ICGOO在线商城 > 电感器,线圈,扼流圈 > 固定值电感器 > NRG4026T220M

- 型号: NRG4026T220M

- 制造商: TAIYO YUDEN-XENTEK

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

NRG4026T220M产品简介:

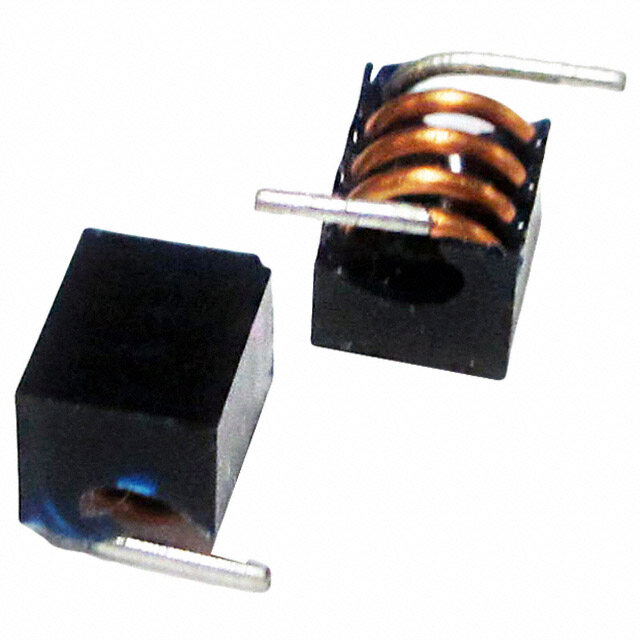

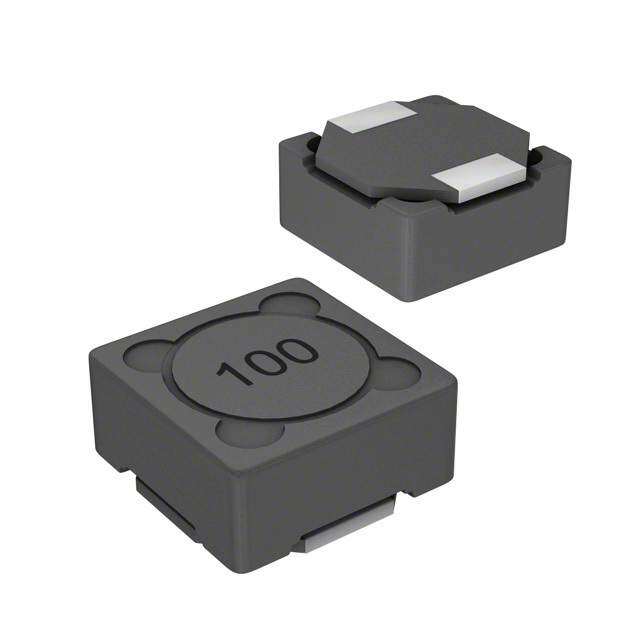

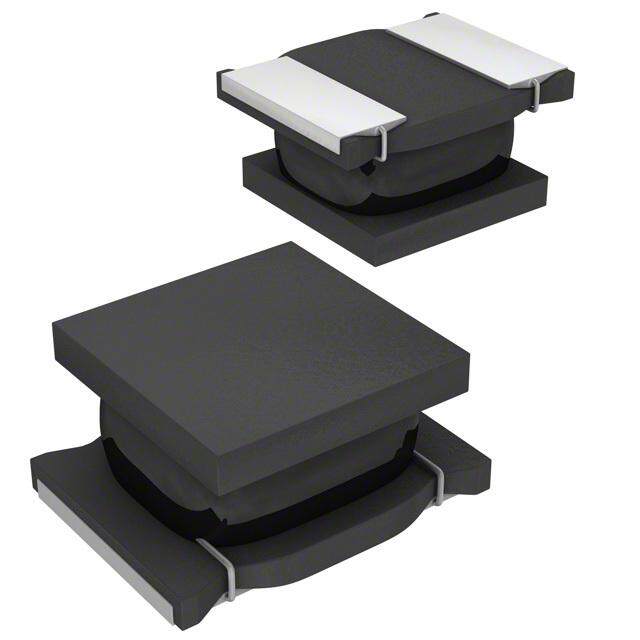

ICGOO电子元器件商城为您提供NRG4026T220M由TAIYO YUDEN-XENTEK设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 NRG4026T220M价格参考。TAIYO YUDEN-XENTEKNRG4026T220M封装/规格:固定值电感器, 22µH 屏蔽 绕线 电感器 900mA 165 毫欧 非标准 。您可以下载NRG4026T220M参考资料、Datasheet数据手册功能说明书,资料中有NRG4026T220M 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| DC电阻(DCR) | 165 毫欧 |

| 描述 | INDUCTOR 22UH .9A 20% SMD固定电感器 INDCTR LW PROFL WND 22uH 20% |

| 产品分类 | |

| 品牌 | Taiyo Yuden |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 固定电感器,Taiyo Yuden NRG4026T220MNRG |

| 数据手册 | |

| 产品型号 | NRG4026T220M |

| 不同频率时的Q值 | - |

| 产品目录绘图 |

|

| 产品目录页面 | |

| 产品种类 | 固定电感器 |

| 供应商器件封装 | - |

| 其它名称 | 587-2378-1 |

| 包装 | 剪切带 (CT) |

| 商标 | Taiyo Yuden |

| 外壳宽度 | 4 mm |

| 外壳长度 | 4 mm |

| 外壳高度 | 2.6 mm |

| 大小/尺寸 | 0.157" 长 x 0.157" 宽(4.00mm x 4.00mm) |

| 安装类型 | 表面贴装 |

| 容差 | ±20% |

| 封装 | Reel |

| 封装/外壳 | 非标准 |

| 屏蔽 | 屏蔽 |

| 工作温度 | -25°C ~ 120°C |

| 工作温度范围 | - 25 C to + 120 C |

| 工厂包装数量 | 2000 |

| 最大直流电流 | 610 mA |

| 最大直流电阻 | 165 mOhms |

| 材料-磁芯 | 铁氧体 |

| 标准包装 | 1 |

| 电感 | 22µH |

| 电流-饱和值 | 610mA |

| 端接类型 | SMD/SMT |

| 类型 | - |

| 系列 | NRG |

| 自谐振频率 | 13 MHz |

| 频率-测试 | 100kHz |

| 频率-自谐振 | 13MHz |

| 额定电流 | 900mA |

| 高度-安装(最大值) | 0.102"(2.60mm) |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

Notice for TAIYO YUDEN products 1 Please read this notice before using the TAIYO YUDEN products. IN F O R M A T IO REMINDERS N O N T H E ■ Product information in this catalog is as of October 2008. All of the contents specified herein are G subject to change without notice due to technical improvements, etc. Therefore, please check for the EN E latest information carefully before practical application or usage of the Products. R A L C Please note that Taiyo Yuden Co., Ltd. shall not be responsible for any defects in products or equipment A T incorporating such products, which are caused under the conditions other than those specified in this A L O catalog or individual specification. G ■ Please contact Taiyo Yuden Co., Ltd. for further details of product specifications as the individual specification is available. ■ Please conduct validation and verification of products in actual condition of mounting and operating environment before commercial shipment of the equipment. ■ All electronic components or functional modules listed in this catalog are developed, designed and intended for use in general electronics equipment.(for AV, office automation, household, office supply, information service, telecommunications, (such as mobile phone or PC) etc.). Before incorporating the components or devices into any equipment in the field such as transportation,( automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network (telephone exchange, base station) etc. which may have direct influence to harm or injure a human body, please contact Taiyo Yuden Co., Ltd. for more detail in advance. Do not incorporate the products into any equipment in fields such as aerospace, aviation, nuclear control, submarine system, military, etc. where higher safety and reliability are especially required. In addition, even electronic components or functional modules that are used for the general electronic equipment, if the equipment or the electric circuit require high safety or reliability function or performances, a sufficient reliability evaluation check for safety shall be performed before commercial shipment and moreover, due consideration to install a protective circuit is strongly recommended at customer's design stage. ■ The contents of this catalog are applicable to the products which are purchased from our sales offices or distributors (so called“ TAIYO YUDEN’s official sales channel”). It is only applicable to the products purchased from any of TAIYO YUDEN’ s official sales channel. ■ Please note that Taiyo Yuden Co., Ltd. shall have no responsibility for any controversies or disputes that may occur in connection with a third party's intellectual property rights and other related rights arising from your usage of products in this catalog. Taiyo Yuden Co., Ltd. grants no license for such rights. ■ Caution for export Certain items in this catalog may require specific procedures for export according to“ Foreign Exchange and Foreign Trade Control Law” of Japan,“ U.S. Export Administration Regulations”, and other applicable regulations. Should you have any question or inquiry on this matter, please contact our sales staff. Should you have any question or inquiry on this matter, please contact our sales staff. △!当社カタログをご使用の際には「当社製品に関するお断り」を必ずお読みください。 9 △!Please read the "Notice for TAIYO YUDEN products" before using this catalog. 3

