ICGOO在线商城 > 传感器,变送器 > 光学传感器 - 光电晶体管 > PT908-7C-F

- 型号: PT908-7C-F

- 制造商: Everlight

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

PT908-7C-F产品简介:

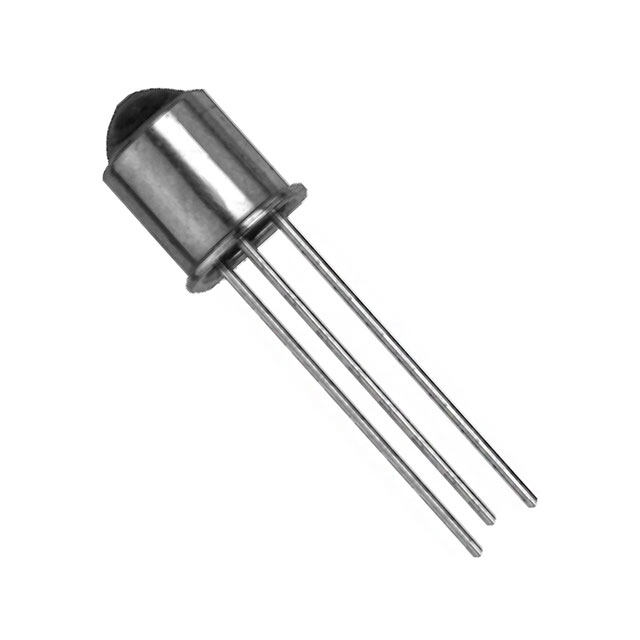

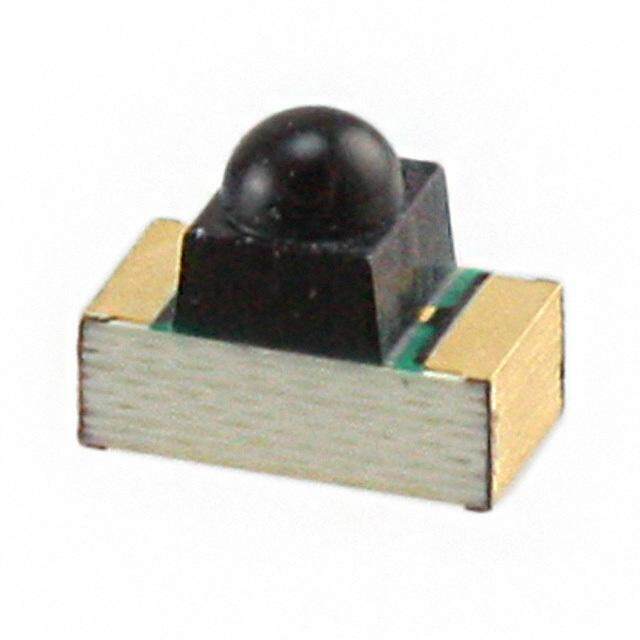

ICGOO电子元器件商城为您提供PT908-7C-F由Everlight设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 PT908-7C-F价格参考¥0.32-¥0.32。EverlightPT908-7C-F封装/规格:光学传感器 - 光电晶体管, Phototransistor 940nm Side View Radial, Side View。您可以下载PT908-7C-F参考资料、Datasheet数据手册功能说明书,资料中有PT908-7C-F 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | PHOTOTRANSISTOR 1.5MM SIDE CLEAR光电晶体管 IR Phototransistor |

| 产品分类 | |

| 品牌 | Everlight Electronics Co Ltd |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 光电晶体管,Everlight PT908-7C-F- |

| 数据手册 | |

| 产品型号 | PT908-7C-F |

| 产品 | Phototransistors |

| 产品种类 | 光电晶体管 |

| 其它名称 | 1080-1164 |

| 功率-最大值 | - |

| 商标 | Everlight |

| 安装类型 | 通孔 |

| 封装/外壳 | 径向,侧视图 |

| 工厂包装数量 | 1000 |

| 朝向 | 侧视图 |

| 标准包装 | 1,000 |

| 波长 | 940nm |

| 电压-集射极击穿(最大值) | 30V |

| 电流-暗(Id)(最大值) | 100nA |

| 电流-集电极(Ic)(最大值) | 20mA |

| 视角 | * |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

Sidelooker Phototransistor PT908-7C-F F e a t u r e s ․Fast response time ․High sensitivity ․Small junction capacitance ․Pb Free ․This product itself will remain within RoHS compliant version ․Compliance with EU REACH ․Compliance Halogen Free(Br < 900ppm, Cl < 900ppm, Br+Cl < 1500ppm) Descriptions ․PT908-7C-F is a phototransistor in miniature package which is molded.in.a plastic with spherical top view lens ․The device is spectrally matched to infrared emitting diode Applications ․Optoelectronic switch ․VCR, Video Camera ․Floppy disk drive ․Infrared applied system Device Selection Guide Part Category Chip Material Lens Color PT Silicon Water Clear 1 Copyright © 2010, Everlight All Rights Reserved. Release Date: 2016/11/23.Issue No: DPT-0000469 Rev.5 www.everlight.com

