ICGOO在线商城 > 传感器,变送器 > 光学传感器 - 光断续器 - 槽型 - 晶体管输出 > PM-K64

- 型号: PM-K64

- 制造商: Panasonic Corporation

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

PM-K64产品简介:

ICGOO电子元器件商城为您提供PM-K64由Panasonic Corporation设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 PM-K64价格参考。Panasonic CorporationPM-K64封装/规格:光学传感器 - 光断续器 - 槽型 - 晶体管输出, Optical Sensor Transmissive 0.197" (5mm) NPN - Dark-ON/Light-ON - Selectable Module, Connector, Slot Type。您可以下载PM-K64参考资料、Datasheet数据手册功能说明书,资料中有PM-K64 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | SENSOR 5MM 5-24VDC NPN |

| 产品分类 | |

| 品牌 | Panasonic Industrial Automation Sales |

| 数据手册 | |

| 产品图片 |

|

| 产品型号 | PM-K64 |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | PM |

| 其它名称 | 1110-2001 |

| 包装 | 散装 |

| 响应时间 | 20µs |

| 安装类型 | 底座安装 |

| 封装/外壳 | 盒 |

| 工作温度 | -25°C ~ 55°C |

| 感应方法 | 可传导的 |

| 感应距离 | 0.197"(5mm) |

| 标准包装 | 1 |

| 特色产品 | http://www.digikey.cn/product-highlights/cn/zh/panasonic-acsd-pm-micro-photoelectric-sensors/3688 |

| 电压-集射极击穿(最大值) | - |

| 电流-DC正向(If) | - |

| 电流-集电极(Ic)(最大值) | - |

| 类型 | 无放大 |

| 输出配置 | NPN - 暗光/亮光 - 可选 |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

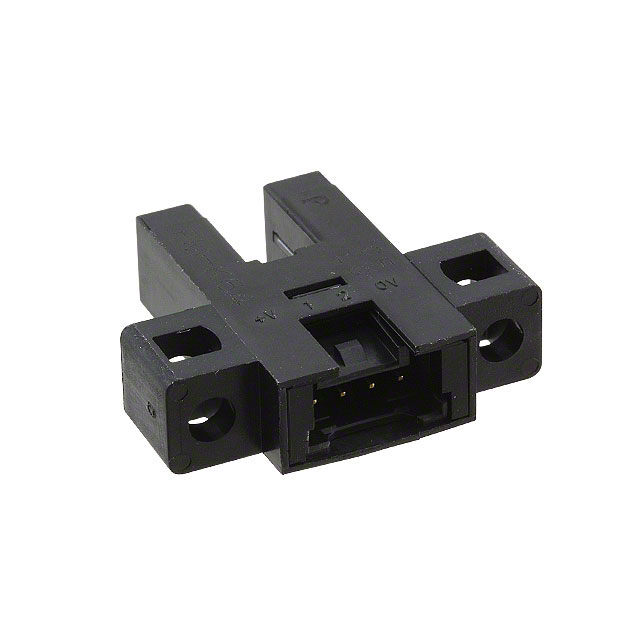

429 Connector Built-in U-shaped Micro Photoelectric Sensor Amplifier Built-in PM-64 SERIES ■ General terms and conditions .............F-7 ■ Sensor selection guide ..................P.427~ FIBER Related Information SENSORS ■ Glossary of terms ........................P.1455~ ■ General precautions ...................P.1458~ LASER SENSORS PHOTOELECTRIC SENSORS Conforming to Recognition MICRO EMC Directive PHOTOELECTRIC SENSORS AREA SENSORS LIGHT CURTAINS / SAFETY COMPONENTS PRESSURE / FLOW SENSORS INDUCTIVE PROXIMITY SENSORS PARTICULAR USE SENSORS SENSOR OPTIONS SIMPLE WIRE-SAVING UNITS WIRE-SAVING SYSTEMS MEASUREMENT panasonic.net/id/pidsx/global SENSORS STATIC ELECTRICITY PREVENTION DEVICES Easy connection with a single touch LASER MARKERS using commercially-available connectors PLC HUMAN MACHINE INTERFACES Built-in connector saves space Can be connected using commercially- ENERGY CONSUMPTION available connectors VISUALIZATION This greatly reduces the amount of space taken up COMPONENTS compared to previous models. The connector connection type eliminates the extra FA COMPONENTS The dimension between the beam axis and cable work of soldering and insulation processing. In addition, bending part has been reduced to half at maximum. the connector used is a commercially-available multi- MACHINE VISION SYSTEMS purpose connector which is also currently used by the DP-100 series of digital pressure sensors. UV CURING SYSTEMS PCroenvnioeucsto mr toydpeel PM-□64 25.4 mm 26 mm 1.000 in 1.024 in 22.3 mm 23 mm 0.878 in 0.906 in Selection Guide U-shaped 11 mm 0.433 in Approximately Convergent 60 % Reflective 2.1 mm of previous 0.083 in model PM-64 Detachable Commercially- PM-24 available connector Digital pressure sensor PM-44/PM-54 DP-100 series

