ICGOO在线商城 > 分立半导体产品 > 二极管 - 整流器 - 单 > RP 1HV1

- 型号: RP 1HV1

- 制造商: Sanken

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

RP 1HV1产品简介:

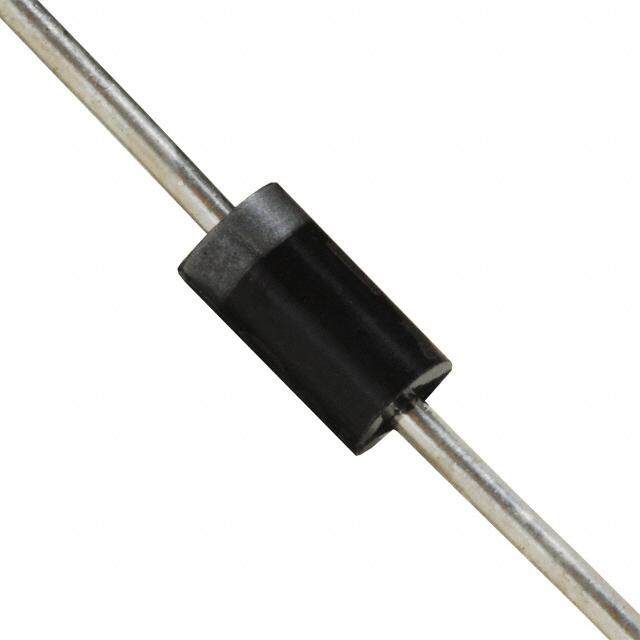

ICGOO电子元器件商城为您提供RP 1HV1由Sanken设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 RP 1HV1价格参考。SankenRP 1HV1封装/规格:二极管 - 整流器 - 单, 标准 通孔 二极管 2000V 100mA 。您可以下载RP 1HV1参考资料、Datasheet数据手册功能说明书,资料中有RP 1HV1 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | DIODE ULT FAST 2000V 0.1A AXIAL |

| 产品分类 | 单二极管/整流器 |

| 品牌 | Sanken |

| 数据手册 | |

| 产品图片 |

|

| 产品型号 | RP 1HV1 |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | - |

| 不同If时的电压-正向(Vf) | 7V @ 100mA |

| 不同 Vr、F时的电容 | - |

| 不同 Vr时的电流-反向漏电流 | 2µA @ 2000V |

| 二极管类型 | 标准 |

| 供应商器件封装 | - |

| 其它名称 | RP 1HV1-ND |

| 包装 | 带盒(TB) |

| 反向恢复时间(trr) | 100ns |

| 安装类型 | 通孔 |

| 封装/外壳 | 轴向 |

| 工作温度-结 | -40°C ~ 150°C |

| 标准包装 | 1,000 |

| 热阻 | 15°C/W Jl |

| 电压-DC反向(Vr)(最大值) | 2000V |

| 电流-平均整流(Io) | 100mA |

| 速度 | 小信号 =< 200mA(Io),任意速度 |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

余白上35mm V = 2000 V, I = 0.1 A, t = 100 ns RM F(AV) rr Fast Recovery Diode RP1H Data Sheet Description Package The RP1H is a high voltage fast recovery diode of Axial (φ4 × 7.2L / φ0.78) 2000 V / 0.1 A. The maximum t of 100 ns is realized rr by optimizing a life-time control. Features Cathode Mark ● V ----------------------------------------------------- 2000 V RM (1) (2) ● I ------------------------------------------------------ 0.1 A F(AV) s ● VF --------------------------------------------------------- 7.0 V n ● t -------------------------------------------------------- 100 ns rr1 g ● Bare Leads: Pb-free (RoHS Compliant) i s e D Applications (1) (2) (1) Cathode ● Sunuber Diode w (2) Anode (Flyback Converter, etc.) e N Not to scale r o f d e d n e m m o c e R t o N RP1H-DSE Rev.1.0 SANKEN ELCTRIC CO., LTD. 1 Sep. 15, 2017 http://www.sanken-ele.co.jp/en © SANKEN ELECTRIC CO., LTD. 2017

