMD2772/ TMD2772WA − Detailed Description Detailed Description The light-to-digital device provides on-chip photodiodes, integrating amplifiers, ADCs, accumulators, clocks, buffers, comparators, a state machine, and an I²C interface. Each device combines one photodiode (CH0), which is responsive to both visible and infrared light, and a second photodiode (CH1), which is responsive primarily to infrared light. Two integrating ADCs simultaneously convert the amplified photodiode currents to a digital value providing up to 16-bits of resolution. Upon completion of the conversion cycle, the conversion result is transferred to the Ch0 and Ch1 data registers. This digital output can be read by a microprocessor where the luminance (ambient light level in lux) is derived using an empirical formula to approximate the human eye response. Figure 21: Detailed Block Diagram of TMD2772/TMD2772WA LDR V DD IR LED Constant Interrupt INT Current Sink Prox Control Upper Limit Prox Prox ADC Prox Data Integration Lower Limit SCL LEDA Wait Control e Upper Limit ac rf e CH0 ADC CH0 Data nt LEDK C I SDA Lower Limit I² ALC Control Channel 0 CH1 ADC CH1 Data Channel 1 TMD2772 GND A fully integrated proximity detection solution is provided with an 850-nm IR LED, LED driver circuit, and proximity detection engine. An internal LED driver pin (LDR) is externally connected to the LED cathode (LEDK) to provide a controlled LED sink current. This is accomplished with a proprietary current calibration technique that accounts for all variances in silicon, optics, package, and most important, IR LED output power. This eliminates or greatly reduces the need for factory calibration that is required for most discrete proximity sensor solutions. The device is factory calibrated to achieve a proximity count ams Datasheet Page 15 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Detailed Description reading at a specified distance with a specific number of pulses. In use, the number of proximity LED pulses can be programmed from 1 to 255 pulses, which allows different proximity distances to be achieved. Each pulse has a 16 μs period with a 7.2 μs on time. Communication with the device is accomplished through a fast (up to 400 kHz), two-wire I²C serial bus for easy connection to a microcontroller or embedded controller. The digital output of the device is inherently more immune to noise when compared to an analog photodiode interface. The device provides a separate pin for level-style interrupts. When interrupts are enabled and a pre-set value is exceeded, the interrupt pin is asserted and remains asserted until cleared by the controlling firmware. The interrupt feature simplifies and improves system efficiency by eliminating the need to poll a sensor for a light intensity or proximity value. An interrupt is generated when the value of an ALS or proximity conversion exceeds either an upper or lower threshold. In addition, a programmable interrupt persistence feature allows the user to determine how many consecutive exceeded thresholds are necessary to trigger an interrupt. Interrupt thresholds and persistence settings are configured independently for both ALS and proximity. Page 16 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Principles of Operation Principles of Operation System State Machine An internal state machine provides system control of the ALS, proximity detection, and power management features of the device. At power up, an internal power-on-reset initializes the device and puts it in a low-power Sleep state. When a start condition is detected on the I²C bus, the device transitions to the Idle state where it checks the Enable register (0x00) PON bit. If PON is disabled, the device will return to the Sleep state to save power. Otherwise, the device will remain in the Idle state until a proximity or ALS function is enabled. Once enabled, the device will execute the Prox, Wait, and ALS states in sequence as indicated in Figure22. Upon completion and return to Idle, the device will automatically begin a new prox−wait−ALS cycle as long as PON and either PEN or AEN remain enabled. If the Prox or ALS function generates an interrupt and the Sleep-After-Interrupt (SAI) feature is enabled, the device will transition to the Sleep state and remain in a low-power mode until an I²C command is received. See Interrupts for additional information. Figure 22: Simplified State Diagram ams Datasheet Page 17 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Principles of Operation Photodiodes Conventional ALS detectors respond strongly to infrared light, which the human eye does not see. This can lead to significant error when the infrared content of the ambient light is high (such as with incandescent lighting). This problem is overcome through the use of two photodiodes. The Channel 0 photodiode, referred to as the CH0 channel, is sensitive to both visible and infrared light, while the Channel 1 photodiode, referred to as CH1, is sensitive primarily to infrared light. Two integrating ADCs convert the photodiode currents to digital outputs. The ADC digital outputs from the two channels are used in a formula to obtain a value that approximates the human eye response in units of lux. ALS Operation The ALS engine contains ALS gain control (AGAIN) and two integrating analog-to-digital converters (ADC), one for the CH0 and one for the CH1 photodiodes. The ALS integration time (ATIME) impacts both the resolution and the sensitivity of the ALS reading. Integration of both channels occurs simultaneously and upon completion of the conversion cycle, the results are transferred to the data registers (C0DATA and C1DATA). This data is also referred to as channel count. The transfers are double-buffered to ensure data integrity. Figure 23: ALS Operation Page 18 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Principles of Operation The registers for programming the integration and wait times are a 2’s compliment values. The actual time can be calculated as follows: ATIME = 256 − Integration Time / 2.73 ms Inversely, the time can be calculated from the register value as follows: Integration Time = 2.73 ms × (256 − ATIME) In order to reject 50/60 Hz ripple strongly present in fluorescent lighting, the integration time needs to be programmed in multiples of 10 / 8.3 ms or the half cycle time. Both frequencies can be rejected with a programmed value of 50 ms (ATIME = 0xED) or multiples of 50 ms (i.e. 100, 150, 200, 400, 600). The registers for programming the AGAIN hold a two-bit value representing a gain of 1×, 8×, 16×, or 120×. The gain, in terms