ICGOO在线商城 > 电位计,可变电阻器 > 旋转式电位计,变阻器 > P11S1V0FLSY00103KA

- 型号: P11S1V0FLSY00103KA

- 制造商: Vishay

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

P11S1V0FLSY00103KA产品简介:

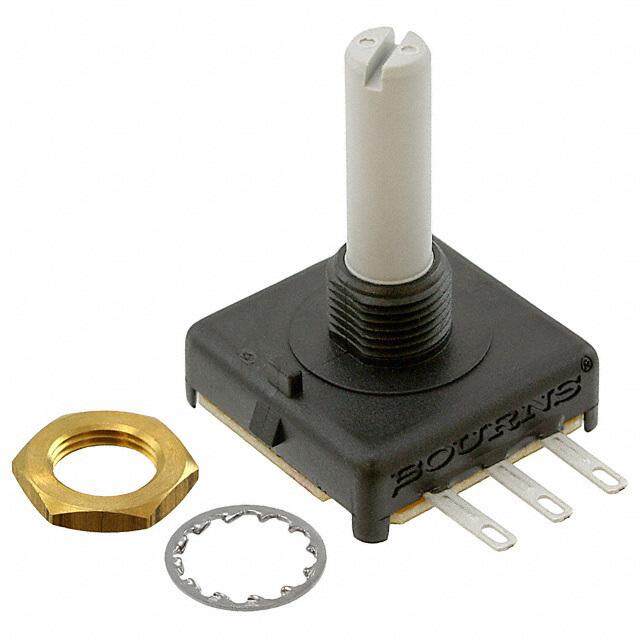

ICGOO电子元器件商城为您提供P11S1V0FLSY00103KA由Vishay设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 P11S1V0FLSY00103KA价格参考¥60.07-¥111.52。VishayP11S1V0FLSY00103KA封装/规格:旋转式电位计,变阻器, 10k Ohm 1 Gang 线性 面板安装 Potentiometer 无 1 Turn 金属陶瓷 1W 焊片。您可以下载P11S1V0FLSY00103KA参考资料、Datasheet数据手册功能说明书,资料中有P11S1V0FLSY00103KA 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | POT PANEL 10K OHM 1W 10% |

| 产品分类 | 旋转式电位计 - 线性 |

| 品牌 | Vishay Sfernice |

| 数据手册 | |

| 产品图片 |

|

| 产品型号 | P11S1V0FLSY00103KA |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | P11S |

| 其它名称 | 716-1009 |

| 功率(W) | 1W |

| 包装 | 散装 |

| 圈数 | 单路 |

| 安装类型 | 面板安装 |

| 容差 | ±10% |

| 尺寸-本体 | 方形 - 0.492" x 0.492" 表面 x 0.437" 长 (12.50mm x 12.50mm x 11.10mm) |

| 旋转 | 300° |

| 标准包装 | 20 |

| 温度系数 | ±150ppm/°C |

| 电阻(Ω) | 10k |

| 电阻材料 | 金属陶瓷 |

| 相关产品 | /product-detail/zh/ACCRFBOUTON29JF/716-1023-ND/2712691 |

| 端子类型 | 焊片 |

| 致动器直径 | 0.236"(6.00mm) |

| 致动器类型 | 开槽轴 |

| 致动器长度 | 0.984"(25.00mm) |

| 调节类型 | 侧面调节 |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

P11S, P11A www.vishay.com Vishay Sfernice 12.5 mm Modular Panel Potentiometer Cermet (P11S) or Conductive Plastic Elements (P11A) FEATURES • 12.5 mm square single turn panel control • Five shaft diameters and 29 terminal styles • Multiple assemblies - up to seven modules • Tests according to CECC 41000 or IEC 60393-1 • GAM T1 • P11S version for industrial, military, and aeronautics applications • P11A version for professional audio applications • Low current compatibility DESIGN SUPPORT TOOLS click logo to get started • Shaft and panel sealed version • Up to twenty-one indent positions Models Available • Rotary and push/push switch options QUICK REFERENCE DATA • Concentric shafts Multiple module Up to 7 modules • Custom designs on request Switch module Yes • Trimmer version T11 (see document no. 51021) Detent module Yes Special electrical A: linear, L: logarithmic, F: reverse • Material categorization: for definitions of compliance laws logarithmic and others see specification please see www.vishay.com/doc?99912 Sealing level IP 64 Lifespan 50K cycles VERSATILE MODULAR COMPACT ROBUST CONFIGURATION EXAMPLE - Dimensions in millimeters (inches) ± 0.5 mm (± 0.02") Single module, single shaft, solder lugs, metric bushing and shaft 12.5 5 M6 x 0.75 2.4 (0.492) (0.197) 1.8 (0.094) 6.85 (0.071) 12.5 (0.270) 13.1 0,9 (0.492) (0.516) 3 8 (0.035) Ø (0.118) (0.315) 5.07 4.9 22 (0.200) DETAIL A A (0.193) (0.866) 4.65 (0.183) 4.65 (0.183) Single module, single shaft, vertical mounting, PC pins with support plate, metric bushing and shaft M10 x 0.75 12.7 8 (0.500) (0.315) 6 9.5 Ø (0.236) (0.374) 2.54 2.54 16 (0.100) (0.100) (0.626) Dual modules, single shaft, PC pins with front support plates, imperial bushing and shaft 9.5 12.5 (0.374) 3/8" x 3/8" (0.492) 13.1 (0.516) 3.6 6.35 Ø (0.250) (0.143) 8 (0.325) 19.05 7.62 (0.750) (0.300) 2.54 2.54 (0.100) (0.100) Revision: 19-Jun-2018 1 Document Number: 51031 For technical questions, contact: sferpottrimmers@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