SMDインダクタ( 低背タイプ) SMD INDUCTORS LOW PROFILE TYPE ー25〜+120℃( 製品自己発熱含む) OPERATING TEMP (Inducting self-generated heat) 特長 FEATURES ・小型、低背インダクタ ・Small and Low profile inductor. ・大電流に対応 ・It corresponds to High current. ・シンプルで独自な磁気シールド構造 ・Simple and original magnetic shield structure. ・耐落下衝撃に強い構造 ・Structure strong against a shock-proof. 用途 APPLICATIONS ・携帯電話、HDD、DVC、DSC、PDA、液晶ディスプレイ等の小型DC/DC For small DC/DC converter( cellular Phone, HDD,DVC, DSC, PDA, LCD コンバータ用途 display etc). 形名表記法 ORDERING CODE 1 2 3 5 形式 外径寸法(W×L×H) 梱包 インダクタンス許容差 NR△, NRG 外装樹脂仕様 例 T△ テーピング M ±20% △=スペース 3010 3.0×3.0×1.0mm △=スペース N ±30% 3012 3.0×3.0×1.2mm 3015 3.0×3.0×1.5mm 6 4010 4.0×4.0×1.0mm 4012 4.0×4.0×1.2mm 当社管理番号 4018 4.0×4.0×1.8mm △ 標準品 4026 4.0×4.0×2.6mm 4 △=スペース 6012 6.0×6.0×1.2mm 公称インダクタンス〔μH〕 6020 6.0×6.0×2.0mm 例 6028 6.0×6.0×2.8mm 2R2 2.2 6045 6.0×6.0×4.5mm 100 010.000 8040 8.0×8.0×4.0mm 101 100.000 N R △ 4 0 1 8 T △ 1 0 0 M △ 1 2 3 4 5 6 1 2 3 5 Type External dimension(s W×L×H) Packaging Inductance tolerance NR△, NRG Coating resin specification example T△ Tape and Reel M ±20% △=Blank Space 3010 3.0×3.0×1.0mm △=Blank Space N ±30% 3012 3.0×3.0×1.2mm 3015 3.0×3.0×1.5mm 6 4010 4.0×4.0×1.0mm 4012 4.0×4.0×1.2mm Internal code 4018 4.0×4.0×1.8mm △ Standard product 4026 4.0×4.0×2.6mm 4 △=Blank Space 6012 6.0×6.0×1.2mm Nominal inductance〔μH〕 6020 6.0×6.0×2.0mm example 6028 6.0×6.0×2.8mm 2R2 2.2 6045 6.0×6.0×4.5mm 100 010.000 8040 8.0×8.0×4.0mm 101 100.000 342 △!当社カタログをご使用の際には「当社製品に関するお断り」を必ずお読みください。 △!Please read the "Notice for TAIYO YUDEN products" before using this catalog.

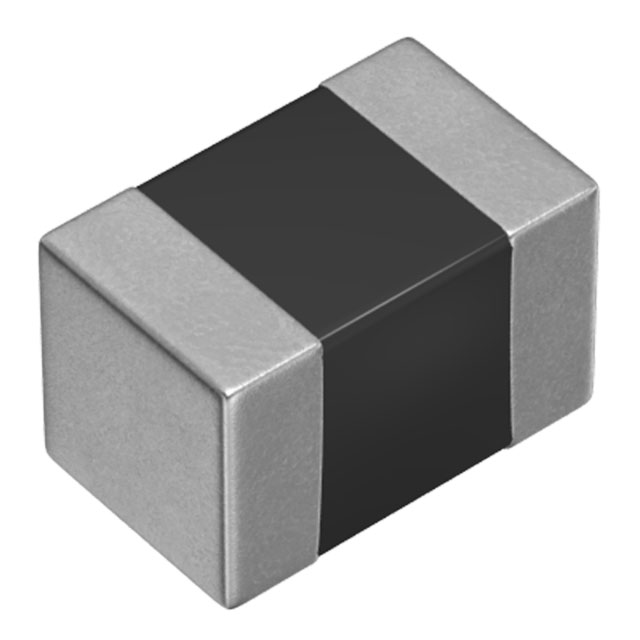

外形寸法 EXTERNAL DIMENSIONS L H L H (2.3) e e W f W f e e Δe Type L W H e f Type L W H e Δe f NR 3010 1.0 max NR 6012 6.0±0.2 6.0±0.2 1.2 max 1.35±0.2 0.3±0.2 4.0±0.2 5 (0.039 max) (E Type)(0.236±0.008)(0.236±0.008)(0.047 max)(0.053±0.008)(0.011±0.008)(0.157±0.008) 3.0±0.1 3.0±0.1 1.2 max 0.9±0.2 1.9±0.2 NR 3012 6.0±0.2 6.0±0.2 2.0 max 1.35±0.2 0.3±0.2 4.0±0.2 (0.118±0.004) (0.118±0.004) (0.047 max) (0.035±0.008) (0.075±0.008) NR 6020 F 1.5 max (0.236±0.008)(0.236±0.008)(0.078 max)(0.053±0.008)(0.011±0.008)(0.157±0.008) E NR 3015 R (0.059 max) 6.0±0.2 6.0±0.2 2.8 max 1.35±0.2 0.3±0.2 4.0±0.2 R NR 6028 1.0 max (0.236±0.008)(0.236±0.008) (0.110 max) (0.053±0.008)(0.011±0.008)(0.157±0.008) IT NR 4010 (0.039 max) E 1.2 max NR 6045 6.0±0.2 6.0±0.2 4.5 max 1.35±0.2 0.3±0.2 4.0±0.2 P NR 4012 (0.236±0.008)(0.236±0.008)(0.177 max)(0.053±0.008)(0.011±0.008)(0.157±0.008) R 4.0±0.2 4.0±0.2 (0.047 max) 1.1±0.2 2.5±0.2 O (0.157±0.008) (0.157±0.008) 1.8 max (0.043±0.008) (0.098±0.008) Unit mm(inch) D NR 4018 (0.071 max) U C NRG4026 2.6 max T (0.102 max) S *1) 4.2max 8.0±0.2 8.0±0.2 (0.165max) 1.6±0.3 5.6±0.3 NR 8040 (0.315±0.008) (0.315±0.008) *2) 4.0max (0.063±0.012) (0.220±0.012) (0.157max) *1)0R9〜6R8タイプ *2)100〜101タイプ Unit mm(inch) 推奨ランド Recommended Land Patterns 【NR3010, NR3012, NR3015】 【NR4010, NR4012, NR4018, NRG4026】 【NR6012,NR6020,NR6028,NR6045】 【NR8040】 2.2 2.8 4.7 5.6 2.7 3.7 5.7 0.8 0.8 7.5 1.2 1.2 1.6 1.6 1.8 1.8 概略バリエーション AVAILABLE INDUCTANCE RANGE Type NR3010 NR3012 NR3015 NR4010 NR4012 NR4018 NR6012 NR6020 NR6028 NR6045 NR8040 NRG4026 Range Ima[xmA]Rdc±20%[Ω]Ima[xmA]Rdc±20%[Ω]Ima[xmA]Rdc±20%[Ω]Ima[xmA]Rdc±20%[Ω]Ima[xmA]Rdc±20%[Ω]Ima[xmA]Rdc±20%[Ω]Ima[xmA]Rdc±20%[Ω]Ima[xmA]Rdc±30%[Ω]Ima[xmA]Rdc±30%[Ω]Ima[xmA]Rdc±30%[Ω]Ima[xmA]Rdc±30%[Ω]Ima[xmA]Rdc±30%[Ω] 0.8 3800 0.020 1300 0.065 1490 0.052100 0.030 1050 0.1001500 0.0601830 0.030 4600 0.0134200 0.0147800 0.0062300 0.03 1.0 3.3 1730 0.095 ] H μ [ nce 10 500 0.450 540 0.290 700 0.230 560 0.380 740 0.240840 0.1801000 0.2401400 0.1251900 0.0652500 0.0473100 0.0341300 0.085 a 950 0.290 ct u Ind 47 220 2.05 250 1.45 320 1.34 240 1.81 350 1.00 650 0.300 320 2.18 620 0.600 700 0.5001000 0.290 100 220 170 4.00 セレクションガイド アイテム一覧 特性図 梱包 信頼性 使用上の注意 Selection Guide Part Numbers Electrical Characteristics Packaging Reliability Data Precautions P.14 P.344 P.348 P.353 P.366 P.374 etc △!当社カタログをご使用の際には「当社製品に関するお断り」を必ずお読みください。 △!Please read the "Notice for TAIYO YUDEN products" before using this catalog. 343

