ICGOO在线商城 > 集成电路(IC) > 嵌入式 - 微处理器 > MPC5200CVR400

- 型号: MPC5200CVR400

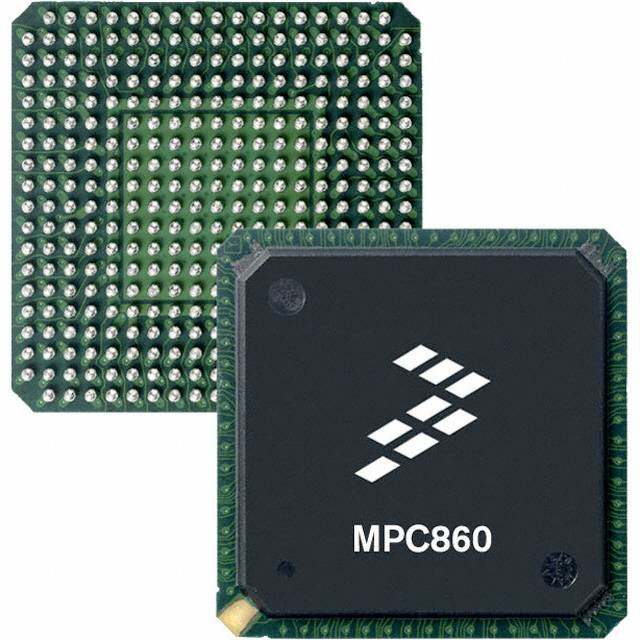

- 制造商: Freescale Semiconductor

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

MPC5200CVR400产品简介:

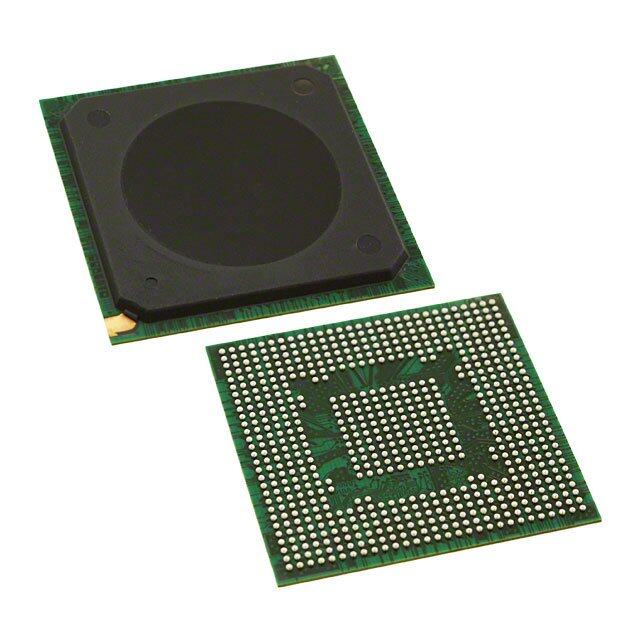

ICGOO电子元器件商城为您提供MPC5200CVR400由Freescale Semiconductor设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 MPC5200CVR400价格参考¥192.95-¥374.70。Freescale SemiconductorMPC5200CVR400封装/规格:嵌入式 - 微处理器, PowerPC G2_LE Microprocessor IC MPC52xx 1 Core, 32-Bit 400MHz 272-PBGA (27x27)。您可以下载MPC5200CVR400参考资料、Datasheet数据手册功能说明书,资料中有MPC5200CVR400 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| AdditionalInterfaces | AC97, CAN, J1850, I²C, I²S, IrDA, PCI, PSC, SPI, UART |

| 产品目录 | 集成电路 (IC) |

| Co-Processors/DSP | - |

| 描述 | IC MPU MPC52XX 400MHZ 272BGA |

| Display&InterfaceControllers | - |

| 产品分类 | |

| GraphicsAcceleration | No |

| 品牌 | Freescale Semiconductor |

| NumberofCores/BusWidth | 1 Core, 32-Bit |

| 数据手册 | |

| 产品图片 | |

| 产品型号 | MPC5200CVR400 |

| RAMControllers | DDR, SDRAM |

| RAM控制器 | DDR, SDRAM |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| SATA | - |

| SecurityFeatures | - |

| 产品系列 | MPC52xx |

| USB | USB 1.1 (2) |

| 以太网 | 10/100 Mbps (1) |

| 供应商器件封装 | 272-PBGA(27x27) |

| 包装 | 托盘 |

| 协处理器/DSP | - |

| 图形加速 | 无 |

| 处理器类型 | 32-位 MPC52xx PowerPC |

| 安全特性 | - |

| 安装类型 | * |

| 封装/外壳 | 272-BBGA |

| 工作温度 | -40°C ~ 85°C |

| 显示与接口控制器 | - |

| 标准包装 | 200 |

| 核心处理器 | PowerPC G2_LE |

| 核数/总线宽度 | 1 코어, 32 位 |

| 特性 | - |

| 电压 | 1.5V |

| 电压-I/O | 2.5V, 3.3V |

| 速度 | 400MHz |

| 附加接口 | AC97, CAN, J1850, I²C, I²S, IrDA, PCI, PSC, SPI, UART |

PDF Datasheet 数据手册内容提取

Freescale Semiconductor MPC5200 Rev. 4, 01/2005 Data Sheet MPC5200 Data Sheet NOTE Table of Contents The information in this 1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 document is subject to 2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 3 Electrical and Thermal Characteristics. . . . . . . . . 6 change. For the latest data 3.1 DC Electrical Characteristics. . . . . . . . . . . . . 6 on the MPC5200, visit 3.2 Oscillator and PLL Electrical www.freescale.com and Characteristics. . . . . . . . . . . . . . . . . . . . . . . 12 3.3 AC Electrical Characteristics. . . . . . . . . . . . 14 proceed to the MPC5200 4 Package Description. . . . . . . . . . . . . . . . . . . . . . 64 Product Summary Page. 4.1 Package Parameters. . . . . . . . . . . . . . . . . . 64 4.2 Mechanical Dimensions. . . . . . . . . . . . . . . . 64 4.3 Pinout Listings. . . . . . . . . . . . . . . . . . . . . . . 66 1 Overview 5 System Design Information. . . . . . . . . . . . . . . . . 71 5.1 Power UP/Down Sequencing . . . . . . . . . . . 71 The MPC5200 integrates a high performance MPC603e 5.2 System and CPU Core AVDD power supply filtering . . . . . . . . . . . . . . . . . . . . . . . 73 series G2_LE core with a rich set of peripheral functions 5.3 Pull-up/Pull-down Resistor Requirements. . 73 focused on communications and systems integration. 5.4 JTAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74 The G2_LE core design is based on the PowerPCTM core 6 Ordering Information. . . . . . . . . . . . . . . . . . . . . . 79 7 Document Revision History. . . . . . . . . . . . . . . . . 79 architecture. MPC5200 incorporates an innovative BestComm I/O subsystem, which isolates routine maintenance of peripheral functions from the embedded G2_LE core. The MPC5200 contains a SDRAM/DDR Memory Controller, a flexible External Bus Interface, PCI Controller, USB, ATA, Ethernet, six Programmable Serial Controllers (PSC), I2C, SPI, CAN, J1850, Timers, and GPIOs. “Definitive Data: Freescale reserves the right to change the production detail specifications as may be required to permit improvements in the design of its products.” ©Freescale Semiconductor, Inc., 2005, 2006. All rights reserved.

Features 2 Features Key features are shown below. (cid:149) MPC603e series G2_LE core (cid:151) Superscalar architecture (cid:151) 760 MIPS at 400 MHz (-40 to +85 oC) (cid:151) 16 k Instruction cache, 16 k Data cache (cid:151) Double precision FPU (cid:151) Instruction and Data MMU (cid:151) Standard and Critical interrupt capability (cid:149) SDRAM / DDR Memory Interface (cid:151) up to 132-MHz operation (cid:151) SDRAM and DDR SDRAM support (cid:151) 256-MByte addressing range per CS, two CS available (cid:151) 32-bit data bus (cid:151) Built-in initialization and refresh (cid:149) Flexible multi-function External Bus Interface (cid:151) Supports interfacing to ROM/Flash/SRAM memories or other memory mapped devices (cid:151) 8 programmable Chip Selects (cid:151) Non multiplexed data access using 8/16/32 bit databus with up to 26-bit address (cid:151) Short or Long Burst capable (cid:151) Multiplexed data access using 8/16/32 bit databus with up to 25-bit address (cid:149) Peripheral Component Interconnect (PCI) Controller (cid:151) Version 2.2 PCI compatibility (cid:151) PCI initiator and target operation (cid:151) 32-bit PCI Address/Data bus (cid:151) 33- and 66-MHz operation (cid:151) PCI arbitration function (cid:149) ATA Controller (cid:151) Version 4 ATA compatible external interface(cid:151)IDE Disk Drive connectivity (cid:149) BestComm DMA subsystem (cid:151) Intelligent virtual DMA Controller (cid:151) Dedicated DMA channels to control peripheral reception and transmission (cid:151) Local memory (SRAM 16 kBytes) (cid:149) 6 Programmable Serial Controllers (PSC), configurable for the following: (cid:151) UART or RS232 interface MPC5200 Data Sheet, Rev. 4 2 Freescale Semiconductor

Features (cid:151) CODEC interface for Soft Modem, Master/Slave CODEC Mode, I2S and AC97 (cid:151) Full duplex SPI mode (cid:151) IrDA mode from 2400 bps to 4 Mbps (cid:149) Fast Ethernet Controller (FEC) (cid:151) Supports 100Mbps IEEE 802.3 MII, 10 Mbps IEEE 802.3 MII, 10 Mbps 7-wire interface (cid:149) Universal Serial Bus Controller (USB) (cid:151) USB Revision 1.1 Host (cid:151) Open Host Controller Interface (OHCI) (cid:151) Integrated USB Hub, with two ports. (cid:149) Two Inter-Integrated Circuit Interfaces (I2C) (cid:149) Serial Peripheral Interface (SPI) (cid:149) Dual CAN 2.0 A/B Controller (MSCAN) (cid:151)Freescale Scalable Controller Area Network (FSCAN) architecture (cid:151) Implementation of version 2.0A/B CAN protocol (cid:151) Standard and extended data frames (cid:149) J1850 Byte Data Link Controller (BDLC) (cid:151) J1850 Class B data communication network interface compatible and ISO compatible for low speed (<125 kbps) serial data communications in automotive applications. (cid:151) Supports 4X mode, 41.6 kbps (cid:151) In-frame response (IFR) types 0, 1, 2, and 3 supported (cid:149) Systems level features (cid:151) Interrupt Controller supports four external interrupt request lines and 47 internal interrupt sources (cid:151) GPIO/Timer functions (cid:150) Up to 56 total GPIO pins (depending on functional multiplexing selections) that support a variety of interrupt/WakeUp capabilities. (cid:150) Eight GPIO pins with timer capability supporting input capture, output compare, and pulse width modulation (PWM) functions (cid:151) Real-time Clock with one-second resolution (cid:151) Systems Protection (watch dog timer, bus monitor) (cid:151) Individual control of functional block clock sources (cid:151) Power management: Nap, Doze, Sleep, Deep Sleep modes (cid:151) Support of WakeUp from low power modes by different sources (GPIO, RTC, CAN) MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 3

Features (cid:149) Test/Debug features (cid:151) JTAG (IEEE 1149.1 test access port) (cid:151) Common On-chip Processor (COP) debug port (cid:149) On-board PLL and clock generation Figure 1 shows a simplified MPC5200 block diagram. MPC5200 Data Sheet, Rev. 4 4 Freescale Semiconductor

