- 型号: PVZ2A104C04R00

- 制造商: Murata

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

PVZ2A104C04R00产品简介:

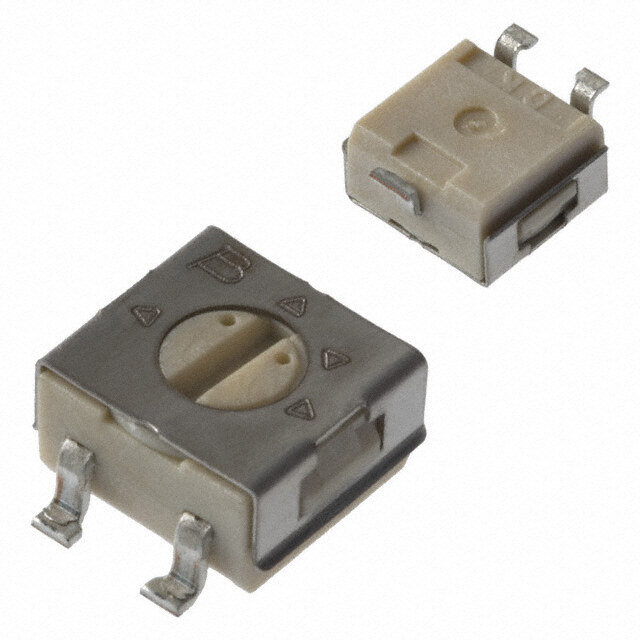

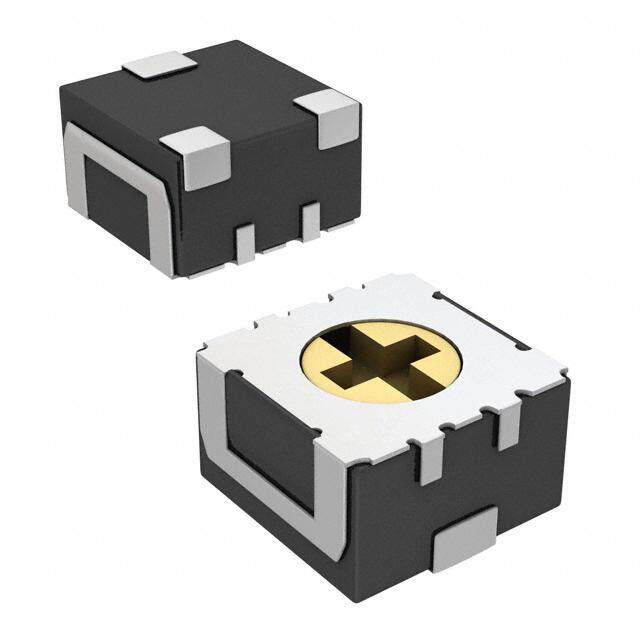

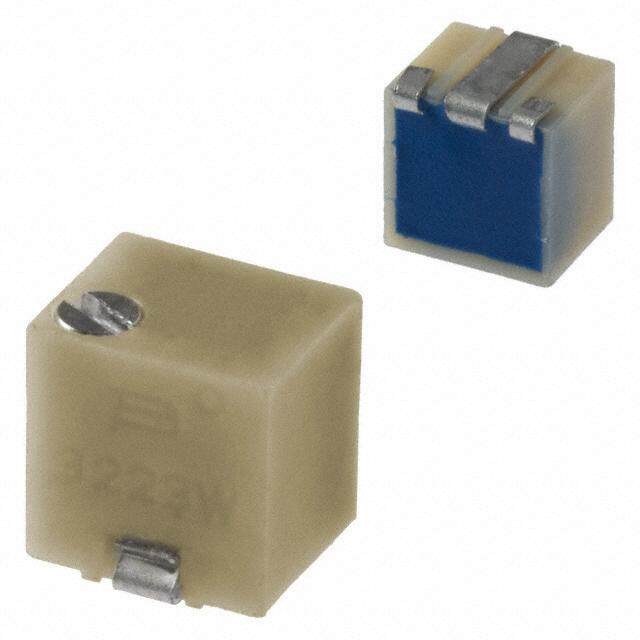

ICGOO电子元器件商城为您提供PVZ2A104C04R00由Murata设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 PVZ2A104C04R00价格参考。MurataPVZ2A104C04R00封装/规格:微调电位计, 100 kOhms 0.05W,1/20W 鸥翼,90° 形弯曲 表面贴装 微调电位器 碳 1 匝 顶部调节。您可以下载PVZ2A104C04R00参考资料、Datasheet数据手册功能说明书,资料中有PVZ2A104C04R00 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | TRIMMER 100K OHM 0.05W SMD微调电阻器 - 表面贴装 100K ohm 2mm 50volt 0.05W Linear Single |

| 产品分类 | |

| 品牌 | Murata Electronics |

| 产品手册 | http://search.murata.co.jp/Ceramy/CatalogAction.do?sHinnm=? &sNHinnm=PVZ2A104C04R00&sNhin_key=PVZ2A104C04R00&sLang=en&sParam=PVZ2A |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 微调电阻器 - 表面贴装,Murata Electronics PVZ2A104C04R00PVZ2 |

