- 型号: MS3106E14S-2S

- 制造商: Amphenol

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

MS3106E14S-2S产品简介:

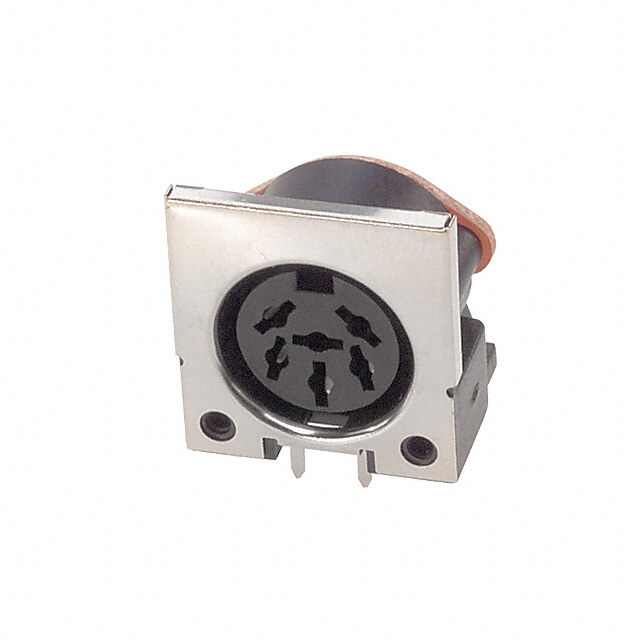

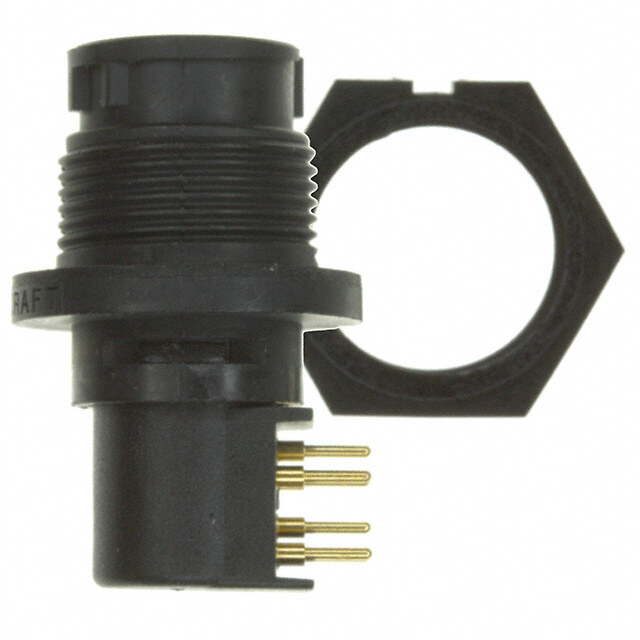

ICGOO电子元器件商城为您提供MS3106E14S-2S由Amphenol设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 MS3106E14S-2S价格参考¥138.35-¥223.80。AmphenolMS3106E14S-2S封装/规格:圆形连接器, 4 位置 圆形连接器 插头,母型插口 焊杯 银。您可以下载MS3106E14S-2S参考资料、Datasheet数据手册功能说明书,资料中有MS3106E14S-2S 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | CONN PLUG 4POS STRAIGHT W/SCKT环形MIL规格连接器 4P #16 SKT CONTACTS |

| 产品分类 | |

| 品牌 | Amphenol Industrial |

| MIL类型 | MIL-DTL-5015 |

| 产品手册 | |

| 产品图片 |

|

| rohs | 否含铅 / 不符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 环形MIL规格连接器,环形MIL规格连接器,Amphenol Industrial MS3106E14S-2SMIL-5015 衍生 |

| 数据手册 | |

| 产品型号 | MS3106E14S-2S |

| 产品培训模块 | http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=25050http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=25182 |

| 产品种类 | MS3106 Cable Mount Straight Plugs |

| 产品类型 | Plugs |

| 位置数量 | 4 |

| 侵入防护 | 抗环境影响 |

| 其它名称 | MS3106E14S-2S-ND |

| 包装 | 散装 |

| 商标 | Amphenol Industrial |

| 商标名 | 5015 |

| 外壳大小 | 14 |

| 外壳尺寸-插件 | 14S-2 |

| 外壳尺寸,MIL | - |

| 外壳材料,镀层 | 铝合金, 草绿色,镀镉 |

| 外壳材质 | Aluminum Alloy |

| 外壳电镀 | Olive Drab Chromate over Cadmium |

| 外壳类型 | In-Line |

| 安装类型 | 自由悬挂 |

| 安装角 | Straight |

| 安装风格 | Free Hanging |

| 工作温度 | -55°C ~ 125°C |

| 插入安排 | 14S-2 |

| 朝向 | N(正常型) |

| 标准包装 | 1 |

| 特性 | - |

| 电压-额定 | 200VAC,250VDC |

| 电压额定值 | 250 V |

| 电流额定值 | 13 A |

| 端接 | 焊杯 |

| 端接类型 | Solder |

| 系列 | MS 5015 |

| 紧固类型 | 有螺纹 |

| 线规 | 16-20 |

| 触头镀层 | 银 |

| 触头镀层厚度 | - |

| 触点电镀 | Silver |

| 触点类型 | Socket (Female) |

| 连接器类型 | 插头,母型插口 |

| 配套产品 | /product-detail/zh/MS3100E14S-2P/AMS3100E14S-2P-ND/2114651/product-detail/zh/MS3102E14S-2P/AMS3102E14S-2P-ND/378613 |

| 针脚数 | 4 |

| 零件号别名 | MS31O6E14S-2S |

| 额定电流 | - |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

None

Table of Contents Page Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Amphenol® MIL-DTL-5015 and MIL-5015 Type Standard Cylindrical Connectors General Information, Class Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 MS-A, MS-C General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 MS3100A or C wall mounting receptacle . . . . . . . . . . . . . . . . . . . . . . . . . 5 MS3101A cable connecting plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 MS3102A or C box mounting receptacle . . . . . . . . . . . . . . . . . . . . . . . . . 7 MS3106A straight plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 MS3108A 90 degree plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 MS-E/F General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 MS3100E/F wall mounting receptacle . . . . . . . . . . . . . . . . . . . . . . . . . 11 MS3101E/F cable connecting plug . . . . . . . . . . . . . . . . . . . . . . . . . . 12 MS3102E box mounting receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . 13 MS3106E/F straight plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 MS3108E 90 degree plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 MS-R General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 MS3100R wall mounting receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . 17 MS3101R cable connecting plug. . . . . . . . . . . . . . . . . . . . . . . . . . . 18 MS3102R box mounting receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . 19 MS3106R straight plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Contact and Insert Arrangements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 MS/Standard insert arrangement charts . . . . . . . . . . . . . . . . . . . . . . . 22, 23 MS/Standard special insert arrangement chart . . . . . . . . . . . . . . . . . . . . . . 24 MS/Standard alternate positioning . . . . . . . . . . . . . . . . . . . . . . . . . . 25 MS/Standard contact arrangements. . . . . . . . . . . . . . . . . . . . . . . . . 26 – 37 MS/Standard special contact arrangements . . . . . . . . . . . . . . . . . . . . . . 38 – 48 MS/Standard thermocouple contact arrangements . . . . . . . . . . . . . . . . . . . . 49 – 53 MS/Standard Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 MS3057A cable clamp, MS3420 sleeve. . . . . . . . . . . . . . . . . . . . . . . . . 55 10-305200 cable clamp, MS3420( )A sleeve. . . . . . . . . . . . . . . . . . . . . . . 56 10-350349 cable clamp, MS3420( )A sleeve. . . . . . . . . . . . . . . . . . . . . . . 57 10-74900 cable clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 Thru-bulkhead shells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59, 60 Assembly instructions for 10-305200 and 10-74900 cable clamps . . . . . . . . . . . . . . . . 61 Grommet/sealing plugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 Plug protection caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 Receptacle protection caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64 Dust caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 Sealing gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 Solder contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67 Crimp contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 MS/Standard Application Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69 MS/Standard How to Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 Additional MS/Standard Connectors offered by Amphenol Matrix® MIL-DTL-5015 with crimp rear release contacts, MIL-5015 Type Modification Connectors, 97 Series (5015 type) Connectors, Pre-Earth FMLB Connectors . . . . . . . . . . . . . . . . . 71 Amphe-Power® 5015 Connectors (AC threaded series with high amperage RADSOK® contacts), MIL-5015 Connectors with PCB contacts . . . . . . . . . . . . . . . . . . . . . . . . 72 Sales Office Listing 1

This catalog covers Amphenol® MIL-DTL-5015 connectors and MIL-5015 type connectors. MIL-C-5015 has been replaced as follows: Environmental Classes F and R are updated to and produced in strict accordance to MIL-DTL-5015. Classes A, C and E are still produced, but are no longer listed on the qualified products listing (QPL). Amphenol gives the user the largest selection of MS/Standard cylindrical connectors available in the market place. This catalog is divided into three sections; the first section by service class, a second section by contacts and insert arrangements, and a third section for accessories. Each section is prefixed with an overview to assist the user in determining selections. Should more information be required concerning the connectors covered in this publication, or if special application needs arise, please contact: Amphenol Corporation Amphenol Industrial Operations 40-60 Delaware Avenue Sidney, New York 13838-1395 Telephone 607-563-5011 Fax: 607-563-5157 www.amphenol-industrial.com Now, also offered within the broad family of Amphenol interconnection products is the Amphenol®/Matrix® MIL-DTL-5015* connector series which incorporates rear release crimp contacts. See page 71 for further description and for complete details ask for catalog 12-026. Also ask for these additional product catalogs: (cid:127) Amphenol Industrial Connector Brochure, SL-381, for an overview of the industrial family of connectors. (cid:127) Amphenol Catalog SL-100, which provides an overview of all prod- ucts, military and industrial, offered through Amphenol Aerospace. (cid:127) Amphenol Amphe-Power ® Brochure SL-391, for AC 5015 type con- nectors with RADSOK® high amperage contacts. See reference on page 72. * Note: MIL-C-5015 is superceded to MIL-DTL-5015 for all Amphenol/Matrix rear release crimp type connectors. Amphenol Aerospace operates Quality Systems that are Certified to ISO-9001 and AS-9100 by third party Registrars. 2

Amphenol® MIL-DTL-5015 and MIL-5015 Type Standard Cylindrical Connectors DESIGN CHARACTERISTICS • Medium to heavy weight cylindrical (cid:127) Durable, field-proven design (cid:127) Environmental resistant (cid:127) Resilient inserts (cid:127) Operating voltage to 3000 VAC (RMS) at sea level (cid:127) Threaded couplings (cid:127) Single key/keyway shell polarization (cid:127) Cost effective CUSTOMER OPTIONS (cid:127) Five shell styles (cid:127) Nineteen shell sizes (cid:127) 305 contact arrangements from 1 to 104 circuits (cid:127) Solder or crimp contacts, sizes 16-0 accepting MS-A, MS-C 22-0 AWG. (cid:127) Coaxial and thermocouple contact options (cid:127) Five class designations (cid:127) Alternate insert positioning (cid:127) Hermetic configurations available (cid:127) Zinc alloy plating (cadmium-free) available MS connectors meet the latest performance require- ments of MIL-DTL-5015. These connectors represent well-proven electrical capability at an acceptable cost for most equipment where durability is important. MIL-DTL-5015 features threaded couplings and single key/keyway polarization, representing maximum simplic- ity in design. Applications include military ground support MS-E/F equipment, ordnance and shipboard installations. Amphenol Industrial Operations manufactures five classes of connectors to meet different requirements. Class designations and brief descriptions are listed below. A – Solid Shell – for general, non-environmental appli- cations. C – Pressurized – for use on pressurized bulkheads or pressure barriers; limits air leakage regardless of type and class of plug mated with them. E/F –Environmental Resisting with Strain Relief – designed for applications where the connector will be exposed to moisture, vibration, and rapid changes in pressure and temperature. MS-R R – Lightweight Environmental Resisting – shorter in length and lighter in weight than the E and F classes, the MS-R offers a high degree of reliability under adverse conditions: recommended for new design applications. 3

MS/Standard MS-A and MS-C MS-A and MS-C MS-A and MS-C class connectors perform many of the vital functions in powering, testing and ground support systems. Class A applications include communications equipment, computers and shipboard installations where mechanical forces and physical parameters are not sub- ject to extreme or rapid environmental changes. Class C connectors are most frequently used on pressur- wall mounting receptacle ized bulkheads or pressure barriers at elevated altitudes or maritime applications. Air leakage is limited to one cubic inch per hour at a pressure differential of 30 lbs. per square inch. Shells: Shell components are fabricated from high grade alumi- num alloy. Electrically conductive cadmium plate finish with an olive drab chromate after-treat offers corrosion cable connecting plug resistance. Contacts: Contacts are available in both solder and crimp versions. Pins and sockets are machined from copper alloy with a silver plated finish. Size 16 and 12 socket contacts incor- porate a closed entry design. Refer to pages 49, 67 and 68 for additional contact information. Inserts: Inserts are resilient neoprene, offering high dielectric box mounting receptacle strength, high arc resistance and resistance to vibration. Proprietary design permits pressurization of either pin or socket insert. straight plug 90 degree plug 4