of amount of gain, will be represented by the value AGAINx, i.e. AGAINx = 1, 8, 16, or 120. With the AGL bit set, the gains will be lowered to 1/6, 8/6, 16/6, and 20×, allowing for up to 60k lux. Lux Equation The lux calculation is a function of CH0 channel count (C0DATA), CH1 channel count (C1DATA), ALS gain (AGAINx), and ALS integration time in milliseconds (ATIME_ms). If an aperture, glass/plastic, or a light pipe attenuates the light equally across the spectrum (300 nm to 1100 nm), then a scaling factor referred to as glass attenuation (GA) can be used to compensate for attenuation. For a device in open air with no aperture or glass/plastic above the device, GA = 1. If it is not spectrally flat, then a custom lux equation with new coefficients should be generated. (See ams application note). Counts per Lux (CPL) needs to be calculated only when ATIME or AGAIN is changed, otherwise it remains a constant. The first segment of the equation (Lux1) covers fluorescent and incandescent light. The second segment (Lux2) covers dimmed incandescent light. The final lux is the maximum of Lux1, Lux2, or 0. Lux formula for TMD2772: CPL = (ATIME_ms × AGAINx) / 20 Lux1 = (C0DATA – (1.75 × C1DATA)) / CPL Lux2 = ((0.63 × C0DATA) – (1.00 × C1DATA)) / CPL Lux = MAX(Lux1, Lux2, 0) Lux formula for TMD2772WA: CPL = (ATIME_ms × AGAINx) / 1.16 Lux1 = (C0DATA - (1.8422 x C1DATA)) / CPL Lux2 = ((0.4106 x C0DATA) - (0.667 x C1DATA)) / CPL Lux = MAX(Lux1, Lux2, 0) ams Datasheet Page 19 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Principles of Operation Proximity Detection Proximity detection is accomplished by measuring the amount of I energy, from the internal IR LED, reflected off an object to R determine its distance. The internal proximity IR LED is driven by the integrated proximity LED current driver as shown in Figure24.The proximity detector will see light reflected from the intended target as well as light reflected through any path. Both surfaces of a transparent cover will reflect some of the IR LEDs energy. An air gap of less the 0.5mm between the top of the module and the cover is recommended. For a detailed explanation of the of the effects of an air gap see ams application note; Application Note DN58: Proximity Detection Behind Glass for a detailed discussion of optical design considerations. Figure 24: Proximity Detection The LED current driver, output on the LDR terminal, provides a regulated current sink that eliminates the need for an external current limiting resistor. The combination of proximity LED drive strength (PDRIVE) and proximity drive level (PDL) determine the drive current. PDRIVE sets the drive current to 100%, 50%, 25%, or 12.5% when PDL is not asserted. However, when PDL is asserted, the drive current is reduced by a factor of 9. Referring to the Detailed State Machine figure, the LED current driver pulses the IR LED as shown in Figure25 during the Prox Accum state. Figure25 also illustrates that the LED On pulse has a fixed width of 7.3μs and period of 16.0μs. So, in addition to setting the proximity drive current, 1 to 255 proximity pulses (PPULSE) can be programmed. When deciding on the number Page 20 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Principles of Operation of proximity pulses, keep in mind that the signal increases proportionally to PPULSE, while noise increases by the square root of PPULSE. Figure 25: Proximity LED Current Driver Waveform Figure24 illustrates light rays emitting from the internal IR LED, reflecting off an object, and being absorbed by the CH0 and CH1 photodiodes. The proximity diode selector (PDIODE) determines which of the two photodiodes is used for a given proximity measurement. Note that neither photodiode is selected when the device first powers up, so PDIODE must be set for proximity detection to work. Referring again to Figure25, the reflected IR LED and the background energy is integrated during the LED On time, then during the LED Off time, the integrated background energy is subtracted from the LED On time energy, leaving the IR LED energy to accumulate from pulse to pulse. The proximity gain (PGAIN) determines the integration rate, which can be programmed to 1×, 2×, 4×, or 8× gain. At power up, PGAIN defaults to 1× gain, which is recommended for most applications. For reference, PGAIN equal to 4× is comparable to the TMD2771’s 1× gain setting. During LED On time integration, the proximity saturation bit in the Status register (0x13) will be set if the integrator saturates. This condition can occur if the proximity gain is set too high for the lighting conditions, such as in the presence of bright sunlight. Once asserted, PSAT will remain set until a special function proximity interrupt clear command is received from the host. See Command Register After the programmed number of proximity pulses have been generated, the proximity ADC converts and scales the proximity measurement to a 16-bit value, then stores the result in two 8-bit proximity data (PDATAx) registers. ADC scaling is controlled by the proximity ADC conversion time (PTIME) which ams Datasheet Page 21 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Principles of Operation is programmable from 1 to 256 2.73ms time units. However, depending on the application, scaling the proximity data will equally scale any accumulated noise. Therefore, in general, it is recommended to leave PTIME at the default value of one 2.73ms ADC conversion time (0xFF). In many practical proximity applications, a number of optical system and environmental conditions can produce an offset in the proximity measurement result. To counter these effects, a proximity offset (POFFSET) is provided which allows the proximity data to be shifted positive or negative. Additional information on the use of the proximity offset feature is provided in available ams application notes. Once the first proximity cycle has completed, the proximity valid (PVALID) bit in the Status register will be set and remain set until the proximity detection function is disabled (PEN). For additional information on using the proximity detection function behind glass and for optical system design guidance, please see available ams application notes. Interrupts The interrupt feature simplifies and improves system efficiency by eliminating the need to poll the sensor for light intensity or proximity values outside of a user-defined range. While the interrupt function is always enabled and its status is available in the status register (0x13), the output of the interrupt state can be enabled using the proximity interrupt enable (PIEN) or ALS interrupt enable (AIEN) fields in the enable register (0x00). Four 16-bit interrupt threshold registers allow the user to set limits below and above a desired light level and proximity range. An interrupt can be generated when the ALS CH0 data (C0DATA) falls outside of the desired light level range, as determined by the values in the ALS interrupt low threshold registers (AILTx) and ALS interrupt high threshold registers (AIHTx). Likewise, an out-of-range proximity interrupt can be generated when the proximity data (PDATA) falls below the proximity interrupt low threshold (PILTx) or exceeds the proximity interrupt high threshold (PIHTx). It is important to note that the thresholds are evaluated in sequence, first the low threshold, then the high threshold. As a result, if the low threshold is set above the high threshold, the high threshold is ignored and only the low threshold is evaluated. To further control when an interrupt occurs, the device provides a persistence filter. The persistence filter allows the user to specify the number of consecutive out-of-range ALS or proximity occurrences before an interrupt is generated. The Interrupt register (0x0C) allows the user to set the ALS persistence filter (APERS) and the proximity persistence filter (PPERS) values. See the Interrupt Register (0x0C) for details on the persistence filter values. Once the persistence filter generates an interrupt, it will continue until a special function interrupt clear command is received. See Command Register Page 22 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Principles of Operation Figure 26: Programmable Interrupt System State Machine Timing The system state machine shown in Figure27 provides an overview of the states and state transitions that provide system control of the device. This section highlights the programmable features, which affect the state machine cycle time, and provides details to determine system level timing. When the proximity detection feature is enabled (PEN), the state machine transitions through the Prox Init, Prox Accum, Prox Wait, and Prox ADC states. The Prox Init and Prox Wait times are a fixed 2.73 ms, whereas the Prox Accum time is determined by the number of proximity LED pulses (PPULSE) and the Prox ADC time is determined by the integration time (PTIME). The formulas to determine the Prox Accum and Prox ADC times are given in the associated boxes in Figure27. If an interrupt is generated as a result of the proximity cycle, it will be asserted at the end of the Prox ADC state and transition to the Sleep state if SAI is enabled. When the power management feature is enabled (WEN), the state machine will transition in turn to the Wait state. The wait time is determined by WLONG, which extends normal operation by 12× when asserted, and WTIME. The formula to determine the wait time is given in the box associated with the Wait state in Figure27. ams Datasheet Page 23 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Principles of Operation When the ALS feature is enabled (AEN), the state machine will transition through the ALS Init and ALS ADC states. The ALS Init state takes 2.73 ms, while the ALS ADC time is dependent on the integration time (ATIME). The formula to determine ALS ADC time is given in the associated box in Figure27. If an interrupt is generated as a result of the ALS cycle, it will be asserted at the end of the ALS ADC state and transition to the Sleep state if SAI is enabled. Figure 27: Detailed State Machine Page 24 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Principles of Operation Power Management Power consumption can be managed with the Wait state, because the Wait state typically consumes only 90μA of I DD current. An example of the power management feature is given below. With the assumptions provided in the example, average I is estimated to be 176μA. DD Figure 28: Power Management System State Programmable Programmed Typical Duration Machine State Parameter Value Current Prox Init 2.73 ms 0.195 mA Prox Accum PPULSE 0x04 0.064 ms Prox Accum − LED On 0.029 ms (1) 103 mA Prox Accum − LED OFF 0.035 ms (2) 0.195 mA Prox Wait 2.73 ms 0.195 mA Prox ADC PTIME 0xFF 2.73 ms 0.195 mA WTIME 0xEE Wait 49 2 ms 0 090 mA WLONG ALS Init 2.73 ms 0.195 mA ALS ADC ATIME 0xEE 49 2 ms 0.195 mA Note(s): 1. Prox Accum − LED On time = 7.3 μs per pulse × 4 pulses = 29.3μs = 0.029 ms 2. Prox Accum − LED Off time = 8.7 μs per pulse × 4 pulses = 34.7μs = 0.035 ms ams Datasheet Page 25 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Principles of Operation Average I Current = DD ((0.029 × 103) + (0.035 x 0.195) + (2.73 × 0.195) + (49.2 × 0.090) + (49.2 × 0.195) + (2.73 × 0.195 × 3)) / 109 ≈ 176 μA. Keeping with the same programmed values as the example, Figure29 shows how the average I current is affected by the DD Wait state time, which is determined by WEN, WTIME, and WLONG. Note that the worst-case current occurs when the Wait state is not enabled. Figure 29: Average I Current DD WEN WTIME WLONG WAIT State Average I Current DD 0 n/a n/a 0 ms 245 μA 1 0xFF 0 2.73 ms 238 μA 1 0xEE 0 49.2 ms 175 μA 1 0x00 0 699 ms 102 μA 1 0x00 1 8389 ms 91 μA Page 26 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Principles of Operation I²C Protocol Interface and control are accomplished through an I²C serial compatible interface (standard or fast mode) to a set of registers that provide access to device control functions and output data. The devices support the 7-bit I²C addressing protocol. The I²C standard provides for three types of bus transaction: read, write, and a combined protocol (Figure30). During a write operation, the first byte written is a command byte followed by data. In a combined protocol, the first byte written is the command byte followed by reading a series of bytes. If a read command is issued, the register address from the previous command will be used for data access. Likewise, if the MSB of the command is not set, the device will write a series of bytes at the address stored in the last valid command with a register address. The command byte contains either control information or a 5-bit register address. The control commands can also be used to clear interrupts. The I²C bus protocol was developed by Phillips (now NXP). For a complete description of the I²C protocol, please review the NXP I²C design specification at http://www.i2c-bus.org/references/ Figure 30: I²C Protocols 1 7 1 1 8 1 8 1 1 S Slave Address W A Command Code A Data Byte A P I2C Write Protocol 1 7 1 1 8 1 8 1 1 S Slave Address R A Data A Data A P I2C Read Protocol 1 