ICGOO在线商城 > 电感器,线圈,扼流圈 > 固定值电感器 > LQH32MN100J23L

- 型号: LQH32MN100J23L

- 制造商: Murata

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

LQH32MN100J23L产品简介:

ICGOO电子元器件商城为您提供LQH32MN100J23L由Murata设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 LQH32MN100J23L价格参考¥0.12-¥0.12。MurataLQH32MN100J23L封装/规格:固定值电感器, 10µH 无屏蔽 绕线 电感器 190mA 1.8 欧姆最大 非标准 。您可以下载LQH32MN100J23L参考资料、Datasheet数据手册功能说明书,资料中有LQH32MN100J23L 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| DC电阻(DCR) | 1.8 欧姆最大 |

| 描述 | INDUCTOR 10UH 5% 190MA 1210固定电感器 10uH 5% |

| 产品分类 | |

| 品牌 | Murata Electronics North America |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 固定电感器,Murata Electronics LQH32MN100J23LLQH32M |

| 数据手册 | |

| 产品型号 | LQH32MN100J23L |

| Q最小值 | 35 |

| 不同频率时的Q值 | 35 @ 1MHz |

| 产品 | SMD Power Inductors |

| 产品培训模块 | http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=5389 |

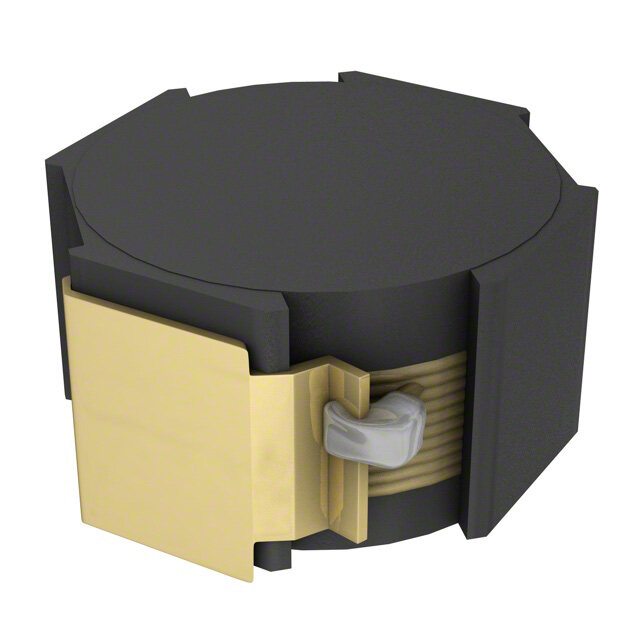

| 产品目录绘图 |

|

| 产品目录页面 | |

| 产品种类 | 固定电感器 |

| 供应商器件封装 | 1210 |

| 其它名称 | 490-2505-6 |

| 包装 | Digi-Reel® |

| 单位重量 | 60 mg |

| 商标 | Murata Electronics |

| 外壳宽度 | 2.5 mm |

| 外壳长度 | 3.2 mm |

| 大小/尺寸 | 0.126" 长 x 0.098" 宽(3.20mm x 2.50mm) |

| 安装类型 | 表面贴装 |

| 容差 | ±5% |

| 封装 | Reel |

| 封装/外壳 | 1210(3225 公制) |

| 封装/箱体 | 1210 (3225 metric) |

| 屏蔽 | 无屏蔽 |

| 工作温度 | -40°C ~ 85°C |

| 工作温度范围 | - 55 C to + 125 C |

| 工厂包装数量 | 2000 |

| 最大直流电流 | 190 mA |

| 最大直流电阻 | 1.8 Ohms |

| 材料-磁芯 | 铁氧体 |

| 标准包装 | 1 |

| 测试频率 | 1 MHz |

| 电感 | 10µH |

| 电流-饱和值 | - |

| 端接类型 | SMD/SMT |

| 类型 | 绕线 |

| 系列 | LQH |

| 自谐振频率 | 20 MHz |

| 频率-测试 | 1MHz |

| 频率-自谐振 | 20MHz |

| 额定电流 | 190mA |

| 高度-安装(最大值) | 0.087"(2.20mm) |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

