- 型号: SFECF10M7HA00-R0

- 制造商: Murata

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

SFECF10M7HA00-R0产品简介:

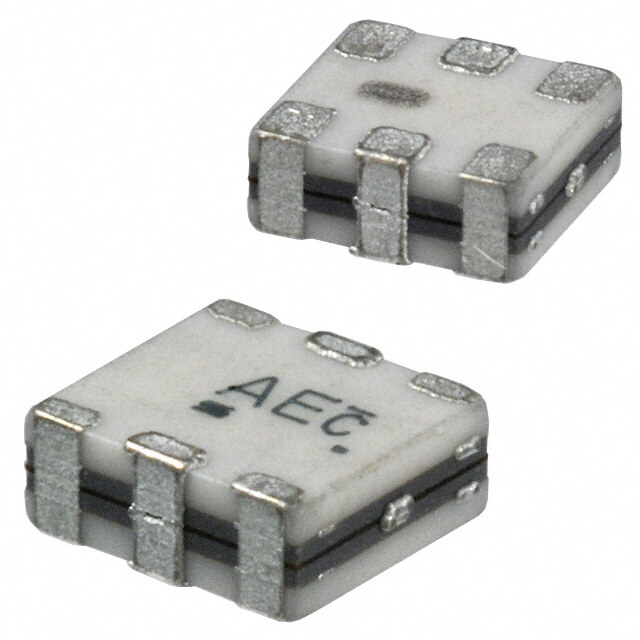

ICGOO电子元器件商城为您提供SFECF10M7HA00-R0由Murata设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 SFECF10M7HA00-R0价格参考¥3.97-¥7.01。MurataSFECF10M7HA00-R0封装/规格:陶瓷滤波器, 。您可以下载SFECF10M7HA00-R0参考资料、Datasheet数据手册功能说明书,资料中有SFECF10M7HA00-R0 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

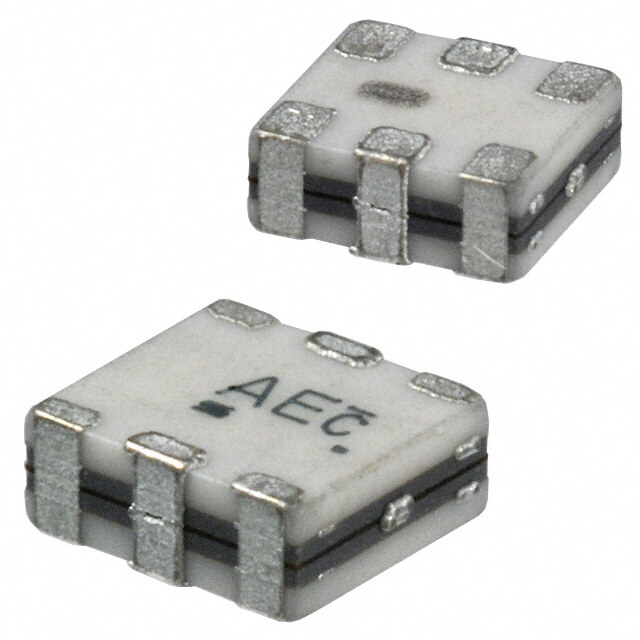

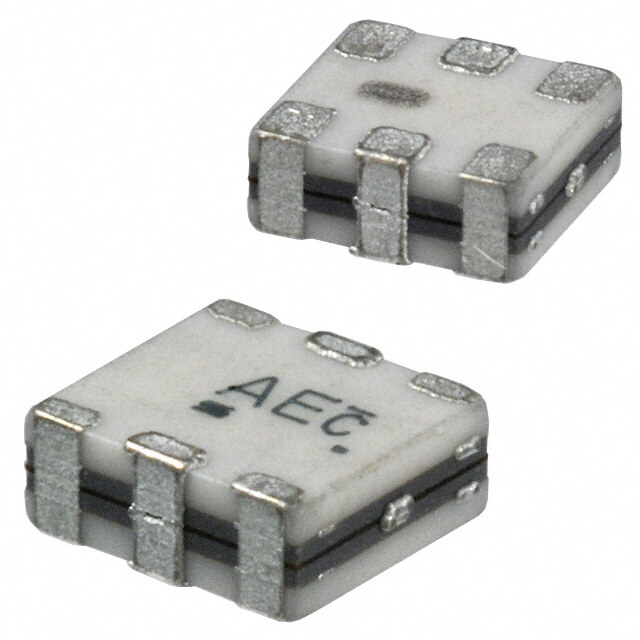

| 描述 | FILTER 10.7 MHZ 180 KHZ BAND SMD信号调节 10.7MHZ 2ELEM. CHIP 180KHZ MS5 |

| 产品分类 | |

| 品牌 | Murata Electronics North America |

| 产品手册 | http://search.murata.co.jp/Ceramy/CatalogAction.do?sHinnm=? &sNHinnm=SFECF10M7HA00-R0&sNhin_key=SFECF10M7HA00-R0&sLang=en&sParam=SFECF |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | Murata Electronics SFECF10M7HA00-R0CERAFIL®, SFECF |

| 数据手册 | |

| 产品型号 | SFECF10M7HA00-R0 |

| 产品 | Ceramic Filters |

| 产品目录绘图 |

|

| 产品目录页面 | |

| 产品种类 | 信号调节 |

| 其它名称 | 490-4682-6 |

| 包装 | Digi-Reel® |

| 商标 | Murata Electronics |

| 商标名 | CERAFIL |

| 大小/尺寸 | 0.136" 长 x 0.122" 宽(3.45mm x 3.10mm) |

| 安装类型 | 表面贴装 |

| 封装 | Reel |

| 封装/外壳 | 1412(3531 公制),6 PC 板 |

| 工作温度范围 | - 20 C to + 80 C |

| 工厂包装数量 | 2000 |

| 带宽 | 180kHz |

| 插入损耗 | 4dB |

| 标准包装 | 1 |

| 滤波器类型 | FM |

| 端接类型 | SMD/SMT |

| 类型 | Ceramic Filter |

| 阻抗 | 330 欧姆 |

| 频率 | 10.7MHz 中心 |

| 高度(最大值) | 0.055"(1.40mm) |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

P51E.pdf Feb.5,2018 Ceramic Filters (CERAFILr)/ Crystal Filters

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 EU RoHS Compliant (cid:70)(cid:3)(cid:5)(cid:42)(cid:42)(cid:3)(cid:50)(cid:38)(cid:35)(cid:3)(cid:46)(cid:48)(cid:45)(cid:34)(cid:51)(cid:33)(cid:50)(cid:49)(cid:3)(cid:39)(cid:44)(cid:3)(cid:50)(cid:38)(cid:39)(cid:49)(cid:3)(cid:33)(cid:31)(cid:50)(cid:31)(cid:42)(cid:45)(cid:37)(cid:3)(cid:33)(cid:45)(cid:43)(cid:46)(cid:42)(cid:55)(cid:3) (cid:53)(cid:39)(cid:50)(cid:38)(cid:3)(cid:9)(cid:25)(cid:3)(cid:22)(cid:45)(cid:12)(cid:23)(cid:64) (cid:70)(cid:3)(cid:9)(cid:25)(cid:3)(cid:22)(cid:45)(cid:12)(cid:23)(cid:3)(cid:39)(cid:49)(cid:3)(cid:159)(cid:50)(cid:38)(cid:35)(cid:3)(cid:9)(cid:51)(cid:48)(cid:45)(cid:46)(cid:35)(cid:31)(cid:44)(cid:3)(cid:8)(cid:39)(cid:48)(cid:35)(cid:33)(cid:50)(cid:39)(cid:52)(cid:35)(cid:3) (cid:124)(cid:122)(cid:123)(cid:123)(cid:71)(cid:128)(cid:127)(cid:71)(cid:9)(cid:25)(cid:3)(cid:45)(cid:44)(cid:3)(cid:50)(cid:38)(cid:35)(cid:3)(cid:22)(cid:35)(cid:49)(cid:50)(cid:48)(cid:39)(cid:33)(cid:50)(cid:39)(cid:45)(cid:44)(cid:3)(cid:45)(cid:36)(cid:3)(cid:50)(cid:38)(cid:35)(cid:3) (cid:25)(cid:49)(cid:35)(cid:3)(cid:45)(cid:36)(cid:3)(cid:7)(cid:35)(cid:48)(cid:50)(cid:31)(cid:39)(cid:44)(cid:3)(cid:12)(cid:31)(cid:56)(cid:31)(cid:48)(cid:34)(cid:45)(cid:51)(cid:49)(cid:3)(cid:23)(cid:51)(cid:32)(cid:49)(cid:50)(cid:31)(cid:44)(cid:33)(cid:35)(cid:49)(cid:3)(cid:39)(cid:44)(cid:3) (cid:9)(cid:42)(cid:35)(cid:33)(cid:50)(cid:48)(cid:39)(cid:33)(cid:31)(cid:42)(cid:3)(cid:31)(cid:44)(cid:34)(cid:3)(cid:9)(cid:42)(cid:35)(cid:33)(cid:50)(cid:48)(cid:45)(cid:44)(cid:39)(cid:33)(cid:3)(cid:9)(cid:47)(cid:51)(cid:39)(cid:46)(cid:43)(cid:35)(cid:44)(cid:50)(cid:64)(cid:159)(cid:3) (cid:70)(cid:3)For(cid:3)(cid:43)(cid:45)(cid:48)(cid:35)(cid:3)(cid:34)(cid:35)(cid:50)(cid:31)(cid:39)(cid:42)(cid:49)(cid:65)(cid:3)(cid:46)(cid:42)(cid:35)(cid:31)(cid:49)(cid:35)(cid:3)(cid:48)(cid:35)(cid:36)(cid:35)r(cid:3)(cid:50)o(cid:3)(cid:45)ur(cid:3)(cid:53)(cid:35)(cid:32)(cid:3) (cid:46)(cid:31)(cid:37)(cid:35)(cid:65)(cid:3)(cid:159)(cid:17)(cid:51)(cid:48)(cid:31)(cid:50)(cid:31)(cid:158)(cid:49)(cid:3)(cid:5)(cid:46)(cid:46)(cid:48)(cid:45)(cid:31)(cid:33)(cid:38)(cid:3)(cid:36)(cid:45)(cid:48)(cid:3)(cid:9)(cid:25)(cid:3)(cid:22)(cid:45)(cid:12)(cid:23)(cid:159)(cid:3) (cid:72)(cid:38)(cid:50)(cid:50)(cid:46)(cid:49)(cid:66)(cid:71)(cid:71)(cid:53)(cid:53)(cid:53)(cid:64)(cid:43)(cid:51)(cid:48)(cid:31)(cid:50)(cid:31)(cid:64)(cid:33)(cid:45)(cid:43)(cid:71)(cid:35)(cid:44)(cid:81)(cid:35)(cid:51)(cid:71)(cid:49)(cid:51)(cid:46)(cid:46)(cid:45)(cid:48)(cid:50)(cid:71) (cid:33)(cid:45)(cid:43)(cid:46)(cid:42)(cid:39)(cid:31)(cid:44)(cid:33)(cid:35)(cid:71)(cid:48)(cid:45)(cid:38)(cid:49)(cid:74)(cid:64)(cid:3)