Data Sheet Sidelooker phototransistor PT908-7C-F Package Dimension Anode Cathode Notes: 1. All dimensions are in millimeters Notes: 2. Tolerances unless dimensions ±0.3mm Absolute Maximum Ratings (Ta=25℃) Parameter Symbol Rating Units Collector-Emitter Voltage VCEO 30 V Emitter-Collector Voltage V 5 V ECO Collector Current I 20 mA C Operating Temperature T -25 ~ +85 ˚C opr Storage Temperature T -40 ~ +85 ˚C stg Soldering Temperature *1 T 260 ˚C sol Power Dissipation at (or below) P 75 mW 25 ˚C Free Air Temperature d Notes: *1. Soldering time≦5 seconds. 2 Copyright © 2010, Everlight All Rights Reserved. Release Date:2016/11/23. Issue No:DPT-0000469 Rev.5 www.everlight.com

Data Sheet Sidelooker phototransistor PT908-7C-F Electro-Optical Characteristics (Ta=25℃) Parameter Symbol Condition Min. Typ. Max. Units Rang of Spectral Bandwidth λ0.5 ---- 450 -- 1100 nm Wavelength of Peak Sensitivity λp ---- -- 940 -- nm I =100μA Collector-Emitter Breakdown Voltage BVCEO EeC=0mW/cm2 30 -- -- V I =100μA Emitter-Collector Breakdown Voltage BVECO Ee=E0mW/cm2 5 -- -- V V =20V Collector Dark Current ICEO Ee=C0EmW/cm2 -- -- 100 nA I =2mA Collector-Emitter Saturation Voltage VCE(sat) Ee=C1mW/cm2 -- -- 0.4 V V =5V On State Collector Current IC(on) Ee=0.5C5E5mW/cm2 0.8 -- 5.0 mA Rank Condition: VCE=5V, Ee=0.555mW/cm2 Symbol condition Ranks Min Max Unit BIN1 0.80 1.53 BIN2 1.11 1.98 V =5V I CE BIN3 1.43 2.68 mA C(ON) Ee=0.555mW/cm2 BIN4 1.59 3.06 BIN5 2.00 5.00 Test Method For I : C(ON) Condition: V =5V, Ee=0.555mW/cm2 CE 3 Copyright © 2010, Everlight All Rights Reserved. Release Date:2016/11/23. Issue No:DPT-0000469 Rev.5 www.everlight.com

Data Sheet Sidelooker phototransistor PT908-7C-F Typical Electro-Optical Characteristics Curves Fig.1 Spectral Sensitivity Fig.2 Collector Current vs. Irradiance Fig.3 Collector Current vs. Collector-Emitter Voltage Fig.3 Collector Current vs. Collector-Emitter Voltage 4 Copyright © 2010, Everlight All Rights Reserved. Release Date:2016/11/23. Issue No:DPT-0000469 Rev.5 www.everlight.com

Data Sheet Sidelooker phototransistor PT908-7C-F Packing Quantity Specification 1000 pcs/bag, 10 bags/box 10 boxes/carton Label Form Specification ‧CPN: Customer Part Number ‧P/N: Part Number ‧QTY: Packing Quantity ‧CAT: Ranks ‧REF: Reference ‧LOT No: Lot Number Notes Lead Forming 1. During lead frame bending, the lead frame should be bent at a distance more than 3mm from bottom of the epoxy. Note: Must fix lead frame and do not touch epoxy before bending to avoid Phototransistors broken. 2. Lead forming should be done before soldering. 3. Avoid stressing the Phototransistor package during leads forming. The stress to the base may damage the Phototransistor’s characteristics or it may break the Phototransistors. 4. Cut the Phototransistor lead frame at room temperature. Cutting the lead frame at high temperatures may cause failure of the Phototransistors. 5. When mounting the Phototransistors onto a PCB, the PCB holes must be aligned exactly with the lead position of the Phototransistor. If the Phototransistors are mounted with stress at the leads, it causes deterioration of the epoxy resin and this will degrade the Phototransistors. Storage 1. The Phototransistors should be stored at 10~30°C and 70%RH or less after being shipped from Everlight and the storage life limits are 3 months. If the Phototransistors are stored for 3 months or more, they can be stored at 10°C~25°C and 20%RH~60%RH for a year in a sealed container with a nitrogen atmosphere. After opening the package, the devices must be stored at 10°C~25°C and 20%RH~60%RH, and suggested to be used within 24 hours or as soon as possible. Besides, suggest that the remaining devices seal in the package bag as soon as possible please. 2. Please avoid rapid transitions in ambient temperature, especially in high humidity environments where condensation can occur. 5 Copyright © 2010, Everlight All Rights Reserved. Release Date:2016/11/23. Issue No:DPT-0000469 Rev.5 www.everlight.com