Features als cu oB L MSCAN 2x ) U SI J1850 ( Systems Interface Unit Real-Time Clock System Functions Interrupt Controller GPIO/Timers Local Plus Controller PCI Bus Controller ATA Host Controller US2SPxBI I2C r DDR DDRntrolle BestComm DMA 2x M / M / Co Ethernet A Ay R Ror D Dm S Se M SRAM 16K PSC 6x s u B m m o e C r o 03 E C OPe ockon 6 G2_L AG / Cnterfac set / Clenerati TI eG J R Figure1. Simplified Block Diagram—MPC5200 MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 5

Electrical and Thermal Characteristics 3 Electrical and Thermal Characteristics 3.1 DC Electrical Characteristics 3.1.1 Absolute Maximum Ratings The tables in this section describe the MPC5200 DC Electrical characteristics. Table 1 gives the absolute maximum ratings. Table1. Absolute Maximum Ratings1 Characteristic Symbol Min Max Unit SpecID Supply voltage - G2_LE core and peripheral logic VDD_CORE –0.3 1.8 V D1.1 Supply voltage - I/O buffers VDD_IO, –0.3 3.6 V D1.2 VDD_MEM_IO Supply voltage - System APLL SYS_PLL_AVDD –0.3 2.1 V D1.3 Supply voltage - G2_LE APLL CORE_PLL_AVDD –0.3 2.1 V D1.4 Input voltage (VDD_IO) Vin –0.3 VDD_IO + 0.3 V D1.5 Input voltage (VDD_MEM_IO) Vin –0.3 VDD_MEM_IO V D1.6 + 0.3 Input voltage overshoot Vinos – 1.0 V D1.7 Input voltage undershoot Vinus – 1.0 V D1.8 Storage temperature range Tstg –55 150 oC D1.9 NOTES: 1 Absolute maximum ratings are stress ratings only, and functional operation at the maximums is not guaranteed. Stresses beyond those listed may affect device reliability or cause permanent damage. 3.1.2 Recommended Operating Conditions Table 2 gives the recommended operating conditions. Table2. Recommended Operating Conditions Characteristic Symbol Min1 Max(1) Unit SpecID Supply voltage - G2_LE core and peripheral VDD_CORE 1.42 1.58 V D2.1 logic Supply voltage - standard I/O buffers VDD_IO 3.0 3.6 V D2.2 Supply voltage - memory I/O buffers (SDR) VDD_MEM_IO 3.0 3.6 V D2.3 SDR Supply voltage - memory I/O buffers (DDR) VDD_MEM_IO 2.42 2.63 V D2.4 DDR Supply voltage - System APLL SYS_PLL_AVDD 1.42 1.58 V D2.5 Supply voltage - G2_LE APLL CORE_PLL_AVDD 1.42 1.58 V D2.6 Input voltage - standard I/O buffers Vin 0 VDD_IO V D2.7 Input voltage - memory I/O buffers (SDR) Vin 0 VDD_MEM_IO V D2.8 SDR SDR MPC5200 Data Sheet, Rev. 4 6 Freescale Semiconductor

Electrical and Thermal Characteristics Table2. Recommended Operating Conditions (continued) Characteristic Symbol Min1 Max(1) Unit SpecID Input voltage - memory I/O buffers (DDR) Vin 0 VDD_MEM_IO V D2.9 DDR DDR Ambient operating temperature range2 T -40 +85 oC D2.10 A Extended ambient operating temperature T -40 +105 oC D2.11 Aext range3 Die junction operating temperature range Tj -40 +115 oC D2.12 Extended die junction operating temperature Tjext -40 +125 oC D2.13 range NOTES: 1 These are recommended and tested operating conditions. Proper device operation outside these conditions is not guaranteed. 2 Maximum G2_LE core operating frequency is 400 MHz 3 Maximum G2_LE core operating frequency is 264 MHz 3.1.3 DC Electrical Specifications Table 3 gives the DC Electrical characteristics for the MPC5200 at recommended operating conditions (see Table 2). Table3. DC Electrical Specifications Characteristic Condition Symbol Min Max Unit SpecID Input high voltage Input type = TTL V 2.0 — V D3.1 IH VDD_IO/VDD_MEM_IO SDR Input high voltage Input type = TTL V 1.7 — V D3.2 IH VDD_MEM_IO DDR Input high voltage Input type = PCI V 2.0 — V D3.3 IH VDD_IO Input high voltage Input type = SCHMITT V 2.0 — V D3.4 IH VDD_IO Input high voltage SYS_XTAL_IN CV 2.0 — V D3.5 IH Input high voltage RTC_XTAL_IN CV 2.0 — V D3.6 IH Input low voltage Input type = TTL V — 0.8 V D3.7 IL VDD_IO/VDD_MEM_IO SDR Input low voltage Input type = TTL V — 0.7 V D3.8 IL VDD_MEM_IO DDR Input low voltage Input type = PCI V — 0.8 V D3.9 IL VDD_IO Input low voltage Input type = SCHMITT V — 0.8 V D3.10 IL VDD_IO Input low voltage SYS_XTAL_IN CV — 0.8 V D3.11 IL Input low voltage RTC_XTAL_IN CV — 0.8 V D3.12 IL MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 7

Electrical and Thermal Characteristics Table3. DC Electrical Specifications (continued) Characteristic Condition Symbol Min Max Unit SpecID Input leakage current Vin = 0 or I — +10 µA D3.13 IN VDD_IO/VDD_IO_MEM SDR 1 (depending on input type ) Input leakage current SYS_XTAL_IN I — +10 µA D3.14 IN Vin = 0 or VDD_IO Input leakage current RTC_XTAL_IN I — +10 µA D3.15 IN Vin = 0 or VDD_IO Input current, pullup resistor PULLUP I 40 109 µA D3.16 INpu VDD_IO Vin = 0 Input current, pullup resistor - PULLUP_MEM I 41 111 µA D3.17 INpu memory I/O buffers VDD_IO_MEM SDR Vin = 0 Input current, pulldown resistor PULLDOWN I 36 106 µA D3.18 INpd VDD_IO Vin = VDD_IO Output high voltage IOH is driver dependent2 V 2.4 — V D3.19 OH VDD_IO, VDD_IO_MEM SDR Output high voltage IOH is driver dependent2 V 1.7 — V D3.20 OHDDR VDD_IO_MEM DDR Output low voltage IOL is driver dependent2 V — 0.4 V D3.21 OL VDD_IO, VDD_IO_MEM SDR Output low voltage IOL is driver dependent2 V — 0.4 V D3.22 OLDDR VDD_IO_MEM DDR DC Injection Current Per Pin3 I -1.0 1.0 mA D3.23 CS Capacitance Vin = 0V, f = 1 MHz C — 15 pF D3.24 in NOTES: 1 Leakage current is measured with output drivers disabled and pull-up/pull-downs inactive. 2 See Table 4 for the typical drive capability of a specific signal pin based on the type of output driver associated with that pin as listed in Table 52. 3 All injection current is transferred to VDD_IO/VDD_IO_MEM. An external load is required to dissipate this current to maintain the power supply within the specified voltage range. Total injection current for all digital input-only and all digital input/output pins must not exceed 10 mA. Exceeding this limit can cause disruption of normal operation. Table4. Drive Capability of MPC5200 Output Pins Driver Type Supply Voltage I I Unit SpecID OH OL DRV4 VDD_IO = 3.3V 4 4 mA D3.25 DRV8 VDD_IO = 3.3V 8 8 mA D3.26 MPC5200 Data Sheet, Rev. 4 8 Freescale Semiconductor

Electrical and Thermal Characteristics Table4. Drive Capability of MPC5200 Output Pins (continued) Driver Type Supply Voltage I I Unit SpecID OH OL DRV8_OD VDD_IO = 3.3V - 8 mA D3.27 DRV16_MEM VDD_IO_MEM = 3.3V 16 16 mA D3.28 DRV16_MEM VDD_IO_MEM = 2.5V 16 16 mA D3.29 PCI VDD_IO = 3.3V 16 16 mA D3.30 3.1.4 Electrostatic Discharge CAUTION This device contains circuitry that protects against damage due to high-static voltage or electrical fields. However, it is advised that normal precautions be taken to avoid application of any voltages higher than maximum-rated voltages. Operational reliability is enhanced if unused inputs are tied to an appropriate logic voltage level (i.e., either GND or V ). Table 7 gives package thermal characteristics for this device. CC Table5. ESD and Latch-Up Protection Characteristics Sym Rating Min Max Unit SpecID V Human Body Model (HBM)—JEDEC JESD22-A114-B 2000 — V D4.1 HBM V Machine Model (MM)—JEDEC JESD22-A115 200 — V D4.2 MM V Charge Device Model (CDM)—JEDEC JESD22-C101 500 — V D4.3 CDM I Latch-up Current at T =85oC D4.4 LAT A positive +100 — mA negative -100 I Latch-up Current at T =27oC D4.5 LAT A positive +200 — mA negative -200 3.1.5 Power Dissipation Power dissipation of the MPC5200 is caused by 3 different components: the dissipation of the internal or core digital logic (supplied by VDD_CORE), the dissipation of the analog circuitry (supplied by SYS_PLL_AVDD and CORE_PLL_AVDD) and the dissipation of the IO logic (supplied by VDD_IO_MEM and VDD_IO). Table 6 details typical measured core and analog power dissipation figures for a range of operating modes. However, the dissipation due to the switching of the IO pins can not be given in general, but must be calculated by the user for each application case using the following formula 2 P = P +∑N×C×VDD_IO ×f IO IOint M MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 9

Electrical and Thermal Characteristics where N is the number of output pins switching in a group M, C is the capacitance per pin, VDD_IO is the IO voltage swing, f is the switching frequency and PIOint is the power consumed by the unloaded IO stage. The total power consumption of the MPC5200 processor must not exceed the value, which would cause the maximum junction temperature to be exceeded. P = P +P +P total core analog IO Table6. Power Dissipation Core Power Supply (VDD_CORE) SYS_XTAL/XLB/PCI/IPG/CORE (MHz) SpecID Mode 33/66/33/33/264 33/132/66/132/396 Unit Notes Typ Typ Operational 727.5 1080 mW 1,2 D5.1 Doze — 600 mW 1,3 D5.2 Nap — 225 mW 1,4 D5.3 Sleep — 225 mW 1,5 D5.4 Deep-Sleep 52.5 52.5 mW 1,6 D5.5 PLL Power Supplies (SYS_PLL_AVDD, CORE_PLL_AVDD) Mode Typ Unit Notes Typical 2 mW 7 D5.6 Unloaded I/O Power Supplies (VDD_IO, VDD_MEM_IO8) Mode Typ Unit Notes Typical 33 mW 9 D5.7 NOTES: 1 Typical core power is measured at VDD_CORE = 1.5 V, Tj = 25 C 2 Operational power is measured while running an entirely cache-resident program with floating-point multiplication instructions in parallel with a continuous PCI transaction via BestComm. 3 Doze power is measured with the G2_LE core in Doze mode, the system oscillator, System PLL and Core PLL are active, all other system modules are inactive 4 Nap power is measured with the G2_LE core in Nap mode, the stem oscillator, System PLL and Core PLL are active, all other system modules are inactive 5 Sleep power is measured with the G2_LE core in Sleep mode, the stem oscillator, System PLL and Core PLL are active, all other system modules are inactive 6 Deep-Sleep power is measured with the G2_LE core in Sleep mode, the stem oscillator, System PLL, Core PLL and all other system modules are inactive 7 Typical PLL power is measured at SYS_PLL_AVDD = CORE_PLL_AVDD = 1.5 V, Tj = 25 C 8 IO power figures given in the table represent the worst case scenario. For the mem_io rail connected to 2.5V the IO power is expected to be lower and bounded by the worst case with VDD_MEM_IO connected to 3.3V. 9 Unloaded typical I/O power is measured in Deep-Sleep mode at VDD_IO = VDD_MEM_IO = 3.3 V, Tj = 25 C SDR MPC5200 Data Sheet, Rev. 4 10 Freescale Semiconductor

