- 型号: KPT06F16-8PW

- 制造商: ITT CANNON

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

KPT06F16-8PW产品简介:

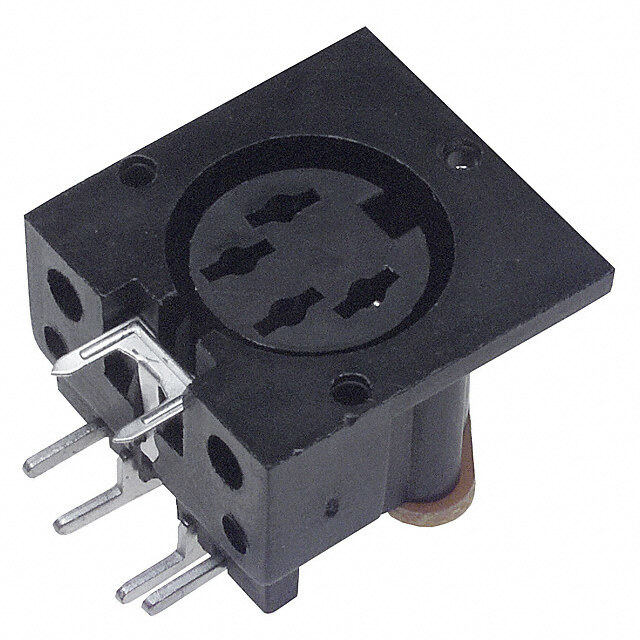

ICGOO电子元器件商城为您提供KPT06F16-8PW由ITT CANNON设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 KPT06F16-8PW价格参考。ITT CANNONKPT06F16-8PW封装/规格:圆形连接器, 8 Position Circular Connector Plug, Male Pins Solder Cup Gold。您可以下载KPT06F16-8PW参考资料、Datasheet数据手册功能说明书,资料中有KPT06F16-8PW 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | CONN PLUG 8POS INLINE W/PIN |

| 产品分类 | |

| 品牌 | ITT Cannon |

| 数据手册 | http://www.ittcannon.com/download/sample/625点击此处下载产品Datasheet点击此处下载产品Datasheet |

| 产品图片 | |

| 产品型号 | KPT06F16-8PW |

| rohs | 含铅 / 不符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | MIL-DTL-26482,系列 I, KPT |

| 侵入防护 | 抗环境影响 |

| 其它名称 | IKPT06F16-8PW |

| 包装 | 散装 |

| 外壳尺寸-插件 | 16-8 |

| 外壳尺寸,MIL | - |

| 外壳材料,镀层 | 铝合金, 草绿色,镀镉 |

| 安装类型 | 自由悬挂 |

| 工作温度 | -55°C ~ 125°C |

| 朝向 | W |

| 标准包装 | 1 |

| 特性 | 应力消除 |

| 电压-额定 | 1000VAC,1400VDC |

| 端接 | 焊杯 |

| 紧固类型 | 插销锁 |

| 触头镀层 | 金 |

| 触头镀层厚度 | 50µin (1.27µm) |

| 连接器类型 | 插头,公引脚 |

| 配套产品 | /product-detail/zh/KPT07E16-8SW/KPT07E16-8SW-ND/3644253/product-detail/zh/KPT01P16-8SW/KPT01P16-8SW-ND/3643732/product-detail/zh/KPT00F16-8SW/KPT00F16-8SW-ND/3643512/product-detail/zh/KPSE01F16-8SW/KPSE01F16-8SW-ND/3151875/product-detail/zh/KPSE00F16-8SW/KPSE00F16-8SW-ND/3151864/product-detail/zh/KPSE07E16-8SW/IKPSE07E16-8SW-ND/2492036/product-detail/zh/KPSE02E16-8SW/IKPSE02E16-8SW-ND/2489363/product-detail/zh/KPT02E16-8SW/IKPT02E16-8SW-ND/2488850 |

| 针脚数 | 8 |

| 额定电流 | 13A |

.jpg)

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

KPT / KPSE / KPTC Connectors In Accordance with VG95328

We Connect When it matters most For more than a century, ITT Cannon has developed innovative interconnect solutions for the world’s harshest environ- ments. With facilities in the United States, Germany, Italy, Mexico, China and Japan, each with its unique strengths, we offer our customers interconnect solutions that are truly Engineered for Life. In addition to this truly global footprint, we offer highly specialized, segmented industry expertise. We have a proven track record as an industry leader in harsh-environment applications. This has equipped us with the knowledge needed to continue to produce the most resilient, reliable connectors for our customers’ most challenging conditions. Interconnect solutions for the harshest environments. Key Features • Simple to install and maintain • Hand insertable contacts • No wedge locks or blind seals required The ITT Cannon difference • From 2 way to 24-way layouts • Global capabilities & local support • Up to IP69K sealing • Proven application expertise • Utilizes Trident Contacts • A century of interconnect leadership • Positive locking latch & polarization key • A committed innovator & business partner • Excellent cost/performance ratio About ITT ITT is a diversified leading manufacturer of highly engineered critical components and customized technology solutions for the energy, transportation and industrial markets. Building on its heritage of innovation, ITT partners with its customers to deliver enduring solutions to the key industries that underpin our modern way of life. Founded in 1920, ITT is headquartered in White Plains, N.Y., with employees in more than 35 countries and sales in a total of approximately 125 countries. For more information, visit www.itt.com. 2 www.ittcannon.com

lndustrial / lnstrumentation Rail Defense Vehicles Oil & Gas Medical Commercial & Military Aerospace Our connector portfolio remains the most extensive Heavy Equipment in the industry, offering a reliable and cost effective range of interconnect solutions www.ittcannon.com 3

Introduction to KPSE /KPT /KPTC ITT Cannon’s KPSE / KPT and KPTC series of miniature positive bayonet locking connectors offer a range of high-density signal solutions. They are designed according to MIL-DTL-26482 Series I or VG95328 – details below. Next to the original use in military vehicles these connector series have become a standard for Industrial uses as eg. off-road vehicles, sensors, factory equipment and other heavy industry applications. All three product lines have specific characteristics and provide a set of unique variants, however, all lines are fully intermateable with each other as well as any other connector series designed to MIL-DTL 26482 Series I or VG95238 standards. Product Series Origin VG 95328 Approved MIL-DTL 26482 Series I Approved KPSE German make/origin Yes No KPSE US make/origin No No KPT German make/origin No No KPT US make/origin No No KPTC German make/origin No No KPSE is the high-performance crimp contact solution featuring a clip-in retention system for fast and simple assembly. ITT Cannon is approved to offer this line with VG marking according to Common features of KPSE / KPT / KPTC: VG95328. ➤ Intermateability with all product lines designed KPT is the first of two general duty series, and equipped with to MIL-DTL-26482 Series I solder pot contacts and glued in contacts. This makes this product ➤ Environmental sealing to IP67 and IP68 ideal for any prototype solution as well as for military ➤ ½ turn positive bayonet coupling for quick mating vehicle applications based on the MIL-DTL-268482 Series I & unmating standard. ➤ Shielded backshell accessories ➤ A range of RoHS compliant plating alternatives to KPTC is the second ITT Cannon general duty series with either Cadmium including Nickel, Zinc Nickel and Zinc crimp or solder pot contact versions. In comparison this series Cobalt versions comes with a simpler design and avoids the high-performance ➤ Customizing options clip-in solution of KPSE as well as the glued contact assembly of KPT which makes this line a good choice for many Industrial applications. Both KPTC as well as KPT add typical Industrial back shells to their portfolio. This document solely applies to European manufactured KPT / KPSE / KPTC products. Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 4 www.ittcannon.com

Contact Principle CONTACT & SEALING PRINCIPLE 1 KPSE uses a three piece insulator stack up consisting of 2 1 - rubber insulator 3 2 - plastic wafer / retaining clips 3 - ubber grommet to seal individual wires 4 - two piece machined contact with retaining clip 4 Rubber insulator (1) and grommet (3) together with the front sealing ring provide the sealing in mated condition as well as the sealing of individual wires protruding through the grommet. Contact retention is provided using a two piece contact with retaining clip. The stiff plastic wafer or individual metal clips provide the specified contact retention. A good tactile response is given when contacts are pushed in the final assembly position. Contacts are installed from the rear by hand or with an insertion tool to ease assembly. Contact removal is done with an extraction tool from the front. 1 2 KPT uses a rubber insulator and sealing grommet 1 - rubber insulator 3 2 - rubber grommet to seal individual wires 3 - one piece machined contact Rubber insulator (1) and grommet (2) together with the front sealing ring provide the sealing in mated condition as well as the sealing of individual wires protruding through the grommet. Contact retention is provided by form fit of the machined contact in the rubber insulator. Additionally, glue is applied to secure contacts in the exact mounting position. KPT is equipped with solder pot contacts only and pre installed by the factory. 1 2 KPTC uses a rubber insulator and sealing grommet 1 - rubber insulator 3 2 - rubber grommet to seal individual wires 3 - one piece machined contact Rubber insulator (1) and grommet (2) together with the front sealing ring provide the sealing in mated condition as well as the sealing of individual wires protruding through the grommet. Contact retention is provided by form fit of the machined contact in the rubber insulator. Solder pot contacts are pre-installed by the factory, crimp contacts are delivered separately. Glue is not applied to KPTC connectors. Contacts are installed from the rear with an insertion tool. Contact removal is done with an extraction tool from the front. Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 5