SpecNo.JELF243A-0041N-01 R e f e r e n c e O n l y P 1/10 CHIP COIL(CHIP INDUCTORS)LQH32MN□□□□23L REFERENCE SPECIFICATION 1.Scope This reference specification applies to LQH32MN Series, Chip coil (Chip Inductors). 2.Part Numbering (ex) LQ H 32 M N 1R0 M 2 3 L Product ID Structure Dimension Applications Category Inductance Tolerance Features Electrode Packaging (L×W) and L:Taping Characteristics 3.Rating ・Operating Temperature Range -40 to+85°C ・Storage Temperature Range. -40 to+85°C Self Inductance DC Rated Customer MURATA Q Resonant Resistance Current Part Number Part Number (μH) Tolerance(%) (min.) (Ω max) Frequency (mA) (MHz min) LQH32MN1R0M23L 1.0 0.5 445 M:±20 100 LQH32MN1R2M23L 1.2 425 LQH32MN1R5M23L 0.6 1.5 75 400 LQH32MN1R5K23L LQH32MN1R8M23L 1.8 0.7 60 390 LQH32MN1R8K23L LQH32MN2R2M23L 2.2 0.8 50 370 LQH32MN2R2K23L LQH32MN2R7M23L 2.7 0.9 43 320 LQH32MN2R7K23L LQH32MN3R3M23L 3.3 20 1.0 38 300 LQH32MN3R3K23L M:±20 LQH32MN3R9M23L K:±10 3.9 1.1 35 290 LQH32MN3R9K23L LQH32MN4R7M23L 4.7 1.2 31 270 LQH32MN4R7K23L LQH32MN5R6M23L 5.6 1.3 28 250 LQH32MN5R6K23L LQH32MN6R8M23L 6.8 1.5 25 240 LQH32MN6R8K23L LQH32MN8R2M23L 8.2 1.6 23 225 LQH32MN8R2K23L LQH32MN100K23L 10 1.8 20 190 LQH32MN100J23L LQH32MN120K23L 12 2.0 18 180 LQH32MN120J23L LQH32MN150K23L 15 2.2 16 170 LQH32MN150J23L K:±10 35 LQH32MN180K23L J:± 5 18 2.5 15 165 LQH32MN180J23L LQH32MN220K23L 22 2.8 14 150 LQH32MN220J23L LQH32MN270K23L 27 3.1 13 125 LQH32MN270J23L MURATA MFG.CO., LTD

SpecNo.JELF243A-0041N-01 R e f e r e n c e O n l y P 2/10 Self Inductance DC Rated Customer MURATA Q Resonant Resistance Current Part Number Part Number (min.) Frequency (μH) Tolerance(%) (Ω max) (mA) (MHz min) LQH32MN330K23L 33 3.5 12 115 LQH32MN330J23L LQH32MN390K23L 39 3.9 110 LQH32MN390J23L 11 LQH32MN470K23L 47 4.3 100 LQH32MN470J23L LQH32MN560K23L 56 4.9 10 85 LQH32MN560J23L LQH32MN680K23L 68 5.5 9.0 80 LQH32MN680J23L LQH32MN820K23L 82 6.2 8.5 70 LQH32MN820J23L LQH32MN101K23L 100 40 7.0 8.0 80 LQH32MN101J23L LQH32MN121K23L 120 8.0 7.5 75 LQH32MN121J23L K:±10 LQH32MN151K23L J:± 5 150 9.3 7.0 70 LQH32MN151J23L LQH32MN181K23L 180 10.2 6.0 LQH32MN181J23L LQH32MN221K23L 220 11.8 5.5 LQH32MN221J23L 65 LQH32MN271K23L 270 12.5 LQH32MN271J23L LQH32MN331K23L 330 13.0 LQH32MN331J23L LQH32MN391K23L 390 22.0 5.0 50 LQH32MN391J23L LQH32MN471K23L 470 50 25.0 45 LQH32MN471J23L LQH32MN561K23L 560 28.0 40 LQH32MN561J23L 4. Testing Conditions <Unless otherwise specified> <In case of doubt> Temperature : Ordinary Temperature (15 to 35°C) Temperature : 20 ± 2°C Humidity : Ordinary Humidity (25 to 85 %(RH)) Humidity : 60 to 70 %(RH) Atmospheric Pressure : 86 to 106 kPa MURATA MFG.CO., LTD