Electrical and Thermal Characteristics 3.1.6 Thermal Characteristics Table7. Thermal Resistance Data Rating Value Unit Notes SpecID Junction to Ambient Single layer board R 30 °C/W 1,2 D6.1 θJA Natural Convection (1s) Junction to Ambient Four layer board (2s2p) R 22 °C/W 1,3 D6.2 θJMA Natural Convection Junction to Ambient (@200 Single layer board R 24 °C/W 1,3 D6.3 θJMA ft/min) (1s) Junction to Ambient (@200 Four layer board R 19 °C/W 1,3 D6.4 θJMA ft/min) (2s2p) Junction to Board R 14 °C/W 4 D6.5 θJB Junction to Case R 8 °C/W 5 D6.6 θJC Junction to Package Top Natural Convection Ψ 2 °C/W 6 D6.7 JT NOTES: 1 Junction temperature is a function of die size, on-chip power dissipation, package thermal resistance, mounting site (board) temperature, ambient temperature, air flow, power dissipation of other components on the board, and board thermal resistance. 2 Per SEMI G38-87 and JEDEC JESD51-2 with the single layer board horizontal. 3 Per JEDEC JESD51-6 with the board horizontal. 4 Thermal resistance between the die and the printed circuit board per JEDEC JESD51-8. Board temperature is measured on the top surface of the board near the package. 5 Thermal resistance between the die and the case top surface as measured by the cold plate method (MIL SPEC-883 Method 1012.1). 6 Thermal characterization parameter indicating the temperature difference between package top and the junction temperature per JEDEC JESD51-2. When Greek letters are not available, the thermal characterization parameter is written as Psi-JT. 3.1.7 Heat Dissipation An estimation of the chip-junction temperature, T , can be obtained from the following equation: J T = T +(R × P ) Eqn.1 J A θJA D where: T = ambient temperature for the package (°C) A R = junction to ambient thermal resistance (°C/W) θJA P = power dissipation in package (W) D The junction to ambient thermal resistance is an industry standard value, which provides a quick and easy estimation of thermal performance. Unfortunately, there are two values in common usage: the value determined on a single layer board, and the value obtained on a board with two planes. For packages such as the PBGA, these values can be different by a factor of two. Which value is correct depends on the power dissipated by other components on the board. The value obtained on a single layer board is appropriate for the tightly packed printed circuit board. The value obtained on the board with the internal planes is usually appropriate if the board has low power dissipation and the components are well separated. MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 11

Electrical and Thermal Characteristics Historically, the thermal resistance has frequently been expressed as the sum of a junction to case thermal resistance and a case to ambient thermal resistance: R = R +R Eqn.2 θJA θJC θCA where: R = junction to ambient thermal resistance (°C/W) θJA R = junction to case thermal resistance (°C/W) θJC R = case to ambient thermal resistance (°C/W) θCA R is device related and cannot be influenced by the user. The user controls the thermal environment to θJC change the case to ambient thermal resistance, R . For instance, the user can change the air flow around θCA the device, add a heat sink, change the mounting arrangement on printed circuit board, or change the thermal dissipation on the printed circuit board surrounding the device. This description is most useful for ceramic packages with heat sinks where some 90% of the heat flow is through the case to the heat sink to ambient. For most packages, a better model is required. A more accurate thermal model can be constructed from the junction to board thermal resistance and the junction to case thermal resistance1-3. The junction to case covers the situation where a heat sink will be used or where a substantial amount of heat is dissipated from the top of the package. The junction to board thermal resistance describes the thermal performance when most of the heat is conducted to the printed circuit board. This model can be used for either hand estimations or for a computational fluid dynamics (CFD) thermal model. To determine the junction temperature of the device in the application after prototypes are available, the Thermal Characterization Parameter (Ψ ) can be used to determine the junction temperature with a JT measurement of the temperature at the top center of the package case using the following equation: T = T +(Ψ × P ) Eqn.3 J T JT D where: T = thermocouple temperature on top of package (°C) T Ψ = thermal characterization parameter (°C/W) JT P = power dissipation in package (W) D The thermal characterization parameter is measured per JESD51-2 specification using a 40-gauge type T thermocouple epoxied to the top center of the package case. The thermocouple should be positioned, so that the thermocouple junction rests on the package. A small amount of epoxy is placed over the thermocouple junction and over approximately one mm of wire extending from the junction. The thermocouple wire is placed flat against the package case to avoid measurement errors caused by cooling effects of the thermocouple wire. 3.2 Oscillator and PLL Electrical Characteristics The MPC5200 System requires a system-level clock input SYS_XTAL. This clock input may be driven directly from an external oscillator or with a crystal using the internal oscillator. MPC5200 Data Sheet, Rev. 4 12 Freescale Semiconductor

Electrical and Thermal Characteristics There is a separate oscillator for the independent Real-Time Clock (RTC) system. The MPC5200 clock generation uses two phase locked loop (PLL) blocks. (cid:149) The system PLL (SYS_PLL) takes an external reference frequency and generates the internal system clock. The system clock frequency is determined by the external reference frequency and the settings of the SYS_PLL configuration. (cid:149) The G2_LE core PLL (CORE_PLL) generates a master clock for all of the CPU circuitry. The G2_LE core clock frequency is determined by the system clock frequency and the settings of the CORE_PLL configuration. 3.2.1 System Oscillator Electrical Characteristics Table8. System Oscillator Electrical Characteristics Characteristic Symbol Notes Min Typical Max Unit SpecID SYS_XTAL frequency f 15.6 33.3 35.0 MHz O1.1 sys_xtal Oscillator start-up time t — — 100 µs O1.2 up_osc 3.2.2 RTC Oscillator Electrical Characteristics Table9. RTC Oscillator Electrical Characteristics Characteristic Symbol Notes Min Typical Max Unit SpecID RTC_XTAL frequency f — 32.768 — kHz O2.1 rtc_xtal 3.2.3 System PLL Electrical Characteristics Table10. System PLL Specifications Characteristic Symbol Notes Min Typical Max Unit SpecID SYS_XTAL frequency f 1 15.6 33.3 35.0 MHz O3.1 sys_xtal SYS_XTAL cycle time T (1) 66.6 30.0 28.5 ns O3.2 sys_xtal SYS_XTAL clock input jitter t 2 — — 150 ps O3.3 jitter System VCO frequency f (1) 250 533 800 MHz O3.4 VCOsys System PLL relock time t 3 — — 100 µs O3.5 lock NOTES: 1 The SYS_XTAL frequency and PLL Configuration bits must be chosen such that the resulting system frequency, CPU (core) frequency, and PLL (VCO) frequency do not exceed their respective maximum or minimum operating frequencies. 2 This represents total input jitter - short term and long term combined - and is guaranteed by design. Two different types of jitter can exist on the input to core_sysclk, systemic and true random jitter. True random jitter is rejected, but the PLL. Systemic jitter will be passed into and through the PLL to the internal clock circuitry, directly reducing the operating frequency. 3 Relock time is guaranteed by design and characterization. PLL-relock time is the maximum amount of time required for the PLL lock after a stable Vdd and core_sysclk are reached during the power-on reset sequence. This specification also applies when the PLL has been disabled and subsequently re-enabled during sleep modes. MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 13

Electrical and Thermal Characteristics 3.2.4 G2_LE Core PLL Electrical Characteristics The internal clocking of the G2_LE core is generated from and synchronized to the system clock by means of a voltage-controlled core PLL. Table11. G2_LE PLL Specifications Characteristic Symbol Notes Min Typical Max Unit SpecID G2_LE frequency f 1 50 — 550 MHz O4.1 core G2_LE cycle time t (1) 2.85 — 40.0 ns O4.2 core G2_LE VCO frequency f (1) 400 — 1200 MHz O4.3 VCOcore G2_LE input clock frequency f 25 — 367 MHz O4.4 XLB_CLK G2_LE input clock cycle time t 2.73 — 50.0 ns O4.5 XLB_CLK G2_LE input clock jitter t 2 — — 150 ps O4.6 jitter G2_LE PLL relock time t 3 — — 100 µs O4.7 lock NOTES: 1 The XLB_CLK frequency and G2_LE PLL Configuration bits must be chosen such that the resulting system frequencies, CPU (core) frequency, and G2_LE PLL (VCO) frequency do not exceed their respective maximum or minimum operating frequencies. 2 This represents total input jitter - short term and long term combined - and is guaranteed by design. Two different types of jitter can exist on the input to core_sysclk, systemic and true random jitter. True random jitter is rejected, but the PLL. Systemic jitter will be passed into and through the PLL to the internal clock circuitry, directly reducing the operating frequency. 3 Relock time is guaranteed by design and characterization. PLL-relock time is the maximum amount of time required for the PLL lock after a stable Vdd and core_sysclk are reached during the power-on reset sequence. This specification also applies when the PLL has been disabled and subsequently re-enabled during sleep modes. 3.3 AC Electrical Characteristics Hyperlinks to the indicated timing specification sections are provided below. (cid:149) AC Operating Frequency Data (cid:149) USB (cid:149) Clock AC Specifications (cid:149) SPI (cid:149) Resets (cid:149) MSCAN (cid:149) External Interrupts (cid:149) I2C (cid:149) SDRAM (cid:149) J1850 (cid:149) PCI (cid:149) PSC (cid:149) Local Plus Bus (cid:149) GPIOs and Timers (cid:149) ATA (cid:149) IEEE 1149.1 (JTAG) AC Specifications (cid:149) Ethernet AC Test Timing Conditions: Unless otherwise noted, all test conditions are as follows: MPC5200 Data Sheet, Rev. 4 14 Freescale Semiconductor

Electrical and Thermal Characteristics (cid:149) TA = -40 to 85 oC (cid:149) Tj = -40 to 115 oC (cid:149) VDD_CORE = 1.42 to 1.58 V VDD_IO = 3.0 to 3.6 V (cid:149) Input conditions: All Inputs: tr, tf <= 1 ns (cid:149) Output Loading: All Outputs: 50 pF 3.3.1 AC Operating Frequency Data Table 12 provides the operating frequency information for the MPC5200. Table12. Clock Frequencies Min Max Units SpecID 1 G2_LE Processor Core — 400 MHz A1.1 2 SDRAM Clock — 133 MHz A1.2 3 XL Bus Clock — 133 MHz A1.3 4 IP Bus Clock — 133 MHz A1.4 5 PCI / Local Plus Bus Clock — 66 MHz A1.5 6 PLL Input Range 15.6 35 MHz A1.6 3.3.2 Clock AC Specifications t CYCLE t t t t DUTY DUTY RISE FALL CV IH SYSCLK VM VM VM CV IL Figure2. Timing Diagram—SYS_XTAL_IN MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 15

