ICGOO在线商城 > 电路保护 > PTC 可复位保险丝 > PRG21BB220MB1RK

- 型号: PRG21BB220MB1RK

- 制造商: Murata

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

PRG21BB220MB1RK产品简介:

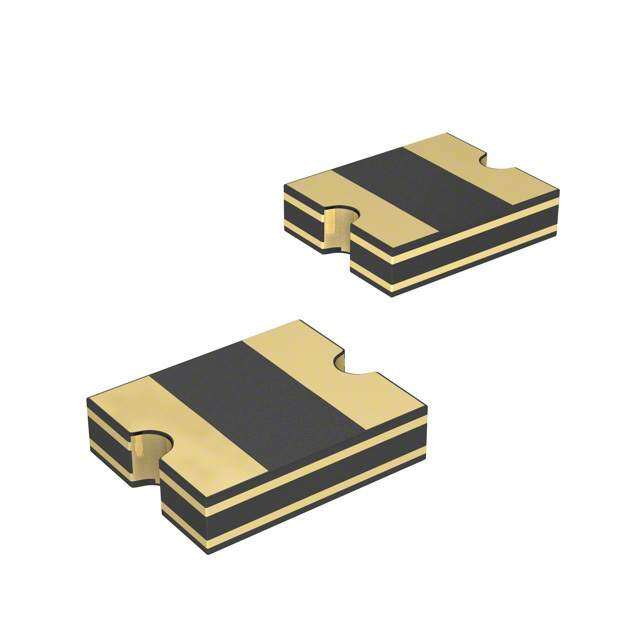

ICGOO电子元器件商城为您提供PRG21BB220MB1RK由Murata设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 PRG21BB220MB1RK价格参考¥1.50-¥1.50。MurataPRG21BB220MB1RK封装/规格:PTC 可复位保险丝, 陶瓷 PTC 自恢复保险丝 20V 44mA Ih 表面贴装 0805(2012 公制)。您可以下载PRG21BB220MB1RK参考资料、Datasheet数据手册功能说明书,资料中有PRG21BB220MB1RK 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | THERMISTOR PTC 22 OHM SMD热敏电阻 - PTC 22 OHM 20V |

| 产品分类 | |

| 品牌 | Murata Electronics North America |

| 产品手册 | http://search.murata.co.jp/Ceramy/CatalogAction.do?sHinnm=? &sNHinnm=PRG21BB220MB1RK&sNhin_key=PRG21BB220MB1RK&sLang=en&sParam=PRG21 |

| 产品图片 |

|

| rohs | 符合RoHS不受无铅要求限制 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | Murata Electronics PRG21BB220MB1RKPOSISTOR® PRG21BB |

