ICGOO在线商城 > M83513/22-B01NP

- 型号: M83513/22-B01NP

- 制造商: Glenair

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

M83513/22-B01NP产品简介:

ICGOO电子元器件商城为您提供M83513/22-B01NP由Glenair设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 提供M83513/22-B01NP价格参考¥509.14-¥565.10以及GlenairM83513/22-B01NP封装/规格参数等产品信息。 你可以下载M83513/22-B01NP参考资料、Datasheet数据手册功能说明书, 资料中有M83513/22-B01NP详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 品牌 | Glenair |

| 产品目录 | |

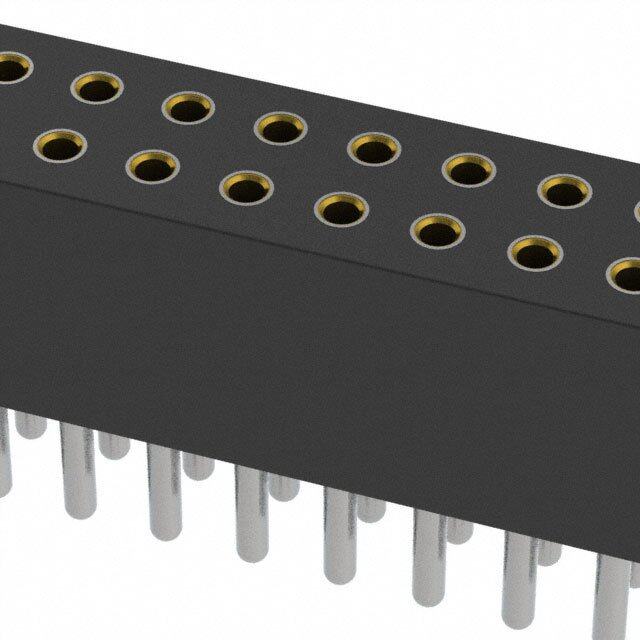

| 描述 | D-Sub军用规格连接器 MICRO D |

| 产品分类 | 军用规格/军用类型 |

| 产品手册 | |

| 产品图片 |

|

| rohs | 否 |

| 产品系列 | D-Sub军用规格连接器,Glenair M83513/22-B01NP |

| 产品型号 | M83513/22-B01NP |

| 产品种类 | D-Sub军用规格连接器 |

| 位置数量 | 15 |

| 商标 | Glenair |

| 型式 | Male |

| 外壳大小 | B |

| 外壳材质 | Aluminum |

| 外壳电镀 | Nickel |

| 安装角 | Vertical |

| 工厂包装数量 | 1 |

| 排数 | 2 |

| 端接类型 | Through Hole |

| 系列 | M83513 |

| 触点材料 | Aluminum |

| 触点电镀 | Gold |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

DURA-CON All-Plastic Strip Connectors Metal Shell Mil-C-83513 Connectors Terminal Blocks Microedge .050" D-microminiature

Dura-Con Introduction Cinch Dura-ConTMconnectors are designed for applications that require a rugged, durable, and high-performance interconnect. Dura-Con is the ideal connector for applications where weight and space must be kept to a minimum while maintaining maximum reliability. Miniaturized airborne electronics and data processing equipment, where shorter signal paths are needed, represent typical applications for these unique connectors. The heart of the Dura-Con system is the Dura-Con pin contact. The Cinch Dura-Con pin contact is made from a precision minia- ture spring cable with a welded tip. The expanded cable provides seven spring members peripherally around the pin so that con- tact is maintained with the mating socket wall no matter what radial forces are applied. This spring may be flexed many times without any evidence of metal fatigue. Reliable mating is further ensured by protecting the pin contact in a tightly toleranced recessed cavity. Cinch’s family of Dura-Con connectors includes MIL-C-83513 Series connectors along with our own commercial equivalents. The commercial Dura-Con product line offers an expanded range of termination and hardware options for all-plastic and metal shell wire versions and right-angle and straight PC board mount “terminal blocks”. Cinch also packages the Dura-Con contact in a very low profile plastic strip connector on .050" centers and in a line of high-density microminiature edge (Microedge) board connectors that meet the requirements of MIL-C-55302. Cinch has created a line of plastic and metal shell Dura-Con connector savers for very high mating cycle applications such as test equipment. Termination Options: Cinch offers the following termination methods for its Dura-Con connectors: Insulated Wire- Insulated wire is crimped to the Dura-Con contacts then epoxy backpotted at the factory. Wire is available in standard lengths of 18, 24, 36, and 48 inches. Uninsulated Wire- 24 AWG, gold-plated, uninsulated wire is crimped to the Dura-Con contact at the factory. Wire is available in standard lengths of 0.5, 1.0, and 2.0 inches. This option allows the user greater flexibility when installing the connector. Solder Cup- For applications that require the lowest contact resistance, Cinch offers Dura-Con connectors with solder cups for termination by the user. 5 Dura-Con is a trademark of CinchConnectors. 5-1 Call Toll Free: 1 (800) 323-9612

Dura-Con Introduction Custom Capabilities: Standard Cinch Dura-Con connectors satisfy a wide variety of applications. Cinch’s line of Dura-Con D-microminiature connectors is one of the most versatile in the industry. There are over 50,000 possible combinations of Cinch standard options such as connector type, size, materials, hardware, and termination. When special application requirements arise, Cinch Dura-Con connectors take this versatility to the next level. Whether specific needs entail new variations of simple end-to-end connector assemblies or more complex and intricate harness assemblies, Cinch Connector Division has the state-of-the-art engineering resources and research facilities in place to meet your needs. Cinch approaches your business with a well-defined goal: to ensure the integrity of your design and to execute our contribution to it in a responsible, cost-effective manner. This philosophy has led Cinch to a position of industry leadership. For complete information regarding the total capabilities of the Dura-Con connector series, or for custom application assistance, contact your nearest Cinch Connectors sales office. 5 Call Toll Free: 1 (800) 323-9612 5-2

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire All-Plastic D-Microminiature ■ Both plug and socket available in 9,15,21,25,31,37,and 51 positions. ■ Termination styles - solder cup,gold-plated solid wire,and insulated stranded wire. ES ■ Several styles of mounting hardware are available for cable-to-cable, R U cable-to-board mount,and cable-to-panel mount applications. T EA ■ High-performance Dura-Con twist-pin contact. F ■ Economical all-plastic shell for lightweight applications where no shielding is required. ■ Meets requirements of MIL-C-83513 except where noted. S L Insulator: UL94V-0 rated glass-filled polyester A ERI Contacts:Pins - Copper alloy, Sockets - Copper alloy (machined) T A Contact Plating:.000050 in gold M L A T N E M N Operating Temperature: -55°C to +135°C O R VI N E L A Current Rating: 3 Amps maximum C TRI Withstanding Voltage: 600 VAC RMS @ sea level C E Contact Resistance: 8 milliohms maximum change L E Maximum Minimum No.of Mating Force Unmating Force Contacts Lb. Kg Lb. Kg 9 5.63 2.56 .28 .13 L A 15 9.38 4.26 .47 .21 C Individual Contact:6 oz.(170.40 g) maximum insertion; NI 21 13.13 5.96 .66 .30 A 0.5 oz.(14.20 g) minimum withdrawal 25 15.63 7.10 .78 .35 H C Mating / Unmating Force: See table 31 19.38 8.80 .97 .44 E M 37 23.13 10.50 1.16 .53 51 31.88 14.47 1.59 .72 Call Toll Free: 1 (800) 323-9612 5-4

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire All-Plastic D-Microminiature Contact Arrangements (Face view of pin insulator) (Use reverse order for socket) Ordering Information DCD A 37 P 6 E 2-18.0 K Cinch Dura-Con D Connector Mounting Hardware** B = No Hardware Insulator Type F = Float Mount *D = Thermoplastic R= Reverse Float Mount Glass Reinforced K= Jackscrew (Standard) L= Jackscrew (Low Profile) Mounting Type P = Jackpost, MIL-C-83513/5-07 *A= Screw Mount Flange Lead Length in inches*** 00.5Solid copper wire only No.of Contacts 01.0Solid copper wire only 9, 15, 21, 25, 31, 37, 51 02.0Solid copper wire only 18.0Stranded wire only Contact Type 24.0Stranded wire only P – Pin (Plug) 36.0Stranded wire only S– Socket (Receptacle) 48.0Stranded wire only Wire Size in AWG Insulation 5= 25 AWGSolid Copper Color or Wire Finish 6= 26 AWG Stranded 1= White S= Solder Cup (Skip to Mounting Hardware) *2 = Yellow (Stranded Wire) 3 = Tin-Plated Wire Type *4= Gold-Plated (Solid Wire Only) E= MIL-W-16878/4, 7 Strand *5 = Color Coded Per MIL-Std.(681) C = Solid Copper - Uninsulated System 1.(Stranded Wire Only) (Consult factory for non-standard wire types) *-Indicates Cinch std.option. **-See p.5-12 for std.hardware dims.See p.5-13 for non-std.hardware & p.5-31 for Mil spec.hardware both sold separately. ***- Length Tolerance:solid wire = ± 3/32”, standard wire = ± 1/4”. 5-5 Call Toll Free: 1 (800) 323-9612