P11S, P11A www.vishay.com Vishay Sfernice GENERAL SPECIFICATIONS ELECTRICAL (initial) P11A P11S Resistive element Conductive plastic Cermet Electrical travel 270° ± 10° 270° ± 10° Linear taper 1 k to 1 M 20 to 10 M Resistance range (1) Non-linear taper 470 to 500 k 100 to 2.2 M Standard ± 20 % ± 20 % Tolerance On request ± 10 % ± 5 % or ± 10 % 90% F S R Vs% 50% Ve A W Taper 20% L 10% 50% 15° Electrical travel 270° 15° Electrical travel 31° with switch 238° 31° Mechanical travel 300° a c Circuit diagram (1) (3) b cw (2) Linear taper 0.5 W at +70 °C 1 W at +70 °C Non-linear taper 0.25 W at +70 °C 0.5 W at +70 °C Multiple assemblies 0.25 W at +70 °C per module 0.5 W at +70 °C per module W) r ( P11S Linear Taper e w 1 o P Power rating at 70 °C d e Rat P11S Non-Linear Taper 0.5 P11A Linear Taper 0.25 P11A Non-Linear Taper 0 0 10 20 30 40 50 60 70 80 90 100 110 120 130 Ambient Temperature (°C) Temperature coefficient (typical) ± 500 ppm ± 150 ppm Limiting element voltage 350 V 350 V End resistance (typical) 2 2 Contact resistance variation (typical) Linear taper 1 % 2 % or 3 Independent linearity (typical) Linear taper ± 5 % ± 5 % Insulation resistance 106 M min. 106 M min. Dielectric strength 1500 V min. 1500 V min. RMS RMS Attenuation 90 dB max./0.05 dB min. - Mechanical endurance 50 000 cycles 50 000 cycles Note (1) Consult Vishay Sfernice for other ohmic values Revision: 19-Jun-2018 2 Document Number: 51031 For technical questions, contact: sferpottrimmers@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