SpecNo.JELF243A-0041N-01 R e f e r e n c e O n l y P 3/10 5.Appearance and Dimensions 2.5±0.2 2.5±0.2 2 0. ± 0 2. 2.5±0.2 3.2±0.3 ■Unit Mass (Typical value) 0.060g ※ Nomarking. (in mm) 0.9 1.3 0.9 ±0.3 ±0.2 ±0.3 6.Electrical Performance No. Item Specification Test Method 6.1 Inductance Inductance shall meet item 3. Measuring Equipment : KEYSIGHT 4192A or equivalent Measuring Frequency : 1MHz / 1.0 to 390 μH 1kH / 470 to 560 μH 6.2 Q Measuring Equipment : KEYSIGHT 4192A or equivalent Measuring Frequency : 1MHz / 1.0 to 82μH 796kHz / 100 to 560μH 6.3 DC Resistance DC Resistance shall meet item 3. Measuring Equipment : Digital multi meter 6.4 Self Resonant S.R.F shall meet item 3. Measuring Equipment : KEYSIGHT 4291A or equivalent Frequency(S.R.F) 6.5 Rated Current Self temperature rise shall be limited to The rated current is applied. 20°C max. Inductance Change : within ± 10% 6.6 Temperature Temperature Coefficient Temperature coefficient on the basis of step 3 shall meet Characteristics 220 to 1400 PPM/°C specification after tested as follows.It shall be subjected to the condition of Table 1, and its inductanse shall be measured at each step after reaching the thermal equilibrium and be calculated. Table 1 Step1 / +20±2°C Step4 / +85±2°C Step2 / -25±2°C Step5 / +20±2°C Step3 / +20±2°C MURATA MFG.CO., LTD

SpecNo.JELF243A-0041N-01 R e f e r e n c e O n l y P 4/10 7.Mechanical Performance No. Item Specification Test Method 7.1 Shear Test Chip coil shall not be damaged. Substrate : Glass-epoxy substrate Applied Direction : Chip Coil F Substrate Force : 10N Hold Duration : 5±1s 7.2 Bending Test Chip coil shall not be damaged. Substrate : Glass-epoxy substrate (100 × 40 × 1.6mm) Speed of Applying Force : 1mm / s Deflection : 2mm Hold Duration : 30 s Pressurejig R340 F Deflection 45 45 Product (in mm) 7.3 Vibration Oscillation Frequency : 10 to 55 to 10Hz for 1 minute Total Amplitude : 1.5mm Testing Time : A period of 2 hours in each of 3 mutually perpendicular directions. (Total 6 hours) 7.4 Solderability The wetting area of the electrode shall Flux : Ethanol solution of rosin, 25(wt)% be at least 90% covered with new solder (Immersed for 5s to 10s) coating. Solder : Sn-3.0Ag-0.5Cu Pre-Heating : 150±10°C / 60 to 90seconds Solder Temperature : 240±5°C Immersion Time : 3±1 s 7.5 Resistance to Appearance: No damage Flux : Ethanol solution of rosin, 25(wt)% Soldering Heat Inductance Change: within ± 5% (Immersed for 5s to 10s) Solder : Sn-3.0Ag-0.5Cu Pre-Heating : 150±10°C / 60 to 90seconds Solder Temperature : 270±5°C Immersion Time : 10±1 s Then measured after exposure in the room condition for 24±2 hours. MURATA MFG.CO., LTD

