ICGOO在线商城 > 集成电路(IC) > PMIC - 稳压器 - DC DC 开关稳压器 > ST1S31PUR

- 型号: ST1S31PUR

- 制造商: STMicroelectronics

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

ST1S31PUR产品简介:

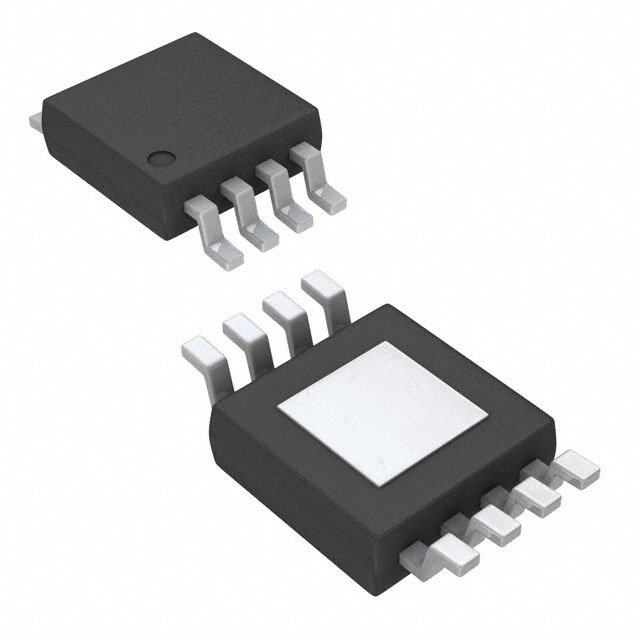

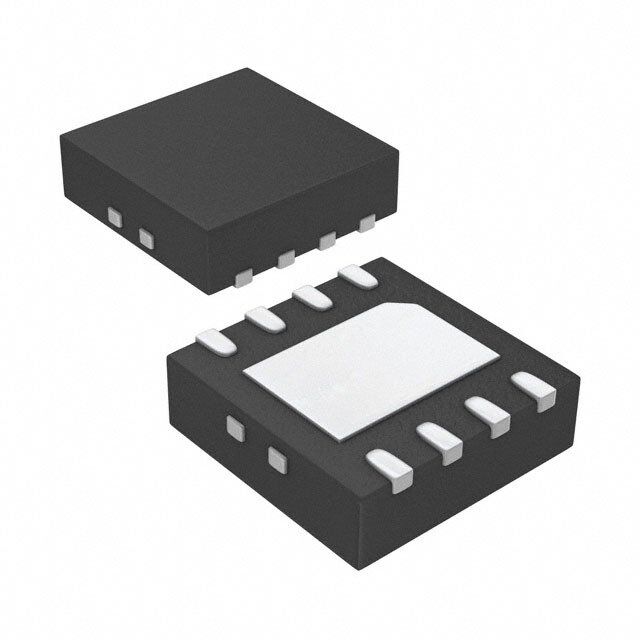

ICGOO电子元器件商城为您提供ST1S31PUR由STMicroelectronics设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 ST1S31PUR价格参考。STMicroelectronicsST1S31PUR封装/规格:PMIC - 稳压器 - DC DC 开关稳压器, 可调式 降压 开关稳压器 IC 正 0.8V 1 输出 3A 8-VDFN 裸露焊盘。您可以下载ST1S31PUR参考资料、Datasheet数据手册功能说明书,资料中有ST1S31PUR 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | 集成电路 (IC)半导体 |

| 描述 | IC REG BUCK SYNC ADJ 3A 8VFDFPN稳压器—开关式稳压器 3A DC Step Down REG 2.8V to 5.5V 1.5MHz |

| 产品分类 | |

| 品牌 | STMicroelectronics |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 电源管理 IC,稳压器—开关式稳压器,STMicroelectronics ST1S31PUR- |

| 数据手册 | |

| 产品型号 | ST1S31PUR |

| PWM类型 | 电流模式 |

| 产品培训模块 | http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=26258 |

| 产品种类 | 稳压器—开关式稳压器 |

| 供应商器件封装 | 8-VFDFPN(3x3) |

| 其它名称 | 497-13213-1 |

| 其它有关文件 | http://www.st.com/web/catalog/sense_power/FM142/CL1456/SC355/PF251697?referrer=70071840 |