P11S, P11A www.vishay.com Vishay Sfernice MECHANICAL (initial) Mechanical travel 300° ± 5° Operating torque (typical) Single and dual assemblies 0.4 Ncm to 1.8 Ncm max. (0.57 oz.-inch to 2.55 oz.-inch max.) Three to seven modules (per module) 0.2 Ncm to 0.3 Ncm max. (0.28 oz.-inch to 0.42 oz.-inch max.) End stop torque (all bushing except G and concentric shaft configuration) 3 mm, 4 mm, and 1/8" dia. shafts 35 Ncm max. (2.9 lb-inch max.) 6 mm and 1/4" dia. shafts 80 Ncm max. (6.8 lb-inch max.) End stop torque for bushing G All shafts dia. 40 Ncm max. (3.4 lb-inch max.) End stop torque for concentric shaft configuration 3 mm and 1/8" dia. shafts 25 Ncm max. (2.1 lb-inch max.) 6 mm and 1/4" dia. shafts 80 Ncm max. (6.8 lb-inch max.) Tightening torque 6 mm, 7 mm, and 1/4" dia. bushings 150 Ncm max. (13 lb-inch max.) 10 mm and 3/8" dia. bushings 250 Ncm max. (21 lb-inch max.) Weight 7 g to 9 g per module (0.25 oz. to 0.32 oz.) ENVIRONMENTAL P11A P11S Operating temperature range -55 °C to +125 °C -55 °C to +125 °C Climatic category 55 / 125 / 21 55 / 125 / 56 Sealing IP64 IP64 MARKING PACKAGING • Potentiometer module Vishay logo, SAP code of ohmic value, tolerance in %, variation law, manufacturing date (four digits), “3” for the lead 3, product series (P11S, P11A) • Switch module • Box Version, manufacturing date (four digits), “c” for common lead • Indent module Version, manufacturing date (four digits) PERFORMANCES TYPICAL VALUE AND DRIFTS TESTS CONDITIONS P11S P11A 1000 h at rated power RT/RT ± 2 % ± 10 % Electrical endurance 90’/30’ - ambient temp. 70 °C Contact resistance variation ± 4 % ± 5 % Change of temperature -55 °C to +125 °C, 5 cycles RT/RT ± 0.2 % ± 0.5 % +40 °C, 93 % relative humidity RT/RT ± 2 % ± 5 % Damp heat, steady state P11S: 56 days, P11A: 21 days Insulation resistance > 1000 M > 10 M RT/RT ± 5 % ± 6 % Mechanical endurance 50 000 cycles Contact resistance variation ± 5 % ± 4 % Dry heat at +125 °C/damp heat Climatic sequence cold -55 °C/damp heat, 5 cycles RT/RT ± 1 % - 50 g’s, 11 ms RT/RT ± 0.2 % ± 0.2 % Shock 3 shocks - 3 directions R1-2/R1-2 ± 0.5 % ± 0.5 % 10 Hz to 55 Hz RT/RT ± 0.2 % ± 0.2 % Vibration 0.75 mm or 10 g’s, 6 h V1-2/V1-3 ± 0.5 % ± 0.5 % Note • Nothing stated herein shall be construed as a guarantee of quality or durability Revision: 19-Jun-2018 3 Document Number: 51031 For technical questions, contact: sferpottrimmers@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

P11S, P11A www.vishay.com Vishay Sfernice ORDERING INFORMATION (part number) P 1 1 S 2 Q 0 E A S Y 0 0 1 0 3 M A NUMBER RESISTANCE CODE/ LOCATING SHAFT MODEL STYLE OF BUSHING SHAFT LEADS TOLERANCE/ PEG STYLE MODULES TAPER OR SPECIAL P11 S = cermet element 1 2 A = conductive plastic 3 (audio) 4 5 6 7 STANDARD RESISTANCE ELEMENT DATA P11S CERMET P11A CONDUCTIVE PLASTIC STANDARD LINEAR TAPER NON-LINEAR TAPER LINEAR TAPER NON-LINEAR TAPER RESISTANCE MAX. MAX. MAX. CUR. MAX. MAX. MAX. CUR. MAX. MAX. MAX. CUR. MAX. MAX. MAX. CUR. VALUES POWER WORKING THROUGH POWER WORKING THROUGH POWER WORKING THROUGH POWER WORKING THROUGH AT 70 °C VOLTAGE WIPER AT 70 °C VOLTAGE WIPER AT 70 °C VOLTAGE WIPER AT 70 °C VOLTAGE WIPER W V mA W V mA W V mA W V mA 22 1 4.69 213 47 1 6.86 146 50 1 7.07 141 100 1 10.0 100 0.5 7.07 70.7 220 1 14.8 67.4 0.5 10.5 47.7 470 1 21.7 46.1 0.5 15.3 32.6 500 1 22.4 44.7 0.5 15.8 31.6 0.25 11.2 22.4 1K 1 31.6 31.6 0.5 22.4 22.4 0.5 22.4 22.4 0.25 15.8 15.8 2.2K 1 46.9 21.3 0.5 33.2 15.1 0.5 33.2 15.1 0.25 23.5 10.7 4.7K 1 69 14.5 0.5 48.5 10.3 0.5 48.5 10.3 0.25 34.3 7.29 5K 1 70.7 14.1 0.5 50.0 10.0 0.5 50.0 10.0 0.25 35.4 7.07 10K 1 100 10.0 0.5 70.7 7.07 0.5 70.7 7.07 0.25 50.0 5.00 22K 1 148 6.74 0.5 105 4.77 0.5 105 4.77 0.25 74.2 3.37 47K 1 217 4.61 0.5 153 3.26 0.5 153 3.26 0.25 108 2.31 50K 1 224 4.47 0.5 158 3.16 0.5 158 3.16 0.25 112 2.24 100K 1 316 3.16 0.5 224 2.24 0.5 224 2.24 0.25 158 1.58 220K 0.56 350 1.59 0.5 332 1.51 0.5 332 1.51 0.25 235 1.07 470K 0.26 350 0.75 0.26 349 0.74 0.26 350 0.74 0.25 343 0.73 500K 0.25 350 0.70 0.25 350 0.71 0.25 350 0.71 0.25 350 0.71 1M 0.12 350 0.35 0.12 350 0.34 0.12 350 0.34 2.2M 0.06 350 0.16 0.056 350 0.16 4.7M 0.03 350 0.074 5M 0.02 350 0.070 10M 0.01 350 0.035 Revision: 19-Jun-2018 4 Document Number: 51031 For technical questions, contact: sferpottrimmers@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

