ICGOO在线商城 > 光电元件 > LED 指示 - 分立 > SML-M13PTT86

- 型号: SML-M13PTT86

- 制造商: ROHM Semiconductor

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

SML-M13PTT86产品简介:

ICGOO电子元器件商城为您提供SML-M13PTT86由ROHM Semiconductor设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 SML-M13PTT86价格参考。ROHM SemiconductorSML-M13PTT86封装/规格:LED 指示 - 分立, 绿色 560nm LED 指示 - 分立 2.2V 0805(2012 公制)。您可以下载SML-M13PTT86参考资料、Datasheet数据手册功能说明书,资料中有SML-M13PTT86 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

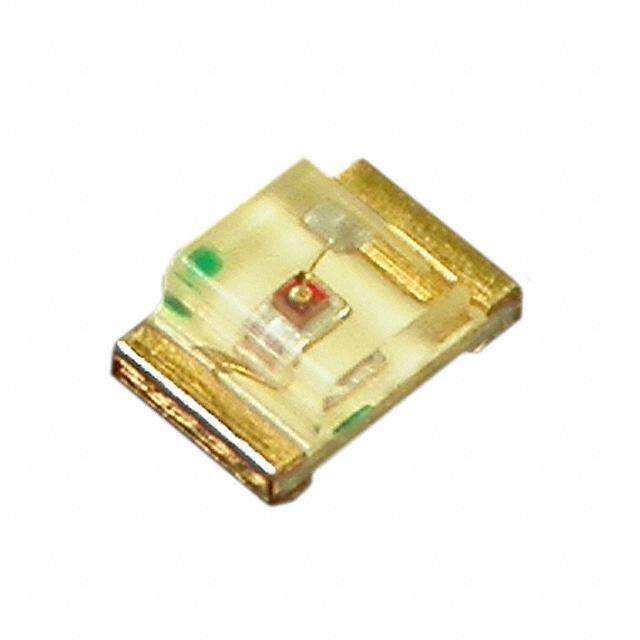

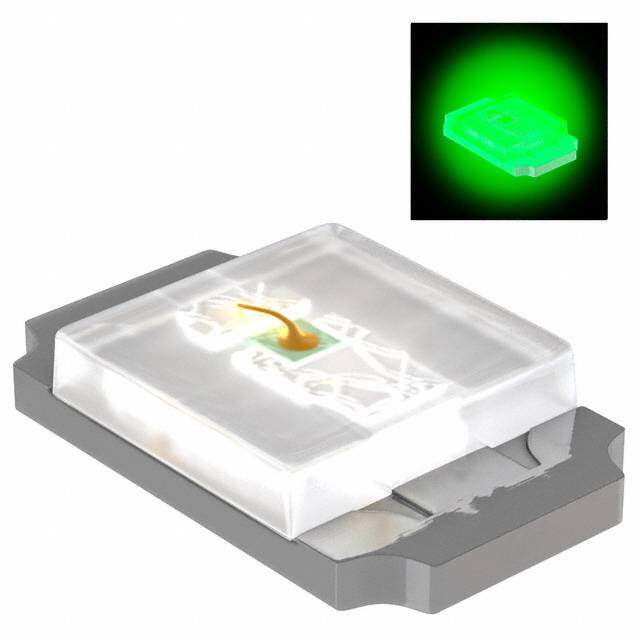

| 描述 | LED COMPACT REFL GRN 560NM 0805标准LED-SMD LED SMD 560nm With Reflector |

| 产品分类 | |

| LED大小 | 2 mm x 1.25 mm x 0.8 mm |

| 品牌 | Rohm Semiconductor |

| 产品手册 | http://www.rohm.com/web/global/products/-/product/SML-M13PT |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | LED发射器,标准LED-SMD,ROHM Semiconductor SML-M13PTT86- |