| 包装 | 剪切带 (CT) |

| 同步整流器 | 是 |

| 商标 | STMicroelectronics |

| 安装类型 | 表面贴装 |

| 安装风格 | SMD/SMT |

| 封装 | Reel |

| 封装/外壳 | 8-VDFN 裸露焊盘 |

| 封装/箱体 | VFDFPN-8L |

| 工作温度 | -40°C ~ 125°C |

| 工厂包装数量 | 3000 |

| 开关频率 | 1.5 MHz |

| 最大输入电压 | 5.5 V |

| 标准包装 | 1 |

| 电压-输入 | 2.8 V ~ 5.5 V |

| 电压-输出 | 0.8 V ~ 5.5 V |

| 电流-输出 | 3A |

| 类型 | 降压(降压) |

| 系列 | ST1S31 |

| 输出数 | 1 |

| 输出电压 | Adj |

| 输出电流 | 3 A |

| 输出端数量 | 1 |

| 输出类型 | 可调式 |

| 频率-开关 | 1.5MHz |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

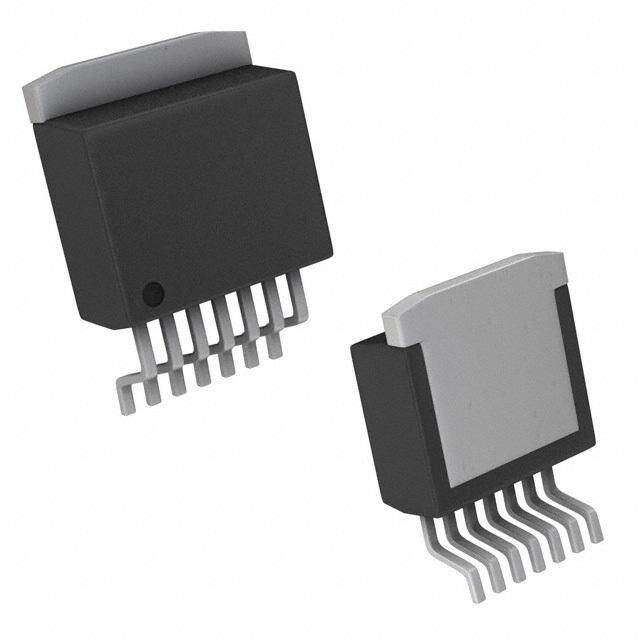

ST1S31 3 A DC step-down switching regulator Datasheet - production data Applications µP/ASIC/DSP/FPGA core and I/O supplies Point of load for: STB, TVs, DVDs Optical storage, hard disk drive, printers, audio/graphic cards VFDFPN 3 x 3 - 8L SO8 Description The ST1S31 device is an internally compensated Features 1.5 MHz fixed-frequency PWM synchronous step- down regulator. The ST1S31 operates from 2.8 V 3 A DC output current to 5.5 V input, while it regulates an output voltage 2.8 V to 5.5 V input voltage as low as 0.8 V and up to V . IN Output voltage adjustable from 0.8 V The ST1S31 integrates a 60 m high-side switch 1.5 MHz switching frequency and a 45 m synchronous rectifier allowing very Internal soft-start and enable high efficiency with very low output voltages. Integrated 60 m and 45 m power MOSFETs The peak current mode control with internal compensation delivers a very compact solution All ceramic capacitor with a minimum component count. Power Good (POR) The ST1S31 device is available in 3 mm x 3 mm, Cycle-by-cycle current limiting 8 lead VFDFPN and SO8 packages. Current foldback short-circuit protection VFDFPN 3 x 3 - 8L, SO8 packages Figure 1. Application circuit (cid:47) (cid:57)(cid:44)(cid:49) (cid:57)(cid:50)(cid:56)(cid:55) (cid:57)(cid:44)(cid:49)(cid:54)(cid:58) (cid:54)(cid:58) (cid:57)(cid:44)(cid:49)(cid:36) (cid:53)(cid:20) (cid:38)(cid:76)(cid:81)(cid:66)(cid:68) (cid:40)(cid:49) (cid:54)(cid:55)(cid:20)(cid:54)(cid:22)(cid:20) (cid:57)(cid:41)(cid:37) (cid:38)(cid:82)(cid:88)(cid:87) (cid:38)(cid:76)(cid:81)(cid:66)(cid:86)(cid:90) (cid:51)(cid:42) (cid:42)(cid:49)(cid:39) (cid:53)(cid:21) August 2018 DocID022998 Rev 5 1/36 This is information on a product in full production. www.st.com

Contents ST1S31 Contents 1 Pin settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.1 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Thermal data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 3 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 4 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 4.1 Output voltage adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 4.2 Soft-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 4.3 Error amplifier and control loop stability . . . . . . . . . . . . . . . . . . . . . . . . . . 10 4.4 Overcurrent protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 4.5 Enable function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 4.6 Light load operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 4.7 Hysteretic thermal shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 5 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 5.1 Input capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 5.2 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 5.3 Output capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 5.4 Thermal dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 5.5 Layout consideration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 6 Demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 7 Typical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 8 Package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 8.1 VFDFPN 3 x 3 - 8L package information . . . . . . . . . . . . . . . . . . . . . . . . . 31 8.2 SO8 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 2/36 DocID022998 Rev 5

ST1S31 Contents 9 Order codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 DocID022998 Rev 5 3/36 36