MS/Standard MS3100A or C wall mounting receptacle S R L A V Thread Thread S R B T 4 Holes M Z K To complete order number, see “how to order” pg. 70. For solder well data, see page 67. B T A Min K M Dia. V Z Shell Thread Full +.020 L +.010 R S +.004 Thread +.050 Size Class 2A Thread –.010 ±.030 –.000 ±.005 ±.031 –.002 Class 2A –.060 8S .5000-28UNEF .391 .672 1.391 .562 .594 .875 .120 .5000-28UNEF .422 10S .6250-24 UNF .391 .672 1.468 .562 .719 1.000 .120 .5000-28UNEF .422 10SL .6250-24 UNF .391 .672 1.468 .562 .719 1.000 .120 .6250-24NEF .422 12S .7500-20UNEF .450 .672 1.468 .562 .812 1.094 .120 .6250-24NEF .422 12 .7500-20UNEF .625 .860 1.843 .750 .812 1.094 .120 .6250-24NEF .672 14S .8750-20UNEF .450 .672 1.468 .562 .906 1.188 .120 .7500-20UNEF .422 14 .8750-20UNEF .625 .860 1.843 .750 .906 1.188 .120 .7500-20UNEF .672 16S 1.0000-20UNEF .450 .672 1.468 .562 .969 1.281 .120 .8750-20UNEF .422 16 1.0000-20UNEF .625 .860 1.843 .750 .969 1.281 .120 .8750-20UNEF .672 18 1.1250-18NEF .625 .891 1.938 .750 1.063 1.375 .120 1.0000-20UNEF .641* 20 1.2500-18NEF .625 .891 1.844 .750 1.156 1.500 .120 1.1875-18NEF .641* 22 1.3750-18NEF .625 .891 1.938 .750 1.250 1.625 .120 1.1875-18NEF .641* 24 1.5000-18NEF .625 .953 1.969 .812 1.375 1.750 .147 1.4375-18NEF .578* 28 1.7500-18NS .625 .953 2.188 .812 1.562 2.000 .147 1.4375-18NEF .578* 32 2.0000-18NS .625 1.031 2.157 .875 1.750 2.250 .173 1.7500-18NS .500* 36 2.2500-16UN .625 1.031 2.219 .875 1.938 2.500 .173 2.0000-18NS .500* 40 2.5000-16UN .625 1.031 2.188 .875 2.188 2.750 .173 2.2500-16UN .500* 44*** 2.7500-16UN .625 1.031† 2.547 .875 2.375 3.000†† .173 2.5000-16UN .751** 48*** 3.0000-16UN .625 1.031† 2.547 .875 2.625 3.000†† .173 3.0000-16UN .751** *Increase Z dimension by.312 for size “0” contact only. **Increase Z dimension by.062 for size “0” contact only. ***Available in proprietary version only. † +.020 –.030 ††±.020 5

MS/Standard MS3101A cable connecting plug L N B V Thread A Thread Z To complete order number, see “how to order” pg. 70. For solder well data, see page 67. B A Min. N V Shell Thread Full L Dia. Thread Z Size Class 2A Thread ±.030 Max. Class 2A ±.040 8S .5000-28UNEF .406 1.390 .532 .5000-28UNEF 1.094 10S .6250-24NEF .406 1.468 .628 .5000-28UNEF 1.094 10SL .6250-24NEF .406 1.468 .755 .6250-24NEF 1.094 12S .7500-20UNEF .422 1.468 .755 .6250-24NEF 1.094 12 .7500-20UNEF .656 1.843 .755 .6250-24NEF 1.532 14S .8750-20UNEF .391 1.468 .882 .7500-20UNEF 1.094 14 .8750-20UNEF .625 1.843 .882 .7500-20UNEF 1.532 16S 1.0000-20UNEF .391 1.468 1.010 .8750-20UNEF 1.094 16 1.0000-20UNEF .625 1.843 1.010 .8750-20UNEF 1.532 18 1.1250-18NEF .625 1.938 1.137 1.0000-20UNEF 1.532* 20 1.2500-18NEF .625 1.844 1.264 1.1875-18NEF 1.532* 22 1.3750-18NEF .625 1.938 1.392 1.1875-18NEF 1.532* 24 1.5000-18NEF .625 1.969 1.519 1.4375-18NEF 1.532* 28 1.7500-18NS .625 2.188 1.774 1.4375-18NEF 1.532* 32 2.0000-18NS .625 2.157 1.996 1.7500-18NS 1.532* 36 2.2500-16UN .625 2.219 2.251 2.0000-18NS 1.532* 40 2.5000-16UN .625 2.188 2.506 2.2500-16UN 1.532* 44*** 2.7500-16UN .625 2.521 3.135 2.5000-16UN 1.782** * Increase Z dimension by.312 for size “0” contact only. ** Increase Z dimension by.062 for size “0” contact only. ***Available in proprietary version only. 6

MS/Standard MS3102A or C box mounting receptacle S R B A Thread S R N T 4 Holes M L K Z To complete order number, see “how to order” pg. 70. For solder well data, see page 67. B N T A Min K L M Dia. Dia. Z Shell Thread Full +.020 +.000 +.010 +.010 R S +.004 +.050 Size Class 2A Thread –.010 –.010 –.000 –.000 ±.005 ±.031 –.002 –.060 8S .5000-28UNEF .391 .672 .297 .562 .375 .594 .875 .120 .422 10S .6250-24NEF .391 .672 .297 .562 .500 .719 1.000 .120 .422 10SL .6250-24NEF .391 .672 .297 .562 .625 .719 1.000 .120 .422 12S .7500-20UNEF .450 .672 .297 .562 .625 .812 1.094 .120 .422 12 .7500-20UNEF .625 .860 .484 .750 .625 .812 1.094 .120 .672 14S .8750-20UNEF .450 .672 .297 .562 .750 .906 1.188 .120 .422 14 .8750-20UNEF .625 .860 .484 .750 .750 .906 1.188 .120 .672 16S 1.0000-20UNEF .450 .672 .297 .562 .875 .969 1.281 .120 .422 16 1.0000-20UNEF .625 .860 .484 .750 .875 .969 1.281 .120 .672 18 1.1250-18NEF .625 .891 .453 .750 1.000 1.062 1.375 .120 .641* 20 1.2500-18NEF .625 .891 .453 .750 1.125 1.156 1.500 .120 .641* 22 1.3750-18NEF .625 .891 .453 .750 1.250 1.250 1.625 .120 .641* 24 1.5000-18NEF .625 .953 .453 .812 1.375 1.375 1.750 .147 .578 28 1.7500-18NS .625 .953 .453 .812 1.625 1.562 2.000 .147 .578* 32 2.0000-18NS .625 1.031 .438 .875 1.875 1.750 2.250 .173 .500* 36 2.2500-16UN .625 1.031 .438 .875 2.062 1.938 2.500 .173 .500* 40 2.5000-16UN .625 1.031 .438 .875 2.312 2.188 2.750 .173 .500* 44*** 2.7500-16UN .625 1.063 .543† .875 2.594 2.375 3.000†† .173 .768** 48*** 3.0000-16UN .625 1.063 .543† .875 2.812 2.625 3.250†† .209 .769** *Increase Z dimension by.312 for size “0” contact only. **Increase Z dimension by.062 for size “0” contact only. ***Available in proprietary version only. † +.020 –.030 ††±.020 7

MS/Standard MS3106A straight plug L J Z Q V A Thread Thread To complete order number, see “how to order” pg. 70. For solder well data, see page 67. All lockwire holes are .045 dia. min. A Q V Shell Thread J L Dia. Thread Z Size Class 2B ±.005 ±.030 Max. Class 2A ±.045 8S .5000-28UNEF .531 .859 .741 .5000-28UNEF .562 10S .6250-24NEF .531 .937 .869 .5000-28UNEF .562 10SL .6250-24NEF .531 .937 .946 .6250-24NEF .562 12S .7500-20UNEF .531 .937 .995 .6250-24NEF .562 12 .7500-20UNEF .719 1.124 .995 .6250-24NEF .812 14S .8750-20UNEF .531 .937 1.123 .7500-20UNEF .562 14 .8750-20UNEF .719 1.124 1.123 .7500-20UNEF .812 16S 1.0000-20UNEF .531 .937 1.250 .8750-20UNEF .562 16 1.0000-20UNEF .719 1.124 1.250 .8750-20UNEF .812 18 1.1250-18NEF .719 1.219 1.333 1.0000-20UNEF .812* 20 1.2500-18NEF .719 1.125 1.461 1.1875-18NEF .812* 22 1.3750-18NEF .719 1.219 1.588 1.1875-18NEF .812* 24 1.5000-18NEF .719 1.251 1.715 1.4375-18NEF .812* 28 1.7500-18NS .719 1.470 1.968 1.4375-18NEF .812* 32 2.0000-18NS .719 1.439 2.209 1.7500-18NS .812* 36 2.2500-16UN .719 1.500 2.463 2.0000-18NS .812* 40 2.5000-16UN .719 1.469 2.719 2.2500-16UN .812* 44*** 2.7500-16UN .719 1.818† 3.084 2.5000-16UN 1.063** 48*** 3.3000-16UN .719 1.818† 3.354 3.0000-16UN 1.063** * Increase Z dimension by.312 for size “0” contact only. ** Increase Z dimension by.062 for size “0” contact only. ***Available in proprietary version only. † +.020 –.030 8

MS/Standard MS3108A 90 degree plug L Z J Q A Thread U W V Thread To complete order number, see “how to order” pg. 70. For solder well data, see page 67. All lockwire holes are .045 dia. min. A Q V Shell Thread J L Dia. U Thread Z Size Class 2B ±.005 Max. Max. Max. Class 2A W ±.045 8S .5000-28UNEF .531 .896 .741 .750 .5000-28UNEF .375 .562 10S .6250-24NEF .531 .927 .869 .750 .5000-28UNEF .375 .562 10SL .6250-24NEF .531 .951 .946 .875 .6250-24NEF .375 .562 12S .7500-20UNEF .531 .956 .995 .875 .6250-24NEF .375 .562 12 .7500-20UNEF .719 1.143 .995 .875 .6250-24NEF .375 .812 14S .8750-20UNEF .531 1.120 1.123 1.000 .7500-20UNEF .375 .562 14 .8750-20UNEF .719 1.207 1.123 1.000 .7500-20UNEF .375 .812 16S 1.0000-20UNEF .531 1.146 1.250 1.062 .8750-20UNEF .375 .562 16 1.0000-20UNEF .719 1.332 1.250 1.062 .8750-20UNEF .375 .812 18 1.1250-18NEF .719 1.395 1.333 1.188 1.0000-20UNEF .375 .812* 20 1.2500-18NEF .719 1.645 1.461 1.250 1.1875-18NEF .375 .812* 22 1.3750-18NEF .719 1.645 1.588 1.312 1.1875-18NEF .375 .812* 24 1.5000-18NEF .719 1.896 1.715 1.438 1.4375-18NEF .375 .812* 28 1.7500-18NS .719 1.896 1.968 1.500 1.4375-18NEF .375 .812* 32 2.0000-18NS .719 2.118 2.209 1.750 1.7500-18NS .438 .812* 36 2.2500-16UN .719 2.176 2.463 1.875 2.0000-18NS .500 .812* 40 2.5000-16UN .719 2.301 2.719 2.031 2.2500-16UN .500 .812* *Increase Z dimension by.312 for size “0” contact only. 9

MS/Standard MS-E/F MS-E & F MS Class F connectors satisfy all the performance requirements of MIL-DTL-5015. Class E, environmental is also produced, but is no longer listed on the qualified products listing (QPL). These connectors are recom- mended for conditions where vibration, moisture, pres- sure and/or temperature are extreme. Strain relief is supplied on most shell sizes. Shells: wall mounting receptacle Shell components are fabricated from high grade alumi- num alloy. The standard hardware plating is electrically conductive cadmium plated finish with an olive drab chro- mate after-treatment for corrosion resistance. Consult Amphenol, Sidney, NY for other plating options. Contacts: Contacts are silver plated copper alloy for maximum cor- rosion resistance, maximum current carrying capacity and low millivolt drop. Size 16 and 12 socket contacts cable connecting plug incorporate a closed entry design. Crimp and solder ver- sions are available. Refer to pages 49, 67 and 68 for additional contact information. Inserts: Resilient neoprene inserts provide an outstanding mois- ture barrier, high dielectric strength, and resistance to vibration. Either pin or socket insert can be pressurized. Strain Relief Clamp: box mounting receptacle Strain relief clamps minimize tension at the solder well connection and provide a positive mechanical moisture seal. Complete field serviceability is possible with the strain relief clamp. straight plug 90 degree plug 10

MS/Standard MS3100E/F wall mounting receptacle S L R A Thread S R XX P B T 4 Holes M K Z To complete order number, see “how to order” pg. 70. For solder well data, see page 67. B T XX A Min. K M Dia. Min. Shell Thread Full +.020 L +.010 P R S +.004 Z* Cable Size Class 2A Thread –.010 Max. –.000 Max. ±.005 ±.010 –.002 Max. Clearance 10SL .6250-24UNEF .391 .672 2.129 .562 .896 .719 1.000 .120 .472 .281 12S .7500-20UNEF .450 .672 2.129 .562 .896 .812 1.094 .120 .472 .281 12 .7500-20UNEF .625 .860 2.129 .750 .896 .812 1.094 .120 .722 .281 14S .8750-20UNEF .450 .672 2.201 .562 1.021 .906 1.188 .120 .472 .406 14 .8750-20UNEF .625 .860 2.524 .750 1.021 .906 1.188 .120 .722 .406 16S 1.0000-20UNEF .450 .672 2.201 .562 1.151 .969 1.281 .120 .472 .500 16 1.0000-20UNEF .625 .860 2.524 .750 1.151 .969 1.281 .120 .722 .500 18 1.1250-18UNEF .625 .891 2.596 .750 1.242 1.063 1.375 .120 .691 .531 20 1.2500-18UNEF .625 .891 2.654 .750 1.499 1.156 1.500 .120 .691 .656 22 1.3750-18UNEF .625 .891 2.654 .750 1.499 1.250 1.625 .120 .691 .740 24 1.5000-18UNEF .625 .953 2.885 .812 1.781 1.375 1.750 .147 .628 .781 28 1.7500-18UNS .625 .953 2.885 .812 1.781 1.562 2.000 .147 .628 .922 32 2.0000-18UNS .625 1.031 2.943 .875 2.087 1.750 2.250 .173 .550 1.156 36 2.2500-16UN .625 1.031 2.943 .875 2.281 1.938 2.500 .173 .550 1.250 40 2.5000-16UN .625 1.031 3.068 .875 2.581 2.188 2.750 .173 .550 1.562 * Increase Z dimension by.312 for size “0” contact only. 11