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 1 Contents Product specifications are as of January 2018. 2 Selection Guide p2 Part Numbering p3 1 Ceramic Filters (CERAFILr) 5 Ceramic Filters (CERAFILr) Chip Type SFECF Series Chip Type SFSKB Series Features/Appearance/Dimensions p6 Features/Applications/Appearance/Dimensions p34 3 Part Number List p6 Part Number List p34 Standard Center Frequency Rank Code p7 Standard Land Pattern Dimensions p35 Standard Land Pattern Dimensions p7 Test Circuit p35 Test Circuit p7 Frequency Characteristics p36 Frequency Characteristics p8 Spurious p37 Spurious p10 Notice p38 Notice p12 Packaging p40 4 Packaging p14 6 Ceramic Trap (CERAFILr) 2 Ceramic Filters (CERAFILr) Chip Type TPSKA Series Chip Type SFECV/SFECK Series Features/Appearance/Dimensions p41 Features/Applications/Appearance/Dimensions p15 Part Number List p41 Part Number List p15 Standard Land Pattern Dimensions p41 Standard Center Frequency Rank Code p16 Test Circuit p41 5 Standard Land Pattern Dimensions p16 Frequency Characteristics p41 Test Circuit p16 Spurious p42 Frequency Characteristics p16 Notice p43 Spurious p17 Packaging p45 Notice p18 Packaging p20 7 Ceramic Discriminator (CERAFILr) 6 Chip Type CDSCB Series 3 Ceramic Filters (CERAFILr) Features/Appearance/Dimensions p46 Chip Type SFSCE Series Part Number List p46 Features/Applications/Appearance/Dimensions p21 Standard Center Frequency Rank Code p46 Part Number List p21 Standard Land Pattern Dimensions p47 Standard Land Pattern Dimensions p21 Test Circuit p47 Test Circuit p21 Recovered Audio Curve p49 7 Frequency Characteristics p22 S Curve p50 Notice p23 Notice p51 Packaging p27 Packaging p53 4 Ceramic Filters (CERAFILr) 8 Crystal Filters Chip Type SFSKA Series Chip Type XDCAF/XDCAG/XDCAH/XDCBA Series Features/Appearance/Dimensions p28 Features/Applications/Appearance/Dimensions p54 8 Part Number List p28 Series p54 Standard Land Pattern Dimensions p28 Part Number List p55 Test Circuit p28 Test Circuit p56 Frequency Characteristics p29 Frequency Characteristics p57 Spurious p30 Spurious p58 Notice p31 Notice p59 Packaging p33 Packaging p61 Please check the MURATA website (https://www.murata.com/) if you cannot find a part number in this catalog.

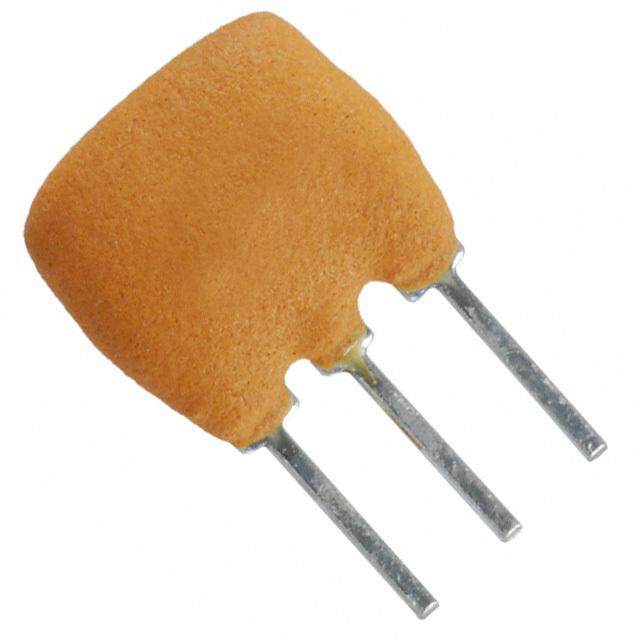

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Selection Guides Applications Audio Visual/Communications Industrial Filters Traps Discriminators Crystal Filters SFECF TPSKA CDSCB XDCAF 3.45×3.1×1.4mm 8.5×3.8×2.0mm 4.5×2.0×1.0mm 7.0×5.0×1.1mm 10.000-11.000MHz 4.500-6.500MHz 10.520-10.800MHz 2 poles SFECV/SFECK XDCAG 6.9×2.9×1.7mm 7.0×5.0×1.1mm 10.700-15.000MHz 4 poles SFSCE XDCAH 4.5×3.8×1.0mm 7.0×5.0×1.1mm 10.700-11.000MHz 4 poles SFSKA XDCBA 8.5×3.8×2.0mm 3.8×3.8×1.0mm 4.500-6.500MHz 2 poles SFSKB 5.2×3.8×1.5mm 2.300-5.700MHz 2

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 o Part Numbering CERAFILr for FM (Part Number) SF E CF 10M7 F A A0 -R0 1 2 3 4 5 6 7 8 1Product ID 6Center Frequency/Tolerance Product ID Code Center Frequency Tolerance SF Ceramic Filters A Center Frequency Mentioned by Specification ±30kHz F Nominal Center Frequency — 2Oscillation/Number of Elements 3dB bandwidth of "F" signifies the frequency difference (both + and -) Code Oscillation/Number of Elements from reference frequency, which is nominal center frequency. E 2 Elements Thickness Expander Mode T 3 Elements Thickness Expander Mode 7Series 2 Elements Thickness Expander Mode Code Series V (2nd Harmonic) A0 Two-digit Alphanumerics Express Series 2 Elements Thickness Expander Mode K (3rd Overtone) 8Packaging Code Packaging 3Structure/Size -B0 Bulk Code Structure/Size -R0 Embossed Taping ø180mm Cp Chip Type -R1 Embossed Taping ø330mm p is "A" or subsequent code, which indicates the structure/size. Radial taping is applied to lead type and embossed taping to chip type. With non-standard products, two-digit alphanumerics indicating 4Nominal Center Frequency "Individual Specification" are added between "7Series" and "8Packaging." Expressed by four-digit alphanumerics. The unit is in hertz (Hz). Decimal point is expressed by capital letter "M" in case of MHz. 53dB Bandwidth Code 3dB Bandwidth C 450kHz min D 350kHz min E 330kHz F 280kHz G 230kHz H 180kHz J 150kHz K 110kHz L 80kHz M 50kHz N 35kHz 3

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 CCEERRAAFFIILLrr (Part Number) SF S KA 4M50 CF 00 -R1 1 2 3 4 5 6 7 1Product ID 5Product Specification Code (1) Product ID Code Product Specification Code (1) SF Ceramic Filters BF Tight Bandwidth Type CF Standard Bandwidth Type 2Oscillation/Numbers of Element DF Broad Bandwidth Type Code Oscillation/Numbers of Element EF Ultra-broad Bandwidth Type S 2 Elements Thickness Shear Mode 6Product Specification Code (2) 3Structure/Size Code Product Specification Code (2) Code Structure/Size 00 Standard Type Kp Chip Type p is "A" or subsequent code, which indicates the structure/size. 7Packaging Code Packaging 4Nominal Center Frequency -B0 Bulk Expressed by four-digit alphanumerics. The unit is in hertz (Hz). -R1 Embossed Taping ø=330mm Decimal point is expressed by capital letter "M" in case of MHz. With non-standard products, two-digit alphanumerics indicating "Individual Specification" is added between "6Product Specification Code (2)" and "7Packaging." Ceramic Traps (Part Number) TP S KA 4M00 B 00 -R0 1 2 3 4 5 6 7 1Product ID 5Product Specification Code (1) Product ID Code Product Specification (1) TP Ceramic Traps B Broad Bandwidth Type C Low Capacitance Type 2Function Code Function 6Product Specification Code (2) S Single Traps Code Product Specification (2) 00 Standard Type 3Structure/Size Code Structure/Size 7Packaging Kp Chip Type Code Packaging p is "A" or subsequent code, which indicates the structure/size. -B0 Bulk -R1 Embossed Taping ø=330mm 4Nominal Center Frequency With non-standard products, three-digit alphanumerics indicating Expressed by four-digit alphanumerics. The unit is in hertz (Hz). "Individual Specification" is added between "6Product Specification Decimal point is expressed by capital letter "M" in case of MHz. Code (2)" and "7Packaging." 4

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Discriminators for FM (Part Number) CD S CB 10M7 G A 001 -R0 1 2 3 4 5 6 7 8 1Product ID 6Center Frequency/Tolerance Product ID Code Center Frequency Tolerance CD Discriminators A Center Frequency Mentioned by Specification ±30kHz F Nominal Center Frequency — 2Oscillation 3dB bandwidth of "F" signifies the frequency difference (both + and -) Code Oscillation from reference frequency, which is nominal center frequency. S Thickness Shear Mode 7IC 3Structure/Size Code IC Code Structure/Size 001 Applicable IC Control Code Cp Chip Type p is "A" or subsequent code, which indicates the structure/size. 8Packaging Code Packaging 4Nominal Center Frequency -B0 Bulk Expressed by four-digit alphanumerics. The unit is in hertz (Hz). -R0 Embossed Taping ø=180mm Decimal point is expressed by capital letter "M" in case of MHz. -R1 Embossed Taping ø=330mm Radial taping is applied to lead type and embossed taping to chip type. 5Series With non-standard products, an alphanumerics indicating "Individual Specification" is added between "7IC" and "8Packaging." Code Series G Two-digit Alphanumerics Express Series Crystal Filter (Part Number) XD C A F 21M400 R A A00 P0 1 2 3 4 5 6 7 8 9 1Product ID 7Number of Poles Product ID Code Number of Poles XD Crystal Filter A 2 (1 Element) G 4 (1 Element) 2Type · Lead Style H 4 (2 Elements) Code Type · Lead Style C Monolithic SMD 8Individual Specification Code 3Size Three-digit Alphanumerics Express *** Code Size Individual Specification. A 7050 B 3838 9Packaging (Packaging quantity is expressed by one-digit number in "*") 4Structure Code Packaging Expressed by one alphabetic character. P*/L* Plastic Taping ø330mm 5Nominal Center Frequency Expressed by six-digit alphanumeric. The unit is in hertz (Hz). Decimal point is expressed by capital letter "M". 6Bandwidth Code Bandwidth (3dB) M 6.800 to 8.199kHz P 10.000 to 11.999kHz Q 12.000 to 14.999kHz R 15.000 to 17.999kHz 5

