- 型号: MPX2102DP

- 制造商: Freescale Semiconductor

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

MPX2102DP产品简介:

ICGOO电子元器件商城为您提供MPX2102DP由Freescale Semiconductor设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 MPX2102DP价格参考。Freescale SemiconductorMPX2102DP封装/规格:压力传感器,变送器, 差分 压力 传感器 14.5 PSI(100 kPa) 公型 - 0.19"(4.93mm) 双管 0 mV ~ 40 mV(10V) 4-SIP 模块。您可以下载MPX2102DP参考资料、Datasheet数据手册功能说明书,资料中有MPX2102DP 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | SENSOR DIFF PRESS 14.5PSI MAX板机接口压力传感器 UNIBODY COMPENSATED |

| 产品分类 | |

| 品牌 | Freescale Semiconductor |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 板机接口压力传感器,Freescale Semiconductor MPX2102DPMPX2102 |

| 数据手册 | |

| 产品型号 | MPX2102DP |

| 产品目录绘图 |

|

| 产品目录页面 | |

| 产品种类 | 板机接口压力传感器 |

| 出厂设置 | - |

| 单位重量 | 5.058 g |

| 压力类型 | Differential |

| 商标 | Freescale Semiconductor |

| 安装风格 | Through Hole |

| 封装 | Tray |

| 封装/外壳 | 4-SIP 模块 |

| 封装/箱体 | Unibody 4-pin |

| 工作压力 | 14.5 psi |

| 工作温度 | -40°C ~ 125°C |

| 工作电源电压 | 10 V |

| 工厂包装数量 | 100 |

| 最大工作温度 | + 125 C |

| 最小工作温度 | - 40 C |

| 标准包装 | 400 |

| 电压-电源 | 16V |

| 端口大小 | 4.93 mm |

| 端口尺寸 | 公型,0.194"(4.9276mm)双管 |

| 端口类型 | Dual Radial Barbed |

| 端子类型 | PCB |

| 精度 | - |

| 系列 | MPXx2102 |

| 输出 | 0 mV ~ 40 mV |

.jpg)