Connector Built-in U-shaped Micro Photoelectric Sensor PM-64 SERIES 430 APPLICATIONS FIBER SENSORS Positioning of a pallet Sensing the starting point and Sensing the starting point LASER SENSORS overrun of a moving body on a rotating body Overrun sensing PHOTOELECTRIC Dog SENSORS Starting point MICRO The starting PHOTOELECTRIC point can be SENSORS sensed by AREA making a slit in SENSORS Starting point sensing the rotating body. LIGHT CURTAINS / Overrun SAFETY sensing COMPONENTS PRESSURE / FLOW Starting point and overrun is SENSORS Pallet is stopped by sensing the dog. sensed using the dog on the base. INDUCTIVE PROXIMITY SENSORS PARTICULAR USE SENSORS Improved maintenance and workability significantly reduces total cost SENSOR The processing cost of the connector cables can be drastically reduced through the use of commercially-available OPTIONS crimping connectors. SIMPLE WIRE-SAVING UNITS WIRE-SAVING Previous model (Soldering: Connector type) • Automation is hard because of soldering. SYSTEMS Insulation processing • Insulation processing is required. MEASUREMENT • A large space is necessary at the terminal area. SENSORS STATIC ELECTRICITY • Connectors are not reliable PREVENTION (not fully connected or seated). DEVICES Soldering LASER MARKERS Previous model (Converted to the cable-type commercially-available connector) • Crimping processing is required in two places. PLC Intermediate box Commercially-available connector • A set of commercially-available connectors is necessary. HUMAN MACHINE • There are many processes for cable connections. INTERFACES • An intermediate box is required. ENERGY CONSUMPTION VISUALIZATION Crimping processing COMPONENTS FA COMPONENTS Suggestion MACHINE VISION PM-64 series (Commercially-available connectors can be used) • Crimping processing makes automation SYSTEMS possible so the connectors are also highly UV CURING reliable. SYSTEMS Crimping processing • Soldering, insulation processing, and an intermediate box are not necessary. • Connectors are widely available. • Mounting in a small space is easy. • Strongly connected using a locking connector. Selection • 1 m 3.281 ft, 2 m 6.562 ft, 3 m 9.843 ft, and 5 m Guide 16.404 ft connector cables are available. U-shaped Convergent Reflective PM-64 PM-24 PM-44/PM-54