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Ceramic Filters (CERAFILr) 1 RoHS Chip Type SFECF Series 3.45±0.2 1.3±0.1 The SFECF10M7 series for FM receivers are small, 2 high-performance and super thin (1.4mm max.) filters. 0. Input electrode 1± The piezoelectric element is sandwiched by ceramic marker 3. substrate. They have 1.4mm max. thickness and a small 0 to 0.4(0.6)(0.6)(0.6)0 to 0.4 mounting area (3.45x3.1mm). The SFECF series and CDSCB series (MHz Discriminator) enable customers to (1.28)(1.28) 0.3 min.0.3 min. make VICS/RKE/TPMS sets very thin and small. 0.65±0.30.7±0.3 0.65±0.3 0.3 (1): Input Features 0.85± ((16)) ((52)) ((43)) 3 ((23))((54)):: GNroo cuonndnection 1. The filters are mountable by automatic placers. 85±0.3 (1.28)(1.28) 0.75±0. ( ( 6 ))::: EROIeuAftJep rMuetnocnethly Code 0. 0 to 0.35 0 to 0.35 (in mm) 2. They are slim, at only 1.4mm max. thickness, and have a small mounting area (3.45x3.1mm) enabling flexible PCB design. 3. Various bandwidths are available. Select a suitable type in accordance with the desired characteristics. 4. Operating Temperature Range: -20 to +80°C (Standard Type) -40 to +85°C (High-reliability Type) Storage Temperature Range: -40 to +85°C (Standard Type) -55 to +85°C (High-reliability Type) Standard Type Center Nominal Center 3dB Attenuation Insertion Loss Ripple Spurious Spurious Input/Output Part Number Frequency Frequency (fn) Bandwidth Attenuation Attenuation Impedance (fo) (MHz) (MHz) (kHz) (kHz) (dB) (dB) (1) (dB) (2) (dB) (ohm) 10.700 30 min. 30 min. SFECF10M7HA00-R0 - 180 ±40kHz 470 max. 4.0±2.0dB 1.0 max. 330 ±30kHz [within 9MHz to fo] [within fo to 12MHz] 8.0max. 30 min. 25 min. SFECF10M7HF00-R0 - 10.700 fn±25 min. 510 max. 1.0 max. 330 [at fn] [within 9MHz to fn][within fn to 12MHz] 10.700 30 min. 30 min. SFECF10M7GA00-R0 - 230 ±50kHz 510 max. 3.5±2.0dB 1.0 max. 330 ±30kHz [within 9MHz to fo] [within fo to 12MHz] 8.0max. 30 min. 25 min. SFECF10M7GF00-R0 - 10.700 fn±45 min. 560 max. 1.0 max. 330 [at fn] [within 9MHz to fn][within fn to 12MHz] 10.700 30 min. 30 min. SFECF10M7FA00-R0 - 280 ±50kHz 590 max. 3.0±2.0dB 1.0 max. 330 ±30kHz [within 9MHz to fo] [within fo to 12MHz] 7.0max. 30 min. 25 min. SFECF10M7FF00-R0 - 10.700 fn±65 min. 620 max. 1.0 max. 330 [at fn] [within 9MHz to fn][within fn to 12MHz] 10.700 30 min. 30 min. SFECF10M7EA00-R0 - 330 ±50kHz 700 max. 3.0±2.0dB 1.0 max. 330 ±30kHz [within 9MHz to fo] [within fo to 12MHz] 10.700 35 min. 25 min. SFECF10M7DA0001-R0 - 420 min. 950 max. 3.0±2.0dB 3.0 max. 330 ±30kHz [within 9MHz to fo] [within fo to 12MHz] 6.0max. 20 min. 20 min. SFECF10M7DF00-R0 - 10.700 fn±150 min. 990 max. 3.0 max. 330 [at fn] [within 9MHz to fn][within fn to 12MHz] Area of Attenuation: [within 20dB] Area of Insertion Loss: at minimum loss point Area of Ripple: within 3dB B.W. Center frequency (fo) defined by the center of 3dB bandwidth. For safety purposes, connect the output of filters to the IF amplifier through a D.C. blocking capacitor. Avoid applying a direct current to the output of ceramic filters. The order quantity should be an integral multiple of the "Minimum Quantity" shown in the packaging page. 6

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 High-reliability Type Part Number FrCeqeunetenrcy NForemqiuneanl cCye (nftne)r Ban3ddwBidth Attenuation Insertion Loss Ripple AtStpeunruioautison AtStpeunruioautison InImpupte/dOauntcpeut 1 (fo) (MHz) (MHz) (kHz) (kHz) (dB) (dB) (1) (dB) (2) (dB) (ohm) 10.700 30 min. 30 min. SFECF10M7HA00S0-R0 - 180 ±40kHz 470 max. 4.0±2.0dB 1.0 max. 330 ±30kHz [within 9MHz to fo][within fo to 12MHz] 8.0max. 30 min. 25 min. SFECF10M7HF00S0-R0 - 10.700 fn±25 min. 510 max. 1.0 max. 330 [at fn] [within 9MHz to fn][within fn to 12MHz] 10.700 30 min. 30 min. SFECF10M7GA00S0-R0 - 230 ±50kHz 510 max. 3.5±2.0dB 1.0 max. 330 ±30kHz [within 9MHz to fo][within fo to 12MHz] 8.0max. 30 min. 25 min. SFECF10M7GF00S0-R0 - 10.700 fn±45 min. 560 max. 1.0 max. 330 [at fn] [within 9MHz to fn][within fn to 12MHz] 10.700 30 min. 30 min. SFECF10M7FA00S0-R0 - 280 ±50kHz 590 max. 3.0±2.0dB 1.0 max. 330 ±30kHz [within 9MHz to fo][within fo to 12MHz] 7.0max. 30 min. 25 min. SFECF10M7FF00S0-R0 - 10.700 fn±65 min. 630 max. 1.0 max. 330 [at fn] [within 9MHz to fn][within fn to 12MHz] 10.700 30 min. 30 min. SFECF10M7EA00S0-R0 - 330 ±50kHz 700 max. 3.0±2.0dB 1.0 max. 330 ±30kHz [within 9MHz to fo][within fo to 12MHz] 6.0max. 20 min. 20 min. SFECF10M7DF00S0-R0 - 10.700 fn±145 min. 990 max. 3.0 max. 330 [at fn] [within 9MHz to fn][within fn to 12MHz] Area of Attenuation: [within 20dB] Area of Insertion Loss: at minimum loss point Area of Ripple: within 3dB B.W. Center frequency (fo) defined by the center of 3dB bandwidth. For safety purposes, connect the output of filters to the IF amplifier through a D.C. blocking capacitor. Avoid applying a direct current to the output of ceramic filters. The order quantity should be an integral multiple of the "Minimum Quantity" shown in the packaging page. Standard Center Frequency Rank Code CODE 30kHz Step 25kHz Step A 10.700MHz±30kHz 10.700MHz±25kHz Standard Land Pattern Dimensions Test Circuit 1 (3) (4) 3 0. (2) (5) 0. (6) (5) (4)0.1 1.05 R1 (1) (6) 3 0. 0 Rg 3 0.1 1.4 S.S.G. E1 R2 C2 E2 RVFoltmeter 0. 5 (1) (2) (3) 0 0.1 1. (1): Input 0.1 0.1 (1): Input ((23))((54)):: GNroo cuonndnection 0.8 0.6 0.8 0.6 0.8 ((23))((54)):: GNroo cuonndnection Rg=50Ω R1=280Ω±5% R2=330Ω±5% (6): Output (6): Output C2=10±2pF (Including stray capacitance and Input capacitance Indicates solder resist land pattern. (in mm) of RF voltmeter) E1: S.S.G. Output Voltage 7

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Frequency Characteristics Standard Type 1 SFECF10M7HA00-R0/SFECF10M7HF00-R0 SFECF10M7GA00-R0/SFECF10M7GF00-R0 0 7.0 0 7.0 1 6.0 1 6.0 2 5.0 ec.) 2 5.0 ec.) B) μ s B) μ s n (d 3 4.0 me ( n (d 3 4.0 me ( Attenuatio 54 32..00 oup Delay Ti Attenuatio 54 32..00 oup Delay Ti Gr Gr 6 1.0 6 1.0 7 0.0 7 0.0 10.300 10.500 10.700 10.900 11.100 10.300 10.500 10.700 10.900 11.100 Frequency (MHz) Frequency (MHz) SFECF10M7FA00-R0/SFECF10M7FF00-R0 SFECF10M7EA00-R0 0 7.0 0 7.0 1 6.0 1 6.0 2 5.0 ec.) 2 5.0 ec.) B) μ s B) μ s n (d 3 4.0 me ( n (d 3 4.0 me ( Attenuatio 54 32..00 oup Delay Ti Attenuatio 54 32..00 oup Delay Ti Gr Gr 6 1.0 6 1.0 7 0.0 7 0.0 10.300 10.500 10.700 10.900 11.100 10.300 10.500 10.700 10.900 11.100 Frequency (MHz) Frequency (MHz) SFECF10M7DA0001-R0 SFECF10M7DF00-R0 0 7.0 0 7.0 1 6.0 1 6.0 2 5.0 ec.) 2 5.0 ec.) B) μ s B) μ s n (d 3 4.0 me ( n (d 3 4.0 me ( Attenuatio 54 32..00 oup Delay Ti Attenuatio 54 32..00 oup Delay Ti Gr Gr 6 1.0 6 1.0 7 0.0 7 0.0 10.300 10.500 10.700 10.900 11.100 10.300 10.500 10.700 10.900 11.100 Frequency (MHz) Frequency (MHz) 8

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Frequency Characteristics High-reliability Type SFECF10M7HA00S0-R0/SFECF10M7HF00S0-R0 SFECF10M7GA00S0-R0/SFECF10M7GF00S0-R0 1 0 7.0 0 7.0 1 6.0 1 6.0 2 5.0ec.) 2 5.0ec.) B) μ s B) μ s n (d 3 4.0me ( n (d 3 4.0me ( Attenuatio 54 32..00oup Delay Ti Attenuatio 54 32..00oup Delay Ti Gr Gr 6 1.0 6 1.0 7 0.0 7 0.0 10.300 10.500 10.700 10.900 11.100 10.300 10.500 10.700 10.900 11.100 Frequency (MHz) Frequency (MHz) SFECF10M7FA00S0-R0/SFECF10M7FF00S0-R0 SFECF10M7EA00S0-R0 0 7.0 0 7.0 1 6.0 1 6.0 2 5.0ec.) 2 5.0ec.) B) μ s B) μ s n (d 3 4.0me ( n (d 3 4.0me ( Attenuatio 54 32..00oup Delay Ti Attenuatio 54 32..00oup Delay Ti Gr Gr 6 1.0 6 1.0 7 0.0 7 0.0 10.300 10.500 10.700 10.900 11.100 10.300 10.500 10.700 10.900 11.100 Frequency (MHz) Frequency (MHz) SFECF10M7DF00S0-R0 0 7.0 1 6.0 2 5.0ec.) B) μ s n (d 3 4.0me ( Attenuatio 54 32..00oup Delay Ti Gr 6 1.0 7 0.0 10.300 10.500 10.700 10.900 11.100 Frequency (MHz) 9