| 数据手册 | |

| 产品型号 | PVZ2A104C04R00 |

| 产品 | Single-Turn Trimmer Potentiometers |

| 产品种类 | 微调电阻器 - 表面贴装 |

| 产品类型 | Single Turn |

| 元件类型 | Carbon |

| 其它名称 | 490-7000-6 |

| 功率(W) | 0.05W,1/20W |

| 功率额定值 | 100 mW |

| 包装 | Digi-Reel® |

| 商标 | Murata Electronics |

| 圈数 | 单路 |

| 大小/尺寸 | 方形 - 0.087" x 0.083" 表面 x 0.032" 高 (2.20mm x 2.10mm x 0.80mm) |

| 安装类型 | 表面贴装 |

| 容差 | 30 % |

| 封装 | Reel |

| 工作温度范围 | - 25 C to + 85 C |

| 工厂包装数量 | 3000 |

| 标准包装 | 1 |

| 温度系数 | ±500ppm/°C |

| 电阻 | 100 kOhms |

| 电阻(Ω) | 100k |

| 电阻材料 | 碳 |

| 端子类型 | 鸥翼型, 90° 形弯曲 |

| 端接类型 | Solder Lug |

| 调整 | Top Crossed |

| 调节类型 | 顶部调节 |

| 转数 | 1 |

| 锥度 | Linear |

PDF Datasheet 数据手册内容提取

!!NNoottee•P Pleleaassee r reeaadd r raatitningg a anndd ! !CCAAUUTTIOIONN ( (foforr s stotorraaggee, ,o oppeerraatitningg, ,r raatitningg, ,s sooldldeerriningg, ,m moouunntitningg a anndd h haannddlilningg)) i nin t hthisis P cDatFa lcoagt atolo pgr teov epnret vsemnot ksimngo kainndg/ oarn db/uorrn binugr,n eintgc., etc. R50E13.pdf 04.6.11 •T Thhisis c caatatalologg h haass o onnlyly t ytyppiciacal sl pspeecicfiicfiactaiotinosn.s T bheecraeufosree ,t hyeorue a isre n roe qsupeasctee dfo tro d aeptapirloevde s opuerc pifircoadtuiocnt ss.p Tehceifirceafotioren,s p oler atos etr aanpsparocvt eth oeu arp pprroodvuacl ts shpeeect iffoicra ptiroondsu cotr strpaencsifaiccat ttihoen sa bpepfroorvea ol rsdheereint gfo.r product specifications before ordering. Trimmer Potentiometers 1 SMD Open Type 2mm Size PVZ2 Series 2.1 *2 n Features 0.8 0.5 #2 2.4 Dia. 0.4 Soldering Part 1 . U2(P.l1tVr(aZW-2s)Amx2_a.Al7l0 (aL4n) xSd0 et.hr8iie5ns me)xatex.r n(Ta)l mdimm.ensions of –0.450.1 1.32.2*–12.70.3 0.5 2. Au plated termination achieves a high density P.C.B. mounting. 1 4 0.5 #1 #3 #2 3. Cross-shaped driver slot allows for in-process 0.55 0.7 0.55 #1 #3 automatic adjustment and it provides superior CLOCKWISE *1 Driver Plate Rotation Area : adjustability. PVZ2A Pmloeraes eth daon n0o.7t mplmac ien ahneyig chot mwpithoinne tnhtiss area. 4. Two-piece parts construction achieves low cost and *2 PPVVZZ22AA__AA0014 :: 00..98––00..105 (Tolerance i:n – m0.m2) excellent quality. 5. Special resin substrate allows high peak temperature for reflow soldering. 2.1 0.8 0.9+-00..21 #2 n Applications (1.0) 2.4* 1Dia. 1. Pick-up module 2. LCD 0.1 3. Cellular-phone 4. PHS –0.45 1.32.25.4 5. Pager 6. DVC 7. Digital camera 8. Portable audio, etc. (1.0) SPoalrdtering #1 #3 #2 0.650.60.65 #1 #3 PVZ2K *1. Driver Plate Rotation Area : CLOCKWISE Please do not place any components ( in mm) more than 0.7mm in height within this area. Tolerance : –0.2 Number of Turns Part Number Power Rating Soldering Method Total Resistance Value TCR (Effective Rotation Angle) PVZ2p501A01 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 500ohm – 30% – 500ppm/°C PVZ2p102A01 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 1k ohm – 30% – 500ppm/°C PVZ2p202A01 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 2k ohm – 30% – 500ppm/°C PVZ2p302A01 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 3k ohm – 30% – 500ppm/°C PVZ2p502A01 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 5k ohm – 30% – 500ppm/°C PVZ2p103A01 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 10k ohm – 30% – 500ppm/°C PVZ2p203A01 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 20k ohm – 30% – 500ppm/°C PVZ2p303A01 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 30k ohm – 30% – 500ppm/°C PVZ2p503A01 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 50k ohm – 30% – 500ppm/°C PVZ2p104A01 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 100k ohm – 30% – 500ppm/°C PVZ2p204A01 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 200k ohm – 30% – 500ppm/°C PVZ2p304A01 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 300k ohm – 30% – 500ppm/°C PVZ2p504A01 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 500k ohm – 30% – 500ppm/°C PVZ2p105A01 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 1M ohm – 30% – 500ppm/°C PVZ2p501A04 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 500ohm – 30% – 500ppm/°C PVZ2p102A04 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 1k ohm – 30% – 500ppm/°C PVZ2p202A04 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 2k ohm – 30% – 500ppm/°C PVZ2p302A04 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 3k ohm – 30% – 500ppm/°C PVZ2p502A04 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 5k ohm – 30% – 500ppm/°C PVZ2p103A04 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 10k ohm – 30% – 500ppm/°C PVZ2p203A04 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 20k ohm – 30% – 500ppm/°C PVZ2p303A04 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 30k ohm – 30% – 500ppm/°C PVZ2p503A04 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 50k ohm – 30% – 500ppm/°C PVZ2p104A04 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 100k ohm – 30% – 500ppm/°C PVZ2p204A04 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 200k ohm – 30% – 500ppm/°C Continued on the following page. 5