Pin settings ST1S31 1 Pin settings 1.1 Pin connection Figure 2. Pin connection (top view) 1.2 Pin description Table 1. Pin description No. Type Description 1 VINA Unregulated DC input voltage Enable input. With EN higher than 1.5 V the device is ON and with EN 2 EN lower than 0.5 V the device is OFF. Feedback input. Connecting the output voltage directly to this pin the 3 FB output voltage is regulated at 0.8 V. To have higher regulated voltages an external resistor divider is required from V to the FB pin. OUT 4 AGND Ground Open drain Power Good (POR) pin. It is released (open drain) when the output voltage is higher than 0.92 * V with a delay of 170 s. If the 5 PG OUT output voltage is below 0.92 * V , the POR pin goes to low impedance OUT immediately. If not used, it can be left floating or to GND. 6 VINSW Power input voltage 7 SW Regulator output switching pin 8 PGND Power ground (VFDFPN package only) exposed pad connected to ground assuring ePAD electrical contact and heat conduction. 4/36 DocID022998 Rev 5

ST1S31 Maximum ratings 2 Maximum ratings Table 2. Absolute maximum ratings Symbol Parameter Value Unit V Input voltage -0.3 to 7 IN V Enable voltage -0.3 to V EN IN V Output switching voltage -1 to V V SW IN V Power-on reset voltage (Power Good) -0.3 to V PG IN V Feedback voltage -0.3 to 1.5 FB 1.5 (VFDFPN) P Power dissipation at T < 60 °C W TOT A 0.9 (SO8) T Operating junction temperature range -40 to 150 °C OP T Storage temperature range -55 to 150 °C stg Thermal data Table 3. Thermal data Symbol Parameter Value Unit Maximum thermal resistance VFDFPN 50 R °C/W thJA junction ambient(1) SO8 100 1. Package mounted on demonstration board. DocID022998 Rev 5 5/36 36

Electrical characteristics ST1S31 3 Electrical characteristics T = 25 °C, V = 5 V, unless otherwise specified. J IN Table 4. Electrical characteristics Values Symbol Parameter Test condition Unit Min. Typ. Max. V Operating input voltage range (1) 2.8 5.5 IN V Turn-on V threshold (1) 2.4 V INON CC V Turn-off V threshold (1) 2.0 INOFF CC R -P High-side switch ON-resistance I = 300 mA 60 m DSON SW R -N Low-side switch ON-resistance I = 300 mA 45 m DSON SW I Maximum limiting current (2) 4.0 A LIM Oscillator F Switching frequency 1.2 1.5 1.9 MHz SW D Maximum duty cycle (2) 95 100 % MAX Dynamic characteristics 0.792 0.8 0.808 V Feedback voltage V FB Io = 10 mA to 4 A(1) 0.776 0.8 0.824 %V / OUT Reference load regulation Io = 10 mA to 4 A(2) 0.2 0.6 % I OUT %V / OUT Reference line regulation V = 2.8 V to 5.5 V(2) 0.2 0.3 % V IN IN DC characteristics I Quiescent current Duty cycle = 0, no load V = 1.2 V 630 1200 µA Q FB I Total standby quiescent current OFF 1 µA QST-BY Enable Device ON level 1.5 V EN threshold voltage V EN Device OFF level 0.5 I EN current 0.1 µA EN Power Good PG threshold 92 %V FB PG hystereris 30 50 PG mV PG output voltage low Isink = 6 mA open drain 400 PG rise delay 170 µs 6/36 DocID022998 Rev 5

ST1S31 Electrical characteristics Table 4. Electrical characteristics (continued) Values Symbol Parameter Test condition Unit Min. Typ. Max. Soft-start T Soft-start duration 400 µs SS Protection Thermal shutdown 150 T °C SHDN Hystereris 20 1. Specification referred to T from -40 to +125 °C. Specifications in the -40 to +125 °C temperature range are assured by J design, characterization and statistical correlation. 2. Guaranteed by design. DocID022998 Rev 5 7/36 36

Functional description ST1S31 4 Functional description The ST1S31 device is based on a “peak current mode”, constant frequency control. The output voltage V is sensed by the feedback pin (FB) compared to an internal reference OUT (0.8 V) providing an error signal that, compared to the output of the current sense amplifier, controls the ON and OFF time of the power switch. The main internal blocks are shown in the block diagram in Figure3. They are: A fully integrated oscillator that provides the internal clock and the ramp for the slope compensation avoiding sub-harmonic instability The soft-start circuitry to limit inrush current during the startup phase The transconductance error amplifier The pulse width modulator and the relative logic circuitry necessary to drive the internal power switches The drivers for embedded P-channel and N-channel power MOSFET switches The high-side current sensing block The low-side current sense to implement diode emulation A voltage monitor circuitry (UVLO) that checks the input and internal voltages A thermal shutdown block, to prevent thermal runaway. Figure 3. Block diagram AM11417v1 8/36 DocID022998 Rev 5

