ICGOO在线商城 > 电路保护 > PTC 可复位保险丝 > MF-R135

- 型号: MF-R135

- 制造商: Bourns

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

MF-R135产品简介:

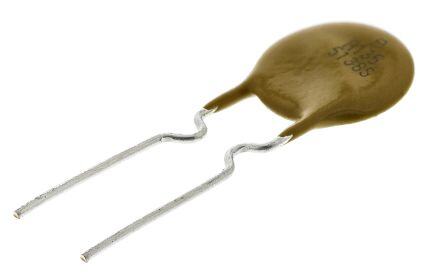

ICGOO电子元器件商城为您提供MF-R135由Bourns设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 MF-R135价格参考。BournsMF-R135封装/规格:PTC 可复位保险丝, 聚合物 PTC 自恢复保险丝 30V 1.35A Ih 通孔 径向,圆片式。您可以下载MF-R135参考资料、Datasheet数据手册功能说明书,资料中有MF-R135 详细功能的应用电路图电压和使用方法及教程。

Bourns Inc. 生产的MF-R135型号PTC可复位保险丝是一种过流保护器件,广泛应用于各种电子设备中以提供过流和过温保护。以下是该型号的主要应用场景: 1. 消费类电子产品:如手机充电器、适配器、笔记本电脑电源、平板电脑等。这些设备在使用过程中可能会遇到电流过载或短路问题,MF-R135可以有效保护电路免受损坏。 2. 家用电器:包括微波炉、电饭煲、洗衣机、空调等家电产品。PTC保险丝能够防止因电路故障或用户误操作引起的过流现象,从而保障设备的安全运行。 3. 通信设备:例如路由器、交换机、基站模块等通讯设施。这类设备对稳定性和可靠性要求较高,MF-R135可以在异常情况下迅速响应并切断电流,避免硬件受损。 4. 汽车电子系统:用于车载音响、导航系统、倒车雷达等车内电子装置。随着汽车智能化发展,越来越多的电子组件需要可靠的过流保护方案,而PTC保险丝正好满足这一需求。 5. 工业控制领域:如电机驱动器、传感器接口、PLC控制器等工业自动化设备。在复杂的工作环境中,PTC保险丝可以帮助抵御意外的电气冲击,确保生产流程连续性。 6. 电池管理系统(BMS):特别适用于锂离子电池组保护电路中,当出现过充、过放或者外部短路时,MF-R135能及时动作限制电流流动,延长电池寿命同时保证使用者安全。 7. 照明设备:LED灯具、节能灯泡等现代照明产品也常配备PTC可复位保险丝,用以防范启动浪涌电流及其他潜在风险。 总之,MF-R135凭借其高可靠性和自动恢复功能,在众多领域内发挥着重要作用,为各类电子设备提供了不可或缺的安全保障措施。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | FUSE PTC RESETTABLE 1.35A HOLD可复位保险丝—PPTC 30v Max 40Amps Max Hold 1.35 Trip 2.7 |

| 产品分类 | |

| 品牌 | Bourns Inc. |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | Bourns MF-R135MF-R |

| mouser_ship_limit | 该产品可能需要其他文件才能进口到中国。 |

| 数据手册 | |

| 产品型号 | MF-R135 |

| RoHS指令信息 | |

| R(最小/最大值) | 0.065 ~ 0.115 欧姆 |

| 产品培训模块 | http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=5252http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=4768 |