Table of contents Contact and sealing principle ................................5 How to use this catalogue ......................................7 Product overview ...................................................8 Panel cutouts .......................................................10 Ordering reference ...............................................11 Contact arrangements ..........................................14 Alternate insert positions ......................................17 Wall mounting receptacles ...................................18 Cable connecting plugs ........................................21 Box mounting receptacles ....................................23 Thru-bulkhead receptacles ....................................24 Straight plugs ......................................................24 Jam nut receptacles ..............................................28 Right angle plugs .................................................31 Receptacles with PCB solder pins ..........................32 Accessories and tooling Protective caps .....................................................33 Dummy receptacle ...............................................35 Cross reference lists .............................................36 Tools and accessories ...........................................37 Product safety information ...................................40 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 6 www.ittcannon.com

How to use This catalog is split in several sections that help you to • get a general overview of all product lines (product overview) • create a product part number step by step (ordering reference) • get all required detail information (dimensions, product details) • get all required support products (accessories, tooling) The fastest way to find your product of choice is to follow these steps 1 3 Select your product using the “ordering reference” option Add accessories and tooling as required on the related pages 2 4 Use the detail pages to better understand the available Use the contact information on the back cover to contact options and choose the best solution for your needs us for further questions or to get advice on where you can purchase our products Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 7

Product overview KPSE (VG95328), KPT, KPTC Electrical Data Contact rating at 60°C: Size Rated current A Test current A Millivolt drop mV 20 7,5 7,5 Less than 50 16 13,0 13,0 Less than 50 Current Rating Current rating vs. ambient temperature: Current Rating 13 1123 1112 1101 190 Rated current in ARated current in A 4567856789 LtCCLtCCeeiooimoommmnnnnipitttpttt aae aaeooccrccrfaftta tt t ##t##uu2121rre06e06 34 23 12 01 20 30 40 50 60 70 80 90 100 110 120 130 0 20 30 40 50 A60mbient T7e0mperatu8r0e in °C 90 100 110 120 130 Ambient Temperature in °C Comment for contact rating and current rating: Rated current values shown are the max. current flowing continuously (not intermittently) through one contact pair with the same cross section with regard to ambient temperature. If multiple contact pairs are loaded into a connector the current rating curve has to be reduced. Minimum air & creepage paths: Contact to contact crimp Contact to contact solder Contact to shell Service Class 1 1,9 mm 0,75 mm 1,0 mm Service Class 2 2,8 mm 1,53 mm 2,8 mm Insulation resistance: ~ 5000 MOhm Operating voltage: Service class VG95328 MIL-C-26482 1 140 VDC/100 VAC 850 VDC/600 VAC 2 165 VDC/115 VAC 1400 VDC/1000 VAC Comment: When connectors in this catalog are used at voltages exceeding > 50VAC / 75VDC safety provisions as defined in the European low voltage directive 2014/35/EU have to be adhered to. For use in other regions see appropriate local regulations. Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 8 www.ittcannon.com

Test voltage: Test voltage Service class Vrms VDC 1 1500 2100 Service Class 1 2 2300 3200 1 375 535 21336 M/70,000ft. 2 550 770 Mechanical data Ambient temperature: -55°C … 125°C Environmental sealing: In mated condition for KPSE, KPT and KPTC product lines: IP67 acc. ISO 20653 VG95328 connectors: IP68 (0,2bar / 48h) – see below According to VG95319 Part 2, Test No. 5.9.2 | For styles A to E and Z1, Z2 and Z3 and gaskets style A only, test pressure 0,2 bar overpressure, test duartion 48h, test temperature 25±3°C, connector shall be free of moisture Vibration test acc. VG95328: Vibration stress 150 m/s2, 10 Hz to 2000 Hz and Random vibration stress, 5 Hz to 500 Hz acc. test 5.52 VG95328-1 Mating cycles: 500 Material: Shell Aluminium alloy - Cadmium, VG approved - ZnCobalt Black - Zinc Cobalt Green Shell finishes - Zinc Nickel Blue Generation, for non-shielded versions - Nickel Insulator Polychloroprene Grommet and seals Contacts Copper alloy, gold and silver plating Product line design principles: KPSE: Clip in crimp contact system, VG approved versions KPT: Solder contacts, pre-installed and fixed with glue, VG approved versions KPTC: Crimp contacts for tool insertion OR pre-installed solder contacts (not fixed with glue) All further details, product line options etc. see following catalog pages Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 9

PANEL CUTOUTS KPT / KPSE / KPTC BOX MOUNTING RECEPTACLE For rear mounting For front mounting Shell size Ø D +0,25 / 0 Ø D +0,25 / 0 R ±0,15 Ø T +0,3 8 14,0 12,7 15,1 3,1 10 17,0 16,0 18,3 3,1 12 22,0 19,0 20,6 3,1 14 25,0 22,2 23,0 3,1 16 28,0 25,5 24,6 3,1 18 31,0 28,5 27,0 3,1 20 34,5 31,7 29,4 3,1 22 37,5 35,0 31,8 3,1 24 41,0 38,0 34,9 3,6 PANEL THICKNESS P – Panel thickness Shell size Height of screw head included 8 2,2 10 2,2 12 2,2 14 2,2 16 2,2 18 2,2 20 5,4 22 5,4 24 5,4 JAM NUT RECEPTACLE KPT / KPSE KPT / KPSE Shell size Ø A +0,25 / –0 B +0 / –0,12 8 14,5 13,6 10 17,7 16,8 12 22,7 20,9 14 25,7 24,1 16 28,8 27,2 18 32,0 30,4 20 35,1 33,6 22 38,4 36,8 24 41,5 40,0 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 10 www.ittcannon.com

How to order Cannon Order reference KPT / KPSE / KPTC KP.. 02 E 22 – 36 P W * Series KPSE – Cannon prefix crimp, contacts supplied KPT – Cannon prefix solder, contacts installed KPTC – Cannon prefix commercial version, contacts to be ordered separately. See modification codes for contact options Shell type (See note below) Cannon designation omit 0 in case of a mod code and KPTC 00 – wall mounting receptacle see page 18-20 01 – cable connecting plug see page 21-23 02 – box mounting receptacle (class E only). see page 23-24 06 – straight plug see page 24-27 07 – jam nut receptacle see page 28-30 08 – 90° angle plug see page 31 KPTB - thru-bulkhead receptacle see page 24 Class A – Endbell with thread, no grommet seal; for jam nut: without endbell E – Pressure nut and grommet seal - for 90° versions: endbell with thread, and grommet seal – with modification DN: Endbell for heat shrink boot and grommet seal – with modification DZ: Endbell for heat shrink boot and grommet seal, shielded F – Endbell with cable clamp and grommet seal PG – endbell for PG glands ME – endbell for metric glands Shell size 8 – 24 Contact arrangement see page 14-16 Contact type P – pin S – socket Alternate insert position W, X, Y and Z (omit for normal position) see page 17 Modification see page 12 Note: * If a modification is used the initial ‚0‘ in the shell style description is omitted e.g. KPT01E10-6P is changed to KPT1E10-6P-DN. KPTC series does not use the initial ‚0‘ e.g. KPTC6E10-6P-C. Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 11