| 数据手册 | |

| 产品型号 | SML-M13PTT86 |

| 产品种类 | 标准LED-SMD |

| 光强度 | 16 mcd |

| 其它名称 | 846-1029-1 |

| 包装 | 剪切带 (CT) |

| 商标 | ROHM Semiconductor |

| 大小/尺寸 | 2.00mm 长 x 1.25mm 宽 |

| 安装类型 | 表面贴装 |

| 封装 | Reel |

| 封装/外壳 | 0805(2012 公制) |

| 封装/箱体 | 0805 (2012 metric) |

| 工厂包装数量 | 3000 |

| 最大工作温度 | + 85 C |

| 最小工作温度 | - 40 C |

| 标准包装 | 1 |

| 正向电压 | 2.2 V |

| 正向电流 | 20 mA |

| 毫烛光等级 | 16mcd |

| 波长-主 | 560nm |

| 波长-峰值 | - |

| 波长/色温 | 560 nm |

| 测试电流时的光通量 | - |

| 照明颜色 | Green |

| 电压-正向(Vf)(典型值) | 2.2V |

| 电流-测试 | 20mA |

| 视角 | - |

| 透镜样式/尺寸 | 矩形,带平顶,1.4mm x 0.85mm |

| 透镜类型 | 透明 |

| 颜色 | 绿 |

| 高度 | 0.80mm |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

SML-M13x/MN2x Series Data Sheet ■Features ■Outline • Compact LED with reflector • Die is located at the center of the package,achieving equivalent distribution of light emission. ■Size Color V U D Y 20125 (0805) Type 2.0×1.25mm (t=0.8mm) M P E B WB ■Dimensions ■Recommended Solder Pattern 2.0 0.8 1.4 0.3 1.1 1.25 0.85 1.25 ThroughHole 1.1 1.25 2-R0.3 0.9 PCB Bonding Direction Electrode 1.0 Tolerance : ±0.2 (unit : mm) (unit : mm) ■Specifications Absolute Maximum Ratings (Ta=25ºC) Electrical and Optical Characteristics (Ta=25ºC) Part No. Chip StructureEmitting Power ForwardPeak ForwardReverseOperating Temp.Storage Temp. Forward Voltage VF Reverse Current IR D/oCmhroinmaantitc Wity acovoerldeinnagtteh(x λ,y)D Luminous Intensity IV Color DissipationCurrent Current Voltage Typ. IF Max. VR Min.*2 Typ. Max.*2 IF Min. Typ. IF PD(mW) IF(mA) IFP(mA) VR(V) Topr(ºC) Tstg(ºC) (V) (mA) (μA) (V) (nm) (nm) (nm) (mA) (mcd) (mcd) (mA) SML-M13VT 625 630 635 40 75 Red SML-M13UT 615 620 625 63 120 75 2.0 SML-M13DT Orange 602 605 608 AlGaInP 30 5 -40 〜 +85 -40 〜 +100 20 10 5 20 100 160 20 SML-M13YT Yellow 587 590 593 SML-M13MT Yellowish green 100*1 569 572 575 25 45 81 2.2 SML-M13PT 557 560 563 6.3 16 Green SMLMN2ECT(C) 70 3.0 - 527 - 56 140 SMLMN2BCT(C) InGaN Blue 20 12 -40 〜 +100 -40 〜 +100 5 10 12 464 470 476 5 14 36 5 68 2.9 SMLMN2WB1CW(C) *3 White (x,y)(0.30, 0.28) 56 140 *1 : 1/10,1kHz *2 : Measurement tolerance:±1nm、*3:Brightness for white color is noted with chromaticity coordinate(x,y). ________________________________________________________ www.rohm.com ©2016 ROHM Co., Ltd. All rights reserved 1/10 2017.11 - Rev.007