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

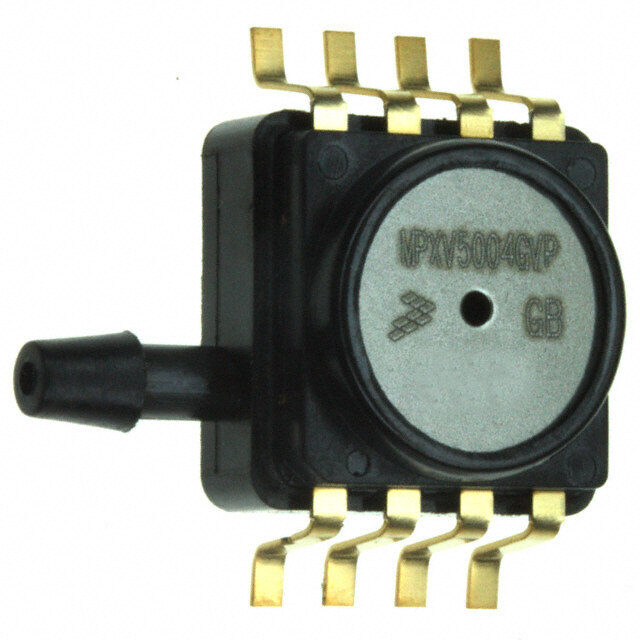

Pressure Freescale Semiconductor Document Number: MPX2102 Rev 9, 01/2012 100 kPa On-Chip Temperature MPX2102 Compensated Silicon Series Pressure Sensors 0 to 100 kPa (0 to 14.5 psi) 40 mV Full Scale The MPX2102 series devices are silicon piezoresistive pressure sensors (Typical) providing a highly accurate and linear voltage output directly proportional to the applied pressure. The sensor is a single, monolithic silicon diaphragm with the strain gauge and a thin-film resistor network integrated on chip. The chip is laser trimmed for precise span and offset calibration and temperature compensation. Application Examples • Pump/Motor Control Features • Robotics • Temperature Compensated Over 0°C to +85°C • Level Detectors • Medical Diagnostics • Easy-to-Use Chip Carrier Package Options • Pressure Switching • Available in Absolute, Differential and Gauge Configurations • Barometers • Absolute, Differential and Gauge Options • Altimeters ORDERING INFORMATION Package Case # of Ports Pressure Type Device Name Device Marking Options No. None Single Dual Gauge Differential Absolute Unibody Package (MPX2102 Series) MPX2102A Tray 344 • • MPX2102A MPX2102AP Tray 344B • • MPX2102AP MPX2102ASX Tray 344F • • MPX2102A MPX2102DP Tray 344C • • MPX2102DP MPX2102GP Tray 344B • • MPX2102GP MPX2102GVP Tray 344D • • MPX2102GVP Small Outline Package (MPXV2102G Series) MPXV2102GP Tray 1369 • • MPXV2102GP MPAK Package (MPXM2102 Series) MPXM2102A Rail 1320 • • MPXM2102A MPXM2102AT1 Tape and Reel 1320 • • MPXM2102A MPXM2102AS Rail 1320A • • MPXM2102AS MPXM2102AST1 Tape and Reel 1320A • • MPXM2102AS MPXM2102D Rail 1320 • • MPXM2102D MPXM2102DT1 Tape and Reel 1320 • • MPXM2102D MPXM2102GS Rail 1320A • • MPXM2102GS MPXM2102GST1 Tape and Reel 1320A • • MPXM2102GS © 2005-2008, 2010, 2012 Freescale Semiconductor, Inc. All rights reserved.