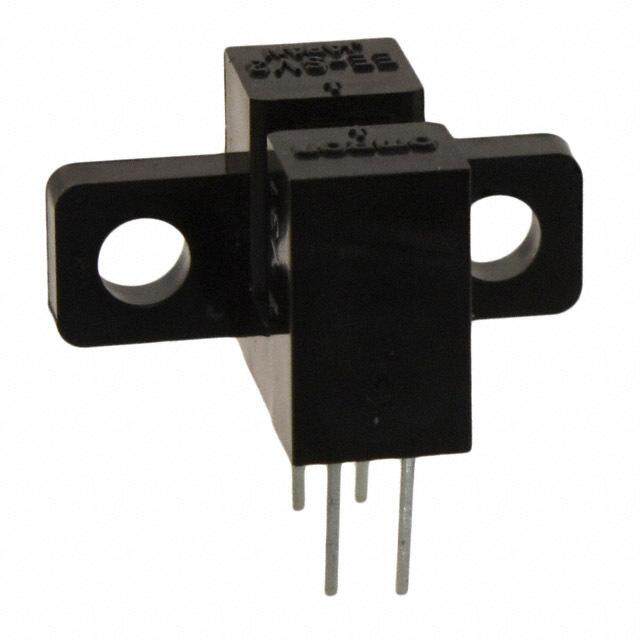

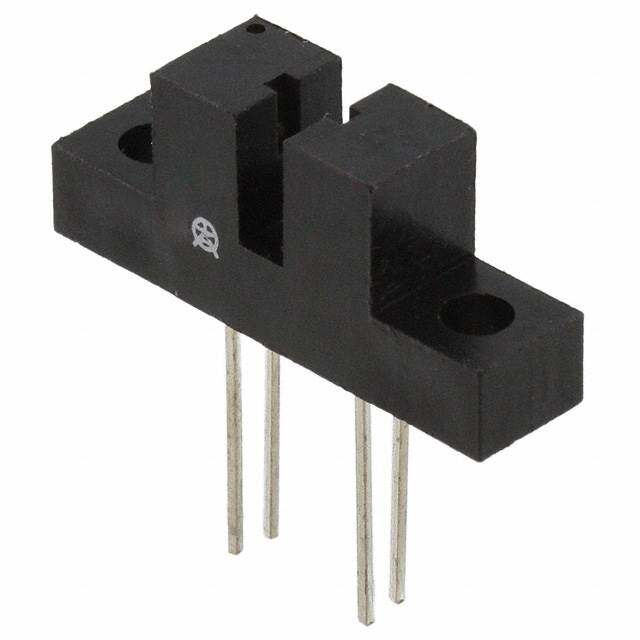

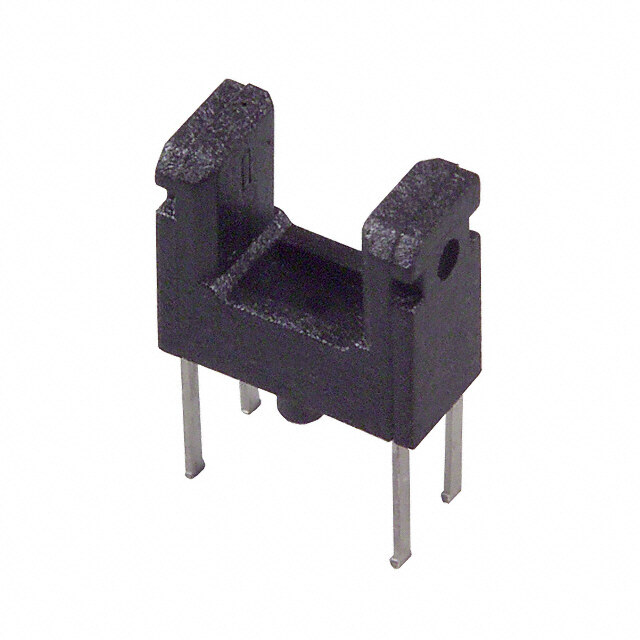

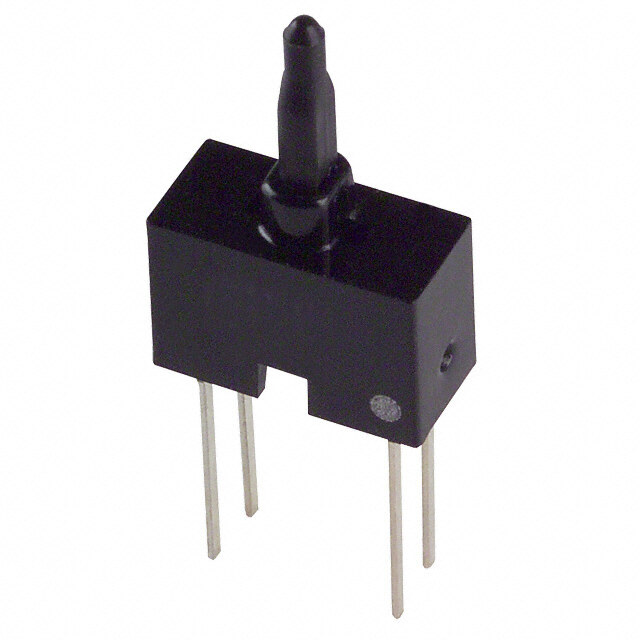

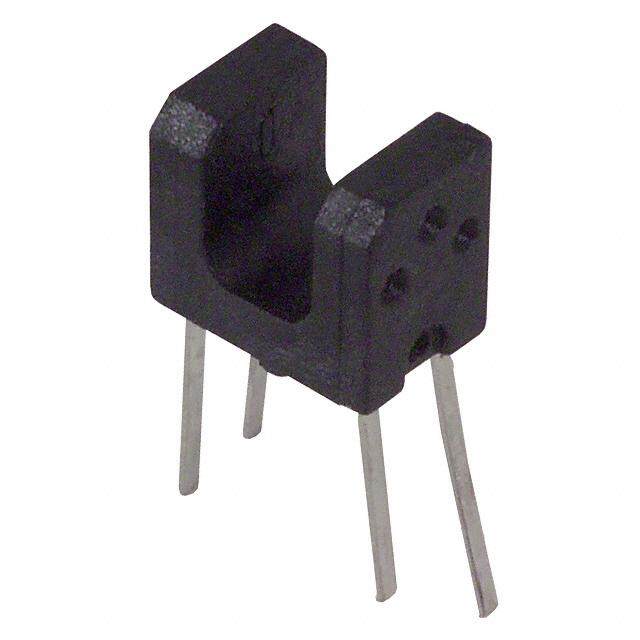

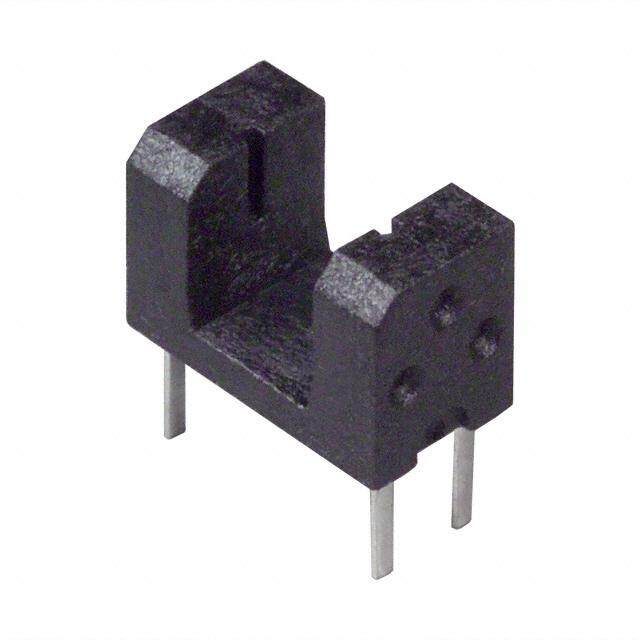

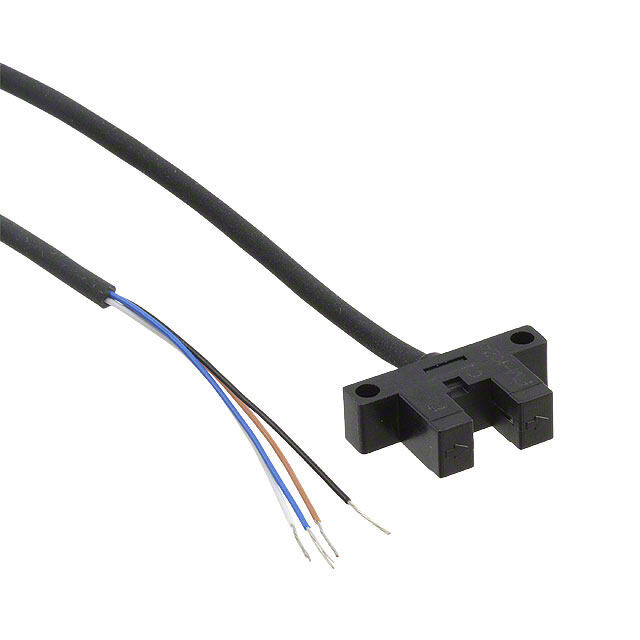

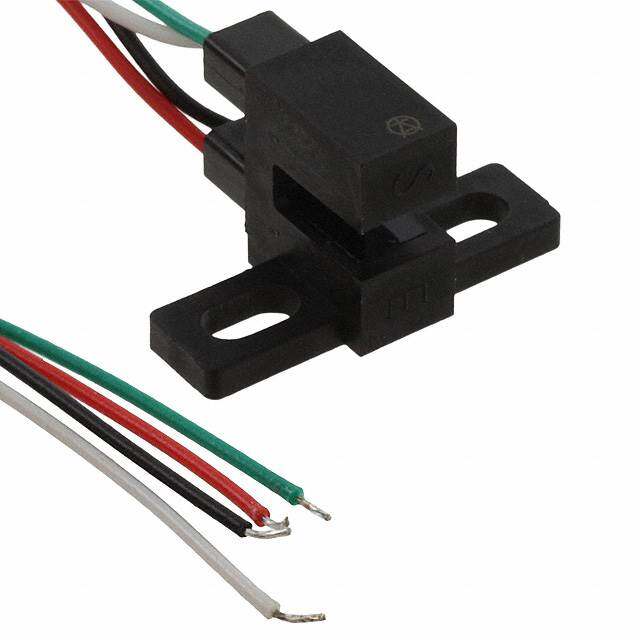

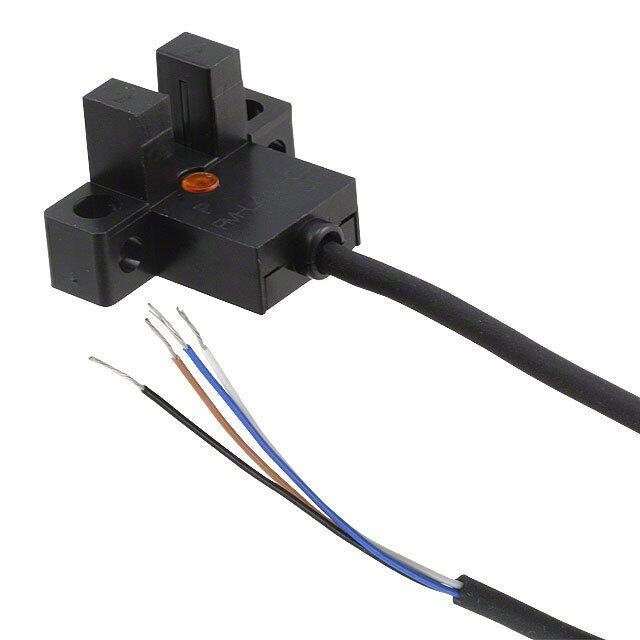

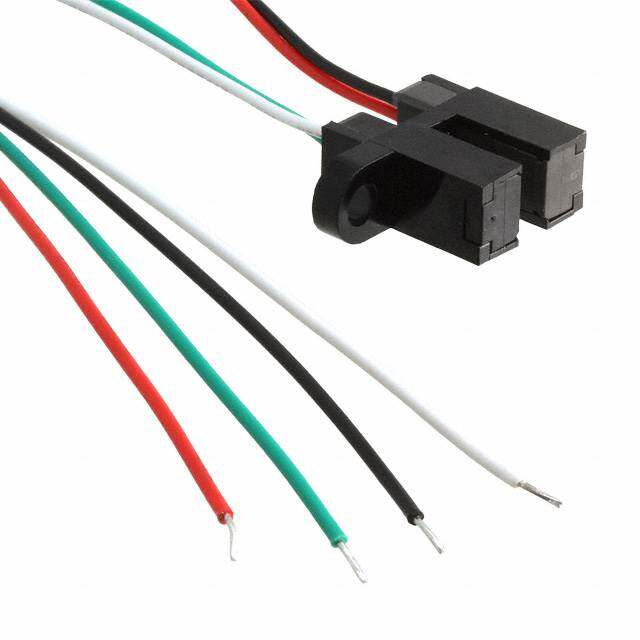

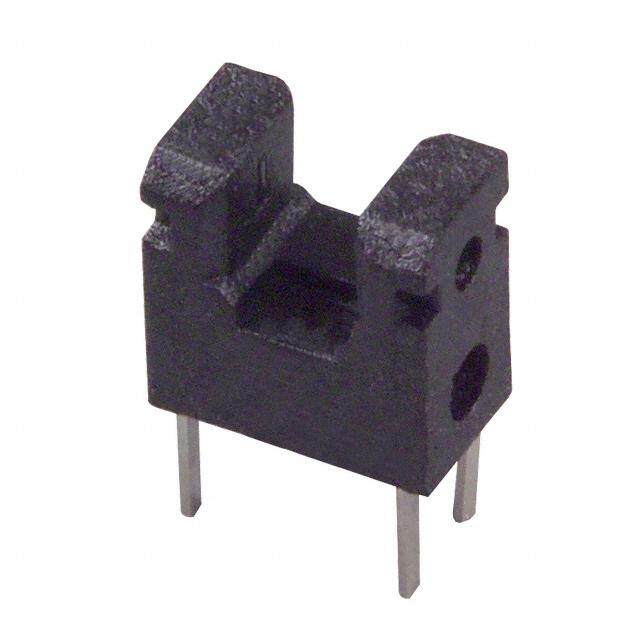

431 Connector Built-in U-shaped Micro Photoelectric Sensor PM-64 SERIES ORDER GUIDE FIBER SENSORS LASER SENSORS Type Appearance (mm in) Sensing range Model No. Output Output operation PHOTO- ELECTRIC SENSORS MICRO NPN open-collector PHOTO- PM-K64 ELECTRIC e transistor SENSORS p SENSAORREAS K ty 26 1.024 in 20.3906 in7 0.207 in PM-K64P PtraNnPs iosptoern-collector LIGHT CURTAINS / SAFETY COMPONENTS NPN open-collector PM-T64 PRESSURE / transistor FLOW 13.7 0.539 in SENSORS PINSRDEOUNXCSIMTOIIRVTESY pe 26 1.024 in 20.3906 in PM-T64P PtraNnPs