SpecNo.JELF243A-0041N-01 R e f e r e n c e O n l y P 5/10 8.Environmental Performance (It shall be soldered on the substrate.) No. Item Specification Test Method 8.1 Heat Resistance Appearance:No damage Temperature : 85±2°C Inductance Change : within ±5% Time : 1000h (+48h , -0h) Q-factor Change : within ±20% Then measured after exposure in the room condition for 24±2 hours. 8.2 Cold Resistance Temperature : -40±2°C Time : 1000h (+48h , -0h) Then measured after exposure in the room condition for 24±2 hours. 8.3 Humidity Temperature : 40±2°C Humidity : 90 to 95%(RH) Time : 1000h (+48h , -0h) Then measured after exposure in the room condition for 24±2 hours. 8.4 Temperature 1 cycle : Cycle 1 step : -40±2°C / 30±3 min 2 step : Ordinary temp. / 10 to 15 min 3 step : +85±2°C / 30±3 min 4 step : Ordinary temp. / 10 to 15 min Total of 10 cycles Then measured after exposure in the room condition for 24±2 hours. 9. Specification of Packaging 9.1 Appearance and Dimensions of plastic tape 1 0. φ1.5+-00.1 ※Lead-in/out wire 1.75± ( 0. 2 ) ※Thepackingdirectionsofthechipcoil intapingareunifiedwiththein/out 5 3.6±0.2 3.5±0.0 8.0±0.2 pDaotis mtihteieon bnsosiottnoo mfoft hsthiedee lC.e aavdityw isir em.easured 4.0±0.1 4.0±0.1 (in mm) 2.1±0.1 2.9±0.2 2.0±0.05 Directionof feed 9.2 Specification of Taping (1) Packing quantity (standard quantity) 2,000 pcs / reel (2) Packing Method Products shall be packed in the each embossed cavity of plastic tape and sealed by cover tape. (3) Sprocket hole The sprocket holes are to the right as the tape is pulled toward the user. (4) Spliced point Plastic tape and Cover tape has no spliced point. (5) Missing components number Missing components number within 0.1 % of the number per reel or 1 pc., whichever is greater, and are not continuous. The specified quantity per reel is kept. 9.3 Pull Strength Embossed carrier tape 10N min. Cover tape 5N min. MURATA MFG.CO., LTD

SpecNo.JELF243A-0041N-01 R e f e r e n c e O n l y P 6/10 9.4 Peeling off force of cover tape 165to180degree Speed of Peeling off 300mm/min F Cover tape 0.2 to 0.7N Peeling off force (minimum value is typical) Plastictape 9.5 Dimensions of Leader-tape, Trailer and Reel There shall be leader-tape (cover tape) and trailer-tape (empty tape) as follows. Trailer Leader 2.0±0.5 160min. Label 190min. 210min. Emptytape Covertape φ13.0±0.2 φ60±10 φ21.0±0.8 Directionoffeed 9±1 0 13±1.4 φ180±0 3 9.6 Marking for reel Customer part number, MURATA part number, Inspection number(∗1), RoHS marking(∗2), Quantity etc ・・・ ∗1) <Expression of Inspection No.> □□ OOOO ××× (1) (2) (3) (1) Factory Code (2) Date First digit : Year / Last digit of year Second digit : Month / Jan. to Sep. → 1 to 9, Oct. to Dec. → O, N, D Third, Fourth digit : Day (3) Serial No. ∗2) « Expression of RoHS marking » ROHS – Y (△) (1) (2) (1) RoHS regulation conformity (2) MURATA classification number 9.7 Marking for Outside package (corrugated paper box) Customer name, Purchasing order number, Customer part number, MURATA part number, RoHS marking (∗2) ,Quantity, etc ・・・ 9.8. Specification of Outer Case Outer Case Dimensions(mm) Standard Reel Quantity Label W D H in Outer Case (Reel) H 186 186 93 5 D ∗Above Outer Case size is typical. It depends on a quantity of an order. W 10. Caution Limitation of Applications Please contact us before using our products for the applications listed below which require especially high reliability for the prevention of defects which might directly cause damage to the third party's life, body or property. (1) Aircraft equipment (6) Transportation equipment (vehicles, trains, ships, etc.) (2) Aerospace equipment (7) Traffic signal equipment (3) Undersea equipment (8) Disaster prevention / crime prevention equipment (4) Power plant control equipment (9) Data-processing equipment (5) Medical equipment (10) Applications of similar complexity and /or reliability requirements to the applications listed in the above MURATA MFG.CO., LTD