Modification Codes KPT: KPSE: KPTC: Multiple codes can be used in Multiple codes can be used in Multiple codes can be used in order of listing below: order of listing below: order of listing below: Contact Endbell Plating PCB solder pin 0,76 x 7mm heat shrink boot adapter, grommet seal DN Nickel plating (RoHS compliant) C EX (style 02 and 07 only) shielded, heat shrink boot adapter, Zinc Cobalt black plating (RoHS DZ R PCB solder pin 0,6 x 7mm grommet seal compliant) EW (style 02 and 07 only) without endbell, grommet and ferrule F42* Zinc Cobalt green plating (RoHS F compliant) Endbell Endbell for PG cable gland, class PG only Zinc Nickel plating (RoHS compliant) heat shrink boot adapter, grommet seal DN H PG09 thread for connectors (not for code DZ) P9 shielded, heat shrink boot with shell size 10 DZ Cadmium with olive drab chromate D adapter, grommet seal PG11 thread for connectors P11 without endbell, grommet and ferrule F42* with shell size 12 Endbell PG13,5 thread for connectors heat shrink boot adapter, grommet seal DN Endbell for PG cable gland, class PG only P13,5 with shell size 14 shielded, heat shrink boot adapter, PG09 thread for connectors DZ P9 PG16 thread for connectors grommet seal with shell size 10 P16 with shell size 16 without endbell, grommet and ferrule F42* PG11 thread for connectors P11 PG21 thread for connectors with shell size 12 P21 with shell size 18, 20, 22 Endbell for PG cable gland, class PG only PG13,5 thread for connectors with shell size 14 P13,5 PwGit2h9 s thherlel asidz ef o2r4 connectors P29 PwGit0h9 s thherlel asidz ef o1r0 connectors P9 PG16 thread for connectors with shell size 16 P16 Endbell for Metric cable gland, class ME only PG11 thread for connectors P11 with shell size 12 PG21 thread for connectors M12 thread for connectors with shell size 18, 20, 22 P21 with shell size 10 M12 PG13,5 thread for connectors P13,5 with shell size 14 PG29 thread for connectors M16 thread for connectors with shell size 24 P29 with shell size 12 M16 PG16 thread for connectors P16 with shell size 16 M20 thread for connectors Endbell for Metric cable gland, class ME only with shell size 16 M20 PG21 thread for connectors P21 with shell size 18, 20, 22 M12 thread for connectors M12 M25 thread for connectors with shell size 10 with shell size 18, 20 M25 PG29 thread for connectors P29 with shell size 24 M16 thread for connectors M16 M32 thread for connectors with shell size 12 M32 with shell size 22, 24 Endbell for Metric cable gland, class ME only M20 thread for connectors with shell size 16 M20 Plating (Cadmium with olive drab chromate M12 thread for connectors M12 plating is standard - without code; with shell size 10 Mwi2th5 sthhreella sdiz feo r1 8co, n2n0ectors M25 Alternative platings below) M16 thread for connectors M16 Zinc Cobalt, black plating (RoHS with shell size 12 Mwi3th2 sthhreella sdiz feo r2 2co, n2n4ectors M32 compliant) A232 M20 thread for connectors M20 Zinc Nickel plating (RoHS compliant) with shell size 16 A240 Plating (Cadmium with olive drab chromate (not for code DZ) M25 thread for connectors M25 plating is standard - without code; Zinc Cobalt, green plating with shell size 18, 20 Alternative platings below) A233 (RoHS compliant) M32 thread for connectors M32 Zinc Cobalt, black plating (RoHS A232 Nickel plating (RoHS compliant) A34 with shell size 22, 24 compliant) Zinc Nickel plating (RoHS compliant) Contact Contact A240 (not for code DZ) Connector without contacts F0 Connector supplied with solder MA Zinc Cobalt, green plating (RoHS pot contacts installed A233 compliant) An example using these modifications: Connector supplied with crimp contacts MB KPSE7F16-8S-A240-F0 Nickel plating (RoHS compliant) A34 PCB solder pin 0,76 x 7mm EX * Note: Modification -F42 can only be used with Styles (style 02 and 07 only) An example using these modifications: 0, 1, 6, 7 and 8. See details on pg 13 KPT2E10-6P-EW-A232 PCB solder pin 0,6 x 7mm EW (style 02 and 07 only) * Note: Modification -F42 can only be used with Styles 0, 1, 6, 7 and 8. See details on pg 13 An example using these modifications: KPTC6F14-18P-H-MB * Note: Modification -F42 can only be used with Styles 0, 1, 6, 7 and 8. See details on pg 13 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 12 www.ittcannon.com

Endbell Modification -F42 Below table shows the different threads that come with the respective shell sizes when choosing the modification -F42 (no endbell/grommet seal). This modification is only applicable to styles 0 (wall mounting receptacle), 1 (cable connecting plug), 6 (straight plug), 7 (jam nut receptacle) and 8 (90° angle plug). The only exception being KP*7A, as this combination already has no endbell/grommet. Shell size Thread 8 7/16-28UNEF 10 9/16-24UNEF 12 11/16-24UNEF 14 13/16-20UNEF 16 15/16-20UNEF 18 1-1/16-18UNEF 20 1-3/16-18UNEF 22 1-5/16-18UNEF 24 1-7/16-18UNEF Drawing shows KP*1 Style How to order VG Order reference VG95328 A 18 – 1 S N – 1 Specification Shell type see page 36 A – wall mounting receptacle with straight endbell B – wall mounting receptacle with cable clamp C – box mounting receptacle D – jam nut receptacle E – jam nut receptacle with cable clamp J – straight plug with adapter DN K – straight plug with cable clamp M – straight plug, version DZ R – wall mounting receptacle, version DZ S – jam nut receptacle with adapter DN Shell size 8, 10, 12, 14, 16, 18, 20, 22 and 24 Contact arrangements see page 14-16 Contact type P – pin S – socket Alternate insert position see page 17 With / without contacts Without identification = with contacts With -1 identification = without contacts Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 13

CONTACT ARRANGEMENTS Contact arrangements Insulator position View on mating face of pin insulator No. of contacts Contact size Service rating W X Y Z AWG 2 8-2 1 58 122 – – 20 3 8-3 1 60 210 – – 20 8-3A 1 60 – – – 3 20 3 8-33 1 90 – – – 20 4 8-4 1 45 – – – 20 10-6 1 90 – – – 6 20 10-7 1 90 – – – 7 20 10-98 1 90 180 240 270 6 20 12-3 2 – – 180 – 3 16 12-8 1 90 112 203 292 8 20 12-10 1 60 155 270 295 10 20 12-14 1 60 155 270 295 14 20 14-5 2 40 92 184 273 5 16 14-12 1 43 90 – – 12 20 (8) 16 (4) Legend KPT KPSE KPTC authorized per VG95328 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 14 www.ittcannon.com

CONTACT ARRANGEMENTS Contact arrangements Insulator position View on mating face of pin insulator No. of contacts Contact size Service rating W X Y Z AWG 14-15 1 17 110 155 234 15 20 (14) 16 (1) 14-18 1 15 90 180 270 18 20 14-19 1 30 165 315 – 19 20 14-22 1 – – – – 5 12 (4) 20 (1) 14A4 1 – – – – 4 Coax RG 188 U (not for receptacle shell style 02) 16-8 2 54 152 180 331 8 16 16-23 1 158 – – – 23 20 (22) 16 (1) 16-26 1 60 – 275 338 26 20 18-11 2 62 119 241 340 11 16 18-32 2 85 138 222 265 32 20 Legend KPT KPSE KPTC authorized per VG95328 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 15

CONTACT ARRANGEMENTS Contact arrangements Insulator position View on mating face of pin insulator No. of contacts Contact size Service rating W X Y Z AWG 20A6 2 90 180 270 – 5 12 Note: contacts are 1 grounding pin and 4 standard size 12 pins 20-16 2 238 318 333 347 16 16 20-24 1 70 145 215 290 24 20 20-39 1 63 144 252 333 39 20 (37) 16 (2) 20-41 1 45 126 225 w– 41 20 22-21 2 16 135 175 349 21 16 22-36 1 72 144 216 288 36 20 22-41 39 135 264 – 41 20 (27) 1 16 (14) 2 22-55 1 30 142 226 314 55 20 24-61 1 90 180 270 324 61 20 Legend KPT KPSE KPTC authorized per VG95328 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 16 www.ittcannon.com

ALTERNATE INSERT POSITION The diagram indicates alternate insert Contact Degree of Rotation Shell size No. of contacts positions. arrangements V W X Y Z The six positions N, V, W, Y, Z differ in 2 8-2 – 58 122 – – degree of rotation for various sizes and 3 8-3 – 60 210 – – arrangements. For the exact degree of 8 3 8-3A – 60 – – – rotation, for the list of contact arrangements 3 8-33 – 90 – – – and for alternate positions available, refer to 4 8-4 – 45 – – – the table at the right. 6 10-6 – 90 – – – 10 7 10-7 – 90 – – – 6 10-98 – 90 180 240 270 3 12-3 – – – 180 – 8 12-8 – 90 112 203 292 12 10 12-10 – 60 155 270 295 14 12-14 – 60 155 270 295 4 14A4 – – – – – 5 14-5 – 40 92 184 273 12 14-12 – 43 90 – – 14 15 14-15 – 17 110 155 234 18 14-18 – 15 90 180 270 19 14-19 – 30 165 315 – 5 14-22 – – – – – 8 16-8 – 54 52 180 331 16 23 16-23 – 158 – – – 26 16-26 – 60 – 275 338 11 18-11 – 62 119 241 340 18 32 18-32 – 85 138 222 265 5 20A6* – 90 180 270 – 16 20-16 – 238 318 333 347 20 24 20-24 – 70 145 215 290 39 20-39 – 63 144 252 333 41 20-41 – 45 126 225 – 21 22-21 – 16 135 175 349 36 22-36 – 72 144 216 288 22 41 22-41 – 39 135 264 – 55 22-55 – 30 142 226 314 24 61 24-61 – 90 180 270 324 * This contact arrangement features five contacts size 12. Four standard contacts and one is a first-to-mate contact. Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 17