iosptoern-collector y PARTICUULASRE T t SENSORS 16.7 0.657 in PM-T64W NPN open-collector SENSOR OPTIONS e (Note) transistor p y 26 1.024 in 23 WIRE-SSAIMVPINLGE or t 0.906 in UNITS ct e n NPN open-collector WIRE-SAVING n PM-L64 MSEEASNYSSSMSUTTOEARERTNMEISTCS- nd built-in co L type 26.2 1.031 in 15.71 50..561 08. 6in10 in 5(fi xmemd) 0.197 in PM-L64P tPtrraaNnnPss iiosspttooerrn-collector ILnigcohrt-pOoNra t/e Dda wrkit-hO 2N outputs: ELECTRICITY a PREVDEENVTICIOENS all NPN open-collector MARLAKSEERRS Sm ype 15.5 0.610 in PM-Y64 transistor Y t 22.7 PNP open-collector PLC 13.8 0.543 in 0.894 in PM-Y64P transistor HUMAN MACHINE NPN open-collector INTERFACES PM-F64 e transistor CONSUEMNPETRIOGNY yp 14 0.551 in VCISOUMAPLOIZNAETNIOTNS F t 23 PNP open-collector 13.4 0.528 in 0.906 in PM-F64P transistor FA COMPONENTS SMYASVCTISHEIIMONNES pe 14 0.551 in PM-R64 NtraPnNs iosptoern-collector y CURINUGV R t 23 PNP open-collector SYSTEMS 13.4 0.528 in 0.906 in PM-R64P transistor Note: PM-T64W is compatible with our