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire All-Plastic D-Microminiature Connector Dimensions - Plastic Shell Plug Socket 5 A B Max. C D E F Max. +.010 (.254) No.of +.010 (.254) -.018 (.457) +.005 (.127) +.010 (.254) Contacts in mm in mm in mm in mm in mm in mm 9 Plug .778 19.76 .292 7.42 .398 10.11 .565 14.35 .208 5.28 .173 4.39 9 Socket .778 19.76 .376 9.55 .398 10.11 .565 14.35 .208 5.28 .173 4.39 15 Plug .928 23.57 .442 11.23 .548 13.92 .715 18.16 .208 5.28 .173 4.39 15 Socket .928 23.57 .526 13.36 .548 13.92 .715 18.16 .208 5.28 .173 4.39 21 Plug 1.078 27.38 .592 15.04 .698 17.73 .865 21.97 .208 5.28 .173 4.39 21 Socket 1.078 27.38 .676 17.17 .698 17.73 .865 21.97 .208 5.28 .173 4.39 25 Plug 1.178 29.92 .692 17.58 .798 20.27 .965 24.51 .208 5.28 .173 4.39 25 Socket 1.178 29.92 .776 19.71 .798 20.27 .965 24.51 .208 5.28 .173 4.39 31 Plug 1.328 33.73 .842 21.39 .948 24.08 1.115 28.32 .208 5.28 .173 4.39 31 Socket 1.328 33.73 .926 23.52 .948 24.08 1.115 28.32 .208 5.28 .173 4.39 37 Plug 1.478 37.54 .992 25.20 1.098 27.89 1.265* 32.13 .208 5.28 .173 4.39 37 Socket 1.478 37.54 1.076 27.33 1.098 27.89 1.265* 32.13 .208 5.28 .173 4.39 51 Plug 1.428 36.27 .942 23.93 1.048 26.62 1.215 30.86 .250 6.35 .220 5.59 51 Socket 1.428 36.27 1.026 26.06 1.048 26.62 1.215 30.86 .250 6.35 .220 5.59 Call Toll Free: 1 (800) 323-9612 5-6

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire All-Plastic D-Microminiature Panel Mounting Dimensions Panel Cutout Dimensions Figure 1. Front Mounting Figure 2. Rear Mounting Figure 3. Edgeboard Mounting A B C Figure +.004 (.101) +.004 (.101) +.005 (.127) No.of Number -.000 (.000) -.000 (.000) -.000 (.000) Contacts in mm in mm in mm 1 .408 10.36 .172 4.37 .570 14.48 9 2 .373 9.47 .216 5.49 .570 14.48 3 - - - - .570 14.48 1 .558 14.17 .172 4.37 .720 18.29 15 2 .523 13.28 .216 5.49 .720 18.29 3 - - - - .720 18.29 5 1 .708 17.98 .172 4.37 .870 22.10 21 2 .674 17.12 .216 5.49 .870 22.10 3 - - - - .870 22.10 1 .808 20.52 .172 4.37 .970 24.64 25 2 .774 19.66 .216 5.49 .970 24.64 3 - - - - .970 24.64 1 .958 24.33 .172 4.37 1.120 28.45 31 2 .924 23.47 .216 5.49 1.120 28.45 3 - - - - 1.120 28.45 1 1.108 28.14 .172 4.37 1.270 32.26 37 2 1.074 27.28 .216 5.49 1.270 32.26 3 - - - - 1.270 32.26 1 1.058 26.87 .215 5.46 1.220 30.99 51 2 1.024 26.01 .259 6.58 1.220 30.99 3 - - - - 1.220 30.99 5-7 Call Toll Free: 1 (800) 323-9612

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire Metal Shell D-Microminiature ■ Both plug and socket available in 9,15,21,25,31,37,51,and 100 positions. ■ Several styles of mounting are available for cable-to-cable,cable-to-panel mount,and cable-to-board mount. ■ Aluminum shell provides extra strength and EMI/RFI shielding capability. S Plating options available. E R U ■ Silicone elastomer compression interfacial seal protects contacts from T A moisture and humidity and isolates contacts from each other and the E F metal shell. ■ Meets requirements of MIL-C-83513 except where noted. ■ Rugged twist-pin contacts resistant to shock and vibration make metal shell Dura-Con an excellent choice for harsh environments such as airborne or space applications. Insulator:UL94V-0 rated glass-filled polyester or diallyl phthalate S Contacts:Pins - Copper alloy, Sockets - Copper alloy (machined) L A RI Contact Plating:.000050 in gold E T Shell: Aluminum alloy A M Shell Plating: Yellow chromate over cadmium (std.) or electroless nickel L A T N E M Operating Temperature: -55°C to +135°C N O R VI N E L A C Current Rating: 3 Amps maximum RI T Withstanding Voltage: 600 VAC RMS @ sea level C LE Contact Resistance: 8 milliohms maximum Maximum Minimum E No.of Mating Force Unmating Force Contacts Lb. Kg Lb. Kg 9 5.63 2.56 .28 .13 15 9.38 4.26 .47 .21 L 21 13.13 5.96 .66 .30 A C Individual Contact:6 oz.(170.40 g) maximum insertion; 25 15.63 7.10 .78 .35 ANI 0.5 oz.(14.20 g) minimum withdrawal 31 19.38 8.80 .97 .44 H 37 23.13 10.50 1.16 .53 C Mating / Unmating Force: See table E 51 31.88 14.47 1.59 .72 M 100 62.50 28.38 3.13 1.42 Call Toll Free: 1 (800) 323-9612 5-8

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire Metal Shell D-Microminiature Contact Arrangements (Face view of pin insert) (Use reverse order for socket side) Ordering Information DCD M 37 P 6 E 2-18.0 K N Cinch Dura-Con D Connector Shell Plating *No Letter= Yellow Chromate Insulator Type over Cadmium C= Diallyl Phthalate N= Electroless Nickel Glass-Reinforced D = Thermoplastic Mounting Hardware** Glass-Reinforced B = No Hardware F = Float Mount Mounting Type R= Reverse Float Mount M= Screw Mount Metal Shell K= Jackscrew (Standard) L= Jackscrew (Low Profile) P = Jackpost, Size 9 through 51 No.of Contacts MIL-C-83513/5-07 9, 15, 21, 25, 31, 37, 51, 100 Size 100 MIL-C-83513/5-17 Contact Type Lead Length in inches*** P = Pin (Plug) 00.5Solid copper wire only S= Socket (Receptacle) 01.0Solid copper wire only 02.0Solid copper wire only Wire Size in AWG 18.0Stranded wire only 5= 25 AWGSolid Copper 24.0Stranded wire only 36.0Stranded wire only 6= 26 AWG Stranded 48.0Stranded wire only S= Solder cup (Skip to Mounting Hardware) Insulation Wire Type Color or Wire Finish C= Solid Copper (Uninsulated) 1= White E= MIL-W-16878/4, 7 Strand *2 = Yellow (Stranded Wire) 3 = Tin-Plated (Consult factory for non-standard wire types) *4= Gold-Plated (Solid Wire) *5 = Color Coded Per MIL-Std. 681, System 1.(Stranded Wire Only) *-Indicates Cinch std.option. **-See p.5-12 for std.hardware dims.See p.5-13 for non-std.hardware & p.5-31 for Mil spec.hardware both sold separately. ***- Length Tolerance:solid wire = ± 3/32”, standard wire = ± 1/4”. 5-9 Call Toll Free: 1 (800) 323-9612

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire Metal Shell D-Microminiature Connector Dimensions - Metal Shell Plug Socket A B Max. C D E F Max. 5 +.010 (.254) No.of +.010 (.254) -.018 (.457) +.005 (.127) +.010 (.254) Contacts in mm in mm in mm in mm in mm in mm 9 Plug .775 19.68 .333 8.46 .390 9.91 .565 14.35 .298 7.57 .270 6.86 9 Socket .775 19.68 .396 10.06 .390 9.91 .565 14.35 .298 7.57 .270 6.86 15 Plug .925 23.50 .483 12.27 .540 13.72 .715 18.16 .298 7.57 .270 6.86 15 Socket .925 23.50 .546 13.87 .540 13.72 .715 18.16 .298 7.57 .270 6.86 21 Plug 1.075 27.30 .633 16.08 .690 17.53 .865 21.97 .298 7.57 .270 6.86 21 Socket 1.075 27.30 .696 17.68 .690 17.53 .865 21.97 .298 7.57 .270 6.86 25 Plug 1.175 29.84 .733 18.62 .790 20.07 .965 24.51 .298 7.57 .270 6.86 25 Socket 1.175 29.84 .796 20.22 .790 20.07 .965 24.51 .298 7.57 .270 6.86 31 Plug 1.325 33.66 .883 21.16 .940 23.88 1.115 28.32 .298 7.57 .270 6.86 31 Socket 1.325 33.66 .946 24.03 .940 23.88 1.115 28.32 .298 7.57 .270 6.86 37 Plug 1.475 37.46 1.033 26.24 1.090 27.69 1.265 32.13 .298 7.57 .270 6.86 37 Socket 1.475 37.46 1.096 27.84 1.090 27.69 1.265 32.13 .298 7.57 .270 6.86 51 Plug 1.425 36.20 .983 24.97 1.040 26.42 1.215 30.86 .341 8.66 .310 7.87 51 Socket 1.425 36.20 1.046 26.57 1.040 26.42 1.215 30.86 .341 8.66 .310 7.87 100 Plug 2.160 54.86 1.383 35.13 1.432 36.38 1.800 45.71 .384 9.75 .360 9.15 100 Socket 2.160 54.86 1.446 36.73 1.432 36.38 1.800 45.71 .384 9.75 .360 9.15 Call Toll Free: 1 (800) 323-9612 5-10