7 1 1 8 1 1 7 1 1 S Slave Address W A Command Code A Sr Slave Address R A 8 1 8 1 1 Data A Data A P I2C Read Protocol – Combined Format A Acknowledge (0) Sr Repeated Start Condition N Not Acknowledged (1) W Write (0) P Stop Condition … Communication of Protocol R Read (1) Master-to-Slave S Start Condition Slave-to-Master ams Datasheet Page 27 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Register Description Register Description The device is controlled and monitored by data registers and a command register accessed through the serial interface. These registers provide for a variety of control functions and can be read to determine results of the ADC conversions. The register set is summarized in Figure31. Figure 31: Register Map Address Register Name R/W Register Function Reset Value --- COMMAND W Specifies register address 0x00 0x00 ENABLE R/W Enables states and interrupts 0x00 0x01 ATIME R/W Integration time 0xFF 0x02 PTIME R/W Proximity ADC time 0xFF 0x03 WTIME R/W Wait time 0xFF 0x04 AILTL R/W ALS interrupt low threshold low byte 0x00 0x05 AILTH R/W ALS interrupt low threshold high byte 0x00 0x06 AIHTL R/W ALS interrupt high threshold low byte 0x00 0x07 AIHTH R/W ALS interrupt high threshold high byte 0x00 0x08 PILTL R/W Proximity interrupt low threshold low byte 0x00 0x09 PILTH R/W Proximity interrupt low threshold high byte 0x00 0x0A PIHTL R/W Proximity interrupt high threshold low byte 0x00 0x0B PIHTH R/W Proximity interrupt high threshold high byte 0x00 0x0C PERS R/W Interrupt persistence filters 0x00 0x0D CONFIG R/W Configuration 0x00 0x0E PPULSE R/W Proximity pulse count 0x00 0x0F CONTROL R/W Control register 0x00 0x11 REVISION R Die revision number Rev Num 0x12 ID R Device ID 0x39 Page 28 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Register Description Address Register Name R/W Register Function Reset Value 0x13 STATUS R Device status 0x00 0x14 C0DATA R Ch0 ADC low data register 0x00 0x15 C0DATAH R Ch0 ADC high data register 0x00 0x16 C1DATA R Ch1 ADC low data register 0x00 0x17 C1DATAH R Ch1 ADC high data register 0x00 0x18 PDATAL R Proximity ADC low data register 0x00 0x19 PDATAH R Proximity ADC high data register 0x00 0x1E POFFSET R/W Proximity offset register 0x00 The mechanics of accessing a specific register depends on the specific protocol used (see I²C Protocol). In general, the COMMAND register is written first to specify the specific control/status register for following read/write operations. ams Datasheet Page 29 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Register Description Command Register The Command Register specifies the address of the target register for future write and read operations. The command register defaults to 0x00 at power-on. Figure 32: Command Register 7 6 5 4 3 2 1 0 COMMAND TYPE ADD Field Bits Description (Reset value = 0x00) COMMAND 7 Select Command Register. Must write as 1 when addressing COMMAND register. Selects type of transaction to follow in subsequent data transfers: Field Value Description 00 Repeated byte protocol transaction 01 Auto-increment protocol transaction TYPE 6:5 10 Reserved — Do not use 11 Special function – See description below Transaction type 00 will repeatedly read the same register with each data access. Transaction type 01 will provide an auto-increment function to read successive register bytes. Address field/special function field. Depending on the transaction type, see above, this field either specifies a special function command or selects the specific control-status-register for following write and read transactions. The field values listed below apply only to special function commands: Field Value Description 00000 Normal — no action ADD 4:0 00101 Proximity interrupt clear 00110 ALS interrupt clear 00111 Proximity and ALS interrupt clear other Reserved — Do not write ALS/Proximity Interrupt Clear clears any pending ALS/Proximity interrupt. This special function is self clearing. Page 30 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Register Description Enable Register (0x00) The Enable Register is used to power the device on/off, enable functions, and interrupts. Figure 33: Enable Register 7 6 5 4 3 2 1 0 Reserved SAI PIEN AIEN WEN PEN AEN PON Field Bits Description (Reset value = 0x00) Reserved 7 Reserved. Write as 0. Sleep after interrupt. When asserted, the device will power down at the end SAI 6 of a proximity or ALS cycle if an interrupt has been generated. Proximity interrupt mask. When asserted, permits proximity interrupts to be PIEN 5 generated. AIEN 4 ALS interrupt mask. When asserted, permits ALS interrupt to be generated. Wait Enable. This bit activates the wait feature. Writing a 1 activates the wait WEN 3 timer. Writing a 0 disables the wait timer. Proximity Enable. This bit activates the proximity function. Writing a 1 PEN 2 enables proximity. Writing a 0 disables proximity. ALS Enable. This bit activates the two channel ADC. Writing a 1 activates the AEN 1 ALS. Writing a 0 disables the ALS. Power ON. This bit activates the internal oscillator to permit the timers and PON 0 ADC channels to operate. Writing a 1 activates the oscillator. Writing a 0 disables the oscillator. ams Datasheet Page 31 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Register Description ALS Time Register (0x01) The ALS Time Register controls the internal integration time of the ALS channel ADS’s in 2.73ms increments. Time is expressed as a 2’s complement number. To calculate the value: 1. Determine the number of 2.73ms intervals required 2. Take the 2’s complement For a 1 x 2.73ms interval, 0xFF should be written. For 2 x 2.73ms intervals, 0xFE should be written. The maximum integration time is 699ms (0x00). Figure 34: ALS Time Register 7 6 5 4 3 2 1 0 ATIME Description (Reset value = 0xFF) Field Bits Value Cycles Time Max Count 0xFF 1 2.73 ms 1024 0xF6 10 27.3 ms 10240 ATIME 7:0 0xDB 37 101 ms 37888 0xC0 64 175 ms 65535 0x00 256 699 ms 65535 Page 32 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Register Description Proximity Time Register (0x02) The Proximity Time Register controls the integration time of the proximity ADC in 2.73 ms increments. Time is expressed as a 2’s complement number. It is recommended that this register be programmed to a value of 0xFF (1 integration cycle). Figure 35: Proximity Time Register 7 6 5 4 3 2 1 0 PTIME Description (Reset value = 0xFF) Field Bits Value Cycles Time Max Count PTIME 7:0 0xFF 1 2.73 ms 1023 Wait Time Register (0x03) Wait time is set in 2.73 ms increments unless the WLONG bit is asserted in which case the wait times are 12x longer. WTIME