conventional PM-T53(B). OPTIONS Selection Guide Connector attached cable U-shaped Designation Model No. Description Convergent • CN-14A(-R)-C□ Reflective CN-14A-C1 Length: 1m 3.281 ft PM-64 Connector CN-14A-C2 Length: 2m 6.562 ft attached PM-24 cable CN-14A-C3 Length: 3m 9.843 ft PM-44/ 0.2 mm2 4-core cabtyre cable with PM-54 CN-14A-C5 Length: 5m 16.404 ft connector on one end Cable outer diameter: ø3.7mm CN-14A-R-C1 Length: 1m 3.281 ft Connector ø0.146 in attached CN-14A-R-C2 Length: 2m 6.562 ft cable Connector Flexible CN-14A-R-C3 Length: 3m 9.843 ft cable • CN-14A CN-14A-R-C5 Length: 5m 16.404 ft Connector CN-14A Set of 10 housings and 40 contacts Contact 4 Recommended connector Housing Contact: SPHD-001T-P0.5, Housing: PAP-04V-S (Manufactured by J.S.T. Mfg. Co., Ltd.) Note: Contact the manufacturer for details of the recommended products. Recommended crimping tool Model No. : YC-610R (Manufactured by J.S.T. Mfg. Co., Ltd.) Note: Contact the manufacturer for details of the recommended products.