アイテム一覧 PART NUMBERS NR 3010 シールドタイプ Shielded type EHS 公 称 インダクタンス 自己共振 直流抵抗 定格電流 ※) 測定 形 名 (Environmental インダクタンス 許容差 Se周lf-r e波so 数nant ResiDstCance Rat〔edm cAu〕rrent M周ea波su数ring Ordering code SHuabzsatardnocuess) Indu[μcHta]nce InTodluecratannccee f〔(reqMmuHienzn.)〕cy (±〔2Ω0〕%) S直a流tu重rat畳Iidoc許n1 c容ur電re流ntT温em度pe上ratu昇Idrec許 r2is容e c電urre流nt fr〔eqkuHezn〕cy NR 3 0 1 0 T 1 R 0 N RoHS 1.0 126 0.065 1,300 1,400 ±30% NR 3 0 1 0 T 1 R 5 N RoHS 1.5 98 0.080 1,200 1,300 NR 3 0 1 0 T 2 R 2 M RoHS 2.2 82 0.095 1,100 1,100 NR 3 0 1 0 T 3 R 3 M RoHS 3.3 63 0.140 870 940 NR 3 0 1 0 T 4 R 7 M RoHS 4.7 56 0.190 750 780 NR 3 0 1 0 T 6 R 8 M RoHS 6.8 46 0.300 610 630 100 NR 3 0 1 0 T 1 0 0 M RoHS 10 ±20% 35 0.450 500 510 NR 3 0 1 0 T 1 5 0 M RoHS 15 30 0.740 400 400 NR 3 0 1 0 T 2 2 0 M RoHS 22 25 1.03 350 350 NR 3 0 1 0 T 3 3 0 M RoHS 33 20 1.55 260 275 NR 3 0 1 0 T 4 7 0 M RoHS 47 17 2.05 220 235 NR 3012 シールドタイプ Shielded type EHS 公 称 インダクタンス 自己共振 直流抵抗 定格電流 ※) 測定 形 名 (Environmental インダクタンス 許容差 Se周lf-r e波so 数nant ResiDstCance Rat〔edm cAu〕rrent M周ea波su数ring Ordering code SHuabzsatardnocuess) Indu[μcHta]nce InTodluecratannccee f〔(reqMmuHienzn.)〕cy (±〔2Ω0〕%) S直a流tu重rat畳Iidoc許n1 c容ur電re流ntT温em度pe上ratu昇Idrec許 r2is容e c電urre流nt fr〔eqkuHezn〕cy NR 3 0 1 2 T 1 R 0 N RoHS 1.0 110 0.050 1,500 1,490 ±30% NR 3 0 1 2 T 1 R 5 N RoHS 1.5 92 0.060 1,360 1,400 NR 3 0 1 2 T 2 R 2 M RoHS 2.2 70 0.080 1,100 1,200 NR 3 0 1 2 T 3 R 3 M RoHS 3.3 55 0.100 910 1,050 NR 3 0 1 2 T 4 R 7 M RoHS 4.7 48 0.130 770 980 NR 3 0 1 2 T 6 R 8 M RoHS 6.8 40 0.190 670 740 100 NR 3 0 1 2 T 1 0 0 M RoHS 10 ±20% 32 0.290 540 630 NR 3 0 1 2 T 1 5 0 M RoHS 15 27 0.450 440 485 NR 3 0 1 2 T 2 2 0 M RoHS 22 22 0.630 375 420 NR 3 0 1 2 T 3 3 0 M RoHS 33 19 1.03 310 330 NR 3 0 1 2 T 4 7 0 M RoHS 47 17 1.45 250 280 NR 3015 シールドタイプ Shielded type EHS 公 称 インダクタンス 自己共振 直流抵抗 定格電流 ※) 測定 形 名 (Environmental インダクタンス 許容差 Se周lf-r e波so 数nant ResiDstCance Rat〔edm cAu〕rrent M周ea波su数ring Ordering code SHuabzsatardnocuess) Indu[μcHta]nce InTodluecratannccee f〔(reqMmuHienzn.)〕cy (±〔2Ω0〕%) S直a流tu重rat畳Iidoc許n1 c容ur電re流ntT温em度pe上ratu昇Idrec許 r2is容e c電urre流nt fr〔eqkuHezn〕cy NR 3 0 1 5 T 1 R 0 N RoHS 1.0 100 0.030 2,100 2,100 ±30% NR 3 0 1 5 T 1 R 5 N RoHS 1.5 87 0.040 1,800 1,820 NR 3 0 1 5 T 2 R 2 M RoHS 2.2 64 0.060 1,480 1,500 NR 3 0 1 5 T 3 R 3 M RoHS 3.3 49 0.080 1,210 1,230 NR 3 0 1 5 T 4 R 7 M RoHS 4.7 40 0.120 1,020 1,040 NR 3 0 1 5 T 6 R 8 M RoHS 6.8 36 0.160 870 880 100 NR 3 0 1 5 T 1 0 0 M RoHS 10 ±20% 28 0.230 700 710 NR 3 0 1 5 T 1 5 0 M RoHS 15 23 0.360 560 560 NR 3 0 1 5 T 2 2 0 M RoHS 22 20 0.520 470 470 NR 3 0 1 5 T 3 3 0 M RoHS 33 18 0.840 390 370 NR 3 0 1 5 T 4 7 0 M RoHS 47 17 1.34 320 300 ※)直流重畳許容電流(Idc1)は、直流重畳によるインダクタンス低下が30%以内となる直流電流値( at 20℃) ※)The saturation current value(Idc1) is the DC current value having inductance decrease down to 30%.( at 20℃) ※)温度上昇許容電流(Idc2)は、温度上昇が40℃となる直流電流値( at 20℃) ※)The temperature rise current value(Idc2) is the DC current value having temperature increase up to 40℃.( at 20℃) ※)定格電流値は直流重畳許容電流、または温度上昇許容電流をいずれも満足する直流電流値 ※)The rated current is the DC current value that satisfies both of current value saturation current value and temperature rise current value. 344 △!当社カタログをご使用の際には「当社製品に関するお断り」を必ずお読みください。 △!Please read the "Notice for TAIYO YUDEN products" before using this catalog.