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire Metal Shell D-Microminiature Panel Mounting Dimensions Panel Cutout Dimensions A B C D Figure +.004 (.101) +.004 (.101) +.005 (.127) +.005 (1.27) No.of Number -.000 (.000) -.000 (.000) -.000 (.000) -.000 (.000) Contacts in mm in mm in mm in mm 1 .408 10.36 .270 6.86 .570 14.48 - - 9 2 .408 10.36 .256 6.50 .570 14.48 .089 2.26 3 - - - - .570 14.48 - - 1 .558 14.17 .270 6.86 .720 18.29 - - 15 2 .558 14.17 .256 6.50 .720 18.29 .089 2.26 3 - - - - .720 18.29 - - 1 .708 17.98 .270 6.86 .870 22.10 - - 21 2 .708 17.98 .256 6.50 .870 22.10 .089 2.26 3 - - - - .870 22.10 - - 1 .808 20.52 .270 6.86 .970 24.64 - - 5 25 2 .808 20.52 .256 6.50 .970 24.64 .089 2.26 3 - - - - .970 24.64 - - 1 .958 24.33 .270 6.86 1.120 28.45 - - 31 2 .958 24.33 .256 6.50 1.120 28.45 .089 2.26 3 - - - - 1.120 28.45 - - 1 1.108 28.14 .270 6.86 1.270 32.26 - - 37 2 1.108 28.14 .256 6.50 1.270 32.26 .089 2.26 3 - - - - 1.270 32.26 - - 1 1.058 26.87 .315 8.00 1.220 30.99 - - 51 2 1.058 26.87 .300 7.62 1.220 30.99 .089 2.26 3 - - - - 1.220 30.99 - - 1 1.450 36.84 .361 9.17 1.805 45.86 .117 2.97 100 2 1.562 39.68 .338 8.58 1.805 45.86 .117 2.97 3 - - - - 1.805 45.86 .117 2.97 5-11 Call Toll Free: 1 (800) 323-9612

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire Mounting Hardware D-Microminiature Mounting Hardware For Plastic &Metal Shell Dura-Con Connectors Option “F” Option “R” 5 Option “K” Option “L” Option “P” Call Toll Free: 1 (800) 323-9612 5-12

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire Mounting Hardware D-Microminiature P/N: DCSL1 Purchased Separately Jackpost - Rear Panel Mount Jackpost (Purchased Separately) Part Panel Thickness A Dimension Number in mm in mm DCJPRM094 .094 2.5 .092/.087 2.34/2.21 DCJPRM063 .063 1.6 .061/.056 1.55/1.42 DCJPRM047 .047 1.2 .047/.042 1.19/1.07 DCJPRM031 .031 0.8 .030/.025 0.76/0.64 5 Panel Cutout Dimensions Part A B C (Plug &Receptacle) Number +.004 (.101) +.004 (.101) (by Shell -.000 (.000) -.000 (.000) +.005 (.127) Size) in mm in mm in mm 9 .398 10.11 .249 6.32 .565 14.35 15 .548 13.92 .249 6.32 .715 18.16 21 .698 17.73 .249 6.32 .865 21.97 25 .798 20.27 .249 6.32 .965 24.51 31 .948 24.08 .249 6.32 1.115 28.34 37 1.098 27.89 .249 6.32 1.265 32.13 51 1.048 26.62 .292 7.42 1.215 30.86 100 1.448 36.78 .336 8.53 1.800 45.72 5-13 Call Toll Free: 1 (800) 323-9612

Dura-Con .050" (1.27mm) Density High Reliability PCB Mount Terminal Block Metal Shell ■ Plug & socket versions available in 9,15,21,25,31,37,51,and 100 positions. ■ Flow-through design facilitates inspection and cleaning after soldering. ■ All terminal block connectors use standard mounting hardware. S ■ Metal shell provides EMI/RFI shielding capability. E UR ■ Available in 3 styles: Straight mount,90°right-angle mount,and 90° right- T A angle narrow profile mounting. E F ■ Silicone elastomer interfacial seal protects contacts from moisture and isolates them from each other and from the metal shell. ■ Meets requirements of MIL-C-83513. ■ Choice of insulator materials. Insulator: UL94V-0 glass-filled polyester or diallyl phthalate S Contacts:Pins - Copper alloy, Sockets - Copper alloy (machined) L A RI Contact Plating:.000050 in gold E T Shell: Aluminum alloy A M Shell Plating: Yellow chromate over cadmium (std.) or electroless nickel L A T N E M N Operating Temperature: -55°C to +135°C O R VI N E L Current Rating: 3 Amps maximum A C RI Withstanding Voltage: 600 VAC RMS @ sea level, 150 VAC CT @ 70,000 ft. E EL Contact Resistance: 8 milliohms maximum Insulation Resistance:1,000 megohms min between adjacent pins Maximum Minimum No.of Mating Force Unmating Force Contacts Lb. Kg Lb. Kg 9 5.63 2.56 .28 .13 L 15 9.38 4.26 .47 .21 A C Individual Contact:6 oz.(170.40 g) maximum insertion force; 21 13.13 5.96 .66 .30 NI A 0.5 oz.(14.20 g) minimum withdrawal force 25 15.63 7.10 .78 .35 H 31 19.38 8.80 .97 .44 C Mating / Unmating Forces: See table E 37 23.13 10.50 1.16 .53 M 51 31.88 14.47 1.59 .72 100 62.50 28.38 3.13 1.42 Call Toll Free: 1 (800) 323-9612 5-14

Dura-Con .050" (1.27mm) Density High Reliability PCB Mount Terminal Block Metal Shell Contact Arrangements Ordering Information DC D M 25 S BR -- -- Shell Finish* Cinch Dura-Con D No Letter= Standard Yellow Connector Chromate over Cadmium N= Electroless Nickel Insulator Type C= Diallyl Phthalate Hardware* Glass Reinforced No Letter= Less Hardware D = Thermoplastic P= Jackpost Glass Reinforced Termination Style BR= 90° PCB Mounting Type BS= Straight 180° PCB M= Screw Mount Metal Shell CBR= 90° Narrow Profile PCB No.of Contacts 9, 15, 21, 25, 31, 37, 51, &100 Contact Type P = Pin (Plug) S= Socket (Receptacle) * For other options consult factory. 5-15 Call Toll Free: 1 (800) 323-9612

Dura-Con .050" (1.27mm) Density High Reliability PCB Mount Terminal Block Metal Shell Recommended Board Layout Typ.Hole Dia.= .040" (1.02 mm) NOTE: For additional connector dimensions, see page 5-10. A B C F No.of Max. +.007 (0.18) +.005 (0.13) Max. Contacts in mm in mm in mm in mm 9 Plug 1.390 35.31 1.150 29.21 .565 14.35 .465 11.81 9 Socket 1.390 35.31 1.150 29.21 .565 14.35 .465 11.81 15 Plug 1.540 39.12 1.300 33.02 .715 18.16 .465 11.81 15 Socket 1.540 39.12 1.300 33.02 .715 18.16 .465 11.81 21 Plug 1.690 42.93 1.450 36.83 .865 21.97 .465 11.81 21 Socket 1.690 42.93 1.450 36.83 .865 21.97 .465 11.81 25 Plug 1.790 45.47 1.550 39.37 .965 24.51 .465 11.81 25 Socket 1.790 45.47 1.550 39.37 .965 24.51 .465 11.81 31 Plug 2.040 51.82 1.800 45.72 1.115 28.32 .465 11.81 31 Socket 2.040 51.82 1.800 45.72 1.115 28.32 .465 11.81 37 Plug 2.340 59.44 2.100 53.34 1.265 32.13 .465 11.81 5 37 Socket 2.340 59.44 2.100 53.34 1.265 32.13 .465 11.81 51 Plug 1.875 47.63 1.600 40.64 1.215 30.86 .565 14.35 51 Socket 1.875 47.63 1.600 40.64 1.215 30.86 .565 14.35 100 Plug 2.780 70.61 2.500 63.50 1.800 45.72 .765 19.43 100 Socket 2.780 70.61 2.500 63.50 1.800 45.72 .765 19.43 G H J K No.of Max. Max. +.005 (0.13) +.015 Contacts in mm in mm in mm in mm 9 Plug .308 7.82 .190 4.83 .096 2.44 .125 3.18 9 Socket .308 7.82 .200 5.08 .096 2.44 .125 3.18 15 Plug .308 7.82 .190 4.83 .096 2.44 .125 3.18 15 Socket .308 7.82 .200 5.08 .096 2.44 .125 3.18 21 Plug .308 7.82 .190 4.83 .096 2.44 .125 3.18 21 Socket .308 7.82 .200 5.08 .096 2.44 .125 3.18 25 Plug .308 7.82 .190 4.83 .096 2.44 .125 3.18 25 Socket .308 7.82 .200 5.08 .096 2.44 .125 3.18 31 Plug .308 7.82 .190 4.83 .096 2.44 .125 3.18 31 Socket .308 7.82 .200 5.08 .096 2.44 .125 3.18 37 Plug .308 7.82 .190 4.83 .096 2.44 .125 3.18 37 Socket .308 7.82 .200 5.08 .096 2.44 .125 3.18 51 Plug .351 8.92 .190 4.83 .096 2.44 .125 3.18 51 Socket .351 8.92 .200 5.08 .096 2.44 .125 3.18 100 Plug .394 10.00 .190 4.83 .125 3.18 .225 5.72 100 Socket .394 10.00 .200 5.08 .125 3.18 .225 5.72 Call Toll Free: 1 (800) 323-9612 5-16