Connector Built-in U-shaped Micro Photoelectric Sensor PM-64 SERIES 432 SPECIFICATIONS FIBER SENSORS LASER Small and built-in connector type SENSORS Type K type T type L type Y type F type R type PEHLEOCTTOR-IC el No. NPN output PM-K64 PM-T64(W) PM-L64 PM-Y64 PM-F64 PM-R64 SMPEHICNORSTOOOR-S Item Mod PNP output PM-K64P PM-T64P PM-L64P PM-Y64P PM-F64P PM-R64P ESLEENCSTORRICS Sensing range 5 mm 0.197 in (fixed) AREA SENSORS Minimum sensing object 0.8 × 1.8 mm 0.031 × 0.071 in opaque object LIGHT CURTAINS / Hysteresis 0.05 mm 0.002 in or less (Note 2) SAFETY COMPONENTS Repeatability 0.01 mm 0.0004 in or less (Note 3) PFLROEWSSURE / SENSORS Supply voltage 5 to 24 V DC ±10 % Ripple P-P 10 % or less INDUCTIVE PROXIMITY Current consumption 15 mA or less SENSORS PARTICULAR <NPN output type> <PNP output type> USE NPN open-collector transistor PNP open-collector transistor SENSORS • Maximum sink current: 50 mA • Maximum source current: 50 mA Output • Applied voltage: 30 V DC or less (between output and 0 V) • Applied voltage: 30 V DC or less (between output and +V) SOEPNTSIOONRS • Residual voltage: 0.7 V or less (at 50 mA sink current) • Residual voltage: 0.7 V or less (at 50 mA source current) 0.4 V or less (at 16 mA sink current) 0.4 V or less (at 16 mA source current) SWIIMRPEL-SEAVING UNITS Utilization category DC-12 or DC-13 WIRE-SAVING SYSTEMS Output operation Incorporated with 2 outputs: Light-ON / Dark-ON MEASURE- MENT Under light received condition: 20 µs or less SENSORS Response time Under light interrupted condition: 100 µs or less STATIC (Response frequency: 1 kHz or more) (Note 4) ELECTRICITY PREVENTION DEVICES Operation indicator Orange LED (lights up under light received condition) LASER MARKERS Pollution degree 3 (Industrial environment) Ambient temperature –25 to +55 °C –13 to +131 °F (No dew condensation or icing allowed), Storage: –30 to +80 °C –22 to +176 °F PLC e c an Ambient humidity 35 to 85 % RH, Storage: 5 to 95 % RH (Note 5) HUMAN st MACHINE esi Ambient illuminance Fluorescent light: 1,000 ℓx at the light-receiving face INTERFACES ntal r EMC EN 60947-5-2 ECVNIOSENURSAGULYIMZ PATTIIOONN e COMPONENTS m Voltage withstandability 1,000 V AC for one min. between all supply terminals connected together and enclosure viron Insulation resistance 50 MΩ, or more, with 250 V DC megger between all supply terminals connected together and enclosure FCAO MPONENTS n E MACHINE Vibration resistance 10 to 2,000 Hz frequency, 1.5 mm 0.059 in amplitude in X, Y and Z directions for two hours each VISION SYSTEMS Shock resistance 15,000 m/s2 acceleration (1,500 G approx.) in X, Y and Z directions for three times each UV CURING Emitting element Infrared LED (Peak emission wavelength: 940 nm 0.037 mil, non-modulated) SYSTEMS Material Enclosure: PBT, Slit cover: Polycarbonate Cable length Total length up to 100 m 328.084 ft is possible with 0.3 mm2, or more, cable. (Note 6) Weight Net weight: 3 g approx. Notes: 1) Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +23 °C +73.4 °F. Selection 2) This is the value when a sensing object is moved in a lateral direction to the U-shape. Guide 3) This is the value when a sensing object is moved in a lateral direction to the U-shape and when the inserting length of the sensing board is 5 mm 0.197 in. U-shaped 4) The response frequency is the value when the disc, given in the figure below, is rotated. Convergent Reflective Disk 1.8 mm 0.071 in Disk PM-64 PM-24 PM-44/ t = 0.2 mm 0.008 in PM-54 1.6 mm 0.063 in 1.6 mm 0.063 in 5) 5-35% RH in an ambient temperature of +23 °C +73.4 °F. 6) Confirm that the sensor terminal voltage is more than 4.5 V when using an extension of over 20 m 65.617 ft.

433 Connector Built-in U-shaped Micro Photoelectric Sensor PM-64 SERIES I/O CIRCUIT AND WIRING DIAGRAMS FIBER SENSORS LASER SENSORS PM-□64(W) NPN output type PHOTO- I/O circuit diagram Terminal arrangement diagram ELECTRIC SENSORS MICRO Color code of connector attached cable PHOTO- ELECTRIC SENSORS (Brown) +V PSCROEECMNSUPRSSOASTNUAORLAEFRIIGRNENEEHTTSAS SYT // Sensor circuit ZTDr22 TZr1D 1 ((((BNWBlloauhtceietke) 1))0 5,OO 2V0)uu mttppAuu tt m12 a (L5Nxo0.oa dtme A1 , 2m) aLxo.a d +– 5±1 t0o %24 V DC 1 2 3 4 FLOW SENSORS Terminal No. Designation INDUCTIVE Internal circuit Users’ circuit PROXIMITY 1 +V SENSORS Notes: 1) Make sure to connect terminals correctly as the sensor does not incorporate a reverse polarity protection circuit. 2 Output1: Light-ON PARTICULAR USE Further, the output is not incorporated with a short-circuit SENSORS protection circuit. Do not connect it directly to a power supply or a 3 Output2: Dark-ON SENSOR capacitive load. Faulty wiring may result in damage. 4 0 V OPTIONS 2) Ensure to insulate the unused output wire. SIMPLE WIRE-SAVING UNITS Symbols … ZD1, ZD2 : Surge absorption zener diode Tr1,Tr2 : NPN output transistor WIRE-SAVING SYSTEMS MEASMUERNET- PM-□64P PNP output type SENSORS STATIC I/O circuit diagram Terminal arrangement diagram ELECTRICITY PREVENTION DEVICES Color code of connector attached cable LASER MARKERS (Brown) +V INTEMRAHFPCUAHMLCIANECNES Sensor circuit Tr2 TZr1D 2 ZD1 ((WBhliate)c Oku)tp Ou5t 02u (tNmpotuAe t1 , 12m) (aNL5xo0o.a tmed A1, 2 m) aLxo.a d +– 5±1 t0o %24 V DC 1 2 3 4 ENERGY (Blue) 0 V VCIOSNUSAULIMZPATTIIOONN Terminal No. Designation COMPONENTS Internal circuit Users’ circuit 1 +V FA Notes: 1) Make sure to connect terminals correctly as the sensor does not COMPONENTS incorporate a reverse polarity protection circuit. 2 Output1: Light-ON MACHINE Further, the output is not incorporated with a short-circuit SYSVTISEIMONS protection circuit. Do not connect it directly to a power supply or a 3 Output2: Dark-ON capacitive load. Faulty wiring may result in damage. UV 4 0 V CURING 2) Ensure to insulate the unused output wire. SYSTEMS Symbols … ZD1, ZD2 : Surge absorption zener diode Tr1,Tr2 : PNP output transistor SENSING CHARACTERISTICS (TYPICAL) Selection Guide U-shaped PM-K64(P) PM-L64(P) Convergent Reflective Sensing position PM-64 PM-24 Dark- Dark- PPMM--4544/ ON 9 mm 0.354 in ON ℓ 7 mm 0.276 in 2.6 mm ℓ 0.102 in Beam axis Light- Light- ON0 1 2 3 4 ON 1 2 3 4 0.039 0.079 0.118 0.157 0.039 0.079 0.118 0.157 Operating point ℓ (mm in) Operating point ℓ (mm in)