アイテム一覧 PART NUMBERS NR 4010 シールドタイプ Shielded type EHS 公 称 インダクタンス 自己共振 直流抵抗 定格電流 ※) 測定 形 名 (Environmental インダクタンス 許容差 Se周lf-r e波so 数nant ResiDstCance Rat〔edm cAu〕rrent M周ea波su数ring Ordering code SHuabzsatardnocuess) Indu[μcHta]nce InTodluecratannccee f〔(reqMmuHienzn.)〕cy (±〔2Ω0〕%) S直a流tu重rat畳Iidoc許n1 c容ur電re流ntT温em度pe上ratu昇Idrec許 r2is容e c電urre流nt fr〔eqkuHezn〕cy NR 4 0 1 0 T 1 R 0 N RoHS 1.0 116 0.100 1,800 1,050 ±30% NR 4 0 1 0 T 2 R 2 N RoHS 2.2 73 0.150 1,150 890 NR 4 0 1 0 T 3 R 3 M RoHS 3.3 58 0.180 1,100 820 NR 4 0 1 0 T 4 R 7 M RoHS 4.7 47 0.210 900 750 NR 4 0 1 0 T 6 R 8 M RoHS 6.8 38 0.300 740 620 100 NR 4 0 1 0 T 1 0 0 M RoHS 10 31 0.380 560 600 5 NR 4 0 1 0 T 1 5 0 M RoHS 15 ±20% 24 0.510 470 510 NR 4 0 1 0 T 2 2 0 M RoHS 22 19 0.870 360 400 NR 4 0 1 0 T 3 3 0 M RoHS 33 15 1.54 280 300 FE NR 4 0 1 0 T 4 7 0 M RoHS 47 13 1.81 240 280 R R IT E NR 4012 シールドタイプ Shielded type P R EHS 公 称 インダクタンス 自己共振 直流抵抗 定格電流 ※) 測定 O 形 名 (Environmental インダクタンス 許容差 Se周lf-r e波so 数nant ResiDstCance Rat〔edm cAu〕rrent M周ea波su数ring DU Ordering code SHuabzsatardnocuess) In[duμcHta]nce InTodluecratannccee f〔(reqMmuHienzn.)〕cy (±〔2Ω0〕%) S直a流tu重rat畳Iidoc許n1 c容ur電re流ntT温em度pe上ratu昇Idrec許 r2is容e c電urre流nt fr〔eqkuHezn〕cy CTS NR 4 0 1 2 T 1 R 0 N RoHS 1.0 ±30% 131 0.060 2,500 1,500 NR 4 0 1 2 T 2 R 2 M RoHS 2.2 66 0.090 1,650 1,200 NR 4 0 1 2 T 3 R 3 M RoHS 3.3 50 0.130 1,200 980 NR 4 0 1 2 T 4 R 7 M RoHS 4.7 45 0.140 1,050 960 NR 4 0 1 2 T 6 R 8 M RoHS 6.8 35 0.180 900 840 NR 4 0 1 2 T 1 0 0 M RoHS 10 ±20% 28 0.240 740 770 100 NR 4 0 1 2 T 1 5 0 M RoHS 15 23 0.400 560 600 NR 4 0 1 2 T 2 2 0 M RoHS 22 18 0.480 510 540 NR 4 0 1 2 T 3 3 0 M RoHS 33 15 0.810 400 420 NR 4 0 1 2 T 4 7 0 M RoHS 47 12 1.00 350 370 NR 4018 シールドタイプ Shielded type EHS 公 称 インダクタンス 自己共振 直流抵抗 定格電流 ※) 測定 形 名 (Environmental インダクタンス 許容差 Se周lf-r e波so 数nant ResiDstCance Rat〔edm cAu〕rrent M周ea波su数ring Ordering code SHuabzsatardnocuess) In[duμcHta]nce InTodluecratannccee f〔(reqMmuHienzn.)〕cy (±〔2Ω0〕%) S直a流tu重rat畳Iidoc許n1 c容ur電re流ntT温em度pe上ratu昇Idrec許 r2is容e c電urre流nt fr〔eqkuHezn〕cy NR 4 0 1 8 T 1 R 0 N RoHS 1.0 ±30% 80 0.030 4,000 1,830 NR 4 0 1 8 T 2 R 2 M RoHS 2.2 52 0.060 2,700 1,440 NR 4 0 1 8 T 3 R 3 M RoHS 3.3 44 0.070 2,000 1,230 NR 4 0 1 8 T 4 R 7 M RoHS 4.7 34 0.090 1,700 1,200 NR 4 0 1 8 T 6 R 8 M RoHS 6.8 29 0.110 1,450 1,060 NR 4 0 1 8 T 1 0 0 M RoHS 10 24 0.180 1,200 840 NR 4 0 1 8 T 1 5 0 M RoHS 15 19 0.250 940 650 100 NR 4 0 1 8 T 2 2 0 M RoHS 22 ±20% 16 0.360 800 590 NR 4 0 1 8 T 3 3 0 M RoHS 33 12 0.530 650 490 NR 4 0 1 8 T 4 7 0 M RoHS 47 10 0.650 570 420 NR 4 0 1 8 T 6 8 0 M RoHS 68 8.3 1.00 470 320 NR 4 0 1 8 T 1 0 1 M RoHS 100 6.5 1.50 400 270 NR 4 0 1 8 T 1 5 1 M RoHS 150 5.5 2.50 310 220 NR 4 0 1 8 T 2 2 1 M RoHS 220 4.0 4.00 270 170 ※)直流重畳許容電流(Idc1)は、直流重畳によるインダクタンス低下が30%以内となる直流電流値( at 20℃) ※)The saturation current value(Idc1) is the DC current value having inductance decrease down to 30%.( at 20℃) ※)温度上昇許容電流(Idc2)は、温度上昇が40℃となる直流電流値( at 20℃) ※)The temperature rise current value(Idc2) is the DC current value having temperature increase up to 40℃.( at 20℃) ※)定格電流値は直流重畳許容電流、または温度上昇許容電流をいずれも満足する直流電流値 ※)The rated current is the DC current value that satisfies both of current value saturation current value and temperature rise current value. △!当社カタログをご使用の際には「当社製品に関するお断り」を必ずお読みください。 △!Please read the "Notice for TAIYO YUDEN products" before using this catalog. 345

アイテム一覧 PART NUMBERS NR 6012 シールドタイプ Shielded type EHS 公 称 インダクタンス 自己共振 直流抵抗 定格電流 ※) 測定 形 名 (Environmental インダクタンス 許容差 Se周lf-r e波so 数nant ResiDstCance Rat〔edm cAu〕rrent M周ea波su数ring Ordering code SHuabzsatardnocuess) In[duμcHta]nce InTodluecratannccee f〔(reqMmuHienzn.)〕cy (±〔2Ω0〕%) S直a流tu重rat畳Iidoc許n1 c容ur電re流ntT温em度pe上ratu昇Idrec許 r2is容e c電urre流nt fr〔eqkuHezn〕cy NR 6 0 1 2 T 2 R 5 NE RoHS 2.5 45 0.090 2,100 1,730 ±30% NR 6 0 1 2 T 4 R 0 NE RoHS 4.0 39 0.105 1,800 1,570 NR 6 0 1 2 T 5 R 3 ME RoHS 5.3 34 0.110 1,500 1,400 NR 6 0 1 2 T 6 R 8 ME RoHS 6.8 30 0.165 1,300 1,180 NR 6 0 1 2 T 1 0 0 ME RoHS 10 22 0.235 1,000 1,000 NR 6 0 1 2 T 1 5 0 ME RoHS 15 18 0.330 800 790 100 NR 6 0 1 2 T 2 2 0 ME RoHS 22 ±20% 12 0.530 760 630 NR 6 0 1 2 T 3 3 0 ME RoHS 33 8 0.700 590 530 NR 6 0 1 2 T 4 7 0 ME RoHS 47 6 1.05 520 460 NR 6 0 1 2 T 6 8 0 ME RoHS 68 3 1.35 440 410 NR 6 0 1 2 T 1 0 1 ME RoHS 100 1 2.18 350 320 NR 6020 シールドタイプ Shielded type 自己共振 定格電流 ※) 直流抵抗 測定 EHS 公称 インダクタンス 周波数 Rated current 形名 DC 周波数 (Environmental インダクタンス 許容差 Self-resonant [mA] Resistance Measuring Hazardous Inductance Inductance frequency 直流重畳飽和電流 温度上昇電流 Ordering code [Ω] frequency Substances) [μH] Tolerance [MHz] Saturation current Temperature rise current (±30%) [kHz] min (Idc1) (Idc2) NR 6020T 0R8N RoHS 0.8 110 0.020 5,500 3,800 NR 6020T 1R5N RoHS 1.5 93 0.026 4,000 3,200 NR 6020T 2R2N RoHS 2.2 73 0.034 3,200 2,700 ±30% NR 6020T 3R3N RoHS 3.3 55 0.040 2,800 2,600 100 NR 6020T 4R7N RoHS 4.7 43 0.058 2,400 2,000 NR 6020T 6R8N RoHS 6.8 30 0.085 2,000 1,800 NR 6020T 100M RoHS 10 18 0.125 1,700 1,400 ±20% NR 6020T 220M RoHS 22 11 0.290 1,050 950 NR 6028 シールドタイプ Shielded type EHS 公 称 インダクタンス 自己共振 直流抵抗 定格電流 ※) 測定 形 名 (Environmental インダクタンス 許容差 Se周lf-r e波so 数nant ResiDstCance Rat〔edm cAu〕rrent M周ea波su数ring Ordering code SHuabzsatardnocuess) In[duμcHta]nce InTodluecratannccee f〔(reqMmuHienzn.)〕cy (±〔3Ω0〕%) S直a(流⊿tuL重ra/Lt畳i≦o許n- 3c容0u%r電re)流ntT温em度p (e⊿上ratTu昇≦re許 r4is0容e℃ c電u)rre流nt fr〔eqkuHezn〕cy NR 6028T 0R9N RoHS 0.9 90 0.013 6,600 4,600 NR 6028T 1R5N RoHS 1.5 78 0.016 5,000 4,200 ±30% NR 6028T 2R2N RoHS 2.2 68 0.020 4,200 3,700 NR 6028T 3R0N RoHS 3.0 55 0.023 3,600 3,400 NR 6028T 4R7M RoHS 4.7 39 0.031 2,700 3,000 NR 6028T 6R0M RoHS 6.0 30 0.040 2,500 2,500 NR 6028T 100M RoHS 10 20 0.065 1,900 1,900 100 NR 6028T 150M RoHS 15 17 0.095 1,600 1,800 NR 6028T 220M RoHS 22 ±20% 12 0.135 1,300 1,400 NR 6028T 330M RoHS 33 10 0.220 1,100 1,100 NR 6028T 470M RoHS 47 8 0.300 950 920 NR 6028T 680M RoHS 68 5 0.420 760 770 NR 6028T 101M RoHS 100 3 0.600 620 660 ※)直流重畳許容電流(Idc1)は、直流重畳によるインダクタンス低下が30%以内となる直流電流値( at 20℃) ※)The saturation current value(Idc1) is the DC current value having inductance decrease down to 30%.( at 20℃) ※)温度上昇許容電流(Idc2)は、温度上昇が40℃となる直流電流値( at 20℃) ※)The temperature rise current value(Idc2) is the DC current value having temperature increase up to 40℃.( at 20℃) ※)定格電流値は直流重畳許容電流、または温度上昇許容電流をいずれも満足する直流電流値 ※)The rated current is the DC current value that satisfies both of current value saturation current value and temperature rise current value. 346 △!当社カタログをご使用の際には「当社製品に関するお断り」を必ずお読みください。 △!Please read the "Notice for TAIYO YUDEN products" before using this catalog.

