- 型号: TA2K0PH1K00KE

- 制造商: Ohmite

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

TA2K0PH1K00KE产品简介:

ICGOO电子元器件商城为您提供TA2K0PH1K00KE由Ohmite设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 TA2K0PH1K00KE价格参考。OhmiteTA2K0PH1K00KE封装/规格:底座安装电阻器, 1 kOhms ±10% 2000W Thick Film Chassis Mount Resistor。您可以下载TA2K0PH1K00KE参考资料、Datasheet数据手册功能说明书,资料中有TA2K0PH1K00KE 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | RES CHAS MNT 1K OHM 10% 2000W平面电阻器 - 底架安装 2000watt 1Kohm 10% |

| 产品分类 | |

| 品牌 | Ohmite |

| 产品手册 | |

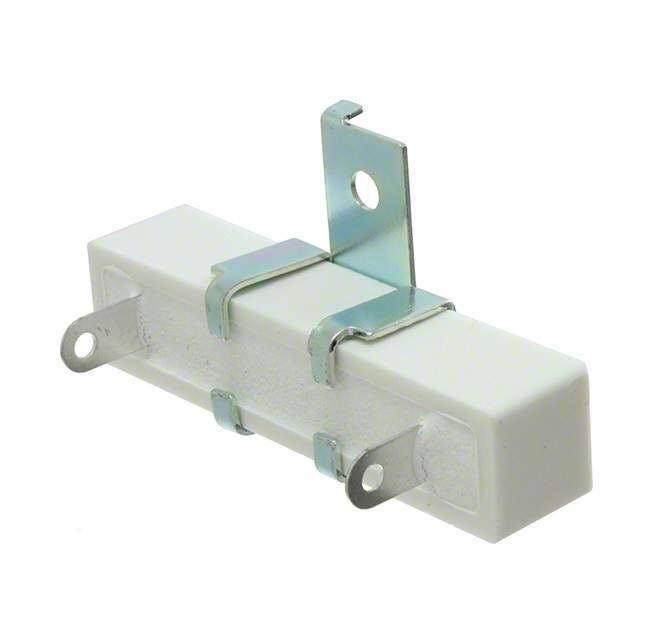

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

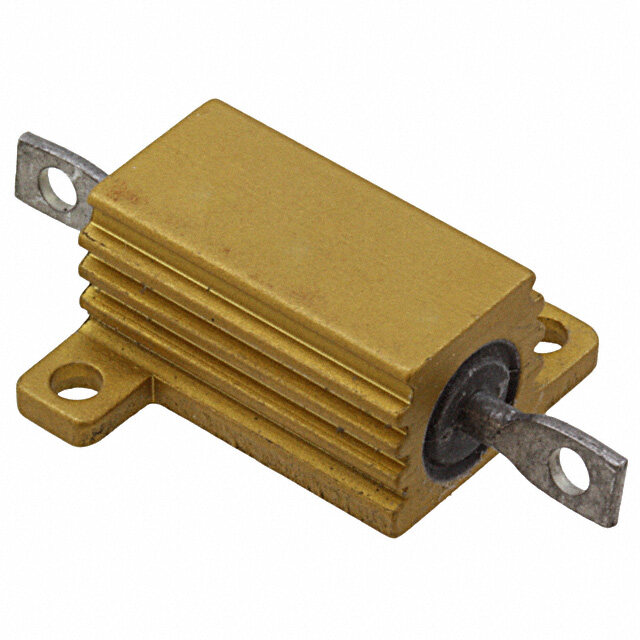

| 产品系列 | 薄膜电阻器,平面电阻器 - 底架安装,Ohmite TA2K0PH1K00KETAP2000 |

| 数据手册 | |

| 产品型号 | TA2K0PH1K00KE |

| 产品种类 | 平面电阻器 - 底架安装 |

| 其它名称 | TA2K0PH1K0KE |

| 功率(W) | 2000W |

| 功率额定值 | 2 kW |

| 包装 | 散装 |

| 商标 | Ohmite |

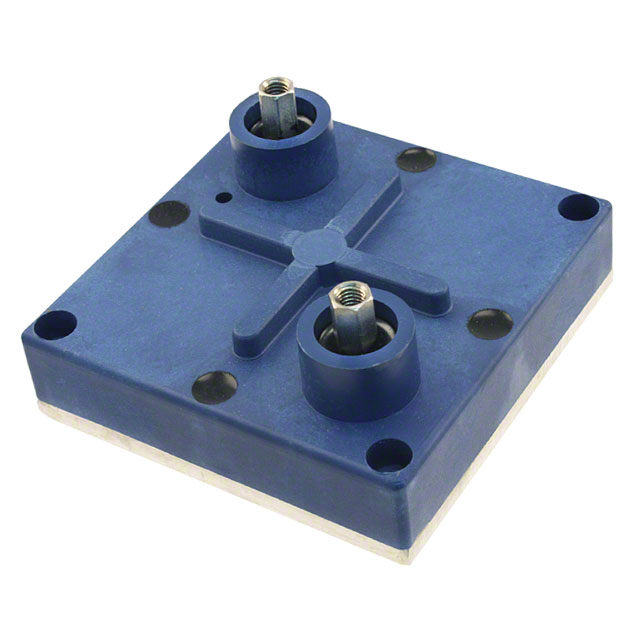

| 外壳宽度 | 76.2 mm |

| 外壳长度 | 76.2 mm |

| 外壳高度 | 39.31 mm |

| 大小/尺寸 | 3.000" 长 x 3.000" 宽(76.20mm x 76.20mm) |

| 安装特性 | 法兰 |

| 容差 | 10 % |

| 封装 | Bulk |

| 封装/外壳 | 盒 |

| 工作温度范围 | - 55 C to + 85 C |

| 引线形式 | #10-32,带螺纹 |

| 成分 | 厚膜 |

| 标准包装 | 1 |

| 涂层,外壳类型 | 涂有环氧树脂 |

| 温度系数 | 250 PPM / C |

| 特性 | - |

| 电压额定值 | 2 kV |

| 电阻 | 1 kOhms |

| 电阻(Ω) | 1k |

| 端接类型 | Flange |

| 类型 | 1000 and 2000 Watt Heat Sinkable Planar |

| 系列 | TAP2000 |

| 高度 | 1.248"(31.69mm) |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

TA1K & TA2K High Wattage Heat Sinkable Planar Resistor The TAP series delivers 1000W or 2000W of contin- uous power when properly mounted to a liquid cooled heat sink (based on 85°C mounting plate tempera- FeATures ApplicATions ture) • High Energy Rating • Power semiconductor balancing Applications include power conditioning, power • Low Inductance • Motor control distribution, power conver- • Resistor Element Electrically Isolated • Inrush Current Limiting sion, and power control. • High Dielectric Strength • Small Footprint chArAcTerisTics Resistor Element Thick Film on Alumina Rating Substrate Test Continuous Pulse Power Rating 1000W or 2000W at Rated Power, max. current and heat sink plate (TA1K0) 1000W 85°C mounting plate temperature limited (TA2K0) 2000W Resistance Values 0.5Ω to 1000Ω Operating Voltage √P*R N/A Resistance Tolerance +10% std. Max. Applied Voltage, ohms law limited 223V 2000VDC Max Operating Voltage 2000VDC Max. Current 10A 53.33A Temperature Coefficient ± 250 PPM/°C Critical Resistance; below this resistance max (TA1K0) 10Ω Dielectric Strength 6KV standard power has to be de-rated due to exceeding max (TA2K0) 20Ω current Operating Temperature -55°C to 85°C Range Test Method Maximum ∆R Terminal Screws #10-32 Short Time 1.14 x √P*R / 10 sec @ 70°C Max % ∆Rsto = Max Contacts Torque 10 in-lb Overload ±(2% + 0.05Ω) Mounting Screws #8-32 Moisture (TA1K0) 1000 hrs @ 40°C, 90-95% RH ≤1% Resistance (TA2K0) 1750 hrs @ 40°C, 90-95% RH ≤1% Max Mounting Torque 15 in-lb Thermal Shock MIL-STD-202, Method 107 MIL-STD-202, Creepage Distance 50mm ± 1mm (min) Method 107 Vibration, elec. MIL-STD-202, Method 201 ±2% Resistance Derating Vibration, mech. MIL-STD-202, Method 201 No Loose 100 Terminal Screws Watts80 Load Life (TA1K0) 1000 Hrs 90 min ON / 30 min OFF ≤1% d 60 (TA2K0) 1750 Hrs 90 min ON / 30 min OFF ≤1% e at ent R40 Pulse Tolerance 5220µ,0F0 0@ P2uKlsVe /s 60 sec intervals, 104J, ≤1% c er20 P Dielectric 6KVDC for 1 minute ≤1% 00 25 50 85 100 125 150 Strength Bottom of base plate Temperature, °C (continued) 142 1-866-9-OHMITE • Int’l 1-847-258-0300 • Fax 1-847-574-7522 • www.ohmite.com • info@ohmite.com