MS/Standard MS3101E/F cable connecting plug L A Thread XX J B Z To complete order number, see “how to order” pg. 70. For solder well data, see page 67. B XX A Min. Min. Shell Thread Full J L Z* Cable Size Class 2A Thread Max. Max. Max. Clearance 10SL .6250-24UNEF .406 .896 2.129 1.134 .281 12S .7500-20UNEF .422 .896 2.129 1.134 .281 12 .7500-20UNEF .656 .896 2.129 1.572 .281 14S .8750-20UNEF .391 1.021 2.201 1.134 .406 14 .8750-20UNEF .625 1.021 2.524 1.572 .406 16S 1.0000-20UNEF .391 1.151 2.201 1.134 .500 16 1.0000-20UNEF .625 1.151 2.524 1.572 .500 18 1.1250-18UNEF .625 1.242 2.596 1.572 .531 20 1.2500-18UNEF .625 1.499 2.654 1.572 .656 22 1.3750-18UNEF .625 1.499 2.654 1.572 .740 24 1.5000-18UNEF .625 1.781 2.885 1.572 .781 28 1.7500-18UNS .625 1.781 2.885 1.572 .922 32 2.0000-18UNS .625 2.087 2.943 1.572 1.156 36 2.2500-16UN .625 2.281 2.943 1.572 1.250 40 2.5000-16UN .625 2.581 3.068 1.572 1.562 * Increase Z dimension by.312 for size “0” contact only. 12

MS/Standard MS3102E box mounting receptacle S R B A Thread S R N T 4 Holes M L K Z To complete order number, see “how to order” pg. 70. For solder well data, see page 67. B N T A Min. K L M Dia. Dia. Z Shell Thread Full +.020 +.000 +.010 +.010 R S +.004 +.050 Size Class 2A Thread –.010 –.010 –.000 –.000 ±.005 ±.031 –.002 –.060 8S .5000-28UNEF .391 .672 .297 .562 .375 .594 .875 .120 .422 10S .6250-24NEF .391 .672 .297 .562 .500 .719 1.000 .120 .422 10SL .6250-24NEF .391 .672 .297 .562 .625 .719 1.000 .120 .422 12S .7500-20UNEF .450 .672 .297 .562 .625 .812 1.094 .120 .422 12 .7500-20UNEF .625 .860 .484 .750 .625 .812 1.094 .120 .672 14S .8750-20UNEF .450 .672 .297 .562 .750 .906 1.188 .120 .422 14 .8750-20UNEF .625 .860 .484 .750 .750 .906 1.188 .120 .672 16S 1.0000-20UNEF .450 .672 .297 .562 .875 .969 1.281 .120 .422 16 1.0000-20UNEF .625 .860 .484 .750 .875 .969 1.281 .120 .672 18 1.1250-18NEF .625 .891 .453 .750 1.000 1.062 1.375 .120 .641* 20 1.2500-18NEF .625 .891 .453 .750 1.125 1.156 1.500 .120 .641* 22 1.3750-18NEF .625 .891 .453 .750 1.250 1.250 1.625 .120 .641* 24 1.5000-18NEF .625 .953 .453 .812 1.375 1.375 1.750 .147 .578* 28 1.7500-18NS .625 .953 .453 .812 1.625 1.562 2.000 .147 .578* 32 2.0000-18NS .625 1.031 .438 .875 1.875 1.750 2.250 .173 .500* 36 2.2500-16UN .625 1.031 .438 .875 2.062 1.938 2.500 .173 .500* 40 2.5000-16UN .625 1.031 .438 .875 2.312 2.188 2.750 .173 .500* *Increase Z dimension by.312 for size “0” contact only. 13

MS/Standard MS3106E/F straight plug L Q Z B A Thread J XX To complete order number, see “how to order” pg. 70. For solder well data, see page 67. All lockwire holes are .045 dia. min. XX A Min. Shell Thread B J L Q Z* Cable Size Class 2A ±.005 Max. Max. Max. ±.045 Clearance 10SL .6250-24UNEF .531 .896 2.129 .946 .607 .281 12S .7500-20UNEF .531 .896 2.129 .995 .607 .281 12 .7500-20UNEF .719 .896 2.129 .995 .857 .281 14S .8750-20UNEF .531 1.021 2.201 1.123 .607 .406 14 .8750-20UNEF .719 1.021 2.524 1.123 .857 .406 16S 1.0000-20UNEF .531 1.151 2.201 1.250 .607 .500 16 1.0000-20UNEF .719 1.151 2.524 1.250 .857 .500 18 1.1250-18UNEF .719 1.242 2.596 1.333 .857 .531 20 1.2500-18UNEF .719 1.499 2.654 1.461 .857 .656 22 1.3750-18UNEF .719 1.499 2.654 1.588 .857 .740 24 1.5000-18UNEF .719 1.781 2.885 1.715 .857 .781 28 1.7500-18UNS .719 1.781 2.885 1.968 .857 .922 32 2.0000-18UNS .719 2.087 2.943 2.209 .857 1.156 36 2.2500-16UN .719 2.281 2.943 2.463 .857 1.250 40 2.5000-16UN .719 2.581 3.068 2.718 .857 1.562 * Increase Z dimension by.312 for size “0” contact only. 14

MS/Standard MS3108E 90 degree plug L J Z Q U A Thread Y N To complete order number, see “how to order” pg. 70. For solder well data, see page 67. All lockwire holes are .045 dia. min. A Q Y Shell Thread J L N Dia. U Thread Z Size Class 2B ±.005 Max. Max. Max. Max. Class 2B ±.045 8S .5000-28UNEF .531 .927 .807 .741 1.445 6-32NC .562 10S .6250-24NEF .531 .927 .807 .869 1.445 6-32NC .562 10SL .6250-24NEF .531 .951 .901 .946 1.508 6-32NC .562 12S .7500-20UNEF .531 .956 .901 .995 1.508 6-32NC .562 12 .7500-20UNEF .719 1.143 .901 .995 1.508 6-32NC .812 14S .8750-20UNEF .531 1.020 1.026 1.123 1.570 6-32NC .562 14 .8750-20UNEF .719 1.207 1.026 1.123 1.570 6-32NC .812 16S 1.0000-20UNEF .531 1.146 1.119 1.250 1.633 6-32NC .562 16 1.1000-20UNEF .719 1.333 1.119 1.250 1.633 6-32NC .812 18 1.1250-18NEF .719 1.395 1.229 1.333 1.759 6-32NC .812* 20 1.2500-18NEF .719 1.598 1.479 1.461 1.931 8-32NC .812* 22 1.3750-18NEF .719 1.598 1.479 1.588 1.993 8-32NC .812* 24 1.5000-18NEF .719 1.786 1.666 1.729 2.119 8-32NC .812* 28 1.7500-18NS .719 1.786 1.666 1.968 2.181 8-32NC .812* 32 2.0000-18NS .719 2.020 2.135 2.209 2.570 10-32NF .812* 36 2.2500-16UN .719 2.145 2.260 2.463 2.695 10-32NF .812* 40 2.5000-16UN .719 2.270 2.510 2.719 2.851 10-32NF .812* *Increase Z dimension by.312 for size “0” contact only. 15

MS/Standard MS-R MS-R Specification requirements for greater reliability in a shorter, lighter weight environmental resistant connector led to the design of the MS-R. MS Class R connectors satisfy all the performance requirements of MIL-DTL- 5015. This low profile assembly was attained by moving the axial compression nut and grommet assembly forward and flush with the rear of the insert. The neoprene grom- met, with its low coefficient of friction, assures easier threading of wire bundles and quicker assembly and ser- wall mounting receptacle viceability of the unit. Molded webs in each wire hole insure a moisture barrier around each wire. The addition of an “O” ring at the main joint of all MS3106R plugs provide a main joint seal supplementary to the interfacial seal, thus insuring a higher degree of reliability when connector halves from different sources are employed. MS-R types are recommended for new design applications. Shells: Shell components are fabricated from high grade alumi- num alloy. All components have the standard electrically cable connecting plug conductive cadmium plated finish with an olive drab chro- mate after-treatment for corrosion resistance. Consult Amphenol, Sidney, NY for other plating options. Contacts: Contacts are machined from copper alloy for maximum corrosion resistance, maximum current carrying capacity and low millivolt drop. Both crimp and solder versions are available. Refer to pages 49, 67 and 68 for additional contact information. Inserts: box mounting receptacle Resilient neoprene inserts provide an outstanding mois- ture barrier, maximum vibration resistance and high dielectric strength. Either pin or socket insert can be pressurized. straight plug 16

MS/Standard MS3100R wall mounting receptacle L S K R M Z P B R S H A Thread T Y 4 Holes To complete order number, see “how to order” pg. 70. For solder well data, see page 67. All lockwire holes are .045 dia. min. B T A Min. H K M P Y Dia. Z Shell Thread Full Dia. +.020 L +.010 Dia. R S Thread +.004 +.050 Size Class 2A Thread Max. –.010 Max. –.000 Max. ±.005 ±.031 Class 2 –.002 –.060 8S .5000-28UNEF .391 .959 .672 1.588 .562 .557 .594 .875 6-32NC .120 .422 10S .6250-24NEF .391 1.026 .672 1.588 .562 .682 .719 1.000 6-32NC .120 .422 10SL .6250-24NEF .391 1.120 .672 1.588 .562 .807 .719 1.000 6-32NC .120 .422 12S .7500-20UNEF .450 1.120 .672 1.588 .562 .807 .812 1.094 6-32NC .120 .422 12 .7500-20UNEF .625 1.120 .860 1.931 .750 .807 .812 1.094 6-32NC .120 .672 14S .8750-20UNEF .450 1.307 .672 1.588 .562 .932 .906 1.188 6-32NC .120 .422 14 .8750-20UNEF .625 1.307 .860 1.931 .750 .932 .906 1.188 6-32NC .120 .672 16S 1.0000-20UNEF .450 1.432 .672 1.588 .562 1.057 .969 1.281 6-32NC .120 .422 16 1.0000-20UNEF .625 1.432 .860 1.931 .750 1.057 .969 1.281 6-32NC .120 .672 18 1.1250-18NEF .625 1.557 .891 1.931 .750 1.182 1.063 1.375 6-32NC .120 .641* 20 1.2500-18NEF .625 1.744 .891 1.931 .750 1.291 1.156 1.500 8-32NC .120 .641* 22 1.3750-18NEF .625 1.869 .891 1.931 .750 1.432 1.250 1.625 8-32NC .120 .641* 24 1.5000-18NEF .625 1.994 .953 2.009 .812 1.557 1.375 1.750 8-32NC .147 .578* 28 1.7500-18NS .625 2.166 .953 2.009 .812 1.807 1.562 2.000 8-32NC .147 .578* 32 2.0000-18NS .625 2.541 1.031 2.072 .875 2.057 1.750 2.250 10-32NF .173 .500* 36 2.2500-16UN .625 2.729 1.031 2.072 .875 2.260 1.938 2.500 10-32NF .173 .500* 40 2.5000-16UN .625 2.979 1.031 2.072 .875 2.260 2.510 2.750 10-32NF .173 .500* *Increase Z dimension by.312 for size “0” contact only. 17

MS/Standard MS3101R cable connecting plug L Z J B F A Thread Y Thread To complete order number, see “how to order” pg. 70. For solder well data, see page 67. All lockwire holes are .045 dia. min. B A Min. F J Y Shell Thread Full Dia. Dia. L Thread Z Size Class 2A Thread Max. Max. Max. Class 2 ±.040 8S .5000-28UNEF .406 .959 .557 1.588 6-32NC 1.094 10S .6250-24NEF .406 1.026 .682 1.588 6-32NC 1.094 10SL .6250-24NEF .406 1.120 .807 1.588 6-32NC 1.094 12S .7500-20UNEF .422 1.120 .807 1.588 6-32NC 1.094 12 .7500-20UNEF .656 1.120 .807 1.931 6-32NC 1.532 14S .8750-20UNEF .391 1.307 .932 1.588 6-32NC 1.094 14 .8750-20UNEF .625 1.307 .932 1.931 6-32NC 1.532 16S 1.0000-20UNEF .391 1.432 1.057 1.588 6-32NC 1.094 16 1.0000-20UNEF .625 1.432 1.057 1.931 6-32NC 1.532 18 1.1250-18NEF .625 1.557 1.182 1.931 6-32NC 1.532* 20 1.2500-18NEF .625 1.744 1.291 1.931 8-32NC 1.532* 22 1.3750-18NEF .625 1.869 1.432 1.931 8-32NC 1.532* 24 1.5000-18NEF .625 1.994 1.557 2.009 8-32NC 1.532* 28 1.7500-18NS .625 2.166 1.807 2.009 8-32NC 1.532* 32 2.0000-18NS .625 2.541 2.057 2.072 10-32NF 1.532* 36 2.2500-16UN .625 2.729 2.260 2.072 10-32NF 1.532* 40 2.5000-16UN .625 2.979 2.510 2.072 10-32NF 1.532* * Increase Z dimension by.312 for size “0” contact only. 18