ST1S31 Functional description 4.1 Output voltage adjustment The error amplifier reference voltage is 0.8 V typical. The output voltage is adjusted according to the following formula (see Figure1 on page1): Equation 1 R 1 V = 0.8 1+------- OUT R 2 The internal architecture of the device requires a minimum off time, cycle-by-cycle, for the output voltage regulation. The minimum off time is typically equal to 94 ns. The control loop compensates for conversion losses with duty cycle control. Since the power losses are proportional to the delivered output power, the duty cycle increases with the load current request. Figure4 shows the maximum regulated output voltage over the input voltage range at different loading conditions. Figure 4. Maximum output voltage over loading conditions 4.2 Soft-start The soft-start is essential to assure the correct and safe startup of the step-down converter. It avoids inrush current surge and makes the output voltage rise monotonically. The soft-start is managed by ramping the reference of the error amplifier from 0 V to 0.8 V. The internal soft-start capacitor is charged with a resistor to 0.8 V, then the FB pin follows the reference so that the output voltage is regulated to rise to the set value monotonically. DocID022998 Rev 5 9/36 36

Functional description ST1S31 4.3 Error amplifier and control loop stability The error amplifier provides the error signal to be compared with the high-side switch current through the current sense circuitry. The non inverting input is connected with the internal 0.8V reference, while the inverting input is the FB pin. The compensation network is internal and connected between the E/A output and GND. The error amplifier of the ST1S31 device is a transconductance operational amplifier, with high bandwidth and high output impedance. Table 5. Characteristics of the uncompensated error amplifier Description Value DC gain 94 dB gm 238 µA/V Ro 96 M The ST1S31 device embeds the compensation network that assures the stability of the loop in the whole operating range. All the tools needed to check the loop stability are shown on the next pages of this section. In Figure5 the simple small signal model for the peak current mode control loop is shown. Figure 5. Block diagram of the loop for the small signal analysis VIN Slope GCO(s) Compensation High side Switch G (s) Current sense L VOUT DIV Logic Cout And Low side Driver Switch PWM comparator 0.8V R1 V C V FB Rc Error Amp R2 Cc G (s) EA AM11418v1 Three main terms can be identified to obtain the loop transfer function: 1. From control (output of E/A) to output, G (s) CO 2. From output (V ) to the FB pin, G (s) OUT DIV 3. From the FB pin to control (output of E/A), G (s). EA The transfer function from control to output G (s) results: CO 10/36 DocID022998 Rev 5

ST1S31 Functional description Equation 2 s 1+------ RLOAD 1 z G s = -------------------------------------------------------------------------------------------------------------------------------------F s CO Ri 1+R-----o---u---t--L----T----S---W----mC1–D–0.5 1+--s---p- H where R represents the load resistance, R the equivalent sensing resistor of the LOAD i current sense circuitry (0.369 ), the single pole introduced by the LC filter and the p z zero given by the ESR of the output capacitor. F (s) accounts for the sampling effect performed by the PWM comparator on the output of H the error amplifier that introduces a double pole at one half of the switching frequency. Equation 3 1 = ------------------------------- Z ESRC OUT Equation 4 1 mC1–D–0.5 = --------------------------------------+--------------------------------------------- p R C LC f LOAD OUT OUT SW where: Equation 5 Se mC = 1+S------ n S = V f e pp SW V –V IN OUT S = ------------------------------R n L i S represents the ON-time slope of the sensed inductor current, S the slope of the external n e ramp (V peak-to-peak amplitude - 0.535 V) that implements the slope compensation to PP avoid sub-harmonic oscillations at duty cycle over 50%. The sampling effect contribution F (s) is: H Equation 6 1 F s = ------------------------------------------- H 2 s s 1+-------------------+------ Q 2 n P n where: Equation 7 1 Q = ---------------------------------------------------------- P m 1–D–0.5 C and Equation 8 = f n SW DocID022998 Rev 5 11/36 36

Functional description ST1S31 The resistor to adjust the output voltage that gives the term from output voltage to the FB pin. G (s) is: DIV R 2 G s = -------------------- DIV R +R 1 2 The transfer function from FB to Vc (output of E/A) introduces the singularities (poles and zeroes) to stabilize the loop. The small signal model of the error amplifier with the internal compensation network can be seen in Figure6. Figure 6. Small signal model for the error amplifier V FB Ro Co Rc Cp Cc Vd Gm*Vd Cc V REF AM11419v1 R and C introduce a pole and a zero in the open loop gain. C does not significantly affect C C P system stability and can be neglected. So G (s) results: EA Equation 9 G 1+sR C EA0 c c G s = ----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- EA 2 s R C +C R C +sR C +R C +C +R C +1 0 0 p c c 0 c 0 0 p c c where G = G · R . EA m o The poles of this transfer function are (if C >> C +C ): c 0 P Equation 10 1 f = ---------------------------------- P LF 2R C 0 c Equation 11 1 f = ---------------------------------------------------- P HF 2R C +C c 0 p whereas the zero is defined as: Equation 12 1 f = --------------------------------- Z 2R C c c 12/36 DocID022998 Rev 5