[SML-M13x/MN2x series] [Data Sheet] ■Electrical Characteristics Curves Reference Fig.1 Forward Current Fig.2 Luminous Intensity - - Forward Voltages Atmosphere Temperature ] . 100 .u 1.6 a A] SSMMLL--MM1133VUTT Ta=25ºC Y [ IF=20mA m SML-M13DT T 1.4 I [ SML-M13YT S F SML-M13MT N : I SML-M13PT TE 1.2 T N N I E S RR 10 OU 1 U N C I M D U 0.8 R L SML-M13VT A SML-M13UT W E SML-M13DT V R I 0.6 SML-M13YT O T SML-M13MT F A SML-M13PT L E R 0.4 1 -40 -20 0 20 40 60 80 100 1.5 2.0 2.5 FORWARD VOLTAGE : V [V] ATMOSPHERE TEMPERATURE : Ta [ºC] F Fig.3 Luminous Intensity - Forward Current Fig.4 Derating ] 1.6 mA40 SML-M13VT Y SML-M13UT T SML-M13VT Ta=25ºC [ SML-M13DT SI 1.4 SML-M13UT : SML-M13YT N SML-M13DT T SML-M13MT E SML-M13YT N SML-M13PT T 1.2 SML-M13MT E30 N SML-M13PT R I R S 1.0 U U C O D N 0.8 R20 MI A W U L 0.6 R E O V F TI 0.4 M 10 A U L M E 0.2 I R X A 0.0 M 0 0 5 10 15 20 25 30 -40 -20 0 20 40 60 80 100 FORWARD CURRENT : I [mA] AMBIENT TEMPERATURE : Ta [ºC] F ________________________________________________________ www.rohm.com ©2016 ROHM Co., Ltd. All rights reserved 2/10 2017.11 - Rev.007

[SML-M13x/MN2x series] [Data Sheet] ■Electrical Characteristics Curves Reference Fig.1 Forward Current Fig.2 Luminous Intensity - - Forward Voltages Atmosphere Temperature ] 100 . u 1.6 . Ta=25ºC a SMLMN2BCT(C) [ SMLMN2BCT(C) I =5mA ] SMLMN2WB1CW(C) Y SMLMN2WB1CW(C) F A SMLMN2ECT(C) T 1.4 SMLMN2ECT(C) m I S [ N F E I T 1.2 : N T I N S RE10 OU 1 R N U I C M D U 0.8 R L A E W V I 0.6 R T O A F L E 1 R 0.4 2.0 2.2 2.4 2.6 2.8 3.0 3.2 3.4 3.6 3.8 4.0 -40-30-20-10 0 102030405060708090100 FORWARD VOLTAGE : V [V] ATMOSPHERE TEMPERATURE : Ta [ºC] F Fig.3 Luminous Intensity - Forward Current Fig.4 Derating ] A Y 4.0 m 30 TENSIT 3333....2468 SSSMMMLLLMMMNNN222WBECCBT1T(C(CCW))(C) NT : [ 222468 SSSMMMLLLMMMNNN222WBECCBT1T(C(CCW)) (C) N 3.0 E 22 I 2.8 R US 2.6 UR 20 O 2.4 C 18 N 2.2 D 16 I 2.0 R UM 1.8 WA 14 L 1.6 12 E 1.4 OR 10 TIV 11..02 M F 8 A 0.8 U 6 L E 0.6 M 4 R 0.4 Ta=25ºC XI 2 0.2 A 0.0 M 0 0.0 5.0 10.0 15.0 20.0 -40 -20 0 20 40 60 80 100 120 FORWARD CURRENT : I [mA] AMBIENT TEMPERATURE : Ta [ºC] F ________________________________________________________ www.rohm.com ©2016 ROHM Co., Ltd. All rights reserved 3/10 2017.11 - Rev.007