Dura-Con .050" (1.27mm) Density High Reliability PCB Mount Terminal Block Metal Shell Straight (180°) Termination Recommended Board Layout Typ.Hole Dia.= .040" (1.02 mm) NOTE: For additional connector dimensions, see page 5-10. A B C D G No.of Max. +.007 (0.18) +.005 (0.13) Max. Max. Contacts in mm in mm in mm in mm in mm 9 Plug 1.390 35.31 1.150 29.21 .565 14.35 .885 22.48 .308 7.75 9 Socket 1.390 35.31 1.150 29.21 .565 14.35 .885 22.48 .308 7.75 15 Plug 1.390 35.31 1.150 29.21 .715 18.16 .945 24.0 .308 7.75 15 Socket 1.390 35.31 1.150 29.21 .715 18.16 .945 24.0 .308 7.75 21 Plug 1.690 42.93 1.450 36.83 .865 21.97 1.185 30.09 .308 7.75 21 Socket 1.690 42.93 1.450 36.83 .865 21.97 1.185 30.09 .308 7.75 25 Plug 1.740 44.20 1.500 38.10 .965 24.51 1.275 32.38 .308 7.75 25 Socket 1.740 44.20 1.500 38.10 .965 24.51 1.275 32.38 .308 7.75 31 Plug 2.040 51.82 1.800 45.72 1.115 28.32 1.575 40.00 .308 7.75 31 Socket 2.040 51.82 1.800 45.72 1.115 28.32 1.576 40.00 .308 7.75 37 Plug 2.340 59.44 2.100 53.34 1.265 32.13 1.875 47.62 .308 7.75 37 Socket 2.340 59.44 2.100 53.34 1.265 32.13 1.875 47.62 .308 7.75 51 Plug 2.270 57.66 2.000 50.80 1.215 30.86 1.775 45.08 .351 8.92 5 51 Socket 2.270 57.66 2.000 50.80 1.215 30.86 1.775 45.08 .351 8.92 100 Plug 3.070 77.98 2.800 71.12 1.800 45.72 2.585 65.55 .455 11.56 100 Socket 3.070 77.98 2.800 71.12 1.800 45.72 2.585 65.65 .455 11.56 H J K L No.of Max. +.005 (0.13) Max. Max. Contacts in mm in mm in mm in mm 9 Plug .190 4.83 .096 2.44 .165 4.19 .355 9.02 9 Socket .200 5.08 .096 2.44 .165 4.19 .355 9.02 15 Plug .190 4.83 .096 2.44 .165 4.19 .355 9.02 15 Socket .200 5.08 .096 2.44 .165 4.19 .355 9.02 21 Plug .190 4.83 .096 2.44 .165 4.19 .355 9.02 21 Socket .200 5.08 .096 2.44 .165 4.19 .355 9.02 25 Plug .190 4.83 .096 2.44 .165 4.19 .355 9.02 25 Socket .200 5.08 .096 2.44 .165 4.19 .355 9.02 31 Plug .190 4.83 .096 2.44 .165 4.19 .355 9.02 31 Socket .200 5.08 .096 2.44 .165 4.19 .355 9.02 37 Plug .190 4.83 .096 2.44 .165 4.19 .355 9.02 37 Socket .200 5.08 .096 2.44 .165 4.19 .355 9.02 51 Plug .190 4.83 .096 2.44 .165 4.19 .355 9.02 51 Socket .200 5.08 .096 2.44 .165 4.19 .355 9.02 100 Plug .190 4.83 .125 3.18 .300 7.62 .550 13.97 100 Socket .200 5.08 .125 3.18 .300 7.62 .550 13.97 5-17 Call Toll Free: 1 (800) 323-9612

Dura-Con .050" (1.27mm) Density High Reliability PCB Mount Terminal Block Metal Shell Recommended Board Layout NOTE: For additional connector dimensions, see page 5-10. Typ.Hole Dia.= .040" (1.02 mm) A B C No.of Max. +.005 (0.13) Max. Contacts in mm in mm in mm 9 Plug .785 19.94 .565 14.35 .308 7.82 9 Socket .785 19.94 .565 14.35 .308 7.82 15 Plug .935 23.75 .715 18.16 .308 7.82 15 Socket .935 23.75 .715 18.16 .308 7.82 21 Plug 1.085 27.56 .865 21.97 .308 7.82 21 Socket 1.085 27.56 .865 21.97 .308 7.82 25 Plug 1.085 30.10 .965 24.51 .308 7.82 25 Socket 1.185 30.10 .965 24.51 .308 7.82 31 Plug 1.335 33.91 1.115 28.32 .308 7.82 31 Socket 1.335 33.91 1.115 28.32 .308 7.82 37 Plug 1.485 37.72 1.265 32.13 .308 7.82 37 Socket 1.485 37.72 1.265 32.13 .308 7.82 5 51 Plug 1.435 36.45 1.215 30.86 .351 8.92 51 Socket 1.435 36.45 1.215 30.86 .351 8.92 100 Plug 2.175 55.25 1.800 45.72 .394 10.00 100 Socket 2.175 55.25 1.800 45.72 .394 10.00 F G H J No.of +.010 (0.25) +.010 (0.25) Max. +.005 (0.13) Contacts in mm in mm in mm in mm 9 Plug .230 5.84 .250 6.35 .420 10.67 .096 2.44 9 Socket .230 5.84 .250 6.35 .420 10.67 .096 2.44 15 Plug .130 3.30 .250 6.35 .420 10.67 .096 2.44 15 Socket .130 3.30 .250 6.35 .420 10.67 .096 2.44 21 Plug .130 3.30 .250 6.35 .420 10.67 .096 2.44 21 Socket .130 3.30 .250 6.35 .420 10.67 .096 2.44 25 Plug .130 3.30 .250 6.35 .420 10.67 .096 2.44 25 Socket .130 3.30 .250 6.35 .420 10.67 .096 2.44 31 Plug .130 3.30 .250 6.35 .520 13.21 .996 2.44 31 Socket .130 3.30 .250 6.35 .520 13.21 .096 2.44 37 Plug .130 3.30 .250 6.35 .520 13.21 .096 2.44 37 Socket .130 3.30 .250 6.35 .520 13.21 .096 2.44 51 Plug .150 3.81 .300 7.62 .650 16.51 .096 2.44 51 Socket .150 3.81 .300 7.62 .650 16.51 .096 2.44 100 Plug .200 5.08 .400 10.16 1.000 25.40 .125 3.18 100 Socket .200 5.08 .400 10.16 1.000 25.40 .125 3.18 Call Toll Free: 1 (800) 323-9612 5-18

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire MIL-C-83513 D-Microminiature ■ All-plastic and metal shell wire versions available in solder cup,gold-plated solid wire,and insulated stranded wire. ■ PCBmount “terminal block”type connectors available in straight or right angle. S E R ■ Sizes offered - 9,15,21,25,31,35,51,and 100 (metal shell only). U AT ■ All products are qualified to the requirements of MIL-C-83513 and marked with E F the M83513 part number. ■ Optional shell platings and insulator materials offer high performance in harsh environments. ■ Mounting hardware per MIL-C-83513. Insulator:UL94V-0 rated glass-filled polyester per MIL-M-24519 or diallyl phthalate (DAP) per MIL-M-14. S AL Contacts:Pins - Copper alloy, Sockets - Copper alloy RI E Contact Plating:.000050 in gold per MIL-G-45204 T A M Shell Material (Metal Shell Only):Aluminum alloy Shell Plating (Metal Shell Only):Yellow chromate over cadmium (std.) or electroless nickel A T N E M NL Operating Temperature: -55°C to +125°C O R VI N E L A Current Rating: 3 Amps maximum Maximum Minimum C TRI Withstanding Voltage: 600 VAC RMS @ sea level No.of Mating Force Unmating Force C Contacts Lb. Kg Lb. Kg LE Contact Resistance: 8 milliohms maximum 9 5.63 2.56 .28 .13 E 15 9.38 4.26 .47 .21 21 13.13 5.96 .66 .30 L 25 15.63 7.10 .78 .35 A Durability: 500 mate/unmate cycles C 31 19.38 8.80 .97 .44 NI Individual Contact:Forces6 oz.(170.40 g) maximum insertion; 37 23.13 10.50 1.16 .53 A H 0.5 oz.(14.20 g) minimum withdrawal 51 31.88 14.47 1.59 .72 C E Mating / Unmating Force: See table M Call Toll Free: 1 (800) 323-9612 5-20