| 产品目录绘图 |

|

| 产品目录页面 | |

| 产品种类 | 可复位保险丝—PPTC |

| 保持电流 | 1.35 A |

| 其它名称 | MFR135 |

| 包装 | 散装 |

| 商标 | Bourns |

| 商标名 | Multifuse |

| 安装风格 | Through Hole |

| 封装/外壳 | 径向,圆盘 |

| 尺寸 | 18.9 mm L x 3 mm W x 3 mm H x 8.9 mm D |

| 工作温度范围 | - 40 C to + 85 C |

| 工具箱 | /product-detail/zh/MF-RLAB-H/MF-RLAB-H-ND/2138816 |

| 工厂包装数量 | 500 |

| 引线间隔 | 5.1 mm |

| 最大电压 | 30 VDC |

| 标准包装 | 500 |

| 电压-最大值 | 30V |

| 电流-保持(Ih)(最大值) | 1.35A |

| 电流-最大值 | 40A |

| 电流-跳闸(It) | 2.7A |

| 电阻 | 115 mOhms |

| 端接类型 | Radial |

| 类型 | PTC Resettable Fuses |

| 系列 | MF-R |

| 跳闸时间 | 7.3s |

| 跳闸电流 | 2.7 A |

| 零件号别名 | MF-R135-0-99 |

| 额定电流—最大值 | 40 A |

PDF Datasheet 数据手册内容提取

Features Applications n Radial Leaded Devices Almost anywhere there is a low voltage power n Cured, flame retardant epoxy polymer supply and a load to be protected, including: 7R118100T insulating material meets UL 94V-0 n Computers & peripherals requirements n General electronics n RoHS compliant* and halogen free** n Agency recognition: MF-R Series - PTC Resettable Fuses Electrical Characteristics Initial 1 Hour (R1) Max. Time Tripped Agency Ihold Itrip Resistance Post-Trip to Trip Power Recognition Vmax Imax Resistance Dissipation Model Ohms Ohms Watts at 23 °C at 23 °C cUL TÜV at 23 °C at 23 °C at 23 °C Volts Amps Amps Min. Max. Max. Amps Seconds Typ. E174545 R50366745 MF-R005 60 40 0.05 0.10 7.3 11.1 22.0 0.5 5.0 0.22 3 3 MF-R010 60 40 0.10 0.20 2.50 4.50 7.50 0.5 4.0 0.38 3 3 MF-R017 60 40 0.17 0.34 2.00 3.20 8.00 0.85 3.0 0.48 3 3 MF-R020 60 40 0.20 0.40 1.50 2.84 4.40 1.0 2.2 0.40 3 3 MF-R025 60 40 0.25 0.50 1.00 1.95 3.00 1.25 2.5 0.45 3 3 MF-R030 60 40 0.30 0.60 0.76 1.36 2.10 1.5 3.0 0.50 3 3 MF-R040 60 40 0.40 0.80 0.52 0.86 1.29 2.0 3.8 0.55 3 3 MF-R050 60 40 0.50 1.00 0.41 0.77 1.17 2.5 4.0 0.75 3 3 MF-R065 60 40 0.65 1.30 0.27 0.48 0.72 3.25 5.3 0.90 3 3 MF-R075 60 40 0.75 1.50 0.18 0.40 0.60 3.75 6.3 0.90 3 3 MF-R090 60 40 0.90 1.80 0.14 0.31 0.47 4.5 7.2 1.00 3 3 MF-R090-0-9 30 40 0.90 1.80 0.07 0.12 0.22 4.5 5.9 0.60 3 3 MF-R110 30 40 1.10 2.20 0.10 0.18 0.27 5.5 6.6 0.70 3 3 MF-R135 30 40 1.35 2.70 0.065 0.115 0.17 6.75 7.3 0.80 3 3 MF-R160 30 40 1.60 3.20 0.055 0.105 0.15 8.0 8.0 0.90 3 3 MF-R185 30 40 1.85 3.70 0.040 0.07 0.11 9.25 8.7 1.00 3 3 MF-R250 30 40 2.50 5.00 0.025 0.048 0.07 12.5 10.3 1.20 3 3 MF-R250-0-10 30 40 