!!NNoottee•P Pleleaassee r reeaadd r raatitningg a anndd ! !CCAAUUTTIOIONN ( (foforr s stotorraaggee, ,o oppeerraatitningg, ,r raatitningg, ,s sooldldeerriningg, ,m moouunntitningg a anndd h haannddlilningg)) i nin t hthisis P cDatFa lcoagt atolo pgr teov epnret vsemnot ksimngo kainndg/ oarn db/uorrn binugr,n eintgc., etc. R50E13.pdf 04.6.11 •T Thhisis c caatatalologg h haass o onnlyly t ytyppiciacal sl pspeceicfiicfiactaiotinosn.s T bheecraeufosree ,t hyeorue a isre n roe qsupeasctee dfo tro d aeptapirloevde s opuerc pifircoadtuiocnt ss.p Tehceifirceafotioren,s p oler atos etr aanpsparocvt eth oeu arp pprroodvuacl ts shpeeect iffoicra ptiroondsu cotr strpaencsifaiccat ttihoens a bpepfroorvea ol rsdheereint gfo.r product specifications before ordering. Continued from the preceding page. Number of Turns 1 Part Number Power Rating Soldering Method Total Resistance Value TCR (Effective Rotation Angle) PVZ2p304A04 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 300k ohm – 30% – 500ppm/°C PVZ2p504A04 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 500k ohm – 30% – 500ppm/°C PVZ2p105A04 0.1W(50°C) Reflow/Soldering Iron 1(240°– 10°) 1M ohm – 30% – 500ppm/°C The blank column is filled with the code of adjustment direction A (top) or K (rear). n Construction n Standard Land Pattern PVZ2A PVZ2A 0.9 0.85 1.55 0.85 1.55 0.6 0.7 0.6 ( in mm) Tolerance : –0.1 n Construction n Standard Land Pattern PVZ2K PVZ2K 0.9 #2-Terminal 0.7 Driver Plate 3.4 Dia. 2.9 #1-Terminal Wiper 2.9 R Eelseimsteivnet 0.7 0.7 0.6 0.7 #3-Terminal Resin Substrate ( in mm) Tolerance : –0.1 n Characteristics Humidity Exposure Res. Change : +10, -2% High Temperature Res. Change : R<=50kohm···+2, -10% Exposure 50kohm<R···+2, -15% Humidity Load Life Res. Change : – 10% Res. Change : R<=50kohm···+2, -10% Load Life 50kohm<R···+2, -15% Temperature Cycle Res. Change : – 5% Temperature Coefficient – 500ppm/˚C of Resistance Rotational Life Res. Change : – 10% (10 cycles) 6

!!NNoottee•P Pleleaassee r reeaadd r raatitningg a anndd ! !CCAAUUTTIOIONN ( (foforr s stotorraaggee, ,o oppeerraatitningg, ,r raatitningg, ,s sooldldeerriningg, ,m moouunntitningg a anndd h haannddlilningg)) i nin t hthisis P cDatFa lcoagt atolo pgr teov epnret vsemnot ksimngo kainndg/ oarn db/uorrn binugr,n eintgc., etc. R50E13.pdf 04.6.11 •T Thhisis c caatatalologg h haass o onnlyly t ytyppiciacal sl pspeceicfiicfiactaiotinosn.s T bheecraeufosree ,t hyeorue a isre n roe qsupeasctee dfo tro d aeptapirloevde s opuerc pifircoadtuiocnt ss.p Tehceifirceafotioren,s p oler atos etr aanpsparocvt eth oeu arp pprroodvuacl ts shpeeect iffoicra ptiroondsu cotr strpaencsifaiccat ttihoens a bpepfroorvea ol rsdheereint gfo.r product specifications before ordering. PVZ2 Series Notice 1 n Notice (Operating and Storage Conditions) 1. Store in temperatures of -10 to +40 deg. C and the following environmental conditions: relative humidity of 30-85%RH. (1) Corrosive gaseous atmosphere 2. Do not store in or near corrosive gases. (Ex. Chlorine gas, Hydrogen sulfide gas, Ammonia 3. Use within six months after delivery. gas, Sulfuric acid gas, Nitric oxide gas, etc.) 4. Open the package