ICGOO在线商城 > 传感器,变送器 > 超声波接收器/发射器 > MA40S4R

- 型号: MA40S4R

- 制造商: Murata

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

MA40S4R产品简介:

ICGOO电子元器件商城为您提供MA40S4R由Murata设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 MA40S4R价格参考¥25.23-¥59.17。MurataMA40S4R封装/规格:超声波接收器/发射器, Ultrasonic Sensor 40kHz。您可以下载MA40S4R参考资料、Datasheet数据手册功能说明书,资料中有MA40S4R 详细功能的应用电路图电压和使用方法及教程。

Murata Electronics North America 生产的型号为 MA40S4R 的超声波接收器/发射器是一种广泛应用于各种电子设备和系统中的传感器。该器件能够在超声波频段内进行信号的发送和接收,具有高灵敏度、低功耗和小型化的特点,适用于多种应用场景。 1. 汽车行业 在汽车领域,MA40S4R 超声波传感器常用于倒车雷达系统。它能够检测车辆后方的障碍物,并将距离信息反馈给车载计算机,帮助驾驶员安全停车或低速行驶时避免碰撞。此外,该传感器还可以用于自动泊车辅助系统,精确测量车辆与路边或其他车辆之间的距离。 2. 工业自动化 在工业自动化环境中,MA40S4R 可以用于物体检测、液位监测和机器人导航等应用。例如,在生产线中,它可以检测传送带上的物品是否存在,确保生产流程顺畅;在储罐或容器中,它可以实时监测液体或固体物料的液位高度,防止溢出或缺料。 3. 家用电器 家用电器如智能吸尘器、扫地机器人等也广泛应用了这种超声波传感器。通过安装 MA40S4R,这些设备可以感知周围的环境,避开障碍物,实现自主导航和清洁路径规划,提高工作效率和用户体验。 4. 医疗设备 在医疗领域,MA40S4R 可以用于非接触式生命体征监测设备中,如呼吸频率监测仪。通过发射和接收超声波信号,它可以准确测量患者的呼吸频率,而无需直接接触患者身体,减少了感染风险。 5. 智能家居 智能家居系统中,MA40S4R 可以作为人体存在检测传感器,用于智能照明、安防监控等场景。例如,当有人进入房间时,它会触发灯光自动亮起;或者在无人时自动关闭电器设备,节省能源。 总之,Murata 的 MA40S4R 超声波接收器/发射器凭借其高性能和多功能性,在多个行业中发挥着重要作用,极大地提升了各类设备的智能化水平。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | RCVR 40KHZ ULTRASONIC音频指示器及警报器 10mm SENSOR |

| 产品分类 | |

| 品牌 | Murata Electronics |

| 产品手册 | http://search.murata.co.jp/Ceramy/CatalogAction.do?sHinnm=? &sNHinnm=MA40S4R&sNhin_key=MA40S4R&sLang=en&sParam=MA40S |

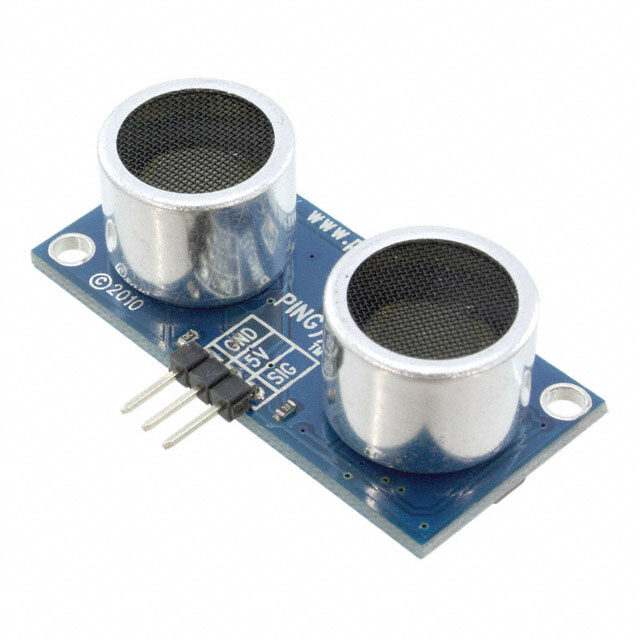

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 音频指示器及警报器,Murata Electronics MA40S4R- |