アイテム一覧 PART NUMBERS NR 6045 シールドタイプ Shielded type 自己共振 直流抵抗 定格電流 ※) 測定 EHS 公称 インダクタンス 周波数 Rated current 形名 DC 周波数 (Environmental インダクタンス 許容差 Self-resonant [mA] Resistance Measuring Hazardous Inductance Inductance frequency 直流重畳飽和電流 温度上昇電流 Ordering code [Ω] frequency Substances) [μH] Tolerance [MHz] Saturation current Temperature rise current min (±30%) (Idc1) (Idc2) [kHz] NR 6045T 1R0N RoHS 1.0 110 0.014 8,500 4,200 NR 6045T 1R3N RoHS 1.3 95 0.016 8,000 4,000 NR 6045T 1R8N RoHS 1.8 ±30% 80 0.018 7,000 3,700 NR 6045T 2R3N RoHS 2.3 60 0.021 6,000 3,500 NR 6045T 3R0N RoHS 3.0 45 0.024 5,000 3,200 5 NR 6045T 4R5M RoHS 4.5 25 0.031 4,000 3,000 NR 6045T 6R3M RoHS 6.3 15 0.038 3,800 2,800 100 F NR 6045T 100M RoHS 10 12 0.047 3,000 2,500 E NR 6045T 150M RoHS 15 10 0.077 2,300 1,900 R R NR 6045T 220M RoHS 22 ±20% 7 0.115 1,900 1,500 IT NR 6045T 330M RoHS 33 6 0.145 1,500 1,400 E NR 6045T 470M RoHS 47 5 0.220 1,300 1,100 P R NR 6045T 680M RoHS 68 4 0.330 1,000 900 O NR 6045T 101M RoHS 100 3 0.500 800 700 D U C T S NR 8040 シールドタイプ Shielded type EHS 公 称 インダクタンス 自己共振 直流抵抗 定格電流 ※) 測定 形 名 (Environmental インダクタンス 許容差 Se周lf-r e波so 数nant ResiDstCance Rat〔edm cAu〕rrent M周ea波su数ring Ordering code SHuabzsatardnocuess) In[duμcHta]nce InTodluecratannccee f〔(reqMmuHienzn.)〕cy (±〔3Ω0〕%) S直a流tu重rat畳Iidoc許n1 c容ur電re流ntT温em度pe上ratu昇Idrec許 r2is容e c電urre流nt fr〔eqkuHezn〕cy NR 8 0 4 0 T 0 R9 N RoHS 0.9 85 0.006 11,000 7,800 NR 8 0 4 0 T 1 R 4 N RoHS 1.4 63 0.007 9,000 7,000 NR 8 0 4 0 T 2 R 0 N RoHS 2.0 50 0.009 7,400 6,300 ±30% NR 8 0 4 0 T 3 R 6 N RoHS 3.6 34 0.015 5,300 4,900 NR 8 0 4 0 T 4 R 7 N RoHS 4.7 30 0.018 4,700 4,100 NR 8 0 4 0 T 6 R 8 N RoHS 6.8 24 0.025 4,000 3,700 NR 8 0 4 0 T 100M RoHS 10 22 0.034 3,400 3,100 100 NR 8 0 4 0 T 150M RoHS 15 16 0.050 2,700 2,400 NR 8 0 4 0 T 220M RoHS 22 13 0.066 2,200 2,200 NR 8 0 4 0 T 330M RoHS 33 ±20% 12 0.100 1,900 1,700 NR 8 0 4 0 T 470M RoHS 47 8 0.150 1,500 1,400 NR 8 0 4 0 T 680M RoHS 68 7 0.230 1,200 1,100 NR 8 0 4 0 T 101M RoHS 100 6 0.290 1,000 1,000 NRG4026 シールドタイプ Shielded type 自己共振 定格電流 ※) 直流抵抗 測定 公称 インダクタンス 周波数 Rated current 形名 DC 周波数 インダクタンス 許容差 Self-resonant [mA] Resistance Measuring Inductance Inductance frequency 直流重畳飽和電流 温度上昇電流 Ordering code [Ω] frequency [μH] Tolerance [MHz] Saturation current Temperature rise current (±30%) [kHz] min (Idc1) (Idc2) NRG4026 T 1R2N 1.2 120 0.030 3,100 2,300 ±30% NRG4026 T 2R3N 2.3 96 0.040 2,100 1,970 NRG4026 T 3R5M 3.5 58 0.050 1,800 1,700 NRG4026 T 4R7M 4.7 46 0.055 1,450 1,600 NRG4026 T 6R6M 6.6 33 0.065 1,300 1,500 100 NRG4026 T 100M 10 26 0.085 1,000 1,300 ±20% NRG4026 T 150M 15 19 0.110 900 1,100 NRG4026 T 220M 22 13 0.165 610 900 NRG4026 T 330M 33 9 0.200 540 800 NRG4026 T 470M 47 6 0.300 410 650 ※)直流電流許容電流(Idc1)は、直流重畳によるインダクタンス低下が30%以内となる直流電流値( at 20℃) ※)The saturation current(Idc1) is DC current value Inductance decrease down to 30%.( at 20℃) ※)温度上昇許容電流(Idc2)は、温度上昇が40℃となる直流電流値( at 20℃) ※)The temperature rise current value(Idc2) is the DC current value having temperature increase up to 40℃.( at 20℃) ※)定格電流はIdc2です。 ※)The rated current is Idc2. △!当社カタログをご使用の際には「当社製品に関するお断り」を必ずお読みください。 △!Please read the "Notice for TAIYO YUDEN products" before using this catalog. 347

特性図 ELECTRICAL CHARACTERISTICS 直流重畳特性例 DC Bias characteristics(Measured by HP4285A) NR 3010 NR 3012 NR 3015 NR 4010 100 100 100 100 470M 470M 470M 470M 〕 220M 〕 220M 〕 220M 〕 220M μH μH μH μH 〔Inductance 10 100M 〔Inductance 10 100M 〔Inductance 10 100M 〔Inductance 10 100M 4R7M 4R7M 4R7M 4R7M 2R2M 2R2M 2R2M 2R2N 1 1 1 1 10 100 1,000 10,000 10 100 1,000 10,000 10 100 1,000 10,000 10 100 1,000 10,000 DC Bia〔smA〕 DC Bia〔smA〕 DC Bia〔smA〕 DC Bia〔smA〕 NR 4012 NR 4018 NR 6012(E Type) NR 6020 100 1000 1000 100 470M 221M 220M 〔μ〕InductanceH 10 212000MM 〔μ〕InductanceH 100 412702010MMM 〔μ〕InductanceH 100 241270001MMM 〔μ〕InductanceH 10 1420RR072MMM 10 100M 10 100M 1 4R7M 0R8N 5R3M 4R7M 2R2M 2R2M 1 1 1 0.1 10 100 1,000 10,000 10 100 1,000 10,000 10 100 1,000 10,000 10 100 1,000 10,000 DC Bia〔smA〕 DC Bia〔smA〕 DC Bia〔smA〕 DC Bia〔smA〕 NR 6028 NR 6045 NR 8040 NRG 4026 1000 1000 1000 100 470M 100 100 100 101M 101M 101M 〕 470M 〕 470M 〕 470M μ〕H 220M 〔μInductanceH 10 12420R007MM 〔μInductanceH 10 421R20005MMN 〔μInductanceH 10 421R20007MMN 〔Inductance 10 100M N 1 2R2 1 2R3N 1 2R0N 4R7M 0R9 1R0N 0R9N 2R3N 0.110 100 1,000 10,000 0.110 100 1,000 10,000 100,000 0.110 100 1,000 10,000 100,000 110 100 1,000 10,000 DC Bia〔smA〕 DC Bia〔smA〕 DC Bia〔smA〕 DC Bia〔smA〕 348 △!当社カタログをご使用の際には「当社製品に関するお断り」を必ずお読みください。 △!Please read the "Notice for TAIYO YUDEN products" before using this catalog.