Data Sheet Sidelooker phototransistor PT908-7C-F Soldering 1. Careful attention should be paid during soldering. When soldering, leave more than 3mm from solder joint to epoxy bulb, and soldering beyond the base of the tie bar is recommended. 2. Recommended soldering conditions: Hand Soldering DIP Soldering Temp. at tip of iron 300°C Max. (30W Max.) Preheat temp. 100°C Max. (60 sec Max.) Soldering time 3 sec Max. Bath temp. & time 260 Max., 5 sec Max 3mm Min.(From solder 3mm Min. (From solder joint Distance Distance joint to epoxy bulb) to epoxy bulb) 3. Recommended soldering profile laminar wave Fluxing Prehead 4. Avoiding applying any stress to the lead frame while the Phototransistors are at high temperature particularly when soldering. 5. Dip and hand soldering should not be done more than one time 6. After soldering the Phototransistors, the epoxy bulb should be protected from mechanical shock or vibration until the Phototransistors return to room temperature. 7. A rapid-rate process is not recommended for cooling the Phototransistors down from the peak temperature. 8. Although the recommended soldering conditions are specified in the above table, dip or hand soldering at the lowest possible temperature is desirable for the Phototransistors. 9. Wave soldering parameter must be set and maintain according to recommended temperature and dwell time in the solder wave. Cleaning Do not clean the Phototransistors by the ultrasonic. Heat Management 1. Heat management of Phototransistors must be taken into consideration during the design stage of Phototransistor application. The current should be de-rated appropriately by referring to the de-rating curve found in each product specification. 2. The temperature surrounding the Phototransistor in the application should be controlled. 6 Copyright © 2010, Everlight All Rights Reserved. Release Date:2016/11/23. Issue No:DPT-0000469 Rev.5 www.everlight.com

Data Sheet Sidelooker phototransistor PT908-7C-F ESD (Electrostatic Discharge) 1. The products are sensitive to static electricity or surge voltage. ESD can damage a die and its reliability. 2. When handling the products, the following measures against electrostatic discharge are strongly recommended: Eliminating the charge Grounded wrist strap, ESD footwear, clothes and floors Grounded workstation equipment and tools ESD table/shelf mat made of conductive materials 3. Proper grounding is required for all devices, equipment, and machinery used in product assembly. Surge protection should be considered when designing of commercial products. 4. If tools or equipment contain insulating materials such as glass or plastic, the following measures against electrostatic discharge are strongly recommended: Dissipating static charge with conductive materials Preventing charge generation with moisture Neutralizing the charge with ionizers DISCLAIMER 1. EVERLIGHT reserves the right(s) on the adjustment of product material mix for the specification. 2. The product meets EVERLIGHT published specification for a period of twelve (12) months from date of shipment. 3. The graphs shown in this datasheet are representing typical data only and do not show guaranteed values. 4. When using this product, please observe the absolute maximum ratings and the instructions for using outlined in these specification sheets. EVERLIGHT assumes no responsibility for any damage resulting from the use of the product which does not comply with the absolute maximum ratings and the instructions included in these specification sheets. 5. These specification sheets include materials protected under copyright of EVERLIGHT. Reproduction in any form is prohibited without obtaining EVERLIGHT’s prior consent. 6. This product is not intended to be used for military, aircraft, automotive, medical, life sustaining or life saving applications or any other application which can result in human injury or death. Please contact authorized Everlight sales agent for special application request. 7 Copyright © 2010, Everlight All Rights Reserved. Release Date:2016/11/23. Issue No:DPT-0000469 Rev.5 www.everlight.com

Datasheet下载

Datasheet下载