2.50 5.00 0.025 0.048 0.07 12.5 10.3 1.20 3 3 MF-R300 30 40 3.00 6.00 0.020 0.05 0.08 15.0 10.8 2.00 3 3 MF-R400 30 40 4.00 8.00 0.010 0.03 0.05 20.0 12.7 2.50 3 3 MF-R500 30 40 5.00 10.00 0.010 0.03 0.05 25.0 14.5 3.00 3 3 MF-R600 30 40 6.00 12.00 0.005 0.02 0.04 30.0 16.0 3.50 3 3 MF-R700 30 40 7.00 14.00 0.005 0.02 0.03 35.0 17.5 3.80 3 3 MF-R800 30 40 8.00 16.00 0.005 0.02 0.03 40.0 18.8 4.00 3 3 MF-R900 30 40 9.00 18.00 0.005 0.01 0.02 40.0 20.0 4.20 3 3 MF-R1100 16 100 11.00 22.00 0.003 0.01 0.014 40.0 20.0 4.50 3 3 Environmental Characteristics Item Condition Criteria Operating Temperature -40 °C to +85 °C Recommended Storage +40 °C max. / 70 % RH max. Passive Aging +85 °C, 1000 hours ±5 % typical resistance change Humidity Aging +85 °C, 85 % R.H. 1000 hours ±5 % typical resistance change Thermal Shock -40 °C to +85 °C, 10 times ±10 % typical resistance change Solvent Resistance MIL-STD-202, Method 215 No change (marking still legible) Vibration MIL-STD-883C, Method 2007.1 Condition A No change (Rmin < R < R1max) Moisture Sensitivity Level (MSL) See Note ESD Classification Class 6 (per AEC-Q200-2, HBM) Test Procedures and Requirements Item Test Condition Accept/Reject Criteria Visual/Mechanical Verify dimensions and materials Per MF physical description Resistance In still air @ 23 °C Rmin ≤ R ≤ Rmax Time to Trip At specified current, Vmax, 23 °C, still air T ≤ max. time to trip (seconds) Hold Current 30 min. at Ihold No trip Trip Cycle Life Vmax, Imax, 100 cycles No arcing or burning Trip Endurance Vmax, 48 hours No arcing or burning Solderability 245 °C ±5 °C, 5 seconds 95 % min. coverage ** Bourns follows the prevailing definition of “halogen free” in the industry. Bourns considers a product to be “halogen free” if (a) the Bromine (Br) content is 900 ppm or less; (b) the Chlorine (Cl) content WARNING Cancer and Reproductive Harm is 900 ppm or less; and (c) the total Bromine (Br) and Chlorine (Cl) content is 1500 ppm or less. www.P65Warnings.ca.gov Specifications are subject to change without notice. Users should verify actual device performance in their specific applications. The products described herein and this document are subject to specific * RoHS Directive 2015/863, Mar 31, 2015 and Annex. disclaimers as set forth on the last page of this document, and at www.bourns.com/legal/disclaimer.pdf.