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Frequency Characteristics (Spurious) Standard Type 1 SFECF10M7HA00-R0/SFECF10M7HF00-R0 SFECF10M7GA00-R0/SFECF10M7GF00-R0 0 0 10 10 20 20 B) B) d d n ( 30 n ( 30 o o ati ati nu 40 nu 40 e e Att Att 50 50 60 60 70 70 8.700 9.700 10.700 11.700 12.700 8.700 9.700 10.700 11.700 12.700 Frequency (MHz) Frequency (MHz) SFECF10M7FA00-R0/SFECF10M7FF00-R0 SFECF10M7EA00-R0 0 0 10 10 20 20 B) B) d d n ( 30 n ( 30 o o ati ati nu 40 nu 40 e e Att Att 50 50 60 60 70 70 8.700 9.700 10.700 11.700 12.700 8.700 9.700 10.700 11.700 12.700 Frequency (MHz) Frequency (MHz) SFECF10M7DA0001-R0/SFECF10M7DF00-R0 0 10 20 B) d n ( 30 o ati nu 40 e Att 50 60 70 8.700 9.700 10.700 11.700 12.700 Frequency (MHz) 10

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Frequency Characteristics (Spurious) High-reliability Type SFECF10M7HA00S0-R0/SFECF10M7HF00S0-R0 SFECF10M7GA00S0-R0/SFECF10M7GF00S0-R0 1 0 0 10 10 20 20 B) B) d d n ( 30 n ( 30 o o ati ati nu 40 nu 40 e e Att Att 50 50 60 60 70 70 8.700 9.700 10.700 11.700 12.700 8.700 9.700 10.700 11.700 12.700 Frequency (MHz) Frequency (MHz) SFECF10M7FA00S0-R0/SFECF10M7FF00S0-R0 SFECF10M7EA00S0-R0 0 0 10 10 20 20 B) B) d d n ( 30 n ( 30 o o ati ati nu 40 nu 40 e e Att Att 50 50 60 60 70 70 8.700 9.700 10.700 11.700 12.700 8.700 9.700 10.700 11.700 12.700 Frequency (MHz) Frequency (MHz) SFECF10M7DF00S0-R0 0 10 20 B) d n ( 30 o ati nu 40 e Att 50 60 70 8.700 9.700 10.700 11.700 12.700 Frequency (MHz) 11

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Notice 1 Ceramic Filters (CERAFILr) Chip Type SFECF Series e Soldering and Mounting e 1. Standard Reflow Soldering Conditions (1) Reflow Filter is soldered twice within the following temperature Peak (260°C max.) conditions. C)260 e (°230 ur at Heating per Pre-heating (230°C) m (150-180°C) e100 T Gradual Cooling 30 sec. 60-120 sec. 40 sec. 120 sec. min. max. min. (2) Soldering Iron Filter is soldered at +350±5°C for 3.0±0.5 seconds. The soldering iron should not touch the filter while soldering. (3) Conditions for Placement Machines The component is recommended for use with placement machines that employ optical placement capabilities. The component might be damaged by excessive mechanical force. Please make sure that you have evaluated by using placement machines before going into mass production. Do not use placement machines that utilize mechanical positioning. Please contact Murata for details beforehand. (4) Other (a) The component may be damaged if excess [Component Direction] mechanical stress is applied to it mounted on the Place the printed circuit board. component (b) Design layout of components on the PC board to lateral to the direction in minimize the stress imposed on the warp or flexure of which stress the board. acts. (c) After installing components, if solder is excessively [Component Layout Close to Board] applied to the circuit board, mechanical stress will cause destruction resistance characteristics to Perforation B Susceptibility to degrade. To prevent this, be extremely careful in stress is in the order of: A>C>B determining shape and dimension before designing A Slit C the circuit board diagram. (d) When the positioning claws and pick-up nozzle are worn, the load is applied to the components while positioning is concentrated on positioning accuracy, etc. Careful checking and maintenance are necessary to prevent unexpected trouble. (e) When correcting components with a soldering iron, the tip of the soldering iron should not directly touch the component. Depending on the soldering conditions, the effective area of terminations may be reduced. Solder containing Ag should be used to prevent electrode erosion. (f) Do not use strong acidity flux, more than 0.2wt% chlorine content, in reflow soldering. Continued on the following page. 12

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Notice 1 Continued from the preceding page. 2. Wash Do not clean or wash the component as it is not hermetically sealed. 3. Coating In case of overcoating the component, conditions such as material of resin, cure temperature, and so on should be evaluated well. e Storage and Operating Conditions e 1. Product Storage Conditions (2) Please do not put the products directly on the floor Please store the products in a room where the without anything under them to avoid damp places temperature/humidity is stable, and avoid places where and/or dusty places. there are large temperature changes. Please store the (3) Please do not store the products in places such as a products under the following conditions: damp heated place or any place exposed to direct Temperature: -10 to +40°C sunlight or excessive vibration. Humidity: 15 to 85% R.H. (4) Please use the products immediately after package is 2. Expiration Date on Storage opened, because quality and solderability may be Expiration date (shelf life) of the products is six months degraded due to storage under poor conditions. after delivery under the conditions of a sealed and (5) To avoid cracking of the ceramic element, please do unopened package. Please use the products within six not drop the products. months after delivery. If you store the products for a long 4. Other time (more than six months), use carefully because Please be sure to consult with our sales representative or solderability may be degraded due to storage under poor engineer whenever the products are to be used in conditions. conditions not listed above. Please confirm solderability and characteristics for the products regularly. 3. Notice on Product Storage (1) Please do not store the products in a chemical atmosphere (Acids, Alkali, Bases, Organic gas, Sulfides and so on), because quality and solderability may be degraded due to storage in a chemical atmosphere. e Rating e The component may be damaged if excessive mechanical stress is applied. e Handling e 1. Accurate test circuit values are required to measure electrical characteristics. Miscorrelation may be caused if there is any deviation, especially stray capacitance, from the test circuit in the specification. 2. The components, packed in a moisture proof bag (dry pack), are sensitive to moisture. The following treatment is required before applying reflow soldering, to avoid reliability degradation caused by thermal stress. When unpacked, store the component in an atmosphere of reflow 30°C and below 60%R.H., and solder within 1 week. 13

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Packaging 1 Minimum Quantity/Dimensions of Reel Embossed Tape ø180mm 2,000 (pcs.) Dimensions of Reel Trailer Leader 160 to 190 Cover film Empty Components Empty 240 to 280 ø13.0±0.5 400 to 560 +1.060-0+0180-1.5 2.0±0.5 17.0±1.0 13.0+-01.0 (in mm) Dimensions of Carrier Tape Dimensions of Carrier Tape 1 4.0±0.1 0. ± 5 ø1.55±0.05 2.0±0.05 7 Chip filter 1. x. a m 4.1±0.1 5.5±0.05 12.0±0.2 3° 1 0. CP(o0ev.1eelr it nfiogl m0 s.t7rNen)gth 10° max. 4.0±0.1 (33°.3)5+-00..015 0.3±0.05 (0.05) 1.84±0.1 4.1± User direction of feed (cid:70)(cid:3)(cid:20)(cid:31)(cid:48)(cid:50)(cid:3)(cid:44)(cid:51)(cid:43)(cid:32)(cid:35)(cid:48)(cid:3)(cid:43)(cid:31)(cid:48)(cid:41)(cid:35)(cid:34)(cid:3)(cid:49)(cid:39)(cid:34)(cid:35)(cid:3)(cid:39)(cid:49)(cid:3)(cid:31)(cid:42)(cid:53)(cid:31)(cid:55)(cid:49)(cid:3)(cid:36)(cid:31)(cid:33)(cid:39)(cid:44)(cid:37)(cid:3)(cid:51)(cid:46)(cid:64) ( ): Reference (in mm) 14

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Ceramic Filters (CERAFILr) RoHS Chip Type SFECV/SFECK Series 6.9±0.3 The SFECV/SFECK10M7 series for FM receivers are 4.05±0.4 1.2±0.5 1.2±0.3 1.2±0.5 1.5±0.2 monolithic type ceramic filters that utilize the thickness expander mode of piezoelectric ceramics. The SFECV series 2 3 enable customers to make an AM/FM set very thin, and it 2.9±0. ** * can be useful to the total chip circuit. (3) (2) (1) Features 2 0. : Marking 1. The piezoelectric element is sandwiched by heat resistant 1.5± (1) : Input (2) : Ground substrate, thus it has excellent mechanical strength, and 1.0±0.5 1.0±0.5 1.0±0.5 (3) : Output it is suitable for automatic mounting. ** : EIAJ Monthly Code ** : Center Frequency Rank Code (in mm) 2. Various bandwidths are available. Select a suitable type in accordance with the desired characteristics. 3. Operating Temperature Range: -20 to +80°C (Standard Type) -40 to +85°C (High-reliability Type) Storage Temperature Range: -40 to +85°C (Standard Type) -55 to +85°C (High-reliability Type) Applications 1. Small, thin radios 2. Automotive radios 3. Headphone stereos Standard Type Center 3dB Attenuation Insertion Loss Ripple Spurious Spurious Input/Output Part Number Frequency Bandwidth Attenuation Attenuation Impedance (fo) (MHz) (kHz) (kHz) (dB) (dB) (1) (dB) (2) (dB) (ohm) 15.000 30 min. 30 min. SFECV15M0EQ0001-R0 300 min. 750 max. 7.0max. 1.0 max. 330 ±50kHz [within 14MHz to fo][within fo to 16MHz] 10.700 35 min. 35 min. SFECV10M7KA00-R0 110 ±30kHz 320 max. 6.0±2.0dB 1.0 max. 330 ±30kHz [within 9MHz to fo] [within fo to 12MHz] 10.700 35 min. 35 min. SFECV10M7JA00-R0 150 ±40kHz 380 max. 5.5±2.0dB 1.0 max. 330 ±30kHz [within 9MHz to fo] [within fo to 12MHz] Area of Attenuation: [within 20dB] Area of Insertion Loss: at minimum loss point Center frequency (fo) defined by the center of 3dB bandwidth. For safety purposes, connect the output of filters to the IF amplifier through a D.C. blocking capacitor. Avoid applying a direct current to the output of ceramic filters. The order quantity should be an integral multiple of the "Minimum Quantity" shown in the packaging page. High-reliability Type Center 3dB Attenuation Insertion Loss Ripple Spurious Spurious Input/Output Part Number Frequency Bandwidth Attenuation Attenuation Impedance (fo) (MHz) (kHz) (kHz) (dB) (dB) (1) (dB) (2) (dB) (ohm) 10.700 35 min. 35 min. SFECK10M7KA00S0-R0 110 ±30kHz 320 max. 6.0±2.0dB 1.0 max. 330 ±30kHz [within 9MHz to fo][within fo to 12MHz] 10.700 35 min. 35 min. SFECK10M7JA00S0-R0 150 ±40kHz 380 max. 5.5±2.0dB 1.0 max. 330 ±30kHz [within 9MHz to fo][within fo to 12MHz] Area of Attenuation: [within 20dB] Area of Insertion Loss: at minimum loss point Center frequency (fo) defined by the center of 3dB bandwidth. For safety purposes, connect the output of filters to the IF amplifier through a D.C. blocking capacitor. Avoid applying a direct current to the output of ceramic filters. The order quantity should be an integral multiple of the "Minimum Quantity" shown in the packaging page. 15