SpecNo.JELF243A-0041N-01 R e f e r e n c e O n l y P 7/10 11. Notice This product is designed for solder mounting. Please consult us in advance for applying other mounting method such as conductive adhesive. 11.1 Land pattern designing Recommended land patterns for flow and reflow soldering are as follows: These have been designed for Electric characteristics and solderability. Please follow the recommended patterns. Otherwise, their performance which includes electrical performance or solderability may be affected, or result to "position shift" in soldering process. Flow Soldering Reflow Soldering ∗ 5.5 ChipCoil 5.5 Land Solder Resist 1.0 2.0 1.0 1.3 1.0 1.3 1.0 (in mm) ∗ Applicable to flow soldering. 11.2 Flux, Solder ・Use rosin-based flux. Flux ・Don’t use highly acidic flux with halide content exceeding 0.2(wt)% (chlorine conversion value). ・Don’t use water-soluble flux. ・Use Sn-3.0Ag-0.5Cu solder Solder ・Standard thickness of solder paste : 200μm to 300μm Other flux (except above) Please contact us for details, then use. 11.3 Flow soldering conditions / Reflow soldering conditions ・Pre-heating should be in such a way that the temperature difference between solder and product surface is limited to 150°C max. Cooling into solvent after soldering also should be in such a way that the temperature difference is limited to 100°C max. Insufficient pre-heating may cause cracks on the product, resulting in the deterioration of product quality. ・Standard soldering profile and the limit soldering profile is as follows. The excessive limit soldering conditions may cause leaching of the electrode and / or resulting in the deterioration of product quality. Soldering profile (1)Flow soldering profile Temp. (℃) 265℃±3℃ 250℃ Limit Profile 150 Heating Time Standard Profile 60s min. Time.(s) Standard Profile Limit Profile Pre-heating 150℃、60s min. Heating 250℃、4s~6s 265℃±3℃、5s Cycle of flow 2 times 1 time MURATA MFG.CO., LTD

SpecNo.JELF243A-0041N-01 R e f e r e n c e O n l y P 8/10 (2)Reflow soldering profile Temp. 260℃ (℃) 245℃±3℃ 230℃ 220℃ Limit Profile 180 150 30s~60s Standard Profile 60s max. 90s±30s Time.(s) Standard Profile Limit Profile Pre-heating 150~180°C 、90s±30s Heating above 220°C、30s~60s above 230°C、60s max. Peak temperature 245±3°C 260°C,10s Cycle of reflow 2 times 1 time 11.4 Reworking with soldering iron. The following conditions must be strictly followed when using a soldering iron. Pre-heating 150°C,1 min Tip temperature 350°C max. Soldering iron output 80W max. Tip diameter φ3mm max. Soldering time 3(+1,-0)s Times 2 times Note : Do not directly touch the products with the tip of the soldering iron in order to prevent the crack on the products due to the thermal shock. 11.5 Solder Volume ・Solder shall be used not to be exceeded the upper limits as shown below. ・Accordingly increasing the solder volume, the mechanical stress to Chip is also increased. Exceeding solder volume may cause the failure of mechanical or electrical performance. UpperLimit 1/3T≦ t ≦T Recommendable (T: Lower flange thickness) T t 11.6 Product's location The following shall be considered when designing and laying out P.C.B.’s. (1) P.C.B. shall be designed so that products are not subject to the mechanical stress due to warping the board. [Products direction] a Products shall be located in the sideways direction b < (Length: a b) to the mechanical stress. 〈Poor example〉 〈Good example〉 MURATA MFG.CO., LTD