ST1S31 Functional description The embedded compensation network is R = 80 k, C = 55 pF while C and C can be C C P O considered as negligible. The error amplifier output resistance is 96 Mso the relevant singularities are: Equation 13 f = 362 kHz f = 30 Hz Z P LF So closing the loop, the loop gain G (s) is: LOOP Equation 14 G s = G sG sG s LOOP CO DIV EA Example 1: V = 5 V, V = 1.2 V, I = 3 A, L = 1.0 H, C t = 47 µF (MLCC), R1 = 10 k, IN OUT omax ou R2 = 20k(see Section5.2 and Section5.3 for inductor and output capacitor selection guidelines). The module and phase bode plot are reported in Figure7 and Figure8. The bandwidth is 117 kHz and the phase margin is 63 degrees. Figure 7. Module bode plot DocID022998 Rev 5 13/36 36

Functional description ST1S31 Figure 8. Phase bode plot 4.4 Overcurrent protection The ST1S31 device implements overcurrent protection sensing the current flowing through the high-side current switch. If the current exceeds the overcurrent threshold the high-side is turned off, implementing a cycle-by-cycle current limitation. Since the regulation loop is no longer fixing the duty cycle, the output voltage is unregulated and the FB pin falls accordingly to the new duty cycle. If the FB falls below 0.2 V, the peak current limit is reduced to around 2.3 A and the switching frequency is reduced to assure that the inductor current is properly limited below the above mentioned value and above 1.2 A. This strategy is called “current foldback”. The mechanism to adjust the switching frequency during the current foldback condition exploits the low-side current sense circuitry. If FB is lower than 0.2 V, the high-side power MOSFET is turned off when the current reaches the current foldback threshold (2.3 A), then, after a proper deadtime that avoids the cross conduction, the low-side is turned on until the low-side current is lower than a valley threshold (1.2 A). Once the low-side is turned off, the high-side is immediately turned on. In this way the frequency is adjusted to keep the inductor current ripple between the current foldback value (2.3 A) and valley threshold (1.2 A), so properly limiting the output current in case of overcurrent or short-circuit. It should be noted that in some cases, mainly with very low output voltages, the hard overcurrent can cause the FB to find the new equilibrium just over the current foldback threshold (0.2 V). In this case no frequency reduction is enabled, then the inductor current may diverge. This means that the ripple current during the minimum ON-time is higher than the ripple current during the OFF-time (the switching period minus the minimum ON-time), so pulse-by-pulse, the average current is rising, exceeding the current limit. In order to avoid too high current, a further protection is activated when the high-side current exceeds a further current threshold (OCP2) slightly over the current limit (OCP1). If the current triggers the second threshold, the converter stops switching, the reference of the error amplifier is pulled down and then it restarts with a soft-start procedure. If the overcurrent condition is still active, the current foldback with frequency reduction properly limits the output current to 2.3 A. 14/36 DocID022998 Rev 5

ST1S31 Functional description 4.5 Enable function The enable feature allows the device to be put into standby mode. With the EN pin is lower than 0.4 V, the device is disabled and the power consumption is reduced to less than 10 A. With the EN pin higher than 1.2 V, the device is enabled. If the EN pin is left floating, an internal pull-down ensures that the voltage at the pin reaches the inhibit threshold and the device is disabled. The pin is also V compatible. IN 4.6 Light load operation With peak current mode control loop the output of the error amplifier is proportional to the load current. In the ST1S31 device, to increase light load efficiency when the output of the error amplifier falls below a certain threshold, the high-side turn-on is prevented. This mechanism reduces the switching frequency at light load in order to save the switching losses. 4.7 Hysteretic thermal shutdown The thermal shutdown block generates a signal that turns off the power stage if the junction temperature goes above 150 °C. Once the junction temperature goes back to about 130 °C, the device restarts in normal operation. DocID022998 Rev 5 15/36 36

Application information ST1S31 5 Application information 5.1 Input capacitor selection The capacitor connected to the input must be capable of supporting the maximum input operating voltage and the maximum RMS input current required by the device. The input capacitor is subject to a pulsed current, the RMS value of which is dissipated over its ESR, affecting the overall system efficiency. So the input capacitor must have an RMS current rating higher than the maximum RMS input current and an ESR value compliant with the expected efficiency. The maximum RMS input current flowing through the capacitor can be calculated as: Equation 15 2 2 2D D I = I D–---------------+------- RMS O 2 where Io is the maximum DC output current, D is the duty cycle, and is the efficiency. Considering = 1, this function has a maximum at D = 0.5 and is equal to Io/2. The peak-to-peak voltage across the input capacitor can be calculated as: Equation 16 IO D D V = ------------------------- 1–---- D+----1–D +ESRI PP C F O IN SW where ESR is the equivalent series resistance of the capacitor. Given the physical dimension, ceramic capacitors can well meet the requirements of the input filter sustaining a higher input RMS current than electrolytic / tantalum types. In this case the equation of C as a function of the target peak-to-peak voltage ripple (V ) can be IN PP written as follows: Equation 17 IO D D C = --------------------------- 1–---- D+----1–D IN V F PP SW neglecting the small ESR of ceramic capacitors. Considering = 1, this function has its maximum in D = 0.5, therefore, given the maximum peak-to-peak input voltage (V ), the minimum input capacitor (C ) value is: PP_MAX IN_MIN Equation 18 I O C = ------------------------------------------------ IN_MIN 2V F PP_MAX SW Typically, C is dimensioned to keep the maximum peak-to-peak voltage ripple in the order IN of 1% of V . INMAX 16/36 DocID022998 Rev 5