P11S, P11A www.vishay.com Vishay Sfernice ORDERING INFORMATION (part number) P 1 1 S 2 Q 0 E A S Y 0 0 1 0 3 M A NUMBER RESISTANCE CODE/ LOCATING SHAFT MODEL STYLE OF BUSHING SHAFT LEADS TOLERANCE/ PEG STYLE MODULES TAPER OR SPECIAL P11 Ø L Old Codes A 1/4"1/4" 7, 77, 77-3 B 1/4"3/8" 71 C 1/4"1/2" 72 D 1/4"3/8" 71H E 1/4"1/2" 72H F 3/8"3/8" 2, 03, 0- G 8 8 TP, QP, VP, 2P, 7P Q 7 8 Q T 6 8 T V 10 9.5 V, CC, CC-3 BUSHING DIMENSIONS PANEL AND SHAFT SEALED: BUSHING G Ø 8 (0.315) B A 8 (0.315) C J 6.7 (0.264) K All models have the same bushing Dia. 8 mm - L 8 mm PANEL CUT OUT BUSHING D AND E WITH LOCKING NUT Bushing G Wrench 10 or 3/8" Bushings Bushings A, B, F and V C, D, E, T and Q 7.2 A B Ø H G (0.284) Ø 8.5 G Ø H (0.335) C J G T Q V A B C D E F BUSHINGS DIMENSIONS mm (± 0.5) DIMENSIONS INCHES (± 0.02) A Shafts Ø All Dia. 3 4 6 1/8" 1/8" 1/8" 1/8" 1/8" 1/4" B Bushing Ø 8 6 7 10 1/4" 1/4" 1/4" 1/4" 1/4" 3/8" C L 8 8 8 9.5 1/4" 3/8" 1/2" 3/8" 1/2" 3/8" J Lead versions X.. Y.. 6.7 5 5 7 0.200 0.200 0.200 0.200 0.200 0.278 K 10.4 9.1 9.1 11.1 0.357 0.357 0.357 0.357 0.357 0.436 G Panel 7.2 5.2 6.2 8.2 0.197 0.197 0.197 0.197 0.197 0.323 H Cutout Ø 8.5 6.5 7.5 10.5 0.268 0.268 0.268 0.268 0.268 0.394 Thread 0.75 32 threads/inch Wrench nut 12 8 10 12 0.313 0.313 0.313 0.313 0.313 0.500 Style Slotted Slotted Notes • Hardware supplied in separate bags • Slotted bushing for locking nut option Revision: 19-Jun-2018 5 Document Number: 51031 For technical questions, contact: sferpottrimmers@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

P11S, P11A www.vishay.com Vishay Sfernice ORDERING INFORMATION (part number) P 1 1 S 2 Q 0 E A S Y 0 0 1 0 3 M A NUMBER RESISTANCE CODE/ LOCATING SHAFT MODEL STYLE OF BUSHING SHAFT LEADS TOLERANCE/ PEG STYLE MODULES TAPER OR SPECIAL Old Codes A = B24 B = B30 C = B53 0 = without peg LOCATING PEGS (anti-rotation lug) The locating peg is provided by a plate mounted on the bushing and positioned by the module sides. Four set positions are BUSHING BUSHING EFFECTIVE available, clock face orientation: 12, 3, 6, 9. CODE VERSION A, B, C, D, F, V HIGH PEG E, T, Q Ø d mm 2 2 0.7 All P11 bushings have a double flat. When panel mounting A holes have been punched accordingly, an anti-rotation lug is L mm 6.2 6.2 not necessary. Ø d mm 2 2 0.7 B L L mm 7.75 7.75 12 Ø d mm - 3.5 1.1 C 9 3 L mm - 13.5 Locating pegs are supplied in separate bags with nuts and 6 Ø d washers Revision: 19-Jun-2018 6 Document Number: 51031 For technical questions, contact: sferpottrimmers@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

