ICGOO在线商城 > M80-5012042

- 型号: M80-5012042

- 制造商: Harwin

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

M80-5012042产品简介:

ICGOO电子元器件商城为您提供M80-5012042由Harwin设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 提供M80-5012042价格参考以及HarwinM80-5012042封装/规格参数等产品信息。 你可以下载M80-5012042参考资料、Datasheet数据手册功能说明书, 资料中有M80-5012042详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

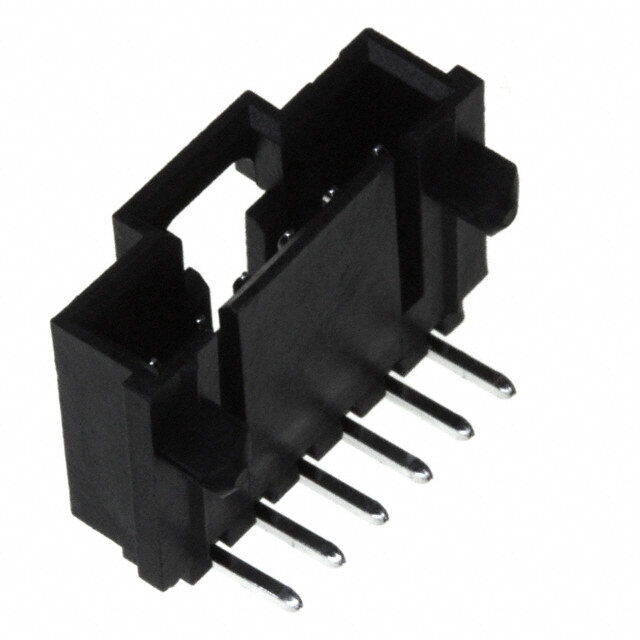

| 描述 | 10+10 WAY M V 4.5MM TAIL W/JS集管和线壳 10+10 POS VERT MALE 4.5mm TL W/JS TIN |

| 产品分类 | |

| 品牌 | Harwin |

| 产品手册 | |

| 产品图片 | |

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | Harwin M80-5012042Datamate J-Tek |

| 数据手册 | |

| 产品型号 | M80-5012042 |

| 产品种类 | 集管和线壳 |

| 产品类型 | Plugs - PCB |

| 位置数量 | 20 |

| 加载的针脚数 | 全部 |

| 包装 | 管件 |

| 商标 | Harwin |

| 商标名 | DATAMATE |

| 安装类型 | 通孔 |

| 安装风格 | - |

| 工厂包装数量 | 8 |

| 排数 | 2 |

| 排距 | 0.079"(2.00mm) |

| 标准包装 | 8 |

| 特性 | - |

| 端接 | |

| 端接类型 | Through Hole |

| 系列 | M80 |

| 紧固类型 | - |

| 节距 | 2 mm |

| 触头类型 | 公形引脚 |

| 触头配接长度 | - |

| 触头镀层 | 金 |

| 触头镀层厚度 | 29.5µin (0.75µm) |

| 触点电镀 | Tin |

| 触点类型 | Pin (Male) |

| 连接器类型 | 接头,有罩 |

| 针脚数 | 20 |

| 间距 | 0.079"(2.00mm) |

| 零件号别名 | M80-5T22042M1-00-000-00-000 |

| 颜色 | 黑 |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

C00532 M80 & M83 SERIES RECTANGULAR CONNECTORS FEBRUARY 18 SECTION TITLE PAGE 1 Description of Connectors and Intended Applications 2 2 Marking of Connector and/or Package 2 3 Ratings 3 Appendix 1 Contact Orientations 7 Appendix 2 Coax Contact Details 10 Appendix 3 Gauges (Low Frequency) 12 Appendix 4 Test for Latch Integrity 13 Appendix 5 Instructions for the use of connectors fitted with Jackscrews 14 Appendix 6 Instructions for the use of Jackscrews 15 Sheet: 1 of 15 Issue: 32 Date: 08.06.20 C/Note: 30051