| 数据手册 | |

| 产品型号 | PRG21BB220MB1RK |

| R(最小/最大值) | - |

| 产品培训模块 | http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=5799 |

| 产品目录绘图 |

|

| 产品目录页面 | |

| 产品种类 | 热敏电阻 - PTC |

| 其它名称 | 490-3989-1 |

| 包装 | 剪切带 (CT) |

| 单位重量 | 4 mg |

| 商标 | Murata Electronics |

| 容差 | 20 % |

| 封装 | Reel |

| 封装/外壳 | 0805(2012 公制) |

| 封装/箱体 | 0805 |

| 尺寸 | 0.9 mm W x 2 mm L x 1.25 mm H |

| 工作温度范围 | - 10 C to + 60 C |

| 工厂包装数量 | 3000 |

| 标准包装 | 1 |

| 电压 | 20 V |

| 电压-最大值 | 20V |

| 电流-保持(Ih)(最大值) | 30mA |

| 电流-最大值 | 1.1A |

| 电流-跳闸(It) | 110mA |

| 电流额定值 | 110 mA |

| 电阻 | 22 Ohms |

| 端接类型 | SMD/SMT |

| 类型 | PTC |

| 系列 | PRG |

| 跳闸时间 | - |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

® Posistor for over current protection PRG SERIES BC-E0167J PRG21BB***MB1RK SERIES 1.Part Numbering ex) PR G 21 BB 150 M B1 RK C Product ID Series Dimensions Temperature Resistance Resistance Individual Packaging Characteristics Tolerance Specifications 2. Ratings *1 *2 *3 Part Number Resistance Max. Max. Hold Current Trip Current (at 25°C) Voltage Current 40mA(+60°C) 140mA(-10°C) PRG21BB150MB1RK 15ohm ±20% 1.6A DC 59mA(+25°C) 116mA(+25°C) 20 V 30mA(+60°C) 110mA(-10°C) PRG21BB220MB1RK 22ohm ±20% 1.1A 44mA(+25°C) 91mA(+25°C) Packaging Tape : Taping (Standard quantity is 3000pcs. Per reel) *1 Shows the Maximum Current value which Shall be passed repeatedly when the circuit runs abnormally. *2 Shows the Maximum Current value which Shall be passed continuously without tripping at 25°C and 60°C *3 Shows the Trip Current value when Posistor® shall protects circuit frow over load at 25°C and -10°C 3. Dimensions [mm] L1 W (1) Electrode (Sn Plating) (2) BaTiO Semiconductive Ceramic 3 (1) L2 L4 L3 (2) W H H L1 W H L2 and L3 L4 2.00±0.20 1.25±0.20 1.25±0.20 Min. 0.2 Min. 0.5 4. Quantity (Standard Quantity) Products quantity in a reel 3,000 pcs. /reel This information may be change d without a previous notice. Murata Manufacturing Co., Ltd. C6S - C - G013

Resistance-Temperature Characteristics Typical Curve 1000 100 ) 5 2 R / R ( e g n a 10 h C e c n a t s i s e R 1 0.1 -20 0 20 40 60 80 100 120 140 160 180 200 Temperature (℃) BB-035' This information may be changed without a previous notice.

Notice for use CAUTION 1. This product is designed for application, which is used under ordinary environment. (room temperature, normal humidity, normal pressure) Do not expose this to the following environments, because all these factors can deteriorate the characteristic of this and can cause failure or burn out. (1) Corrosive gas or deoxidizing gases (Cl , H S, NH , SOx, NOx etc.) 2 2 3 (2) Volatile, flammable gas (3) Dusty place (4) Place in a vacuum, reducing or putting pressure (5) Place in splashed water, or high humidity and dewing place (6) Salt water, oil, chemical liquid and solvent (7) Vibratile place (8) Other place equivalent to the above 2. Limitation of Applications This product is designed to use for a general application and general electric equipment such as office equipment, communication equipment, measurement equipment and electric household appliance. Please provide an appropriate fail-safe function or redundant design on your product in order to prevent an accident and other magnifying inquiry, in case of a special quality or reliability are required and using our products for the following applications which might directly cause damage to a human life or property by an accident of your product, or using except general applications, which we intend. (1) Aircraft equipment (2) Aerospace equipment (3) Undersea equipment (4) Power plant control equipment (5) Medical equipment (6) Transportation equipment (automobiles, trains, ships, etc.) (7) Traffic signal equipment (8) Disaster prevention / Crime prevention equipment (9) Data-processing equipment (10) Applications of similar complexity or with reliability requirements comparable to the applications listed in the above 3. Be sure to provide an appropriate fail-safe function on your product to prevent a second damage that may be caused by the abnormal function or the failure of our product. Notice 1. Do not apply abnormal voltage exceeding the specified maximum value. Because they may deteriorate or destroy PTC element. 2. Use this product within the specified temperature. A higher temperature may deteriorate the characteristic or material. 3. The body of this product is not insulated. Please keep an adequate distance to surrounding components and wiring. 4. Storage conditions To keep solderability from declining, following storage condition is recommended. (1) Condition Temperature : -10 to +40°C Humidity : Less than 85%RH (not dewing condition) (2) Term: Please use this POSISTOR within 6 months after shipment by first-in and first-out stocking system. (3) Handling after seal open: After unpacking of the minimum package, reseal it promptly or store it inside a sealed container with a drying agent. (4) Place: Do not store this product in corrosive gas (SOx, Cl etc) or under sunlight. This information may be changed wi thout a previous notice. Murata Manufacturing Co., Ltd. CE-018U