TA1K & TA2K High Wattage Heat Sinkable Planar Resistor dimensions ApplicATion noTes (in./mm) Proper heat sinking techniques are essential to performance of 0.193" ø0.172" 0.689" a TAP resistor. Pleased follow these guidelines when designing (4.89mm) (4.37mm) ø10-32 (17.50mm) TAP system: • Heats sink plate (base plate of the resistor) temperature must be monitored to establish proper de-rating. Best tech- 1.308" nique is to attach a thermocouple to the side of the base (33.21mm) plate of the resistor. Temperature of plastic housing or heat sink cannot be used to establish rating of the resistor. Usage 3.000" 1.622" of laser thermometers should be avoided. (76.20mm) (41.20mm) • To obtain a power rating of 1000W or 2000W, the bottom 1.308" case temp must not exceed 85°C. This can only be achieved (33.21mm) if the thermal conduction to the heatsink Rth-cs<0.025°K/W. This value can be reached by using thermal transfer com- pound with a heat conductivity of 1W/mK. The flatness of (same dimensions) the cooling plate must be better than 0.05mm overall. The roughness of the surface should not exceed 6.4µm. 0.300" (7.62mm) • Due to very high power density, only liquid cooled heat sinks 0.450" are recommended for applications when >300W power rating (11.43mm) is desired. 0.798" • Properly designed heat sink should have more than 2 cooling 0.188" (20.26mm) pipes under the surface of the TAP resistor. The Ohmite CP4 (4.76mm) heat sink (http://www.ohmite.com/cat/sink_cp4.pdf) is an example of properly designed heat sink. ordering inFormATion RoHS Compliant Standard Part Numbers Test Method Maximum ∆R TA 1 K 0 P H 2 R 5 0 KE 1000 Watt 2000 Watt Ohms 10% Tolerance Ohms 10% Tolerance Short Time 1.14 x √P*R / 10 sec @ 70°C Max % ∆Rsto = Overload ±(2% + 0.05Ω) Style Wattage Package Resistance Tolerance 0.5 TA1K0PHR500KE 0.5 TA2K0PHR500KE Type 2.5Ω = 2R50 K = 10% (standard) 1 TA1K0PH1R00KE 1 TA2K0PH1R00KE Moisture (TA1K0) 1000 hrs @ 40°C, 90-95% RH ≤1% 50Ω = 50R0 L = 20% 2.5 TA1K0PH2R50KE 2.5 TA2K0PH2R50KE 5 TA1K0PH5R00KE 5 TA2K0PH5R00KE Resistance (TA2K0) 1750 hrs @ 40°C, 90-95% RH ≤1% 7.5 TA1K0PH7R50KE 7.5 TA2K0PH7R50KE Thermal Shock MIL-STD-202, Method 107 MIL-STD-202, 10 TA1K0PH10R0KE 10 TA2K0PH10R0KE 15 TA1K0PH15R0KE 15 TA2K0PH15R0KE Method 107 25 TA1K0PH25R0KE 25 TA2K0PH25R0KE 50 TA1K0PH50R0KE 50 TA2K0PH50R0KE Vibration, elec. MIL-STD-202, Method 201 ±2% Resistance 100 TA1K0PH100RKE 100 TA2K0PH100RKE Vibration, mech. MIL-STD-202, Method 201 No Loose 250 TA1K0PH250RKE 250 TA2K0PH250RKE Terminal Screws 500 TA1K0PH500RKE 500 TA2K0PH500RKE 750 TA1K0PH750RKE 750 TA2K0PH750RKE Load Life (TA1K0) 1000 Hrs 90 min ON / 30 min OFF ≤1% 1000 TA1K0PH1K00KE 1000 TA2K0PH1K00KE (TA2K0) 1750 Hrs 90 min ON / 30 min OFF ≤1% Pulse Tolerance 52µF @ 2KV / 60 sec intervals, 104J, ≤1% 20,000 Pulses Dielectric 6KVDC for 1 minute ≤1% Strength rev 11/18-1 1-866-9-OHMITE • Int’l 1-847-258-0300 • Fax 1-847-574-7522 • www.ohmite.com • info@ohmite.com 143

Datasheet下载

Datasheet下载