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire MIL-C-83513 D-Microminiature - Metal Shell Metal Shell Contact Arrangements (Face view of pin insert) (Use reverse order for socket side) Ordering Information M83513/04 - A 03 C Shell Finish C= Cadmium Connector Type N= Electroless Nickel 01 - Metal Shell D Plugs with Wire Type (Use only for /03 & /04,otherwise omit) Solder Cup Termination 01- M22759/11-26-9, 18 inches, White (see note below) 02- Metal Shell D Sockets with 02- M22759/11-26-9, 36 inches, White (see note below) Solder Cup Termination 03- M22759/11-26-( ), 18 inches, Color Coded (see note below) 04- M22759/11-26-( ), 36 inches, Color Coded (see note below) 03 - Metal Shell D Plugs 05- QQ-W-343, 25 AWG, 0.5 inch, Gold-Plated with Wire Leads 06- QQ-W-343, 25 AWG, 1.0 inch, Gold-Plated 04 - Metal Shell D Sockets 07- QQ-W-343, 25 AWG, 0.5 inch, Tin-Plated with Wire Leads 08- QQ-W-343, 25 AWG, 1.0 inch, Tin-Plated 09- M22759/33-26-9, 18 inches, White 10- M22759/33-26-9, 36 inches, White Insert Arrangements 11- M22759/33-26-( ), 18 inches, Color Coded (No.of Contacts) 12- M22759/33-26-( ), 36 inches, Color Coded A= 9 13- M22759/11-26-9, 72 inches, White B= 15 14- M22759/11-26-( ), 72 inches, Color Coded C= 21 15- M22759/33-26-9, 72 inches, White D = 25 16- M22759/33-26-( ), 72 inches, Color Coded E = 31 F = 37 G = 51 Note:See page 5-31 for M83513 mounting hardware. H = 100 5-21 Call Toll Free: 1 (800) 323-9612

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire MIL-C-83513 D-Microminiature - Metal Shell Connector Dimensions - Metal Shell Plug Socket A B Max.(Plug) C D E F Max. 5 Min.(Socket) + .010" (.254) No. ± .010" (.254) - .018" (.457) ± .005" (.127) ± .010" (.254) of Contacts in mm in mm in mm in mm in mm in mm 9 Plug .775 19.68 .3338 8.48 .390 9.91 .565 14.35 .298 7.57 .270 6.68 9 Socket .775 19.68 .3342 8.49 .390 9.91 .565 14.35 .298 7.57 .270 6.68 15 Plug .925 23.50 .4838 12.29 .540 13.72 .715 18.16 .298 7.57 .270 6.68 15 Socket .925 23.50 .4842 12.30 .540 13.72 .715 18.16 .298 7.57 .270 6.68 21 Plug 1.075 27.30 .6338 16.10 .690 17.53 .865 21.97 .298 7.57 .270 6.68 21 Socket 1.075 27.30 .6342 16.11 .690 17.53 .865 21.97 .298 7.57 .270 6.68 25 Plug 1.175 29.84 .7338 18.64 .790 20.07 .965 24.51 .298 7.57 .270 6.68 25 Socket 1.175 29.84 .7342 18.65 .790 20.07 .965 24.51 .298 7.57 .270 6.68 31 Plug 1.325 33.66 .8838 22.45 .940 23.88 1.115 28.32 .298 7.57 .270 6.68 31 Socket 1.325 33.66 .8842 22.46 .940 23.88 1.115 28.32 .298 7.57 .270 6.68 37 Plug 1.475 37.46 1.0338 26.26 1.090 27.69 1.265 32.13 .298 7.57 .270 6.68 37 Socket 1.475 37.46 1.0342 26.27 1.090 27.69 1.265 32.13 .298 7.57 .270 6.68 51 Plug 1.425 36.20 .9838 24.99 1.040 26.42 1.215 30.86 .341 8.66 .310 7.87 51 Socket 1.425 36.20 .9842 25.00 1.040 26.42 1.215 30.86 .341 8.66 .310 7.87 100 Plug 2.160 54.86 1.3838 35.15 1.432 36.38 1.800 45.71 .384 9.75 .360 9.15 100 Socket 2.160 54.86 1.3842 35.16 1.432 36.38 1.800 45.71 .384 9.75 .360 9.15 Call Toll Free: 1 (800) 323-9612 5-22

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire MIL-C-83513 D-Microminiature - Metal Shell Panel Mounting Dimensions - Metal Shell Panel Mounting Dimensions Panel Cutout Dimensions - Metal Shell A B C D +.004" (.101mm) +.004" (.101mm) +.005" (.127mm) +.005" (.127mm) No.of -.000" (.000mm) -.000" (.000mm) -.000" (.000mm) -.000" (.000mm) Contacts in mm in mm in mm in mm 9 .408 10.36 .270 6.86 .570 14.48 .089 2.26 15 .558 14.17 .270 6.86 .720 14.48 .089 2.26 21 .708 17.98 .270 6.86 .870 22.10 .089 2.26 Front Mounting 25 .808 20.52 .270 6.86 .970 24.64 .089 2.26 31 .958 24.33 .270 6.86 1.120 28.45 .089 2.26 37 1.108 28.14 .270 6.86 1.270 32.26 .089 2.26 51 1.058 26.87 .315 8.00 1.220 30.99 .089 2.26 100 1.450 36.84 .361 9.17 1.805 45.86 .117 2.97 A B C D +.004" (.101mm) +.004" (.101mm) +.005" (.127mm) +.005" (.127mm) No.of -.000" (.000mm) -.000" (.000mm) -.000" (.000mm) -.000"(.000mm) Contacts in mm in mm in mm in mm 9 .408 10.36 .256 6.50 .570 14.48 .089 2.26 15 .558 14.17 .256 6.50 .720 18.29 .089 2.26 21 .708 17.98 .256 6.50 .870 22.10 .089 2.26 5 Rear Mounting 25 .808 20.52 .256 6.50 .970 24.64 .089 2.26 31 .958 24.33 .256 6.50 1.120 28.45 .089 2.26 37 1.108 28.14 .256 6.50 1.270 32.26 .089 2.26 51 1.058 26.87 .300 7.62 1.220 30.99 .089 2.26 100 1.450 36.84 .338 8.58 1.805 45.86 .117 2.97 C D No.of +.005" (.127mm) +.005" (.127mm) Contacts -.000" (.000mm) -.000" (.000mm) in mm in mm 9 .570 14.48 .089 2.26 15 .720 18.29 .089 2.26 21 .870 22.10 .089 2.26 Edgeboard Mounting 25 .970 24.64 .089 2.26 31 1.120 28.45 .089 2.26 37 1.270 32.26 .089 2.26 51 1.220 30.99 .089 2.26 100 1.805 45.86 .117 2.97 5-23 Call Toll Free: 1 (800) 323-9612

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire MIL-C-83513 D-Microminiature - Plastic Plastic Shell Contact Arrangements (Face view of pin insert) (Use reverse order for socket side) Ordering Information M83513/06-A 04 Connector Type Wire Type (Use only for /08 & /09,otherwise omit) 01- M22759/11-26-9, 18 inches, White 06 - Plastic Shell Plugs with 02- M22759/11-26-9, 36 inches, White Solder Cup Termination 03- M22759/11-26-( ), 18 inches, Color Coded 04- M22759/11-26-( ), 36 inches, Color Coded 07 - Plastic Shell Sockets with 05- QQ-W-343, 25 AWG, 0.5 inch, Gold-Plated Solder Cup Termination 06- QQ-W-343, 25 AWG, 1.0 inch, Gold-Plated 5 08 - Plastic Shell Plugs 07- QQ-W-343, 25 AWG, 0.5 inch, Tin-Plated with Wire Leads 08- QQ-W-343, 25 AWG, 1.0 inch, Tin-Plated 09- M22759/33-26-9, 18 inches, White 09 - Plastic Shell Sockets 10- M22759/33-26-9, 36 inches, White with Wire Leads 11- M22759/33-26-( ), 18 inches, Color Coded 12- M22759/33-26-( ), 36 inches, Color Coded 13- M22759/11-26-9, 72 inches, White Insert Arrangements 14- M22759/11-26-( ), 72 inches, Color Coded (No.of Contacts) 15- M22759/33-26-9, 72 inches, White A= 9 16- M22759/33-26-( ), 72 inches, Color Coded B= 15 C= 21 D = 25 Note: See page 5-31 for M83513 mounting hardware. E = 31 F = 37 G = 51 Call Toll Free: 1 (800) 323-9612 5-24