just before using. (2) In liquid 5. Do not store under direct sunlight. (Ex. Oil, Medical liquid, Organic solvent, etc.) 6. If you use the trimmer potentiometer in an (3) Dusty / dirty atmosphere environment other than listed below, please (4) Direct sunlight consult with a Murata factory representative prior (5) Static voltage nor electric/magnetic fields to using. (6) Direct sea breeze The trimmer potentiometer should not be used under (7) Other variations of the above n Notice (Rating) 1. When using with partial load (rheostat), minimize the power depending on the resistance value. 2. The maximum input voltage to a trimmer potentiometer should not exceed (P.R)^1/2 or the maximum operating voltage, whichever is smaller. 3. The maximum input current to a trimmer potentiometer should not exceed (P/R)^1/2 or the allowable wiper current, whichever is smaller. 4. If the trimmer potentiometer is used in DC and high humidity conditions, please connect wiper (#2) for plus and resistive element (#1 or #3) for minus. n Notice (Soldering and Mounting) 1. Soldering The thickness of solder paste should be printed (1) Reflow soldering and Soldering Iron are from 100 micro m to 150 micro m and the available. Cannot be soldered using the flow dimension of land pattern used should be Murata's soldering method. If you use the flow soldering standard land pattern at reflow soldering. method, the trimmer potentiometer may not Insufficient amounts of solder can lead to function. insufficient soldering strength on PCB. (2) Use our standard land dimension. Excessive land Excessive amounts of solder may cause bridging area causes displacement due to the effect of the between the terminals. surface tension of the solder. Insufficient (5) The soldering iron should not come in contact land area leads to insufficient soldering with the case of the trimmer potentiometer. If strength of the chip. such contact does occur, the trimmer (3) Standard soldering condition potentiometer may be damaged. (a) Reflow soldering : 2. Mounting Refer to the standard temperature profile. (1) Do not apply excessive force (preferably 4.9N (b) Soldering iron: (Ref.; 500gf) max.), when the trimmer >Temperature of tip 360 deg. C max. potentiometer is mounted to the PCB. >Soldering time 3 sec. max. (2) Do not warp and/or bend PC board to prevent >Diameter 1mm max. trimmer potentiometer from breakage. >Wattage of iron 30W max. (3) In chip placers, the recommended size of the Before using other soldering conditions than cylindrical pick-up nozzle should be outer those listed above, please consult with Murata dimension 1.5-1.8mm dia. and inner dimension factory representative prior to using. If the 1.3mm dia. soldering conditions are not suitable, e.g., 3. Cleaning excessive time and/or excessive temperature, the (1) In case there is flux on the resistive element, trimmer potentiometer may deviate from the clean sufficiently with cleaning solvents and specified characteristics. completely remove all residual flux. (4) Apply the appropriate amount of solder paste. (2) Isopropyl-alcohol and Ethyl-alcohol are Continued on the following page. 7