MS/Standard MS3102R box mounting receptacle S R B A Thread S R N T 4 Holes M L K Z To complete order number, see “how to order” pg. 70. For solder well data, see page 67. B N T A Min. K L M Dia. Dia. Z Shell Thread Full +.020 +.000 +.010 +.010 R S +.004 +.050 Size Class 2A Thread –.010 –.010 –.000 –.000 ±.005 ±.031 –.002 –.060 8S .5000-28UNEF .391 .672 .297 .562 .375 .594 .875 .120 .422 10S .6250-24NEF .391 .672 .297 .562 .500 .719 1.000 .120 .422 10SL .6250-24NEF .391 .672 .297 .562 .625 .719 1.000 .120 .422 12S .7500-20UNEF .450 .672 .297 .562 .625 .812 1.094 .120 .422 12 .7500-20UNEF .625 .860 .484 .750 .625 .812 1.094 .120 .672 14S .8750-20UNEF .450 .672 .297 .562 .750 .906 1.188 .120 .422 14 .8750-20UNEF .625 .860 .484 .750 .750 .906 1.188 .120 .672 16S 1.0000-20UNEF .450 .672 .297 .562 .875 .969 1.281 .120 .422 16 1.0000-20UNEF .625 .860 .484 .750 .875 .969 1.281 .120 .672 18 1.1250-18NEF .625 .891 .453 .750 1.000 1.062 1.375 .120 .641* 20 1.2500-18NEF .625 .891 .453 .750 1.125 1.156 1.500 .120 .641* 22 1.3750-18NEF .625 .891 .453 .750 1.250 1.250 1.625 .120 .641* 24 1.5000-18NEF .625 .953 .453 .812 1.375 1.375 1.750 .147 .578* 28 1.7500-18NS .625 .953 .453 .812 1.625 1.562 2.000 .147 .578* 32 2.0000-18NS .625 1.031 .438 .875 1.875 1.750 2.250 .173 .500* 36 2.2500-16UN .625 1.031 .438 .875 2.062 1.938 2.500 .173 .500* 40 2.5000-16UN .625 1.031 .438 .875 2.312 2.188 2.750 .173 .500* *Increase Z dimension by.312 for size “0” contact only. 19

MS/Standard MS3106R straight plug L N Z J Q A Thread F Y To complete order number, see “how to order” pg. 70. For solder well data, see page 67. All lockwire holes are .045 dia. min. A F N Q Y Shell Thread Dia. J L Dia. Dia. Thread Z Size Class 2B Max. ±.005 Max. Max. Max. Class 2 ±.045 8S .5000-28UNEF .959 .531 1.057 .557 .741 6-32NC .562 10S .6250-24NEF 1.026 .531 1.057 .682 .869 6-32NC .562 10SL .6250-24NEF 1.120 .531 1.057 .807 .946 6-32NC .562 12S .7500-20UNEF 1.120 .531 1.057 .807 .995 6-32NC .562 12 .7500-20UNEF 1.120 .719 1.212 .807 .995 6-32NC .812 14S .8750-20UNEF 1.307 .531 1.057 .932 1.123 6-32NC .562 14 .8750-20UNEF 1.307 .719 1.212 .932 1.123 6-32NC .812 16S 1.0000-20UNEF 1.432 .531 1.057 1.057 1.250 6-32NC .562 16 1.0000-20UNEF 1.432 .719 1.212 1.057 1.250 6-32NC .812 18 1.1250-18NEF 1.557 .719 1.212 1.182 1.333 6-32NC .812* 20 1.2500-18NEF 1.744 .719 1.212 1.291 1.461 8-32NC .812* 22 1.3750-18NEF 1.869 .719 1.212 1.432 1.588 8-32NC .812* 24 1.5000-18NEF 1.994 .719 1.291 1.557 1.715 8-32NC .812* 28 1.7500-18NS 2.166 .719 1.291 1.807 1.968 8-32NC .812* 32 2.0000-18NS 2.541 .719 1.353 2.057 2.209 10-32NF .812* 36 2.2500-16UN 2.729 .719 1.353 2.260 2.463 10-32NF .812* 40 2.5000-16UN 2.979 .719 1.353 2.510 2.719 10-32NF .812* * Increase Z dimension by.312 for size “0” contact only. 20

MS/Standard contact and insert arrangements 21

MS/Standard insert arrangements Insert Service Total Contact Size Insert Service Total Contact Size Arrangement Rating Contacts 0 4 8 12 16 Arrangement Rating Contacts 0 4 8 12 16 8S-1 A 1 1 18-31 A 5 5 10S-2 A 1 1 20-2 D 1 1 10SL-3 A 3 3 20-3 D 3 3 10SL-4† A 2 2 20-4 D 4 4 12S-3 A 2 2 20-6 D 3 3 12S-4 D 1 1 20-7 D/A 8 8 12-5 D 1 1 20-8 Inst. 6 2 4 14S-1 A 3 3 20-9 D/A 8 1 7 14S-2 Inst. 4 4 20-11 Inst. 13 13 14S-4 D 1 1 20-12 A 2 1 1 14S-5 Inst. 5 5 20-14 A 5 2 3 14S-6 Inst. 6 6 20-15 A 7 7 14S-7 A 3 3 20-16 A 9 2 7 14S-9 A 2 2 20-17 A 6 5 1 14S-10 Inst. 4 4 20-18 A 9 3 6 14S-12 A 3 3 20-19 A 3 3 14-3 A 1 1 20-20 A 4 1 3 16S-1 A 7 7 20-21 A 9 1 8 16S-3 B 1 1 20-22 A 6 3 3 16S-4 D 2 2 20-23 A 2 2 16S-5 A 3 3 20-24 A 4 2 2 16S-6 A 3 3 20-25 Inst. 13 13 16S-8 A 5 5 20-27 A 14 14 16-2 E 1 1 20-29 A 17 17 16-7 A 3 1 2 20-30 Inst. 13 13 16-9 A 4 2 2 20-33 A 11 11 16-10 A 3 3 22-1 D 2 2 16-11 A 2 2 22-2 D 3 3 16-12 A 1 1 22-4 A 4 2 2 16-13 A 2 2 22-5 D 6 2 4 18-1 A/Inst. 10 10 22-6 D 3 2 1 18-3 D 2 2 22-7 E 1 1 18-4 D 4 4 22-8 E 2 2 18-5 D 3 2 1 22-9 E 3 3 18-6 D 1 1 22-10 E 4 4 18-7 B 1 1 22-11 B 2 2 18-8 A 8 1 7 22-12 D 5 2 3 18-9 Inst. 7 2 5 22-13 D/A 5 4 1 18-10 A 4 4 22-14 A 19 19 18-11 A 5 5 22-15 E/A 6 5 1 18-12 A 6 6 22-16 A 9 3 6 18-13 A 4 1 3 22-17 D/A 9 1 8 18-14 A 2 1 1 22-18 D/A 8 8 18-15 A 4 4 22-19 A 14 14 18-16 C 1 1 22-20 A 9 9 18-17 Inst. 7 2 5 22-21 A 3 1 2 18-19 A 10 10 22-22 A 4 4 18-20 A 5 5 22-23 D/A 8 8 18-22 D 3 3 22-24 D/A 6 2 4 18-24 A/Inst. 10 10 22-27 D/A 9 1 8 18-29 A 5 5 22-28 A 7 7 18-30 A 5 5 † 10SL-4 arrangement available only with pin contacts in receptacle and socket 22 contacts in plug

MS/Standard insert arrangements, cont. Insert Service Total Contact Size Insert Service Total Contact Size Arrangement Rating Contacts 0 4 8 12 16 Arrangement Rating Contacts 0 4 8 12 16 22-33 D/A 7 7 32-1 E/D 5 2 3 22-34 D 5 3 2 32-2 E 5 3 2 22-36 D/A 8 8 32-3 D 9 1 2 2 4 24-2 D 7 7 32-4 A/D 14 2 12 24-3 D 7 2 5 32-5 D 2 2 24-5 A 16 16 32-6 A 23 2 3 2 16 24-6 D/A 8 8 32-7 Inst./A 35 7 28 24-7 A 16 2 14 32-8 A 30 6 24 24-9 A 2 2 32-9 D 14 2 12 24-10 A 7 7 32-10 E/B/D/A 7 2 2 3 24-11 A 9 3 6 32-12 A/D 15 5 10 24-12 A 5 2 3 32-13 D 23 5 18 24-16 D/A 7 1 3 3 32-15 D 8 2 6 24-17 D 5 2 3 32-16 A 23 2 3 2 16 24-20 D 11 2 9 32-17 D 4 4 24-21 D 10 1 9 32-22 A 54 54 24-22 D 4 4 36-1 D 22 4 18 24-27 E 7 7 36-3 D 6 3 3 24-28 Inst. 24 24 36-4 D/A 3 3 28-1 D/A 9 3 6 36-5 A 4 4 28-2 D 14 2 12 36-6 A 6 2 4 28-3 E 3 3 36-7 A 47 7 40 28-4 E/D 9 2 7 36-8 A 47 1 46 28-5 D 5 2 1 2 36-9 A 31 1 2 14 14 28-6 D 3 3 36-10 A 48 48 28-7 D 2 2 36-11 A 48 48 28-8 E/D/A 12 2 10 36-12 A 48 48 28-9 D 12 6 6 36-13 E/A 17 2 15 28-10 D/A 7 2 2 3 36-14 D 16 5 5 6 28-11 A 22 4 18 36-15 D/A 35 35 28-12 A 26 26 36-16 A 47 7 40 28-13 A 26 26 36-17 A 47 7 40 28-15 A 35 35 36-18 A 31 1 2 14 14 28-16 A 20 20 36-20 A 34 2 2 30 28-17 B/D/A 15 15 36-52 A 52 52 28-18 C/D/A/Inst. 12 12 40-1 D 30 6 24 28-19 B/D/A 10 4 6 40-9 A 47 1 22 24 28-20 A 14 10 4 40-56 A 85 85 28-21 A 37 37 48-62 D 85 85 28-22 D 6 3 3 23

MS/Standard special insert arrangements Contact Size Contact Size Insert Total Insert Total Arrange Service Con- Coax** Arrange Service Con- Coax** ment Rating tacts 4/0 2/0 0 4 8 12 16 0 4 8 12 ment Rating tacts 4/0 2/0 0 4 8 12 16 0 4 8 12 14S-A7 A 7 7 32-AF A 55 55 16-59 A 4 4 36-22 D 22 22 20-26 A 19 19 36-51 D 4 2 2 20-51 A 3 3 36-54 A 39 8 31 20-57 A 7 7* 36-55 A 39 8* 31 20-58 A 10 5 5 36-59 A 53 3* 50 20-59 A 3 3* 36-60 A 47 7* 40 20-66 A 6 5* 1 36-64 Coax 4 4 20-79 A/D 8 1 7 36-65 Coax 4 4 22-63 A 12 4 8 36-71 A 53 3 50 22-65 A/D 8 8* 36-73 Coax 7 7 22-70 A 13 8 5 36-74 A 44 43 1 22-80 A 3 3* 36-75 A 48 48* 24-19 A 12 12 36-76 A 47 47 24-51 A 5 5 36-77 D 7 7 24-52 Hi Volt. 1 1 36-78 A 14 12 2 24-53 A 5 5 36-79 A 20 20 24-58 A 13 3 3 7 36-80 A 20 20* 24-59 A 14 7 7 36-83 Coax 7 7 24-60 A 7 7* 36-85 A/D 35 35* 24-65 A 15 11 4 36-97 C 1 1 24-66 D 7 7 36-99 D 12 3 3 3 3 24-67 Inst. 19 19 36-AF A 48 48 24-71 A 7 7* 40-5 A 5 5 24-75 A 7 7* 40-10 A 29 4 9 16 24-79 A 5 5 40-30 A 30 1 29 24-80 Inst. 23 23 40-35 D 35 35 24-84 A 19 1 18 40-53 A 60 60 24-96 Inst. 28 28 40-57 E 4 4 24-AJ A 25 25 40-61 A 59 1 3 55 28-51 A 12 12 40-62 A 60 60 28-59 A 17 7 10 40-63 A 61 61* 28-66 A 16 2 14 40-64 Coax 36 3 20 13 28-72 Coax 3 3 40-66 Coax 4 4 28-74 A 16 7* 9 40-67 A 11 1 10 28-75 A 16 7* 9 40-68 A 21 21 28-79 A 16 7 9 40-70 A 61 61 28-82 D 6 2 4 40-72 A 11 1 10 28-84 A 9 9 40-73 A 61 61 28-AY A 9 4 5 40-74 A 6 1 4 1 32-14 D 13 13 40-75 E 5 4 1 32-25 A 25 25 40-80 A 11 10 1 32-31 A 31 31 40-81 A 62 62* 32-48 Inst. 48 48 40-82 A 62 62 32-52 D 8 2 6 40-85 A 60 60* 32-53 Inst./E 42 5 37 40-86 E 4 4 32-56 A 30 6* 24 40-87 D 7 7 32-57 Coax 8 6 2 40-AD A 8 4 4 32-58 Coax 4 4 40-AG A 38 38 32-59 A 42 40 2 40-AP E 2 2 32-60 A 23 15 8 40-AR Inst. 13 3 3 7 32-62 Coax 23 2 1 2 16 2 40-AS A 40 25 15 32-64 Inst. 54 54 40-AT A 43 1 24 18 32-68 A 16 12 4 40-AU A 14 3 10 1 32-73 A 46 46 40-AV D 3 3 32-75 Coax 9 2 7 44-52 A 104 104 32-76 A 19 19 44-53 A 36 18 18 32-79 D 5 4 1 48-51 A 56 10 42 4 32-82 A 16 4 12 48-52 A 61 56 5 48-53 D 37 37 * Crimp contacts accommodate wire the same size as the contact as well as wire of the next smaller, even size. Arrangements identified with an asterisk (*) are excep- 48-54 A 56 10 42 4 tions. See insert arrangement drawings on pages 38-48 for application wire size. 24 48-55 A 78 6 2 2 68 **Coaxial cable data can be found on insert arrangement drawings, pages 38-48. For 48-57 A 56 4 10 42 furtherinformationoncoaxialcontactsandcableseecatalog12130