[SML-M13x/MN2x series] [Data Sheet] ■Viewing Angle Reference X -Y SCANNING ANGLE (deg) (Scannスiキnャgン 方Di向rection) X' -Y' SCANNING ANGLE (deg) SML-M13VT 20 10 0 10 20 20 10 0 10 20 SSMMLL--MM1133UDTT 30 30 30 30 40 40 (Scannスiキnャgン 方Di向rection) 40 40 SML-M13YT SML-M13MT 50 50 50 50 SML-M13PT 60 60 60 60 70 70 70 70 80 80 80 80 9010X0 RE50LATIVE 0INTENSI5T0Y (%)10Y090 9010X0' RELA5T0IVE INT0ENSITY5 0 (%) 1Y00'90 SCANNING ANGLE (deg) SCANNING ANGLE (deg) X' -Y' X -Y (Scannスiキnャgン 方Di向rection) 20 10 0 10 20 20 10 0 10 20 SMLMN2BCT(C) 30 30 (Scannスiキnャgン 方Di向rection) 30 30 SMLMN2WB1CW(C) 40 40 40 40 SMLMN2ECT(C) 50 50 50 50 60 60 60 60 70 70 70 70 80 80 80 80 9010X0 RELA50TIVE IN0TENSIT5Y0 (%) 10Y090 901X00' RELA5T0IVE INT0ENSITY50 (%) 1Y00'90 ________________________________________________________ www.rohm.com ©2016 ROHM Co., Ltd. All rights reserved 4/10 2017.11 - Rev.007

[SML-M13x/MN2x series] [Data Sheet] ■Rank Reference of Brightness* *Measurement tolerance:±10% Red(V,U) (Ta=25ºC, IF=20mA) Rank K L M N P Q R S T U V W Iv (mcd) 4.0〜6.3 6.3〜10 10〜16 16〜25 25〜40 40〜63 63〜100 100〜160 160〜250 250〜400 400〜630 630〜1000 SML-M13VT SML-M13UT Orange(D) (Ta=25ºC, IF=20mA) Rank K L M N P Q R S T U V W Iv (mcd) 4.0〜6.3 6.3〜10 10〜16 16〜25 25〜40 40〜63 63〜100 100〜160 160〜250 250〜400 400〜630 630〜1000 SML-M13DT Yellow(Y) (Ta=25ºC, IF=20mA) Rank K L M N P Q R S T U V W Iv (mcd) 4.0〜6.3 6.3〜10 10〜16 16〜25 25〜40 40〜63 63〜100 100〜160 160〜250 250〜400 400〜630 630〜1000 SML-M13YT Yellowish Green(M) (Ta=25ºC, IF=20mA) Rank K L M N P Q R S T U V W Iv (mcd) 4.0〜6.3 6.3〜10 10〜16 16〜25 25〜40 40〜63 63〜100 100〜160 160〜250 250〜400 400〜630 630〜1000 SML-M13MT Green(P,E) (Ta=25ºC, IF=20mA(P),Ta=25ºC, IF=5mA(E)) Rank K L M N P Q R S T U V W Iv (mcd) 4.0〜6.3 6.3〜10 10〜16 16〜25 25〜40 40〜63 63〜100 100〜160 160〜250 250〜400 400〜630 630〜1000 SML-M13PT SMLMN2ECT(C) Blue(B) (Ta=25ºC, IF=5mA) Rank K L M N P Q R S T U V W Iv (mcd) 4.0〜6.3 6.3〜10 10〜16 16〜25 25〜40 40〜63 63〜100 100〜160 160〜250 250〜400 400〜630 630〜1000 SMLMN2BCT(C) White(WB) (Ta=25ºC, IF=5mA) Rank K L M N P Q R S T U V W Iv (mcd) 4.0〜6.3 6.3〜10 10〜16 16〜25 25〜40 40〜63 63〜100 100〜160 160〜250 250〜400 400〜630 630〜1000 SMLMN2WB1CW(C) ■Chromaticity Diagram (Ta=25℃、If=5mA) 0.36 0 1 2 0.35 x y x y x y 0.34 0.286 0.244 0.280 0.252 0.296 0.259 0.33 0.32 5 0.280 0.252 0.273 0.261 0.291 0.268 0.31 4 0.291 0.268 0.285 0.279 0.310 0.297 E y0.30 0.296 0.259 0.291 0.268 0.313 0.284 CI0.29 3 0.28 2 3 4 5 0.27 1 x y x y x y 0.26 0 0.291 0.268 0.313 0.284 0.310 0.297 0.25 0.285 0.279 0.310 0.297 0.307 0.312 0.24 0.307 0.312 0.330 0.330 0.330 0.347 0.23 0.26 0.27 0.28 0.29 0.30 0.31 0.32 0.33 0.34 0.310 0.297 0.330 0.310 0.330 0.330 CIE x Measurement tolerance:±0.01 ________________________________________________________ www.rohm.com ©2016 ROHM Co., Ltd. All rights reserved 5/10 2017.11 - Rev.007