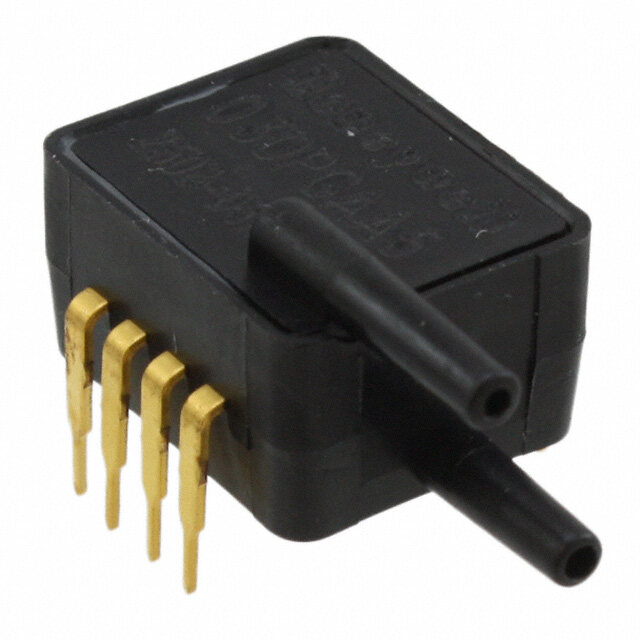

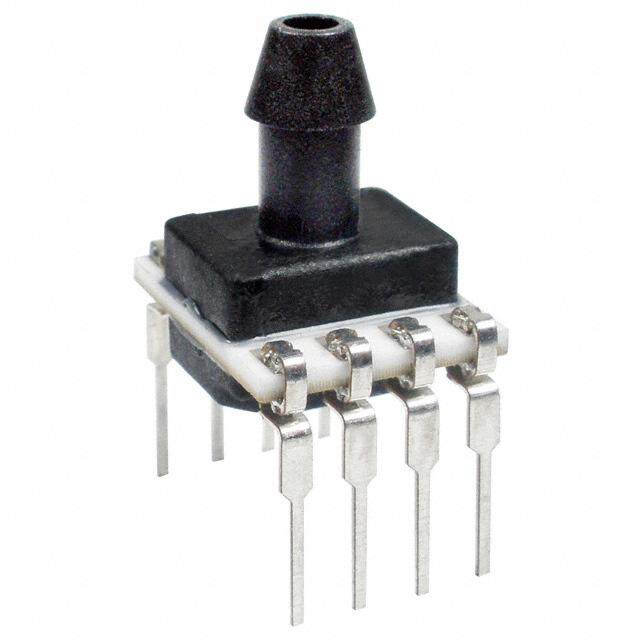

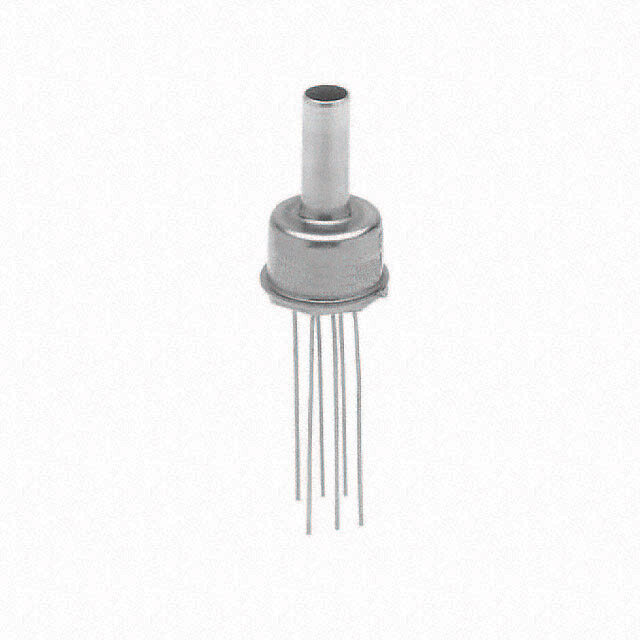

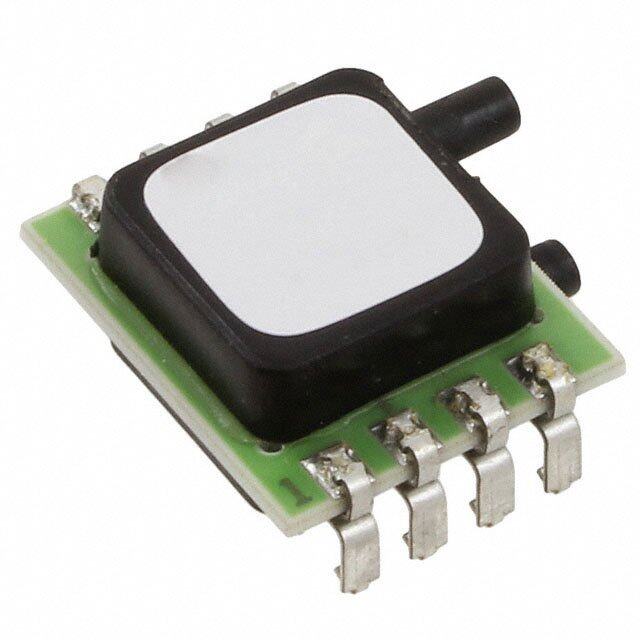

Pressure UNIBODY PACKAGES MPX2102A MPX2102AP/GP MPX2102DP MPX2102GVP MPX2102ASX CASE 344 CASE 344B CASE 344C CASE 344D CASE 344F SMALL OUTLINE PACKAGE MPAK MPXV2102GP MPXM2102A/ATI MPXM2102AS/AST1 CASE 1369 MPXM2102D/DT1 MPXM2102GS/AS CASE 1320 CASE 1320A MPX2102 Sensors 2 Freescale Semiconductor, Inc.