Connector Built-in U-shaped Micro Photoelectric Sensor PM-64 SERIES 434 PRECAUTIONS FOR PROPER USE Refer to p.1458~ for general precautions. FIBER SENSORS Cable extension LSAESNESRORS • Never use this product as a sensing device for personnel protection. • Cable extension is possible up to an overall length of PHOTO- ELECTRIC • In case of using sensing devices for 100 m 328.084 ft with a 0.3 mm2, or more, cable. SENSORS However, since a voltage drop shall occur due to the MICRO personnel protection, use products which PHOTO- cable extension, ensure that the power supply voltage ELECTRIC meet laws and standards, such as OSHA, SENSORS at the end of the cable attached to the sensor or at the ANSI or IEC etc., for personnel protection AREA applicable in each region or country. sensor terminals is within the rating. SENSORS LIGHT Total cable length 100 m 328.084 ft CURTAINS / Catotancnheecdto cr able +V Extension cable SCAOFMEPTOYNENTS Make sure to connect terminals correctly as the Output + 5 to 24V DC PFLROEWSSURE / sensor does not incorporate a reverse polarity – ±10 % SENSORS protection circuit. Supply voltage: 0 V 4.5 V or more INDUCTIVE Further, the output is not incorporated with a PROXIMITY SENSORS short-circuit protection circuit. Do not connect it But, when the overall cable length, including the cable PARTICULAR directly to a power supply or a capacitive load. attached to the sensor, is as given below, there is no USE SENSORS Faulty wiring may result in damage. need to confirm the voltage. SENSOR OPTIONS Conductor cross- Mounting section area of Total cable length SWIIMRPEL-SEAVING extension cable UNITS • When fixing the sensor with screws, use M3 screws and 0.08 to 0.1 mm2 Up to 5 m 16.404 ft WIRE-SAVING the tightening torque should be 0.5 N·m or less. SYSTEMS Further, use small, round type plain washers (ø6 mm 0.2 mm2 Up to 10 m 32.808 ft MEASURE- ø0.236 in). MENT 0.3 mm2 Up to 20 m 65.617 ft SENSORS STATIC M3 screws ELECTRICITY PREVENTION Others DEVICES Spring washer • Since the sensor is intended for LMAASREKRERS Plain washer (Outer diameter) use inside machines, no special ø6 mm countermeasures have been PLC ø0.236 in taken against extraneous light. HUMAN Take care that extraneous light is MACHINE INTERFACES not directly incident on the beam ENERGY receiving section. CONSUMPTION VISUALIZATION COMPONENTS • Do not use during the initial transient time (50 ms) after the power supply is switched on. FA Wiring COMPONENTS • If the sensor is used in a place having excessive dust, MACHINE Connection method periodically clean the emitting and receiving sections with VISION SYSTEMS • Insert the connector attached cable Projection a dry, soft cloth. UV CN-14A(-R)-C□ in the connector part • If there is a large surge generating equipment, such as, CURING SYSTEMS of this product as shown in the right CN-14A(-R)-C□ motor, solenoid, electromagnetic valve, etc., in the vicinity figure. <Connector> of the sensor, use a surge absorber on that equipment. Housing: PAP-04V-S (Manufactured by J.S.T. ) Further, do not run the sensor cables along power lines <Connector pin position> Mfg. Co., Ltd. and use a capacitor between +V and 0 V, if required. Use the sensor after confirming that the surge has been eliminated. Selection Guide Connector pin No. 1 2 3 4 U-shaped 1 2 3 4 Terminal designation +V Output 1 Output 2 0V Convergent Reflective Disconnection method • Pressing the projection of the connector attached cable, PM-64 pull out the connector. PM-24 Note: Take care that if the cable is pulled out without pressing the projection, PM-44/ the cable may break. PM-54