Electrical and Thermal Characteristics Table13. SYS_XTAL_IN Timing Sym Description Min Max Units SpecID t SYS_XTAL_IN cycle time.1 28.6 64.1 ns A2.1 CYCLE t SYS_XTAL_IN rise time. — 5.0 ns A2.2 RISE t SYS_XTAL_IN fall time. — 5.0 ns A2.3 FALL t SYS_XTAL_IN duty cycle (measured at V ).2 40.0 60.0 % A2.4 DUTY M CV SYS_XTAL_IN input voltage high 2.0 — V A2.5 IH CV SYS_XTAL_IN input voltage low — 0.8 V A2.6 IL NOTES: 1 CAUTION—The SYS_XTAL_IN frequency and system PLL_CFG[0-6] settings must be chosen such that the resulting system frequencies do not exceed their respective maximum or minimum operating frequencies. See the MPC5200 User Manual [1]. 2 SYS_XTAL_IN duty cycle is measured at V . M 3.3.3 Resets The MPC5200 has three reset pins: (cid:149) PORRESET - Power on Reset (cid:149) HRESET - Hard Reset (cid:149) SRESET - Software Reset These signals are asynchronous I/O signals and can be asserted at any time. The input side uses a Schmitt trigger and requires the same input characteristics as other MPC5200 inputs, as specified in the DC Electrical Specifications section. Table 14 specifies the pulse widths of the Reset inputs. Table14. Reset Pulse Width Max Pulse Name Description Min Pulse Width Reference Clock SpecID Width PORRESET Power On Reset t +t +t — SYS_XTAL_IN A3.1 VDD_stable up_osc lock HRESET Hardware Reset 4 clock cycles — SYS_XTAL_IN A3.2 SRESET Software Reset 4 clock cycles — SYS_XTAL_IN A3.3 Notes: 1. For PORRESET the value of the minimum pulse width reflects the power on sequence. If PORRESET is asserted afterwards its minimum pulse width equals the minimum given for HRESET related to the same reference clock. 2. The t describes the time which is needed to get all power supplies stable. VDD_stable 3. For t refer to the Oscillator/PLL section of this specification for further details. lock, 4. For t refer to the Oscillator/PLL section of this specification for further details. up_osc, 5. Following the deassertion of PORRESET, HRESET and SRESET remain low for 4096 reference clock cycles. 6. The deassertion of HRESET for at least the minimum pulse width forces the internal resets to be active for an additional 4096 clock cycles. NOTE As long as VDD is not stable the HRESET output is not stable. MPC5200 Data Sheet, Rev. 4 16 Freescale Semiconductor

Electrical and Thermal Characteristics Table15. Reset Rise / Fall Timing Description Min Max Unit SpecID PORRESET fall time — 1 ms A3.4 PORRESET rise time — 1 ms A3.5 HRESET fall time — 1 ms A3.6 HRESET rise time — 1 ms A3.7 SRESET fall time — 1 ms A3.8 SRESET rise time — 1 ms A3.9 For additional information, see the MPC5200 User Manual [1]. NOTE Make sure that the PORRESET does not carry any glitches. The MPC5200 has no filter to prevent them from getting into the chip. NOTE HRESET and SRESET must have a monotonous rise time. 3.3.3.1 Reset Configuration Word During reset (HRESET and PORRESET) the Reset Configuration Word is cached in the related Reset Configuration Word Register with each rising edge of the SYS_XTAL signal. If both resets (HRESET and PORRESET) are inactive (high), the contents of this register get locked after two further SYS_XTAL cycles (see Figure 3). 4096 clocks 2 clocks SYS_XTAL PORRESET HRESET RST_CFG_WRD sample sample sample sample sample sample sample sample sample sample sample sample LOCK Figure3. Reset Configuration Word Locking MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 17

Electrical and Thermal Characteristics NOTE Beware of changing the values on the pins of the reset configuration word after the deassertion of PORRESET. This may cause problems because it may change the internal clock ratios and so extend the PLL locking process. 3.3.4 External Interrupts The MPC5200 provides three different kinds of external interrupts: (cid:149) Four IRQ interrupts (cid:149) Eight GPIO interrupts with simple interrupt capability (not available in power-down mode) (cid:149) Eight WakeUp interrupts (special GPIO pins) The propagation of these three kinds of interrupts to the core is shown in the following graphic: IRQ0 cint Encoder core_cint 8 8 GPIOs GPIO Std core_int int 8 8 GPIOs GPIO WakeUp G2_LE Core Grouper IRQ1 Encoder IRQ2 PIs Main Interrupt IRQ3 Controller Notes: 1. PIs = Programmable Inputs 2. Grouper and Encoder functions imply programmability in software Figure4. External interrupt scheme Due to synchronization, prioritization, and mapping of external interrupt sources, the propagation of external interrupts to the core processor is delayed by several IP_CLK clock cycles. The following table specifies the interrupt latencies in IP_CLK cycles. The IP_CLK frequency is programmable in the Clock Distribution Module (see Note Table 16). Table16. External interrupt latencies Interrupt Type Pin Name Clock Cycles Reference Clock Core Interrupt SpecID Interrupt Requests IRQ0 10 IP_CLK critical (cint) A4.1 IRQ0 10 IP_CLK normal (int) A4.2 IRQ1 10 IP_CLK normal (int) A4.3 IRQ2 10 IP_CLK normal (int) A4.5 10 IP_CLK normal (int) A4.6 IRQ3 MPC5200 Data Sheet, Rev. 4 18 Freescale Semiconductor

Electrical and Thermal Characteristics Table16. External interrupt latencies (continued) Interrupt Type Pin Name Clock Cycles Reference Clock Core Interrupt SpecID Standard GPIO Interrupts 12 IP_CLK normal (int) A4.7 GPIO_PSC3_4 12 IP_CLK normal (int) A4.8 GPIO_PSC3_5 GPIO_PSC3_8 12 IP_CLK normal (int) A4.9 GPIO_USB_9 12 IP_CLK normal (int) A4.10 GPIO_ETHI_4 12 IP_CLK normal (int) A4.11 GPIO_ETHI_5 12 IP_CLK normal (int) A4.12 GPIO_ETHI_6 12 IP_CLK normal (int) A4.13 GPIO_ 12 IP_CLK normal (int) A4.14 ETHI_7 GPIO WakeUp Interrupts GPIO_ 12 IP_CLK normal (int) A4.15 PSC1_4 GPIO_PSC2_4 12 IP_CLK normal (int) A4.16 GPIO_PSC3_9 12 IP_CLK normal (int) A4.17 GPIO_ETHI_8 12 IP_CLK normal (int) A4.18 GPIO_IRDA_0 12 IP_CLK normal (int) A4.19 DGP_IN0 12 IP_CLK normal (int) A4.20 DGP_IN1 12 IP_CLK normal (int) A4.21 Notes: 1) The frequency of IP_CLK depends on register settings in Clock Distribution Module. See the MPC5200 User Manual [1]. 2) The interrupt latency descriptions in the table above are related to non competitive, non masked but enabled external interrupt sources. Take care of interrupt prioritization which may increase the latencies. Since all external interrupt signals are synchronized into the internal processor bus clock domain, each of these signals has to exceed a minimum pulse width of more than one IP_CLK cycle. Table17. Minimum pulse width for ex ternal interrupts to be recognized Name Min Pulse Width Max Pulse Width Reference Clock SpecID All external interrupts (IRQs, GPIOs) > 1 clock cycle — IP_CLK A4.22 NOTES: 1) The frequency of the IP_CLK depends on the register settings in Clock Distribution Module. See the MPC5200 User Manual [1] for further information. 2) If the same interrupt occurs a second time while its interrupt service routine has not cleared the former one, the second interrupt will not be recognized at all. Besides synchronization, prioritization, and mapping the latency of an external interrupt to the start of its associated interrupt service routine also depends on the following conditions: To get a minimum interrupt service response time, it is recommended to enable the instruction cache and set up the maximum core clock, XL bus, and IP bus frequencies (depending on board design and programming). In addition, it is advisable to execute an interrupt handler, which has been implemented in assembly code. MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 19

Electrical and Thermal Characteristics 3.3.5 SDRAM 3.3.5.1 Memory Interface Timing-Standard SDRAM Read Command Table18. Standard SDRAM Memory Read Timing Sym Description Min Max Units SpecID t MEM_CLK period 7.5 — ns A5.1 mem_clk t Control Signals, Address and MBA Valid after — t *0.5+0.4 ns A5.2 valid mem_clk rising edge of MEM_CLK t Control Signals, Address and MBA Hold after t *0.5 — ns A5.3 hold mem_clk rising edge of MEM_CLK DM DQM valid after rising edge of MEM_CLK — t *0.25+0.4 ns A5.4 valid mem_clk DM DQM hold after rising edge of MEM_CLK t *0.25-0.7 — ns A5.5 hold mem_clk data MDQ setup to rising edge of MEM_CLK — 0.3 ns A5.6 setup data MDQ hold after rising edge of MEM_CLK 0.2 — ns A5.7 hold MEM_CLK t valid t hold Control Signals Active NOP READ NOP NOP NOP NOP NOP DMvalid DMhold DQM (Data Mask) datasetup datahold MDQ (Data) t valid t hold MA (Address) Row Column t valid t hold MBA (Bank Selects) NOTE: Control Signals are composed of RAS, CAS, MEM_WE, MEM_CS, MEM_CS1 and CLK_EN Figure5. Timing Diagram—Standard SDRAM Memory Read Timing 3.3.5.2 Memory Interface Timing-Standard SDRAM Write Command In Standard SDRAM, all signals are activated on the Mem_clk from the Memory Controller and captured on the Mem_clk clock at the memory device. MPC5200 Data Sheet, Rev. 4 20 Freescale Semiconductor

Electrical and Thermal Characteristics Table19. Standard SDRAM Write Timing Sym Description Min Max Units SpecID t MEM_CLK period 7.5 — ns A5.8 mem_clk t Control Signals, Address and MBA Valid — t *0.5+0.4 ns A5.9 valid mem_clk after rising edge of MEM_CLK t Control Signals, Address and MBA Hold after t *0.5 — ns A5.10 hold mem_clk rising edge of MEM_CLK DM DQM valid after rising edge of MEM_CLK — t *0.25+0.4 ns A5.11 valid mem_clk DM DQM hold after rising edge of Mem_clk t *0.25-0.7 — ns A5.12 hold mem_clk data MDQ valid after rising edge of MEM_CLK — t *0.75+0.4 ns A5.13 valid mem_clk data MDQ hold after rising edge of MEM_CLK t *0.75-0.7 — ns A5.14 hold mem_clk MEM_CLK t valid t hold Control Signals Active NOP WRITE NOP NOP NOP NOP NOP DMvalid DMhold DQM (Data Mask) datavalid datahold MDQ (Data) t valid t hold MA (Address) Row Column t valid t hold MBA (Bank Selects) NOTE: Control Signals are composed of RAS, CAS, MEM_WE, MEM_CS, MEM_CS1 and CLK_EN Figure6. Timing Diagram—Standard SDRAM Memory Write Timing 3.3.5.3 Memory Interface Timing-DDR SDRAM Read Command The SDRAM Memory Controller uses an internally skewed clock for reading DDR memory. The programmable bits in the Reset Configuration Register used to account for unknown board delays are in the CDM module. The internal read clock can be delayed up to 3 ns under worst operating conditions in 32 increments of 95 ps, (1.4 ns in 45 ps increments under best case operating conditions) by programming the CDM Reset Configuration Register tap delay bits. Note: These bits in the CDM Reset Configuration register are not (cid:145)reset configured(cid:146) but have a hard coded reset value and are writable during operation. MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 21

Electrical and Thermal Characteristics Table20. DDR SDRAM Memory Read Timing Sym Description Min Max Units SpecID t MEM_CLK period 7.5 — ns A5.15 mem_clk t Control Signals, Address and MBA — t *0.5+0.4 ns A5.16 valid mem_clk valid after rising edge of MEM_CLK t Control Signals, Address and MBA t *0.5 — ns A5.17 hold mem_clk hold after rising edge of MEM_CLK t Read Data sample window — 4.591 ns A5.18 data_sample_max t Read Data sample window 1.552 — ns A5.19 data_sample_min NOTES: 1 Calculated with maximum number of Tap delay, 31 Tap delay are selected. 2 Calculated with minimum number of Tap delay, 0 Tap delay are selected. MPC5200 Data Sheet, Rev. 4 22 Freescale Semiconductor