[SML-M13x/MN2x series] [Data Sheet] ■Taping(T86) 2±0.405±0.1 φ1.5+00.1 ±0.11.75 2.5 5.5 3.5 8.0 1.7 ~0.5 0 1.1±0.1 11.4±1 +1φ6000φ180-3 Unit:mm φ13 Note)Tolerance is within ±0.2mm unless otherwise specified. Packing quantity 3,000pcs / reel Pull direction ■Part No. Construction *"-"will be taken out for emitting color Special Code will be applied for Chromaticity rank Rank sign WB/B/E series. Emitting color WB/B/E series. (for white LED) (Brightness Rank)* S M L - M 1 3 U T T 8 6 S Series name Package Type Chip type Emitting Color Resin Color Taping Specification SMLChip LED P1 1.0x0.6 t=0.2mm 0 Standard Type V Red T Transparent Colorless T86 Cathode at sprocket hole side(the top) E1 1.6x0.8 t=0.36mm 1 Low Current Type U Red W Milkey White T87 Anode at sprocket hole side(the top) D11.6x0.8 t=0.55mm 2 High Brightness type U2 Red B Black 1 For white LED, H1 3 D Orange 3 csthode at sprocket hole side 2.0x1.25 t=0.8mm M1 4 Y3 Yellow 01 3.0x2.0 t=1.3mm 5 Y2 Yellow notice)S1 series、81 seires Ultra High Brightness type Z1/ZN 3.5x2.8 t=1.9mm 6 Y Yellow T86 Cathode at sprocket hole side(the back) A1 1.6x1.15 t=0.55mm 7 W Yellow T68 Cathode at sprocket hole side(the top) 81/823.4x1.25 t=1.1mm 8 M2 Yellowish green K1 4.5x2.0 t=0.6mm M Yellowish green *Concerning the Brightness rank. S1 3.2x1.6 t=1.85mm F Green *Please refer to the rank chart above for P2 1.0x1.0 t=0.2mm P Green luminous intensity classification. 52 1.3x1.5 t=0.6mm E Green *Part name is individual for each rank. P34 1.0x1.0 t=0.2mm B Blue *When shipped as sample,the part name will P36 1.5x1.0 t=0.2mm WB White be a representative part name. VN 3.5x2.8 t=0.6mm T Phototransistors General products are free of ranks. RGB Red/Green/Blue Please contact sales if rank appointment SCMChip LED 01 3.0x1.5 t=2.2mm is needed. ■Packing Specification ROHM LED products are being shipped with desiccant (silica gel) included in moisture-proof bags. Pasting the moisture sensitive label on the outer surface of the moisture-proof bags or enclosing the humidity indication card inside the bag is available upon request. _Pl_ea_se_ c_on_ta_ct_ t_he_ n_ea_re_st_ s_ale_s _of_fic_e _or_ d_ist_rib_u_te_r i_f n_ec_e_ss_ar_y.________________________ www.rohm.com ©2016 ROHM Co., Ltd. All rights reserved 6/10 2017.11 - Rev.007