is programmed as a 2’s complement number. Figure 36: Wait Time Register 7 6 5 4 3 2 1 0 WTIME Description (Reset value = 0xFF) Field Bits Time Time Register Value Wait Time (WLONG=0) (WLONG=1) 0xFF 1 2.73 ms 0.033 s WTIME 7:0 0xB6 74 202 ms 2.4 s 0x00 256 699 ms 8.4 s Note(s): 1. The Proximity Wait Time Register should be configured before PEN and/or AEN is/are asserted. ams Datasheet Page 33 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Register Description ALS Interrupt Threshold Register (0x04 − 0x07) The ALS Interrupt Threshold Registers provide the values to be used as the high and low trigger points for the comparison function for interrupt generation. If C0DATA is not between the low and high thresholds and the persistence criteria is met, an interrupt is asserted on the interrupt pin. Figure 37: ALS Interrupt Threshold Registers Register Address Bits Description (Reset value = 0x00) AILTL 0x04 7:0 ALS low threshold lower byte AILTH 0x05 7:0 ALS low threshold upper byte AIHTL 0x06 7:0 ALS high threshold lower byte AIHTH 0x07 7:0 ALS high threshold upper byte Proximity Interrupt Threshold Register (0x08 − 0x0B) The Proximity Interrupt Threshold Registers provide the values to be used as the high and low trigger points for the comparison function for interrupt generation. If the value generated by proximity channel is not between the low and high thresholds and the persistence criteria is met, an interrupt is signaled to the host processor. Figure 38: Proximity Interrupt Threshold Registers Register Address Bits Description (Reset value = 0x00) PILTL 0x08 7:0 Proximity low threshold lower byte PILTH 0x09 7:0 Proximity low threshold upper byte PIHTL 0x0A 7:0 Proximity high threshold lower byte PIHTH 0x0B 7:0 Proximity high threshold upper byte Page 34 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Register Description Interrupt Register (0x0C) The Interrupt Register controls the filtering interrupt capabilities of the device. Configurable filtering is provided to allow interrupts to be generated after each ADC integration cycle or if the ADC integration has produced a result that is outside of the values specified by threshold register for some specified amount of time. Separate filtering is provided for proximity and ALS functions. ALS interrupts are generated by looking only at the C0DATA ADC integration results. Figure 39: Interrupt Register 7 6 5 4 3 2 1 0 PPERS APERS Field Bits Description (Reset value = 0x00) Proximity interrupt persistence filter. Controls rate of proximity interrupt to the host processor. Field Value Meaning Interrupt Persistence Every proximity cycle generates an 0000 Every interrupt 1 proximity value outside of threshold PPERS 7:4 0001 1 range 2 consecutive proximity values out of 0010 2 range … … … 15 consecutive proximity values out of 1111 15 range ams Datasheet Page 35 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Register Description Field Bits Description (Reset value = 0x00) ALS Interrupt persistence filter. Controls rate of interrupt to the host processor. Field Value Persistence Interrupt Persistence 0000 Every Every ALS cycle generates an interrupt 0001 1 1 value outside of threshold range 0010 2 2 consecutive values out of range 0011 3 3 consecutive values out of range 0100 5 5 consecutive values out of range 0101 10 10 consecutive values out of range 0110 15 15 consecutive values out of range APERS 3:0 0111 20 20 consecutive values out of range 1000 25 25 consecutive values out of range 1001 30 30 consecutive values out of range 1010 35 35 consecutive values out of range 1011 40 40 consecutive values out of range 1100 45 45 consecutive values out of range 1101 50 50 consecutive values out of range 1110 55 55 consecutive values out of range 1111 60 60 consecutive values out of range Page 36 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Register Description Configuration Register (0x0D) The Configuration Register sets the proximity LED drive level, wait long time, and ALS gain level Figure 40: Configuration Register. 7 6 5 4 3 2 1 0 Reserved AGL WLONG PDL Field Bits Description (Reset value = 0x00) Reserved 7:3 Reserved. Write as 0. ALS Gain Level. When asserted, the 1× and 8× ALS gain (AGAIN) modes AGL 2 are scaled by 0.16. Otherwise, AGAIN is scaled by 1. Should be set = 0 anytime AGAIN is greater than 8x, or if using a TMD module. Wait Long. When asserted, the wait cycles are increased by a factor 12x WLONG 1 from that programmed in the WTIME register. Proximity drive level. When asserted, the proximity LDR drive current is PDL 0 reduced by 9. Proximity Pulse Count Register (0x0E) The Proximity Pulse Count Register sets the number of proximity pulses that the LDR pin will generate during the Prox Accum state. The pulses are generated at a 62.5kHz rate. Figure 41: Proximity Pulse Count Register 7 6 5 4 3 2 1 0 PPULSE Field Bits Description Proximity Pulse Count. Specifies the number of proximity pulses PPULSE 7:0 to be generated. ams Datasheet Page 37 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Register Description Control Register (0x0F) The Control Register provides eight bits of miscellaneous control to the analog block. These bits typically control functions such as gain settings and/or diode selection. Figure 42: Control Register 7 6 5 4 3 2 1 0 PDRIVE PDIODE PGAIN AGAIN Field Bits Description (Reset value = 0x00) Proximity LED Drive Strength. Field Value LED Strength – PDL=0 LED Strength – PDL=1 00 100 % 11.1 % PDRIVE (1) 7:6 01 50 % 5.6 % 10 25 % 2.8 % 11 12.5 % 1.4 % Proximity Diode Selector. Field Value Diode Selection 00 Proximity uses neither diode PDIODE 5:4 01 Proximity uses the CH0 diode 10 Proximity uses the CH1 diode 11 Reserved — Do not write Proximity Gain. Field Value Proximity Gain Value 00 1x gain PGAIN 3:2 01 2x gain 10 4x gain 11 8x gain Page 38 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Register Description Field Bits Description (Reset value = 0x00) ALS Gain Field Value ALS Gain Value 00 1X Gain AGAIN 1:0 01 8X Gain 10 16X Gain 11 120X Gain Note(s): 1. LED STRENGTH values are nominal operating values. Specifications can be found in the Proximity Characteristics table. Revision Register (0x11) The Revision Register shows the silicon revision number. It is a read-only register and shows the revision level of the silicon used internally. Figure 43: Revision Register 7 6 5 4 3 2 1 0 Reserved DIE_REV Field Bits Description (Reset value = Rev Num) RESERVED 7:4 Reserved. DIE_REV 3:0 Die revision number ams Datasheet Page 39 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Register Description