RP1H Absolute Maximum Ratings Unless otherwise specified, T = 25 °C A Parameter Symbol Rating Unit Conditions Peak Repetitive Reverse Voltage V 2000 V RSM Repetitive Reverse Voltage V 2000 V RM Average Forward Current I 0.1 A See Figure 2 and Figure 3 F(AV) Half cycle sine wave, Surge Forward Current I 5 A positive side, 10 ms, FSM 1 shot s I2t Limiting Value I2t 0.125 A2s 1 ms ≤ t ≤ 10n ms Junction Temperature T −40 to 150 °C g J i Storage Temperature T −40 to 150 °C s STG e D Electrical Characteristics w Unless otherwise specified, T = 25 °C A e Parameter Symbol Conditions N Min. Typ. Max. Unit TJ = 25 °C, IF = 0.1 A — — 7.0 V Forward Voltage Drop V r F TJ = 100 °C, IFo = 0.1 A — 2.0 — V f Reverse Leakage Current I V = V — — 2 µA R R RM , d Reverse Leakage Current H∙I V = V , T = 100 °C — — 10 µA Under High Temperature R R eRM J Id = I = 100 mA F RP t n90% recovery point, — — 100 ns rr1 T = 25 °C e J Reverse Recovery Time m IF = 100 mA, I = 200 mA, t RP — — 50 ns m rr2 75% recovery point, T = 25 °C J Thermal Resistance (1) o R See Figure 1 — — 15 °C/W th(J-L) c e R 10 mm TL t Device o 1.6 mm N Diameter of soldering area: φ3 mm Cupper thickness: 50 µm Figure 1 Lead Temperature Measurement Conditions (1) R is thermal resistance between junction and lead. th (J-L) RP1H-DSE Rev.1.0 SANKEN ELCTRIC CO., LTD. 2 Sep. 15, 2017 http://www.sanken-ele.co.jp/en © SANKEN ELECTRIC CO., LTD. 2017

RP1H Rating and Characteristic Curves 0.10 0.10 ) DC ) A A ( ( V) t/T = 1/2 V) DC A A F( F( I I nt, nt, re re Sine wave ur t/T = 1/3, sine wave ur t/T = 1/2 s C 0.05 C 0.05 d t/T = 1/6 d n ar ar t/T = 1/3 g w w For For t/T = 1/6 si ge ge e a T = 150 °C a T = 150 °C r J r J D e e v v A A t t T T w 0.00 0.00 e 135 140 145 150 135 140 145 150 N Lead Temperature, T (°C) Lead Temperature, T (°C) L L r Figure 2. I vs. T Typical Characteristics(2) Foigure 3. I vs. T Typical Characteristics(2) F(AV) L F(AV) L f (V = 0 V) (V = 2000 V) R R d e d 1 1.E-03 n e m 1.E-04 A) TJ = 15m0 °C A) TJ = 150 °C urrent, I (F 0.1 eco urrent, I (R1.E-05 TJ = 100 °C C R C ward 0.01 TJ = 100 °C verse 1.E-06 r t e Fo o R N 1.E-07 T = 25 °C J T = 25 °C J 0.001 1.E-08 0 1 2 3 4 5 6 7 8 0 500 1000 1500 2000 Forward Voltage, VF (V) Reverse Voltage, VR (V) Figure 4. V vs. I Typical Characteristics Figure 5. V vs. I Typical Characteristics F F R R (2) See Figure 1 for the lead temperature measurement conditions. RP1H-DSE Rev.1.0 SANKEN ELCTRIC CO., LTD. 3 Sep. 15, 2017 http://www.sanken-ele.co.jp/en © SANKEN ELECTRIC CO., LTD. 2017

RP1H Physical Dimensions ● Axial (φ4 × 7.2L / φ0.78) 62.5±0.7 Φ0.78±0.05 7.2±0.2 Φ2.4±0.2 s n g NOTES: i s - Dimensions in millimeters e - Bare leads: Pb-free (RoHS compliant) D - When soldering the products, it is required to minimize the working time, within the following limits: Flow: 260 ± 5 °C / 10 ± 1 s, 2 times w Soldering Iron: 380 ± 10 °C / 3.5 ± 0.5 s, 1 time (Soldering should be at a distance of at least 1.5 mm from the body of the product.) e N r Marking Diagram o f d Cathode Meark RP1H RP1H Part Numdber n Y M D Y M D Lot Number: e Y is the last digit of the year of manufacture (0 to 9) m M is the month of the year (1 to 9, O, N or D) m D is the period of days represented by: • : the first 10 days of the month (1st to 10th) o •• : the second 10 days of the month (11th to 20th) c ••• : the last 10–11 days of the month (21st to 31st) e R t o N RP1H-DSE Rev.1.0 SANKEN ELCTRIC CO., LTD. 4 Sep. 15, 2017 http://www.sanken-ele.co.jp/en © SANKEN ELECTRIC CO., LTD. 2017