MS/Standard insert alternate positioning To avoid cross-plugging problems in applications requiring the use of more than one connector of the The following insert arrangements have the same alter- same size and arrangement, alternate rotations are nate insert rotations for W, X, Y and Z, which are: available as indicated in the accompanying charts. Degrees As shown in the diagram below, the front face of the pin W X Y Z insert is rotated within the shell in a clockwise direction 80 110 250 280 from the normal shell key. The socket insert would be rotated counter-clockwise the same number of degrees 16-7 20-22 22-29 24-17 28-16 32-13 in respect to the normal shell key. 18-5 22-6 22-33 24-20 28-17 32-22 18-9 22-12 22-34 24-21 28-19 32-AF 18-13 22-14 24-1 24-28 28-20 36-1 18-14 22-15 24-3 28-1 28-21 36-7 A A B B 20-7 22-16 24-4 28-4 32-1 36-8 B B A A 20-8 22-17 24-5 28-8 32-3 36-13 20-9 22-18 24-6 28-9 32-4 40-AR Position W Position X Position Y Position Z 20-12 22-19 24-7 28-10 32-6 40-AS 20-14 22-21 24-12 28-11 32-9 40-AT View looking into front face of pin insert or rear of socket insert. 20-16 22-24 24-14 28-14 32-10 40-AU 20-20 22-25 24-16 28-15 32-12 Insert Degrees Insert Degrees Insert Degrees Arrangement W X Y Z Arrangement W X Y Z Arrangement W X Y Z 10SL-4 63 – – – 20-23 35 110 250 325 32-5 35 110 250 325 12S-3 70 145 215 290 20-24 35 110 250 325 32-7 80 125 235 280 14S-2 – 120 240 – 20-27 35 110 250 325 32-8 80 125 235 280 14S-5 – 110 – – 20-29 80 – – 280 32-14 65 130 230 295 14S-7 90 180 270 – 22-1 35 110 250 325 32-15 35 110 250 280 14S-9 70 145 215 290 22-2 70 145 215 290 32-17 45 110 250 – 16-9 35 110 250 325 22-4 35 110 250 325 32-25 60 120 – – 16-10 90 180 270 – 22-5 35 110 250 325 32-48 80 – – – 16-11 35 110 250 325 22-8 35 110 250 325 32-64 80 100 110 250 16-13 35 110 250 325 22-9 70 145 215 290 32-68 30 – – – 16S-1 80 – – 280 22-10 35 110 250 325 32-82 30 – – – 16S-4 35 110 250 325 22-11 35 110 250 325 36-3 70 145 215 290 16S-5 70 145 215 290 22-13 35 110 250 325 36-4 70 145 215 290 16S-6 90 180 270 – 22-20 35 110 250 325 36-5 – 120 240 – 16S-8 – 170 265 – 22-22 – 110 250 – 36-6 35 110 250 325 18-1 70 145 215 290 22-23 35 – 250 – 36-9 80 125 235 280 18-3 35 110 250 325 22-27 80 – 250 280 36-10 80 125 235 280 18-4 35 110 250 325 22-28 80 – – 280 36-14 90 180 270 – 18-8 70 – – 290 22-63 20 – – – 36-15 60 125 245 305 18-10 – 120 240 – 24-2 80 – – 280 36-AF 65 – – – 18-11 – 170 265 – 24-9 35 110 250 325 40-1 65 130 235 300 18-12 80 – – 280 24-10 80 – – 280 40-5 33 – – 270 18-15 – 120 240 – 24-11 35 110 250 325 40-9 65 125 225 310 18-20 90 180 270 – 24-22 45 110 250 – 40-10 65 125 225 310 18-22 70 145 215 290 24-27 80 – – 280 40-35 70 130 230 290 18-29 90 180 270 – 28-2 35 110 250 325 40-AD 45 – – – 20-3 70 145 215 290 28-3 70 145 215 290 40-AG 37 74 285 322 20-4 45 110 250 – 28-5 35 110 250 325 40-AP 35 110 250 325 20-5 35 110 250 325 28-6 70 145 215 290 40-AV 90 180 270 – 20-6 70 145 215 290 28-7 35 110 250 325 20-15 80 – – 280 28-12 90 180 270 – 20-17 90 180 270 – 28-18 70 145 215 290 20-18 35 110 250 325 28-22 70 145 215 290 20-19 90 180 270 – 28-AY 45 110 250 – 20-21 35 110 250 325 32-2 70 145 215 290 25

MS/Standard contact arrangements front face of pin insert or rear face of socket insert illustrated B A B A A C B Front of Front of Socket Insert Socket Insert Insert Arrangement 8S-1 10S-2 10SL-3 10SL-4 12S-3 12S-4 12-5 Service Rating A A A A A D D Number of Contacts 1 1 3 2 2 1 1 Contact Size 16 16 16 16 16 16 12 D A E A F A B A C A C B D B E B C A B C D C B Insert Arrangement 14S-1 14S-2 14S-4 14S-5 14S-6 14S-7 14S-9 Service Rating A Inst. D Inst. Inst. A A Number of Contacts 3 4 1 5 6 3 2 Contact Size 16 16 16 16 16 16 16 100˚ 100˚ F A CD AB C A E G B B A B D C 100° Rotation 100° Rotation of 14S-2 of 14S-7 Insert Arrangement 14S-10 14S-12 14-3 16S-1 16S-3 16S-4 Service Rating Inst. A A A B D Number of Contacts 4 3 1 7 1 2 Contact Size 16 16 8 16 16 16 A E A B A C A D A C D B C B B C B C Insert Arrangement 16S-5 16S-6 16S-8 16-2 16-7 16-9 Service Rating A A A E A A Number of Contacts 3 3 5 1 1 2 2 2 Contact Size 16 16 16 12 8 16 12 16 CONTACT LEGEND 16 12 8 4 0 26

MS/Standard contact arrangements front face of pin insert or rear face of socket insert illustrated C A A G H A B A I B B F J C B A B E D Insert Arrangement 16-10 16-11 16-12 16-13 18-1 18-3 Service Rating A A A A B, C, F, G = A; Bal. = Inst. D Number of Contacts 3 2 1 2* 10 2 Contact Size 12 12 4 12 16 12 G A F A F C D A E B E H B G C B C B D C D A Insert Arrangement 18-4 18-5 18-6 18-7 18-8 18-9 Service Rating D D D B A Inst. Number of Contacts 4 2 1 1 1 1 7 2 5 Contact Size 16 12 16 4 8 12 16 12 16 D A D E A E F A D A C A B D B C B C B D C B B A C Insert Arrangement 18-10 18-11 18-12 18-13 18-14 18-15 Service Rating A A A A A A Number of Contacts 4 5 6 1 3 1 1 4** Contact Size 12 12 16 8 12 4 16 12 100˚ F C B A C A B G G H A E B D E F G I B G 250˚ F J D A H K J E D C A B E D C 100° Rotation 250° Rotation of 18-9 of 18-1 Insert Arrangement 18-16 18-17 18-19 18-20 18-22 18-24 Service Rating C Inst. A A D B, C, F, G = A; Bal. = Inst. Number of Contacts 1 2 5 10 5 3 10 Contact Size 12 12 16 16 16 16 16 CONTACT LEGEND 16 12 8 4 0 * A = Iron; B = Constantan ** A, C = Iron; B, D = Constantan 27

MS/Standard contact arrangements front face of pin insert or rear face of socket insert illustrated E A 110˚ A B A B A D A C D B E C E C C B D 260˚ D C B 110° Rotation 260° Rotation of 18-20 of 18-20 Insert Arrangement 18-29 18-30 18-31 20-2 20-3 20-4 Service Rating A A A D D D Number of Contacts 5 5 5 1 3 4 Contact Size 16 16 16 0 12 12 A G HA B E F C B G HA B M B L C F A F C E C B F E D C D A E D N DG A HJ K B Insert Arrangement 20-6 20-7 20-8 20-9 20-11 20-12 Service Rating D A, B, H, G = D; C, D, E, F = A Inst. H = D; Bal. = A Inst. A Number of Contacts 3 8 2 4 1 7 13 1 1 Contact Size 16 16 8 16 12 16 16 4 16 E F A E F G E H A A E G B D I H D F A FG I AB D C B D C C B A C B E D C C B Insert Arrangement 20-14 20-15 20-16 20-17 20-18 20-19 Service Rating A A A A A A Number of Contacts 2 3 7 2 7 5 1 3 6 3 Contact Size 8 12 12 12 16 12 16 12 16 8 CONTACT LEGEND 16 12 8 4 0 28

MS/Standard contact arrangements front face of pin insert or rear face of socket insert illustrated A F A 100˚ D A H B A B L C C G I C E A M F D B E F D D B N G H K B E C B C D A J 100° Rotation of 20-11 Insert Arrangement 20-20 20-21 20-22 20-23 20-24 20-25 Service Rating A A A A A Inst. Number of Contacts 1 3 1 8 3 3 2 2 2 13 Contact Size 4 12 12 16 8 16 8 8 16 16 HGINJFM KEALBDC KLJMTSHA NGBRPFCED 250˚MN BDG AEL HCJ FK JHKFLMAE BDC B A C A B 250° Rotation of 20-11 Insert Arrangement 20-27 20-29 20-30 20-33 22-1 22-2 Service Rating A A Inst. A D D Number of Contacts 14 17 13 11 2 3 Contact Size 16 16 16 16 8 8 A F A A E B B B A D B C D C C Insert Arrangement 22-4 22-5 22-6 22-7 22-8 Service Rating A D D E E Number of Contacts 2 2 2 4 2 1 1 2 Contact Size 8 12 12 16 8 16 0 12 CONTACT LEGEND 16 12 8 4 0 29

MS/Standard contact arrangements front face of pin insert or rear face of socket insert illustrated A A D A E B D A B A E C B C B C B D C Insert Arrangement 22-9 22-10 22-11 22-12 22-13 Service Rating E E B D E = D; A, B, C, D = A Number of Contacts 3 4 2 2 3 4 1 Contact Size 12 16 16 8 16 12 16 L M A A A A G A K U N B F B F G H B H B J T V P C G C F H B HGS F RED E D C E DJ C F JE D E D C Insert Arrangement 22-14 22-15 22-16 22-17 22-18 Service Rating A D = E; A, B, C, E, F = A A A = D; Bal. = A A, B, F, G, H = D; C, D, E = A Number of Contacts 19 5 1 3 6 1 8 8 Contact Size 16 12 16 12 16 12 16 16 A J KP L MB C GF HJ AB C A D A F G H AB H N D B C B E G F E E D C D C Insert Arrangement 22-19 22-20 22-21 22-22 22-23 Service Rating A A A A H = D; Bal. = A Number of Contacts 14 9 1 2 4 8 Contact Size 16 16 0 16 8 12 CONTACT LEGEND 16 12 8 4 0 30

MS/Standard contact arrangements front face of pin insert or rear face of socket insert illustrated A H A B F A D A G A F B F B G J E G B H E C C C B E C D F D E E D C G F D Insert Arrangement 22-24 22-27 22-28 22-33 22-36 Service Rating C, D, E = D; A, B, F = A J = D; Bal. = A A A, B, C, D = D; E, F, G = A H = D; Bal. = A* Number of Contacts 2 4 1 8 7 7 8 Contact Size 12 16 8 16 12 16 12 A F A F A A C B G A C B E G B E G B F DJ G KE H F H B L M N E D E C D C D C P R S D Insert Arrangement 22-34 24-2 24-3 24-5 24-6 Service Rating D D D A A, G, H = D; Bal. = A Number of Contacts 3 2 7 2 5 16 8 Contact Size 12 16 12 12 16 16 12 L A B A B C K P M N C B A EF G AB D E F E A J D D B I H O G F E D C G H I C Insert Arrangement 24-7 24-9 24-10 24-11 24-12 Service Rating A A A A A Number of Contacts 2 14 2 7 3 6 2 3 Contact Size 12 16 4 8 8 12 4 12 * A, C, E, G = Iron B, D, F, H = Constantan CONTACT LEGEND 16 12 8 4 0 31

MS/Standard contact arrangements front face of pin insert or rear face of socket insert illustrated F A B D J A B H A B D A G C E H K L C G J K C E C G D B A F D C B D F E E Insert Arrangement 24-16 24-17 24-20 24-21 24-22 Service Rating A, B, F, G = D; C, D, E, = A D D D D Number of Contacts 1 3 3 2 3 2 9 1 9 4 Contact Size 8 12 16 12 16 12 16 8 16 8 H A B K A A A A B C D J L B F B KELFMGNHPJQ G J C H P M C G R S T U V E C D W X Y Z G N D C B F E D F E Insert Arrangement 24-27 24-28 28-1 28-2 28-3 Service Rating E Inst. A, J, E = D; Bal. = A D E Number of Contacts 7 24 3 6 2 12 3 Contact Size 16 16 8 12 12 16 8 A S A B A P C D E B B A G E F D C C B Insert Arrangement 28-4 28-5 28-6 28-7 Service Rating G, P, S = E; Bal. = D D D D Number of Contacts 2 7 2 1 2 3 2 Contact Size 12 16 4 12 16 4 4 CONTACT LEGEND 16 12 8 4 0 32