WALL MOUNTING RECEPTACLES KPT00A / KPSE00A / KPTC0A Description: Wall Mounting Receptacle with an endbell with thread, no grommet seal. Shell size Ø A K M R S Ø T Ø DA LA VTHD +0,03 – 0,13 ±0,1 ±0,15 ±0,15 max. ±0,15 min. max. Thread Type 2A 8 12,00 1,9 11,6 15,1 21,0 3,05 8,5 38,0 1/2-28UNEF 10 15,00 1,9 11,6 18,3 24,2 3,05 11,8 38,0 5/8-24UNEF 12 19,05 1,9 11,6 20,6 26,6 3,05 15,0 38,0 3/4-20UNEF 14 22,23 1,9 11,6 23,0 29,0 3,05 17,9 38,0 7/8-20UNEF 16 25,40 1,9 11,6 24,6 31,3 3,05 21,1 38,0 1-20UNEF 18 28,58 1,9 11,6 27,0 33,7 3,05 24,1 38,0 1-3/16-18UNEF 20 31,75 2,2 14,25 29,4 36,9 3,05 26,5 43,1 1-3/16-18UNEF 22 34,93 2,2 14,25 31,8 40,1 3,05 30,4 43,1 1-7/16-18UNEF 24 38,10 2,2 15,1 34,9 43,3 3,75 32,8 43,1 1-7/16-18UNEF WALL MOUNTING RECEPTACLES KPT00E / KPSE00E (VG95328A) / KPTC0E Description: Wall Mounting Receptacle with pressure nut and grommet seal. Shell size Ø A K M R S Ø T Ø BE LE +0,03 – 0,13 ±0,1 ±0,15 ±0,15 max. ±0,15 max. max. 8 12,00 1,9 11,6 15,1 21,0 3,05 14,2 32,5 10 15,00 1,9 11,6 18,3 24,2 3,05 17,2 32,5 12 19,05 1,9 11,6 20,6 26,6 3,05 20,4 32,5 14 22,23 1,9 11,6 23,0 29,0 3,05 23,4 32,5 16 25,40 1,9 11,6 24,6 31,3 3,05 26,6 32,5 18 28,58 1,9 11,6 27,0 33,7 3,05 29,6 32,5 20 31,75 2,2 14,25 29,4 36,9 3,05 32,8 34,5 22 34,93 2,2 14,25 31,8 40,1 3,05 36,0 34,5 24 38,10 2,2 15,1 34,9 43,3 3,75 39,2 34,5 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 18 www.ittcannon.com

WALL MOUNTING RECEPTACLES KPT00F / KPSE00F (VG95328B) / KPTC0F Description: Wall Mounting Receptacle with endbell, cable clamp and grommet seal. Shell size Ø A K M R S Ø T Ø GF HF LF +0,03 – 0,13 ±0,1 ±0,15 ±0,15 max. ±0,15 min. max. max. 8 12,00 1,9 11,6 15,1 21,0 3,05 2,9 19,3 56,0 10 15,00 1,9 11,6 18,3 24,2 3,05 4,5 20,8 56,0 12 19,05 1,9 11,6 20,6 26,6 3,05 7,7 24,4 56,0 14 22,23 1,9 11,6 23,0 29,0 3,05 9,3 27,2 56,0 16 25,40 1,9 11,6 24,6 31,3 3,05 12,4 28,7 56,0 18 28,58 1,9 11,6 27,0 33,7 3,05 15,6 35,3 56,0 20 31,75 2,2 14,25 29,4 36,9 3,05 15,6 35,3 61,0 22 34,93 2,2 14,25 31,8 40,1 3,05 18,8 39,9 61,0 24 38,10 2,2 15,1 34,9 43,3 3,75 20,1 43,2 61,0 WALL MOUNTING RECEPTACLES KPT0E...DN / KPSE0E...DN / KPTC0E...DN Description: Wall Mounting Receptacle with endbell for heat shrink boot and grommet seal. Ø A K M R S Ø T Ø D2 L1 L2 Shell size +0,03 – 0,13 ±0,1 ±0,15 ±0,15 max. ±0,15 –0,5 max. ±0,5 8 12,00 1,9 11,6 15,1 21,0 3,05 15,6 35,0 12,2 10 15,00 1,9 11,6 18,3 24,2 3,05 18,4 35,0 12,2 12 19,05 1,9 11,6 20,6 26.6 3,05 23,7 35,0 12,2 14 22,23 1,9 11,6 23,0 29,0 3,05 24,5 35,0 12,2 16 25,40 1,9 11,6 24,6 31,3 3,05 29,8 37,0 14,5 18 28,58 1,9 11,6 27,0 33,7 3,05 32,0 37,0 14,5 20 31,75 2,2 14,25 29,4 36,9 3,05 36,1 42,0 15,8 22 34,93 2,2 14,25 31,8 40,1 3,05 38,5 42,0 15,8 24 38,10 2,2 15,1 34,9 43,3 3,75 41,6 42,0 14,9 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 19

WALL MOUNTING RECEPTACLES KPT0E...DZ / KPSE0E...DZ (VG95328R) / KPTC0E…DZ Description: Wall Mounting Receptacle with endbell for heat shrink boot and grommet seal, shielded. Ø A Ø B Ø C Ø D E K L M R S Ø T Shell size +0,03 – 0,13 min. ±0,5 max. ±1,0 ±0,1 max. ±0,15 ±0,15 max. ±0,15 8 12,00 6,6 16,0 13,3 15,0 1,9 52,0 11,6 15,1 21,0 3,05 10 15,00 9,2 18,0 16,1 15,0 1,9 52,0 11,6 18,3 24,2 3,05 12 19,05 12,2 22,0 20,0 17,0 1,9 52,0 11,6 20,6 26,6 3,05 14 22,23 15,2 25,0 22,2 18,0 1,9 53,0 11,6 23,0 29,0 3,05 16 25,40 18,3 28,0 26,2 18,0 1,9 53,0 11,6 24,6 31,3 3,05 18 28,58 20,0 32,0 28,5 18,0 1,9 53,0 11,6 27,0 33,7 3,05 20 31,75 23,0 34,0 32,5 18,0 2,2 58,0 14,25 29,4 36,9 3,05 22 34,93 26,0 38,0 34,8 18,0 2,2 58,0 14,25 31,7 40,1 3,05 24 38,10 28,8 41,0 37,9 18,0 2,2 58,0 15,1 34,9 43,3 3,75 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 20 www.ittcannon.com

CABLE CONNECTING PLUGS KPT01A / KPSE01A / KPTC1A Description: Cable connecting plug with an endbell with thread, no grommet seal. Shell size Ø A K M S Ø Y Ø DA LA VTHD +0,03 – 0,13 ±0,1 ±0,15 max. ±0,15 min. max. Thread Type 2A 8 12,00 1,9 11,6 20,6 23,8 8,5 38,0 1/2-28UNEF 10 15,00 1,9 11,6 23,8 26,9 11,8 38,0 5/8-24UNEF 12 19,05 1,9 11,6 26,15 29,3 15,0 38,0 3/4-20UNEF 14 22,23 1,9 11,6 28,5 31,7 17,9 38,0 7/8-20UNEF 16 25,40 1,9 11,6 30,7 34,1 21,1 38,0 1-20UNEF 18 28,58 1,9 11,6 33,3 36,5 24,1 38,0 1-3/16-18UNEF 20 31,75 2,2 14,25 36,5 39,6 26,5 43,1 1-3/16-18UNEF 22 34,93 2,2 14,25 39,5 42,8 30,4 43,1 1-7/16-18UNEF 24 38,10 2,2 15,1 42,8 46,0 32,8 43,1 1-7/16-18UNEF CABLE CONNECTING PLUGS KPT01E / KPSE01E / KPTC1E Description: Cable connecting plug with pressure nut and grommet seal. Shell size Ø A K M S Ø Y Ø BE LE +0,03 – 0,13 ±0,1 ±0,15 max. ±0,15 max. max. 8 12,00 1,9 11,6 20,6 23,8 14,2 32,5 10 15,00 1,9 11,6 23,8 26,9 17,2 32,5 12 19,05 1,9 11,6 26,15 29,3 20,4 32,5 14 22,23 1,9 11,6 28,5 31,7 23,4 32,5 16 25,40 1,9 11,6 30,7 34,1 26,6 32,5 18 28,58 1,9 11,6 33,3 36,5 29,6 32,5 20 31,75 2,2 14,25 36,5 39,6 32,8 34,5 22 34,93 2,2 14,25 39,5 42,8 36,0 34,5 24 38,10 2,2 15,1 42,8 46,0 39,2 34,5 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 21