COMPONENT SPECIFICATION C00531 1. DESCRIPTION OF CONNECTOR AND INTENDED APPLICATION A range of 2mm pitch male and female rectangular, fully shrouded unsealed connectors with replaceable contacts for interconnecting board to board, cable to board and cable to cable. The range covers 2 to 96 ways, in various application methods. Female connectors are available for crimp, vertical through-board and surface mount termination. Male connectors are available for crimp, vertical or horizontal (90°) through- board and vertical surface-mount termination. Pre-Crimped wires and cable assemblies are also available in various options. The connectors are provided with a range of contact terminations (as shown in Appendix 1) that are gold or gold/tin plated. The contact zone of a gold plated contact is hard acid gold of 98% purity. The connector is intended for use as a low voltage connector in high packing density electronic equipment. The connector is polarised to prevent mis-matching and can be produced with a latching feature (L-Tek) or in a jackscrew (J-Tek) format, with or without board mounting. L-Tek and J-Tek connectors are available with low-frequency (LF) contacts, while Mixed Technology (Mix-Tek) connectors are also available with jackscrews, with a choice of power or coax contacts. NOTE: Some connector styles are available manufactured and tested to BS9525 F0033. All other connectors in the range are designed to the same specification. For cable assembly specifications see Component Specification C049XX (where XX is latest issue). 2. MARKING OF THE CONNECTOR AND/OR PACKAGE [ORDER CODE] The marking (order code) shall appear on the package and shall be as follows: 2.1. ORDER CODE M80 - XXX XX XX Series No. Connector Style Number of Ways Contact Finish For details of styles, as well as Mix-Tek and M83 markings and styles see the latest catalogue, or individual drawings. 2.1.1. Number of ways: No. of SINGLE 2 3 4 5 6 7 17 22 ways ROW Order (L-Tek) 02 03 04 05 06 07 17 22 Code No. of DOUBLE 2+2 3+3 4+4 5+5 6+6 7+7 8+8 9+9 10+10 13+13 17+17 22+22 ways ROW Order (L-Tek) 04 06 08 10 12 14 16 18 20 26 34 44 Code No. of 2+2 3+3 4+4 5+5 6+6 7+7 8+8 9+9 10+10 11+11 12+12 13+13 ways Order DOUBLE 04 06 08 10 12 14 16 18 20 22 24 26 Code ROW No. of (J-Tek) 14+14 15+15 16+16 17+17 18+18 19+19 20+20 21+21 22+22 23+23 24+24 25+25 ways Order 28 30 32 34 36 38 40 42 44 46 48 50 Code - 2 -

COMPONENT SPECIFICATION C00531 2.1. ORDER CODE (continued) 2.1.2. Contact Finish: Finish Code 01 05 22 42 Gold on Contact area Gold on Contact area Male PC Tail -- Gold all over Tin /Lead on tail 100% Tin on tail Male Crimp -- Gold all over -- -- Female PC Gold on Contact area Gold on Contact area Gold all over -- Tail Tin /Lead on tail 100% Tin on tail Female Gold clip, Gold clip, -- -- Crimp Gold shell Gold shell 3. RATINGS All materials are listed on individual drawings. 3.1. LOW-FREQUENCY SIGNAL CONNECTORS 3.1.1. Current Ratings Standard Signal Contacts Current – per individual contact at an ambient temperature of 25°C ................................... 3.3A max Current – per individual contact at an ambient temperature of 85°C .................................. 2.6A max Current – per contact through all contacts at an ambient temperature of 25°C .................. 3.0A max Current – per contact through all contacts at an ambient temperature of 85°C .................. 2.2A max T-Contacts Current – per individual contact at an ambient temperature of 25°C ................................... 8.5A max Current – per individual contact at an ambient temperature of 85°C .................................. 6.5A max Current – per contact through all contacts at an ambient temperature of 25°C .................. 3.5A max Current – per contact through all contacts at an ambient temperature of 85°C .................. 2.6A max Flex Circuits Current – per individual track at an ambient temperature of 25°C ...................................... 1.0A max 3.1.2. Other electrical characteristics Working Voltage (at 1013mbar, sea level) .................................................................. 800V DC or AC peak Pre-Crimped Wires & Cable Assemblies (at 1013mbar, sea level) ............................. 300V DC or AC peak Voltage Proof (at 1013mbar, sea level) ....................................................................... 1200V DC or AC peak Contact resistance (initial) ...................................................................................................... 20mΩ max Contact resistance (after conditioning) .................................................................................. 25mΩ max Insulation resistance (initial) .................................................................................................. 1,000MΩ min Insulation resistance (hot after conditioning) ....................................................................... 100MΩ min Creepage path contact-to-contact .......................................................................................... 0.35mm min Air gap contact-to-contact ...................................................................................................... 0.35mm min 3.1.3. Environmental characteristics Environmental classification.............................................................................-55/+125/56 Days at 95% RH Low air pressure severity when only one contact is electrically loaded.......300 mbar (9,144m/30,000ft) The connector will function correctly using a simultaneous combination of high temperature and low air pressure down to 300mbar (altitude of 9,144m/30,000ft) up to 360V DC. - 3 -