梱包 PACKAGING ①最小受注単位数 Minimum Quantity (2)エンボステープ(12mm幅) Embossed tape(0.47 inches wide) 標準数量[個] 形式 Standard Quantity[ pcs] Type テーピング (φ01..055ー+900ー+ .1 00 .0 0 4 ) チCッHプIP 装ca入vi部ty (10.7.056±90±.10.004)TK Tape & Reel ) NNNNRRRR 3344000011112205 5224000500000000 B A ±5.50.1(±0.2170.004±12.00.3(±)0.4720.012 NR 4018 3500 F 電極位置(裏面) 5 NR 6012 1000 2.0±0.1 4.0±0.1 Electrode(bottom view) (0.079±0.004)(0.157±0.004) NR 6020 2500 F NR6028 2000 E R NR 6045 1500 チップ挿入部 挿入ピッチ テープ厚み R NR 8040 1000 IT 形式 Insertion E Type Chip cavity pitch Tape thickness P R A B F T K O ②テーピング材質 Tape Material 4.3±0.1 4.3±0.1 8.0±0.1 0.3±0.05 1.4±0.1 D NR 4010 U (0.169±0.004)(0.169±0.004)(0.315±0.004)(0.012±0.002)(0.055±0.004) C T 4.3±0.1 4.3±0.1 8.0±0.1 0.3±0.05 1.6±0.1 S NR 4012 (0.169±0.004)(0.169±0.004)(0.315±0.004)(0.012±0.002)(0.063±0.004) 4.3±0.1 4.3±0.1 8.0±0.1 0.3±0.05 2.1±0.1 NR 4018 (0.169±0.004)(0.169±0.004)(0.315±0.004)(0.012±0.002)(0.083±0.004) 4.3±0.1 4.3±0.1 8.0±0.1 0.3±0.05 3.1±0.1 NRG 4026 (0.169±0.004)(0.169±0.004)(0.315±0.004)(0.012±0.002)(0.122±0.004) 6.3±0.1 6.3±0.1 8.0±0.1 0.4±0.1 1.6±0.1 NR 6012 (0.248±0.004)(0.248±0.004)(0.315±0.004)(0.016±0.004)(0.063±0.004) 6.3±0.1 6.3±0.1 8.0±0.1 0.4±0.1 2.3±0.1 NR 6020 (0.248±0.004)(0.248±0.004)(0.315±0.004)(0.016±0.004)(0.090±0.004) 6.3±0.1 6.3±0.1 8.0±0.1 0.4±0.1 3.1±0.1 NR 6028 (0.248±0.004) (0.248±0.004) (0.315±0.004) (0.016±0.004) (0.122±0.004) 6.3±0.1 6.3±0.1 8.0±0.1 0.4±0.1 4.7±0.1 NR 6045 (0.248±0.004)(0.248±0.004)(0.315±0.004)(0.016±0.004)(0.185±0.004) Unit:mm(inch) (3)エンボステープ(16mm幅) Embossed tape(0.63 inches wide) 2.0±0.1 (0.079±0.004) (0.φ0519.5±±00.0.104) F (0.145.07±±00..1004) チCッHプIP 装ca入vi部ty (0.10.6795±±00..0104) TK ) ③テーピング寸法 Taping dimensions ±16.00.3(±0.6300.012 B (1)エンボステープ(8mm幅) Embossed tape(0.315 inches wide) A (0.279.55±±00..1004) 電極位置(裏面) Electrode(bottom view) (φ01..055ー+900ー+ .1 00 .0 0 4 ) チCッHプIP 装ca入vi部ty (10.7.056±90±.10.004)TK ) チップ挿入部 挿入ピッチ テープ厚み B A ±3.50.1(±0.1380.004±8.00.2(±)0.3150.008 形Ty p 式e 8.3±AC 0h.i1p ca8v.i3ty±B 0.1 1In2se.0rtioF±n p0it.c1h 0.5T±Ta p0e.1 t hic4k.n5e±sKs 0.1 NR 8040 (0.327±0.004)( 0.327±0.004)( 0.472±0.004) (0.020±0.004)( 0.177±0.004) F 電極位置(裏面) 2.0±0.05 4.0±0.1 Electrode(bottom view) Unit:mm(inch) (0.079±0.002)(0.157±0.004) チップ挿入部 挿入ピッチ テープ厚み 形 式 Chip cavity Insertion pitch Tape thickness Type A B F T K 3.2±0.1 3.2±0.1 4.0±0.1 0.3±0.05 1.4±0.1 NR 3010 (0.126±0.004)( 0.126±0.004)( 0.157±0.004) (0.012±0.002)( 0.055±0.004) 3.2±0.1 3.2±0.1 4.0±0.1 0.3±0.05 1.6±0.1 NR 3012 (0.126±0.004)( 0.126±0.004)( 0.157±0.004) (0.012±0.002)( 0.063±0.004) 3.2±0.1 3.2±0.1 4.0±0.1 0.3±0.05 1.9±0.1 NR 3015 (0.126±0.004)( 0.126±0.004)( 0.157±0.004) (0.012±0.002)( 0.075±0.004) Unit:mm(inch) △!当社カタログをご使用の際には「当社製品に関するお断り」を必ずお読みください。 △!Please read the "Notice for TAIYO YUDEN products" before using this catalog. 353

梱包 PACKAGING ④リーダー部・空部 Leader and Blank portion ⑤リール寸法 Reel size W 2±0.5 (1)NR 3010, NR 3012, NR 3015 空部 チップ装着部 リーダー部 Blank portions Chip cavity Leader φd φD φ13±0.5 2.5以下 (0.098inches or Less) 280mm以上 600mm〜700mm (11.0 inches or more) (23.6 inches to 27.6 inches) リール寸法 Reel size〔mm〕 形 式 1400mm〜1600mm (参考値 Reference values) (55.1 inches to 63.0 inches) Type φD φd w 引き出し方向 Direction of tape feed 180±0.5 60±1.0 10.0±1.5 NR 3010 (7.087±0.019) (2.36±0.04) ( 0.394±0.059) 180±0.5 60±1.0 10.0±1.5 (2)NR 4010, NR 4012, NR 4018 NR 3 012 (7.087±0.019) (2.36±0.04) ( 0.394±0.059) 180±0.5 60±1.0 10.0±1.5 空部 チップ装着部 リーダー部 NR 3015 Blank portions Chip cavity Leader (7.087±0.019) (2.36±0.04) ( 0.394±0.059) 180±3.0 60±2.0 14.0±1.5 NR6012 (7.087±0.019) (2.36±0.08) ( 0.551±0.059) Unit:mm(inch) 280mm以上 1100mm〜1200mm (11.0 inches or more) (43.3 inches to 47.2 inches) 2000mm〜2200mm W (78.7 inches to 86.6 inches) 2±0.5 引き出し方向 Direction of tape feed φd φD (3)NR 6012 φ13±0.5 空部 チップ装着部 リーダー部 Blank portions Chip cavity Leader t リール寸法 Reel size[mm] 形式 80mm以上 104mm〜136mm (参考値 Reference values) (3.14 inches or more) (4.09 inches to 5.35 inches) Type φD φd t( max) w 330±3.0 80±2.0 18.5 13.5±1.0 408mm〜536mm NR4010 (16.1 inches to 21.1 inches) (12.99±0.118)(3.15±0.078) (0.72) (0.531±0.04) 引き出し方向 330±3.0 80±2.0 18.5 13.5±1.0 Direction of tape feed NR4012 (12.99±0.118)(3.15±0.078) (0.72) (0.531±0.04) 330±3.0 80±2.0 18.5 13.5±1.0 NR4018 (12.99±0.118)(3.15±0.078) (0.72) (0.531±0.04) (4)NR 6020, NR 6028, NR 6045, NR 8040 330±3.0 80±2.0 18.5 13.5±1.0 NRG4026 (12.99±0.118)(3.15±0.078) (0.72) (0.531±0.04) 空部 チップ装着部 空部 リーダー部 Blank portions Chip cavity Blank portions Leader 330±3.0 80±2.0 18.5 13.5±1.0 NR6020 (12.99±0.118)(3.15±0.078) (0.72) (0.531±0.04) 330±3.0 80±2.0 18.5 13.5±1.0 NR6028 (12.99±0.118) (3.15±0.078) (0.72) (0.531±0.04) 330±3.0 80±2.0 18.5 13.5±1.0 NR6045 160mm以上 100mm以上 (12.99±0.118)(3.15±0.078) (0.72) (0.531±0.04) (6.3inches or more) (6.3inches or more) 330±3.0 80±2.0 22.5 17.5±1.0 NR8040 400mm以上 (12.99±0.118)(3.15±0.078) (0.89) (0.689±0.04) (15.75inches or more) Unit : mm( inch) 引き出し方向 Direction of tape feed ⑥トップテープ強度 Top Tape Strength トップテープのはがし力は、下図矢印方向にて0.1〜0.7Nとなります。 The top tape requires a peel-off force of 0.1 to 0.7N in the direction of the arrow as illus trated below. 354 △!当社カタログをご使用の際には「当社製品に関するお断り」を必ずお読みください。 △!Please read the "Notice for TAIYO YUDEN products" before using this catalog.