ST1S31 Application information The placement of the input capacitor is very important to avoid noise injection and voltage spikes on the input voltage pin. So the C must be placed as close as possible to the IN VIN_SW pin. In Table6 some multilayer ceramic capacitors suitable for this device are given. Table 6. Input MLCC capacitors Manufacturer Series Cap value (µF) Rated voltage (V) Murata GRM21 10 10 C3225 10 25 TDK C3216 10 16 TAIYO YUDEN LMK212 22 10 A ceramic bypass capacitor, as close as possible to the VINA pin so that additional parasitic ESR and ESL are minimized, is suggested in order to prevent instability on the output voltage due to noise. The value of the bypass capacitor can go from 330 nF to 1 µF. 5.2 Inductor selection The inductance value fixes the current ripple flowing through the output capacitor. So the minimum inductance value to have the expected current ripple must be selected. The rule to fix the current ripple value is to have a ripple at 20% - 40% of the output current. In continuous current mode (CCM), the inductance value can be calculated by Equation 19: Equation 19 V –V V IN OUT OUT I = ------------------------------T = --------------T L L ON L OFF where T is the conduction time of the high-side switch and T is the conduction time of ON OFF the low-side switch (in CCM, F = 1/(T + T )). The maximum current ripple, given the SW ON OFF V , is obtained at maximum T , that is, at minimum duty cycle (see previous section to OUT OFF calculate minimum duty). So by fixing I = 20% to 30% of the maximum output current, the L minimum inductance value can be calculated: Equation 20 V 1–D OUT MIN L = --------------------------------------- MIN I F MAX SWMIN where F is the minimum switching frequency, according to Table4. The slope SWMIN compensation, to prevent the sub-harmonic instability in the peak current control loop, is internally managed and so fixed. This implies a further lower limit for the inductor value. To assure sub-harmonic stability: Equation 21 LV 2V f out pp sw where V is the peak-to-peak value of the slope compensation ramp. The inductor value PP selected based on Equation 20 must satisfy Equation 21. The peak current through the inductor is given by Equation 22: DocID022998 Rev 5 17/36 36

Application information ST1S31 Equation 22 I L I = I +-------- LPK O 2 So if the inductor value decreases, the peak current (which must be lower than the current limit of the device) increases. The higher the inductor value, the higher the average output current that can be delivered, without reaching the current limit. In Table7 some inductor part numbers are listed. Table 7. Inductors Manufacturer Series Inductor value (µH) Saturation current (A) XAL50xx 1.2 to 3.3 6.3 to 9 Coilcraft XAL60xx 2.2 to 5.6 7.4 to 11 MSS1048 1.0 to 3.8 6.5 to 11 WE-HCI 7030 1.5 to 4.7 7 to 14 Würth WE-PD type L 1.5 to 3.5 6.4 to 10 DR73 1.0 to 2.2 5.5 to7.9 Coiltronics DR74 1.5 to 3.3 5.4 to 8.35 5.3 Output capacitor selection The current in the output capacitor has a triangular waveform which generates a voltage ripple across it. This ripple is due to the capacitive component (charge or discharge of the output capacitor) and the resistive component (due to the voltage drop across its ESR). So the output capacitor must be selected in order to have a voltage ripple compliant with the application requirements. The amount of the voltage ripple can be calculated starting from the current ripple obtained by the inductor selection. Equation 23 I MAX V = ESRI +------------------------------------- OUT MAX 8C f OUT SW For a ceramic (MLCC) capacitor, the capacitive component of the ripple dominates the resistive one. While for an electrolytic capacitor the opposite is true. As the compensation network is internal, the output capacitor should be selected in order to have a proper phase margin and then a stable control loop. The equations of Section5.2 help to check loop stability given the application conditions, the value of the inductor and of the output capacitor. 18/36 DocID022998 Rev 5