P11S, P11A www.vishay.com Vishay Sfernice ORDERING INFORMATION (part number) P 1 1 S 2 Q 0 E A S Y 0 0 1 0 3 M A NUMBER RESISTANCE CODE/ LOCATING SHAFT MODEL STYLE OF BUSHING SHAFT LEADS TOLERANCE/ PEG STYLE MODULES TAPER OR SPECIAL Ø L Old Codes S = slotted AA 3 9.5 K R = round AB 3 12.5 M F = flatted AJ 3 22 R knurled/ K = AP = custom shaft splined BA 1/8" 3/8" CK D = custom BB1/8" 1/2" CM BG1/8" 5/8" CDM BG1/8" 5/8" CD BH1/8" 3/4" CH BJ 1/8" 7/8" CR CC = concentric shaft EA 4 9.5 E EB 4 12.5 F EJ 4 22 G FG 6 16 D FH 6 19 I FL 6 25 N FR 6 50 S GG1/4" 5/8" VD GH1/4" 3/4" VHM, VH GJ 1/4" 7/8" VR GL 1/4" 1" VN GO1/4" 1.5" VL SHAFTS in millimeters ± 0.5 The shaft length is always measured from the mounting face. BUSHING: Q Standard shafts are designed by a 3 letters code (3 digits). SPLINED SHAFT: FHK Shafts slots are aligned to ± 10° of the wiper position. All standard shafts are slotted except flatted and splined, see Ø 7 exeptions for bushing. FLATTED SHAFT Ø 6 Bushing: F Bushing: A Shaft: GHF Shaft: BGF 19 15.9 198.1 ± 0.5 5.5 ± 0.05 Ø 3.170.3 at 45° 2.4 ± 0.05 CWUheSnT OspMe cSiaHl AsFhTaSfts are required - flat, threated ends, special shaft lengths, etc. a drawing is required. 8 ± 0.5 Ø 6.35 STANDARD COMBINATION OF SHAFT STYLES AND BUSHINGS SHAFT DIA. BUSHING CODE SHAFT LENGTH AND STYLE AVAILABLE IN STANDARD (others on request) 3 T AAS ABS AJS 3.17 A BAS BBS BGS BGF BHS BJS 3.17 B BBS BGS BHS BJS 3.17 C BGS BHS BJS 4 Q EAS EBS EJS FHK 6 V FGS FLS FRS 6.35 F GGS GHS GJS GLS GOS GHF Revision: 19-Jun-2018 7 Document Number: 51031 For technical questions, contact: sferpottrimmers@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

P11S, P11A www.vishay.com Vishay Sfernice ORDERING INFORMATION (part number) P 1 1 S 2 Q 0 E A S Y 0 0 1 0 3 M A NUMBER RESISTANCE CODE/ LOCATING SHAFT MODEL STYLE OF BUSHING SHAFT LEADS TOLERANCE/ PEG STYLE MODULES TAPER OR SPECIAL Available leads A00 W00 X00 Y00 Z00 A10 W10 X03 Y03 Z03 A13 W20 X04 Y04 Z04 A14 X10 Z10 A20 X13 Z13 A23 X14 Z14 A24 X20 Z20 X23 Z23 X24 Z24 FIRST DIGIT SECOND DIGIT THIRD DIGIT Y Soldering lugs Y = 4.65 (0.183") 0 5.08 (0.200") space between modules X PCB pins 0 A, X, Z, W = 5.08 (0.200") pin spacing 3 7.62 (0.300") space between modules Z PCB pins with front support plate pins section 0.9 x 0.3 (0.035" x 0.012") 4 10.16 (0.400") space between modules PCB pins with front and back support 2.54 (0.100") pin spacing A 1 plates pin section 0.6 x 0.3 (0.024" x 0.012") PCB pins - vertical mounting with 2 extra 5.08 (0.200") pin spacing W 2 pins - 1 module only pins section 0.6 x 0.3 (0.024" x 0.012") DIMENSIONS in millimeters (inches) ± 0.5 mm (± 0.02") SOLDER LUGS Y PCB PIN OUT 12.5 X-X2 X1 (0.492) 1.8 5 (0.07) 6.85 12.5 13 (0.197) (02..049) (0.270) (0.492) (0.512) 0.9 0.9 J (03..17416) (0.41.875) (0.41.875) (0.035)(0.035) 1 2 3 123 5.08 2.54 (0.200) (0.100) HORIZONTAL MOUNTING VERTICAL MOUNTING FRONT AND REAR SUPPORT PLATES FRONT SUPPORT PLATE A B 12.7 Rear support (0.500) plate Z Z1 Z2 4 C K (0.157) W-W2 W1 E 6.35 F (0.250) 1 2 3 123 1 2 3 A/A2 A1 1 2 5.08 (03..18510) (03..18510) (102.5.700) ( 01.25.070) 3 (0.200) 3.81 3.81 5.08 2.54 5.08 1 2 3 12 3 (0.150) (0.150) (0.200) (0.100) (0.200) 5.08 2.54 (0.200) (0.100) THE POSITION OF EACH MODULE IS FREE G T Q V A B C D E F BUSHINGS DIMENSIONS mm (± 0.5) DIMENSIONS INCHES (± 0.02) E Leads Z00 3.15 1.85 1.85 3.85 0.071 0.071 0.071 0.071 0.071 0.150 E Leads Z1. Z2. A.. 2.8 1.6 1.6 3.6 0.063 0.063 0.063 0.063 0.063 0.140 F Leads Z0.: 5.08 (0.200") Leads A.. Z1. Z2.: 3.81 (0.150") J Leads X.. Y.. 6.7 5 5 7 0.200 0.200 0.200 0.200 0.200 0.278 E Leads Z0. with Rotary Switch 1.45 0.15 0.15 2.15 0.006 0.006 0.006 0.006 0.006 0.0846 Revision: 19-Jun-2018 8 Document Number: 51031 For technical questions, contact: sferpottrimmers@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