MS/Standard contact arrangements front face of pin insert or rear face of socket insert illustrated H A H J A F A N J E M G J G K B G U P K F A B E B V R G B F K F M L C W S L H C L X D E M D C E D D C T I Insert Arrangement 28-8 28-9 28-10 28-11 Service Rating L, M = E; B = D; Bal. = A D G = D; Bal. = A A Number of Contacts 2 10 6 6 2 2 3 4 18 Contact Size 12 16 12 16 4 8 12 12 16 MNLKZYPXaRSbdAWT VUBFCED 100M˚NLKZYPXaRSbdAWT VUBFCED PHdXRCjJYDASeKZETfaLUgBFMbGVkchNW HJSR VKT LQAUMPBNCD J H G J H G l m G F E 100° Rotation of 28-12 Insert Arrangement 28-12 28-13 28-15 28-16 Service Rating A A A A Number of Contacts 26 26 35 20 Contact Size 16 16 16 16 BH C J DK E L A B L A B C A G L F K C K M E M R M J D P E N H G F J H G Insert Arrangement 28-17 28-18 28-19 Service Rating R = B; M, N, P = D; A to L = A M = C; G, H, J, K, L = D; A, B = A; Bal. = Inst. H, M = B; A, B = D; Bal. = A Number of Contacts 15 12 4 6 Contact Size 16 16 12 16 CONTACT LEGEND 16 12 8 4 0 33

MS/Standard contact arrangements front face of pin insert or rear face of socket insert illustrated J A B C A B A D C A N K E F G H J F H P K L M N P R E B C S T U V W X Z a b c d e f B G M L D g h j k m E D D C F E n p r s Insert Arrangement 28-20 28-21 28-22 32-1 Service Rating A A D A = E; B, C, D, E = D Number of Contacts 10 4 37 3 3 2 3 Contact Size 12 16 16 4 16 0 12 A A B C A F K A E D E F B G L C O B H G J D M D H C E N J B Insert Arrangement 32-2 32-3 32-4 32-5 Service Rating E D F, J, K, N = A; Bal. = D D Number of Contacts 3 2 1 2 2 4 2 12 2 Contact Size 4 16 0 4 12 16 12 16 0 OKUEWPCI AGL MTHB JDRXFVNS khjg dcebf WXaYZ RSUPT NMJKL IHGEFDCAB dec ZYba XVTWU MRSNOP KHJIL DEGF CAB CAHDL I E MJ FN KBG V O Insert Arrangement 32-6 32-7 32-8 32-9 Service Rating A A, B, h, j = Inst.; Bal. = A A D Number of Contacts 2 3 2 16 7 28 6 24 2 12 Contact Size 4 8 12 16 12 16 12 16 4 16 CONTACT LEGEND 16 12 8 4 0 34

MS/Standard contact arrangements front face of pin insert or rear face of socket insert illustrated A B N A A F A M B C D E F G L X P R C B C Y E G B H J K K W S D D E Z V T J E D C L M N U F H H F O P G G Insert Arrangement 32-10 32-12 32-13 32-15 Service Rating A, F = E; G = B; B, E = D; C, D = A C, D, E, F, G = A; Bal. = D D D Number of Contacts 2 2 3 5 10 5 18 2 6 Contact Size 4 8 16 12 16 12 16 0 12 100˚ C A B D F C AG D HB E J A B C E I G H J F D A N K O L P M R D E F G H K P L M R N S X T Y U Z V a W b c d e f I J K L M N O T S m g n h p j q k r U W X V C B ABs AwD zt x AuA AyEvAC O P R S T AF AG U V W 100° Rotation of 32-6 Insert Arrangement 32-16 32-17 32-22 36-1 Service Rating A D A D Number of Contacts 2 3 2 16 4 54 4 18 Contact Size 4 8 12 16 4 16 12 16 F A A A A F B D B E B E C C B D C C D Insert Arrangement 36-3 36-4 36-5 36-6 Service Rating D A = D; B, C = A A A Number of Contacts 3 3 3 4 2 4 Contact Size 0 12 0 0 0 4 CONTACT LEGEND 16 12 8 4 0 35

MS/Standard contact arrangements front face of pin insert or rear face of socket insert illustrated YO K UCHZP ALF VDRIa WBGM SJbE XN Tc WN SI XOBG TJ D AMFY EKU PHCZ VLRa ed ZaY VU S POM IJ HED AB h nr djx ue wt f vyk sgp m mbf sx vg ncz uk pwd yth rej f cb WX T R N LK FG C z Insert Arrangement 36-7 36-8 36-9 Service Rating A A A Number of Contacts 7 40 1 46 1 2 14 14 Contact Size 12 16 12 16 4 8 12 16 A B A B A B C D E F G 100˚ C D E F G C D E F G 110˚ H J K L M N H J K L M N H J K L M N O P Q R S T U O P Q R S T U O P Q R S T U V W X Y Z a b c V W X Y Z a b c V W X Y Z a b c d e f g h j k d e f g h j k d e f g h j k m n p q r s m n p q r s m n p q r s t u v w x t u v w x t u v w x y z y z y z 100° Rotation 110° Rotation of 36-10 of 36-10 Insert Arrangement 36-10 36-11 36-12 Service Rating A A A Number of Contacts 48 48 48 Contact Size 16 16 16 A S A P N J B R T B M L Q d U C R S I P K C P c k e V D K A Q j m f J B H N L D N b W E H Q C M M a h g X F G F E D G E L Z Y G F K H J Insert Arrangement 36-13 36-14 36-15 Service Rating N, P, Q = E; Bal. = A D M = D; Bal. = A Number of Contacts 2 15 5 5 6 35 Contact Size 12 16 8 12 16 16 CONTACT LEGEND 16 12 8 4 0 36

MS/Standard contact arrangements front face of pin insert or rear face of socket insert illustrated A B A D B S M 10Y0O˚ dKhrCHPUn FLZj uVe IwRaDt WGMfv JbkSE sNXpg Tmc YO KdhrCHUPn LFjZ ueV wIRat WGMfv EbkSJ sNXpg Tmc110˚ 10e0d˚ bfcZaYWXVU RPO JILKHEDGF ACB x y x y T N z z 100° Rotation 110° Rotation 100° Rotation of 36-7 of 36-7 of 36-9 Insert Arrangement 36-16 36-17 36-18 Service Rating A A A Number of Contacts 7 40 7 40 1 2 14 14 Contact Size 12 16 12 16 4 8 12 16 A B A B C D A B C C D E F G E F H J K D E F G H J K L M N L M N P R S H I J K L P R S T U V W T U V W X Y Z X Y Z a b c a b c d f g h i M N O P R S d e h j f g j k m n p q r T U V W X s t u v w x k m y z AA AB AC Y Z a b AD AH c d e AE AF Insert Arrangement 36-20 36-52 40-1 Service Rating A A D Number of Contacts 2 2 30 52 6 24 Contact Size 8 12 16 16 12 16 1 2 3 4 A B A B C D 5 6 7 8 9 10 11 C F D E E F H J K L M 12 13 14 15 16 17 18 19 G H I J K L X N YPZRaSbTc UdVf Wg 20 21 22 23 24 25 26 27 28 M N O P Q R S T h i j k m n p q r s 29 30 31 32 33 34 35 36 37 38 U V W X Y Z a t u v w x y z AA AB 39 40 41 42 43 44 45 46 47 b c d e f g h i ACAPADARAEASAFATAHAUAJAVAKAWALAXAMAY AN 48 49 50 51 52 53 54 55 56 57 l m AZ BA BB BC BD BE BF BH 58 59 60 61 62 63 64 65 66 j o k n BJ BK BL BM BN BP BR 67 68 69 70 71 72 73 74 p q BS BT BU BV r s 75 76 77 78 79 80 81 t u 82 83 84 85 Insert Arrangement 40-9 40-56 48-62 Service Rating A A D Number of Contacts 1 22 24 85 85 Contact Size 8 12 16 16 16 CONTACT LEGEND 16 12 8 4 0 37

Special contact arrangements Requirements for more complex circuits prompted Many of these special inserts are also available in alter- Amphenol to provide inserts not covered by the MS draw- nate keyway arrangements. Please contact Amphenol, ings. Illustrated here and on the following pages are Sidney, NY for additional information on special circuit insert layouts which have from one contact (high tension) application requirements. to the 104 contact insert in shell size 44. front face of pin insert or rear face of socket insert illustrated M J FE AGD BC CA DB JHKTLUS V RNPABDC C A EDF G AC B DCH LE KBA G F E B F Insert Arrangement 14S-A7 16-59 20-26 20-51 20-57 20-58 Service Rating A A A A A A Number of Contacts 7 4 19 3* 7* 5 5 Contact Size 16 12 16 8 12 for #14 or 16 wire 12 16 C A D E A G HA B B L C F G H A H J K A B B C F B FE DC AKJN H MFED E D C B F EP NL MD C Insert Arrangement 20-59 20-66 20-79 22-63 22-65 22-70 Service Rating A A H = D; Bal. = A A H = D; Bal. = A A Number of Contacts 3* 1 5 7* 1* 4 8 8* 8 5 Contact Size 8 for #10 or 12 wire 16 12 for #10 wire 16 12 for #16 wire 12 16 12 for #14 or 16 wire 12 16 A N A P H J M B E A E A N K F D L C D B D B M L C B K D E J H FE C C C B A Insert Arrangement 22-80 24-19 24-51 24-52 24-53 24-58 Service Rating A A A Hi-Volt A A Number of Contacts 3* 12 5* 1 5* 3 3 7 Contact Size 8 for #10 or 12 wire 16 B, E for AN #10 or 12 wire 12 8 8 12 16 A, C, D for AN #8 wire * Solderless CONTACT LEGEND 16 12 8 4 0 38

Special contact arrangements front face of pin insert or rear face of socket insert illustrated MNHP RJA KL EF G AB J KS L MNA B E F G A B G FS RVE PD 9C0˚ F B H R P C HJ T U N AB E C D C F D D C K M D E L Insert Arrangement 24-59 24-60 24-65 24-66 24-67 Service Rating A A A D Inst. Number of Contacts 7 7 7* 11 4 7 19 Contact Size 12 16 8 for #10 or 12 wire 12 16 12 12 A B C D E 90˚ F A F A E F G H J F R D E G B E G B DE AB KR LSMTNUP VQ HGJ ST UV NP CAB D C D C C W X Z K M L Insert Arrangement 24-71 24-75 24-79 24-80 24-84 Service Rating A A A Inst. A Number of Contacts 2* 5* 5 2 5 23 1 18 Contact Size 8 8 for #10 or 12 wire 8 8 for #16 wire 8 16 12 12 (Coax) RG-188/U or RG-174/U 15 16 1 J A L M N 131423 2284 172 3 EAFB G CHDJ H K B P R S T U 12 22 27 2518 4 K L M T N P Q N L A B C D 111021 2260 196 5 RWSX YUZV F M C E F H 9 8 7 a E D J K Insert Arrangement 24-96 24-AJ 28-51 28-59 Service Rating Inst. A A A Number of Contacts 28 25 12 7 10 Contact Size 16 16 12 12 16 * Solderless CONTACT LEGEND 16 12 8 4 0 39

Special contact arrangements front face of pin insert or rear face of socket insert illustrated N P SR C D A L MT N PA RB C L MT N PA RB C L MT N PA RB C K D K D K D M E B A L K T H F C B JH S FE JH S FE JH S FE J Insert Arrangement 28-66 28-72 28-74 28-75 28-79 Service Rating A – A A A Number of Contacts 2 14 3 9* 4* 3* 9* 7* 7 9 Contact Size 8 12 4 (Coax) RG-59A/U 16 8 8 for #10 wire 16 8 for #10 wire 8 16 or RG-62A/U (S, T, R) 1 13 1 B C 10 2 12 2 1 3 2 H A A 11 11 23 14 3 G I B D E F 9 12 13 3 19 22 25 24 16 15 F C 21 17 4 5 G H 8 4 10 20 18 4 6 E D J 7 5 9 5 6 8 7 6 Insert Arrangement 28-82 28-84 28-AY 32-14 32-25 Service Rating D A A D A Number of Contacts 2 4 9 4 5 13 25 Contact Size 8 12 8 4 16 12 12 16 1 2 C DA E BF H 90˚ A L M N P R 11314211512254226330 23219177 122818 173290 645 YRhJqZwSi Kar TxjsLbUykMctmVzNudAWnAvfPpXg BF D E CH FAHJvWKXYBhZi qajtpsCbkr umcnDdfSgwTUEV 10 292 8 BB CC G 90° CW Rotation of 32-15 Insert Arrangement 32-31 32-48 32-52 32-53 Service Rating A Inst. D t, u = E; Bal. = Inst. Number of Contacts 31 48 6 2 5 37 Contact Size 16 16 12 0 12 16 * Solderless CONTACT LEGEND 16 12 8 4 0 40

Special contact arrangements front face of pin insert or rear face of socket insert illustrated M T H A X Y A B Y N D W p q Z C dec Zba XVWU RSOP KJIL EGF CAB FB D E CH CD AB TUVS Rkmnj iwUv hsTgtafKdbcJHDFE G P N M L Insert Arrangement 32-56 32-57 32-58 32-59 Service Rating A ** – A Number of Contacts 24 6 6 2 4 40 2 Contact Size 16 12 for #10 wire 12 0 (Coax) RG-71/U 4 (Coax) RG-161/U 16 8 (Coax) RG-161/U or RG-179/U PF ZR S HT AJ KE PCI AGL MHB JDR FN S NF CTK AGO ULD HPB MVE JR W CA D B E Y a U b X c Y d Z e a f E B O S g h j k F G H K L M N X V K T m s n t p u q v r J D W C UW X V AB w z xAA y AC N P M L AD AF AG AE Q R Insert Arrangement 32-60 32-62 32-64 32-68 Service Rating A ** Inst. A Number of Contacts 15 8 2 1 2 16 2 54 12 4 Contact Size 16 8 (Coax) RG-124/U 4 8 12 16 8 (Coax) RG-124/U 16 16 4 (Coax) RG-58C/U 20 21 1 111657141383334213934513424346 4144356274203283829232722423654765 6 8 17 9 2 8143 91145102 61531171612 D EA NFCA G H JD K BL PME 13 12 3101 2190 9 8 5 4 3 17 18 19 C B Q R Insert Arrangement 32-73 32-75 32-76 32-79 32-82 Service Rating A 8, 9 = D A D A Number of Contacts 46 2 7 19 4 1 4 12 Contact Size 16 12 8 (Coax) RG-180B/U 12 4 8 4 16 ** Consult Amphenol, Sidney, NY for service rating of power contacts. CONTACT LEGEND 16 12 8 4 0 41