ST1S31 Application information In Table8 some capacitor series are listed. Table 8. Output capacitors Manufacturer Series Cap value (µF) Rated voltage (V) ESR (m) GRM32 22 to 100 6.3 to 25 < 5 Murata GRM31 10 to 47 6.3 to 25 < 5 ECJ 10 to 22 6.3 < 5 Panasonic EEFCD 10 to 68 6.3 15 to 55 Sanyo TPA/B/C 100 to 470 4 to 16 40 to 80 TDK C3225 22 to 100 6.3 < 5 5.4 Thermal dissipation The thermal design is important to prevent the thermal shutdown of the device if junction temperature goes above 150 °C. The three different sources of losses within the device are: a) conduction losses due to the on-resistance of high-side switch (R ) and low-side HS switch (R ); these are equal to: LS Equation 24 2 2 P = R I D+R I 1–D COND HS OUT LS OUT where D is the duty cycle of the application. Note that the duty cycle is theoretically given by the ratio between V and V , but it is actually slightly higher to compensate the losses of OUT IN the regulator. b) switching losses due to high-side power MOSFET turn-on and turn-off; these can be calculated as: Equation 25 T +T RISE FALL P = V I -------------------------------------------Fsw = V I T F SW IN OUT 2 IN OUT SW SW where T and T are the overlap times of the voltage across the high-side power RISE FALL switch (V ) and the current flowing into it during the turn-on and turn-off phases, as shown DS in Figure9. T is the equivalent switching time. For this device the typical value for the SW equivalent switching time is 20 ns. c) Quiescent current losses, calculated as: Equation 26 P = V I Q IN Q where I is the quiescent current (I = 1.2 mA maximum). Q Q DocID022998 Rev 5 19/36 36

Application information ST1S31 The junction temperature T can be calculated as: J Equation 27 T = T +Rth P J A JA TOT where T is the ambient temperature and P is the sum of the power losses just seen. A TOT Rth is the equivalent thermal resistance junction to ambient of the device; it can be JA calculated as the parallel of many paths of heat conduction from the junction to the ambient. For this device the path through the exposed pad is the one conducting the largest amount of heat. The Rth measured on the demonstration board described in Section5.5 is about JA 50 °C/W for the VFDFPN and 100 °C/W for the SO8 package. Figure 9. Switching losses V IN V SW I SW,HS V DS,HS P SW P P COND,HS COND,LS T T FALL RISE AM11422v1 5.5 Layout consideration The PC board layout of the switching DC-DC regulator is very important to minimize the noise injected in high impedance nodes, to reduce interference generated by the high switching current loops and to optimize the reliability of the device. In order to avoid EMC problems, the high switching current loops must be as short as possible. In the buck converter there are two high switching current loops: during the on-time, the pulsed current flows through the input capacitor, the high-side power switch, the inductor and the output capacitor; during the off-time, through the low-side power switch, the inductor and the output capacitor. The input capacitor connected to VINSW must be placed as close as possible to the device, to avoid spikes on VINSW due to the stray inductance and the pulsed input current. In order to prevent dynamic unbalance between VINSW and VINA, the trace connecting the VINA pin to the input must be derived from VINSW. 20/36 DocID022998 Rev 5

ST1S31 Application information The feedback pin (FB) connection to the external resistor divider is a high impedance node, so the interference can be minimized by routing the feedback node with a very short trace and as far as possible from the high current paths. A single point connection from signal ground to power ground is suggested. Thanks to the exposed pad of the device, the ground plane helps to reduce the thermal resistance junction to ambient; so a large ground plane, soldered to the exposed pad, enhances the thermal performance of the converter allowing high power conversion. Figure 10. PCB layout example Via to connect the thermal pad To bottom or inner ground plane Star center for common ground Short high switching current loop Input cap as close as possible to VINSW pin Short FB trace VINA derived from Cin To avoid dynamic voltage drop Between VINA and VINSW AM11423v1 DocID022998 Rev 5 21/36 36

Demonstration board ST1S31 6 Demonstration board Figure 11. Demonstration board schematic 5V VIN UU11 SSTT11SS3311 1 VIN_A PGND 8 LL11 3.3V CC33 2 EN SW 7 Vout 11uu 3 6 22..22uuHH FB VIN_SW 4 5 CC11 CC22 AGND ePAD PGOOD 1100uu 2222uu RR33 RR11 1100kk RR22 6622..55kk CC44 2200kk NNCC 0 0 AM11424v1 Table 9. Component list Reference Part number Description Manufacturer U1 ST1S31 ST L1 DR73 2R2 2.2 µH, Isat = 5.5 A Coiltronics C1 C3225X7RE106K 10 µF 25 V X7R TDK C2 C3225X7R1C226M 22 µF 16 V X7R TDK C3 1 µF 25 V X7R C4 NC R1 62.5 k R2 20 k R3 10 k 22/36 DocID022998 Rev 5

ST1S31 Demonstration board Figure 12. Demonstration board PCB top and bottom, DFN package Figure 13. Demonstration board PCB top and bottom, SO8 package DocID022998 Rev 5 23/36 36

Typical characteristics ST1S31 7 Typical characteristics Figure 14. Efficiency curves: V = 3.3 V IN Figure 15. Efficiency curves: V = 3.3 V (log scale) IN 24/36 DocID022998 Rev 5

ST1S31 Typical characteristics Figure 16. Load regulation (V = 3.3 V) IN Figure 17. Efficiency curves: V = 4.0 V IN DocID022998 Rev 5 25/36 36