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Standard Center Frequency Rank Code CODE 30kHz Step 25kHz Step A 10.700MHz±30kHz 10.700MHz±25kHz Standard Land Pattern Dimensions Test Circuit 1.2 1.2 1.2 2 R1 (1) (3) Rg (2) 4.0 E1 R2 C2 E2 RVFoltmeter S.S.G. =-10dBm (1): Input 1.65 1.65 (2): Ground 2.85 2.85 (3): Output Rg=50Ω R1=280Ω±5% R2=330Ω±5% C2=10±2pF (Including stray capacitance and Input capacitance of RF voltmeter) Land (in mm) E1: S.S.G. Output Voltage Frequency Characteristics Standard Type SFECV15M0EQ0001-R0 SFECV10M7KA00-R0 0 10.0 0 7.0 1 6.5 2 8.0 ec.) 2 6.0 ec.) B) μ s B) μ s n (d 4 6.0 me ( n (d 3 5.5 me ( Attenuatio 6 4.0 oup Delay Ti Attenuatio 54 45..50 oup Delay Ti Gr Gr 8 2.0 6 4.0 10 0.0 7 3.5 14.700 14.800 14.900 15.000 15.100 15.200 15.300 10.300 10.500 10.700 10.900 11.100 Frequency (MHz) Frequency (MHz) SFECV10M7JA00-R0 0 8.0 1 7.5 2 7.0 ec.) B) μ s n (d 3 6.5 me ( Attenuatio 54 65..05 oup Delay Ti Gr 6 5.0 7 4.5 10.300 10.500 10.700 10.900 11.100 Frequency (MHz) 16

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Frequency Characteristics High-reliability Type SFECK10M7KA00S0-R0 SFECK10M7JA00S0-R0 0 7.0 0 8.0 1 6.5 1 7.5 2 6.0ec.) 2 7.0ec.) B) μ s B) μ s n (d 3 5.5me ( n (d 3 6.5me ( Attenuatio 54 45..50oup Delay Ti Attenuatio 54 65..05oup Delay Ti 2 Gr Gr 6 4.0 6 5.0 7 3.5 7 4.5 10.300 10.500 10.700 10.900 11.100 10.300 10.500 10.700 10.900 11.100 Frequency (MHz) Frequency (MHz) Frequency Characteristics (Spurious) Standard Type SFECV15M0EQ0001-R0 SFECV10M7KA00-R0 0 0 10 10 20 20 dB) 30 dB) n ( n ( 30 atio 40 atio nu nu 40 Atte 50 Atte 50 60 70 60 80 70 13.000 14.000 15.000 16.000 17.000 8.700 9.700 10.700 11.700 12.700 Frequency (MHz) Frequency (MHz) SFECV10M7JA00-R0 0 10 20 B) d n ( 30 o ati nu 40 e Att 50 60 70 8.700 9.700 10.700 11.700 12.700 Frequency (MHz) Frequency Characteristics (Spurious) High-reliability Type SFECK10M7KA00S0-R0 SFECK10M7JA00S0-R0 0 0 10 10 20 20 B) B) d d n ( 30 n ( 30 o o ati ati nu 40 nu 40 e e Att Att 50 50 60 60 70 70 8.700 9.700 10.700 11.700 12.700 8.700 9.700 10.700 11.700 12.700 Frequency (MHz) Frequency (MHz) 17

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Notice Ceramic Filters (CERAFILr) Chip Type SFECV/SFECK Series e Soldering and Mounting e 1. Standard Reflow Soldering Conditions (1) Reflow Filter is soldered twice within the following temperature Peak 2 conditions. C)240 (240°C max.) e (°230 ur at Heating per Pre-heating (230°C) m (150-180°C) e100 T Gradual Cooling 30 sec. 60-120 sec. 30 sec. 120 sec. min. max. min. (2) Soldering Iron Filter is soldered at +350±5°C for 3.0±0.5 seconds. The soldering iron should not touch the filter while soldering. (3) Conditions for Placement Machines The component is recommended for use with placement machines that employ optical placement capabilities. Damage may result from excessive mechanical force. Please make sure that you have evaluated by using placement machines before going into mass production. Do not use placement machines that utilize mechanical positioning. Please contact Murata for details beforehand. (4) Other (a) The component may be damaged if excess [Component Direction] mechanical stress is applied to it mounted on the Put the printed circuit board. component (b) Design layout of components on the PC board to lateral to the direction in minimize the stress imposed on the warp or flexure of which stress the board. acts. (c) After installing components, if solder is excessively [Component Layout Close to Board] applied to the circuit board, mechanical stress will cause destruction resistance characteristics to Perforation B Susceptibility to degrade. To prevent this, be extremely careful in stress is in the order of: A>C>B determining shape and dimension before designing A Slit C the circuit board diagram. (d) When the positioning claws and pick-up nozzle are worn, the load is applied to the components while positioning is concentrated to one positioning accuracy, etc. Careful checking and maintenance are necessary to prevent unexpected trouble. (e) When correcting components with a soldering iron, the tip of the soldering iron should not directly touch the component. Depending on the soldering conditions, the effective area of terminations may be reduced. Solder containing Ag should be used to prevent electrode erosion. (f) Do not use strong acidity flux, more than 0.2wt% chlorine content, in reflow soldering. Continued on the following page. 18

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Notice Continued from the preceding page. 2. Wash Do not clean or wash the component as it is not hermetically sealed. 3. Coating In case of overcoating the component, conditions such as 2 material of resin, cure temperature, and so on should be evaluated well. e Storage and Operating Conditions e 1. Product Storage Conditions (2) Please do not put the products directly on the floor Please store the products in room where the without anything under them to avoid damp places temperature/humidity is stable, and avoid places where and/or dusty places. there are large temperature changes. Please store the (3) Please do not store the products in the places such as products under the following conditions: a damp heated place or any place exposed to direct Temperature: -10 to +40°C sunlight or excessive vibration. Humidity: 15 to 85% R.H. (4) Please use the products immediately after package is 2. Expiration Date on Storage opened, because quality and solderability may be Expiration date (Shelf life) of the products is six months degraded due to storage under the poor conditions. after delivery under the conditions of a sealed and (5) To avoid cracking of the ceramic element, please do unopened package. Please use the products within six not drop the products. months after delivery. If you store the products for a long 4. Other time (more than six months), use carefully because the Please be sure to consult with our sales representative or products may be degraded in solderability due to storage engineer whenever the products are to be used in under poor conditions. conditions not listed above. Please confirm solderability and characteristics for the products regularly. 3. Notice on Product Storage (1) Please do not store the products in a chemical atmosphere (Acids, Alkali, Bases, Organic gas, Sulfides and so on), because quality and solderability may be degraded due to the storage in a chemical atmosphere. e Rating e The component may be damaged if excessive mechanical stress is applied. e Handling e Accurate test circuit values are required to measure electrical characteristics. Miscorrelation may be caused if there is any deviation, especially stray capacitance, from the test circuit in the specification. 19

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Packaging Minimum Quantity/Dimensions of Reel Embossed Tape ø180mm 2,000 (pcs.) 2 Dimensions of Reel Trailer Leader 160-190 Cover film Empty Components Empty 240-280 ø13.0±0.5 400-560 +1.060–0 +0180–1.5 2.0±0.5 13.0+–10.0 17.0±1.0 (in mm) Dimensions of Carrier Tape (cid:8)(cid:39)(cid:43)(cid:35)(cid:44)(cid:49)(cid:39)(cid:45)(cid:44)(cid:49)(cid:3)(cid:45)(cid:36)(cid:3)(cid:7)(cid:31)(cid:48)(cid:48)(cid:39)(cid:35)(cid:48)(cid:3)(cid:24)(cid:31)(cid:46)(cid:35) 1 0. ø1.5+–00..10 2.0±0.05 4.0±0.1 75± 1. 5 0 * * * * * 0.01 5.5±0. 0±0.2 ** ** ** ** ** 7.3± 12. PCeoevlienrg fi sltmrengt1h0 0°. 1m taox 40...07±N0.1 3.0±0.1 (3(cid:7)°(cid:38))(cid:39)(cid:46)(cid:3)(cid:113)(cid:42)(cid:50)(cid:35)(cid:48) 0.3±0.05+0.11.7–0.05 1.9±0.1 (cid:25)(cid:49)(cid:35)(cid:48)(cid:3)(cid:34)(cid:39)(cid:48)(cid:35)(cid:33)(cid:50)(cid:39)(cid:45)(cid:44)(cid:3)(cid:45)(cid:36)(cid:3)(cid:36)(cid:35)(cid:35)(cid:34) (cid:70)(cid:3)(cid:20)(cid:31)(cid:48)(cid:50)(cid:3)(cid:44)(cid:51)(cid:43)(cid:32)(cid:35)(cid:48)(cid:3)(cid:43)(cid:31)(cid:48)(cid:41)(cid:35)(cid:34)(cid:3)(cid:49)(cid:39)(cid:34)(cid:35)(cid:3)(cid:39)(cid:49)(cid:3)(cid:31)(cid:42)(cid:53)(cid:31)(cid:55)(cid:49)(cid:3)(cid:36)(cid:31)(cid:33)(cid:39)(cid:44)(cid:37)(cid:3)(cid:51)(cid:46)(cid:64) ( ) : Reference (in mm) 20

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Ceramic Filters (CERAFILr) RoHS Chip Type SFSCE Series The SFSCE series are chip surface mount filters available (1) 4.5 (2) 0.4 for 3dB bandwidth at 700kHz to 1.3MHz (more than twice the width compared with current types). 3.8 * 3.5) ( They have 1.0mm max. thickness and small mounting area (4.5x3.8mm). (4) (3) (4.0) max. 0 Features 1. (4-R0.3) 15 0. (1): Input 1. The filters are mountable by automatic placers. (0.3) 85 (2): Output 2. They are slim, at only 1.0mm max. thickness, and 8) (4) (3) 0. ((34)):: NGroo Cuonndnection 3 have a small mounting area (4.5x3.8mm) enabling (1. (1) (2) 0.3 Toleran*c:e E uIAnJle Mssonthly Code otherwise specified: ±0.1 flexible PCB design. 0.61.1 0.15 ( ): Reference (2.25) (in mm) 3. Available lead (Pb) free solder reflow. 4. Operating temperature range: -20 to +80°C Storage temperature range: -40 to +85°C Applications 1. SS digital communication system 2. Digital wireless audio 3. PHS Evolution system 4. RFID Reader Writer 5. RKE Nominal Center 3dB Stop Insertion Loss Ripple Spurious GDT Deviation Input/Output Part Number Frequency (fn) Bandwidth Bandwidth Response Impedance (MHz) (kHz) (MHz) (dB) (dB) (dB) (µs) (ohm) fn±500.0 2.2 max. (Total) 6.0 max. 2.0 max. 30/25 min. 0.6 max. SFSCE10M7WF03-R0 10.700 470 min. [within 20dB] [at minimum loss point] [within 3dB Bandwidth] [within 5.7MHz to fn / fn to 15.7MHz] [within fn±400kHz] fn±400.0 1.8 max. (Total) 6.0 max. 1.5 max. 35/25 min. 0.6 max. SFSCE10M7WF04-R0 10.700 470 min. [within 20dB] [at minimum loss point] [within 3dB Bandwidth] [within 5.7MHz to fn / fn to 15.7MHz] [within fn±325kHz] fn±325.0 1.7 max. (Total) 6.0 max. 1.5 max. 40/30 min. 0.6 max. SFSCE10M7WF05-R0 10.700 470 min. [within 20dB] [at minimum loss point] [within 3dB Bandwidth] [within 5.7MHz to fn / fn to 15.7MHz] [within fn±250kHz] For safety purposes, connect the output of filters to the IF amplifier through a DC blocking capacitor. Avoid applying a direct current to the output of ceramic filters. The order quantity should be an integral multiple of the "Minimum Quantity" shown in packaging page in this catalog. Standard Land Pattern Dimensions Test Circuit 1.05 1.4 (4) (3) 0.1 0.1 R1 (3) (4)0.1 (1) (2) Rg 3 1. 8 R2 C2 0.5 S.S.G. RF 1 1. Voltmeter 5 0. (2) (1) (1): Input 0.5 (1): Input (2): Output (2): Output (3): No Connection (3): No Connection (4): Ground (4): Ground R1+Rg=R2=Input/Output Impedance, Rg=50Ω Indicates solder resist land pattern. (in mm) C2=10pF (Including stray capacitance and Input capacitance of RF Voltmeter) E1: S.S.G. Output Voltage 21