Pressure Operating Characteristics Table1. Operating Characteristics (V = 10 V , T = 25°C unless otherwise noted, P1 > P2) S DC A Characteristic Symbol Min Typ Max Units Pressure Range(1) Absolute Pressure Range MPX2102A POP 20 — 100 kPa Differential Pressure Range MPX2102D POP 0 — 100 kPa Supply Voltage(2) VS — 10 16 VDC Supply Current I — 6.0 — mAdc O Full Scale Span(3) VFSS 38.5 40 41.5 mV Offset(4) MPX2102D Series VOFF -1.0 — 1.0 mV MPX2102A Series -2.0 — 2.0 MPXM2102D/G Series VOFF -1.0 — 1.0 mV MPXM2102A Series -2.0 — 2.0 Sensitivity ΔV/ΔΡ — 0.4 — mV/kPa Linearity(5) MPX2102D Series — -0.6 — 0.4 %VFSS MPX2102A Series — -1.0 — 1.0 MPXM2102D/G Series — -0.6 — 0.4 %VFSS MPXM2102A Series — -1.0 — 1.0 Pressure Hysteresis(5) (0 to 100 kPa) — — ±0.1 — %VFSS Temperature Hysteresis(5)(-40°C to +125°C) — — ±0.5 — %VFSS Temperature Coefficient of Full Scale Span(5) TCVFSS -2.0 — 2.0 %VFSS Temperature Coefficient of Offset(5) TCVOFF -1.0 — 1.0 mV Input Impedance Z 1000 — 2500 W IN Output Impedance Z 1400 — 3000 W OUT Response Time(6) (10% to 90%) tR — 1.0 — ms Warm-Up Time — — 20 — ms Offset Stability(7) — — ±0.5 — %VFSS 1. 1.0 kPa (kiloPascal) equals 0.145 psi. 2. Device is ratiometric within this specified excitation range. Operating the device above the specified excitation range may induce additional error due to device self-heating. 3. Full Scale Span (V ) is defined as the algebraic difference between the output voltage at full rated pressure and the output voltage at the FSS minimum related pressure. 4. Offset (V ) is defined as the output voltage at the minimum rated pressure. OFF 5. Accuracy (error budget) consists of the following: Linearity: Output deviation from a straight line relationship with pressure, using end point method, over the specified pressure range. Temperature Hysteresis:Output deviation at any temperature within the operating temperature range, after the temperature is cycled to and from the minimum or maximum operating temperature points, with zero differential pressure applied. Pressure Hysteresis: Output deviation at any pressure with the specified range, when this pressure is cycled to and from the minimum or maximum rated pressure at 25°C. TcSpan: Output deviation at full rated pressure over the temperature range of 0 to 85°C, relative to 25°C. TcOffset: Output deviation with minimum rated pressure applied, over the temperature range of 0 to 85°C, relative to 25°C. 6. Response Time is defined as the time from the incremental change in the output to go from 10% to 90% of its final value when subjected to a specified step change in pressure. 7. Offset stability is the product’s output deviation when subjected to 1000 hours of Pulsed Pressure, Temperature Cycling with Bias Test. MPX2102 Sensors Freescale Semiconductor, Inc. 3

Pressure Maximum Ratings Table2. Maximum Ratings(1) Rating Symbol Value Unit Maximum Pressure (P1 > P2) P 400 kPa MAX Storage Temperature T -40 to +125 °C STG Operating Temperature T -40 to +125 °C A 1. Exposure beyond the specified limits may cause permanent damage or degradation to the device. Voltage Output vs. Applied Differential The differential voltage output of the sensor is directly (P1) side relative to the vacuum (P2) side. Similarly, output proportional to the differential pressure applied. voltage increases as increasing vacuum is applied to the The absolute sensor has a built-in reference vacuum. The vacuum (P2) side relative to the pressure (P1) side. output voltage will decrease as vacuum, relative to ambient, Figure1 illustrates a block diagram of the internal circuitry is drawn on the pressure (P1) side. on the stand-alone pressure sensor chip. The output voltage of the differential or gauge sensor increases with increasing pressure applied to the pressure V S 3 Thin Film X-ducer Temperature 2 + V Sensing Compensation OUT Element and 4 Calibration - VOUT Circuitry 1 GND Figure1. Temperature Compensated Pressure Sensor Schematic MPX2102 Sensors 4 Freescale Semiconductor, Inc.