MF-R Series - PTC Resettable Fuses Product Dimensions (see next page for outline drawing) Model A B C D E Physical Characteristics Max. Max. Nom. Tol. ± Min. Max. Style Lead Dia. Material 8.0 8.3 5.1 0.7 7.6 3.1 0.405 MF-R005 4 Sn/NiCu (0.315) (0.327) (0.201) (0.028) (0.299) (0.122) (0.016) 7.4 12.7 5.1 0.7 7.6 3.1 0.51 MF-R010 1 Sn/NiCu (0.291) (0.5) (0.201) (0.028) (0.299) (0.122) (0.020) 7.4 12.7 5.1 0.7 7.6 3.1 0.51 MF-R017 1 Sn/CuFe (0.291) (0.5) (0.201) (0.028) (0.299) (0.122) (0.020) 7.4 12.7 5.1 0.7 7.6 3.1 0.51 MF-R020 1 Sn/CuFe (0.291) (0.5) (0.201) (0.028) (0.299) (0.122) (0.020) 7.4 12.7 5.1 0.7 7.6 3.1 0.51 MF-R025 1 Sn/CuFe (0.291) (0.5) (0.201) (0.028) (0.299) (0.122) (0.020) 7.4 13.4 5.1 0.7 7.6 3.1 0.51 MF-R030 1 Sn/CuFe (0.291) (0.528) (0.201) (0.028) (0.299) (0.122) (0.020) 7.4 13.7 5.1 0.7 7.6 3.1 0.51 MF-R040 1 Sn/CuFe (0.291) (0.539) (0.201) (0.028) (0.299) (0.122) (0.020) 7.9 13.7 5.1 0.7 7.6 3.1 0.51 MF-R050 1 Sn/Cu (0.311) (0.539) (0.201) (0.028) (0.299) (0.122) (0.020) 9.7 15.2 5.1 0.7 7.6 3.1 0.51 MF-R065 1 Sn/Cu (0.382) (0.598) (0.201) (0.028) (0.299) (0.122) (0.020) 10.4 16.0 5.1 0.7 7.6 3.1 0.51 MF-R075 1 Sn/Cu (0.409) (0.630) (0.201) (0.028) (0.299) (0.122) (0.020) 11.7 16.7 5.1 0.7 7.6 3.1 0.51 MF-R090 1 Sn/Cu (0.461) (0.657) (0.201) (0.028) (0.299) (0.122) (0.020) 7.4 12.2 5.1 0.7 7.6 3.0 0.51 MF-R090-0-9 3 Sn/CuFe (0.291) (0.480) (0.201) (0.028) (0.299) (0.118) (0.020) 8.9 14.0 5.1 0.7 7.6 3.0 0.51 MF-R110 1 Sn/Cu (0.350) (0.551) (0.201) (0.028) (0.299) (0.118) (0.020) 8.9 18.9 5.1 0.7 7.6 3.0 0.51 MF-R135 1 Sn/Cu (0.350) (0.744) (0.201) (0.028) (0.299) (0.118) (0.020) 10.2 16.8 5.1 0.7 7.6 3.0 0.51 MF-R160 1 Sn/Cu (0.402) (0.661) (0.201) (0.028) (0.299) (0.118) (0.020) 12.0 18.4 5.1 0.7 7.6 3.0 0.51 MF-R185 1 Sn/Cu (0.472) (0.724) (0.201) (0.028) (0.299) (0.118) (0.020) 12.0 18.3 5.1 0.7 7.6 3.0 0.81 MF-R250 2 Sn/Cu (0.472) (0.720) (0.201) (0.028) (0.299) (0.118) (0.032) 12.0 18.3 5.1 0.7 7.6 3.0 0.51 MF-R250-0-10 3 Sn/CuFe (0.472) (0.720) (0.201) (0.028) (0.299) (0.118) (0.020) 12.0 18.3 5.1 0.7 7.6 3.0 0.81 MF-R300 2 Sn/Cu (0.472) (0.720) (0.201) (0.028) (0.299) (0.118) (0.032) 14.4 24.8 5.1 0.7 7.6 3.0 0.81 MF-R400 2 Sn/Cu (0.567) (0.976) (0.201) (0.028) (0.299) (0.118) (0.032) 17.4 24.9 10.2 0.7 7.6 3.0 0.81 MF-R500 2 Sn/Cu (0.685) (0.980) (0.402) (0.028) (0.299) (0.118) (0.032) 19.3 31.9 10.2 0.7 7.6 3.0 0.81 MF-R600 2 Sn/Cu (0.760) (1.256) (0.402) (0.028) (0.299) (0.118) (0.032) 22.1 29.8 10.2 0.7 7.6 3.0 0.81 MF-R700 2 Sn/Cu (0.870) (1.173) (0.402) (0.028) (0.299) (0.118) (0.032) 24.2 32.9 10.2 0.7 7.6 3.0 0.81 MF-R800 2 Sn/Cu (0.953) (1.295) (0.402) (0.028) (0.299) (0.118) (0.032) 24.2 32.9 10.2 0.7 7.6 3.0 0.81 MF-R900 2 Sn/Cu (0.953) (1.295) (0.402) (0.028) (0.299) (0.118) (0.032) 24.2 32.9 10.2 0.7 7.6 3.0 0.81 MF-R1100 2 Sn/Cu (0.953) (1.295) (0.402) (0.028) (0.299) (0.118) (0.032) MM DIMENSIONS: (INCHES) Specifications are subject to change without notice. Users should verify actual device performance in their specific applications. The products described herein and this document are subject to specific disclaimers as set forth on the last page of this document, and at www.bourns.com/legal/disclaimer.pdf.