[SML-M13x/MN2x series] [Data Sheet] ■Precaution (Surface Mount Device) 1.Storage If the product is heated during the reflow under the condition of hygroscopic state, it may vaporize and expand which will influence the performance of the product. Therefore, the package is waterproof. Please use the product following the conditions: ・Using Conditions Classification Temperature Humidity Expiration Date Remark Within 1 year ①Before using 5〜30℃ 30〜70%RH Storage with waterproof package from Receiving ②After opening Please storing in the airtight container 5〜30℃ Below 70%RH Within 72h package with our desiccant (silica gel) ・Baking Bake the product in case of below: ①The expiration date is passed. ②The color of indicator (silica gel) turned from blue to colorless or from green to pink. (Even if the product is within the expiration date.) ・Baking Conditions Temperature Time Humidity 60±3℃ 40〜48h Below 20%RH ・Bake products in reel. ・Reel and embossed tape are easy to be deformed when baking, Remark so please try not to apply stress on it. ・Recommend bake once. 2.Application Methods 2-1.Precaution for Drive System and Off Mode Design the circuit without the electric load exceeding the ABSOLUTE MAXIMUM RATING that applies on the products. If drive by constant voltage, it may cause current deviation of the LED and result in deviation of luminous intensity, so we recommend to drive by constant current. (Deviation of VF Value will cause deviation of current in LED.) Furthermore, for off mode, please do not apply voltage neither forward nor reverse. Especially, for the products with the Ag-paste used in the die bonding, thereʼs high possibility to cause electro migration and result in function failure. 2-2.Derating The Derating Characteristics are based on the lifetime of luminous intensity and assumption of degradation & color change of sealing resin or reflector. About its reliability, please evaluate its using conditions and environment and use it after confirmed there is no problem. 2-3.Operation Life Span Thereʼs possibility for intensity of light drop according to working conditions and environments (applied current, surrounding temperature and humidity, corrosive gases), please call our Sales staffs for inquiries about the concerned application below. ①Longtime intensity of light life ②On mode all the time 2-4.Applied Stress on Product The top of the LED is very soft, which the silicon resin is used as sealing resin. Therefore, please pay attention to the overstress on it which may influence its reliability. 2-5.Usage The Product is LED. We are not responsible for the usage as the diode such as Protection Chip, Rectifier, Switching and so on. ________________________________________________________ www.rohm.com ©2016 ROHM Co., Ltd. All rights reserved 7/10 2017.11 - Rev.007

[SML-M13x/MN2x series] [Data Sheet] 3.Others 3-1.Surrounding Gas Notice that if it is stored under the condition of acid gas (chlorine gas, sulfured gas) or alkali gas (ammonia), it may result in low soldering ability (caused by the change in quality of the plating surface ) or optical characteristics changes (light intensity, chrominance) and change in quality of cause die bonding (Ag-paste) materials. All of the above will function failure of the products. Therefore, please pay attention to the storage environment for mounted product (concern the generated gas of the surrounding parts of the products and the atmospheric environment). 3-2.Electrostatic Damage The product is part of semiconductor and electrostatic sensitive, thereʼs high possibility to be damaged by the electrostatic discharge. Please take appropriate measures to avoid the static electricity from human body and earthing of production equipment. Especially, InGaN type LEDs have lower resistance value of electrostatic discharge and it is recommended to introduce the ESD protection circuit. The resistance values of electrostatic discharge (actual values) vary with products, therefore, please call our Sales staffs for inquiries. 3-3. Electromagnetic Wave Applications with strong electromagnetic wave such as, IH cooker, will influence the reliability of LED, therefore please evaluate before using it. ________________________________________________________ www.rohm.com ©2016 ROHM Co., Ltd. All rights reserved 8/10 2017.11 - Rev.007