SpecNo.JELF243A-0041N-01 R e f e r e n c e O n l y P 9/10 (2) Components location on P.C.B. separation. It is effective to implement the following measures, to reduce stress in separating the board. It is best to implement all of the following three measures; however, implement as many measures as possible to reduce stress. Contents of Measures Stress Level (1) Turn the mounting direction of the component parallel to A > D ∗1 the board separation surface. (2) Add slits in the board separation part. A > B (3) Keep the mounting position of the component away from A > C the board separation surface. C Seam B ∗1 A > D is valid when stress is added vertically to the perforation as with Hand Separation. If a Cutting Disc is used, stress will be diagonal to D the PCB, therefore A > D is invalid. b A Slit Length:a<b a (3) Mounting Components Near Screw Holes When a component is mounted near a screw hole, it may be affected by the board deflection that occurs during the tightening of the screw. Mount the component Screw Hole Recommended in a position as far away from the screw holes as possible. 11.7 Cleaning Conditions Products shall be cleaned on the following conditions. (1) Cleaning temperature shall be limited to 60°C max.(40°C max for IPA.) (2) Ultrasonic cleaning shall comply with the following conditions with avoiding the resonance phenomenon at the mounted products and P.C.B. Power : 20 W / l max. Frequency : 28kHz to 40kHz Time : 5 minutes max. (3) Cleaner 1. Alternative cleaner ・Isopropyl alcohol (IPA) 2. Aqueous agent ・PINE ALPHA ST-100S (4) There shall be no residual flux and residual cleaner after cleaning. In the case of using aqueous agent, products shall be dried completely after rinse with de-ionized water in order to remove the cleaner. (5) Other cleaning Please contact us. 11.8 Resin coating The inductance value may change due to high cure-stress of resin to be used for coating/molding products. An open circuit issue may occur by mechanical stress caused by the resin, amount/cured shape of resin, or operating condition etc. Some resin contains some impurities or chloride possible to generate chlorine by hydrolysis under some operating condition may cause corrosion of wire of coil, leading to open circuit. So, please pay your careful attention when you select resin in case of coating/molding the products with the resin. Prior to use the coating resin, please make sure no reliability issue is observed by evaluating products mounted on your board. 11.9 Caution for use ・Sharp material such as a pair of tweezers or other material such as bristles of cleaning brush, shall not be touched to the winding portion to prevent the breaking of wire. ・Mechanical shock should not be applied to the products mounted on the board to prevent the breaking of the core. 11.10 Handling of a substrate After mounting products on a substrate, do not apply any stress to the product caused by bending or twisting to the substrate when cropping the substrate, inserting and removing a connector from the substrate or tightening screw to the substrate. Excessive mechanical stress may cause cracking in the product. Bending Twisting MURATA MFG.CO., LTD

SpecNo.JELF243A-0041N-01 R e f e r e n c e O n l y P 10/10 11.11 Storage and Handling Requirements (1) Storage period Use the products within 12 months after delivered. Solderability should be checked if this period is exceeded. (2) Storage conditions ・Products should be stored in the warehouse on the following conditions. Temperature : -10 ~ 40°C Humidity : 15 to 85% relative humidity No rapid change on temperature and humidity The electrode of the products is coated with solder. Don't keep products in corrosive gases such as sulfur,chlorine gas or acid, or it may cause oxidization of electrode, resulting in poor solderability. ・Products should not be stored on bulk packaging condition to prevent the chipping of the core and the breaking of winding wire caused by the collision between the products. ・Products should be stored on the palette for the prevention of the influence from humidity, dust and so on. ・Products should be stored in the warehouse without heat shock, vibration, direct sunlight and so on. (3) Handling Condition Care should be taken when transporting or handling product to avoid excessive vibration or mechanical shock. 12. Note (1)Please make sure that your product has been evaluated in view of your specifications with our product being mounted to your product. (2)You are requested not to use our product deviating from the reference specifications. (3)The contents of this reference specification are subject to change without advance notice. Please approve our product specifications or transact the approval sheet for product specifications before ordering MURATA MFG.CO., LTD

Datasheet下载

Datasheet下载