| mouser_ship_limit | 该产品可能需要其他文件才能进口到中国。 |

| 数据手册 | |

| 产品型号 | MA40S4R |

| 产品 | Sensors |

| 产品种类 | 音频指示器及警报器 |

| 光束孔径角 | 80° |

| 其它名称 | 490-7706 |

| 包装 | * |

| 发送灵敏度 | - |

| 商标 | Murata Electronics |

| 声压级 | - 63 dB |

| 安装 | PCB |

| 尺寸 | 10 mm H |

| 工厂包装数量 | 100 |

| 带宽 | - |

| 接收灵敏度 | -63dB |

| 标准包装 | 540 |

| 电压-额定 | - |

| 直径 | 10 mm |

| 系列 | MA40 |

| 频率 | 40 kHz |

| 高度 | 10 mm |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

Reference Only Product Specification for Reference Only Issued Date: April 30, 2015 Rev.: N Part Description: Ultrasonic Transducer MURATA Part No.: MA40S4R The product specification in this sheet is for reference only. The contents of this specification are subject to change. You are requested to receive the latest specification and to return one copy of the specification to us with your receipt signature before going into mass production. Sensor products department 1 Sensor products division Murata Manufacturing Co., Ltd.

Reference Only P 1 / 6 Reference specification of Ultrasonic Transducer Type: MA40S4R 1. Scope This product specification is applied to the Receiver of Ultrasonic Transducer (Open Type Structure). 2. Customer Part Number 3. Murata Part Number MA40S4R 4. Structure Dimension : As per Fig.1 5. Absolute Maximum Ratings Items Specification Note 5-1 Operating temperature range -40 to +85 degC - 5-2 Storage temperature range -40 to +85 degC - 6. Specifications (* Temperature 25 ± 3°C, 45 to 75 % R.H, unless otherwise noted) Items Specification Note 6-1 Operating Frequency 40.0 kHz For reference at 40 kHz / 0 dB = 10 V/Pa 6-2 Sensitivity -63 dB +/- 3 dB (per measuring circuit Fig.2) 6-3 Capacitance 2,550 pF +/- 20 % at 1 kHz 6-4 Insulation Resistance More than 100 Mohm at 50 V D.C. Within +/- 3dB against initial 6-5 Temperature Characteristics -40 to +85 degC value at 25 degC MURATA MANUFACTURING Co., LTD. Rev.N

Reference Only P 2 / 6 7. Environmental tests (Standard Test Condition: 25 +/- 3 degC, 45 to 75 %R.H) 7.1 Shock Test The variation of the sensitivity at 40 kHz is within +/-3 dB compared with initial stage at 25 degC after applied following test conditions Acceleration : sine 980 m/s2 (100 G), 6 ms Direction : 3 directions Shock time : 3 times / directions 7.2 Vibration Test The variation of the sensitivity at 40 kHz is within +/-3 dB compared with initial stage at 25 degC after applied following test conditions Vibration frequency : 10 to 55 Hz Sweep Period : 1 min. Amplitude : 1.5 mm Directions : 3 directions Time : 2 hours / direction 7.3 Resistance to Soldering Heat The variation of the sensitivity at 40 kHz is within +/-3 dB compared with Initial stage at 25 degC in 1hour after touching soldering iron (Iron temperature : 350 degC), 3 seconds with the terminal. (Touching point must be 2mm or more away from the transducer body.) 7.4 High Temperature Test The variation of the sensitivity at 40 kHz is within +/-3 dB compared with initial stage at 25 degC in 24 hours after applied following test conditions Temperature : +85 +/-2 degC Time : 100 hours 7.5 Low Temperature Test The variation of the sensitivity at 40 kHz is within +/-3 dB compared with initial stage at 25 degC in 24 hours after applied following test conditions Temperature : -40 +/- 2 degC Time : 100 hours 7.6 Humidity Test The variation of the sensitivity at 40 kHz is within +/-3 dB compared with initial stage at 25 degC in 24 hours after following test conditions Temperature : +60 +/-2 degC Humidity : 90 to 95 %R.H. Time : 100 hours 7.7 Pull Strength There should be no substantial damage until 9.8 N pulling force. MURATA MANUFACTURING Co., LTD. Rev.N