ID Register (0x12) The ID Register provides the value for the part number. The ID register is a read-only register whose value never changes. Figure 44: ID Register 7 6 5 4 3 2 1 0 ID Field Bit Description (Reset value = ID) TMD27721 = 0x30 TMD27723 = 0x39 TMD27725 = 0x30 ID 7:0 TMD27727 = 0x39 TMD27721WA = 0x30 TMD27723WA = 0x39 Page 40 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Register Description Status Register (0x13) The Status Register provides the internal status of the device. This register is read only. Figure 45: Status Register 7 6 5 4 3 2 1 0 Reserved PSAT PINT AINT Reserved PVALID AVALID Field Bits Description (Reset value = 0x00) Reserved 7 Reserved. Bit reads as 0. PSAT 6 Proximity Saturation. Indicates the proximity measurement saturated. Proximity Interrupt. Indicates that the device is asserting a proximity PINT 5 interrupt. AINT 4 ALS Interrupt. Indicates that the device is asserting an ALS interrupt. Reserved 3:2 Reserved. Bits read as 0. Proximity Valid. Indicates that the Proximity channel has completed PVALID 1 an integration cycle after the PEN bit has been asserted. ALS Valid. Indicates that the ALS channels have completed an AVALID 0 integration cycle after AEN has been asserted. ADC Channel Data Registers (0x14 − 0x17) ALS data is stored as two 16-bit values. To ensure the data is read correctly, a two-byte read I²C transaction should be used with auto increment protocol bits set in the command register. With this operation, when the lower byte register is read, the upper eight bits are stored in a shadow register, which is read by a subsequent read to the upper byte. The upper register will read the correct value even if additional ADC integration cycles end between the reading of the lower and upper registers. Figure 46: ADC Channel Data Registers Register Address Bits Description (Reset value = 0x00) C0DATA 0x14 7:0 ALS CH0 data low byte C0DATAH 0x15 7:0 ALS CH0 data high byte C1DATA 0x16 7:0 ALS CH1 data low byte C1DATAH 0x17 7:0 ALS CH1 data high byte ams Datasheet Page 41 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Register Description Proximity Data Registers (0x18 − 0x19) Proximity data is stored as a 16-bit value. To ensure the data is read correctly, a two-byte read I²C transaction should be utilized with auto increment protocol bits set in the command register. With this operation, when the lower byte register is read, the upper eight bits are stored into a shadow register, which is read by a subsequent read to the upper byte. The upper register will read the correct value even if the next ADC cycle ends between the reading of the lower and upper registers. Figure 47: Proximity Data Registers Register Address Bits Description (Reset value = 0x00) PDATAL 0x18 7:0 Proximity data low byte PDATAH 0x19 7:0 Proximity data high byte Page 42 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Register Description Proximity Offset Register (0x1E) The 8-bit proximity offset register provides compensation for proximity offsets caused by device variations, optical crosstalk, and other environmental factors. Proximity offset is a sign-magnitude value where the sign bit, bit 7, determines if the offset is negative (bit 7 = 0) or positive (bit 7 = 1). The magnitude of the offset compensation depends on the proximity gain (PGAIN), proximity LED drive strength (PDRIVE), and the number of proximity pulses (PPULSE). Because a number of environmental factors contribute to proximity offset, this register is best suited for use in an adaptive closed-loop control system. See available ams application notes for proximity offset register application information. The default value on power up is factory trimmed to provide a typical proximity offset of 100. This is achieved with no glass or reflective object above the sensor, and PPULSE=08, PGAIN=10, PDRIVE=00. If the value is changed during use but power is removed it will return to the default value on power up. Figure 48: Proximity Offset Register 7 6 5 4 3 2 1 0 SIGN MAGNITUDE Field Bits Description (Reset value = trimmed value) Proximity Offset Sign. The offset sign shifts the proximity data SIGN 7 negative when equal to 0 and positive when equal to 1. Proximity Offset Magnitude. The offset magnitude shifts the proximity data positive or negative, depending on the proximity offset MAGNITUDE 6:0 sign. The actual amount of the shift depends on the proximity gain (PGAIN), proximity LED drive strength (PDRIVE), and the number of proximity pulses (PPULSE). ams Datasheet Page 43 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Application Information Application Information LED Driver Pin with Proximity Detection In a proximity sensing system, the included IR LED can be pulsed with more than 100 mA of rapidly switching current, therefore, a few design considerations must be kept in mind to get the best performance. The key goal is to reduce the power supply noise coupled back into the device during the LED pulses. Averaging of multiple proximity samples is recommended to reduce the proximity noise. The first recommendation is to use two power supplies; one for the device V and the other for the IR LED. In many systems, DD there is a quiet analog supply and a noisy digital supply. By connecting the quiet supply to the V pin and the noisy supply DD to the LEDA pin, the key goal can be met. Place a 1μF low-ESR decoupling capacitor as close as possible to the V pin and DD another at the LEDA pin, and at least 10μF of bulk capacitance to supply the 100mA current surge. This may be distributed as two 4.7μF capacitors. Figure 49: Proximity Sensing Using Separate Power Supplies VBUS Voltage Regulator VDD TMD2772 RP RP RPI 1µF Or GND TMD2772WA INT SCL LEDA Voltage SDA Regulator 1µF LEDK LDR If it is not possible to provide two separate power supplies, the device can be operated from a single supply. A 22Ω resistor in series with the V supply line and a 1μF low ESR capacitor DD effectively filter any power supply noise. The previous capacitor placement considerations apply. Page 44 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Application Information Figure 50: Proximity Sensing Using Single Power Supply VBUS 22 RVeogultlaagteor VDD TMD2772 RP RP RPI 1µF Or Per GND TMD2772WA INT regulator SCL datasheet LEDA SDA 1µF LEDK LDR V in the above figures refers to the I²C bus voltage which is BUS either V or 1.8V. Be sure to apply the specified I²C bus voltage DD shown in the Available Options table for the specific device being used. The I²C signals and the Interrupt are open-drain outputs and require pull-up resistors. The pull-up resistor (RP) value is a function of the I²C bus speed, the I²C bus voltage, and the capacitive load. The ams EVM running at 400 kbps, uses 1.5kΩ resistors. A 10kΩ pull-up resistor (RPI) can be used for the interrupt line. ams Datasheet Page 45 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − PCB Pad Layout PCB Pad Layout Suggested PCB pad layout guidelines for the surface mount module are shown below. Flash Gold is recommended surface finish for the landing pads. This footprint is recommended for both the TMD2772 and the TMD2772WA. Figure 51: Suggested Module PCB Layout Note(s): 1. All linear dimensions are in millimeters. 