CABLE CONNECTING PLUGS KPT01F / KPSE01F / KPTC1F Description: Cable connecting plug with endbell, cable clamp and grommet seal. Shell size Ø A K M S Ø Y Ø GF HF LF +0,03 – 0,13 ±0,1 ±0,15 max. ±0,15 min. max. max. 8 12,00 1,9 11,6 20,6 23,8 2,9 19,3 56,0 10 15,00 1,9 11,6 23,8 26,9 4,5 20,8 56,0 12 19,05 1,9 11,6 26,15 29,3 7,7 24,4 56,0 14 22,23 1,9 11,6 28,5 31,7 9,3 27,2 56,0 16 25,40 1,9 11,6 30,7 34,1 12,4 28,7 56,0 18 28,58 1,9 11,6 33,3 36,5 15,6 35,3 56,0 20 31,75 2,2 14,25 36,5 39,6 15,6 35,3 61,0 22 34,93 2,2 14,25 39,5 42,8 18,8 39,9 61,0 24 38,10 2,2 15,1 42,8 46,0 20,1 43,2 61,0 CABLE CONNECTING PLUGS KPT1E...DN / KPSE1E...DN / KPTC1E...DN Description: Cable connecting plug with endbell for heat shrink boot and grommet seal. Ø A K M S Ø Y Ø D2 L1 L2 Shell size +0,03 – 0,13 ±0,1 ±0,15 max. ±0,15 –0,5 max. ±0,5 8 12,00 1,9 11,6 20,6 23,8 15,6 35,0 12,2 10 15,00 1,9 11,6 23,8 26,9 18,4 35,0 12,2 12 19,05 1,9 11,6 26,15 29,3 23,7 35,0 12,2 14 22,23 1,9 11,6 28,5 31,7 24,5 35,0 12,2 16 25,40 1,9 11,6 30,7 34,1 29,8 37,0 14,5 18 28,58 1,9 11,6 33,3 36,5 32,0 37,0 14,5 20 31,75 2,2 14,25 36,5 39,6 36,1 42,0 15,8 22 34,93 2,2 14,25 39,5 42,8 38,5 42,0 15,8 24 38,10 2,2 15,1 42,8 46,0 41,6 42,0 14,9 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 22 www.ittcannon.com

CABLE CONNECTING PLUGS KPT1E...DZ / KPSE1E...DZ / KPTC1E...DZ Description: Cable connecting plug with endbell for heat shrink boot and grommet seal, shielded. Ø A M Ø B Ø C Ø D E K L S Ø Y Shell size +0,03 – 0,13 ±0,15 min. ±0,5 max. ±1,0 ±0,1 max. max. max. 8 12,00 11,6 6,6 16,0 13,3 15,0 1,9 52,0 18,5 21,0 10 15,00 11,6 9,2 18,0 16,1 15,0 1,9 52,0 23,0 24,2 12 19,05 11,6 12,2 22,0 20,0 17,0 1,9 52,0 29,0 26,6 14 22,23 11,6 15,2 25,0 22,2 18,0 1,9 53,0 29,5 29,0 16 25,40 11,6 18,3 28,0 26,2 18,0 1,9 53,0 32,0 31,3 18 28,58 11,6 20,0 32,0 28,5 18,0 1,9 53,0 35,0 33,7 20 31,75 14,25 23,0 34,0 32,5 18,0 2,2 58,0 38,5 36,9 22 34,93 14,25 26,0 38,0 34,8 18,0 2,2 58,0 42,0 40,1 24 38,10 14,25 28,8 41,0 37,9 18,0 2,2 58,0 46,0 43,3 BOX MOUNTING RECEPTACLES KPT02E (VG95328H) / KPSE02E (VG95328C) / KPTC2E Description: box mounting receptacle with through holes in flange. KPT / KPSE / KPTC KPT / KPTC Ø A L Ø N K M R S Ø T Z Shell size +0,03 – 0,13 max. max. ±0,1 ±0,15 ±0,15 max. ±0,15 max. 8 12,00 21,1 11,1 1,9 11,6 15,1 21,0 3,05 12,3 10 15,00 21,1 14,3 1,9 11,6 18,3 24,2 3,05 12,3 12 19,05 21,1 17,5 1,9 11,6 20,6 26,6 3,05 12,3 14 22,23 21,1 20,6 1,9 11,6 23,0 29,0 3,05 12,3 16 25,40 21,1 23,8 1,9 11,6 24,6 31,3 3,05 12,3 18 28,58 21,1 27,0 1,9 11,6 27,0 33,7 3,05 12,3 20 31,75 22,7 30,2 2,2 14,25 29,4 36,9 3,05 10,8 22 34,93 22,7 33,4 2,2 14,25 31,8 40,1 3,05 10,8 24 38,10 22,7 36,5 2,2 15,1 34,9 43,3 3,75 10,0 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 23

THRU-BULKHEAD RECEPTACLES KPTB (VG95328P) Description: Bulkhead receptacle with mounting flange – with through holes. Socket on Pin on this side this side INSERT:For example: KPTB14-19PS Ø A K L M T R S Ø X Shell size +0,03 – 0,13 ±0,1 max ±0,25 max ±0,15 max. ±0,5 8 12,00 1,8 28,6 14,5 6,0 15,1 21,0 3,05 10 15,00 1,8 28,6 14,5 6,0 18,3 24,2 3,05 12 19,05 1,8 28,6 14,5 6,0 20,6 26,6 3,05 14 22,23 1,8 28,6 14,5 6,0 23,0 29,0 3,05 16 25,40 1,8 28,6 14,5 6,0 24,6 31,3 3,05 18 28,58 1,8 28,6 14,5 6,0 27,0 33,7 3,05 20 31,75 2,5 31,9 17,7 9,2 29,4 36,9 3,05 22 34,93 2,5 31,9 17,7 9,2 31,8 40,1 3,05 24 38,10 2,5 31,9 17,7 8,0 34,9 43,3 3,75 STRAIGHT PLUGS KPT06A / KPSE06A / KPTC6A Description: Straight plug with an endbell with thread, no grommet seal. Shell size Ø G Ø DA LA VTHD max. min. max. Thread Type 2A 8 19,8 8,5 42,0 1/2-28UNEF 10 23,6 11,8 42,0 5/8-24UNEF 12 26,5 15,0 42,0 3/4-20UNEF 14 30,1 17,9 42,0 7/8-20UNEF 16 33,2 21,1 42,0 1-20UNEF 18 35,4 24,1 42,0 1-3/16-18UNEF 20 39,0 26,5 45,0 1-3/16-18UNEF 22 42,1 30,4 45,0 1-7/16-18UNEF 24 45,2 32,8 45,0 1-7/16-18UNEF Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 24 www.ittcannon.com

STRAIGHT PLUGS KPT06E / KPSE06E / KPTC6E Description: Straight plug with pressure nut and grommet seal. Shell size Ø G Ø BE LE max. max. max. 8 19,8 14,2 32,5 10 23,6 17,2 32,5 12 26,5 20,4 32,5 14 30,1 23,4 32,5 16 33,2 26,6 32,5 18 35,4 29,6 32,5 20 39,0 32,8 34,5 22 42,1 36,0 34,5 24 45,2 39,2 34,5 STRAIGHT PLUGS KPT06F / KPSE06F (VG95328K) / KPTC6F Description: Straight plug with endbell, cable clamp and grommet seal. Shell size Ø G Ø GF HF LF max. min. max. max. 8 19,8 2,9 19,3 56,0 10 23,6 4,5 20,8 56,0 12 26,5 7,7 24,4 56,0 14 30,1 9,3 27,2 56,0 16 33,2 12,4 28,7 59,0 18 35,4 15,6 35,3 59,0 20 39,0 15,6 35,3 59,0 22 42,1 18,8 39,9 59,0 24 45,2 20,1 43,2 59,0 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 25