Pressure On-Chip Temperature Compensation and Calibration Figure2 shows the output characteristics of the MPX2102 The effects of temperature on Full Scale Span and Offset series at 25°C. The output is directly proportional to the are very small and are shown under Operating differential pressure and is essentially a straight line. Characteristics. 40 VS = 10 VDC TA = 25°C 35 MPX2102 30 P1 > P2 TYP 25 Span )C 20 MAX Range VD (TYP) m 15 put ( 10 MIN ut O 5 0 -5 Offset kPa 0 25 50 75 100 (TYP) PSI 3.62 7.25 10.88 14.5 Figure2. Output vs. Pressure Differential Silicone Gel DDiifeferential/Gauge Stainless Steel Silicone Gel AbDsoielute MSteatianll eCsosv Setreel Die Coat P1 Metal Cover Die Coat P1 Epoxy Epoxy Case Wire Bond Wire Bond Case Lead Frame Bond Lead Frame Differential/GaugeElement Die Absolute Element Die P2 P2 Bond Figure3. Cross Sectional Diagrams (Not to Scale) Figure3 illustrates the absolute sensing configuration Freescale’s specified pressure sensor linearities are based (right) and the differential or gauge configuration in the basic on the end point straight line method measured at the chip carrier (Case 344). A silicone gel isolates the die surface midrange pressure. and wire bonds from the environment, while allowing the pressure signal to be transmitted to the silicon diaphragm. Least Squares Fit The MPX2102 series pressure sensor operating Least Square characteristics and internal reliability and qualification tests Exaggerated Deviation are based on use of dry air as the pressure media. Media Performance other than dry air may have adverse effects on sensor Curve Straight Line performance and long term reliability. Contact the factory for Deviation information regarding media compatibility in your application. ut p ut O LINEARITY e g a Linearity refers to how well a transducer's output follows olt End Point Straight V the equation: V = V + sensitivity x P over the operating e Line Fit OUT OFF v pressure range. There are two basic methods for calculating elati R nonlinearity: (1) end point straight line fit (see Figure4) or (2) a least squares best line fit. While a least squares fit gives the Offset “best case” linearity error (lower numerical value), the calculations required are burdensome. 0 50 100 Conversely, an end point fit will give the “worst case” error Pressure (% Full scale) (often more desirable in error budget calculations) and the calculations are more straightforward for the user. Figure4. Linearity Specification Comparison MPX2102 Sensors Freescale Semiconductor, Inc. 5

Pressure PRESSURE (P1)/VACUUM (P2) SIDE IDENTIFICATION TABLE Freescale designates the two sides of the pressure sensor as the Pressure (P1) side and the Vacuum (P2) side. The Table3. Pressure (P1) Side Delineation Pressure (P1) side is the side containing the silicone gel Case Pressure (P1) Side which isolates the die. The differential or gauge sensor is Part Number Type Identifier designed to operate with positive differential pressure MPX2102A 344 Stainless Steel Cap applied, P1 > P2. The absolute sensor is designed for vacuum applied to P1 side. MPX2102DP 344C Side with Part Marking The Pressure (P1) side may be identified by using Table3. MPX2102AP, 344B Side with Port Attached MPX2102GP MPX2102GVP 344D Stainless Steel Cap MPX2102ASX 344F Side with Port Marking MPXV2102GP 1369 Side with Port Attached MPXM2102A, MPX2102ATI, 1320 Stainless Steel Cap MPXM2102D, MPXM2102DT1 MPXM2102AS, MPXM2102GS, 1320A Side with Port Attached MPXM2102ASTI, MPXM2102GSTI MPX2102 Sensors 6 Freescale Semiconductor, Inc.