2. Dimension tolerances are ±0.05mm unless otherwise noted. 3. This drawing is subject to change without notice. Page 46 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Packaging Mechanical Data Packaging Mechanical Data Figure 52: TMD2772 Module Dimensions RoHS Green Note(s): 1. All linear dimensions are in millimeters. 2. Dimension tolerance is ± 0.05 mm unless otherwise noted. 3. Contacts are copper with NiPdAu plating. 4. This package contains no lead (Pb). 5. This drawing is subject to change without notice. ams Datasheet Page 47 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Packaging Mechanical Data Figure 53: TMD2772WA Module Dimensions RoHS Green Note(s): 1. All linear dimensions are in millimeters. 2. Dimension tolerance is ± 0.05 mm unless otherwise noted. 3. Contacts are copper with NiPdAu plating. 4. This package contains no lead (Pb). 5. This drawing is subject to change without notice. Page 48 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Carrier Tape & Reel Information Carrier Tape & Reel Information Figure 54: TMD2772 Module Carrier Tape Note(s): 1. All linear dimensions are in millimeters. Dimension tolerance is ± 0.10mm unless otherwise noted. 2. The dimensions on this drawing are for illustrative purposes only. Dimensions of an actual carrier may vary slightly. 3. Symbols on drawing A , B , and K are defined in ANSI EIA Standard 481−B 2001. o o o 4. Each reel is 330 millimeters in diameter and contains 2500 parts. 5. ams packaging tape and reel conform to the requirements of EIA Standard 481−B. 6. In accordance with EIA standard, device pin 1 is located next to the sprocket holes in the tape. 7. This drawing is subject to change without notice. ams Datasheet Page 49 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Carrier Tape & Reel Information Figure 55: TMD2772WA Module Carrier Tape Note(s): 1. All linear dimensions are in millimeters. Dimension tolerance is ± 0.10mm unless otherwise noted. 2. The dimensions on this drawing are for illustrative purposes only. Dimensions of an actual carrier may vary slightly. 3. Symbols on drawing A , B , and K are defined in ANSI EIA Standard 481−B 2001. o o o 4. Each reel is 330 millimeters in diameter and contains 2500 parts. 5. ams packaging tape and reel conform to the requirements of EIA Standard 481−B. 6. In accordance with EIA standard, device pin 1 is located next to the sprocket holes in the tape. 7. This drawing is subject to change without notice. Page 50 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Manufacturing Information Manufacturing Information The module has been tested and has demonstrated an ability to be reflow soldered to a PCB substrate. The solder reflow profile describes the expected maximum heat exposure of components during the solder reflow process of product on a PCB. Temperature is measured on top of component. The components should be limited to a maximum of three passes through this solder reflow profile. Figure 56: Solder Reflow Profile Parameter Reference Device Average temperature gradient in preheating 2.5°C/s Soak time t 2 to 3 minutes soak Time above 217°C (T ) t Max 60 s 1 1 Time above 230°C (T ) t Max 50 s 2 2 Time above 250°C (T ) t Max 10 s 3 3 Peak temperature in reflow T 260°C peak Temperature gradient in cooling Max −5°C/s Figure 57: Solder Reflow Profile Graph Not to scale — for reference only T peak T 3 T 2 T 1 C) (cid:2) e ( r u at r e p m e T Time ((ss)ec) t 3 t 2 tsoak t1 ams Datasheet Page 51 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Storage Information Storage Information Moisture Sensitivity Optical characteristics of the device can be adversely affected during the soldering process by the release and vaporization of moisture that has been previously absorbed into the package. To ensure the package contains the smallest amount of absorbed moisture possible, each device is baked prior to being dry packed for shipping. Devices are dry packed in a sealed aluminized envelope called a moisture-barrier bag with silica gel to protect them from ambient moisture during shipping, handling, and storage before use. Shelf Life The calculated shelf life of the device in an unopened moisture barrier bag is 12 months from the date code on the bag when stored under the following conditions: • Shelf Life: 12 months • Ambient Temperature: < 40°C • Relative Humidity: < 90% Rebaking of the devices will be required if the devices exceed the 12 month shelf life or the Humidity Indicator Card shows that the devices were exposed to conditions beyond the allowable moisture region. Floor Life The module has been assigned a moisture sensitivity level of MSL 3. As a result, the floor life of devices removed from the moisture barrier bag is 168 hours from the time the bag was opened, provided that the devices are stored under the following conditions: • Floor Life: 168 hours • Ambient Temperature: ≤ 30°C • Relative Humidity: < 60% If the floor life or the temperature/humidity conditions have been exceeded, the devices must be rebaked prior to solder reflow or dry packing. Rebaking Instructions When the shelf life or floor life limits have been exceeded, rebake at 50°C for 12 hours. Page 52 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Ordering & Contact Information Ordering & Contact Information Figure 58: Configuration and Ordering Information Ordering Package I²C Angular Description ID (0x12) Code − Leads Address Response TMD27721 I²C V = V Interface Module − 8 0x30 0x39 ± 25° BUS DD TMD27723 I²C V = 1.8V Interface Module − 8 0x39 0x39 ± 25° BUS TMD27725 (1) I²C VBUS = VDD Interface Module − 8 0x30 0x29 ± 25° TMD27727 (1) I²C VBUS = 1.8V Interface Module − 8 0x39 0x29 ± 25° TMD27721WA (1) I²C VBUS = VDD Interface Module − 8 0x30 0x39 ± 50° TMD27723WA I²C V = 1.8V Interface Module − 8 0x39 0x39 ± 50° BUS Note(s): 1. Contact ams for availability. Buy our products or get free samples online at: www.ams.com/ICdirect Technical Support