P11S, P11A www.vishay.com Vishay Sfernice ORDERING INFORMATION (part number) P 1 1 S 2 Q 0 E A S Y 0 0 1 0 3 M A NUMBER RESISTANCE CODE/ LOCATING SHAFT MODEL STYLE OF BUSHING SHAFT LEADS TOLERANCE/ PEG STYLE MODULES TAPER OR SPECIAL From 20 to 10 M see instructions on electrical specifications Resistance code: 200 = 20 to 106 = 10 M Tolerance code: standard: M = ± 20 % On request: K = ± 10 %, J = ± 5 % (cermet only) Taper: A, L, W, F, S, R or special code given by Vishay SPECIAL CODES GIVEN BY VISHAY Option available: • Custom shaft • Custom design on request • Specific linearity • Specific interlinerarity • Specific taper • Multiple assemblies with various modules Revision: 19-Jun-2018 9 Document Number: 51031 For technical questions, contact: sferpottrimmers@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

P11S, P11A www.vishay.com Vishay Sfernice P11 OPTION: ROTARY SWITCH MODULES • Rotary switches • Current up to 2 A • Actuation CW or CCW position • Sealing IP60 MODULES: RS ON/OFF SWITCH SWITCH SPECIFICATIONS RSI CHANGEOVER SWITCH 62.5 VA Switching power maximum The position of each module is free. 15 VA = RS and RSI rotary switches are housed in a standard P11 0.25 A 250 V Switching current maximum module size 12.7 mm x 12.7 mm x 5.08 mm (0.5" x 0.5" x 0.2"). 0.5 A 30 V = They have the same terminal styles as the assembled electrical Maximum current through element 2 A modules. Contact resistance 100 m An assembly can comprise 1 or more switch modules. Dielectric Terminal to terminal 1000 VRMS Switch actuation is described as seen from the shaft end. strength Terminal to bushing 2000 V D: Means actuation in maximum CCW position RMS F: Means actuation in maximum CW position Maximum voltage operation 250 V 30 V = The switch actuation travel is 25° with a total mechanical travel of 300° ± 5° and electrical travel of electrical modules is Insulation resistance between contacts 106 M 238° ± 10°. Life at P 10 000 actuations max. Leads finish: Gold plated Minimal travel 25° RDS SINGLE POLE SWITCH, NORMALLY OPEN Operating temperature -40 °C to +85 °C In full CCW position, the contact between 1 and 3 is open. It is made at the beginning of the travel in CW direction. ELECTRICAL DIAGRAM RSF SINGLE POLE SWITCH, NORMALLY OPEN RSD RSID RSIF In full CW position, the contact between 1 and 3 is open. It is RSF CCW POSITION CW POSITION made at the beginning of the travel in CCW direction. RSID SINGLE POLE CHANGEOVER In full CCW position, the contact is made between 3 and 2 and open between 3 and 1. Switch actuation (CW direction) reverses these positions. RSIF SINGLE POLE CHANGEOVER 1 3 1 2 3 (1) 1 (1)2 3 In full CW position, the contact is made between 1 and 2 and Note open between 1 and 3. Switch actuation (CCW direction) reverses these positions. (1) Common ORDERING INFORMATION (First order only) RSID RSD SPST: Single pole, open switch in CCW position - 2 pins RSF SPST: Single pole, open switch in CW position - 2 pins RSID SPDT: Single pole, changeover switch in CCW position - 3 pins RSIF SPDT: Single pole, changeover switch in CW position - 3 pins Revision: 19-Jun-2018 10 Document Number: 51031 For technical questions, contact: sferpottrimmers@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