STRAIGHT PLUGS KPT6E...DN / KPSE6E...DN(VG95328J) / KPTC6E...DN Description: Straight plug with endbell for heat shrink boot and grommet seal. Ø G Ø D2 L1 L2 Shell size max. –0,5 max. ±0,5 8 19,8 15,6 35,0 12,2 10 23,6 18,4 35,0 12,2 12 26,5 23,7 35,0 12,2 14 30,1 24,5 35,0 12,2 16 33,2 29,8 37,0 14,5 18 35,4 32,0 37,0 14,5 20 39,0 36,1 42,0 15,8 22 42,1 38,5 42,0 15,8 24 45,2 41,6 42,0 14,9 STRAIGHT PLUGS KPT6E...DZ / KPSE6E...DZ (VG95328M) / KPTC6E…DZ Description: Straight plug with endbell for heat shrink boot and grommet seal, shielded. Ø B Ø C Ø G Ø D E L S Shell size min. +0,5 max. max. 1,0 max. +0,2 8 6,6 16,0 19,1 13,3 15,0 48,0 17,00 10 9,2 18,0 22,0 16,1 15,0 48,0 19,00 12 12,2 22,0 26,2 20,0 17,0 48,0 23,00 14 15,2 25,0 29,4 22,2 18,0 49,0 26,00 16 18,3 28,0 32,8 26,2 18,0 49,0 29,00 18 20,0 32,0 35,4 28,5 18,0 49,0 33,00 20 23,0 34,0 39,0 32,5 18,0 53,0 35,00 22 26,0 38,0 42,1 34,8 18,0 53,0 39,00 24 28,8 41,0 45,2 37,9 18,0 53,0 42,00 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 26 www.ittcannon.com

STRAIGHT PLUG KPT6PG / KPTC6PG Description: Straight plug with adapter for PG gland nut. Gland nut is not included. Shell size mØa Gx. mØa Bx. mCin. mLPaGx. PGTHD 10 23,6 19,0 10,5 58,5 PG 09 12 26,5 22,5 10,5 58,5 PG 11 14 30,1 25,0 10,5 58,5 PG 13,5 16 33,2 28,0 10,5 73,0 PG 16 18 35,4 32,5 11,5 73,0 PG 21 20 39,0 34,5 11,5 76,0 PG 21 22 42,1 38,0 11,5 82,0 PG 21 24 45,2 40,5 11,5 82,0 PG 29 STRAIGHT PLUG KPT6ME / KPTC6ME Description: Straight plug with adapter for ME gland nut. Gland nut is not included. Shell size Ø G Ø B C LME Metric Thread max. max. min. max. 10 23,6 19,0 10,5 58,5 M 12 x 1,5 12 26,5 22,5 10,5 58,5 M 16 x 1,5 14 30,1 25,0 10,5 58,5 M 20 x 1,5 16 33,2 28,0 10,5 73,0 M20 x 1,5 18 35,4 32,5 11,5 73,0 M 25 x 1,5 20 39,0 34,5 11,5 76,0 M 25 x 1,5 22 42,1 38,0 11,5 82,0 M 32 x 1,5 24 45,2 40,5 11,5 82,0 M 32 x 1,5 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 27

JAM NUT RECEPTACLES KPT07A / KPTC7A Description: Jam nut receptacle without endbell. Shell size Ø A F H K M RTHD S T Panel Thickness Ø N Z +0,03 – 0,13 ±0,15 ±0,15 ±0,25 ±0,15 Thread Type 2A max. min. max. max. max. 8 12,00 13,3 19,0 3,2 17,7 9/16-24UNEF 24,0 1,6 3,5 28,0 7,9 10 15,00 16,5 22,2 3,2 17,7 11/16-24UNEF 27,0 1,6 3,5 31,0 7,9 12 19,05 20,6 27,0 3,2 17,7 7/8-20UNEF 32,0 1,6 3,5 36,0 7,9 14 22,23 23,8 30,2 3,2 17,7 1-20UNEF 35,0 1,6 3,5 39,0 7,9 16 25,40 26,9 33,3 3,2 17,7 1-1/8-18UNEF 38,5 1,6 3,5 42,0 7,9 18 28,58 30,1 36,5 3,2 17,7 1-1/4-18UNEF 41,5 1,6 3,5 45,0 7,9 20 31,75 33,3 39,7 4,0 22,5 1-3/8-18UNEF 46,0 1,6 6,5 50,0 4,7 22 34,93 36,5 42,9 4,0 22,5 1-1/2-18UNEF 49,5 1,6 6,5 55,0 4,7 24 38,10 39,6 46,0 4,0 23,3 1-5/8-18UNEF 52,5 1,6 6,5 57,0 3,8 JAM NUT RECEPTACLES KPT07E / KPSE07E (VG95328D) / KPTC7E Description: Jam nut receptacle with pressure nut and grommet seal. Shell size Ø A F H K M RTHD S T Panel Thickness Ø N Ø BE LE +0,03 – 0,13 ±0,15 ±0,15 ±0,25 ±0,15 Thread Type 2A max. min. max. max. max. max. 8 12,00 13,3 19,0 3,2 17,7 9/16-24UNEF 24,0 1,6 3,5 28,0 18,2 33,5 10 15,00 16,5 22,2 3,2 17,7 11/16-24UNEF 27,0 1,6 3,5 31,0 21,5 33,5 12 19,05 20,6 27,0 3,2 17,7 7/8-20UNEF 32,0 1,6 3,5 36,0 24,6 33,5 14 22,23 23,8 30,2 3,2 17,7 1-20UNEF 35.0 1,6 3,5 39,0 27,8 33,5 16 25,40 26,9 33,3 3,2 17,7 1-1/8-18UNEF 38,5 1,6 3,5 42,0 31,0 33,5 18 28,58 30,1 36,5 3,2 17,7 1-1/4-18UNEF 41,5 1,6 3,5 45,0 34,1 33,5 20 31,75 33,3 39,7 4,0 22,5 1-3/8-18UNEF 46,0 1,6 6,5 50,0 38,1 39,0 22 34,93 36,5 42,9 4,0 22,5 1-1/2-18UNEF 49,5 1,6 6,5 55,0 41,3 39,0 24 38,10 39,6 46,0 4,0 23,3 1-5/8-18UNEF 52,5 1,6 6,5 57,0 44,5 39,0 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 28 www.ittcannon.com

JAM NUT RECEPTACLES KPT07F / KPSE07F (VG95328E) / KPTC7F Description: Jam nut receptacle with endbell, cable clamp and grommet seal. Shell size Ø A F H K M RTHD S T Panel Thickness Ø N LF Ø GF HF +0,03 – 0,13 ±0,15 ±0,15 ±0,25 ±0,15 Thread Type 2A max. min. max. max. max. max. max. 8 12,00 13,3 19,0 3,2 17,7 9/16-24UNEF 24,0 1,6 3,5 28,0 44,9 2,9 19,3 10 15,00 16,5 22,2 3,2 17,7 11/16-24UNEF 27,0 1,6 3,5 31,0 44,9 4,5 20,8 12 19,05 20,6 27,0 3,2 17,7 7/8-20UNEF 32,0 1,6 3,5 36,0 44,9 7,7 24,4 14 22,23 23,8 30,2 3,2 17,7 1-20UNEF 35,0 1,6 3,5 39,0 44,9 9,3 27,2 16 25,40 26,9 33,3 3,2 17,7 1-1/8-18UNEF 38,5 1,6 3,5 42,0 48,4 12,4 28,7 18 28,58 30,1 36,5 3,2 17,7 1-1/4-18UNEF 41,5 1,6 3,5 45,0 48,4 15,6 35,3 20 31,75 33,3 39,7 4,0 22,5 1-3/8-18UNEF 46,0 1,6 6,5 50,0 50,3 15,6 35,3 22 34,93 36,5 42,9 4,0 22,5 1-1/2-18UNEF 49,5 1,6 6,5 55,0 50,3 18,8 39,9 24 38,10 39,6 46,0 4,0 23,3 1-5/8-18UNEF 52,5 1,6 6,5 57,0 50,3 20,1 43,2 JAM NUT RECEPTACLES KPT7E...DN / KPSE7E...DN (VG95328S) / KPTC7E…DN Description: Jam nut receptacle with endbell for heat shrink boot and grommet seal. Shell size Ø A F H K M RTHD S T Panel Thickness Ø N L1 L2 Ø D2 +0,03 – 0,13 ±0,15 ±0,15 ±0,25 ±0,15 Thread Type 2A max. min. max. max. max. ±0,15 max. 8 12,00 13,3 19,0 3,2 17,7 9/16-24UNEF 24,0 1,6 3,5 28,0 43,0 12,2 15,6 10 15,00 16,5 22,2 3,2 17,7 11/16-24UNEF 27,0 1,6 3,5 31,0 43,0 12,2 18,4 12 19,05 20,6 27,0 3,2 17,7 7/8-20UNEF 32,0 1,6 3,5 36,0 43,0 12,2 23,7 14 22,23 23,8 30,2 3,2 17,7 1-20UNEF 35,0 1,6 3,5 39,0 43,0 12,2 24,5 16 25,40 26,9 33,3 3,2 17,7 1-1/8-18UNEF 38,5 1,6 3,5 42,0 45,5 14,5 29,8 18 28,58 30,1 36,5 3,2 17,7 1-1/4-18UNEF 41,5 1,6 3,5 45,0 45,5 14,5 32,0 20 31,75 33,3 39,7 4,0 22,5 1-3/8-18UNEF 46,0 1,6 6,5 50,0 52,6 15,8 36,1 22 34,93 36,5 42,9 4,0 22,5 1-1/2-18UNEF 49,5 1,6 6,5 55,0 52,6 15,8 38,5 24 38,10 39,6 46,0 4,0 23,3 1-5/8-18UNEF 52,5 1,6 6,5 57,0 51,6 14,9 41,6 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 29