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Frequency Characteristics SFSCE10M7WF03-R0 SFSCE10M7WF03-R0 0 2.0 0 2 1.6 c.) 20 e B) μ s B) n (d 4 1.2 me ( n (d uatio ay Ti uatio 40 Atten 6 0.8 up Del Atten o Gr 60 8 0.4 10 0.0 80 9.500 9.900 10.300 10.700 11.100 11.500 11.900 6.700 8.700 10.700 12.700 14.700 Frequency (MHz) Frequency (MHz) 3 22

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Notice SFSCE10M7WF03-R0 Notice e Soldering and Mounting e 1. Standard Reflow Soldering Conditions (1) Reflow Filter is soldered twice within the following temperature Peak (240°C max.) conditions. 240 C) 230 ure (° (H2e3a0t°inCg) at er Pre-heating mp 100 e (150-180°C) Gradual T Cooling 3 30 sec. 60-120 sec. 30 sec. 120 sec. min. max. min. (2) Soldering Iron Filter is soldered at +280±5°C for 3.0±0.5 seconds. The soldering iron should not touch the filter while soldering. (3) Condition for Placement Machines The component is recommended for placement machines that employ optical placement capabilities. The component might be damaged by excessive mechanical force. Please make sure that you have evaluated by using placement machines before going into mass production. Do not use placement machines that utilize mechanical positioning. Please contact Murata for details beforehand. (4) Other (a) The component may be damaged if excess [Component Layout Close to Board] mechanical stress is applied to it mounted on the printed circuit board. (b) Design layout of components on the PC board to Susceptibility to Perforation B stress is in the order minimize the stress imposed on the warp or flexure of of: A>C>B the board. A Slit C (c) After installing components, if solder is excessively applied to the circuit board, mechanical stress will cause destruction resistance characteristics to [Component Direction] degrade. To prevent this, be extremely careful in Place the compon- determining shape and dimension before designing ent laterally to the direction in which the circuit board diagram. stress acts. (d) When the positioning claws and pick-up nozzle are worn, the load is applied to the components while positioning is concentrated on positioning accuracy, etc. Careful checking and maintenance are necessary to prevent unexpected trouble. (e) When correcting components with a soldering iron, the tip of the soldering iron should not directly touch the component. (f) Do not use strong acidity flux, more than 0.2wt% chlorine content, in reflow soldering. Continued on the following page. 23

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Notice Continued from the preceding page. 2. Wash Do not clean or wash the component as it is not hermetically sealed. 3. Coating In case of overcoating the component, conditions such as material of resin, cure temperature, and so on should be evaluated well. e Storage and Operating Conditions e 1. Product Storage Condition (2) Please do not put the products directly on the floor 3 Please store the products in a room where the without anything under them to avoid damp places temperature/humidity is stable, and avoid places where and/or dusty places. there are large temperature changes. Please store the (3) Please do not store the products in places such as a products under the following conditions: damp heated place or any place exposed to direct Temperature: -10 to + 40°C sunlight or excessive vibration. Humidity: 15 to 85% R.H. (4) Please use the products immediately after the 2. Expiration Date on Storage package is opened, because the characteristics may Expiration date (shelf life) of the products is six months be reduced in quality and/or be degraded in after delivery under the conditions of a sealed and solderability due to storage under poor condition. unopened package. Please use the products within six (5) Please do not drop the products to avoid cracking of months after delivery. If you store the products for a long the ceramic element. time (more than six months), use carefully because 4. Other solderability may be degraded due to storage under poor Please be sure to consult with our sales representative or conditions. engineer whenever the products are to be used in Please confirm solderability and characteristics for the conditions not listed above. products regularly. 3. Notice on Product Storage (1) Please do not store the products in a chemical atmosphere (Acids, Alkali, Bases, Organic gas, Sulfides and so on), because the characteristics may be reduced in quality and may be degraded in solderability due to storage in a chemical atmosphere. e Rating e The component may be damaged if excessive mechanical stress is applied. e Handling e Accurate test circuit values are required to measure electrical characteristics. Miscorrelation may be caused if there is any deviation, especially stray capacitance, from the test circuit in the specification. 24

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Notice SFSCE10M7WF04/05-R0 Notice e Soldering and Mounting e 1. Standard Reflow Soldering Conditions (1) Reflow Filter is soldered twice within the following temperature Peak (260°C max.) conditions. 260 C) 230 ure (° (H2e3a0t°inCg) at er Pre-heating mp 100 e (150-180°C) Gradual T Cooling 3 30 sec. 60-120 sec. 40 sec. 120 sec. min. max. min. (2) Soldering Iron Filter is soldered at +280±5°C for 3.0±0.5 seconds. The soldering iron should not touch the filter while soldering. (3) Condition for Placement Machines The component is recommended for placement machines that employ optical placement capabilities. The component might be damaged by excessive mechanical force. Please make sure that you have evaluated by using placement machines before going into mass production. Do not use placement machines that utilize mechanical positioning. Please contact Murata for details beforehand. (4) Other (a) The component may be damaged if excess [Component Layout Close to Board] mechanical stress is applied to it mounted on the printed circuit board. (b) Design layout of components on the PC board to Susceptibility to Perforation B stress is in the order minimize the stress imposed on the warp or flexure of of: A>C>B the board. A Slit C (c) After installing components, if solder is excessively applied to the circuit board, mechanical stress will cause destruction resistance characteristics to [Component Direction] degrade. To prevent this, be extremely careful in Place the compon- determining shape and dimension before designing ent laterally to the direction in which the circuit board diagram. stress acts. (d) When the positioning claws and pick-up nozzle are worn, the load is applied to the components while positioning is concentrated on positioning accuracy, etc. Careful checking and maintenance are necessary to prevent unexpected trouble. (e) When correcting components with a soldering iron, the tip of the soldering iron should not directly touch the component. (f) Do not use strong acidity flux, more than 0.2wt% chlorine content, in reflow soldering. Continued on the following page. 25

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Notice Continued from the preceding page. 2. Wash Do not clean or wash the component as it is not hermetically sealed. 3. Coating In case of overcoating the component, conditions such as material of resin, cure temperature, and so on should be evaluated well. e Storage and Operating Conditions e 1. Product Storage Condition (2) Please do not put the products directly on the floor 3 Please store the products in a room where the without anything under them to avoid damp places temperature/humidity is stable, and avoid places where and/or dusty places. there are large temperature changes. Please store the (3) Please do not store the products in places such as a products under the following conditions: damp heated place or any place exposed to direct Temperature: -10 to + 40°C sunlight or excessive vibration. Humidity: 15 to 85% R.H. (4) Please use the products immediately after the 2. Expiration Date on Storage package is opened, because the characteristics may Expiration date (shelf life) of the products is six months be reduced in quality and/or be degraded in after delivery under the conditions of a sealed and solderability due to storage under poor condition. unopened package. Please use the products within six (5) Please do not drop the products to avoid cracking of months after delivery. If you store the products for a long the ceramic element. time (more than six months), use carefully because 4. Other solderability may be degraded due to storage under poor Please be sure to consult with our sales representative or conditions. engineer whenever the products are to be used in Please confirm solderability and characteristics for the conditions not listed above. products regularly. 3. Notice on Product Storage (1) Please do not store the products in a chemical atmosphere (Acids, Alkali, Bases, Organic gas, Sulfides and so on), because the characteristics may be reduced in quality and may be degraded in solderability due to storage in a chemical atmosphere. e Rating e The component may be damaged if excessive mechanical stress is applied. e Handling e Accurate test circuit values are required to measure electrical characteristics. Miscorrelation may be caused if there is any deviation, especially stray capacitance, from the test circuit in the specification. 26

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Packaging Minimum Quantity/Dimensions of Reel Embossed Tape ø180mm 1,500 (pcs.) Dimensions of Reel Trailer Leader 160 to 190 Cover film Empty Components Empty 240 to 280 ø13.0±0.5 400 to 560 3 5 +00-1. 8 1 2.0±0.5 17.0±1.0 13.0+-01.0 (in mm) Dimensions of Carrier Tape Dimensions of Carrier Tape (cid:123) (cid:122)(cid:64) (cid:126)(cid:64)(cid:122)±(cid:122)(cid:64)(cid:123) ± (cid:129)(cid:127) (cid:124)(cid:64)(cid:122)±(cid:122)(cid:64)(cid:122)(cid:127) (cid:462)(cid:123)(cid:64)(cid:127)(cid:127)±(cid:122)(cid:64)(cid:122)(cid:127) (cid:122)(cid:64)(cid:125)±(cid:122)(cid:64)(cid:122)(cid:127) (cid:123)(cid:64) (cid:54)(cid:64) (cid:31) (cid:127) (cid:43) ±(cid:123)(cid:124)(cid:64)(cid:122)(cid:122)(cid:64)(cid:124)±(cid:127)(cid:64)(cid:127)(cid:122)(cid:64)(cid:122) (cid:125)(cid:157)(cid:3)±(cid:127)(cid:64)(cid:122)(cid:122)(cid:64)(cid:123) (cid:123)(cid:64)(cid:123)±(cid:122)(cid:64)(cid:123) (cid:130)(cid:64)(cid:122)±(cid:122)(cid:64)(cid:123) (cid:462)(cid:123)(cid:64)(cid:127)(cid:127)±(cid:122)(cid:64)(cid:122)(cid:127) (cid:20)(cid:35)(cid:35)(cid:42)(cid:39)(cid:44)(cid:37)(cid:3)(cid:49)(cid:50)(cid:48)(cid:35)(cid:44)(cid:37)(cid:50)(cid:38) (cid:127) (cid:122)(cid:64)(cid:123)(cid:3)(cid:50)(cid:45)(cid:3)(cid:122)(cid:64)(cid:129)(cid:18) (cid:127)(cid:122)(cid:64)(cid:122) (cid:7)(cid:45)(cid:52)(cid:35)(cid:48)(cid:3)(cid:113)(cid:42)(cid:43) (cid:126)(cid:64)(cid:125)±(cid:122)(cid:64)(cid:123) (3°) (cid:123)(cid:122)(cid:157)(cid:3)(cid:43)(cid:31)(cid:54)(cid:64) (cid:122)(cid:64)(cid:122)±(cid:122)(cid:64)(cid:125) (cid:25)(cid:49)(cid:35)(cid:48)(cid:3)(cid:34)(cid:39)(cid:48)(cid:35)(cid:33)(cid:50)(cid:39)(cid:45)(cid:44)(cid:3)(cid:45)(cid:36)(cid:3)(cid:36)(cid:35)(cid:35)(cid:34) (cid:70)(cid:3)(cid:20)(cid:31)(cid:48)(cid:50)(cid:3)(cid:18)(cid:51)(cid:43)(cid:32)(cid:35)(cid:48)(cid:3)(cid:43)(cid:31)(cid:48)(cid:41)(cid:35)(cid:34)(cid:3)(cid:49)(cid:39)(cid:34)(cid:35)(cid:3)(cid:39)(cid:49)(cid:3)(cid:31)(cid:42)(cid:53)(cid:31)(cid:55)(cid:49)(cid:3)(cid:36)(cid:31)(cid:33)(cid:39)(cid:44)(cid:37)(cid:3)(cid:51)(cid:46)(cid:64) (cid:72)(cid:3)(cid:3)(cid:3)(cid:3)(cid:3)(cid:74)(cid:3)(cid:66)(cid:3)(cid:22)(cid:35)(cid:36)(cid:35)(cid:48)(cid:35)(cid:44)(cid:33)(cid:35) (in mm) 27