[SML-M13x/MN2x series] [Data Sheet] 4.Mounting 4-1. Soldering ・No resin hardening agent such as filler is used in the sealing resin of the product. Therefore, resin expansion and moisture absorption at humidity will cause heat stress during soldering process and finally has bad influence on the productʼs reliability. ・The product is not guaranteed for flow soldering. ・Do not expose the product in the environment of high temperature (over 100℃) or rapid temperature shift (within 3℃/sec. of temperature gradient) during the flow soldering of surrounding parts. In case of carrying out flow soldering of surrounding parts without recommended conditions, please contact us for inquiries. ・Please set appropriate reflow temperature based on our product usage conditions and specification. ・The max for reflowing is 2 times, please finish the second reflow soldering and flow soldering with other parts within the usage limitation after open the moistureproof package. ・Compare with N2 reflow, during air reflow, because of the heat and surrounding conditions, it may cause the discoloration of the resin. ・For our product that has no solder resist, because of its solder amount and soldering conditions, one of its specific characteristics is that solder will penetrate into LED. Thus, there's high possibility that will influence its reliability.Therefore, please be informed, concerning it before using it. 4-2. Automatic Mounting 4-2-1. Silicon Resin Sealing Product The sealing resin of LED is very soft, so please select adsorption nozzle that would not apply stress directly on the sealing section. 4-2-2. Mini Package (Smaller than 1608 size) ・Vibration may result in low mounting rate since it will cause the static electricity of product and adhere to top cover tape. Therefore, the magnet should be set on parts feeder cassette of the mounter to control the product stabilization. In addition, it is recommended to set ionizer to prevent electrostatic charge. 4-3. Mounting Location The stress like bending stress of circuit board dividing after mounting, may cause LED package crack or damage of LED internal junction, therefore, please concern the mounting direction and position to avoid bending or screwing with great stress of the circuit board. Stress strength according to he mounting position: A>B>C>D 1.1mm 4―4. Mechanical Stress after Mounting The mechanical stress may damage the LED after Circuit Mounting, 1.25mm so please pay attention to the touch on product. 4-5.Soldering Pattern for Recommendation 1.1mm We recommend the soldering pattern that shows on the right. It will be different according to mounting situation of circuit board, 1.25mm therefore, please concern before designing. ※The product has adopted the electrode structure that it should solder PCB Bonding Direction with back electrode of the product. Thus, please be informed that the shape of electrode pin of solder fillet formation is not guaranteed. The through hole on electrode surface is for conduction of front and rear electrodes but not for formation of solder fillet. ________________________________________________________ www.rohm.com ©2016 ROHM Co., Ltd. All rights reserved 9/10 2017.11 - Rev.007

[SML-M13x/MN2x series] [Data Sheet] 4-6.Reflow Profile For reflow profile, please refer to the conditions below:(※) ■Meaning of marks, Conditions Mark Meanings Conditions Tsmax Maximum of pre-heating temperature 180℃ Tsmin Minimum of pre-heating temperature 140℃ t Time from Tsmin to Tsmax Over 60sec. s T Reference temperature 230〜250℃ L t Retention time for TL Within 40sec. L T Peak temperature 250℃(Max) P t Time for peak temperature Within 10sec. P ΔT /Δt Temperature rising rate Under 3℃/sec. R ΔTD/Δt Temperature decreasing rate Over -3℃/sec. ※Above conditions are for reference. Therefore, evaluate by customerʼs own circuit boards and reflow furnaces before using, because stress from circuit boards and temperature variations of reflow furnaces vary by customerʼs own conditions. 4-7.Attention Points in Soldering Operation This product was developed as a surface mount LED especially suitable for reflow soldering. So reflow soldering is recommended. In case of implementing manual soldering, please take care of following points. ①SOLDER USED Sn-Cu,Sn-Ag-Cu,Sn-Ag-Bi-Cu ②HAND SOLDERING CONDITION LED products do not contain reinforcement material such as a glass fillers. So thermal stress by soldering greatly influence its reliability. Please keep following points for manual soldering. ITEM RECOMMENDED CONDITION Condition ) Temp. of iron top less than 325℃ within 3 sec. a) Heating method Heating on PCB pattern, not direct to the Fig-1 SOLDERING IRON LED. (Fig-1) Handling after Please handle after the part temp. b) soldering goes down to room temp. SOLDERING LAND 4-8.Cleaning after Soldering Please follow the conditions below if the cleaning is necessary after soldering. Solvent We recommend to use alcohols solvent such as, isopropyl alcohols Temperature Under 30℃ within 3 minutes Ultrasonic Cleaning 15W/Below 1 liter (capacity of tank) Drying Under 100℃ within 3 minutes ________________________________________________________ www.rohm.com ©2016 ROHM Co., Ltd. All rights reserved 10/10 2017.11 - Rev.007