Typical characteristics ST1S31 Figure 18. Efficiency curves: V = 4.0 V (log scale) IN Figure 19. Load regulation (V = 4.0 V) IN 26/36 DocID022998 Rev 5

ST1S31 Typical characteristics Figure 20. Efficiency curves: V = 5.0 V IN Figure 21. Efficiency curves: V = 5.0 V (log scale) IN DocID022998 Rev 5 27/36 36

Typical characteristics ST1S31 Figure 22. Load regulation (V = 5.0 V) IN 28/36 DocID022998 Rev 5

ST1S31 Typical characteristics Figure 23. Zero load operation Figure 24. Overcurrent protection VIN=5V, V OUT=1.2V, I O=0A VIN=5.5V , VOUT=1.2V, I LOAD=0.5A -> 4.8A Green: IL (100mA/div) Timescale 2us/div Green: IL (1A/div) Timescale 100us/div Yellow: SW (1V/div) Yellow: SW (1V/div) Red: VOUT (20mV/div) Red: VOUT (200mV/div) AM11429v1 AM11430v1 Figure 25. 100 mA operation Figure 26. Short-circuit protection VIN=5V, VOUT=1.2V, IO=100mA VIN=5.5V, VOUT=1.2V Green: IL (1A/div) Timescale 50us/div Green: IL (100mA/div) Timescale 2us/div Yellow: SW (1V/div) Yellow: SW (1V/div) Red: VOU(T2 00mV/div) Red: VOUT (20mV/div) AAMM1111443300vv11 AM11431v1 DocID022998 Rev 5 29/36 36

Package information ST1S31 8 Package information In order to meet environmental requirements, ST offers these devices in different grades of ECOPACK® packages, depending on their level of environmental compliance. ECOPACK specifications, grade definitions and product status are available at: www.st.com. ECOPACK is an ST trademark. 30/36 DocID022998 Rev 5

ST1S31 Package information 8.1 VFDFPN 3 x 3 - 8L package information Figure 27. VFDFPN 3 x 3 - 8L package outline 8057023 Table 10. VFDFPN 3 x 3 - 8L package mechanical data Dimensions (mm) Symbol Min. Typ. Max. A 0.80 0.90 1.00 A1 0.0 0.05 b 0.25 0.30 0.35 D 3.00 D2 2.234 2.384 2.484 E 3.00 E2 1.496 1.646 1.746 e 0.65 L 0.30 0.40 0.50 DocID022998 Rev 5 31/36 36

Package information ST1S31 Figure 28. VFDFPN 3 x 3 - 8L recommended footprint(1) (cid:51)(cid:50)(cid:36)(cid:66)(cid:27)(cid:19)(cid:24)(cid:26)(cid:19)(cid:21)(cid:22) 1. Dimensions are in mm. 32/36 DocID022998 Rev 5

ST1S31 Package information 8.2 SO8 package information Figure 29. SO8 package outline 0016023_Rev_E Table 11. SO8 package mechanical data Dimensions (mm) Symbol Min. Typ. Max. A 1.75 A1 0.10 0.25 A2 1.25 b 0.28 0.48 c 0.17 0.23 D 4.80 4.90 5.00 E 5.80 6.00 6.20 E1 3.80 3.90 4.00 e 1.27 h 0.25 0.50 L 0.40 1.27 L1 1.04 k 0° 8° ccc 0.10 DocID022998 Rev 5 33/36 36

Order codes ST1S31 9 Order codes Table 12. Ordering information Order codes Package ST1S31PUR VFDFPN 3 x 3 - 8 L ST1S31D-R SO8 34/36 DocID022998 Rev 5

ST1S31 Revision history 10 Revision history T able 13. Document revision history Date Revision Changes Updated Figure 2: Pin connection (top view) on page 3 (replaced 12-Nov-2014 3 by new figure). Minor modifications throughout document. Updated value in Table 3 on page 5 and Section 5.4 on page 19 (replaced 40 °C/W by 50 °C/W). Added Section 4.1 on page 9. 03-Mar-2016 4 Updated Section 7 on page 24 [added Figure 14 on page 24 to Figure 22 on page 28 (replaced figures 13 and 14)]. Minor modifications throughout document. 03-Aug-2018 5 Updated Figure1: Application circuit on the cover page. DocID022998 Rev 5 35/36 36

ST1S31 IMPORTANT NOTICE – PLEASE READ CAREFULLY STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement. Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of Purchasers’ products. No license, express or implied, to any intellectual property right is granted by ST herein. Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product. ST and the ST logo are trademarks of ST. All other product or service names are the property of their respective owners. Information in this document supersedes and replaces information previously supplied in any prior versions of this document. © 2018 STMicroelectronics – All rights reserved 36/36 DocID022998 Rev 5

Mouser Electronics Authorized Distributor Click to View Pricing, Inventory, Delivery & Lifecycle Information: S TMicroelectronics: ST1S31PUR ST1S31D-R

Datasheet下载

Datasheet下载