435 Connector Built-in U-shaped Micro Photoelectric Sensor PM-64 SERIES DIMENSIONS (Unit: mm in) FIBER The CAD data in the dimensions can be downloaded from our website. SENSORS LASER SENSORS PM-K64(P) Sensor PM-T64(P) Sensor PHOTO- ELECTRIC 26 13.7 SENSORS 1.024 3.5 0.539 MICRO 20 0.138 7 PHOTO- 0.787 0.276 3 ESLEENCSTORRICS 0.277 6 Beam axis 0.118 AREA SENSORS 2-ø3.2 ø0.126 mounting holes 7 CURSTALAFIIGNEHTSYT / 01.35.248 O(Oprearnagtieo)n indicator 6.8 0.276 O(OpBreaernaagmtieo )an x iinsdicator PCROEMSPSONUERNET S/ 0.519 7 02.1.60 2 0.268 B0.e8a 0m.0 a3x1is width: 13.4 PINSRSDEOEUNXNCSIFSMTOLOIOIRVTRWESYS 0.2930 60 .739.54 4 Lpoacrtk ing 03.1.22 6 01.35.48B3 e am axis 06.2.24 4 40.1.611 1.2062 4 B0.e8a 0m.0 a3x1is width: 9 0.05.5129 78 02.1.60B 2e am axis PARTICUULASRE 0.291 03.1.22 6 13 0.354 SENSORS (2 . 1 ) 0.512 23 3.7 0.083 0.906 OSPETNISOONRS 0.114.76 2-mounting oblong holes 07.2.49 1 01.04.153 WIRE-SSAIUMVNPIINTLGES 0.067 0.2708 7 Connector attached cable CN-14A(-R)-C□ (Optional) 0.016.63 0.2708 7 2o-bmloonugn htionlge s Lpoacrtk ing CCoNn-1n4(e20 Ac .. t10 (o - 8 Rr 3 a ) )-t Cta□c h(Oedp tcioanbalel) WIRE-SAVING SYSTEMS MEASURE- PM-T64W Sensor PM-L64(P) Sensor MENT SENSORS ELECTSRTICATITICY 16.7 26.2 PREVENTION 0.657 1.031 DLEAVSICEERS 0.13094 4 13..77 00..016476 0.2708 7 03.1.53 8 MARKERS 0.157 7 Beam axis 15.7 0.276 PLC 7 Beam axis 0.618 3.2 2-mounting oblong holes 0.276 0.126 Operation indicator (Orange) HUMAN MACHINE Operation indicator Locking part INTERFACES (Orange) ( 2 . 1 ) VCIOSNUSAULEIMZNPAETTRIIOOGNNY B0.e8a 0m.0 a3x1is width: 2.6 01.352.48 0.083 01.25.084 CCoNn-1n4eAct(o-Rr a)-tCta□c h(Oedp tcioanbalel) 6.4 COMPONENTS 0.102 5 13.4 0.252 COMPONENFTSA 0.146.11 9 0.197 Beam axis 02.1.60 2 08.3.32 7 0.05.5192 78 B0.e8a 0m.0 a3x1is width: 3.2 0.354 MACHINE 0.126 0.15312 23 9 Beam axis SYSVTISEIMOUNVS 0.2636 07.2.491 0.906 01.04.153 01.56.150 0.354 PM-L64 07.2.28 3 PM-L64 SYCSUTREINMGS 1.6 20 Lpoacrtking (20 .. 10 8 3 ) 0.395 4 0.2708 7 2-ø3.2 ø0.126 mounting holes 0.063 0.27687 2-mounting Connector attached cable 1.024 oblong holes CN-14A(-R)-C□ (Optional) Selection PM-Y64(P) Sensor PM-F64(P) Sensor Guide U-shaped 2-ø3.5 ø0.138 mounting holes 3 Convergent 7 3.5 0.118 Reflective 0.276 0.138 Beam axis and boss 7 PM-64 7 0.276 22.7 0.276 Beam axis Operation indicator (Orange) PM-24 0.894 Center of beam axis and boss PM-44/ Operation indicator (Orange) 13.4 2.5 7 ø2.4 ø0.094 PM-54 Beam axis width: 0.528 0.098 0.276 Locking part 0.8 0.031 5 2.6 Center of beam 0.197 0.102 axis and boss ( 2 . 1 ) Connector attached cable 0.083 12.8 CN-14A(-R)-C□ (Optional) 9 0.504 0.354 0.395 4 010.35.519.4 78 3 02.1.60 2 06.2.542 B0.e8a 0m.0 a3x1is width: 0.29306 01.66.432 8.2 0.323 Beam axis 2.5 15.5 12.9 0.098 Locking part 7 0.610 0.508 6.5 Connector attached cable ( 2 . 1 ) 0.276 ø3.2 ø0.126 0.256 CN-14A(-R)-C□ (Optional) 0.083 14 mounting holes 0.551

Connector Built-in U-shaped Micro Photoelectric Sensor PM-64 SERIES 436 DIMENSIONS (Unit: mm in) The CAD data in the dimensions can be downloaded from our website. FIBER SENSORS LASER PM-R64(P) Sensor SENSORS PHOTO- 3 ELECTRIC 0.118 SENSORS MICRO Beam axis and boss PHOTO- ELECTRIC 7 SENSORS 0.276 AREA Operation indicator (Orange) SENSORS ø2.4 Center of beam ø0.094 7 2.5 13.4 axis and boss LCIUGRHTTAINS / 0.276 0.098 0.528 Beam axis width: SAFETY Center of beam axis 2.6 5 0.8 0.031 COMPONENTS and boss 0.102 0.197 PRESSURE / FLOW SENSORS INDUCTIVE 16.3 23 PROXIMITY 0.642 0.906 9 SENSORS 8.2 0.354 PARTICULAR 0.323 USE SENSORS øm3o.u2n øti0n.g1 2h6o les 0.127476 (0 2. 0 . 18 3 ) Locking part SOEPNTSIOONRS 0.551 Connector attached cable CN-14A(-R)-C□ (Optional) SIMPLE WIRE-SAVING UNITS WIRE-SAVING SYSTEMS CN-14A-C□ CN-14A-R-C□ Connector attached cable (Optional) MEASURE- MENT SENSORS L • Length L STATIC ( 3 5 ) ( 5 0 ) ELECTRICITY 1.378 1.969 Model No. Length L PDREEVVICEENSTION ( 8 ) ( 8 ) 0.315 0.315 CN-14A(-R)-C1 1,000 39.370 LASER MARKERS CN-14A(-R)-C2 2,000 78.740 PLC CN-14A(-R)-C3 3,000 118.110 ø3.7 ø0.146 cable CN-14A(-R)-C5 5,000 196.850 HUMAN MACHINE INTERFACES ENERGY CONSUMPTION VISUALIZATION COMPONENTS FA COMPONENTS MACHINE VISION SYSTEMS UV CURING SYSTEMS Selection Guide U-shaped Convergent Reflective PM-64 PM-24 PM-44/ PM-54

Datasheet下载

Datasheet下载