COMPONENT SPECIFICATION C00531 3. RATINGS (continued) 3.1. LOW-FREQUENCY SIGNAL CONNECTORS (continued) 3.1.3. Environmental characteristics (continued) Salt Spray: L-Tek ..................................................................... BS2011 Part 2.1Kb Severity 2 (5% Solution – 6.5/7.2pH @ 40°C / 93% Humidity for 66 hours) J-Tek & Mix-Tek ................................................... EIA364 Test Procedure 26 condition A (5% Solution – 6.5/7.2pH @ 35°C / 95% Humidity for 96 hours) Standard Signal Contacts Vibration severity (10G test) ............................... 10Hz to 2000Hz over 0.75mm at 98m/s² (10G), duration 6 hours Vibration severity (20G test) ............................... 10Hz to 81.73Hz at 1.5mm peak to peak, 57.55Hz to 2000Hz at 196.2 m/s² (20G), duration 2 hours Shock severity ..................................................... 981m/s² (100G), 18 shocks total Bump severity ..................................................... 390m/s² (40G), 4000 ±10 bumps T-Contacts Vibration severity ................................................ 10Hz to 13.6Hz at 35mm peak to peak, 13.6Hz to 41.6Hz at 1. 5mm peak to peak, 41.6Hz to 2000Hz at 392.4 m/s² (40G), duration 6 hours Shock severity ..................................................... 981m/s² (100G) 3.1.4. Mechanical characteristics All Signal Contacts Clip retention in body.............................................................................................................. 18N min Minimum retention force may be 10N from a sample of 10 sockets, providing the average of the samples is 22N. High temperature, long term (current as in 3.1.) ....................................................... 1000 hours at 85°C High temperature, short term (no electrical load) ..................................................... 250 hours at 125°C Contact retention in moulding ................................................................................................ 10N min Male Crimp Jackscrew contact replacement – 2 operations at 10N Standard Signal Contacts Durability ...................................................................................................................... 500 operations Contact holding force ................................................................................................... 0.2N min M80 insertion force (per contact, using mating pin, no latch fitted) ........................ 2.0N max M80 withdrawal force (per contact, using mating pin, no latch fitted) .................... 0.2N min M83 insertion force (per contact, using mating pin, no latch fitted) ........................ 1.0N max M83 withdrawal force (per contact, using mating pin, no latch fitted) .................... 0.2N min Contact wipe ................................................................................................................. 1.30mm min Contact replacement in moulding ............................................................................... up to 2 times max T-Contact Durability ...................................................................................................................... 1000 operations Insertion force (per contact, using mating pin, no latch fitted) ................................ 4.0N max Withdrawal force (per contact, using mating pin, no latch fitted) ............................ 0.5N min Contact wipe ................................................................................................................. 2.00mm min Contact replacement in moulding ............................................................................... up to 2 times max - 4 -