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Ceramic Filters (CERAFILr) RoHS Chip Type SFSKA Series The SFSKA_CF ceramic filter is a small and thin SMD filter sealed with a metal cap. The SFSKA_CF is recommended for LCD-TVs, and small and 7.9±0.2 3.0±0.1 thin tuners. 1.8±0.2 0.5±0.1 Features 8.5±0.2 3.8±0.2 0.6±0.2 1.0±0.1 1. High attenuation outside bandwidth 1.3±0.2 2. Small and thin package 0.3±0.1 (1) : Input 3. Reflow-solderable 1.3±0.2 ((23)) :: GOurotupnudt (1) (2) (3) (in mm) 2.5±0.2 2.5±0.2 Nominal Center 3dB 20dB Insertion Spurious Spurious Input/Output Part Number Frequency (fn) Bandwidth Bandwidth Loss Attenuation(1) Attenuation(2) Impedance (MHz) (kHz) (kHz) (dB) (dB) (dB) (ohm) 20 min. 15 min. SFSKA4M50CF00-R3 4.500 fn±60 min. 600 max. 6.0 max. 1000 4 [within 0 to fn] [within fn to 7.0MHz] 25 min. 15 min. SFSKA5M50CF00-R3 5.500 fn±60 min. 600 max. 6.0 max. 600 [within 0 to fn] [within fn to 7.0MHz] 25 min. 15 min. SFSKA6M00CF00-R3 6.000 fn±60 min. 600 max. 6.0 max. 470 [within 0 to fn] [within fn to 7.5MHz] 25 min. 15 min. SFSKA6M50CF00-R3 6.500 fn±60 min. 600 max. 6.0 max. 470 [within 0 to fn] [within fn to 8.5MHz] Area of Insertion Loss: at minimum loss point For safety purposes, connect the output of filters to the IF amplifier through a D.C. blocking capacitor. Avoid applying a direct current to the output of ceramic filters. The order quantity should be an integral multiple of the "Minimum Quantity" shown in the packaging page. Standard Land Pattern Dimensions Test Circuit SFSKA4M50CF00-R3 (1)(2)(3) 1.0 1.0 1.0 R1 1.5 1.5 Rg RF E1 R2 C2 E2 Voltmeter 8 4. S.S.G. (1): Input (2): Ground (3): Output (in mm) R1+Rg=R2=1000Ω ±5%, Rg=50Ω C2=10pF (Including stray capacitance and Input capacitance of RF Voltmeter) E1: S.S.G. Output voltage Continued on the following page. 28

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Continued from the preceding page. Test Circuit SFSKA5M50CF00-R3 SFSKA6M00CF00-R3 (1)(2)(3) (1)(2)(3) R1 R1 Rg Rg RF RF E1 R2 C2 E2 Voltmeter E1 R2 C2 E2 Voltmeter S.S.G. S.S.G. (1): Input (1): Input (2): Ground (2): Ground (3): Output (3): Output R1+Rg=R2=600Ω ±5%, Rg=50Ω R1+Rg=R2=470Ω ±5%, Rg=50Ω C2=10pF (Including stray capacitance and Input capacitance of RF Voltmeter) C2=10pF (Including stray capacitance and Input capacitance of RF Voltmeter) E1: S.S.G. Output voltage E1: S.S.G. Output voltage SFSKA6M50CF00-R3 (1)(2)(3) R1 Rg RF E1 R2 C2 E2 Voltmeter 4 S.S.G. (1): Input (2): Ground (3): Output R1+Rg=R2=470Ω ±5%, Rg=50Ω C2=10pF (Including stray capacitance and Input capacitance of RF Voltmeter) E1: S.S.G. Output voltage Frequency Characteristics SFSKA4M50CF00-R3 SFSKA5M50CF00-R3 0 0 10 10 20 20 B) B) d d n ( 30 n ( 30 o o ati ati nu 40 nu 40 e e Att Att 50 50 60 60 70 70 3.5 3.7 3.9 4.1 4.3 4.5 4.7 4.9 5.1 5.3 5.5 4.5 4.7 4.9 5.1 5.3 5.5 5.7 5.9 6.1 6.3 6.5 Frequency (MHz) Frequency (MHz) SFSKA6M00CF00-R3 SFSKA6M50CF00-R3 0 0 10 10 20 20 B) B) d d n ( 30 n ( 30 o o ati ati nu 40 nu 40 e e Att Att 50 50 60 60 70 70 5.0 5.2 5.4 5.6 5.8 6.0 6.2 6.4 6.6 6.8 7.0 5.5 5.7 5.9 6.1 6.3 6.5 6.7 6.9 7.1 7.3 7.5 Frequency (MHz) Frequency (MHz) 29

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Frequency Characteristics (Spurious) SFSKA4M50CF00-R3 SFSKA5M50CF00-R3 0 0 10 10 20 20 B) B) d d n ( 30 n ( 30 o o ati ati nu 40 nu 40 e e Att Att 50 50 60 60 70 70 0.0 2.0 4.0 6.0 8.0 10.0 0 2.0 4.0 6.0 8.0 10.0 Frequency (MHz) Frequency (MHz) SFSKA6M00CF00-R3 SFSKA6M50CF00-R3 0 0 10 10 20 20 B) B) d d n ( 30 n ( 30 o o 4 ati ati nu 40 nu 40 e e Att Att 50 50 60 60 70 70 0 2.0 4.0 6.0 8.0 10.0 0 2.0 4.0 6.0 8.0 10.0 Frequency (MHz) Frequency (MHz) 30

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Notice Ceramic Filters (CERAFILr) Chip Type SFSKA Series e Soldering and Mounting e 1. Standard Reflow Soldering Conditions (1) Reflow Filter is soldered twice within the following temperature Peak (260°C max.) conditions. C)260 e (°230 ur at Heating per Pre-heating (230°C) m (150-180°C) e100 T Gradual Cooling 30 sec. 60-120 sec. 40 sec. 120 sec. min. max. min. (2) Soldering Iron Filter is soldered at +350±5°C for 3.0±0.5 seconds. The soldering iron should not touch the filter while soldering. 4 (3) Conditions for Placement Machines The component is recommended for use with placement machines that employ optical placement capabilities. Damage may result from excessive mechanical force. Please make sure that you have evaluated by using placement machines before going into mass production. Do not use placement machines that utilize mechanical positioning. Please contact Murata for details beforehand. (4) Other (a) The component may be damaged if excess [Component Direction] mechanical stress is applied to it mounted on the printed circuit board. Put the component (b) Design layout of components on the PC board to lateral to the minimize the stress imposed on the warp or flexure of direction in which stress the board. acts. (c) After installing chips, if solder is excessively applied to [Component Layout Close to Board] the circuit board, mechanical stress will cause destruction resistance characteristics to degrade. To Susceptibility to prevent this, be extremely careful in determining Perforation B stress is in the order of: A>C>B shape and dimension before designing the circuit A Slit C board diagram. (d) When the positioning claws and pick-up nozzle are worn, the load is applied to the components while positioning is concentrated to one positioning accuracy, etc. Careful checking and maintenance are necessary to prevent unexpected trouble. (e) When correcting chips with a soldering iron, the tip of the soldering iron should not directly touch the chip component. 2. Wash Do not clean or wash the component as it is not hermetically sealed. Continued on the following page. 31

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Notice Continued from the preceding page. 3. Coating In case of overcoating the component, conditions such as material of resin, cure temperature, and so on should be evaluated well. e Storage and Operating Conditions e 1. Product Storage Conditions (2) Please do not put the products directly on the floor Please store the products in room where the without anything under them to avoid damp places temperature/humidity is stable, and avoid places where and/or dusty places. there are large temperature changes. Please store the (3) Please do not store the products in the places such as products under the following conditions: a damp heated place or any place exposed to direct Temperature: -10 to +40°C sunlight or excessive vibration. Humidity: 15 to 85% R.H. (4) Please use the products immediately after package is 2. Expiration Date on Storage opened, because quality and solderability may be Expiration date (Shelf life) of the products is six months degraded due to storage under the poor conditions. after delivery under the conditions of a sealed and (5) To avoid cracking of the ceramic element, please do unopened package. Please use the products within six not drop the products. months after delivery. If you store the products for a long 4. Other 4 time (more than six months), use carefully because the Please be sure to consult with our sales representative or products may be degraded in solderability due to storage engineer whenever the products are to be used in under poor conditions. conditions not listed above. Please confirm solderability and characteristics for the products regularly. 3. Notice on Product Storage (1) Please do not store the products in a chemical atmosphere (Acids, Alkali, Bases, Organic gas, Sulfides and so on), because quality and solderability may be degraded due to the storage in a chemical atmosphere. e Rating e The component may be damaged if excessive mechanical stress is applied. e Handling e Accurate test circuit values are required to measure electrical characteristics. Miscorrelation may be caused if there is any deviation, especially stray capacitance, from the test circuit in the specification. 32

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Packaging Minimum Quantity/Dimensions of Reel Embossed Tape ø330mm 3,000 (pcs.) Dimensions of Reel Trailer Leader 160 to 190 Cover film Empty Components Empty 240 to 280 min. 2.2±0.5 400 to 560 80±1330±2 ø13.0±0.2 17.5±0.5 21.5±1.0 4 (in mm) Dimensions of Carrier Tape Dimensions of Carrier Tape 1 ø1.5–+00..10 2.0±0.14.0±0.1 5±0. 7 1. 1 ±0.1 7.5±0. 0±0.2 9.0 16. P(0eC.1eol vitneogr 0 sfi.t7lmrNen)gth ø1.5–+00..10 108°.0 m±0a.x1. 4.3±0.1C(3h°ip) filter 0.3±0.05 +0.12.1–0.05 2.3±0.1 User direction of feed (cid:70)(cid:3)(cid:20)(cid:31)(cid:48)(cid:50)(cid:3)(cid:44)(cid:51)(cid:43)(cid:32)(cid:35)(cid:48)(cid:3)(cid:43)(cid:31)(cid:48)(cid:41)(cid:35)(cid:34)(cid:3)(cid:49)(cid:39)(cid:34)(cid:35)(cid:3)(cid:39)(cid:49)(cid:3)(cid:31)(cid:42)(cid:53)(cid:31)(cid:55)(cid:49)(cid:3)(cid:36)(cid:31)(cid:33)(cid:39)(cid:44)(cid:37)(cid:3)(cid:51)(cid:46)(cid:49)(cid:39)(cid:34)(cid:35)(cid:64) ( ) : Reference (in mm) 33