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire/PCB MIL-C-83513 D-Microminiature - Plastic Shell Dimensions - (All-Plastic Version) Plug Socket A B Max.(Plug) C D E F Max. Min.(Socket) +.010" (.254) No. ±.010" (.254) -.018" (.457) ±.005" (.127) ±.010" (.254) of Contacts in mm in mm in mm in mm in mm in mm 5 9 Plug .778 19.76 .2918 7.41 .398 10.11 .565 14.35 .208 5.28 .173 4.39 9 Socket .778 19.76 .2922 7.42 .398 10.11 .565 14.35 .208 5.28 .173 4.39 15 Plug .928 23.57 .4418 11.22 .548 13.92 .715 18.16 .208 5.28 .173 4.39 15 Socket .928 23.57 .4422 11.23 .548 13.92 .715 18.16 .208 5.28 .173 4.39 21 Plug 1.078 27.38 .5918 15.03 .698 17.73 .865 21.97 .208 5.28 .173 4.39 21 Socket 1.078 27.38 .5922 15.04 .698 17.73 .865 21.97 .208 5.28 .173 4.39 25 Plug 1.178 29.92 .6918 17.57 .798 20.27 .965 24.51 .208 5.28 .173 4.39 25 Socket 1.178 29.92 .6922 17.58 .798 20.27 .965 24.51 .208 5.28 .173 4.39 31 Plug 1.328 33.73 .8418 21.38 .948 24.08 1.115 28.32 .208 5.28 .173 4.39 31 Socket 1.328 33.73 .8422 21.39 .948 24.08 1.115 28.32 .208 5.28 .173 4.39 37 Plug 1.478 37.54 .9918 25.19 1.098 27.89 1.265 32.13 .208 5.28 .173 4.39 37 Socket 1.478 37.54 .9922 25.20 1.098 27.89 1.265 32.13 .208 5.28 .173 4.39 51 Plug 1.428 36.27 .9418 23.92 1.048 26.62 1.215 30.86 .250 6.35 .220 5.59 51 Socket 1.428 36.27 .9422 23.93 1.048 26.62 1.215 30.86 .250 6.35 .220 5.59 5-25 Call Toll Free: 1 (800) 323-9612

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire/PCB MIL-C-83513 D-Microminiature - Plastic Panel Mounting Dimensions - All-Plastic Panel Cutout Dimensions A B C +.004" (.101mm) +.004" (.101mm) +.005" (.127mm) No.of -.000" (.000mm) -.000" (.000mm) -.000" (.000mm) Contacts in mm in mm in mm 9 .408 10.36 .172 4.37 .570 14.48 15 .558 14.17 .172 4.37 .720 14.48 21 .708 17.98 .172 4.37 .870 22.10 Front Mounting 25 .808 20.52 .172 4.37 .970 24.64 31 .958 24.33 .172 4.37 1.120 28.45 37 1.108 28.14 .172 4.37 1.270 32.26 51 1.058 26.87 .215 5.46 1.220 30.99 Rear Cutout Dimensions A B C +.004" (.101mm) +.004" (.101mm) +.005" (.127mm) No.of -.000" (.000mm) -.000" (.000mm) -.000" (.000mm) Contacts in mm in mm in mm 9 .373 9.47 .216 5.49 .570 14.48 15 .523 13.28 .216 5.49 .720 18.29 5 21 .674 17.12 .216 5.49 .870 22.10 Rear Mounting 25 .774 19.66 .216 5.49 .970 24.64 31 .924 23.47 .216 5.49 1.120 28.45 37 1.074 27.28 .216 5.49 1.270 32.26 51 1.024 26.01 .259 6.58 1.220 30.99 Edgeboard Mounting Cutout Dimensions D +.005" (.127mm) No.of -.000" (.000mm) Contacts in mm 9 .570 14.48 15 .720 18.29 21 .870 22.10 25 .970 24.64 Edgeboard Mounting 31 1.120 28.45 37 1.270 32.26 51 1.220 30.99 Call Toll Free: 1 (800) 323-9612 5-26

Dura-Con .050" (1.27mm) Density High Reliability D-Microminiature MIL-C-83513 PC Board Mount Terminal Block Contact Arrangements (Face view of pin insert) (Use reverse order for socket side) Ordering Information M83513/10 - C 02 CN Connector Description Hardware N= No Jackpost 5 10 =Plug, 9-37 Pos., Narrow Profile, Rt.Angle P= Jackpost Attached 11= Plug, 51 Pos., Narrow Profile, Rt.Angle 12= Plug, 100 Pos., Narrow Profile, Rt.Angle 13= Socket, 9-37 Pos., Narrow Profile, Rt.Angle Shell Finish 14= Socket, 51 Pos., Narrow Profile, Rt.Angle C= Cadmium 15= Socket, 100 Pos., Narrow Profile, Rt.Angle N= Electroless Nickel 16= Plug, 9-37 Pos., Std.Profile, Rt.Angle 17 = Plug, 51 Pos., Std.Profile, Rt.Angle Termination Length 18= Plug, 100 Pos., Std.Profile, Rt.Angle 01= 0.109 19= Socket, 9-37 Pos., Std.Profile, Rt.Angle 02= 0.140 20= Socket, 51 Pos., Std.Profile, Rt.Angle 03= 0.172 21= Socket, 100 Pos., Std.Profile, Rt.Angle 22= Plug, 9-37 Pos., Straight Mount Insert Arrangement Length 23= Plug, 51 Pos., Straight Mount (No.of Contacts) 24= Plug, 100 Pos., Straight Mount A= 9 25= Socket, 9-37 Pos., Straight Mount B= 15 26= Socket, 51 Pos., Straight Mount C= 21 27= Socket, 100 Pos., Straight Mount D = 25 E = 31 F = 37 G = 51 H = 100 5-27 Call Toll Free: 1 (800) 323-9612

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire/PCB MIL-C-83513 D-Microminiature Recommended Board Layout (/16-/21) Typ.Hole Dia.= .040" (1.02 mm) NOTE: For additional connector dimensions, see page 5-22. A B C F No.of Max. ±.007 (0.18) ±.005 (0.13) Max. Contacts in mm in mm in mm in mm 9 Plug 1.390 35.31 1.150 29.21 .565 14.35 .465 11.81 9 Socket 1.390 35.31 1.150 29.21 .565 14.35 .465 11.81 15 Plug 1.540 39.12 1.300 33.02 .715 18.16 .465 11.81 15 Socket 1.540 39.12 1.300 33.02 .715 18.16 .465 11.81 21 Plug 1.690 42.93 1.450 36.83 .865 21.97 .465 11.81 21 Socket 1.690 42.93 1.450 36.83 .865 21.97 .465 11.81 25 Plug 1.790 45.47 1.550 39.37 .965 24.51 .465 11.81 25 Socket 1.790 45.47 1.550 39.37 .965 24.51 .465 11.81 31 Plug 2.040 51.82 1.800 45.72 1.115 28.32 .465 11.81 31 Socket 2.040 51.82 1.800 45.72 1.115 28.32 .465 11.81 37 Plug 2.340 59.44 2.100 53.34 1.265 32.13 .465 11.81 5 37 Socket 2.340 59.44 2.100 53.34 1.265 32.13 .465 11.81 51 Plug 1.875 47.63 1.600 40.64 1.215 30.86 .565 14.35 51 Socket 1.875 47.63 1.600 40.64 1.215 30.86 .565 14.35 100 Plug 2.780 70.61 2.500 63.50 1.800 45.72 .765 19.43 100 Socket 2.780 70.61 2.500 63.50 1.800 45.72 .765 19.43 G H J K No.of Max. Max. ± .005 (0.13) ± .015 Contacts in mm in mm in mm in mm 9 Plug .308 7.82 .190 4.83 .096 2.44 .125 3.18 9 Socket .308 7.82 .200 5.08 .096 2.44 .125 3.18 15 Plug .308 7.82 .190 4.83 .096 2.44 .125 3.18 15 Socket .308 7.82 .200 5.08 .096 2.44 .125 3.18 21 Plug .308 7.82 .190 4.83 .096 2.44 .125 3.18 21 Socket .308 7.82 .200 5.08 .096 2.44 .125 3.18 25 Plug .308 7.82 .190 4.83 .096 2.44 .125 3.18 25 Socket .308 7.82 .200 5.08 .096 2.44 .125 3.18 31 Plug .308 7.82 .190 4.83 .096 2.44 .125 3.18 31 Socket .308 7.82 .200 5.08 .096 2.44 .125 3.18 37 Plug .308 7.82 .190 4.83 .096 2.44 .125 3.18 37 Socket .308 7.82 .200 5.08 .096 2.44 .125 3.18 51 Plug .351 8.92 .190 4.83 .096 2.44 .125 3.18 51 Socket .351 8.92 .200 5.08 .096 2.44 .125 3.18 100 Plug .394 10.00 .190 4.83 .125 3.18 .225 5.72 100 Socket .394 10.00 .200 5.08 .125 3.18 .225 5.72 Call Toll Free: 1 (800) 323-9612 5-28