MF-R Series - PTC Resettable Fuses Product Dimensions (see previous page for dimensions) Style 1 Style 2 Style 3 Style 4 A E A E A E A E B B B B D C D D D C C C NOTE: Kinked lead option is NOTE: Also available with straight available for board standoff. leads. (See How to Order.) (See How to Order.) Thermal Derating Table - Ihold / Itrip (Amps) Ambient Operating Temperature Model -40 ºC -20 ºC 0 ºC 23 ºC 40 ºC 50 ºC 60 ºC 70 ºC 85 ºC MF-R005 0.08 / 0.16 0.07 / 0.14 0.06 / 0.12 0.05 / 0.10 0.04 / 0.08 0.04 / 0.08 0.03 / 0.07 0.03 / 0.07 0.02 / 0.05 MF-R010 0.16 / 0.32 0.14 / 0.28 0.12 / 0.24 0.10 / 0.20 0.08 / 0.16 0.07 / 0.14 0.06 / 0.12 0.05 / 0.10 0.04 / 0.08 MF-R017 0.26 / 0.52 0.23 / 0.46 0.20 / 0.40 0.17 / 0.34 0.14 / 0.28 0.12 / 0.24 0.11 / 0.22 0.09 / 0.18 0.07 / 0.14 MF-R020 0.31 / 0.62 0.27 / 0.54 0.24 / 0.48 0.20 / 0.40 0.16 / 0.32 0.14 / 0.28 0.13 / 0.26 0.11 / 0.22 0.08 / 0.16 MF-R025 0.39 / 0.78 0.34 / 0.68 0.30 / 0.60 0.25 / 0.50 0.20 / 0.40 0.18 / 0.36 0.16 / 0.32 0.14 / 0.28 0.10 / 0.20 MF-R030 0.47 / 0.94 0.41 / 0.82 0.36 / 0.72 0.30 / 0.60 0.24 / 0.48 0.22 / 0.44 0.19 / 0.38 0.16 / 0.32 0.12 / 0.24 MF-R040 0.62 / 1.24 0.54 / 1.08 0.48 / 0.96 0.40 / 0.80 0.32 / 0.64 0.29 / 0.58 0.25 / 0.50 0.22 / 0.44 0.16 / 0.32 MF-R050 0.78 / 1.56 0.68 / 1.36 0.60 / 1.20 0.50 / 1.00 0.41 / 0.82 0.36 / 0.72 0.32 / 0.64 0.27 / 0.54 0.20 / 0.40 MF-R065 1.01 / 2.02 0.88 / 1.76 0.77 / 1.54 0.65 / 1.30 0.53 / 1.06 0.47 / 0.94 0.41 / 0.82 0.35 / 0.70 0.26 / 0.52 MF-R075 1.16 / 2.32 1.02 / 2.04 0.89 / 1.78 0.75 / 1.50 0.61 / 1.22 0.54 / 1.08 0.47 / 0.94 0.41 / 0.82 0.30 / 0.60 MF-R090 1.40 / 2.80 1.22 / 2.44 1.07 / 2.14 0.90 / 1.80 0.73 / 1.46 0.65 / 1.30 0.57 / 1.14 0.49 / 0.98 0.36 / 0.72 MF-R090-0-9 1.40 / 2.80 1.22 / 2.44 1.07 / 2.14 0.90 / 1.80 0.73 / 1.46 0.65 / 1.30 0.57 / 1.14 0.49 / 0.98 0.36 / 0.72 MF-R110 1.60 / 3.20 1.43 / 2.86 1.27 / 2.54 1.10 / 2.20 0.91 / 1.82 0.85 / 1.70 0.75 / 1.50 0.67 / 1.34 0.57 / 1.14 MF-R135 1.96 / 3.92 1.76 / 3.52 1.55 / 3.10 1.35 / 2.70 1.12 / 2.24 1.04 / 2.08 0.92 / 1.84 0.82 / 1.64 0.70 / 1.40 MF-R160 2.32 / 4.64 2.08 / 4.16 1.84 / 3.68 1.60 / 3.20 1.33 / 2.66 1.23 / 2.46 1.09 / 2.18 0.98 / 1.96 0.83 / 1.66 MF-R185 2.68 / 5.36 2.41 / 4.82 2.13 / 4.26 1.85 / 3.70 1.54 / 3.08 1.42 / 2.84 1.26 / 2.52 1.13 / 2.26 0.96 / 1.92 MF-R250 3.63 / 7.26 3.25 / 6.50 2.88 / 5.76 2.50 / 5.00 2.08 / 4.16 1.93 / 3.86 1.70 / 3.40 1.53 / 3.06 1.30 / 2.60 MF-R250-0-10 3.63 / 7.26 3.25 / 6.50 2.88 / 5.76 2.50 / 5.00 2.08 / 4.16 1.93 / 3.86 1.70 / 3.40 1.53 / 3.06 1.30 / 2.60 MF-R300 4.35 / 8.70 3.90 / 7.80 3.45 / 6.90 3.00 / 6.00 2.49 / 4.98 2.31 / 4.62 2.04 / 4.08 1.83 / 3.66 1.56 / 3.12 MF-R400 5.80 / 11.6 5.20 / 10.4 4.60 / 9.20 4.00 / 8.00 3.32 / 6.64 3.08 / 6.16 2.72 / 5.44 2.44 / 4.88 2.08 / 4.16 MF-R500 7.25 / 14.5 6.50 / 13.0 5.75 / 11.5 5.00 / 10.0 4.15 / 8.30 3.85 / 7.70 3.40 / 6.80 3.05 / 6.10 2.60 / 5.20 MF-R600 8.70 / 17.4 7.80 / 15.6 6.90 / 13.8 6.00 / 12.0 4.98 / 9.96 4.62 / 9.24 4.08 / 8.16 3.66 / 7.32 3.12 / 6.24 MF-R700 10.1 / 20.3 9.10 / 18.2 8.05 / 16.1 7.00 / 14.0 5.81 / 11.6 5.39 / 10.7 4.76 / 9.52 4.27 / 9.44 3.64 / 7.28 MF-R800 11.6 / 23.2 10.4 / 20.8 9.20 / 18.4 8.00 / 16.0 6.64 / 13.2 6.16 / 12.3 5.44 / 10.8 4.88 / 9.76 4.16 / 8.32 MF-R900 13.0 / 26.1 11.7 / 23.4 10.3 / 20.7 9.00 / 18.0 7.47 / 14.9 6.93 / 12.7 6.12 / 12.2 5.49 / 10.9 4.68 / 9.36 MF-R1100 16.1 / 32.0 14.6 / 29.2 13.1 / 26.2 11.0 / 22.1 9.40 / 18.4 8.80 / 17.6 7.80 / 15.6 6.90 / 13.8 5.20 / 10.4 Specifications are subject to change without notice. Users should verify actual device performance in their specific applications. The products described herein and this document are subject to specific disclaimers as set forth on the last page of this document, and at www.bourns.com/legal/disclaimer.pdf.