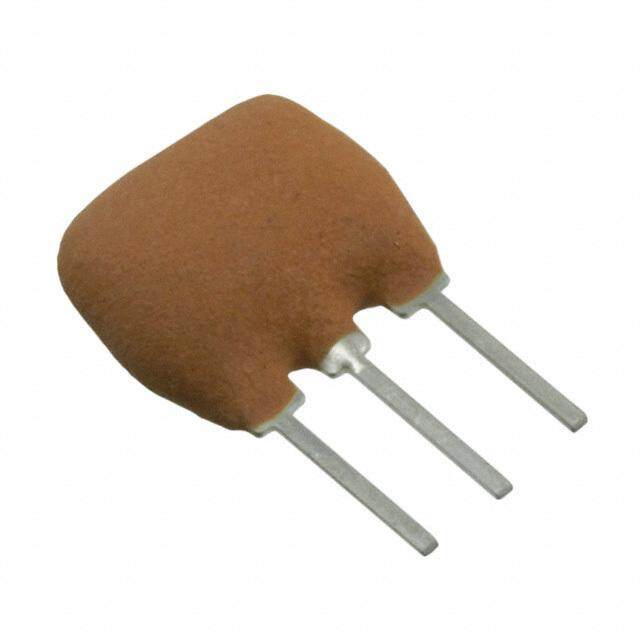

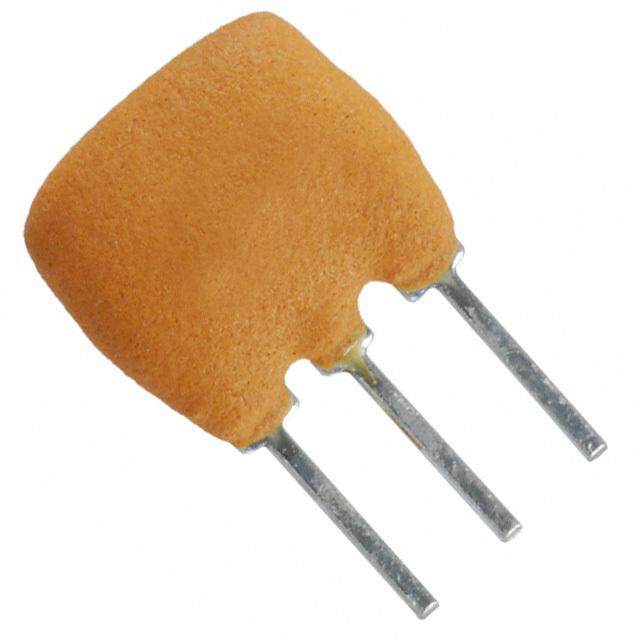

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Ceramic Filters (CERAFILr) RoHS Chip Type SFSKB Series 5.2±0.1 The SFSKB series are SMD ceramic filters suitable (4) (1) fCoern IRte hr efraedqpuheonnceie asp opfl i2c.a3t,i o2n.8s,. 3.2, 3.8, 4.3, 4.8, 5.2, 3.8±0.1 * (3.5) (2) 5.7MHz are available. (3) (4.93) Realized small, thin and lightweight package, 15 0. compared with conventional LC filters. 1.35± Terminal Connection It helps to compose multi-channel circuit on one PCB. (0.1)1.5±0.1(2.0) 4-0.35 ((12)) :: IOnuptuptut Ncoon ftrreibquuteensc tyo a tdhjeu srtemduecntti oisn r oefq puriroeddu ocnti oPnC cBo asnt.d it (1.6) 0.3±0.1(3) (2) 1 4-0.35 (( * 34 : )) E :: c IGTAaeJrpor aMmucnoiintdnoatrlh floyr C eoxdteernal Features 1.0±0.1(0.1) (4) (1) 0.25±0. Ts( p o)e l:e cRriafienefecdre :e ±un0ncl.ee1sms moth(einrw misme ) 1. SMD package in plastic emboss tape, available for automatic placing. 2. They are slim, at only 1.5mm max. thickness, and have a small mounting area (5.2x3.8mm) enabling flexible PCB design. 3. Available for lead (Pb) free reflow soldering process. 4. Operating temperature range: 0 to +70°C Storage temperature range: -55 to +85°C 5. No frequency adjustment is required in production process. 6. Small, thin and lightweight package compared with 5 conventional LC filters Applications 1. IR headphone 2. Set Top Box for satellite broadcasting Nominal Center 3dB 20dB Insertion Spurious Spurious Input/Output Part Number Frequency (fn) Bandwidth Bandwidth Loss Attenuation(1) Attenuation(2) Impedance (MHz) (kHz) (kHz) (dB) (dB) (dB) (ohm) 25 min. 23 min. SFSKB2M30GF00-R1 2.300 fn±75 min. 650 max. 6.0 max. 1000 [within 1.3 to 1.8MHz] [within 2.8 to 3.3MHz] 25 min. 25 min. SFSKB2M80GF00-R1 2.800 fn±75 min. 650 max. 6.0 max. 1000 [within 1.8 to 2.3MHz] [within 3.3 to 3.8MHz] 30 min. 30 min. SFSKB3M20FF00-R1 3.200 fn±75 min. 650 max. 6.0 max. 1000 [within 2.2 to 2.8MHz] [within 3.8 to 4.2MHz] 30 min. 30 min. SFSKB3M80GF00-R1 3.800 fn±75 min. 650 max. 6.0 max. 1000 [within 2.8 to 3.2MHz] [within 4.3 to 4.8MHz] 30 min. 30 min. SFSKB4M30GF00-R1 4.300 fn±75 min. 650 max. 6.0 max. 1000 [within 3.3 to 3.8MHz] [within 4.8 to 5.3MHz] 30 min. 30 min. SFSKB4M80GF00-R1 4.800 fn±75 min. 650 max. 6.0 max. 1000 [within 3.8 to 4.3MHz] [within 5.2 to 5.8MHz] 30 min. 30 min. SFSKB5M20GF00-R1 5.200 fn±75 min. 650 max. 6.0 max. 1000 [within 4.2 to 4.8MHz] [within 5.7 to 6.2MHz] 30 min. 30 min. SFSKB5M70GF00-R1 5.700 fn±75 min. 650 max. 6.0 max. 1000 [within 4.7 to 5.2MHz] [within 6.2 to 6.7MHz] For safety purposes, connect the output of filters to the IF amplifier through a D.C. blocking capacitor. Avoid applying a direct current to the output of ceramic filters. The order quantity should be an integral multiple of the "Minimum Quantity" shown in the packaging page. 34

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Standard Land Pattern Dimensions 1.8 2.0 1.8 3 1. 6 1. 3 1. (in mm) Test Circuit SFSKB2M30GF00-R1/SFSKB3M80GF00-R1 SFSKB2M80GF00-R1/SFSKB3M20FF00-R1 R1 (1) (4) R1 (1) (4) g g R (2) (3) R (2) (3) S.S.G. E1 Cc R2 C2 E2 RVFoltmeter S.S.G. E1 Cc R2 C2 E2 RVFoltmeter (1): Input (1): Input R1+Rg=R2=1.0kΩ (2): Output R1+Rg=R2=1.0kΩ (2): Output Cc=22pF±5% (3): Ground Cc=39pF±5% (3): Ground C2=10pF (Including stray capacitance and (4): Terminal for C2=10pF (Including stray capacitance and (4): Terminal for Input capacitance of RF Voltmeter) external capacitor Input capacitance of RF Voltmeter) external capacitor E1: S.S.G. Output Voltage E1: S.S.G. Output Voltage 5 SFSKB4M30GF00-R1/SFSKB5M70GF00-R1 SFSKB4M80GF00-R1 R1 (1) (4) R1 (1) (4) g g R (2) (3) R (2) (3) S.S.G. E1 Cc R2 C2 E2 RVFoltmeter S.S.G. E1 Cc R2 C2 E2 RVFoltmeter (1): Input (1): Input R1+Rg=R2=1.0kΩ (2): Output R1+Rg=R2=1.0kΩ (2): Output Cc=33pF±5% (3): Ground Cc=15pF±5% (3): Ground C2=10pF (Including stray capacitance and (4): Terminal for C2=10pF (Including stray capacitance and (4): Terminal for Input capacitance of RF Voltmeter) external capacitor Input capacitance of RF Voltmeter) external capacitor E1: S.S.G. Output Voltage E1: S.S.G. Output Voltage SFSKB5M20GF00-R1 R1 (1) (4) g R (2) (3) S.S.G. E1 Cc R2 C2 E2 RVFoltmeter (1): Input R1+Rg=R2=1.0kΩ (2): Output Cc=27pF±5% (3): Ground C2=10pF (Including stray capacitance and (4): Terminal for Input capacitance of RF Voltmeter) external capacitor E1: S.S.G. Output Voltage 35

!Note (cid:129) Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc. P51E.pdf (cid:129) This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. Feb.5,2018 Frequency Characteristics SFSKB2M30GF00-R1 SFSKB2M80GF00-R1 0 0 10 10 20 20 B) B) d d n ( 30 n ( 30 o o ati ati nu 40 nu 40 e e Att Att 50 50 60 60 70 70 1.300 1.800 2.300 2.800 3.300 1.800 2.300 2.800 3.300 3.800 Frequency (MHz) Frequency (MHz) SFSKB3M20FF00-R1 SFSKB3M80GF00-R1 0 0 10 10 20 20 B) B) d d n ( 30 n ( 30 o o ati ati nu 40 nu 40 e e Att Att 50 50 60 60 70 70 2.200 2.700 3.200 3.700 4.200 2.800 3.300 3.800 4.300 4.800 Frequency (MHz) Frequency (MHz) 5 SFSKB4M30GF00-R1 SFSKB4M80GF00-R1 0 0 10 10 20 20 B) B) d d n ( 30 n ( 30 o o ati ati nu 40 nu 40 e e Att Att 50 50 60 60 70 70 3.300 3.800 4.300 4.800 5.300 3.800 4.300 4.800 5.300 5.800 Frequency (MHz) Frequency (MHz) SFSKB5M20GF00-R1 SFSKB5M70GF00-R1 0 0 10 10 20 20 B) B) d d n ( 30 n ( 30 o o ati ati nu 40 nu 40 e e Att Att 50 50 60 60 70 70 4.200 4.700 5.200 5.700 6.200 4.700 5.200 5.700 6.200 6.700 Frequency (MHz) Frequency (MHz) 36