RELIABILITY DATA 1/4 Specifled Value Item BRC16B0R8L,2 B5R1L82, 0B1R2L,3 B2R2C52016, NRH24, NR30/40/60/80, NR10050 Type Test Method and Remarks Type NRG40 Type 1.Operating Temperature −25℃〜+105℃ −25℃〜+120℃ −25℃〜+105℃ Including self-generated heat Range 2.Storage Temperature −40℃〜+85℃ BRC1608,BRL2012,BRC2016,BRL2518,BRL3225Type, Range NRH24, NR30/40/60/80, NRG4026Type :0 to 40℃ for the product with taping. NR10050 Type:0 〜40℃ for the product with taping. 5 3.Rated current Within the specified tolerance The maximum DC value having inductance decrease within specified value and temperature increase within 40℃ by the application of DC bias. F E Inductance decrease R R BRC1608,BRL2012,BRC2016,BRL2518, BRL3225Type, IT NRH24, NR30/40/60/80,NRG40Type, NR10050Type E 30% P R 4.Inductance Within the specified tolerance BRC1608,BRL2012,BRC2016,BRL2518,BRL3225Type O LCR Meter:HP 4285A or equivalent, Measuring frequency:Specified frequency D U NRH24, NR30/40/60/80, NRG4026Type : C LCR Meter:HP 4285A or equivalent, 100KHz, 1V T S NR10050Type:LCR Meter:HP 4263A or equivalent, 100KHz, 1V 5.DC Resistance Within the specified tolerance DC ohmmeter:HIOKI 3227 or equivalent 6.Self resonance frequency Within the specification BRC1608,BRL2012,BRC2016,BRL2518,BRL3225Type, NRH24, NR30/40/60/80Type, NR10050Type: Inpedance analyzer/material analyzer:HP4291A or equivalent HP4191A, 4192A or equivalent 7.Temperature characteristic BRL2012, BRC2016, Inductance change: BRC1608,BRL2012,BRC2016,BRL2518,BRL3225Type, BRL2518, BRL3225 Within±20% NRH24, NR30/40/60/80, NRG4026Type , NR10050Type: Inductance change: Measurement of inductance shall be taken at temperature Within±15% range within −25℃〜+85℃. With reference to inductance value at +20℃., change rate BRC1608 shall be calculated. Inductance change: Change of maximum inductance deviation in step 1 to 5 Within±20% Temperature at step 1 20℃ Temperature at step 2 Minimum operating temperature Temperature at step 3 20℃(Standard temperature) Temperature at step 4 Maximum oparating temperature Temperature st step 5 20℃ 8.Resistance to flexure of No damage. BRC1608,BRL2012,BRC2016,BRL2518,BRL3225Type, substrate NRH24, NR30/40/60/80, NRG4026Type : The test samples shall be soldered to the test board by the reflow . As illustrated below, apply force in the direction of the arrow indicating until deflection of the test board reaches to 2 mm. Test board size:100×40×1.0 Test board material:glass epoxy-resin Solder cream thickness:0.15(BR Series) 0.10(NR Series) Land dimension(BRC1608) Land dimension(BRC2016) 1.0 1.8 0.550.80.55 0.70.80.7 Land dimension(B RL2012) Lan d dimension(BRL2518) 1.4 1.95 0.65 0.9 0.65 0.651.50.65 Land dimension(BRL3225) Land dimension(NRH24) 2.7 2.4 1.0 1.6 1.0 0.80.80.8 Land dimension(NR30) Land dimension(NR40) 2.7 3.7 0.81.40.8 1.21.61.2 Land dimension(NR60) Land dimension(NR80) 5.7 7.5 1.153.71.15 1.83.81.8 Force Rod10 20 R230 Board Printed board thickness: 1.0mm R5 45±2mm 4Te5s±t S2ammpmle Unit:mm 9.Insulation resistance: between wires 10.Insulation resistance: between wire and core 11.Withstanding voltage: between wires and core △!当社カタログをご使用の際には「当社製品に関するお断り」を必ずお読みください。 △!Please read the "Notice for TAIYO YUDEN products" before using this catalog. 367

RELIABILITY DATA 2/4 Specifled Value 12.Adhesion of terminal electrodeItem BRC16B0R8L,2 B5R1L82, 0B1R2L,3 B2R2C52016, NRH24, NR30/40/60/80, NR10050 Type Test Method and Remarks Type NRG40 Type Shall not come off PC board. BRC1608,BRL2012,BRC2016,BRL2518, BRL3225Type, NRH24, NR30/40/60/80, NRG40Type : The test samples shall be soldered to the test board by the reflow. pplied force:10N to X and Y directions. Duration:5s. 5 Solder cream thickness:0.15mm. 10N, 5s F E R R NR10050Type: IT Applied force:5N to X and Y directions. Duration:5s. E P R O D U C 13.Resistance to vibration Inductance change:Within±10% BRC1608,BRL2012,BRC2016,BRL2518, T S No significant abnormality in appearance. BRL3225Type, NRH24, NR30/40/60/80, NRG40Type, NR10050Type: The test samples shall be soldered to the test board by the reflow. Then it shall be submitted to below test conditions. Frequency Range 10〜55Hz 1.5mm(May not exceed Total Amplitude acceleration 196 m/S2) Sweeping Method 10Hz to 55Hz to 10 Hz for 1 min. X For 2 hours on each X, Time Y Y, and Z axis. Z Recovery:At least 2hrs of recovery under the standard con- dition sfter the test, followed by the measurement within 48 hrs. 14.Solderability At least 90%of surface of terminal electrode is BRC1608,BRL2012,BRC2016,BRL2518, covered by new solder. BRL3225Type, NRH24, NR30/40/60/80, NRG40Type, NR10050Type: The test samples shall be dipped in flux, and then im- mersed in molten solder as shown in below table Flux:Methanol solution containing rosin 25%. NRH24, NR30/40/60/80Type,NR10050 Type : Solder Temperature 245±5℃ Time 5±1.0sec BRC1608,BRL2012,BRC2016,BRL2518,BRL3225Type: Solder Temperature 245±5℃ Time 5±0.5sec ※Immersion depth:All sides of mounting terminal shall be immersed. △!当社カタログをご使用の際には「当社製品に関するお断り」を必ずお読みください。 △!Please read the "Notice for TAIYO YUDEN products" before using this catalog. 369

RELIABILITY DATA 3/4 Specifled Value Item BRC1608, BRL2012, BRC2016, Test Method and Remarks BRL2518, BRL3225 NRH24, NR30/40/60/80, NR10050 Type Type NRG40 Type 15.Resistance to soldering Inductance change:Within±10% BRC1608,BRL2012,BRC2016,BRL2518,BRL3225Type: heat No significant abnormality in appearance. 3 times of reflow oven at 230℃MIN for 40 sec. with peak temperature at 260+−05℃ for 5 sec. NRH24, NR30/40/6012・6028・6045/80, NRG40Type, NR10050 Type: 5 The test sample shall be exposed to reflow oven at 230± 5℃ for 40 seconds, with peak temperature at 260±5℃ F E for 5 seconds, 2 times. R NR6020Type: R The test sample shall be exposed to reflow oven at 230± IT E 5℃ for 40 seconds, with peak temperature at 250+−50℃ P for 5 seconds, 2 times. R O Test board thickness:1.0 mm D Test board material : glass epoxy-resin U C T S 16.Thermal shock Inductance change:Within±10% BRC1608,BRL2012,BRC2016,BRL2518, No significant abnormality in appearance. BRL3225Type, NRH24, NR30/40/60/80, NRG40Type, NR10050 Type: The test samples shall be soldered to the test board by the reflow. The test samples shall be placed at specified temperature for specified time by step 1 to step 4 as shown in below table in sequence. The temperature cycle shall be repeated 100 cycles. Conditions of 1 cycle Step Temperature(℃) Duration(min) 1 −40±3 30±3 2 Room temperature Within 3 3 +85±2 30±3 4 Room temperature Within 3 17.Damp heat Inductance change:Within±10% BRC1608,BRL2012,BRC2016,BRL2518,BRL3225Type: No significant abnormality in appearance. Temperature 60±2℃ Humidity 90〜95%RH Time 1000 hours. Recovery :At least 2hrs of recovery under the standard condition after the test, followed by the measurement within 48 hrs. NRH24, NR30/40/60/80, NRG40Type: The test samples shall be soldered to the test board by the reflow. The test samples shall be placed in thermostatic oven set at specified temperature and humidity as shown in below table. Temperature 60±2℃ Humidity 90〜95%RH Time 500±24hour △!当社カタログをご使用の際には「当社製品に関するお断り」を必ずお読みください。 △!Please read the "Notice for TAIYO YUDEN products" before using this catalog. 371