P11S, P11A www.vishay.com Vishay Sfernice P11 OPTION: PUSH/PUSH OR MOMENTARY/PUSH SWITCH MODULES 3.3 40.8 (1.60) (0.013) a b c 1 2 3 • Push/push or momentary push • Current up to 2 A • Sealing IP60 1.3 28 3.6 (0.14) (0.051) (1.10) 44 (0.15)(0.15) MODULES: PUSH/PUSH SWITCH RSPP SWITCH SPECIFICATIONS MOMENTARY/PUSH SWITCH RSMP Switching power maximum 50 VA They have to be the last element of potentiometer Switching current maximum 0.5 A Options: Maximum current through element 2 A 2 reversing switches F2 4 reversing switches F4 Contact resistance 100 m 6 reversing switches F6 8 reversing switches F8 Dielectric Terminal to terminal 1500 VRMS Not available with panel sealed option. strength Terminal to bushing 2000 V RMS Number of modules before the switch limited to 3 modules. Maximum voltage operation 250 V Length of shaft (FMF) 25 mm maximum. Insulation resistance between contacts 103 M RSPP F2: PUSH/PUSH SWITCH WITH TWO REVERSING SWITCHES Life at P 100 000 actuations max. Idle position: The contact is made between 1 and 2 and a and Minimal travel 3.3 mm to 4.7 mm b. It is open between 2 and 3 and b and c. Operating temperature -40 °C to +70 °C Pushed position: The contact is made between 2 and 3 and b and c. It is open between 1 and 2 and a and b. ELECTRICAL DIAGRAM RSPP F2 IDLE POSITION PUSHED POSITION a b c 1 2 3 ORDERING INFORMATION (First order only for special code creation) RSPP F2 RSPP: Push/push F2: 2 reversing switches (standard version) RSMP: Momentary/push F4: 4 reversing switches F6: 6 reversing switches F8: 8 reversing switches Revision: 19-Jun-2018 11 Document Number: 51031 For technical questions, contact: sferpottrimmers@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

P11S, P11A www.vishay.com Vishay Sfernice P11 OPTION: CONCENTRIC SHAFTS The CC concentric shaft versions allies the total flexibility of the P11 modular system to the advantage of having two separate shafts. 5.08 2.54 The outer 6 mm or 1/4" or 1/8" dia. shaft drives the modules situated immediately behind the panel, before the spacer module. The inner 3 mm or 1/8" or 0.07" dia. shaft drives the modules situated after the spacer module. L Spacer is available with a choice of two spacer thickness: l 5.08 mm designations or 2.54 mm designation. See dimensional drawing Spacer module BUSHING OUTER SHAFT DIAMETER INNER SHAFT DIAMETER CODE DIAMETER LENGTH L SHAFT STYLE DIAMETER LENGTH l SHAFT STYLE V 6 16 R 3 28.5 R F 6.35 (1/4") 16 R 3.17 (1/8") 28.5 R A 3.17 (1/8") 12.7 (1/2") R 1.8 (0.07") 22.2 (7/8") R ORDERING INFORMATION (First order only for special code creation) 5.08 2.54: Mechanical spacer of 2.54 mm 5.08: Mechanical spacer of 5.08 mm Customer should define witch modules is driven by each shaft (see example of ordering information at the end of the datasheet) P11 OPTION: DETENT MODULES The detents mechanism is housed in a standard P11 module. Up to 21 detent positions available. α Count detents as follows: 1 for CCW position, 1 for full CW position, plus the other positions forming equal resistance increments (linear taper) - not equal angles. Available: CVID - CVIF - CVIM β β α = 270° n - 1 CV3 - CV11 - CV21 CVID CVIM CVIF CV11 β = α+ 15° Mechanical endurance: 10 000 cycles ORDERING INFORMATION (First order only for special code creation) CV1M CV1M 1 detent at half travel CV1M J84 CV1M with accuracy of center point ± 2 % (all tapers except S) CV1D 1 detent at CCW position CV1F 1 detent at CW position CV3 3 detents CV11 11 detents CV21 21 detents P11 OPTION: NEUTRAL MODULES “EN” Neutral or screen module is housed in a standard P11 module. It is used as a screen between two electrical modules. The leads can be connected to ground. ORDERING INFORMATION (First order only for special code creation) EN EN Neutral module Revision: 19-Jun-2018 12 Document Number: 51031 For technical questions, contact: sferpottrimmers@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