!!NNoottee•P Pleleaassee r reeaadd r raatitningg a anndd ! !CCAAUUTTIOIONN ( (foforr s stotorraaggee, ,o oppeerraatitningg, ,r raatitningg, ,s sooldldeerriningg, ,m moouunntitningg a anndd h haannddlilningg)) i nin t hthisis P cDatFa lcoagt atolo pgr teov epnret vsemnot ksimngo kainndg/ oarn db/uorrn binugr,n eintgc., etc. R50E13.pdf 04.6.11 •T Thhisis c caatatalologg h haass o onnlyly t ytyppiciacal sl pspeceicfiicfiactaiotinosn.s T bheecraeufosree ,t hyeorue a isre n roe qsupeasctee dfo tro d aeptapirloevde s opuerc pifircoadtuiocnt ss.p Tehceifirceafotioren,s p oler atos etr aanpsparocvt eth oeu arp pprroodvuacl ts shpeeect iffoicra ptiroondsu cotr strpaencsifaiccat ttihoens a bpepfroorvea ol rsdheereint gfo.r product specifications before ordering. PVZ2 Series Notice 1 Continued from the preceding page. applicable solvents for cleaning. If you use any performance by your product. other types of solvents, please evaluate n Reflow Soldering Standard Profile For reflow soldering Gradual Cooling Pre-heating (in the air) Soldering (in the air) 230 C) 200 (cid:176)mperature ( Te 100 0 60-120 sec. 30 sec. max. Time (Melting zone) n Notice (Handling) 1. Use suitable screwdrivers that fit comfortably in 3. Please use within the effective rotational angle. driver slot. We recommend the screwdriver below. The potentiometer does not have a mechanical stop * Recommended screwdriver for manual adjustment for over rotation. In cases out of effective PVZ2A_A01=Murata P/N : KMDR090 rotational angle, the trimmer potentiometer may PVZ2A_A04=Murata P/N : KMDR150 not function. 2. Don't apply more than 4.9N (Ref.; 500gf) of twist 4. When using a lock paint to fix slot position, and stress after mounting onto PCB to prevent please consult with a Murata factory representative contact intermittence. If excessive force is prior to using to prevent corrosion and contact applied, the trimmer potentiometer may not intermittence. function. n Notice (Other) 1. Please make sure that your product has been evaluated and confirmed against your specifications when our product is mounted to your product. 2. Murata cannot guarantee trimmer potentiometer integrity when used under conditions other than those specified in this document. 8