Pressure PACKAGE DIMENSIONS C NOTES: 1. DIMENSIONING AND TOLERANCING PER ASME R Y14.5M, 1994. 2. CONTROLLING DIMENSION: INCH. 3. DIMENSION -A- IS INCLUSIVE OF THE MOLD M STOP RING. MOLD STOP RING NOT TO EXCEED Z 16.00 (0.630). 1 4 B -A- 2 3 INCHES MILLIMETERS DIM MIN MAX MIN MAX A 0.595 0.630 15.11 16.00 N B 0.514 0.534 13.06 13.56 PIN 1 1 2 3 4 L C 0.200 0.220 5.08 5.59 D 0.016 0.020 0.41 0.51 -T- F 0.048 0.064 1.22 1.63 SEATING G 0.100 BSC 2.54 BSC PLANE F J 0.014 0.016 0.36 0.40 J G L 0.695 0.725 17.65 18.42 F Y M 30˚ NOM 30˚ NOM D4 PL N 0.475 0.495 12.07 12.57 0.136 (0.005) M T A M DAMBAR TRIM ZONE: R 0.430 0.450 10.92 11.43 THIS IS INCLUDED Y 0.048 0.052 1.22 1.32 WITHIN DIM. "F" 8 PL Z 0.106 0.118 2.68 3.00 STYLE 1: STYLE 2: STYLE 3: PIN 1. GROUND PIN 1. VCC PIN 1. GND 2. + OUTPUT 2. - SUPPLY 2. -VOUT 3. + SUPPLY 3. + SUPPLY 3. VS 4. - OUTPUT 4. GROUND 4. +VOUT CASE 344-15 ISSUE AA UNIBODY PACKAGE NOTES: SEATING -T- -A- 1. DIMENSIONING AND TOLERANCING PER ANSI PLANE U Y14.5M, 1982. R L 2. CONTROLLING DIMENSION: INCH. H INCHES MILLIMETERS DIM MIN MAX MIN MAX A 1.145 1.175 29.08 29.85 N B 0.685 0.715 17.40 18.16 PORT #1 -Q- C 0.305 0.325 7.75 8.26 POSITIVE PRESSURE D 0.016 0.020 0.41 0.51 (P1) F 0.048 0.064 1.22 1.63 G 0.100 BSC 2.54 BSC B H 0.182 0.194 4.62 4.93 J 0.014 0.016 0.36 0.41 K 0.695 0.725 17.65 18.42 1 2 3 4 L 0.290 0.300 7.37 7.62 PIN 1 K N 0.420 0.440 10.67 11.18 -P- P 0.153 0.159 3.89 4.04 0.25 (0.010) M T Q S S QR 00..125330 00..125590 35..8894 46..0345 J F US 0.202.0910 B0S.2C40 5.2539.11 BS6C.10 C G D4 PL 0.13 (0.005) M T S S Q S STYLE 1: PIN 1. GROUND 2. + OUTPUT 3. + SUPPLY 4. - OUTPUT CASE 344B-01 ISSUE B UNIBODY PACKAGE MPX2102 Sensors 7 Freescale Semiconductor, Inc.