MF-R Series - PTC Resettable Fuses Typical Time to Trip at 23 ºC R005R010 R017R020R025R030R040R050R065R075R090 MF-MF- MF-MF-MF-MF-MF-MF-MF-MF-MF- The Time to Trip curves represent typical performance of a 100 device in a simulated application environment. Actual performance in specific customer applications may differ s) from these values due to the influence of other variables. d n 10 o c e S ( p 1 ri o t e t m 0.1 Ti 0.01 0.001 0.1 1 10 100 Fault Current (Amps) MF- R-009-09MF-R110MF-R135MF-R160MF-R18M5F-R22550,0-0-10MF-R30M0F-R400MF-R50M0F-R60M0F-R700MF-R800MF-R900MF-R1100 100 ) s d n 10 o c e S ( p 1 ri o t e t m 0.1 Ti 0.01 0.001 1 10 100 Fault Current (Amps) Specifications are subject to change without notice. Users should verify actual device performance in their specific applications. The products described herein and this document are subject to specific disclaimers as set forth on the last page of this document, and at www.bourns.com/legal/disclaimer.pdf.

MF-R Series - PTC Resettable Fuses How to Order Typical Part Marking: MF-R005 - R025 Typical Part Marking: MF-R030 - R1100 MF - R 110 - 0 - 14 Represents total content. Layout may vary. Represents total content. Layout may vary. Multifuse® PART MANUFACTURER'S Product Designator IDENTIFICATION TRADEMARK PART Series IDENTIFICATION R = Radial Leaded Component 025 R250 MANUFACTURING Hold Current, Ihold MTRAANDUEFMACATRUKRER'S 7A S MLOACNAUTFIAOCNT:URING 7180 S LSO =C CAHTIIONNA: 005-1100 (0.05 Amps - 11.0 Amps) S = CHINA Packaging Options DATE CODE: DATE CODE: - __ = Bulk Packaging without part number WEEK 1 OF 2017 = 7A (YEAR & WEEK) FIRST DIGIT = LAST DIGIT OF YEAR; suffix option WEEK 27 OF 2017 = A7 (WEEK & YEAR) NEXT THREE DIGITS = DAY OF YEAR - 0 = Bulk Packaging with part number suffix option - 2 = Tape and Reel* - AP = Ammo-Pak* Part Number Suffix Option - 14 = Kinked leads where straight leads are standard - 17 = Straight leads where kinked leads are standard - 99 = RoHS Compliancy As of date code April 1, 2005 all MF-R models are RoHS compliant. The suffix “-99” was originally provided to help customers distinguish between RoHS compliant and non-RoHS com- pliant products, but the -99 suffix option is no longer necessary. The -99 suffix option will no longer be available starting January 1, 2020. See Note for more details. *Packaged per EIA-468 Packaging Quantity Unit Quantity Packaging options Models Unit (Pcs.) Bulk All models 500 Bag MF-R005 ~ MF-R160 3000 Tape & Reel MF-R185 ~ MF-R400 1500 Reel MF-R500 ~ MF-R1100 1000 MF-R005 ~ MF-R160 2000 Ammo-Pack MF-R185 ~ MF-R400 1000 Pack MF-R500 ~ MF-R1100 500 MF-R SERIES, REV. AK, EFFECTIVE 04/06/20 Specifications are subject to change without notice. Users should verify actual device performance in their specific applications. The products described herein and this document are subject to specific disclaimers as set forth on the last page of this document, and at www.bourns.com/legal/disclaimer.pdf.

MF-R Series Tape and Reel Specifications Devices taped using EIA-468/IEC 60286-2 standards. See table below and figures for details. IEC EIA Dimension Description Mark Mark Dimensions Tolerance 18 -0.5/+1.0 Carrier tape width W W (.709) (-0.02/+.039) 5 H old down tape width W 0 W0 (.197) min. Hold down tape No protrusion 3 A dhesive tape position W2 W2 (.118) max. 9 -0.5/+0.75 S procket hole position W 1 W 1 (.354) (-0.02/+0.03) 4 ±0.2 S procket hole diameter D 0 D 0 (.157) (±.0078) 18 ~ 20 Height to seating plane (straight lead) H H (.709 ~ .787) 16 ±0.5 H eight to seating plane (formed lead) H0 H0 (.63) (±.02) 38.5 O verall height above abscissa H1 H1 (1.516) max. 11 Cutout Length L max. (.433) 12.7 ±0.3 Sprocket hole pitch P0 P0 (0.5) (±.012) 12.7 ±0.3 Device pitch: MF-R005 ~ MF-R160 P P (0.5) (±.012) 25.4 ±0.6 Device pitch: MF-R185 ~ MF-R1100 P P (1.0) (±.024) ±1 Pitch tolerance 20 consecutive (±.039) 0.9 Composite tape thickness t t max. (.035) 2.0 O verall tape and lead thickness: MF-R005 ~ MF-R185 t1 t1 (0.079) max. 2.3 O verall tape and lead thickness: MF-R250 ~ MF-R1100 t1 t1 (0.091) max. ±0.3 Splice sprocket hole alignment 0 (±.012) F ront-to-back deviation Δh Δh 0 (±±.10.309 ) S ide-to-side deviation Δp Δp 0 (±±.10.531 ) 3.81 ±0.7 Ordinate to adjacent component lead P 1 P 1 (0.150) (±0.028) 5.08 +0.6/-0.2 Lead spacing: MF-R005 ~ MF-R400 F F (0.2) (+0.024/-0.008) 10.2 +0.6/-0.2 Lead spacing: MF-R500 ~ MF-R1100 F F (0.4) (+0.024/-0.008) — Continued on next page — MM DIMENSIONS: (INCHES) Specifications are subject to change without notice. Users should verify actual device performance in their specific applications. The products described herein and this document are subject to specific legal disclaimers as set forth on the last page of this document, and at www.bourns.com/docs/legal/disclaimer.pdf.