Electrical and Thermal Characteristics MEM_CLK MEM_CLK tvalid thold Control Signals Active NOP READ NOP NOP NOP NOP NOP MDQS (Data Strobe) t data_valid_min t data_valid_max MDQ (Data) Sample position A t data_sample_min t data_sample_max Read Data Sample Window MDQS (Data Strobe) t data_valid_min t data_valid_max MDQ (Data) Sample position 0.5 * MEM_CLK t B data_sample_min t data_sample_max Read Data Sample Window t valid t hold MA (Address) Row Column t valid t hold MBA (Bank Selects) Sample position A: data are sampled on the expected edge of MEM_CLK, the MDQS signal indicate the valid data Sample position B: data are sampled on a later edge of MEM_CLK, SDRAM controller is waiting for the vaild MDQS signal NOTE: Control Signals signals are composed of RAS, CAS, MEM_WE, MEM_CS, MEM_CS1 and CLK_EN Figure7. Timing Diagram—DDR SDRAM Memory Read Timing MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 23

Electrical and Thermal Characteristics 8.34 delay [ns] t data_valid_max Possible sample time over PVT for one selected Tap delay Memory Data valid window 4.59 t data_sample_min t data_sample_min t data_valid_min Working Tap Delay range Working Tap Delay range for sample position A 1.55 for sample position B 0 selected Tap delay 31 Tap delay number Figure8. Read Data sample window depend on the number of Tap delay The position of the t window is depend on the clock / data flight time on the board. The MDQS data_valid signal indicate if the read data are valid. If the controller is not able to detect a valid MDQS signal on the sample time (sample position A) then the controller will look for valid MDQS / data on the next edge of the MEM_CLK signal (sample position B). Depend on the board travel time, different working tap delay configurations are possible. For a fast connection the data will be sampled with the next edge of MEM_CLK, this shows Figure8, sample position A. With a longer connection maybe two sample positions are possible. Figure 8 shows a example with two working sample position (A and B). With a bigger board delay only sample position B will be possible. The equation below shows how to calculate the upper and lower limit. The right Tap delay number is selected, when the possible max and min sample timing is within the memory data valid window. (cid:149) t = max((1.55 + TapNum * 0.095), (1.74 + TapNum * 0.045)) data_sample_max (cid:149) t = min((1.55 + TapNum * 0.095), (1.74 + TapNum * 0.045)) data_sample_min MPC5200 Data Sheet, Rev. 4 24 Freescale Semiconductor

Electrical and Thermal Characteristics 3.3.5.4 Memory Interface Timing-DDR SDRAM Write Command Table21. DDR SDRAM Memory Write Timing Sym Description Min Max Units SpecID t MEM_CLK period 7.5 — ns A5.20 mem_clk t Delay from write command to first — t +0.4 ns A5.21 DQSS mem_clk rising edge of MDQS MEM_CLK MEM_CLK Control Signals Write Write Write Write MDQS (Data Strobe) t dqss MDQ (Data) NOTE: Control Signals signals are composed of RAS, CAS, MEM_WE, MEM_CS, MEM_CS1 and CLK_EN Figure9. DDR SDRAM Memory Write Timing 3.3.6 PCI The PCI interface on the MPC5200 is designed to PCI Version 2.2 and supports 33-MHz and 66-MHz PCI operations. See the PCI Local Bus Specification [4]; the component section specifies the electrical and timing parameters for PCI components with the intent that components connect directly together whether on the planar or an expansion board, without any external buffers or other (cid:147)glue logic.(cid:148) Parameters apply at the package pins, not at expansion board edge connectors. The MPC5200 is always the source of the PCI CLK. The clock waveform must be delivered to each 33-MHz or 66-MHz PCI component in the system. Figure 10 shows the clock waveform and required measurement points for 3.3 V signaling environments. Table 22 summarizes the clock specifications. MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 25

Electrical and Thermal Characteristics T cyc T T high low 0.6Vcc 0.5Vcc 0.4Vcc 0.4Vcc, p-to-p PCI CLK 0.3Vcc 0.2Vcc (minimum) Figure10. PCI CLK Waveform Table22. PCI CLK Specifications 66 MHz 33 MHz Sym Description Units Notes SpecID Min Max Min Max T PCI CLK Cycle Time 15 30 30 ns 1,3 A6.1 cyc T PCI CLK High Time 6 11 ns A6.2 high t PCI CLK Low Time 6 A6.3 low - PCI CLK Slew Rate 1.5 4 1 4 V/ns 2 A6.4 NOTES: 1. In general, all 66-MHz PCI components must work with any clock frequency up to 66 MHz. CLK requirements vary depending upon whether the clock frequency is above 33 MHz. 2. Rise and fall times are specified in terms of the edge rate measured in V/ns. This slew rate must be met across the minimum peak-to-peak portion of the clock waveform as shown in Figure10. 3. The minimum clock period must not be violated for any single clock cycle, i.e., accounting for all system jitter. MPC5200 Data Sheet, Rev. 4 26 Freescale Semiconductor

Electrical and Thermal Characteristics Table23. PCI Timing Parameters 66 MHz 33 MHz Sym Description Units Notes SpecID Min Max Min Max T CLK to Signal Valid Delay - bused 2 6 2 11 ns 1,2,3 A6.5 val signals T (ptp) CLK to Signal Valid Delay - point 2 6 2 12 ns 1,2,3 A6.6 val to point T Float to Active Delay 2 2 ns 1 A6.7 on T Active to Float Delay 14 28 ns 1 A6.8 off T Input Setup Time to CLK - bused 3 7 ns 3,4 A6.9 su signals T (ptp) Input Setup Time to CLK - point 5 10,12 ns 3,4 A6.10 su to point T Input Hold Time from CLK 0 0 ns 4 A6.11 h NOTES: 1. See the timing measurement conditions in the PCI Local Bus Specification [4]. It is important that all driven signal transitions drive to their Voh or Vol level within one Tcyc. 2. Minimum times are measured at the package pin with the load circuit, and maximum times are measured with the load circuit as shown in the PCI Local Bus Specification [4]. 3. REQ# and GNT# are point-to-point signals and have different input setup times than do bused signals. GNT# and REQ# have a setup of 5 ns at 66 MHz. All other signals are bused. 4. See the timing measurement conditions in the PCI Local Bus Specification [4]. For Measurement and Test Conditions, see the PCI Local Bus Specification [4]. MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 27

Electrical and Thermal Characteristics 3.3.7 Local Plus Bus The Local Plus Bus is the external bus interface of the MPC5200. Maximum eight configurable Chip-selects are provided. There are two main modes of operation: non-MUXed (Legacy and Burst) and MUXED. The reference clock is the PCI CLK. The maximum bus frequency is 66 MHz. Definition of Acronyms and Terms: WS = Wait State DC = Dead Cycle LB = Long Burst DS = Data size in Byte tPCIck = PCI clock period tIPBIck = IPBI clock period tPCIck PCI CLK tIPBIck IPBI CLK Figure11. Timing Diagram—IPBI and PCI clock (example ratio: 4:1) 3.3.7.1 Non-MUXed Mode Table24. Non-MUXed Mode Timing Sym Description Min Max Units Notes SpecID t PCI CLK to CS assertion - 1.8 ns A7.1 CSA t PCI CLK to CS negation - 1.8 ns A7.2 CSN t CS pulse width (2+WS)*t (2+WS)*t ns 1 A7.3 1 PCIck PCIck t ADDR valid before CS assertion t t ns A7.4 2 IPBIck PCIck t ADDR hold after CS negation t - ns 2 A7.5 3 IPBIck t OE assertion before CS assertion - 0.4 ns A7.6 4 t OE negation before CS negation - 0.4 ns A7.7 5 t RW valid before CS assertion t - ns A7.8 6 PCIck t RW hold after CS negation t - ns A7.9 7 IPBIck t DATA output valid before CS assertion t - ns A7.10 8 IPBIck t DATA output hold after CS negation t - ns A7.11 9 IPBIck t DATA input setup before CS negation 2.8 - ns A7.12 10 t DATA input hold after CS negation 0 (DC+1)*t ns A7.13 11 PCIck t ACK assertion after CS assertion t - ns 3 A7.14 12 PCIck t ACK negation after CS negation - t ns 3 A7.15 13 PCIck MPC5200 Data Sheet, Rev. 4 28 Freescale Semiconductor

Electrical and Thermal Characteristics Table24. Non-MUXed Mode Timing (continued) Sym Description Min Max Units Notes SpecID t TS assertion before CS assertion - 0.8 ns 4 A7.16 14 t TS pulse width t t ns 4 A7.17 15 PCIck PCIck t TSIZ valid before CS assertion t - ns 5 A7.18 16 IPBIck t TSIZ hold after CS negation t - ns 5 A7.19 17 IPBIck NOTES: 1. ACK can shorten the CS pulse width. Wait States (WS) can be programmed in the Chip Select X Register, Bit field WaitP and WaitX. It can be specified from 0 - 65535. 2. In Large Flash and MOST Graphics mode the shared PCI/ATA pins, used as address lines, are released at the same moment as the CS. This can cause that the address is changing earlier as CS is deasserted. 3. ACK is input and can be used to shorten the CS pulse width. 4. Only available in Large Flash and MOST Graphics mode. 5. Only available in MOST Graphics mode. t1 CS[x] t2 t3 ADDR t4 t5 OE t6 t7 R/W t8 t9 DATA (wr) t10 t11 DATA (rd) t12 ACK t13 t14 t15 TS t17 TSIZ[1:2] t16 Figure12. Timing Diagram—Non-MUXed Mode MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 29

Electrical and Thermal Characteristics 3.3.7.2 Burst Mode Table25. Burst Mode Timing Sym Description Min Max Units Notes SpecID t PCI CLK to CS assertion - 1.8 ns A7.20 CSA t PCI CLK to CS negation - 1.8 ns A7.21 CSN t CS pulse width (1+WS+4LB*2*(32/DS))* (1+WS+4LB*2*(32/DS)) ns 1,2 A7.22 1 t *t PCIck PCIck t ADDR valid before CS assertion t t ns A7.23 2 IPBIck PCIck t ADDR hold after CS negation - -0.7 ns A7.24 3 t OE assertion before CS assertion - 0.4 ns A7.25 4 t OE negation before CS negation - 0.4 ns A7.26 5 t RW valid before CS assertion t - ns A7.27 6 PCIck t RW hold after CS negation t - ns A7.28 7 PCIck t DATA setup before rising edge of 1.8 - ns A7.29 8 PCI t DATA hold after rising edge of PCI 0 - ns A7.30 9 t DATA hold after CS negation 0 (DC+1)*t ns A7.31 10 PCIck t ACK assertion after CS assertion - (WS+1)*t ns A7.32 11 PCIck t ACK negation before CS negation - 0.6 ns 3 A7.33 12 t ACK pulse width 4LB*2*(32/DS)*t 4LB*2*(32/DS)*t ns 2,3 A7.34 13 PCIck PCIck t CS assertion after TS assertion - 0.8 ns A7.35 14 t TS pulse width t t ns A7.36 15 PCIck PCIck NOTES: 1. Wait States (WS) can be programmed in the Chip Select X Register, Bit field WaitP and WaitX. It can be specified 0 - 65535. 2. Example: Long Burst is used, this means the CS related BERx and SLB bits of the Chip Select Burst Control Register are set and a burst on the internal XLB is executed. => LB = 1 Data bus width is 8 bit. => DS = 8 => 41*2*(32/8) = 32 => ACK is asserted for 32 PCI cycles to transfer one cache line. Wait State is set to 10. => WS = 10 1+10+32 = 43 => CS is asserted for 43 PCI cycles. 3. ACK is output and indicates the burst. MPC5200 Data Sheet, Rev. 4 30 Freescale Semiconductor

Electrical and Thermal Characteristics PCI CLK t1 CS[x] t2 t3 ADDR t4 t5 OE t6 t7 R/W t8 t10 DATA (rd) t9 t11 t12 ACK t13 t14 t15 TS Figure13. Timing Diagram—Burst Mode MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 31