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire/PCB D-Microminiature MIL-C-83513 Straight (180°) Termination Recommended Board Layout (/22-/27) Typ.Hole Dia.= .040" (1.02 mm) NOTE: For additional connector dimensions, see page 5-22. A B C D G No.of Max. ± .007 (0.18) ±.005 (0.13) Max. Max. Contacts in mm in mm in mm in mm in mm 9 Plug 1.390 35.31 1.150 29.21 .565 14.35 .885 22.48 .308 7.75 9 Socket 1.390 35.31 1.150 29.21 .565 14.35 .885 22.48 .308 7.75 15 Plug 1.390 35.31 1.150 29.21 .715 18.16 .945 24.0 .308 7.75 15 Socket 1.390 35.31 1.150 29.21 .715 18.16 .945 24.0 .308 7.75 21 Plug 1.690 42.93 1.450 36.83 .865 21.97 1.185 30.09 .308 7.75 21 Socket 1.690 42.93 1.450 36.83 .865 21.97 1.185 30.09 .308 7.75 25 Plug 1.740 44.20 1.500 38.10 .965 24.51 1.275 32.38 .308 7.75 25 Socket 1.740 44.20 1.500 38.10 .965 24.51 1.275 32.38 .308 7.75 31 Plug 2.040 51.82 1.800 45.72 1.115 28.32 1.575 40.00 .308 7.75 31 Socket 2.040 51.82 1.800 45.72 1.115 28.32 1.576 40.00 .308 7.75 37 Plug 2.340 59.44 2.100 53.34 1.265 32.13 1.875 47.62 .308 7.75 37 Socket 2.340 59.44 2.100 53.34 1.265 32.13 1.875 47.62 .308 7.75 5 51 Plug 2.270 57.66 2.000 50.80 1.215 30.86 1.775 45.08 .351 8.92 51 Socket 2.270 57.66 2.000 50.80 1.215 30.86 1.775 45.08 .351 8.92 100 Plug 3.070 77.98 2.800 71.12 1.800 45.72 2.585 65.55 .455 11.56 100 Socket 3.070 77.98 2.800 71.12 1.800 45.72 2.585 65.65 .455 11.56 H J K L No.of Max. ± .005 (0.13) Max. Max. Contacts in mm in mm in mm in mm 9 Plug .190 4.83 .096 2.44 .165 4.19 .355 9.02 9 Socket .200 5.08 .096 2.44 .165 4.19 .355 9.02 15 Plug .190 4.83 .096 2.44 .165 4.19 .355 9.02 15 Socket .200 5.08 .096 2.44 .165 4.19 .355 9.02 21 Plug .190 4.83 .096 2.44 .165 4.19 .355 9.02 21 Socket .200 5.08 .096 2.44 .165 4.19 .355 9.02 25 Plug .190 4.83 .096 2.44 .165 4.19 .355 9.02 25 Socket .200 5.08 .096 2.44 .165 4.19 .355 9.02 31 Plug .190 4.83 .096 2.44 .165 4.19 .355 9.02 31 Socket .200 5.08 .096 2.44 .165 4.19 .355 9.02 37 Plug .190 4.83 .096 2.44 .165 4.19 .355 9.02 37 Socket .200 5.08 .096 2.44 .165 4.19 .355 9.02 51 Plug .190 4.83 .096 2.44 .165 4.19 .355 9.02 51 Socket .200 5.08 .096 2.44 .165 4.19 .355 9.02 100 Plug .190 4.83 .125 3.18 .300 7.62 .550 13.97 100 Socket .200 5.08 .125 3.18 .300 7.62 .550 13.97 5-29 Call Toll Free: 1 (800) 323-9612

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire/PCB MIL-C-83513 D-Microminiature Recommended Board Layout (/10-/15) NOTE: For additional connector dimensions, see page 5-22. Typ.Hole Dia.= .040" (1.02 mm) A B C No.of Max. ± .005 (0.13) Max. Contacts in mm in mm in mm 9 Plug .785 19.94 .565 14.35 .308 7.82 9 Socket .785 19.94 .565 14.35 .308 7.82 15 Plug .935 23.75 .715 18.16 .308 7.82 15 Socket .935 23.75 .715 18.16 .308 7.82 21 Plug 1.085 27.56 .865 21.97 .308 7.82 21 Socket 1.085 27.56 .865 21.97 .308 7.82 25 Plug 1.085 30.10 .965 24.51 .308 7.82 25 Socket 1.185 30.10 .965 24.51 .308 7.82 31 Plug 1.335 33.91 1.115 28.32 .308 7.82 31 Socket 1.335 33.91 1.115 28.32 .308 7.82 37 Plug 1.485 37.72 1.265 32.13 .308 7.82 37 Socket 1.485 37.72 1.265 32.13 .308 7.82 5 51 Plug 1.435 36.45 1.215 30.86 .351 8.92 51 Socket 1.435 36.45 1.215 30.86 .351 8.92 100 Plug 2.175 55.25 1.800 45.72 .394 10.00 100 Socket 2.175 55.25 1.800 45.72 .394 10.00 F G H J No.of ±.010 (0.25) ±.010 (0.25) Max. ±.005 (0.13) Contacts in mm in mm in mm in mm 9 Plug .230 5.84 .250 6.35 .420 10.67 .096 2.44 9 Socket .230 5.84 .250 6.35 .420 10.67 .096 2.44 15 Plug .130 3.30 .250 6.35 .420 10.67 .096 2.44 15 Socket .130 3.30 .250 6.35 .420 10.67 .096 2.44 21 Plug .130 3.30 .250 6.35 .420 10.67 .096 2.44 21 Socket .130 3.30 .250 6.35 .420 10.67 .096 2.44 25 Plug .130 3.30 .250 6.35 .420 10.67 .096 2.44 25 Socket .130 3.30 .250 6.35 .420 10.67 .096 2.44 31 Plug .130 3.30 .250 6.35 .520 13.21 .996 2.44 31 Socket .130 3.30 .250 6.35 .520 13.21 .096 2.44 37 Plug .130 3.30 .250 6.35 .520 13.21 .096 2.44 37 Socket .130 3.30 .250 6.35 .520 13.21 .096 2.44 51 Plug .150 3.81 .300 7.62 .650 16.51 .096 2.44 51 Socket .150 3.81 .300 7.62 .650 16.51 .096 2.44 100 Plug .200 5.08 .400 10.16 1.000 25.40 .125 3.18 100 Socket .200 5.08 .400 10.16 1.000 25.40 .125 3.18 Call Toll Free: 1 (800) 323-9612 5-30

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire/PCB MIL-C-83513 D-Microminiature Mounting Hardware 5 Ordering Information Military Type Style Screwhead Thread Part No. Jackscrew Low Profile Recessed Hex 2/56 M83513/5-02 Jackscrew High Profile Recessed Hex 2/56 M83513/5-03 Jackscrew Low Profile Slotted 2/56 M83513/5-05 Jackscrew High Profile Slotted 2/56 M83513/5-06 Jackpost -- -- 2/56 M83513/5-07 Jackscrew Low Profile Hex 4/40* M83513/5-12 Jackscrew High Profile Hex 4/40* M83513/5-13 Jackscrew Low Profile Slotted 4/40* M83513/5-15 Jackscrew High Profile Slotted 4/40* M83513/5-16 Jackpost -- -- 4/40* M83513/5-17 *100 Size Only 5-31 Call Toll Free: 1 (800) 323-9612

Dura-Con .050" (1.27mm) Density High Reliability Connector Saver All-Plastic & Metal Shell ■ Designed to significantly reduce damage to already mounted Dura-Con connectors during routine system tests. ■ Eliminates numerous mating & unmating cycles experienced by connectors S on test harnesses. E R U ■ Plug connector on one end,socket connector on the other. T A E ■ Available in all-plastic (polyester) or in metal shell with diallyl phthalate or F polyester insulators (both UL94V-0 rated). ■ Locking hardware must be ordered separately. Insulator: UL94V-0 glass-filled polyester or diallyl phthalate S L Contacts: Copper alloy A RI Contact Plating:.000050 in gold E T A Shell (Metal Only): Aluminum alloy M Shell Plating: Yellow chromate over cadmium L A T N E M N Operating Temperature: -55°C to +135°C O R VI N E L A Current Rating: 3 Amps maximum C TRI Withstanding Voltage: 600 VAC RMS @ sea level C E Contact Resistance: 8 milliohms maximum L E L A C Individual Contact:Insertion force, 6 oz.(170.40 g) maximum; NI A Withdrawal force 0.5 oz.(14.20 g) minimum H C Mating / Unmating Forces:See previous tables E M Metal Shell All Plastic No.of Diallyl Phthalate Glass-Filled Polyester Glass-Filled Polyester Contacts Catalog No. Catalog No. Catalog No. 9 DCCM9CS DCDM9CS DCDA9CS 15 DCCM15CS DCDM15CS DCDA15CS 21 DCCM21CS DCDM21CS DCDA21CS 25 DCCM25CS DCDM25CS DCDA25CS 31 DCCM31CS DCDM31CS DCDA31CS 37 DCCM37CS DCDM37CS DCDA37CS 51 DCCM51CS DCDM51CS DCDA51CS 100 DCCM100CS DCDM100CS – Call Toll Free: 1 (800) 323-9612 5-32