Special contact arrangements front face of pin insert or rear face of socket insert illustrated C A D B E 13 14 1 2 A Z a b A B C bS NFX cTK OYGdUL HPZ MVe aJR Wf 1112 20 21 22 15 16 34 WXYk r s t mcn d DEF mAgsB wn hzt p xAHuAjAqy AkvCr 10 19 18 17 5 D C VUTji qh p gfKJH AD AE 9 6 S L AF AG 8 7 B R P N M Insert Arrangement 32-AF 36-22 36-51 36-54 Service Rating A D D A Number of Contacts 55 22 2 2 8 31 Contact Size 16 12 0 4 8 16 Y Z a b Ac B C D L ME NFA PBHCR DJS KT U CH AF DI BG JE A WX k r s t m n d EF cVdW fXg Y hZi aj bk YO K UZP L V Ra WM Sb XN Tc D B VU ji q p gf JH um vnwp xq y rz sAA tAB h n dj ue t f vk gp m T S R hP N M L K AC AD AEAJAF AH r x wz y s C Insert Arrangement 36-55 36-59 36-60 36-64 Service Rating A A ** – Number of Contacts 31 8 50 3 40 7 4 Contact Size 16 8 for #6 wire 16 12 for #10 wire 16 12 for #10 wire 0 (Coax) RG-11/U, RG-12/U or RG-13/U A B C D A A E F H J K 48 49 L M N P R S T U F B 5053 5154 52 D B V W X Y Z a b 58 5559 5660 5761 c d f g h i j k 6267 6368 6469 657066 m n p q r s t E C 71 72 73 74 75 u v w x y z AA AB G 8076 8177 78 827983 AC AE AH 84 86 91 8785 C AD AF D 88 89 AJ 90 Insert Arrangement 36-65 36-71 36-73 36-74 Service Rating – A – A Number of Contacts 4 3 50 7 43 1 Contact Size 0 (Coax) RG-59/U, RG-62/U 12 16 4 (Coax) RG-62B/U 16 8 (Coax) RG-187/U or RG-71/U ** Consult Amphenol, Sidney, NY for service rating of power contacts. CONTACT LEGEND 16 12 8 4 0 42

Special contact arrangements front face of pin insert or rear face of socket insert illustrated 1 2 1 3 2 A 10 1 31 32 3 4 5 4 5 29 33 34 37 6 7 6 7 8 F B 9 11 2 9 10 11 12 28 30 36 35 38 9 8 13 14 15 16 17 27 26 48 41 40 39 10 11 18 19 20 21 8 14 12 3 22 23 24 25 26 25 47 46 42 43 13 12 27 28 29 30 E C 24 23 45 44 15 14 31363237 33 383439 35 G 7 13 4 22 21 20 18 16 40 41 42 43 44 19 17 45 46 47 D 6 5 Insert Arrangement 36-75 36-76 36-77 36-78 Service Rating A A D A Number of Contacts 48 47 7 2 12 Contact Size 16 for #14 wire 16 4 16 8 1 1 A R S A 2 3 4 5 2 3 4 5 Q d T UB 6 7 8 9 10 6 7 8 9 10 F B P c k e V C D 11 12 13 14 15 11 12 13 14 15 E G C NM b j h m g f W E 16 17 18 19 16 17 18 19 L a Z Y X F D K G 20 20 J H Insert Arrangement 36-79 36-80 36-83 36-85 Service Rating A A – M = D; Bal. = A Number of Contacts 20 20 7 35 Contact Size 12 12 for #10 wire 4 (Coax) RG-58/U 16 for #12 wire 1 A z d e 3 42 10 119 12 86 7 vuwxtMNsLyOKXPWYcJbQVAaZHRUBGTSnCFfEDmgkhj N C G B r q p 5 Insert Arrangement 36-97 36-99 36-AF 40-5 Service Rating C D A A Number of Contacts 1 3 3 3 3 48 5 Contact Size 4/0 4 8 12 16 16 0 CONTACT LEGEND 16 12 8 4 0 4/0 43

Special contact arrangements front face of pin insert or rear face of socket insert illustrated F B J C GA D KE H 1617 1829 19 31020 221 3 4 5 1314 271528 163417291 18 192 34 20212420 245313544224 24535514426245273284 5 I L 28 22 33 35 30 19 39 56 29 6 M N O P Q 15 27 23 6 12 26 25 32 31 2120 5 18 38 52 6509 57 4746 30 7 R V SY Wc bT X U 1413 12 26 25 249 8 7 1110 24 23 22 7 6 1716 1357 35615305 538449 3438 3210319 8 Z a 11 10 9 8 14 13 12 11 Insert Arrangement 40-10 40-30 40-35 40-53 Service Rating A A D A Number of Contacts 4 9 16 29 1 35 60 Contact Size 4 8 16 12 4 12 16 1 2 1 1 3 4 5 6 7 23 24 25 2 3 8 9 10 11 12 13 14 15 22 42 26 4 21 41 43 27 5 16 17 18 19 20 21 22 23 24 40 54 44 28 25 26 27 28 29 30 31 32 20 39 53 60 55 56 45 29 6 33 34 35 36 37 38 39 40 41 19 52 46 7 42 43 44 45 46 47 48 49 18 38 51 59 58 57 47 30 8 4 2 50 51 52 53 54 55 56 37 50 48 31 17 36 49 32 9 57 59 16 35 33 10 15 34 11 14 12 3 58 13 Insert Arrangement 40-57 40-61 40-62 Service Rating E A A Number of Contacts 4 1 3 55 60 Contact Size 0 8 12 16 16 1920231389420252451233556944022442653515125466547242574632832409 56 L M dNf gnPhp R iSAjTUVB CD 1 1817 37 5150 58 4847 31 87 c m q k W 4 2 16 36 35 49 33 32 9 K b a Z Y X E 15 14 34 11 10 J F 3 13 12 H Insert Arrangement 40-63 40-64 40-66 Service Rating A – – Number of Contacts 61 3 20 13 4 Contact Size 16 for #14 wire 12 16 8 (Coax) RG-124/U 0 (Coax) RG-63B/U CONTACT LEGEND 16 12 8 4 0 44

Special contact arrangements front face of pin insert or rear face of socket insert illustrated N A A B 1 M P B 2 3 4 5 W R 6 7 8 9 10 L X C 11 12 13 14 15 16 17 18 C D E K V S D 19 20 21 22 23 24 25 26 27 F H J 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 J U T E 45 46 47 48 49 50 51 52 53 54 55 56 57 K L H F 58 59 60 61 M G Insert Arrangement 40-67 40-68 40-70 Service Rating A A A Number of Contacts 1 10 21 61 Contact Size 16 4 (Coax) RG-59/U 8 16 24 1 A B 22 2342 25 26 2 3 1 21 41 27 4 6 20 40 54 43 44 28 5 2 53 55 45 5 C D E 19 39 52 60 61 56 46 29 6 38 59 57 30 F H J 18 51 47 7 17 37 50 58 48 31 8 4 3 16 36 35 49 33 32 9 K M L 15 14 133412 11 10 Insert Arrangement 40-72 40-73 40-74 Service Rating A A A Number of Contacts 1 10 61 1 1 4 Contact Size 16 4 (Coax) RG-9B/U 16 12 4 (Coax) RG-62/U 0 (Coax) RG-9B/U or RG-214/U 1 A B 1 2 3 4 5 6 7 8 9 10 11 5 12 13 14 15 16 17 18 19 4 2 20 21 22 23 24 25 26 27 28 C D E 29 30 31 32 33 34 35 36 F H J 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 3 K L M Insert Arrangement 40-75 40-80 40-81 Service Rating E A A Number of Contacts 1 4 1 10 62 Contact Size 12 0 16 4 16 for #14 wire CONTACT LEGEND 16 12 8 4 0 45

Special contact arrangements front face of pin insert or rear face of socket insert illustrated 5 6172839410 11 22 23 4224 25 1 262 3 1 6 1 2012211322142315241625172618271928 202140 451354 435544 4527284 5 29 30 31 32 33 34 35 36 19 39 56 29 6 5 7 2 52 60 46 37 38 39 40 41 42 43 44 45 18 38 59 57 47 30 7 4 2 46 47 48 49 50 51 52 53 51 58 545955605661576258 1716 1357 365305 3449 3438 3210319 8 3 4 3 14 13 12 11 Insert Arrangement 40-82 40-85 40-86 40-87 Service Rating A A – D Number of Contacts 62 60 4 7 Contact Size 16 16 for #14 wire 0(Coax) RG-115A/U 4 A 38 20 H B 37 8 21 N B C 36 19 9 22 M D 18 10 A B G C 35 7 2 23 6 1 3 A 34 11 24 L E 17 F E D 33 16 5 4 12 25 K H F 32 15 14 13 26 31 27 J G 30 29 28 Insert Arrangement 40-AD 40-AG 40-AP 40-AR Service Rating A A E Inst. Number of Contacts 4 4 38 2 7 3 3 Contact Size 8 0 12 4/0 12 4 0 29301931 32 83334 359 3637 15 16 1725 118 2 3 P BE F A B 22682717 186 7 1 2 310 11393480 14 2344 233605 233716 233827 233938 3199 4 N A D G 12 13 23 40 41 42 43 20 5 C 25 16 5 4 20 M H 24 15 14 13 21 12 22 21 6 C 23 22 11 7 L K J 10 9 8 Insert Arrangement 40-AS 40-AT 40-AU 40-AV Service Rating A A A D Number of Contacts 15 25 24 18 1 3 10 1 3 Contact Size 16 12 12 16 8 4 8 16 2/0 CONTACT LEGEND 16 12 8 4 0 2/0 4/0 46

Special contact arrangements front face of pin insert or rear face of socket insert illustrated 30 1 2 A B S A 29 3 C D E F H J K R B 28 51 33 4 L M N P R S T U T 27 52 32 5 V W X Y Z a b c d P h U C 26 50 31 34 f g h i j k m n p q g V 25 49 35 6 rACsADtAEuAFvAHwAJxAKyALzAMAAANAB N f n p i j W D 24 48 D A 36 78 AP AR AS AT AU AV AW AX AY AZ BA d m q k X 2223 47 C B 37 9 BBBNBCBPBDBRBEBSBFBTBHBUBJBVBKBWBLBXBM M c Y E 21 46 38 11 10 BY BZ CA CB CC CD CE CF b a Z 20 45 42 39 12 CH CJ CK CL CM CN CP L F 19 44 40 13 CR CS K J H 18 4317 16 1541 14 Insert Arrangement 44-52 44-53 48-51 Service Rating A A A Number of Contacts 104 18 18 42 10 4 Contact Size 16 16 8 (Coax) RG-124/U 16 8 0 (Coax) RG-41/U 31 32 1 2 30 A 3 A B C D 29 44 33 4 43 34 5 28 E F G H J 6 27 52 45 26 42 51 56 53 46 35 78 K L M N P R 25 D B S T U V W X Z 24 9 23 41 50 55 E 54 47 36 10 a b c d e f 22 40 49 48 37 11 g h j k m 21 12 39 38 20 13 n p r s 19 18 C 15 14 17 16 Insert Arrangement 48-52 48-53 Service Rating A D Number of Contacts 56 5 37 Contact Size 16 0 (Coax) RG-41/U 12 CONTACT LEGEND 16 12 8 4 0 47

Special contact arrangements front face of pin insert or rear face of socket insert illustrated 27 28 5219 5230 1 2 32 333 45 333453855936767307 33891 24061431 4425 6 2526 4950 31 3435 6 31325657 7873 74 62 74534478 224223 4487 CD BA 3376 798 232908 67 72 69 71 70 76 68 11910 21 46 38 11 10 27 55 45 12 20 45 42 39 12 26 54 66 65 50 64 63 46 13 19 4148 4317 16 1541 401413 2524532352225121 2109 1849174816471514 Insert Arrangement 48-54 48-55 Service Rating A A Number of Contacts 42 10 4 68 2 2 6 Contact Size 16 8 0 (Coax) RG-59/U 16 12 8 4 30 1 2 30 1 2 29 3 29 3 28 28 51 33 4 51 33 4 27 52 32 5 27 52 32 5 26 50 31 34 26 50 31 34 6 6 25 49 35 25 49 35 7 7 24 8 24 8 48 D A 36 48 D A 36 2223 47 C B 37 9 2223 47 C B 37 9 21 46 38 11 10 21 46 38 11 10 20 45 42 39 12 20 45 42 39 12 19 44 40 13 19 44 40 13 16 14 16 14 18 43 41 18 43 41 17 15 17 15 Insert Arrangement 48-57 48-60 Service Rating A A Number of Contacts 42 10 4 42 10 4 Contact Size 16 8 0 16 8 0 (Coax) RG-214/U CONTACT LEGEND 16 12 8 4 0 48