Electrical and Thermal Characteristics 3.3.7.3 MUXed Mode Table26. MUXed Mode Timing Sym Description Min Max Units Notes SpecID t PCI CLK to CS assertion - 1.8 ns A7.15 CSA t PCI CLK to CS negation - 1.8 ns A7.16 CSN t PCI CLK to ALE assertion - 1 ns A7.16 ALEA t ALE assertion before Address, Bank, - 0.8 ns A7.17 1 TSIZ assertion t CS assertion before Address, Bank, - 0.7 ns A7.18 2 TSIZ negation t CS assertion before Data wr valid - 0.7 ns A7.19 3 t Data wr hold after CS negation t - ns A7.20 4 IPBIck t Data rd setup before CS negation 2.8 - ns A7.21 5 t Data rd hold after CS negation 0 (DC+1)*t ns 1 A7.22 6 PCIck t ALE pulse width - t ns A7.23 7 PCIck t CS assertion after TS assertion - 0.8 ns A7.24 TSA t TS pulse width - t ns A7.24 8 PCIck t CS pulse width (2+WS)*t (2+WS)*t ns A7.25 9 PCIck PCIck t OE assertion before CS assertion - 0.4 ns A7.26 OEA t OE negation before CS negation - 0.4 ns A7.27 OEN t RW assertion before ALE assertion t - ns A7.26 10 IPBIck t RW negation after CS negation - t ns A7.27 11 PCIck t ACK assertion after CS assertion t - ns 2 A7.28 12 IPBIck t ACK negation after CS negation - t ns 2 A7.28 13 PCIck Note: 1. ACK can shorten the CS pulse width. Wait States (WS) can be programmed in the Chip Select X Register, Bit field WaitP and WaitX. It can be specified 0 - 65535. 2. ACK is input and can be used to shorten the CS pulse width. MPC5200 Data Sheet, Rev. 4 32 Freescale Semiconductor

Electrical and Thermal Characteristics PCI CLK t1 t2 t4 AD[31,27] (wr) Data AD[30:28] (wr) TSIZ[0:2] bits Data AD[26:25] (wr) Bank[0:1] bits Data AD[24:0] (wr) Address[7:31] Data t3 t5 t6 AD[31:0] (rd) Data t7 ALE Address latch t8 TS t9 CSx OE t10 t11 RW ACK t12 t13 Address tenure Data tenure Figure14. Timing Diagram—MUXed Mode 3.3.8 ATA The MPC5200 ATA Controller is completely software programmable. It can be programmed to operate with ATA protocols using their respective timing, as described in the ANSI ATA-4 specification. The ATA interface is completely asynchronous in nature. Signal relationships are based on specific fixed timing in terms of timing units (nano seconds). ATA data setup and hold times, with respect to Read/Write strobes, are software programmable inside the ATA Controller. Data setup and hold times are implemented using counters. The counters count the number of ATA clock cycles needed to meet the ANSI ATA-4 timing specifications. For details, see the ANSI ATA-4 specification [5] and how to program an ATA Controller and ATA drive for different ATA protocols and their respective timing. See the MPC5200 User Manual [1]. MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 33

Electrical and Thermal Characteristics The MPC5200 ATA Host Controller design makes data available coincidentally with the active edge of the WRITE strobe in PIO and Multiword DMA modes. (cid:149) Write data is latched by the drive at the inactive edge of the WRITE strobe. This gives ample setup-time beyond that required by the ATA-4 specification. (cid:149) Data is held unchanged until the next active edge of the WRITE strobe. This gives ample hold-time beyond that required by the ATA-4 specification. All ATA transfers are programmed in terms of system clock cycles (IP bus clocks) in the ATA Host Controller timing registers. This puts constraints on the ATA protocols and their respective timing modes in which the ATA Controller can communicate with the drive. Faster ATA modes (i.e., UDMA 0, 1, 2) are supported when the system is running at a sufficient frequency to provide adequate data transfer rates. Adequate data transfer rates are a function of the following: (cid:149) The MPC5200 operating frequency (IP bus clock frequency) (cid:149) Internal MPC5200 bus latencies (cid:149) Other system load dependent variables The ATA clock is the same frequency as the IP bus clock in MPC5200. See the MPC5200 User Manual [1]. NOTE All output timing numbers are specified for nominal 50 pF loads. Table27. PIO Mode Timing Specifications Min/Max Mode 0 Mode 1 Mode 2 Mode 3 Mode 4 PIO Timing Parameter SpecID (ns) (ns) (ns) (ns) (ns) (ns) t0 Cycle Time min 600 383 240 180 120 A8.1 t1 Address valid to DIOR/DIOW setup min 70 50 30 30 25 A8.2 t2 DIOR/DIOW pulse width 16-bit min 165 125 100 80 70 A8.3 8-bit min 290 290 290 80 70 t2i DIOR/DIOW recovery time min — — — 70 25 A8.4 t3 DIOW data setup min 60 45 30 30 20 A8.5 t4 DIOW data hold min 30 20 15 10 10 A8.6 t5 DIOR data setup min 50 35 20 20 20 A8.7 t6 DIOR data hold min 5 5 5 5 5 A8.8 t9 DIOR/DIOW to address min 20 15 10 10 10 A8.9 valid hold tA IORDY setup max 35 35 35 35 35 A8.10 tB IORDY pulse width max 1250 1250 1250 1250 1250 A8.11 MPC5200 Data Sheet, Rev. 4 34 Freescale Semiconductor

Electrical and Thermal Characteristics CS[0]/CS[3]/DA[2:0] t2 t9 t8 t1 t0 DIOR/DIOW t3 t4 WDATA t5 t6 RDATA tA tB IORDY Figure15. PIO Mode Timing Table28. Multiword DMA Timing Specifications Multiword DMA Timing Parameters Min/Max Mode 0(ns) Mode 1(ns) Mode 2(ns) SpecID t0 Cycle Time min 480 150 120 A8.12 tC DMACK to DMARQ delay max — — — A8.13 tD DIOR/DIOW pulse width (16-bit) min 215 80 70 A8.14 tE DIOR data access max 150 60 50 A8.15 tG DIOR/DIOW data setup min 100 30 20 A8.16 tF DIOR data hold min 5 5 5 A8.17 tH DIOW data hold min 20 15 10 A8.18 tI DMACK to DIOR/DIOW setup min 0 0 0 A8.19 tJ DIOR/DIOW to DMACK hold min 20 5 5 A8.20 tKr DIOR negated pulse width min 50 50 25 A8.21 tKw DIOW negated pulse width min 215 50 25 A8.22 tLr DIOR to DMARQ delay max 120 40 35 A8.23 tLw DIOW to DMARQ delay max 40 40 35 A8.24 MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 35

Electrical and Thermal Characteristics t0 DMARQ (Drive) tL tC DMACK (Host) tI tD tK tJ DIOR DIOW (Host) tE RDATA (Drive) tS tF WDATA (Host) tG tH NOTE:Thedirectionofsignalassertionistowardsthe top of the page, and the direction of negation is towards the bottom of the page, irrespective of the electrical properties of the signal. Figure16. Multiword DMA Timing Table29. Ultra DMA Timing Specification MODE 0 MODE 1 MODE 2 (ns) (ns) (ns) Name Comment SpecID Min Max Min Max Min Max (t) 240 — 160 — 120 — Typical sustained average two cycle time. A8.26 2CYC For information only, do not test. (t) 114 — 75 — 55 — Cycle time allowing for asymmetry and clock A8.27 CYC variations from STROBE edge to STROBE edge (t) 235 — 156 — 117 — Two-cycle time allowing for clock variations, from A8.28 2CYC rising edge to next rising edge or from falling edge to next falling edge of STROBE. (t) 15 — 10 — 7 — Data setup time at recipient. A8.29 DS (t) 5 — 5 — 5 — Data hold time at recipient. A8.30 DH (t) 70 — 48 — 34 — Data valid setup time at sender, to STROBE edge. A8.31 DVS (t) 6 — 6 — 6 — Data valid hold time at sender, from STROBE edge. A8.32 DVH (t) 0 230 0 200 0 170 First STROBE time for drive to first negate DSTROBE A8.33 FS from STOP during a data-in burst. MPC5200 Data Sheet, Rev. 4 36 Freescale Semiconductor

Electrical and Thermal Characteristics Table29. Ultra DMA Timing Specification (continued) MODE 0 MODE 1 MODE 2 (ns) (ns) (ns) Name Comment SpecID Min Max Min Max Min Max (t) 0 150 0 150 0 150 Limited Interlock time.1,2 A8.34 LI (t) 20 — 20 — 20 — Interlock time with minimum.1,2 A8.35 MLI (t) 0 — 0 — 0 — Unlimited interlock time. 1,2 A8.36 UI (t) — 10 — 10 — 10 Maximum time allowed for output drivers to release A8.37 AZ from being asserted or negated (t) 20 — 20 — 20 — Minimum delay time required for output drivers to A8.38 ZAH assert or negate from released state (t) 0 — 0 — 0 — A8.39 ZAD (t) 20 70 20 70 20 70 Envelope time—from DMACK to STOP and A8.40 ENV HDMARDY during data out burst initiation. (t) — 50 — 30 — 20 STROBE to DMARDY time, if DMARDY is negated A8.41 SR before this long after STROBE edge, the recipient receives no more than one additional data word. (t) — 75 — 60 — 50 Ready-to-Final STROBE time—no STROBE edges A8.42 RFS are sent this long after negation of DMARDY. (t) 160 — 125 — 100 — Ready-to-Pause time—the time recipient waits to A8.43 RP initiate pause after negating DMARDY. (t) — 20 — 20 — 20 Pull-up time before allowing IORDY to be released. A8.44 IORDYZ (t) 0 — 0 — 0 — Minimum time drive waits before driving IORDY A8.45 ZIORDY (t) 20 — 20 — 20 — Setup and hold times for DMACK, before assertion or A8.46 ACK negation. (t) 50 — 50 — 50 — Time from STROBE edge to negation of DMARQ or A8.47 SS assertion of STOP, when sender terminates a burst. NOTES: 1 t , t , t indicate sender-to-recipient or recipient-to-sender interlocks. That is, one agent (either sender or recipient) UI MLI LI is waiting for the other agent to respond with a signal before proceeding. (cid:127) t is an unlimited interlock that has no maximum time value. UI (cid:127) t is a limited time-out that has a defined minimum. MLI (cid:127) t is a limited time-out that has a defined maximum. LI 2 All timing parameters are measured at the connector of the drive to which the parameter applies. For example, the sender shall stop generating STROBE edges t after negation of DMARDY. Both STROBE and DMARDY timing RFS measurements are taken at the connector of the sender. Even though the sender stops generating STROBE edges, the receiver may receive additional STROBE edges due to propagation delays. All timing measurement switching points (low to high and high to low) are taken at 1.5 V. MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 37

Electrical and Thermal Characteristics DMARQ (device) t UI DMACK (device) t t t ACK ENV FS STOP tZAD (host) t t t ACK ENV FS HDMARDY (host) t ZAD t ZIORDY DSTROBE (device) tAZ tDVS tDVH DD(0:15) t ACK DA0, DA1, DA2, CS[0:1]1 Figure17. Timing Diagram—Initiating an Ultra DMA Data In Burst t 2CYC t t CYC CYC t 2CYC DSTROBE at device t t t t t DVH DVS DVH DVS DVH DD(0:15) at device DSTROBE at host t t t t t DH DS DH DS DH DD(0:15) at host Figure 18. Timing Diagram—Sustained Ultra DMA Data In Burst MPC5200 Data Sheet, Rev. 4 38 Freescale Semiconductor