JAM NUT RECEPTACLES KPT7E...DZ / KPSE7E...DZ / KPTC7E...DZ Description: Jam nut receptacle with endbell for heat shrink boot and grommet seal, shielded. Ø A Ø B Ø C Ø D E L S T Shell size min. +0,5 max. max. ±1,0 max. ±0,25 ±0,25 8 6,6 16,0 18,2 13,3 15,0 47,0 23,0 19,0 10 9,2 18,0 21,4 16,1 15,0 47,0 27,0 22,2 12 12,2 22,0 24,6 20,0 17,0 49,0 31,7 27,0 14 15,2 25,0 27,8 22,2 18,0 50,0 34,9 30,2 16 18,3 28,0 30,9 26,2 18,0 50,0 38,1 33,3 18 20,0 32,0 34,1 28,5 18,0 50,0 41,3 36,5 20 23,0 34,0 38,1 32,5 18,0 55,0 46,0 39,7 22 26,0 38,0 41,3 34,8 18,0 55,0 49,2 42,9 24 28,8 41,0 44,4 37,9 18,0 55,0 52,3 46,0 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 30 www.ittcannon.com

RIGHT ANGLE PLUG KPT08A / KPSE08A / KPTC8A Description: Plug with 90° endbell without cable clamp, no grommet seal. Shell size Ø G LA DA VTHD max. max. max. Thread Type 2A 8 19,8 36,1 20,9 1/2-28UNEF 10 23,6 38,3 21,7 5/8-24UNEF 12 26,5 40,9 23,3 3/4-20UNEF 14 30,1 41,6 24,9 7/8-20UNEF 16 33,2 42,5 26,5 1-20UNEF 18 35,4 44,7 28,1 1-3/16-18UNEF 20 39,0 48,3 29,6 1-3/16-18UNEF 22 42,1 52,1 31,7 1-7/16-18UNEF 24 45,2 52,1 33,6 1-7/16-18UNEF RIGHT ANGLE PLUG KPT08E / KPSE08E / KPTC8E Description: Plug with 90° endbell without cable clamp, with grommet seal. Shell size Ø G LE DE VTHD max. max. max. Thread Type 2A 8 19,8 36,1 20,9 1/2-28UNEF 10 23,6 38,3 21,7 5/8-24UNEF 12 26,5 40,9 23,3 3/4-20UNEF 14 30,1 41,6 24,9 7/8-20UNEF 16 33,2 42,5 26,5 1-20UNEF 18 35,4 44,7 28,1 1-3/16-18UNEF 20 39,0 48,3 29,6 1-3/16-18UNEF 22 42,1 52,1 31,7 1-7/16-18UNEF 24 45,2 52,1 33,6 1-7/16-18UNEF RIGHT ANGLE PLUG KPT08F / KPSE08F / KPTC8F Description: Plug with 90° endbell with cable clamp and grommet seal. Shell size Ø G L DF LF max. max. max. max. 8 19,8 47,0 31,4 36,1 10 23,6 49,5 32,2 38,3 12 26,5 53,5 35,4 40,9 14 30,1 55,5 38,6 41,6 16 33,2 57,0 40,2 42,5 18 35,4 62,5 41,8 44,7 20 39,0 67,0 43,4 48,3 22 42,1 71,5 47,9 52,1 24 45,2 74,0 49,9 52,1 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 31

BOX MOUNTING RECEPTACLE KPT2 / KPTC2 … EX OR EW Description: Box mounting receptacle with PCB solder pins: EX – PCB solder pin 0,76 x 7mm EW – PCB solder pin 0,6 x 7mm Ø A K L M Ø N R S Ø T Shell size +0,03 – 0,13 ±0,1 max. ±0,15 max. ±0,15 max. ±0,15 8 12,00 1,9 21,1 11,60 11,1 15,1 21,0 3,05 10 15,00 1,9 21,1 11,60 14,3 18,3 24,2 3,05 12 19,05 1,9 21,1 11,60 17,5 20,6 26,6 3,05 14 22,23 1,9 21,1 11,60 20,6 23,0 29,0 3,05 16 25,40 1,9 21,1 11,60 23,8 24,6 31,3 3,05 18 28,58 1,9 21,1 11,60 27,0 27,0 33,7 3,05 20 31,75 2,2 22,7 14,25 30,2 29,4 36,9 3,05 22 34,93 2,2 22,7 14,25 33,4 31,7 40,1 3,05 24 38,10 2,2 22,7 15,10 36,5 34,9 43,3 3,75 JAM NUT RECEPTACLES KPT7 / KPTC7 …EX OR EW Description: Jam nut receptacle with PCB solder pins: EX – PCB solder pin 0,76 x 7mm EW – PCB solder pin 0,6 x 7mm Shell size Ø A F H K M RTHD S T (Panel Thickness) Ø N +0,03 – 0,13 ±0,15 ±0,15 ±0,25 ±0,15 Thread Type 2A ±0,5 min. max. max. 8 12,0 13,3 19,0 3,2 17,7 9/16-24UNEF 24,0 1,6 3,5 28,0 10 15,0 16,5 22,2 3,2 17,7 11/16-24UNEF 27,0 1,6 3,5 31,0 12 19,1 20,6 27,0 3,2 17,7 7/8-20UNEF 32,0 1,6 3,5 36,0 14 22,2 23,8 30,2 3,2 17,7 1-20UNEF 35,0 1,6 3,5 39,0 16 25,4 26,9 33,3 3,2 17,7 1-1/8-18UNEF 38,5 1,6 3,5 42,0 18 28,6 30,1 36,5 3,2 17,7 1-1/4-18UNEF 41,5 1,6 3,5 45,0 20 31,8 33,3 39,7 4,0 22,5 1-3/8-18UNEF 46,0 1,6 6,5 50,0 22 34,9 36,5 42,9 4,0 22,5 1-1/2-18UNEF 49,5 1,6 6,5 55,0 24 38,1 39,6 46,0 4,0 23,3 1-5/8-18UNEF 52,5 1,6 6,5 57,0 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 32 www.ittcannon.com

PROTECTIVE CAPS KPT / KPSE / KPTC HOW TO ORDER KPT80- 10 D- A34 KPTC80- 10 C- C Series Series KPT80 – for plug KPTC80 – for plug KPT81 – for receptacle KPTC81 – for receptacle Shell size Shell size 8 – 24 8 – 24 Termination Termination D – Nylon cord 400 mm C – Nylon cord and endlink Clip and end link attached (not assembled) N - Nylon cord with ring (KPTC81 only) Crimp tool for end link: M317 (selector position 6) C – sash chain and terminal link Modification CB – Nylon cord and terminal link C – Nickel plated (RoHS compliant) N – chain with ring (KPT81 only) D – Cadmium plated NB – Nylon cord with ring (KPT81 only) R – Zinc cobalt, black (RoHS compliant) F – Zinc cobalt, green (RoHS compliant) Modification H – Zinc nickel plating (RoHS compliant) A34 – Nickel plated (RoHS compliant) A232 – Zinc cobalt, black (RoHS compliant) A233 – Zinc cobalt, green (RoHS compliant) A240 – Zinc nickel plating (RoHS compliant) VG95328 Z2 C 10 (without code) – Olive drab chromate over cadmium VG Specification Style Z1 – for receptacle Z2 – for plug Z3 – for jam nut receptacle Termination A – chain and terminal link B - for Z1 and Z2: Nylon cord and terminal link C – for Z1 and Z2: Nylon cord 400 mm and end link Clip and end link attached (not mounted) Crimp tool for end link: M317 (selector position 6) C – for Z3: Nylon cord with ring Shell size 8 – 24 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 33

PROTECTIVE CAPS KPT / KPSE / KPTC Cap with end link (not assembled) For receptacle For plug KPT81 termination D KPT80 termination D VG95328 Z1 termination C VG95328 Z2 termination C Cap with terminal link For receptacle For plug KPT81 termination C (with chain) and CB (with nylon cord) KPT80 termination C (with chain) and CB (with nylon cord) VG95328 Z1 termination A (with chain) VG95328 Z2 termination A (with chain) Cap with ring For receptacle KPT81 termination N (with chain) and NB (with nylon chord) VG95328 Z3 termination C (with nylon cord) Shell size Ø A L1 Ø B L2 H Ø N max. max. max. max. max. ±0,5 8 18,26 19,84 18,0 21,44 76 14,7 10 21,44 19,84 20,3 21,44 76 17,9 12 25,40 19,84 25,1 21,44 89 22,6 14 28,58 19,84 28,2 21,44 89 25,8 16 31,75 19,84 31,5 21,44 89 29,0 18 34,92 19,84 34,5 21,44 89 32,2 20 38,10 21,44 37,8 21,44 101 35,3 22 41,28 21,44 40,9 21,44 101 38,5 24 44,45 22,22 44,2 22,22 101 41,7 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 34 www.ittcannon.com