Notice Notes 1) The information contained herein is subject to change without notice. 2) Before you use our Products, please contact our sales representativeand verify the latest specifica- tions : 3) Although ROHM is continuously working to improve product reliability and quality, semicon- ductors can break down and malfunction due to various factors. Therefore, in order to prevent personal injury or fire arising from failure, please take safety measures such as complying with the derating characteristics, implementing redundant and fire prevention designs, and utilizing backups and fail-safe procedures. ROHM shall have no responsibility for any damages arising out of the use of our Poducts beyond the rating specified by ROHM. 4) Examples of application circuits, circuit constants and any other information contained herein are provided only to illustrate the standard usage and operations of the Products. The peripheral conditions must be taken into account when designing circuits for mass production. 5) The technical information specified herein is intended only to show the typical functions of and examples of application circuits for the Products. ROHM does not grant you, explicitly or implicitly, any license to use or exercise intellectual property or other rights held by ROHM or any other parties. ROHM shall have no responsibility whatsoever for any dispute arising out of the use of such technical information. 6) The Products are intended for use in general electronic equipment (i.e. AV/OA devices, communi- cation, consumer systems, gaming/entertainment sets) as well as the applications indicated in this document. 7) The Products specified in this document are not designed to be radiation tolerant. 8) For use of our Products in applications requiring a high degree of reliability (as exemplified below), please contact and consult with a ROHM representative : transportation equipment (i.e. cars, ships, trains), primary communication equipment, traffic lights, fire/crime prevention, safety equipment, medical systems, servers, solar cells, and power transmission systems. 9) Do not use our Products in applications requiring extremely high reliability, such as aerospace equipment, nuclear power control systems, and submarine repeaters. 10) ROHM shall have no responsibility for any damages or injury arising from non-compliance with the recommended usage conditions and specifications contained herein. 11) ROHM has used reasonable care to ensur the accuracy of the information contained in this document. However, ROHM does not warrants that such information is error-free, and ROHM shall have no responsibility for any damages arising from any inaccuracy or misprint of such information. 12) Please use the Products in accordance with any applicable environmental laws and regulations, such as the RoHS Directive. For more details, including RoHS compatibility, please contact a ROHM sales office. ROHM shall have no responsibility for any damages or losses resulting non-compliance with any applicable laws or regulations. 13) When providing our Products and technologies contained in this document to other countries, you must abide by the procedures and provisions stipulated in all applicable export laws and regulations, including without limitation the US Export Administration Regulations and the Foreign Exchange and Foreign Trade Act. 14) This document, in part or in whole, may not be reprinted or reproduced without prior consent of ROHM. Thank you for your accessing to ROHM product informations. More detail product informations and catalogs are available, please contact us. ROHM Customer Support System http://www.rohm.com/contact/ www.rohm.com R1102A © 201(cid:24) ROHM Co., Ltd. All rights reserved.

Mouser Electronics Authorized Distributor Click to View Pricing, Inventory, Delivery & Lifecycle Information: R OHM Semiconductor: SML-M13DTT86 SML-M13MTT86 SML-M13PTT86 SML-M13UTT86 SML-M13VTT86 SML-M13YTT86 SMLMN2BCTT86C

Datasheet下载

Datasheet下载