MF-R Series Tape and Reel Specifications IEC EIA Dimension Description Mark Mark Dimensions Tolerance 62.0 R eel width including flanges and hub W 4 w 2 (2.44) max. Dimension between flanges (measured at hub) W 3 w 1 allow proper reeling and unreeling 370.0 Reel diameter A a max. (14.57) 4.75 ±3.25 Space between flanges (at hub, excluding device) (.187) (±.128) 26.0 ±12.0 Arbor hole diameter C c (1.024) (±.472) h h 80 p p Core diameter N n min. (3.15) 62 372 372 Box dimensions max. (2.44) (14.6) (14.6) Reference plane Consecutive missing places 3 max. H1 P1 F W2 H1 Empty places per reel Not specified H H L A B 0 W Taped Component Dimensions - W 1 0 per EIA Mark - h h W p p Figure 1 P0 ReDfe0rence plane t UCsreors sd isreeccttiioonn Ao f- f Beed t H1 P1 F W2 1 H1 H H L A B 0 W W 1 0 W User direction of feed P0 D0 t Cross section A - B t 1 Reel Dimensions - per EIA Mark - Figure 2 Reel Upper side n Tape User a direction of feed DIMENSIONS: MM c Lower side (INCHES) Reel w1 Upper side w2 n MM D IMENSIONS: (INCHTEaSp)e User Specifications are subject to change without notice. a direction Users should verify actual device performance in their specific applications. of The products described herein and this document are subject to specific legal disclaimers as set forth on the lafsete dpage of this document, and at www.bourns.com/docs/legal/disclaimer.pdf. c Lower side w 1 w 2

3B3o1u2rn -s ®2 Mmumlti fSuMseD® TPrPimTCm Rinegse Pttoatbelnet Fioumseester Application Notice • Users are responsible for independent and adequate evaluation of Bourns® Multifuse® Polymer PTC devices in the user’s application, including the PPTC device characteristics stated in the applicable data sheet. • Polymer PTC devices must not be allowed to operate beyond their stated maximum ratings. Operation in excess of such maximum ratings could result in damage to the PTC device and possibly lead to electrical arcing and/or fire. Circuits with inductance may generate a voltage above the rated voltage of the polymer PTC device and should be thoroughly evaluated within the user’s application during the PTC selection and qualification process. • Polymer PTC devices are intended to protect against adverse effects of temporary overcurrent or overtemperature conditions up to rated limits and are not intended to serve as protective devices where overcurrent or overvoltage conditions are expected to be repetitive or prolonged. • In normal operation, polymer PTC devices experience thermal expansion under fault conditions. Thus, a polymer PTC device must be protected against mechanical stress, and must be given adequate clearance within the user’s application to accommodate such thermal expansion. Rigid potting materials or fixed housings or coverings that do not provide adequate clearance should be thoroughly examined and tested by the user, as they may result in the malfunction of polymer PTC devices if the thermal expansion is inhibited. • Exposure to lubricants, silicon-based oils, solvents, gels, electrolytes, acids, and other related or similar materials may adversely affect the performance of polymer PTC devices. • Aggressive solvents may adversely affect the performance of polymer PTC devices. Conformal coating, encapsulating, potting, molding, and sealing materials may contain aggressive solvents including but not limited to xylene and toluene, which are known to cause adverse effects on the performance of polymer PTCs. Such aggressive solvents must be thoroughly cured or baked to ensure their complete removal from polymer PTCs to minimize the possible adverse effect on the device. • Recommended storage conditions should be followed at all times. Such conditions can be found on the applicable data sheet and on the Multifuse® Polymer PTC Moisture/Reflow Sensitivity Classification (MSL) note: https://www.bourns.com/docs/RoHS-MSL/msl_mf.pdf MFAN 12/18 Specifications are subject to change without notice. Users should verify actual device performance in their specific applications. The products described herein and this document are subject to specific legal disclaimers as set forth on the last page of this document, and at www.bourns.com/docs/legal/disclaimer.pdf.