P11S, P11A www.vishay.com Vishay Sfernice P11 OPTION: CENTER CURRENT TAP “J” The extra terminal is a solder lug connected at 50 % of electrical travel and siluated in the potentiometer module opposite the terminals. Center tap presents a short circuit of 11° of travel. 100 % 50 % • Sealing IP60 0 % 11° ORDERING INFORMATION (First order only) J J Center tap P11 OPTION: SPECIAL LINEARITY - CONFORMITY V E The independent linearity (conformity for the non-linear laws) is the maximum gap V between the actual variation curve and the theorical variation curve the nearest to it. The linearity and V the conformity are expressed in percentage of the total applied voltage E ± V linearity conformity = --------------m----a---x--. E They are measured over 90 % of actual electrical travel (centered). linLeiamriittsy otefst Degrees On request linearity can be guaranteed in linear taper. Effective electrical travel ORDERING INFORMATION (First order only) J123 J123 Independent linearity ± 3 % (linear law) For other request, contact us. J145 Independent linearity ± 2 % (linear law) P11 OPTION: SPECIAL INTERLINEARITY - INTERCONFORMITY V It is the maximum deviation between the actual voltage outputs E of 2 or more pot modules in the same assembly. It is expressed as a percentage of the total applied voltage, or in dB attenuation. C Interlinearity is measured between 2 pot modules, over 20 to V1 90 % of the attenuation. V2 The interlinearity or interconformity is expressed as a percentage of the total applied voltage: Limits of test Effective electrical travel Degrees I % = --C----- E Or in decibels by comparison between outputs V1 and V2 I dB = 20 log V----1-- V1 V2 V 2 ORDERING INFORMATION (First order only) J44 J44 Interlinearity ± 2 % (linear taper) For other request, contact us. Revision: 19-Jun-2018 13 Document Number: 51031 For technical questions, contact: sferpottrimmers@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

P11S, P11A www.vishay.com Vishay Sfernice EXAMPLES OF FIRST ORDER INFORMATION FIRST EXAMPLE: Triple module (switch is counted as a module) P 1 1 S 3 Q 0 A P S Y 0 0 MODEL STYLE BUSHING Q WITHOUT CUSTOM SHAFT SPECIAL TO BE 3 MODULES SOLDER LUGS P11 S (Ø 7: L8) LOCATING PEG SLOTTED DEFINED BY VISHAY ORDERING INFORMATION: PART NUMBER P11S3Q0APSY00..... SHAFT AND BUSHING See drawing of special shaft attached MODULE NO. 1 RSID MODULE NO. 2 103 M A J123 MODULE NO. 3 503 M A J SECOND EXAMPLE: Concentric shaft with 2 modules on each shaft P 1 1 S 5 V 0 C C R Y 0 0 STANDARD MODEL STYLE BUSHING Q WITHOUT SPECIAL TO BE 5 MODULES CONCENTRIC SOLDER LUGS P11 S (Ø 10: L9.5) LOCATING PEG DEFINED BY VISHAY SHAFT CCR ORDERING INFORMATION: PART NUMBER P11S5V0CCRY00..... SHAFT AND BUSHING MODULE NO. 1 CV1M Driven by outer shaft MODULE NO. 2 502 K A Driven by outer shaft MODULE NO. 3 5.08 Mechanical spacer 5.08 mm MODULE NO. 4 103 M A J44 Driven by inner shaft MODULE NO. 5 103 M A J44 Driven by inner shaft PART NUMBER DESCRIPTION (used on some Vishay document or label, for information only) P11S 2 Q 0 EA S Y00 10K 20 % A e3 LOCATING SHAFT LEAD MODEL MODULES BUSHING SHAFT LEADS VALUE TOL. TAPER SPECIAL SPECIAL PEG STYLE (Pb)-FREE RELATED DOCUMENTS APPLICATION NOTES Potentiometers and Trimmers www.vishay.com/doc?51001 Guidelines for Vishay Sfernice Resistive and Inductive Components www.vishay.com/doc?52029 Revision: 19-Jun-2018 14 Document Number: 51031 For technical questions, contact: sferpottrimmers@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice www.vishay.com Vishay Disclaimer ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE. Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively, “Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other disclosure relating to any product. Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special, consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular purpose, non-infringement and merchantability. Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of typical requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements about the suitability of products for a particular application. It is the customer’s responsibility to validate that a particular product with the properties described in the product specification is suitable for use in a particular application. Parameters provided in datasheets and / or specifications may vary in different applications and performance may vary over time. All operating parameters, including typical parameters, must be validated for each customer application by the customer’s technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase, including but not limited to the warranty expressed therein. Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining applications or for any other application in which the failure of the Vishay product could result in personal injury or death. Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk. Please contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners. © 2017 VISHAY INTERTECHNOLOGY, INC. ALL RIGHTS RESERVED Revision: 08-Feb-17 1 Document Number: 91000

Datasheet下载

Datasheet下载.jpg)