RELIABILITY DATA 4/4 Specifled Value Item BRC1608, BRL2012, BRC2016, Test Method and Remarks BRL2518, BRL3225 NRH24, NR30/40/60/80, NR10050 Type Type NRG40 Type 18.Loading under damp Inductance change:Within±10% BRC1608,BRL2012,BRC2016,BRL2518,BRL3225Type: heat No significant abnormality in appearance. Temperature 60±2℃ Humidity 90〜95%RH Applied current Rated current Time 1000hours. Recovery :At least 2hrs of recovery under the standard 5 condition after the test, followed by the measurement within 48 hrs. F NRH24, NR30/40/60/80, NRG40Type, NR10050 Type: E R The test samples shall be soldered to the test board R by the reflow. IT E The test samples shall be placed in thermostatic oven P set at specified temperature and humidity and applied R the rated current continuously as shown in below O table. D Temperature 60±2℃ U C Humidity 90〜95%RH T Applied current Rated current S Time 500±2hour 19.Low temperature life test Inductance change:Within±10% BRC1608,BRL2012,BRC2016,BRL2518,BRL3225Type: No significant abnormality in appearance. Temperature ー40±2℃ Duration 1000hours Recovery :At least 2hrs of recovery under the standard condition after the test, followed by the measurement within 48 hrs. NRH24, NR30/40/60/80, NRG40Type, NR10050 Type: The test samples shall be soldered to the test board by the reflow. After that, the test samples shall be placed at test conditions as shown in below table. Temperature −40±3℃ Time 500±24hour 20.High temperature life Inductance change: Inductance change: BRC1608,BRL2012,BRC2016,BRL2518,BRL3225Type: test Within±10% Within±10% Temperature 85±2℃ No significant abnormality in No significant abnormality in Duration 1000hours appearance. appearance. Recovery :At least 2hrs of recovery under the standard condition after the test, followed by the measurement within 48 hrs. NR10050 Type: Temperature 105±3℃ Time 500±24hour Recovery :At least 2hrs of recovery under the standard condition after the test, followed by the measurement within 48 hrs. 21.Loading at high Inductance change: NRH24, NR30/40/60/80, NRG40Type: temperature life test Within±10% The test samples shall be soldered to the test board No significant abnormality in by the reflow soldering appearance. Temperature 85±2℃ Applied current Rated current Time 500±24hour 22.Standard condition Standard test condition:Unless otherwise specified, temperature is 20±15% and 65±20%of relative humidity. When there are question concerning measurement result : In order to provide correlation date, the test shall be condition of 20±2℃ of temperature, 65±5% relative humidity. Inductance is in accordance with our measured value. △!当社カタログをご使用の際には「当社製品に関するお断り」を必ずお読みください。 △!Please read the "Notice for TAIYO YUDEN products" before using this catalog. 373

PRECAUTIONS SMD Inductors Stages Precautions Technical considerations 1.Circuit Design Operating environment, 1.The products described in this specification are intended for use in general electronic equipment,(office supply equipment, telecommunications systems, measuring equipment, and household equipment). They are not intended for use in mission-critical equipment or systems requiring special quality and high reliability (traffic systems, safety equipment, aerospace systems, nuclear control systems and medical equipment including life-support systems,) where product failure might result in loss of life, injury or damage. For such uses, contact TAIYO YUDEN Sales Department in advance. 5 2.PCB Design Land pattern design Surface Mounting 1.Please refer to a recommended land pattern. ・ Mounting and soldering conditions should be checked beforehand. ・ Applicable soldering process to this products is reflow soldering only. 3.Considerations for Adjustment of mounting machine 1. When installing products, care should be taken not to apply distortion stress as it F automatic placement 1.Excessive impact load should not be imposed on the may deform the products. E products when mounting onto the PC boards. R R 2.Mounting and soldering conditions should be checked beforehand. IT 4.Soldering R1.ePflleoaws es ocldoenrtiancgt any of our offices for a reflow soldering, and 1.Imf paryo ddeufcotrsm a rteh eu sperodd buecytos,n adn tdh ec orannsgeeq uoefn tthlye dreecgoramdme ethned eredl icaobnilidtyit ioofn tsh, eh pearot dsutrcetsss.es E P refer to the recommended condition specified. 【BRC1608, BRL2012, BRL2518, BRC2016, BRL3225Type】 R 23..TPhleisa sper oddou cntost isa dredf laonwy ssotrldeessri ntgo oan plyr.oduct until it returns in Recommended reflow condition( Pb free solder) OD L1e.Wrnuaeosdhser eimfs rntetaa heuln e stcsmeionem gldtpa oepef rtsrrieonoardgtl duucerceorti nsna fgfwitr emhitreh irna eltgef,la osdowo flf drseaeoedrldi hnseegors lideniotegcnr. i,sn ugtfe,f imwciepe enrertlaqyt.uuerest toof [℃]mperature321000000 150〜1980±030sec 3203±0℃10 5msseiencc mPaexak:260+5/ー0℃ UCTS Recommended conditions for using a soldering iron: Te ( NR10050 type) 0 Heating Time【sec】 Put the soldering iron on the land-pattern. 【NRH24, NR30/40/60/80Type】 Soldering iron's temperature - Below 350 ℃ Recommended reflow condition( Pb free solder) DThuera stioolnd e-r i3n gs eircoonn sdhso ourl dle nssot directly touch the inductor. ]300 5sec max [℃mperature210000 150〜19800±30sec 3203±0℃10 mseinc Peak:250+5/ー0℃ Te 0 Heating Time【sec】 【NR10050Type】 Recommended reflow condition( Pb free solder) ]300 5sec max [℃mperature210000 150〜19800±30sec 3203±0℃10 mseinc Peak:250+5/ー0℃ Te 0 Heating Time【sec】 5.Cleaning Cleaning conditions 1.Washing by supersonic waves shall be avoided. 1.If washing by supersonic waves, supersonic waves may cause broken products. 6.Handling Handling 1.Keep the product away from all magnets and magnetic objects. Breakaway PC boards (splitting along perforations) 1.When splitting the PC board after mounting product, care 1.Planning pattern configurations and the position of products should be carefully should be taken not to give any stresses of deflection or performed to minimize stress. twisting to the board. 2.Board separation should not be done manually, but by using the appropriate devices. Mechanical considerations 1.Please do not give the product any excessive mechanical shocks. 1.There is a case to be damaged by a mechanical shock. 2.Please do not add any shock and power to a product in 2.There is a case to be broken by the handling in transportation. transportation. Pick-up pressure 1.Please do not push to add any pressure to a winding part. 1.Damage and a characteristic can vary with an excessive shock or stress. Please do not give any shock and push into a ferrite core exposure part. Packing 1.Please avoid accumulation of a packing box as much as possible. 1.There is a case that transformation and a product of tape are damaged by accumulation of a packing box. 7.Storage conditions Storage 1.To maintain the solderability of terminal electrodes and to 1.Under a high temperature and humidity environment, problems such as reduced keep the packing material in good condition, temperature solderability caused by oxidation of terminal electrodes and deterioration of and humidity in the storage area should be controlled. taping/packaging materials may take place. ・Recommended conditions Ambient temperature 0〜40℃ Humidity Below 70% RH The ambient temperature must be kept below 30℃. Even under ideal storage conditions, solderability of products electrodes may decrease as time passes. For this reason, product should be used within 6 months from the time of delivery. In case of storage over 6 months, solderability shall be checked before actual usage. △!当社カタログをご使用の際には「当社製品に関するお断り」を必ずお読みください。 △!Please read the "Notice for TAIYO YUDEN products" before using this catalog. 375

Datasheet下载

Datasheet下载

,NRG4026%20Series%20Bottom.jpg)

,NRG4026%20Series%20Top.jpg)