COMPONENT SPECIFICATION C00531 3. RATINGS (continued) 3.1. LOW-FREQUENCY SIGNAL CONNECTORS (continued) 3.1.5. Wire Termination Range Wire type (recommended) ............................................................................................... BS 3G 210 Type A Crimp Type Small Bore Small Bore Small Bore Large Bore T-Contact No. & Nominal dia. (mm) 7 / 0.12 7 / 0.15 7 / 0.2 19 / 0.15 19 / 0.15 of wires A.W.G. 28 26 24 22 22 Minimum pull-off force 12.5N 25N 44N 50N 50N M22520/2-01 6 6 6 6 6 Crimp tool setting Max. insulation diameter Ø1.10mm Crimp type Extra Small Bore No. & nominal dia. (mm) of wires 7/0.12 1/0.25 7/0.08 AWG 28 30 32 Min. pull off force 12.5N 7N 4N M22520/2-01 crimp tool setting 5 4 4 Max. insulation diameter Ø0.75mm 3.2. COAX CONTACTS 3.2.1. Electrical characteristics Impedance ............................................................................................................................................. 50Ω Frequency Range ................................................. 6GHz (Also dependent on cable type or board layout) V.S.W.R. (Voltage Standing Wave Ratio) .............................................. 1.05 + (0.04 x Frequency) GHz max Operating Voltage (at 1013mbar, sea level) .................................................................... 180V AC at 500mA Maximum Voltage (at 1013mbar, sea level) .................................................................... 1,000V AC rms Contact Resistance ....................................................................................................................... 6 mΩ max Insulation Resistance (at 250V rms) ..................................................................................................... 106 MΩ 3.2.2. Wire Termination Range Cable Type Max. Insulation Diameter Compatible contacts RG 178 Ø2.0mm M80-305, M80-308, M80-315, M80-318 RG 174 Ø2.7mm M80-307, M80-309, M80-317, M80-319 RG 179 Ø2.7mm M80-307, M80-309, M80-317, M80-319 RG 316 Ø2.7mm M80-307, M80-309, M80-317, M80-319 3.2.3. Mechanical characteristics Durability ...................................................................................................................... 500 operations Insertion force (per contact, using mating contact, no latch fitted) .......................... 8.0N max Withdrawal force (per contact, using mating pin, no latch fitted) ............................ 0.5N min Contact wipe ................................................................................................................. 1.30mm min Contact replacement in moulding ............................................................................... 5 times max - 5 -

COMPONENT SPECIFICATION C00531 3. RATINGS (continued) 3.3. POWER CONTACTS 3.3.1. Electrical characteristics Current rating (M80-3XX contact only) ........................................................................ 20A max Current rating (M80-PXX contact only) ....................................................................... 40A max Working Voltage (at 1013mbar, sea level) .................................................................. 800V DC or AC peak Voltage Proof (at 1013mbar, sea level) ....................................................................... 1200V DC or AC peak Contact Resistance ....................................................................................................... 6mΩ max 3.3.2. Wire Termination Range A.W.G. Current Rating of cable Compatible contacts 10 40A max M80-PF5, M80-PM5 12 20A max M80-325, M80-335, M80-32A 14 15A max M80-326, M80-336, M80-32B 16 10A max M80-327, M80-337, M80-32C 18 8A max M80-328, M80-338 20 5A max M80-329, M80-339 3.3.3. Mechanical characteristics Durability ...................................................................................................................... 500 operations High temperature, long term (no electrical load) ...................................................... 1000 hours at 150°C Insertion force (M80-3XX contacts) ............................................................................. 8.0N max Insertion force (M80-PXX contacts) ............................................................................. 15.0N max Withdrawal force .......................................................................................................... 0.5N min Contact wipe ................................................................................................................. 1.30mm min Contact replacement in moulding ............................................................................... 5 times max - 6 -

COMPONENT SPECIFICATION C00531 APPENDIX 1 – CONTACT ORIENTATIONS These diagrams show pin numbers with reference to the polarisation feature. They represent male connectors, shown looking onto the contact face. A1.1. L-TEK – SINGLE ROW 2 1 3 1 4 1 5 1 6 1 2-way 3-way 4-way 5-way 6-way 7 1 17 1 7-way 17-way Polarising Key 22 1 22-way 90° tail (typical) A1.2. L-TEK – DOUBLE ROW 2 1 3 1 4 1 5 1 6 1 4 3 6 4 8 5 10 10-way 6 12 12-way 7 4-way 6-way 8-way 7 1 8 1 9 1 14 14-way 8 16 16-way 9 18 18-way 10 10 1 13 1 20 20-way 11 26 26-way 14 17 1 Polarising Key 34 34-way 18 22 1 44 23 90° tail (typical) 44-way - 7 -