Electrical and Thermal Characteristics DMARQ (device) DMARQ (host) t RP STOP (host) t SR HDMARDY (host) t RFS DSTROBE (device) DD[0:15] (device) Figure19. Timing Diagram—Host Pausing an Ultra DMA Data In Burst DMARQ (device) DMACK (host) t t t t LI LI MLI ACK STOP (host) t t LI ACK HDMARDY (host) t SS t IORDYZ DSTROBE (device) t ZAH t DVS tAZ tDVH DD[0:15] CRC t DA0,DA1,DA2, ACK CS[0:1] Figure20. Timing Diagram—Drive Terminating Ultra DMA Data In Burst MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 39

Electrical and Thermal Characteristics DMARQ (device) t t LI MLI DMACK (host) t t t RP ZAH ACK STOP (host) t ACK tAZ HDMARDY (host) t t t RFS LI MLI t IORDYZ DSTROBE (device) t DVS t DVH DD[0:15] CRC t ACK DA0,DA1,DA2, CS[0:1] Figure21. Timing Diagram—Host Terminating Ultra DMA Data In Burst MPC5200 Data Sheet, Rev. 4 40 Freescale Semiconductor

Electrical and Thermal Characteristics DMARQ (device) t UI DMACK (host) t ENV t ACK STOP (host) t t t LI UI ZIORDY DDMARDY (host) t ACK HSTROBE (device) t DVS t DVH DD[0:15] (host) t ACK DA0,DA1,DA2, CS[0:1] Figure22. Timing Diagram—Initiating an Ultra DMA Data Out Burst t 2CYC t t CYC CYC t 2CYC HSTROBE (host) t t DVS DVS t t t DVH DVH DVH DD[0:15] (host) HSTROBE (device) tDS tDS t DH tDH tDH DD[0:15] (device) Figure23. Timing Diagram—Sustained Ultra DMA Data Out Burst MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 41

Electrical and Thermal Characteristics t RP DMARQ (device) DMACK (host) STOP (host) t SR DDMARDY (device) t RFS HSTROBE DD[0:15] (host) Figure24. Timing Diagram—Drive Pausing an Ultra DMA Data Out Burst DMARQ (device) t t LI MLI DMACK (host) t t t SS LI ACK STOP (host) tLI tIORDYZ DDMARDY (device) t ACK HSTROBE (host) t t DVS DVH DD[0:15] CRC (host) t DA0,DA1,DA2, ACK CS[0:1] Figure25. Timing Diagram—Host Terminating Ultra DMA Data Out Burst MPC5200 Data Sheet, Rev. 4 42 Freescale Semiconductor

Electrical and Thermal Characteristics DMARQ (device) DMACK (host) t t t LI MLI ACK STOP (host) t RP t IORDYZ DDMARDY (device) t t t t RFS LI MLI ACK HSTROBE (host) t t DVS DVH DD[0:15] CRC (host) t ACK DA0,DA1,DA2, CS[0:1] Figure26. Timing Diagram—Drive Terminating Ultra DMA Data Out Burst Table30. Timing Specification ata_isolation Sym Description Min Max Units SpecID 1 ata_isolation setup time 7 - IP Bus cycles A8.48 2 ata_isolation hold time - 19 IP Bus cycles A8.49 DIOR ATA_ISOLATION 1 2 Figure27. Timing Diagram-ATA-ISOLATION MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 43

Electrical and Thermal Characteristics 3.3.9 Ethernet AC Test Timing Conditions: (cid:149) Output Loading All Outputs: 25 pF Table31. MII Rx Signal Timing Sym Description Min Max Unit SpecID M1 RXD[3:0], RX_DV, RX_ER to RX_CLK setup 10 — ns A9.1 M2 RX_CLK to RXD[3:0], RX_DV, RX_ER hold 10 — ns A9.2 M3 RX_CLK pulse width high 35% 65% RX_CLK Period1 A9.3 M4 RX_CLK pulse width low 35% 65% RX_CLK Period1 A9.4 NOTES: 1 RX_CLK shall have a frequency of 25% of data rate of the received signal. See the IEEE 802.3 Specification [6]. M3 RX_CLK (Input) M4 RXD[3:0] (inputs) RX_DV RX_ER M1 M2 Figure28. Ethernet Timing Diagram—MII Rx Signal MPC5200 Data Sheet, Rev. 4 44 Freescale Semiconductor

Electrical and Thermal Characteristics Table32. MII Tx Signal Timing Sym Description Min Max Unit SpecID M5 TX_CLK rising edge to TXD[3:0], TX_EN, TX_ER 0 25 ns A9.5 Delay M6 TX_CLK pulse width high 35% 65% TX_CLK Period1 A9.6 M7 TX_CLK pulse width low 35% 65% TX_CLK Period(1) A9.7 NOTES: 1 the TX_CLK frequency shall be 25% of the nominal transmit frequency, e.g., a PHY operating at 100 Mb/s must provide a TX_CLK frequency of 25 MHz and a PHY operating at 10 Mb/s must provide a TX_CLK frequency of 2.5 MHz. See the IEEE 802.3 Specification [6]. M6 TX_CLK (Input) M5 M7 TXD[3:0] (Outputs) TX_EN TX_ER Figure29. Ethernet Timing Diagram—MII Tx Signal Table33. MII Async Signal Timing Sym Description Min Max Unit SpecID M8 CRS, COL minimum pulse width 1.5 — TX_CLK Period A9.8 CRS, COL M8 Figure30. Ethernet Timing Diagram—MII Async MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 45

Electrical and Thermal Characteristics Table34. MII Serial Management Channel Signal Timing Sym Description Min Max Unit SpecID M9 MDC falling edge to MDIO output delay 0 25 ns A9.9 M10 MDIO (input) to MDC rising edge setup 10 — ns A9.10 M11 MDIO (input) to MDC rising edge hold 10 — ns A9.11 M12 MDC pulse width high1 160 — ns A9.12 M13 MDC pulse width low(1) 160 — ns A9.13 M14 MDC period2 400 — ns A9.14 NOTES: 1 MDC is generated by MPC5200 with a duty cycle of 50% except when MII_SPEED in the FEC MII_SPEED control register is changed during operation. See the MPC5200 User Manual [1]. 2 The MDC period must be set to a value of less then or equal to 2.5 MHz (to be compliant with the IEEE MII characteristic) by programming the FEC MII_SPEED control register. See the MPC5200 User Manual [1]. M12 M13 MDC (Output) M14 M9 MDIO (Output) MDIO (Input) M10 M11 Figure31. Ethernet Timing Diagram—MII Serial Management 3.3.10 USB Table35. Timing Specifications—USB Output Line Sym Description Min Max Units SpecID 1 USB Bit width1 83.3 667 ns A10.1 2 Transceiver enable time 83.3 667 ns A10.2 3 Signal falling time — 7.9 ns A10.3 4 Signal rising time — 7.9 ns A10.4 NOTES: 1 Defined in the USB config register, (12 Mbit/s or 1.5 Mbit/s mode). MPC5200 Data Sheet, Rev. 4 46 Freescale Semiconductor

Electrical and Thermal Characteristics NOTE Output timing was specified at a nominal 50 pF load. 2 USB_OE 4 3 USB_TXN 1 1 3 4 USB_TXP Figure32. Timing Diagram—USB Output Line 3.3.11 SPI Table36. Timing Specifications — SPI Master Mode, Format 0 (CPHA = 0) Sym Description Min Max Units SpecID 1 Cycle time 4 1024 IP-Bus Cycle1 A11.1 2 Clock high or low time 2 512 IP-Bus Cycle1 A11.2 3 Slave select clock delay 15.0 — ns A11.3 4 Output Data valid after Slave Select (SS) — 20.0 ns A11.4 5 Output Data valid after SCK — 20.0 ns A11.5 6 Input Data setup time 20.0 — ns A11.6 7 Input Data hold time 20.0 — ns A11.7 8 Slave disable lag time 15.0 — ns A11.8 9 Sequential transfer delay 1 — IP-Bus Cycle1 A11.9 10 Clock falling time — 7.9 ns A11.10 11 Clock rising time — 7.9 ns A11.11 NOTES: 1 Inter Peripheral Clock is defined in the MPC5200 User Manual [1]. NOTE Output timing was specified at a nominal 50 pF load. MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 47

Electrical and Thermal Characteristics 1 11 10 SCK (CLKPOL=0) Output 2 2 10 11 SCK (CLKPOL=1) Output 8 9 3 SS Output 5 4 MOSI Output 6 6 MISO Input 7 7 Figure33. Timing Diagram — SPI Master Mode, Format 0 (CPHA = 0) Table37. Timing Specifications — SPI Slave Mode, Format 0 (CPHA = 0) Sym Description Min Max Units SpecID 1 Cycle time 4 1024 IP-Bus Cycle1 A11.12 2 Clock high or low time 2 512 IP-Bus Cycle1 A11.13 3 Slave select clock delay 15.0 — ns A11.14 4 Output Data valid after Slave Select (SS) — 50.0 ns A11.15 5 Output Data valid after SCK — 50.0 ns A11.16 6 Input Data setup time 50.0 — ns A11.17 7 Input Data hold time 0.0 — ns A11.18 8 Slave disable lag time 15.0 — ns A11.19 9 Sequential Transfer delay 1 — IP-Bus Cycle1 A11.20 NOTES: 1 Inter Peripheral Clock is defined in the MPC5200 User Manual [1]. NOTE Output timing was specified at a nominal 50 pF load. MPC5200 Data Sheet, Rev. 4 48 Freescale Semiconductor

Electrical and Thermal Characteristics 1 SCK (CLKPOL=0) Input 2 2 SCK (CLKPOL=1) Input 8 9 3 SS Input 6 7 MOSI Input 4 5 MISO Output Figure34. Timing Diagram — SPI Slave Mode, Format 0 (CPHA = 0) Table38. Timing Specifications — SPI Master Mode, Format 1 (CPHA = 1) Sym Description Min Max Units SpecID 1 Cycle time 4 1024 IP-Bus Cycle1 A11.21 2 Clock high or low time 2 512 IP-Bus Cycle1 A11.22 3 Slave select clock delay 15.0 — ns A11.23 4 Output data valid — 20.0 ns A11.24 5 Input Data setup time 20.0 — ns A11.25 6 Input Data hold time 20.0 — ns A11.26 7 Slave disable lag time 15.0 — ns A11.27 8 Sequential Transfer delay 1 — IP-Bus Cycle1 A11.28 9 Clock falling time — 7.9 ns A11.29 10 Clock rising time — 7.9 ns A11.30 NOTES: 1 Inter Peripheral Clock is defined in the MPC5200 User Manual [1]. NOTE Output timing was specified at a nominal 50 pF load. MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 49

Electrical and Thermal Characteristics 1 10 9 SCK (CLKPOL=0) Output 2 2 9 10 SCK (CLKPOL=1) Output 7 8 3 SS Output 4 MOSI Output 5 MISO Input 6 Figure35. Timing Diagram — SPI Master Mode, Format 1 (CPHA = 1) Table39. Timing Specifications — SPI Slave Mode, Format 1 (CPHA = 1) Sym Description Min Max Units SpecID 1 Cycle time 4 1024 IP-Bus Cycle1 A11.31 2 Clock high or low time 2 512 IP-Bus Cycle1 A11.32 3 Slave select clock delay 15.0 — ns A11.33 4 Output data valid — 50.0 ns A11.34 5 Input Data setup time 50.0 — ns A11.35 6 Input Data hold time 0.0 — ns A11.36 7 Slave disable lag time 15.0 — ns A11.37 8 Sequential Transfer delay 1 — IP-Bus Cycle1 A11.38 NOTES: 1 Inter Peripheral Clock is defined in the MPC5200 User Manual [1]. NOTE Output timing was specified at a nominal 50 pF load. MPC5200 Data Sheet, Rev. 4 50 Freescale Semiconductor