Pressure 16 PACKAGE DIMENSIONS -A- NOTES: V U 1. DY1IM4.E5NMS, I1O9N8I2N.G AND TOLERANCING PER ANSI R PORT #1 W L 2. CONTROLLING DIMENSION: INCH. H INCHES MILLIMETERS PORT #2 PORT #2 PORT #1 DIM MIN MAX MIN MAX N V(PA2C)UUM (PPO1S)ITIVE PRESSURE AB 10..164855 10..177155 2197..0480 2198..8156 -Q- C 0.405 0.435 10.29 11.05 D 0.016 0.020 0.41 0.51 F 0.048 0.064 1.22 1.63 SEATING B SEATING G 0.100 BSC 2.54 BSC PLANE PLANE H 0.182 0.194 4.62 4.93 J 0.014 0.016 0.36 0.41 PIN 1 1 2 3 4 K 0.695 0.725 17.65 18.42 K -P- L 0.290 0.300 7.37 7.62 N 0.420 0.440 10.67 11.18 -T- -T- 0.25 (0.010)M T Q S S P 0.153 0.159 3.89 4.04 Q 0.153 0.159 3.89 4.04 J F R 0.063 0.083 1.60 2.11 C G S 0.220 0.240 5.59 6.10 D4 PL U 0.910 BSC 23.11 BSC V 0.248 0.278 6.30 7.06 0.13 (0.005) M T S S Q S W 0.310 0.330 7.87 8.38 STYLE 1: PIN 1. GROUND 2. + OUTPUT 3. + SUPPLY 4. - OUTPUT CASE 344C-01 ISSUE B UNIBODY PACKAGE NOTES: -A- 1. DIMENSIONING AND TOLERANCING PER ASME Y14.5M, 1994. U 2. CONTROLLING DIMENSION: INCH. -T- SPELAATNIENG L INCHES MILLIMETERS DIM MIN MAX MIN MAX R PORT #2 H A 1.145 1.175 29.08 29.85 VACUUM POSITIVE B 0.685 0.715 17.40 18.16 (P2) PRESSURE C 0.305 0.325 7.75 8.26 N (P1) D 0.016 0.020 0.41 0.51 F 0.048 0.064 1.22 1.63 -Q- G 0.100 BSC 2.54 BSC H 0.182 0.194 4.62 4.93 J 0.014 0.016 0.36 0.41 K 0.695 0.725 17.65 18.42 B L 0.290 0.300 7.37 7.62 N 0.420 0.440 10.67 11.18 P 0.153 0.159 3.89 4.04 1 2 3 4 K Q 0.153 0.158 3.89 4.04 R 0.230 0.250 5.84 6.35 PIN 1 S 0.220 0.240 5.59 6.10 S U 0.910 BSC 23.11 BSC C F -P- G J 0.25 (0.010) M T Q S D 4 PL STYLE 1: PIN 1. GROUND 0.13 (0.005) M T S S Q S 2. + OUTPUT 3. + SUPPLY 4. - OUTPUT CASE 344D-01 ISSUE B UNIBODY PACKAGE MPX2102 Sensors Freescale Semiconductor, Inc. 8

Pressure PACKAGE DIMENSIONS -T- NOTES: C A 1. DIMENSIONING AND TOLERANCING PER ANSI -Q- Y14.5M, 1982. E U 2. CONTROLLING DIMENSION: INCH. INCHES MILLIMETERS DIM MIN MAX MIN MAX A 1.080 1.120 27.43 28.45 B 0.740 0.760 18.80 19.30 C 0.630 0.650 16.00 16.51 N D 0.016 0.020 0.41 0.51 V B E 0.160 0.180 4.06 4.57 F 0.048 0.064 1.22 1.63 R G 0.100 BSC 2.54 BSC J 0.014 0.016 0.36 0.41 PORT #1 PIN 1 K 0.220 0.240 5.59 6.10 POSITIVE -P- N 0.070 0.080 1.78 2.03 PRESSURE P 0.150 0.160 3.81 4.06 (P1) 0.25 (0.010) M T Q M 4 3 2 1 S Q 0.150 0.160 3.81 4.06 R 0.440 0.460 11.18 11.68 S 0.695 0.725 17.65 18.42 K U 0.840 0.860 21.34 21.84 V 0.182 0.194 4.62 4.92 J F G D4 PL STYPLINE 11.: GROUND 0.13 (0.005) M T P S Q S 2. V (+) OUT 3. V SUPPLY 4. V (-) OUT CASE 344F-01 ISSUE B UNIBODY PACKAGE MPX2102 Sensors 9 Freescale Semiconductor, Inc.

Pressure PACKAGE DIMENSIONS PAGE 1 OF 2 CASE 1369-01 ISSUE B SMALL OUTLINE PACKAGE MPX2102 Sensors Freescale Semiconductor, Inc. 10

Pressure PACKAGE DIMENSIONS PAGE 2 OF 2 CASE 1369-01 ISSUE B SMALL OUTLINE PACKAGE MPX2102 Sensors 11 Freescale Semiconductor, Inc.

Pressure CASE 1320-02 ISSUE B MPAK MPX2102 Sensors 12 Freescale Semiconductor, Inc.