COMPONENT SPECIFICATION C00531 APPENDIX 1 – CONTACT ORIENTATIONS (continued) These diagrams show pin numbers with reference to the polarisation feature. They represent male connectors, shown looking onto the contact face. A1.3. M80 DOUBLE ROW 3 1 5 1 7 1 6 4 6-way 10 10-way 6 14 14-way 8 10 1 13 1 20 20-way 11 26 26-way 14 17 1 34 34-way 18 21 1 42 42-way 22 Polarising Key 25 1 50 90° tail (typical) 50-way 26 A1.4. M80 DOUBLE ROW Polarising Key 6 1 Non-symmetrical C A (e.g. 3 special, 12 signal) 12 7 4 1 Symmetrical D C B A (e.g. 2 special, 8 signal, 2 special) 8 5 Special contacts only F A (e.g. 6 special) 90° tail (typical) - 8 -

COMPONENT SPECIFICATION C00531 APPENDIX 1 – CONTACT ORIENTATIONS (continued) These diagrams show pin numbers with reference to the polarisation feature. They represent male connectors, shown looking onto the contact face. A1.5 M83 3 ROW 6 1 All signal contacts only 18 13 A1.6. M83 3 ROW 8 1 Signal and special contacts D C B A - 9 -

COMPONENT SPECIFICATION C00531 APPENDIX 2 – COAX CONTACT DETAILS A2.1. COAX INTERFACE DIMENSIONS Male Female A2.2. COAX ASSEMBLY INSTRUCTIONS – M80-305/307, M80-315/317 1) Strip cable to dimensions shown against relevant part (see appropriate engineering drawings). Braid Outer Insulator Inner Insulator Inner Conductor 2) Identify pieces of coax connector to be assembled. Body Sleeve Contact 3) Slide sleeve onto cable past stripped area. Sleeve 4) Crimp contact to end of cable inner conductor. Contact Crimp here 5) Insert cable and contact into coax body from back end – make sure that the braid goes outside and over the end section. Braid Body 6) Slide sleeve back over the end of the coax body and the braid. Crimp into place on the cable insulation, using a hexagonal crimping tool. Crimp here - 10 -

COMPONENT SPECIFICATION C00531 APPENDIX 2 – COAX CONTACT DETAILS (continued). A2.3. COAX ASSEMBLY INSTRUCTIONS – M80-308/309, M80-318/319. 1) Strip cable to dimensions shown against relevant part (see appropriate engineering drawings). Braid Outer Insulator Inner Insulator Inner Conductor 2) Identify pieces of coax connector to be assembled. Body Sleeve Insulator Cover (PTFE) (metal) 3) Slide sleeve onto cable past stripped area. Sleeve 4) Push the cable and sleeve into the body, as far as it will go. The cable inner conductor will be visible through the hole in the top of the coax body, and should go into the slot in the inner contact of the body. Make sure that the braid goes outside and over the end section. Inner Conductor 5) Solder the cable inner conductor to the body inner contact. When cool, place the insulator inside the top, and press the cover into place. Slide the sleeve up to meet the coax body, and hexagonal crimp in place. Cover Insulator Solder here Crimp here - 11 -

COMPONENT SPECIFICATION C00531 APPENDIX 3 – GAUGES (LOW FREQUENCY) NOTES: 1. Material = Steel to BS1407 or equivalent. 2. Gauging surfaces to be hardened/ground to 650 H.V.5 minimum. 3. These gauges to be used for testing fully assembled components only. 4. Ultimate wear limit of 0.005mm is allowable on gauging diameters. 5. Loading force (Bending moment) to give 0.002Nm (Test prod only). 6. All dimensions are in millimetres. 7. For explanation of dimensions, etc. see BS8888. 8. Unless otherwise stated, all dimensions are maxima. A3.1. TEST PROD R 3.16 LAP 2.362 Spherical rad Ø 2.350 0.2 0.500 Ø 0.495 2.70 9.40 2.65 9.27 A3.2. SIZING GAUGE LAP Spherical rad 0.505 0.2 Ø 0.500 6.25 6.15 A3.3. HOLDING GAUGE (Mass = 20 +0/-1 gm) LAP Spherical rad 0.465 0.1 Ø 0.460 5.35 5.15 - 12 -