Dura-Con .050" (1.27mm) Density High Reliability PC Board Mount Microedge Connectors Metal Shell ■ Variety of available PC board mounting styles. - “Coke Bottle”for edge mounting on double-sided PCBs - Right-angle (90°) mounting for single- or double-sided daughter boards - “Claw Foot”leads - Gold-plated solid copper wire pigtails S RE ■ Harnessing capabilities exist for both plug & socket. U T ■ Standard sizes are 128 and 184 positions. A E F ■ Utilizes high-reliability Dura-Con twist pin contact system assuring electrical continuity under extreme shock and vibration. ■ Aluminum shells and diallyl phthalate insulators make Dura-Con microedge connectors ideal for airborne or space applications. ■ Microedge metal shell connectors meet the requirement of MIL-C-55302. Insulator: UL94V-0 glass-filled polyester or diallyl phthalate per MIL-M-14 (green) S L Contacts: Copper alloy A ERI Contact Plating:.000050 in Gold T A Shell: Aluminum alloy M Shell Plating: Electroless Nickel L A T N E M N Operating Temperature: -55°C to +135°C O R VI N E L A Current Rating: 3 Amps maximum C TRI Withstanding Voltage: 600 VAC RMS @ sea level, 300 VAC @ 70,000 ft. C E Contact Resistance: 8 milliohms maximum L E L A C Insertion/Withdrawal Force: NI A 6 oz.(170.40 g[f]) maximum insertion force, per contact; H C 0.5 oz.(14.20 g[f]) minimum withdrawal force, per contact E M Call Toll Free: 1 (800) 323-9612 5-34

Dura-Con .050" (1.27mm) Density High Reliability PC Board Mount Microedge Connectors Metal Shell 5 5-35 Call Toll Free: 1 (800) 323-9612

Dura-Con .050" (1.27mm) Density High Reliability PC Board Mount Microedge Connectors Metal Shell Recommended PCB thickness .047-.062. Consult factory for other thicknesses. 5 * Narrow Version (DNEB) .250 Wide Call Toll Free: 1 (800) 323-9612 5-36

Dura-Con .050" (1.27mm) Density High Reliability PC Board Mount Microedge Connectors Metal Shell 184 Contact Plug (Standard Insulated Wire) Side View *Narrow Version (DNEB) .250 Wide Shell Polarization Kit Key L Order No. “L” Used On DNEBP0L1 .250 DNEBNarrow Only DMEBP0L1 .312 DMEBStd.Width Mounting Hardware Removable Jackscrew/Jackpost Standard Jackscrew/Jackpost Assembly Assembly 5 Consult factory if required. Plug with Jackscrew Receptacle with Jackscrew Ordering Information DMEB 1-128 P 6 E 2 180 Series Prefix DMEB= Microedgeboard DNEB= Microedgeboard, Narrow (184 Only) Lead Length in Inches Contact Spacing 1= .050" (1.27mm) centers Termination, 128/184 Color of Finish 2= .100" (2.54mm) centers 1= White 64/92 (every other contact hole) *2= Yellow For other contact spacing accommodations, consult the factory. 3= Tin-Plated *4 = Gold-Plated (Solid Copper Wire Only) *5= Color Coded per MIL-Std.681, System 1 No.of Contacts 128, 184 Wire Type/Termination Style C= Solid Copper Contact Type E= MIL-W-16878/4, 7 Strand P= Pin BS= PCBoard (Coke Bottle) S= Socket BRA= PCBoard Right-Angle (Formed to “A”Side) BRB= PC Board Right-Angle (Formed to “B”Side) Wire Size in AWG W= PCBoard (Claw Foot) 5= 25 AWGSolid Copper 6= 26 AWG Stranded Wire *Indicates Cinch std Option S= Solder Cup 5-37 Call Toll Free: 1 (800) 323-9612

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire Strip Connectors All-Plastic ■ Lightweight. ■ Slim Profile. ES ■ High-Density Interconnect. R TU ■ High-reliability Dura-Con twist pin contact system for extreme shock & A E vibration applications. F ■ Optional polarization with guide pins to prevent mismating connectors. ■ Plug & socket available in sizes from 1 to 60 positions. S L Insulator:UL94V-0glass-filled polyester A ERI Contacts:Copper alloy T A Contact Plating:.000050 in gold M L A T N E M N Operating Temperature: -55°C to +135°C O R VI N E L Current Rating: 3 Amps maximum A C RI Withstanding Voltage: 600 VAC @ sea level; T C 150 VAC @ 70,000 ft. E EL Contact Resistance: 8 milliohms maximum L A C Insertion &Withdrawal Force (Per Contact): NI A 6 oz.(170.40 g[f]) maximum insertion; H C 0.5 oz.(14.20 g[f]) minimum withdrawal E M Call Toll Free: 1 (800) 323-9612 5-38

Dura-Con .050" (1.27mm) Density High Reliability Solder Cup/Wire Strip Connectors All Plastic Dimensions Socket Connector Pin Connector Epoxy 24 Gauge Stainless Steel Guide Pin* NOTE: Dimension A is number of positions less 1 multiplied by .050 * Assembly in socket connector only. Ordering Information CS A 1 10 P 4 C 4-00.5 G Cinch Dura-Con Strip Thermoplastic Guide Pin (Socket Only) Glass-Reinforced Empty Cavity (Pin Only) Strip Connector G02= Guide Pin Position No.2 GX= Special Position, Contact Centers Consult Factory A= .050 (24 Ga.) Contact Position 1 = Contacts in every position Lead Length in inches 00.5Solid copper wire only No.of Contact Positions 01.0Solid copper wire only 1 through 60** 02.0Solid copper wire only 18.0Stranded wire only 24.0Stranded wire only Contact Type 36.0Stranded wire only P= Pin 48.0Stranded wire only S= Socket Insulation Color, Wire Size in AWG Solid Wire Finish, 5= 25 AWGSolid Copper Wire Solid Cup Finish 6= 26 AWG Stranded Wire 1= All White S= Solder Cup (Skip to *2 = All Yellow guide pin field if necessary) 3 = Tin-Plated *4= Gold-Plated (Solid Wire Only) *5 = Color Coded Per MIL-Std. 681, System 1 System 1.(Stranded Wire Only) Insulation Wire or Solid Wire Type * - Indicates Cinch std.option. C=Solid Copper **- Consult factory for larger sizes and multi-row. E= MIL-W-168 78/4, 7 Strand 5-39 Call Toll Free: 1 (800) 323-9612

Mouser Electronics Authorized Distributor Click to View Pricing, Inventory, Delivery & Lifecycle Information: C inch Connectivity Solutions: M83513/27-H01CP M83513/22-F01CP M83513/03-H03C M83513/12-H01CP M83513/22-B01CP M83513/03-C01N M83513/04-E02N M83513/25-C01NP M83513/03-D04N M83513/03-A04C M83513/04-B04C M83513/13-C01NP M83513/01-GN M83513/03-B04C M83513/23-G01NP M83513/03-H01N M83513/04-C01N M83513/04-E01C M83513/03-B02C M83513/01-GC M83513/03-D03N M83513/03-E03N M83513/02-FC M83513/03-E02C M83513/03-G03C M83513/02-CC M83513/02-GC M83513/04-G03N M83513/13-A01NP M83513/11-G01CP M83513/04-C03C M83513/03-F01C M83513/03-B04N M83513/01-CN M83513/01-FN M83513/04-G01N M83513/01-FC M83513/04-G03C M83513/10-E01NP M83513/01-BN M83513/03-G01C M83513/22-C01NP M83513/04-B01N M83513/26-G01CP M83513/03-B02N M83513/25-F01NP M83513/22-D01NP M83513/04-H04C M83513/04-E04C M83513/02-GN M83513/04-B03C M83513/03-C03C M83513/04-H02C M83513/04-F01N M83513/04-B01C M83513/03-G02N M83513/04-A03N M83513/11-G01NP M83513/02-DC M83513/02-DN M83513/04-G04N M83513/02-EC M83513/10-D01CP M83513/01-DC M83513/04-B02N M83513/03-G04C M83513/22-A01NP M83513/10-F01CP M83513/04-A02C M83513/04-F04N M83513/14-G01NP M83513/03-A03N M83513/02-AC M83513/04-F03N M83513/01-EN M83513/03-E02N M83513/04-A04C M83513/25-A01CP M83513/13-F01NP M83513/04-D04C M83513/03-F01N M83513/04-A01C M83513/10-A01CP M83513/22-C01CP M83513/04-D03N M83513/10-C01CP M83513/03-F02N M83513/04-G02N M83513/03-B01N M83513/03-G01N M83513/25-B01NP M83513/04-A02N M83513/03-G04N M83513/04-E03C M83513/04-G01C M83513/03-B03C M83513/10-B01CP M83513/03-D01N M83513/26-G01NP M83513/10-E01CP

Datasheet下载

Datasheet下载