Pressure CASE 1320-02 ISSUE B MPAK MPX2102 Sensors Freescale Semiconductor, Inc. 13

Pressure PIN 4 PIN 1 CASE 1320A-02 ISSUE A MPAK MPX2102 Sensors 14 Freescale Semiconductor, Inc.

Pressure CASE 1320A-02 ISSUE A MPAK MPX2102 Sensors Freescale Semiconductor, Inc. 15

Pressure REVISION HISTORY Revision Revision Description of changes number date 9 01/2012 • In Table 1. Operating Characteristics, in the Characteristic column under Pressure Range, added rows for Absolute Pressure Range MPX2102A and Differential Pressure Range MPX2102D devices MPX2102 Sensors Freescale Semiconductor, Inc. 16

How to Reach Us: Home Page: www.freescale.com Web Support: http://www.freescale.com/support USA/Europe or Locations Not Listed: Freescale Semiconductor, Inc. Technical Information Center, EL516 2100 East Elliot Road Tempe, Arizona 85284 1-800-521-6274 or +1-480-768-2130 www.freescale.com/support Information in this document is provided solely to enable system and software Europe, Middle East, and Africa: implementers to use Freescale Semiconductor products. There are no express or Freescale Halbleiter Deutschland GmbH implied copyright licenses granted hereunder to design or fabricate any integrated Technical Information Center circuits or integrated circuits based on the information in this document. Schatzbogen 7 81829 Muenchen, Germany +44 1296 380 456 (English) Freescale Semiconductor reserves the right to make changes without further notice to +46 8 52200080 (English) any products herein. Freescale Semiconductor makes no warranty, representation or +49 89 92103 559 (German) guarantee regarding the suitability of its products for any particular purpose, nor does +33 1 69 35 48 48 (French) Freescale Semiconductor assume any liability arising out of the application or use of any www.freescale.com/support product or circuit, and specifically disclaims any and all liability, including without Japan: limitation consequential or incidental damages. “Typical” parameters that may be Freescale Semiconductor Japan Ltd. provided in Freescale Semiconductor data sheets and/or specifications can and do vary Headquarters in different applications and actual performance may vary over time. All operating ARCO Tower 15F parameters, including “Typicals”, must be validated for each customer application by 1-8-1, Shimo-Meguro, Meguro-ku, customer’s technical experts. Freescale Semiconductor does not convey any license Tokyo 153-0064 under its patent rights nor the rights of others. Freescale Semiconductor products are Japan not designed, intended, or authorized for use as components in systems intended for 0120 191014 or +81 3 5437 9125 surgical implant into the body, or other applications intended to support or sustain life, support.japan@freescale.com or for any other application in which the failure of the Freescale Semiconductor product Asia/Pacific: could create a situation where personal injury or death may occur. Should Buyer Freescale Semiconductor China Ltd. purchase or use Freescale Semiconductor products for any such unintended or Exchange Building 23F unauthorized application, Buyer shall indemnify and hold Freescale Semiconductor and No. 118 Jianguo Road its officers, employees, subsidiaries, affiliates, and distributors harmless against all Chaoyang District claims, costs, damages, and expenses, and reasonable attorney fees arising out of, Beijing 100022 directly or indirectly, any claim of personal injury or death associated with such China unintended or unauthorized use, even if such claim alleges that Freescale +86 010 5879 8000 Semiconductor was negligent regarding the design or manufacture of the part. support.asia@freescale.com For Literature Requests Only: Freescale and the Freescale logo are trademarks of Freescale Semiconductor, Inc., Freescale Semiconductor Literature Distribution Center Reg. U.S. Pat. & Tm. Off. 1-800-441-2447 or +1-303-675-2140 All other product or service names are the property of their respective owners. Fax: +1-303-675-2150 LDCForFreescaleSemiconductor@hibbertgroup.com © 2012 Freescale Semiconductor, Inc. All rights reserved. MPX2102 Rev. 9 01/2012

Datasheet下载

Datasheet下载