Electrical and Thermal Characteristics 1 SCK (CLKPOL=0) Input 2 2 SCK (CLKPOL=1) Input 7 8 3 SS Input 5 6 MOSI Input 4 MISO Output Figure36. Timing Diagram — SPI Slave Mode, Format 1 (CPHA = 1) 3.3.12 MSCAN The CAN functions are available as RX and TX pins at normal IO pads (I2C1+GPTimer or PSC2). There is no filter for the WakeUp dominant pulse. Any High-to-Low edge can cause WakeUp, if configured. 2 3.3.13 I C Table40. I2C Input Timing Specifications—SCL and SDA Sym Description Min Max Units SpecID 1 Start condition hold time 2 — IP-Bus Cycle1 A13.1 2 Clock low period 8 — IP-Bus Cycle1 A13.2 4 Data hold time 0.0 — ns A13.3 6 Clock high time 4 — IP-Bus Cycle1 A13.4 7 Data setup time 0.0 — ns A13.5 8 Start condition setup time (for repeated start condition 2 — IP-Bus Cycle1 A13.6 only) 9 Stop condition setup time 2 — IP-Bus Cycle1 A13.7 NOTES: 1 Inter Peripheral Clock is defined in the MPC5200 User Manual [1]. MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 51

Electrical and Thermal Characteristics Table41. I2C Output Timing Specifications—SCL and SDA Sym Description Min Max Units SpecID 11 Start condition hold time 6 — IP-Bus Cycle3 A13.8 21 Clock low period 10 — IP-Bus Cycle3 A13.9 32 SCL/SDA rise time — 7.9 ns A13.10 41 Data hold time 7 — IP-Bus Cycle3 A13.11 51 SCL/SDA fall time — 7.9 ns A13.12 61 Clock high time 10 — IP-Bus Cycle3 A13.13 71 Data setup time 2 — IP-Bus Cycle3 A13.14 81 Start condition setup time (for repeated start condition 20 — IP-Bus Cycle3 A13.15 only) 91 Stop condition setup time 10 — IP-Bus Cycle3 A13.16 NOTES: 1 Programming IFDR with the maximum frequency (IFDR=0x20) results in the minimum output timings listed. The I2C interface is designed to scale the data transition time, moving it to the middle of the SCL low period. The actual position is affected by the prescale and division values programmed in IFDR. 2 Because SCL and SDA are open-drain-type outputs, which the processor can only actively drive low, the time SCL or SDA takes to reach a high level depends on external signal capacitance and pull-up resistor values 3 Inter Peripheral Clock is defined in the MPC5200 User Manual [1]. NOTE Output timing was specified at a nominal 50 pF load. 2 6 5 SCL 3 1 4 7 8 9 SDA Figure37. Timing Diagram—I2C Input/Output 3.3.14 J1850 See the MPC5200 User Manual [1]. MPC5200 Data Sheet, Rev. 4 52 Freescale Semiconductor

Electrical and Thermal Characteristics 3.3.15 PSC 2 3.3.15.1 Codec Mode (8,16,24 and 32-bit) / I S Mode Table42. Timing Specifications—8,16, 24 and 32-bit CODEC / I2S Master Mode Sym Description Min Typ Max Units SpecID 1 Bit Clock cycle time, programmed in CCS register 40.0 — — ns A15.1 2 Clock pulse width — 50 — %1 A15.2 3 Bit Clock fall time — — 7.9 ns A15.3 4 Bit Clock rise time — — 7.9 ns A15.4 5 FrameSync valid after clock edge — — 8.4 ns A15.5 6 FrameSync invalid after clock edge — — 8.4 ns A15.6 7 Output Data valid after clock edge — — 9.3 ns A15.7 8 Input Data setup time 6.0 — — ns A15.8 NOTES: 1 Bit Clock cycle time NOTE Output timing was specified at a nominal 50 pF load. MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 53

Electrical and Thermal Characteristics 1 BitClk (CLKPOL=0) 3 Output 2 2 4 BitClk (CLKPOL=1) Output 4 3 5 Frame (SyncPol = 1) 6 Output Frame (SyncPol = 0) Output 7 TxD Output 8 RxD Input Figure38. Timing Diagram — 8,16, 24, and 32-bit CODEC / I2S Master Mode Table43. Timing Specifications — 8,16, 24, and 32-bit CODEC / I2S Slave Mode Sym Description Min Typ Max Units SpecID 1 Bit Clock cycle time 40.0 — — ns A15.9 2 Clock pulse width — 50 — %1 A15.10 3 FrameSync setup time 1.0 — — ns A15.11 4 Output Data valid after clock edge — — 14.0 ns A15.12 5 Input Data setup time 1.0 — — ns A15.13 6 Input Data hold time 1.0 — — ns A15.14 NOTES: 1 Bit Clock cycle time NOTE Output timing was specified at a nominal 50 pF load. MPC5200 Data Sheet, Rev. 4 54 Freescale Semiconductor

Electrical and Thermal Characteristics 1 BitClk (CLKPOL=0) Input 2 2 BitClk (CLKPOL=1) Input 3 Frame (SyncPol = 1) Input Frame (SyncPol = 0) Input 4 TxD Output 5 RxD Input 6 Figure39. Timing Diagram — 8,16, 24, and 32-bit CODEC / I2S Slave Mode 3.3.15.2 AC97 Mode Table44. Timing Specifications — AC97 Mode Sym Description Min Typ Max Units SpecID 1 Bit Clock cycle time — 81.4 — ns A15.15 2 Clock pulse high time — 40.7 — ns A15.16 3 Clock pulse low time — 40.7 — ns A15.17 4 Frame valid after rising clock edge — — 13.0 ns A15.18 5 Output Data valid after rising clock edge — — 14.0 ns A15.19 6 Input Data setup time 1.0 — — ns A15.20 7 Input Data hold time 1.0 — — ns A15.21 NOTE Output timing was specified at a nominal 50 pF load. MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 55

Electrical and Thermal Characteristics 1 BitClk (CLKPOL=0) 3 2 Input 4 Sync (SyncPol = 1) Output 5 Sdata_out Output 6 7 Sdata_in Input Figure40. Timing Diagram — AC97 Mode 3.3.15.3 IrDA Mode Table45. Timing Specifications — IrDA Transmit Line Sym Description Min Max Units SpecID 1 Pulse high time, defined in the IrDA protocol definition 0.125 10000 µs A15.22 2 Pulse low time, defined in the IrDA protocol definition 0.125 10000 µs A15.23 3 Transmitter rising time — 7.9 ns A15.24 4 Transmitter falling time — 7.9 ns A15.25 NOTE Output timing was specified at a nominal 50 pF load. 4 IrDA_TX (SIR / FIR / MIR) 3 1 2 Figure41. Timing Diagram — IrDA Transmit Line MPC5200 Data Sheet, Rev. 4 56 Freescale Semiconductor

Electrical and Thermal Characteristics 3.3.15.4 SPI Mode Table46. Timing Specifications — SPI Master Mode, Format 0 (CPHA = 0) Sym Description Min Max Units SpecID 1 SCK cycle time, programable in the PSC CCS register 30.0 — ns A15.26 2 SCK pulse width, 50% SCK cycle time 15.0 — ns A15.27 3 Slave select clock delay, programable in the PSC CCS register 30.0 — ns A15.28 4 Output Data valid after Slave Select (SS) — 8.9 ns A15.29 5 Output Data valid after SCK — 8.9 ns A15.30 6 Input Data setup time 6.0 — ns A15.31 7 Input Data hold time 1.0 — ns A15.32 8 Slave disable lag time — 8.9 ns A15.33 9 Sequential Transfer delay, programable in the PSC CTUR / CTLR 15.0 — ns A15.34 register 10 Clock falling time — 7.9 ns A15.35 11 Clock rising time — 7.9 ns A15.36 NOTE Output timing was specified at a nominal 50 pF load. 1 11 10 SCK (CLKPOL=0) Output 2 2 10 11 SCK (CLKPOL=1) Output 8 9 3 SS Output 5 4 MOSI Output 6 6 MISO Input 7 7 Figure42. Timing Diagram — SPI Master Mode, Format 0 (CPHA = 0) MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 57

Electrical and Thermal Characteristics Table47. Timing Specifications — SPI Slave Mode, Format 0 (CPHA = 0) Sym Description Min Max Units SpecID 1 SCK cycle time, programable in the PSC CCS register 30.0 — ns A15.37 2 SCK pulse width, 50% SCK cycle time 15.0 — ns A15.38 3 Slave select clock delay 1.0 — ns A15.39 4 Input Data setup time 1.0 — ns A15.40 5 Input Data hold time 1.0 — ns A15.41 6 Output data valid after SS — 14.0 ns A15.42 7 Output data valid after SCK — 14.0 ns A15.43 8 Slave disable lag time 0.0 — ns A15.44 9 Minimum Sequential Transfer delay = 2 * IP Bus clock cycle time 30.0 — — A15.45 NOTE Output timing was specified at a nominal 50 pF load. 1 SCK (CLKPOL=0) Input 2 2 SCK (CLKPOL=1) Input 8 9 3 SS Input 4 5 MOSI Input 6 7 MISO Output Figure43. Timing Diagram — SPI Slave Mode, Format 0 (CPHA = 0) MPC5200 Data Sheet, Rev. 4 58 Freescale Semiconductor

Electrical and Thermal Characteristics Table48. Timing Specifications — SPI Master Mode, Format 1 (CPHA = 1) Sym Description Min Max Units SpecID 1 SCK cycle time, programable in the PSC CCS register 30.0 — ns A15.46 2 SCK pulse width, 50% SCK cycle time 15.0 — ns A15.47 3 Slave select clock delay, programable in the PSC CCS register 30.0 — ns A15.48 4 Output data valid — 8.9 ns A15.49 5 Input Data setup time 6.0 — ns A15.50 6 Input Data hold time 1.0 — ns A15.51 7 Slave disable lag time — 8.9 ns A15.52 8 Sequential Transfer delay, programable in the PSC CTUR / CTLR 15.0 — ns A15.53 register 9 Clock falling time — 7.9 ns A15.54 10 Clock rising time — 7.9 ns A15.55 NOTE Output timing was specified at a nominal 50 pF load. 1 10 9 SCK (CLKPOL=0) Output 2 2 9 10 SCK (CLKPOL=1) Output 7 8 3 SS Output 4 MOSI Output 5 MISO Input 6 Figure44. Timing Diagram — SPI Master Mode, Format 1 (CPHA = 1) MPC5200 Data Sheet, Rev. 4 Freescale Semiconductor 59

Electrical and Thermal Characteristics Table49. Timing Specifications — SPI Slave Mode, Format 1 (CPHA = 1) Sym Description Min Max Units SpecID 1 SCK cycle time, programable in the PSC CCS register 30.0 — ns A15.56 2 SCK pulse width, 50% SCK cycle time 15.0 — ns A15.57 3 Slave select clock delay 0.0 — ns A15.58 4 Output data valid — 14.0 ns A15.59 5 Input Data setup time 2.0 — ns A15.60 6 Input Data hold time 1.0 — ns A15.61 7 Slave disable lag time 0.0 — ns A15.62 8 Minimum Sequential Transfer delay = 2 * IP-Bus clock cycle time 30.0 — ns A15.63 NOTE Output timing was specified at a nominal 50 pF load. 1 SCK (CLKPOL=0) Input 2 2 SCK (CLKPOL=1) Input 7 8 3 SS Input 5 6 MOSI Input 4 MISO Output Figure45. Timing Diagram — SPI Slave Mode, Format 1 (CPHA = 1) MPC5200 Data Sheet, Rev. 4 60 Freescale Semiconductor