COMPONENT SPECIFICATION C00531 APPENDIX 4 – TEST FOR LATCH INTEGRITY ON L-TEK A4.1. LATCH INTEGRITY GAUGE Dim ‘A’ 10 Remove all burrs and sharp edges A ‘A’ and ‘B’ stamped 20 in positions shown B Dim ‘B’ 5 No. of contacts 2 3 4 5 6 7 8 9 10 13 17 22 per row Dim ‘A’ 6.00 8.00 10.00 12.00 14.00 16.00 18.00 20.00 22.00 28.00 36.00 46.00 +0.00 / -0.02 Dim ‘B’ 5.00 7.00 9.00 11.00 13.00 15.00 17.00 19.00 21.00 27.00 35.00 45.00 +0.02 / -0.00 A4.2. LATCH INTEGRITY TEST B A A B Figure 1 Figure 2 Figure 3 When Gauge A is placed between the two faces of the latch clips (as shown in Figure 1), the connector shall be held against its own weight. When Gauge B is placed between the two faces of the latch clips (as shown in Figure 2), the connector shall not be held against its own weight. When an unloaded female connector moulding is mated with a latched male connector, and a force of 20N is applied for 10 seconds in the directions shown in Figure 3, there shall be no failure of any part of the latch mechanism. - 13 -

COMPONENT SPECIFICATION C00531 APPENDIX 5 – INSTRUCTIONS FOR THE USE OF CONNECTORS FITTED WITH JACKSCREWS Connectors are fitted with jackscrews where it is considered necessary to provide mechanical assistance in ensuring a satisfactory engagement and separation of the connector. This may apply in cases where engagement and separation forces are so high as to prevent satisfactory hand engagement, or where access to connector is restricted. Jackscrews also provide a locking feature, preventing the connector from disengaging under adverse conditions. In order to obtain maximum effectiveness from the jackscrew system, the following rules for their use should be observed. 1. The connector with boardmount jackscrews should be fixed to the mounting board with fixings and tightened to a torque of 21±2cmN. 2. On engaging the two halves of the connector after ensuring correct polarity, lightly push home the floating half until the jackscrews touch. Then, maintaining the pressure, turn one of the floating jackscrews clockwise, until it engages with the fixed screw. Repeat with the other screw. Then screw in each jackscrew, ensuring even loading by applying a maximum of one turn to each screw in sequence until the connector is bottomed. This will be evident by a sudden increase in the torque required on the screw. This torque should not exceed 23cmN. NB: Care to be taken when aligning male and female threads to avoid cross-threading and possible failure of parts. 3. On disengaging the two halves of the connector turn each of the floating jackscrews anti- clockwise. Again ensure even loading by turning each screw in sequence for a maximum of one turn until the jackscrew disengage. The connector can then be easily pulled apart. 4. Board mounting fixings must be fitted before Wave soldering. 5. Board mounting fixings can be fitted before or after reflow soldering, as preferred by customer. If fitted before soldering, check that the fixings remain tight after soldering. - 14 -

COMPONENT SPECIFICATION C00531 APPENDIX 6 – INSTRUCTIONS FOR THE USE OF JACKSCREWS 1. Before engaging, the slot on the jackscrew should be at right angles to the length of the connector. 2. Push the connectors together. Once the connectors are mated, use a screwdriver to push down onto each 101Lok Jackscrew until the spring is compressed. Turn the Jackscrew 101 degreess, and release. The Jackscrew should remain partially compressed. 3. To disengage, use a screwdriver to push down on each 101Lok Jackscrew until the spring is compressed. Turn the Jackscrew anti-clockwise 101 degrees, and release. The Jackscrew will spring back to its uncompressed position. - 15 -

Datasheet下载

Datasheet下载