Legal Disclaimer Notice This legal disclaimer applies to purchasers and users of Bourns® products manufactured by or on behalf of Bourns, Inc. and its affiliates (collectively, “Bourns”). Unless otherwise expressly indicated in writing, Bourns® products and data sheets relating thereto are subject to change without notice. Users should check for and obtain the latest relevant information and verify that such information is current and complete before placing orders for Bourns® products. The characteristics and parameters of a Bourns® product set forth in its data sheet are based on laboratory conditions, and statements regarding the suitability of products for certain types of applications are based on Bourns’ knowledge of typical requirements in generic applications. The characteristics and parameters of a Bourns® product in a user application may vary from the data sheet characteristics and parameters due to (i) the combination of the Bourns® product with other components in the user’s application, or (ii) the environment of the user application itself. The characteristics and parameters of a Bourns® product also can and do vary in different applications and actual performance may vary over time. Users should always verify the actual performance of the Bourns® product in their specific devices and applications, and make their own independent judgments regarding the amount of additional test margin to design into their device or application to compensate for differences between laboratory and real world conditions. Unless Bourns has explicitly designated an individual Bourns® product as meeting the requirements of a particular industry standard (e.g., ISO/TS 16949) or a particular qualification (e.g., UL listed or recognized), Bourns is not responsible for any failure of an individual Bourns® product to meet the requirements of such industry standard or particular qualification. Users of Bourns® products are responsible for ensuring compliance with safety-related requirements and standards applicable to their devices or applications. Bourns® products are not recommended, authorized or intended for use in nuclear, lifesaving, life-critical or life-sustaining ap- plications, nor in any other applications where failure or malfunction may result in personal injury, death, or severe property or environmental damage. Unless expressly and specifically approved in writing by two authorized Bourns representatives on a case-by-case basis, use of any Bourns® products in such unauthorized applications might not be safe and thus is at the user’s sole risk. Life-critical applications include devices identified by the U.S. Food and Drug Administration as Class III devices and generally equivalent classifications outside of the United States. Bourns expressly identifies those Bourns® standard products that are suitable for use in automotive applications on such products’ data sheets in the section entitled “Applications.” Unless expressly and specifically approved in writing by two authorized Bourns representatives on a case-by-case basis, use of any other Bourns® standard products in an automotive application might not be safe and thus is not recommended, authorized or intended and is at the user’s sole risk. If Bourns expressly identifies a sub-category of automotive application in the data sheet for its standard products (such as infotainment or lighting), such identification means that Bourns has reviewed its standard product and has determined that if such Bourns® standard product is considered for potential use in automotive applications, it should only be used in such sub-category of automotive applications. Any reference to Bourns® standard product in the data sheet as compliant with the AEC-Q standard or “automotive grade” does not by itself mean that Bourns has approved such product for use in an automotive application. Bourns® standard products are not tested to comply with United States Federal Aviation Administration standards generally or any other generally equivalent governmental organization standard applicable to products designed or manufactured for use in aircraft or space applications. Bourns expressly identifies Bourns® standard products that are suitable for use in aircraft or space applications on such products’ data sheets in the section entitled “Applications.” Unless expressly and specifically approved in writing by two authorized Bourns representatives on a case-by-case basis, use of any other Bourns® standard product in an aircraft or space application might not be safe and thus is not recommended, authorized or intended and is at the user’s sole risk. The use and level of testing applicable to Bourns® custom products shall be negotiated on a case-by-case basis by Bourns and the user for which such Bourns® custom products are specially designed. Absent a written agreement between Bourns and the user regarding the use and level of such testing, the above provisions applicable to Bourns® standard products shall also apply to such Bourns® custom products. Users shall not sell, transfer, export or re-export any Bourns® products or technology for use in activities which involve the design, development, production, use or stockpiling of nuclear, chemical or biological weapons or missiles, nor shall they use Bourns® products or technology in any facility which engages in activities relating to such devices. The foregoing restrictions apply to all uses and applications that violate national or international prohibitions, including embargos or international regulations. Further, Bourns® products and Bourns technology and technical data may not under any circumstance be exported or re-exported to countries subject to international sanctions or embargoes. Bourns® products may not, without prior authorization from Bourns and/or the U.S. Government, be resold, transferred, or re-exported to any party not eligible to receive U.S. commodities, software, and technical data. To the maximum extent permitted by applicable law, Bourns disclaims (i) any and all liability for special, punitive, consequential, incidental or indirect damages or lost revenues or lost profits, and (ii) any and all implied warranties, including implied warranties of fitness for particular purpose, non-infringement and merchantability. For your convenience, copies of this Legal Disclaimer Notice with German, Spanish, Japanese, Traditional Chinese and Simplified Chinese bilingual versions are available at: Web Page: http://www.bourns.com/legal/disclaimers-terms-and-policies PDF: http://www.bourns.com/docs/Legal/disclaimer.pdf C1753 05/17/18R

Datasheet下载

Datasheet下载