!!NNoottee•P Pleleaassee r reeaadd r raatitningg a anndd ! !CCAAUUTTIOIONN ( (foforr s stotorraaggee, ,o oppeerraatitningg, ,r raatitningg, ,s sooldldeerriningg, ,m moouunntitningg a anndd h haannddlilningg)) i nin t hthisis P cDatFa lcoagt atolo pgr teov epnret vsemnot ksimngo kainndg/ oarn db/uorrn binugr,n eintgc., etc. R50E13.pdf 04.6.11 •T Thhisis c caatatalologg h haass o onnlyly t ytyppiciacal sl pspeceicfiicfiactaiotinosn.s T bheecraeufosree ,t hyeorue a isre n roe qsupeasctee dfo tro d aeptapirloevde s opuerc pifircoadtuiocnt ss.p Tehceifirceafotioren,s p oler atos etr aanpsparocvt eth oeu arp pprroodvuacl ts shpeeect iffoicra ptiroondsu cotr strpaencsifaiccat ttihoens a bpepfroorvea ol rsdheereint gfo.r product specifications before ordering. SSpMeDc Oifpiceant iToynpse aanndd STMeDst S Meaeltehdo Tdyspe PVM4A_C01 Series Specifications and Test Methods The tests and measurements should be conducted under the condition of 15 to 35°C of temperature, 25 to 75% of relative humidity and 86 to 106 kpa of atmospheric pressure unless otherwise specified. If questionable results occur that have been measured in accordance with the above mentioned conditions, the tests and measurements should be conducted under the condition of 25±2°C of temperature and, 45 to 55% of relative humidity and 86 to 106 kpa of atmospheric pressure. No. Item Test Methods Measure total resistance between the resistance element and terminals (terminals #1 and #3) with the contact arm positioned against a stop. The positioning of the contact arm and terminal should be the same for subsequent total resistance measurements on the same device. Use the test voltage specified in Table-1 for total resistance measurements. This voltage should be used whenever a subsequent total resistance measurement is made. Total Resistance, Maximum Test 1 Total Resistance Nominal (ohm) Voltage (V) 10VRV100 1.0 100FRV1k 3.0 1kFRV10k 10.0 10kFRV100k 30.0 100kFR 100.0 Table 1: Total resistance test voltage Position the contact arm at the extreme counterclockwise limit of mechanical travel and measure the resistance between the contact arm and the corresponding end terminal. Then, position the contact arm at the extreme clock- 2 Residual Resistance wise limit of mechanical travel and measure the resistance between the contact arm and the corresponding end ter- minal. During this test, take suitable precautions to ensure that the rated current of the resistance element is not exceeded. Contact resistance variation should be measured with the measuring circuit shown below, or its equivalent. The operating wiper should be rotated in both directions through 90% of the actual effective-electrical travel for a total of 6 cycles. The rate of rotation of the operating wiper should be such that the wiper completes 1 count in determining whether or not a contact resistance variation is observed at least twice in the same location. The test current should follow the value given in Table-2 unless otherwise limited by the power rating. 3 Contact Resistance ReSstisatnadnacred RT o(otahlm) Test Current #1 Rx #3 Oscilloscope 100VRF10k 10mA max. Constant Current #2 10kVRF100k 1mA max. S(Toeusrtc ceu rrent PRreosoisfrteeandce AC 100kVR 100µA max. shown in Table 2) Amplifier Table 2: Test current for CRV Rx : Trimmer Potentiometer Oscilloscope bandwidth :100Hz to 50kHz Figure 1: CRV measuring circuit The wiper contact point should be preset at about 50% position of effective rotational angle. After that, the poten- 4 Humidity Exposure tiometer should be placed in a chamber at 40±2°C and 90 - 95% without loading for 500±12 hours. The resistance value should be measured after keeping the potentiometer in a room for 5±1/6 hours. The wiper contact point should be preset at about 50% position of effective rotational angle. After that, the poten- High Temperature 5 tiometer should be placed in a chamber at 70±2°C without loading for 500±12 hours. The resistance value should be Exposure measured after keeping the potentiometer in a room for 1.5±1/6 hours. The wiper contact point should be preset at about 50% position of effective rotational angle. After that, the poten- tiometer should be placed in a chamber at 40±2°C and 90 - 95% with loading the 1/2 rated voltage between #1 and 6 Humidity Load Life #2 terminals, intermittently 1.5 hours ON and 0.5 hours OFF for 1000±12hours. The resistance value should be measured after keeping the potentiometer in a room for 5±1/6 hours. The wiper contact point should be preset at about 50% position of effective rotational angle. After that, the poten- tiometer should be placed in a chamber at 70±2°C (50±2°C for PVZ) with loading the 1/2 rated voltage between #1 7 Load Life and #2 terminals, intermittently 1.5 hours ON and 0.5 hours OFF for 1000±12 hours. The resistance value should be measured after keeping the potentiometer in a room for 1.5±1/6 hours. The wiper contact point should be preset at about 50% position of effective rotational angle. After that, the poten- tiometer should be subjected to Table 3,Table 4 temperature for 5 cycles. The resistance value should be measured after keeping the potentiometer in a room for 1.5±10 minutes. 8 Temperature Cycle Sequence 1 2 3 4 Sequence 1 2 3 4 Temp. (°C) -25±3 +25±2 +85±3 +25±2 Temp. (°C) -55±3 +25±2 +125±3 +25±2 Time (min.) 30±3 10max. 30±3 10max. Time (min.) 30±3 10max. 30±3 10max. Table 3: PVZ Table 4: PVA3/PVS3/PVM4A---C01 9 Continued on the following page. 1 77