Thermocouple contact availability A complete line of cylindrical connectors containing ther- mocouple insert arrangements is available. The contact layout for a particular arrangement will be found in either the MS/Standard contact arrangement section, pages 26-37, or the Special contact arrangement section, pages 38-48. All thermocouple contact layouts may contain either iron, alumel, chromel, constantan, standard (cop- per) or brass (dummy) contacts. See the thermocouple tabulations on the following pages. The following abbreviations are used in the contact mate- rial column in the charts that follow. Also, thermocouple contacts are color coded as shown. (This identification is made by means of small dots of stain on the solder well end of the contact). Abbreviation Material Color Code Ir. Iron Black Con. Constantan Yellow Cu. Copper Alloy N/A Ch. Chromel White Al. Alumel Green Dummy Brass N/A WIRE WELL DATA Well Inside Dia. Well Depth Solder Well Contact +.004 +.031 Barrel Size –.002 –.000 Outside Dia. 12 .125 .250 .166 ±.003 +.002 16 .094 .188 .125 –.004 RECOMMENDED WIRE Use wire in accordance I Chromel - Alumel with MIL-W-5848 Use wire in accordance II Iron - Constantan with MIL-W-5845 49

Thermocouple contact arrangements Contact Pin Shell Similar Total Size Insert Size to Contact Material Contacts Rotation and Arrg. MS Arrg. 12 16 C W 10SL-51 10SL-4 2 2 45° A = Ir.; B = Con. 10SL-52 10SL-4 2 2 45° A = Cu.; B = Con. 10SL-53 10SL-4 2 2 45° A = Al.; B = Ch. 10SL-54 10SL-3 3 3 None A = Ir.; B = Con.; C = Cu. 10SL-55 10SL-3 3 3 None A = Al.; B = Ch.; C = Cu. 10SL-56 10SL-4 2 2 None A = Al.; B = Ch. 10SL-57 10SL-4 2 2 None A = Ch.; B = Con. 10SL-58 10SL-3 3 3 None A = Ch.; B = Al.; C = Cu. 10SL-59 10SL-4 2 2 None A = Ch.; B = Al. 10SL-60 10SL-4 2 2 None A = Ir.; B = Con. 10SL-61 10SL-4 2 2 None A = Cu.; B = Con. 10SL-62 10SL-3 3 3 None A = Cu.; B = Al.; C = Ir. 10SL-63 10SL-3 3 3 None A, C = Con.; B = Ch. 10SL-64 10SL-3 3 3 None A, C = Ch.; B = Al. 12S-51 12S-3 2 2 315° A = Ch.; B = Al. 12S-54 12S-3 2 2 315° A = Ir.; B = Con. 12S-55 12S-3 2 2 45° A = Cu.; B = Con. 12S-56 12S-3 2 2 None A = Al.; B = Ch. 12S-57 12S-3 2 2 60° A = Ch.; B = Al. 12S-58 12S-3 2 2 120° A = Ir.; B = Con. 12S-59 12S-3 2 2 None A = Ir.; B = Con. 12S-60 12S-3 2 2 None A = Cu.; B = Con. 12S-61 12S-3 2 2 None A = Ch.; B = Con. 12S-62 12S-3 2 2 None A = Ch.; B = Al. 14S-51 14S-9 2 2 90° A = Al.; B = Ch. 14S-52 14S-2 4 4 45° A, B = Cu.; C = Al.; D = Ch. 14S-53 14S-9 2 2 90° A = Ir.; B = Con. 14S-54 14S-6 6 6 45° A, C, E = Ir.; B, D, F = Con. 14S-55 14S-2 4 4 45° A, C = Ir.; B, D = Con. 14S-56 14S-2 4 4 45° A = Ir.; B = Con.; C, D = Cu. 14S-57 14S-2 4 4 45° A, C = Al.; B, D = Ch. 14S-58 14S-7 3 3 45° A = Al.; B = Ch.; C = Cu. 14S-59 14S-9 2 2 90° A = Cu.; B = Con. 14S-60 14S-9 2 2 None A = Al.; B = Ch. 14S-61 14S-6 6 6 45° A = Al.; B = Ch.; C = Ir.; D = Con.; E, F = Cu. 14S-63 14S-6 6 6 None A, C = Al.; B, D = Ch.; E = Ir.; F = Con. 14S-64 14S-2 4 4 None A, C = Con.; B, D = Cu. 14S-65 14S-6 6 6 None A, C., E = Cu.; B, D, F = Con. 14S-67 14S-6 6 6 None A = Al.; B = Ch.; Balance = Cu. 14S-68 14S-2 4 4 45° A = Ch.; B = Con.; C, D = Cu. 14S-69 14S-7 3 3 None A = Con.; B = Ch.; C = Cu. 14S-70 14S-2 4 4 None A, D = Ch.; B, C = Al. 14S-71 14S-2 4 4 None A, B, D = Cu.; C = Con. 14S-72 14S-9 2 2 None A = Con.; B = Cu. 14S-73 14S-2 4 4 None A, B = Cu.; C = Al.; D = Ch. 50

Thermocouple contact arrangements Contact Pin Shell Similar Total Size Insert Size to Contact Material Contacts Rotation and Arrg. MS Arrg. 12 16 C W 14S-74 14S-2 4 4 None A, B = Ch.; C, D = Al. 14S-75 14S-2 4 4 None A, B = Cu.; C, D = Con. 14S-76 14S-2 4 4 None A, C = Al.; B, D = Ch. 14S-77 14S-2 4 4 None A, D = Al.; B, C = Ch. 14S-78 14S-9 2 2 None A = Ch.; B = Al. 16S-52 16S-4 2 2 None A = Ch.; B = Al. 16S-54 16S-1 7 7 None A = Al.; B = Ch.; Balance = Cu. 16S-55 16S-1 7 7 None A = Con.; Balance = Cu. 16-52 16-11 2 2 90° A = Al.; B = Ch. 16-53 16-9 4 2 2 70° A = Al.; C = Ch.; B, D = Cu. 16-55 16-10 3 3 45° A = Al.; B = Ch.; C = Cu. 16-56 16-13 2 2 90° A = Con.; B = Cu. 16-57 16-10 3 3 None A = Al.; B = Cu.; C = Ch. 16-58 16-10 3 3 None A = Con.; B, C = Cu. 16-60 16-13 2 2 None A = Al.; B = Ch. 16-62 16-11 2 2 None A = Con.; B = Cu. 18-51 18-12 6 6 None A = Ir.; B, E = Con.; D = Cu.; C, F = Dummy 18-52 18-11 5 5 None A = Ir.; B = Con.; C = Ch.; D = Al.; E = Dummy 18-53 18-12 6 6 None A, D = Ir.; B, E = Con.; C, F = Dummy 18-54 18-15 4 4 None A, C = Al.; B, D = Ch. 18-56 18-1 10 10 45° A, C, E, G, I = Ir.; B, D, F, H, J = Con. 18-57 18-12 6 6 45° A, C, E = Al.; B, D, F = Ch. 18-59 18-12 6 6 45° A, C = Ir.; B, E, F = Con.; D = Cu. 18-60 18-11 5 5 45° A, D = Al.; B, C, = Ch.; E = Cu. 18-61 18-12 6 6 None A, C = Ir.; B, D = Con.; E = Ch.; F = Al. 18-62 18-12 6 6 None A, B, C = Ir.; D, E, F = Con. 18-63 18-15 4 4 None A, C = Con.; B, D = Cu. 18-65 18-12 6 6 None A = Ir.; B = Con.; Balance = Cu. 18-66 18-1 10 10 None A, C, E, G, I = Cu.; B, D, F, H, J = Con. 18-67 18-12 6 6 None A, C, E = Cu.; B, D, F = Con. 18-68 18-11 5 5 None A, D = Al.; B, C = Ch.; E = Cu. 18-69 18-1 10 10 None A = Al.; B = Ch.; Balance = Cu. 18-70 18-11 5 5 None A = Ir.; B = Con.; C = Ch.; D = Al.; E = Cu. 18-71 18-15 4 4 None A = Con.; Balance = Cu. 18-72 18-15 4 4 None D = Con.; Balance = Cu. 18-73 18-9 7 2 5 None A = Al.; D = Ch.; Balance = Cu. 18-74 18-12 6 6 None A = Ch.; B = Al.; D = Ir.; E = Cu.; C, F = Con. 20-52 20-4 4 4 315° A = Ir.; B = Con.; C = Ch.; D = Al. 20-56 20-7 8 8 45° A, B, G, H = Ir.; C, D, E, F = Con. 20-60 20-7 8 8 45° D = Ch.; E = Al.; Balance = Cu. 20-61 20-29 17 17 45° A, B, M = Cu.; Balance = Con. 20-62 20-15 7 7 80° A, C, E = Al.; B, D, F = Ch.; G = Cu. 20-64 20-27 14 14 None A = Al.; C = Ch.; Balance = Cu. 51

Thermocouple contact arrangements Contact Pin Shell Similar Total Size Insert Size to Contact Material Contacts Rotation and Arrg. MS Arrg. 12 16 C W 20-65 20-27 14 14 None A, B, C, D, E, F, G = Ir.; H, I, J, K, L, M, N = Con. 20-67 20-16 9 2 7 None H = Al.; I = Ch.; Balance = Cu. 20-68 20-7 8 8 None A, B, G, H = Con.; C, D, E, F = Cu. 20-69 20-27 14 14 None A, B, C, D, E, F, G = Cu.; H, I, J, K, L, M, N = Con. 20-70 20-29 17 17 None A, C, E, G, J, L, N, R, T = Ir.; B, D, F, H, K, M, P, S = Con. 20-71 20-29 17 17 None S = Al.; R = Ch.; Balance = Cu. 20-74 20-29 17 17 None A, C, E, G, J, L, N, R = Ir.; B, D, F, H, K, M, P, S = Con.; T = Cu. 20-75 20-15 7 7 None G = Al.; Balance = Ch. 20-77 20-16 9 2 7 None A = Con.; Balance = Std. 20-80 20-27 14 14 None A, C, E, G, I, K, M = Cu.; B, D, F, H, J, L, N = Con. 20-81 20-27 14 14 None A, C, E, G, I, K, M = Ch.; B, D, F, H, J, L, N = Al. 20-82 20-29 17 17 None A, C, E, G, J, L, N, R = Al.; B, D, F, H, K, M, P, S = Ch.; T = Cu. 22-36 22-23 8 8 347° A, C, E, G = Ir.; B, D, F, H = Con. 22-57 22-14 19 19 45° A, C, E, G, J, L, N, R = Ir.; B, D, F, H, K, M, P, S = Con.; T, U, V = Cu. 22-60 22-14 19 19 45° U = Al.; N = Ch.; Balance = Cu. 22-62 22-23 8 8 60° A, B, F, G = Al.; C, D, E, H = Ch. 22-68 22-19 14 14 45° A, C, E, G, J, L, M = Ir.; B, D, F, H, K, P, N = Con. 22-69 22-19 14 14 45° A, C, E, G, J, L, M = Cu.; B, D, F, H, K, P, N = Con. 22-71 22-14 19 19 None V = Al.; U = Ch.; Balance = Cu. 22-72 22-5 6 2 4 None B = Al.; E = Ch.; Balance = Cu. 22-73 22-5 6 2 4 None E = Al.; B = Ch.; Balance = Cu. 22-74 22-23 8 8 None A, C, E, G = Ir.; B, D, F, H = Con. 22-75 22-23 8 8 None A = Al.; B, D, G, H = Cu.; C = Ch.; E = Ir.; F = Con. 22-76 21 21 None W = Con.; Balance = Cu. 22-77 22-19 14 14 None B, D, F, H, J, K, M, P = Cu.; A, E, L = Ir.; C, G, N = Con. 22-78 22-14 19 19 None A, C, E, G, H, K, M, P, R, T = Con.; Balance = Cu. 22-79 22-10 4 4 None A, C, = Con.; B, D = Cu. 24-56 24-20 11 2 9 45° E = Al.; F = Ch.; Balance = Cu. 24-57 24-28 24 24 45° A, C, J, V, Y, W, K, E, H, U, S, M = Ch.; Balance = Al. 24-62 24-28 24 24 None A, C, E, G = Ir.; B, D, F, H = Con.; R, T = Ch.; S, U = Al.; Balance = Cu. A, C, E, G, J, L, K, N, S, U, W, Y = Cu.; B, D, F, H, Q, R, M, P, T, V, X, Z = 24-63 24-28 24 24 None Con. 24-64 24-5 16 16 None A, B, C, D, E, F, G, H = Ir.; J, K, L, M, N, P, R, S = Con. 24-68 24-28 24 24 None D = Con.; Balance = Cu. 24-81 24-7 16 2 14 None A, C, E, G, I, K, M, N, P = Cu.; B, D, F, H, J, L, O = Con. 28-53 28-11 22 4 18 45° J, L = Al.; K, M = Ch.; Balance = Cu. 28-58 28-20 14 10 4 45° A, C, E, G, K, M = Al.; B, D, F, H, L, N = Ch.; J, P = Cu. 28-61 28-21 37 37 45° A, C, J, Z, m, r, n, a, K, F, H, X, k, h, T, M, N, d = Ir.; Balance = Con. 28-63 28-20 14 10 4 45° A, C, E, G, J = Al.; B, D, F, H, P = Ch.; Balance = Cu. A, d = Al.; B, j = Ch.; C, D, E, F, G, N, P, R, S, H, J, K, L, M, W, X, Y, Z = Con.; 28-64 28-15 35 35 None Balance = Cu. A, C, E, G, J, L, N, R, T, V = Ir.; X, Z = Al.; B, D, F, H, K, M, P, S, U, W = Con.; 28-65 28-12 26 26 None Y, a = Ch.; b, d = Cu. 28-67 28-16 20 20 None U = Con.; Balance = Cu. 28-68 28-15 35 35 45° T = Al.; U = Ch.; Balance = Cu. 52