Reference Only P 3 / 6 8. Caution 8-1 Limitation of Applications Please do not use in the applications listed below which require a high reliability to prevent the defects which might cause a damage to the Peoples’ life and/or property. 1) Aircraft equipment 2) Aerospace equipment 3) Undersea equipment 4) Power plant control equipment 5) Medical equipment 6) Transportation equipment (trains, ships, etc.) 7) Traffic signal equipment 8) Disaster prevention / crime prevention equipment 9) Data-processing equipment 10) Military equipment (regardless of directly/indirectly) 11) Security device/system 12) Outside-usage, in which the transducer is exposed to splashes or dusts 13) Application of similar complexity and/or reliability requirement to the applications listed in the above 8-2 Fail-safe Please make sure to provide an appropriate fail-safe function on your product to prevent a second d amage that may be caused by the abnormal function or the failure of our product. 9. Caution in use 9-1 (Notice in design and usage) 1) The transducer may generate surge voltage by mechanical or thermal shock. 2) Please do not apply D.C. voltage for ultrasonic transducer to avoid migration. 3) Please do not use this ultrasonic transducer in water. 4) Please do not apply an excessive mechanical shock or force on the top of this ultrasonic transducer and terminal pins. It may cause of disconnection and malfunction. 5) Please do not use nor storage this ultrasonic transducer in heavy dust condition. It may be a cause of clogging and low performance. Also, please do not use this transducer in high humidity or high concentrated exhaust gas. It may be a cause of corrosion and malfunction. 6) Care should be taken when select the material to hold, or cover backside of transducer. If it contains sulfur or sulfide, electrode on piezo-electric element may be corroded and became malfunction. 7) This transducer does not have a definition of terminal polarity. Please check a signal before using if you need a signal phase control for your application. 9-2 (Notice in storage) 1) The products should not be used or stored in a corrosive atmosphere, especially where chloride gas, sulfide gas, acid, alkali, salt or the like are present. Store the products in the room where is normal temperature and humidity, and avoid the sunlight, sudden changes in temperature and humidity. It may cause of failure or malfunction in such conditions. 2) Store the products where the temperature and relative humidity do not exceed -10 to 40 degC, and 30 to 80 %RH. Use the products within 6 months after receiving. 9-3 (Notice in mounting) 1) Please do not apply excessive force to terminals, when soldering. 2) Please use soldering temperature with not exceeds 350 degC, 3 seconds. 3) Flow soldering is not applicable. 4) Please do not clean by water and dissolving agent. 5) This product cannot be used mounted on PCB. Soldering fillet at the bottom of case may interfere with throughhole of PCB. Please contact products engineering section of Murata if you will use this product mounted on PCB. MURATA MANUFACTURING Co., LTD. Rev.N

Reference Only P 4 / 6 10. Note 1) Please make sure that your product has been evaluated in view of your specifications with our product being mounted to your product. 2) You are requested not to use our product deviating from the agreed specifications. 3) We consider inappropriate to include any terms or conditions with regard to the business transaction in the product specifications, drawings or other technical documents. Therefore, if your technical documents as above include such terms and conditions such as warranty clause, product liability clause, or intellectual property infringement liability clause, they will be deemed to be invalid. Dimensions 3 0. ± 9 9. a. Di 3 0. ± 1 7. ) 0 2. Caution) ( There is a fillet of solder in this area. 0 Please refer to 9-3 (Notice in mounting) 2- 0.64± 0.1 1. ± 0 0. Prohibited area of customer 1 soldering () : Reference value Unit: mm. 5.0 ± 0.3 Lot No. 6 digits X X XXXX x x x x R Year (1 digit) Month (1 digit) Serial Number (4 digits) x x 0~9 (cycle 10 years) Jan.~Sep. → 1 ~ 9 0001~9999 Ex.. 2013 → 3 Oct. → X Run number is reset 2014 → 4 Nov. → Y every month. 2015 → 5 Dec. → Z 2016 → 6 Fig.1: Product Dimension MURATA MANUFACTURING Co., LTD. Rev.N

Reference Only P 5 / 6 Measuring Circuit Amp. SP. S.C.M. U.S. OSC. 30 cm RL Voltmeter Freq. Counter OSC. : Oscillator (Brüel & Kjær 1013) U.S. : Ultrasonic Sensor S.C.M : Standard Condenser Microphone (Brüel & Kjær 4135) Amp. : Amplifier (Brüel & Kjær 2610) SP. : Tweeter RL : 3.9 k ohm Fig. 2: Murata standard measuring Condition : U.S. and S.C.M must be aligned with the line of SP., and fixed distance: 30 cm when measuring. An input Sound Pressure Level is 94 dB at 40 kHz. How to measure a temperature characteristic : After inputting a product into the thermostatic chamber in 15 min. or more, Measure the product according to the above method immediately MURATA MANUFACTURING Co., LTD. Rev.N

Datasheet下载

Datasheet下载