!!NNoottee•P Pleleaassee r reeaadd r raatitningg a anndd ! !CCAAUUTTIOIONN ( (foforr s stotorraaggee, ,o oppeerraatitningg, ,r raatitningg, ,s sooldldeerriningg, ,m moouunntitningg a anndd h haannddlilningg)) i nin t hthisis P cDatFa lcoagt atolo pgr teov epnret vsemnot ksimngo kainndg/ oarn db/uorrn binugr,n eintgc., etc. R50E13.pdf 04.6.11 •T Thhisis c caatatalologg h haass o onnlyly t ytyppiciacal sl pspeceicfiicfiactaiotinosn.s T bheecraeufosree ,t hyeorue a isre n roe qsupeasctee dfo tro d aeptapirloevde s opuerc pifircoadtuiocnt ss.p Tehceifirceafotioren,s p oler atos etr aanpsparocvt eth oeu arp pprroodvuacl ts shpeeect iffoicra ptiroondsu cotr strpaencsifaiccat ttihoens a bpepfroorvea ol rsdheereint gfo.r product specifications before ordering. SSMpDec Oifpicean tTioynpes aanndd S TMeDs tS Meaelethd oTdyspe PVM4A_C01 Series Specifications and Test Methods Continued from the preceding page. No. Item Test Methods The trimmer potentiometer should be subjected to each of the following temperatures (see Table 5, Table 6) for 30 to 45 minutes. The resistance value should be measured in the chamber. TCR= R2– R1 Z106(ppm/°C) R1(T2– T1) T1 : Reference temperature in degrees celsius 9 Temperature Coefficient of T2 : Test temperature in degrees celsius Resistance R1 : Resistance at reference temperature in ohm R2 : Resistance at test temperature in ohm Sequence 1* 2 3* 4 Sequence 1 2 3* 4 Temp. (°C) +25±2 -25±3 +25±2 +85±3 Temp. (°C) +25±2 -55±3 +25±2 +125±3 Note*: Norm temp. Table 6: PVA3/PVS3/PVM4A---C01 Table 5: PVZ The wiper should be rotated over 90% of the effective rotational angle without loading at a speed of 10 cycles per 10 Rotational Life minute, for 10 cycles continuously. The resistance value should be measured after keeping the potentiometer in a room for 10±5 minutes. 9 78

Datasheet下载

Datasheet下载