is available at: www.ams.com/Technical-Support Provide feedback about this document at: www.ams.com/Document-Feedback For further information and requests, e-mail us at: ams_sales@ams.com For sales offices, distributors and representatives, please visit: www.ams.com/contact Headquarters ams AG Tobelbaderstrasse 30 8141 Premstaetten Austria, Europe Tel: +43 (0) 3136 500 0 Website: www.ams.com ams Datasheet Page 53 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − RoHS Compliant & ams Green Statement RoHS Compliant & ams Green RoHS: The term RoHS compliant means that ams AG products fully comply with current RoHS directives. Our semiconductor Statement products do not contain any chemicals for all 6 substance categories, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, RoHS compliant products are suitable for use in specified lead-free processes. ams Green (RoHS compliant and no Sb/Br): ams Green defines that in addition to RoHS compliance, our products are free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material). Important Information: The information provided in this statement represents ams AG knowledge and belief as of the date that it is provided. ams AG bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. ams AG has taken and continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals. ams AG and ams AG suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release. Page 54 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Copyrights & Disclaimer Copyrights & Disclaimer Copyright ams AG, Tobelbader Strasse 30, 8141 Premstaetten, Austria-Europe. Trademarks Registered. All rights reserved. The material herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. Devices sold by ams AG are covered by the warranty and patent indemnification provisions appearing in its General Terms of Trade. ams AG makes no warranty, express, statutory, implied, or by description regarding the information set forth herein. ams AG reserves the right to change specifications and prices at any time and without notice. Therefore, prior to designing this product into a system, it is necessary to check with ams AG for current information. This product is intended for use in commercial applications. Applications requiring extended temperature range, unusual environmental requirements, or high reliability applications, such as military, medical life-support or life-sustaining equipment are specifically not recommended without additional processing by ams AG for each application. This product is provided by ams AG “AS IS” and any express or implied warranties, including, but not limited to the implied warranties of merchantability and fitness for a particular purpose are disclaimed. ams AG shall not be liable to recipient or any third party for any damages, including but not limited to personal injury, property damage, loss of profits, loss of use, interruption of business or indirect, special, incidental or consequential damages, of any kind, in connection with or arising out of the furnishing, performance or use of the technical data herein. No obligation or liability to recipient or any third party shall arise or flow out of ams AG rendering of technical or other services. ams Datasheet Page 55 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Document Status Document Status Document Status Product Status Definition Information in this datasheet is based on product ideas in the planning phase of development. All specifications are Product Preview Pre-Development design goals without any warranty and are subject to change without notice Information in this datasheet is based on products in the design, validation or qualification phase of development. Preliminary Datasheet Pre-Production The performance and parameters shown in this document are preliminary without any warranty and are subject to change without notice Information in this datasheet is based on products in ramp-up to full production or full production which Datasheet Production conform to specifications in accordance with the terms of ams AG standard warranty as given in the General Terms of Trade Information in this datasheet is based on products which conform to specifications in accordance with the terms of Datasheet (discontinued) Discontinued ams AG standard warranty as given in the General Terms of Trade, but these products have been superseded and should not be used for new designs Page 56 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Revision Information Revision Information Changes from 1-20 (2014-Jul-21) to current revision 1-21 (2016-Feb-16) Page Updated Figure 5 5 Updated Figure 58 53 Note(s): 1. Page and figure numbers for the previous version may differ from page and figure numbers in the current revision. 2. Correction of typographical errors is not explicitly mentioned. ams Datasheet Page 57 [v1-21] 2016-Feb-16 DocumentFeedback

TMD2772/ TMD2772WA − Content Guide Content Guide 1 General Description 1 Key Benefits & Features 2 Applications 3 Block Diagram 4 Pin Assignment 5 Absolute Maximum Ratings 6 Electrical Characteristics 11 Timing Characteristics 11 Timing Diagrams 12 Typical Operating Characteristics 15 Detailed Description 17 Principles of Operation 17 System State Machine 18 Photodiodes 18 ALS Operation 19 Lux Equation 20 Proximity Detection 22 Interrupts 23 System State Machine Timing 25 Power Management 27 I²C Protocol 28 Register Description 30 Command Register 31 Enable Register (0x00) 32 ALS Time Register (0x01) 33 Proximity Time Register (0x02) 33 Wait Time Register (0x03) 34 ALS Interrupt Threshold Register (0x04 − 0x07) 34 Proximity Interrupt Threshold Register (0x08 − 0x0B) 35 Interrupt Register (0x0C) 37 Configuration Register (0x0D) 37 Proximity Pulse Count Register (0x0E) 38 Control Register (0x0F) 39 Revision Register (0x11) 40 ID Register (0x12) 41 Status Register (0x13) 41 ADC Channel Data Registers (0x14 − 0x17) 42 Proximity Data Registers (0x18 − 0x19) 43 Proximity Offset Register (0x1E) Page 58 ams Datasheet DocumentFeedback [v1-21] 2016-Feb-16

TMD2772/ TMD2772WA − Content Guide 44 Application Information 44 LED Driver Pin with Proximity Detection 46 PCB Pad Layout 47 Packaging Mechanical Data 49 Carrier Tape & Reel Information 51 Manufacturing Information 52 Storage Information 52 Moisture Sensitivity 52 Shelf Life 52 Floor Life 52 Rebaking Instructions 53 Ordering & Contact Information 54 RoHS Compliant & ams Green Statement 55 Copyrights & Disclaimer 56 Document Status 57 Revision Information ams Datasheet Page 59 [v1-21] 2016-Feb-16 DocumentFeedback

Datasheet下载

Datasheet下载