RP1H Important Notes ● All data, illustrations, graphs, tables and any other information included in this document (the “Information”) as to Sanken’s products listed herein (the “Sanken Products”) are current as of the date this document is issued. The Information is subject to any change without notice due to improvement of the Sanken Products, etc. Please make sure to confirm with a Sanken sales representative that the contents set forth in this document reflect the latest revisions before use. ● The Sanken Products are intended for use as components of electronic equipment or apparatus (transportation equipment and its control systems, home appliances, office equipment, telecommunication equipment, measuring equipment, etc.). Prior to use of the Sanken Products, please put your signature, or affix your name and seal, on the specification documents of the Sanken Products and return them to Sanken. If considering use of the Sanken Products for any applications that require higher reliability (traffic signal control systems or equipment, disaster/crime alarm systems, etc.), you must contact a Sanken sales representative to discuss the suitability of such use and put your signature, or affix your name and seal, on the specification documents of the Sanken Products and return them to Sanken, prior to the use of the Sanken Products. The Sanken Products are not intended for use in any s applications that require extremely high reliability such as: aerospace equipment; nuclear power control systems; and medical n equipment or systems, whose failure or malfunction may result in death or serious injury to people, i.e., medical devices in Class III or a higher class as defined by relevant laws of Japan (collectively, the “Specific Applications”). Sanken agssumes no liability or responsibility whatsoever for any and all damages and losses that may be suffered by you, users or any thiird party, resulting from the use of the Sanken Products in the Specific Applications or in manner not in compliance with the instsructions set forth herein. ● In the event of using the Sanken Products by either (i) combining other products or materials or boteh therewith or (ii) physically, chemically or otherwise processing or treating or both the same, you must duly consider all possiDble risks that may result from all such uses in advance and proceed therewith at your own responsibility. ● Although Sanken is making efforts to enhance the quality and reliability of its products, it is impossible to completely avoid the w occurrence of any failure or defect or both in semiconductor products at a certain rate. You must take, at your own responsibility, preventative measures including using a sufficient safety design and confirming safeety of any equipment or systems in/for which the Sanken Products are used, upon due consideration of a failure occurrence raNte and derating, etc., in order not to cause any human injury or death, fire accident or social harm which may result from any failure or malfunction of the Sanken Products. Please refer to the relevant specification documents and Sanken’s official web site in relation to derating. r ● No anti-radioactive ray design has been adopted for the Sanken Products. ● The circuit constant, operation examples, circuit examples, pattern layouot examples, design examples, recommended examples, all information and evaluation results based thereon, etc., described in thfis document are presented for the sole purpose of reference of use of the Sanken Products. d ● Sanken assumes no responsibility whatsoever for any and all damages and losses that may be suffered by you, users or any third party, or any possible infringement of any and all property rigehts including intellectual property rights and any other rights of you, users or any third party, resulting from the Information. d ● No information in this document can be transcribed orn copied or both without Sanken’s prior written consent. ● Regarding the Information, no license, express, implied or otherwise, is granted hereby under any intellectual property rights and e any other rights of Sanken. m ● Unless otherwise agreed in writing between Sanken and you, Sanken makes no warranty of any kind, whether express or implied, including, without limitation, any warranty (i) as to the quality or performance of the Sanken Products (such as implied warranty of merchantability, or implied warranty omf fitness for a particular purpose or special environment), (ii) that any Sanken Product is delivered free of claims of third parties by way of infringement or the like, (iii) that may arise from course of performance, course of dealing or usage of trade, and (ivo) as to the Information (including its accuracy, usefulness, or reliability). ● In the event of using the Sankenc Products, you must use the same after carefully examining all applicable environmental laws and regulations that regulate the einclusion or use or both of any particular controlled substances, including, but not limited to, the EU RoHS Directive, so as to bRe in strict compliance with such applicable laws and regulations. ● You must not use the Sanken Products or the Information for the purpose of any military applications or use, including but not limited to the develo pment of weapons of mass destruction. In the event of exporting the Sanken Products or the Information, or t providing them for non-residents, you must comply with all applicable export control laws and regulations in each country o including the U.S. Export Administration Regulations (EAR) and the Foreign Exchange and Foreign Trade Act of Japan, and N follow the procedures required by such applicable laws and regulations. ● Sanken assumes no responsibility for any troubles, which may occur during the transportation of the Sanken Products including the falling thereof, out of Sanken’s distribution network. ● Although Sanken has prepared this document with its due care to pursue the accuracy thereof, Sanken does not warrant that it is error free and Sanken assumes no liability whatsoever for any and all damages and losses which may be suffered by you resulting from any possible errors or omissions in connection with the Information. ● Please refer to our official website in relation to general instructions and directions for using the Sanken Products, and refer to the relevant specification documents in relation to particular precautions when using the Sanken Products. ● All rights and title in and to any specific trademark or tradename belong to Sanken and such original right holder(s). DSGN-AEZ-16003 RP1H-DSE Rev.1.0 SANKEN ELCTRIC CO., LTD. 5 Sep. 15, 2017 http://www.sanken-ele.co.jp/en © SANKEN ELECTRIC CO., LTD. 2017

Datasheet下载

Datasheet下载