5. Solder and Flux (1) Solder Paste Use Sn:Pb=60:40wt% ,Sn:Pb=63:37wt%, Sn:Ag:Cu=96.5:3.0:0.5wt% or equivalent type of solder paste. Do not use strong acidic flux (with halide content exceeding 0.2wt%). Use of the solder containing Zn may reduce adhesive strength. When you use the solder containing Zn, please contact us in advance. For your reference, we are using ‘63Sn/37Pb RMA9086 90-3-M18’, manufactured by Alpha Metals Japan Ltd., ’96.5Sn/3.0Ag/0.5Cu M705-GRN360-K2-V’, manufactured by Senju Metal Industry Co.,LTD. for any Internal tests of this product. (2) Flux Use rosin type flux in soldering process. If below flux is used, some problems might be caused in the product characteristics and reliability. Please do not use below flux. ・Strong acidic flux (with halide content exceeding 0.2wt%). ・Water-soluble flux(*Water-soluble flux can be defined as non rosin type flux including wash-type flux and non-wash-type flux.) 6. For removing the flux after soldering, observe the following points in order to avoid deterioration of the characteristics or any change of the external electrodes quality. (1) Cleaning Conditions Solvent Dipping Cleaning Ultrasonic Cleaning Less than 5 min. A sufficient cleaning shall Less than 1 min. at room temp. be applied to remove flux 2-propanol or 20W/L max. completely. Frequency of several 10 kHz Less than 2 min. to several 100 kHz. at 40°C max. (2) D rying: After cleaning, dry promptly this product. 7. In your mounting process, observe the following points in order to avoid deterioration of the characteristics or destruction of this product. The mounting quality of this product may also be affected by the mounting conditions, shown the points below. This product is for only reflow soldering. Flow soldering shall not be allowed. Please mount this product by soldering. When mounted by other methods, such as conductive adhesives, please contact us in advance. (1) Standard Land Size Too big land size gives too much solder paste on the land. It may cause destruction of this product, because of the mechanical stress especially in the case of board bending. b a b c a c 1.0~1.2 0.5~0.7 1.0~1.2 (mm) (2) Printing Conditions of Solder Paste i. Standard thickness of solder paste printing shall be from 0.10 to 0.15 mm. ii. After soldering, the solder fillet shall be a height from 0.2 mm to the thickness of this product. (See the figures below.) iii. Too much solder gives too strong mechanical stress to this product, such stress may cause cracking or any mechanical damage. And also, it can destroy the electrical performance of this product. This information may be changed wi thout a previous notice. Murata Manufacturing Co., Ltd. CE-018U

(3) Allowable Soldering Temperature and Time i. Solder within the temperature and time combinations, indicated by the slanted lines in the following graphs. ii. The excessive soldering conditions may cause dissolution of metallization or deterioration of solder-wetting on the external electrode. iii. In case of repeated soldering, the total accumulated soldering time should be within the range shown below figure. (For example, Reflow peak temperature : 250°C, twice → The total accumulated soldering time at 250°C is within 20sec.) <Allowable Reflow Soldering Temp. and Time> 270 2 60 C ) 250 e ( ° 240 ur t a 230 per m 220 e T 210 200 0 10 20 30 40 50 60 Time (sec.) (4) Standard Temperature Profile for Soldering i. Insufficient preheating may cause a crack on ceramic body. Difference between preheating temperature and maximum temperature in the profile shall be 100 °C. ii.Rapid cooling by dipping in solvent or by other means is not recommended. <Reflow Soldering Condition> Gradual cooling Preheating: 150 +/- 10 °C Preheating (in air) Soldering (in air) 1min. to 2 min. Soldering: 240 °C C ) 200 240°C 20sec. ° e( ur perat100 #: In case of repeated soldering, the total m accumulated soldering time should be Te within the range shown above figure (3). 0 ~~ # 1~2 min. 20sec. (5) There is a fear of unexpected failures (tombstone, insufficient solder-wetting, etc.) in your mounting process, caused by the mounting conditions. Please evaluate if this product is correctly mounted under your mounting conditions. (6) Conditions with Soldering Iron When hand soldering by iron is applied, be sure to keep following conditions. Item Conditions Preheating at 150°C for 1 to 2 minute Temperature of Iron-tip 350°C max. Soldering Iron Wattage 30W max. Diameter of Iron-tip 3mm dia. max. Soldering Time 5sec. max. Solder H60A (Sn:Pb=60:40wt%) type , H63A (Sn:Pb=63:37wt%) type, Sn:Ag:Cu=96.5:3.0:0.5wt% or equivalent type. Flux Do not use strong acidic flux (with halide content exceeding 0.2wt%). Caution ・Do not allow the iron-tip to directly touch the ceramic body. ・Preheat the ceramic body and mounting board. 8. D o not give this product a strong press-force nor a mechanical shock. Because such mechanical forces may cause cracking or chipping of this ceramic product. 9. Rapid cooling or heating during soldering is not recommended. Such treatment may destroy the element. This information may be changed wi thout a previous notice. Murata Manufacturing Co., Ltd. CE-018U

10. Resin coating Please select the resin of which hardness shrinkage is much less, on selecting a resin materials. 11. Location on Printed Circuit Board(PC Board) <Component Direction> <Mounting Close to Board Separation Line> Locate this product horizontal to Put this product on the PC Board near the Slit, the direction in which stress acts. not near the Perforation Holes. Keep this product on the PC Board away from the Separation Line. (Worse) (Better) Worst ”A”-“C”-“B”-“D” Better Perforation Holes C B A D Slit Separation Line This information may be changed wi thout a previous notice. Murata Manufacturing Co., Ltd. CE-018U

Datasheet下载

Datasheet下载