DUMMY RECEPTACLES KPT/KPSE/KPTC HOW TO ORDER Below the order reference for Dummy Receptacles KPT series (can be mated with KPSE or KPTC connectors) and separately for VG95328. The table contains the available shell sizes with their respective dimensions. KPT 15- 8 A VG95328 T07 C 8 Series Series Dummy receptacle Dummy receptacle Shell size Style (back side closed) Flange Shell size A – Standard Ø A K M R S Ø T Shell size +0,03 – 0,13 ±0,4 ±0,15 ±0,15 max. ±0,15 KPT-15-8 A 12,00 1,6 12,1 15,1 21,0 3,05 KPT-15-10 A 15,00 1,6 12,1 18,3 24,2 3,05 KPT-15-12 A 19,05 1,6 12,1 20,6 26,6 3,05 KPT-15- 14 A 22,23 1,6 12,1 23,0 29,0 3,05 KPT-15-16 A 25,40 1,6 12,1 24,6 31,3 3,05 KPT-15-18 A 28,58 1,6 12,1 27,0 33,7 3,05 KPT-15- 20 A 31,75 2,4 14,5 29,4 36,9 3,05 KPT-15- 22 A 34,93 2,4 14,5 31,8 40,1 3,05 KPT-15-24 A 38,10 2,4 15,4 34,9 43,3 3,75 GASKETS Shell Size Alu-Flex Conductive Chloroprene non conductive Shell Size Alu-Flex Conductive Chloroprene non conductive 8 075-8543-000 075-8543-010 18 075-8543-005 075-8543-015 10 075-8543-001 075-8543-011 20 075-8543-006 075-8543-016 12 075-8543-002 075-8543-012 22 075-8543-007 075-8543-017 14 075-8543-003 075-8543-013 24 075-8543-008 075-8543-018 16 075-8543-004 075-8543-014 WIRE HOLE FILLERS Contact Size Colour code Cannon 20 Red 225-1012-000 16 Blue 225-1011-000 12* Yellow 225-0072-000 Coaxial 14a4* Yellow 225-0018-000 *KPSE only Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 35

CROSS REFERENCE LIST KPT / KPSE / VG95328 / MIL-C-26482 All three product lines have specific characteristics and provide a set of unique variants, however, all lines are fully intermateable with each other as well as any other connector series designed according to MIL-DTL 26482 Series I or VG95238 standards. Solder Crimp ITT Cannon MIL-DTL-26482-Style VG95328 ITT Cannon MIL-DTL-26482-Style VG95328 KPT00E MS3110E KPSE00E MS3120E VG95328A KPT00F MS3110F KPSE00F MS3120F VG95328B KPT0E-DN KPSE0E-DN KPT0E-DZ KPSE0E-DZ VG95328R KPT01A KPSE01A KPT01E MS3111E KPSE01E MS3121E KPT01F MS3111F KPSE01F MS3121F KPT1E-DN KPSE1E-DN KPT1E-DZ KPSE1E-DZ KPT02E MS3112E VG95328H KPSE02E MS3122E VG95328C KPT06A KPSE06A KPT06E MS3116E KPSE06E MS3126E KPT06F MS3116F KPSE06F MS3126F VG95328K KPT6E-DN KPSE6E-DN VG95328J KPT6E-DZ KPSE6E-DZ VG95328M KPT07A KPSE07A KPT07E MS3114E KPSE07E MS3124E VG95328D KPT07F MS3114F KPSE07F MS3124F VG95328E KPT7E-DN KPSE7E-DN VG95328S KPT7E-DZ KPSE7E-DZ KPT08E KPSE08E KPT08F KPSE08F KPTB MS3119 VG95328P CROSS REFERENCE LIST PROTECTIVE CAPS KPT / VG95328 / MIL-C-26482 This table shows which commercial protective caps are available per VG95328. Additionally, it can be used when cross-referencing a MS protective cap for a KPT (ITT Cannon) substitute. Part No. Part No. Part No. ITT Cannon MIL-DTL-26482-Style VG95328 KPT80..C MS3180..C VG95328Z2A.. KPT80..CB VG95328Z2B.. KPT80..D VG95328Z2C.. KPT81..C MS3181..C VG95328Z1A.. KPT81..CB VG95328Z1B.. KPT81..D VG95328Z1C.. KPT81..N MS3181..N KPT81..NB VG95328Z3C.. Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 36 www.ittcannon.com

TOOLS AND ACCESSORIES KPT / KPSE / KPTC Hand crimping tool M22520/1-01 and Locator: Order No.: 995-0001-585 This universal tool features just one crimp locator with different adjustments for crimping contacts. The tool provides an 8-indent crimp. Note: The locator needs to be purchased separately: Descripton Locator Name Order-No. Contact Size 12 M22520/1-02 Locator 995-0001-736 16 20 M22520/1-01 Hand Crimp Tool 995-0001-585 Pneumatic crimping tool WA27F-CE: Pneumatic operated crimp tool for higher volume production. A pedal for foot operation can also be provided. The tool provides an 8-indent crimp equivalent to hand crimping tool. Gauge Crimp tool and Bench mount Foot pedal Description Name Order No. Pneumatic crimp tool (AWG12-20) WA27F-CE 121586-5067 Bench mount BM-2A 121586-5068 Foot pedal WA10A 121586-5069 Gauge M22520-3-1 995-0001-684 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 37

Insertion Tools To insert crimped contacts into the insulator insertion tools are required. KPSE Description Name Order No. insertion tool for contact size # 20 MS24256-A20 995-0001-950 Insertion Tool insertion tool for contact size # 16 MS24256-A16 995-0001-951 insertion tool for contact size # 12 MS24256-A12 995-0001-913 KPTC Description Name Order No. Insertion Tool insertion tool for contact size # 20 CITG-20A 121086-3104 insertion pliers for contact size # 20 CIT-KPTC-20 121086-3101 insertion tool for contact size # 16 CIT-16 121086-3008 CIT-KPTC-20 insertion pliers for contact size # 16 CIT-F80-16 121086-0097 insertion TIP for insertion tool # 20 CITG-20A-TIP 121086-3105 insertion TIP for insertion tool # 16 CIT-16-TIP 317-1153-000 CIT-F80-16 Extraction Tools In case a contact has to be exchanged the following extraction tools are to be used: KPSE Description Name Order No. Replacement-TIP extraction tool for contact size # 20 MS24256-R20 995-0001-965 317-7130-000 Extraction tool extraction tool for contact size # 16 MS24256-R16 995-0001-964 317-7129-000 extraction tool for contact size # 12 MS24256-R12 995-0001-966 317-7131-000 extraction tool for coax contacts (KPT14A4) CET-C6B 070064-0000 121586-0046 Extraction tool for coax contacts KPTC Description Name Order No. Replacement-TIP extraction tool for contact size # 20 CET-KPTC-20 121086-3212 317-8668-000 Extraction tool extraction tool for contact size # 16 CET-KPTC-16 121086-3277 317-8649-025 Notes 1. For insertion and extraction of the contacts and for connector assembly, see Assembly Instructions CAS25098E Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 38 www.ittcannon.com

Pipe Wrench Soft Jaw Adjustable Pliers for tightening the endbell housing. Order No.: 550014-1644 Dimensions for Single Conductor and Wire Stripping In order to assure proper function according to connector specification, especially concerning water tightness, the diameter of the wire insulation must correlate with the following data: KPSE KPTC Insulation dimensions Insulation dimensions Contact Size Conductor dimensions Contact Size Conductor dimensions Waterproof / Ø mm Waterproof / Ø mm AWG mm² min. max. AWG mm² min. max. 20 24 - 18 0,2 – 0,75 1.3 2.1 20 24 - 18 0,2 – 0,75 1.4 2.15 16 20 - 14 0,5 – 2,0 1.8 2.7 16 20 - 14 0,5 – 2,0 1.6 2.7 12 14 - 12 - 2.5 3.4 Contacts KPTC Contact Termination For shell size 8 and contact layout 12 – 14 only Contact type size AWG mm² Contact order reference Contact order reference 20 28 - 24 0,08 – 0,20 Pin 430-8588-029 Gold plating Silver plating Socket 031-8704-508 031-8704-509 031-8704-506 20 24 – 18 0,20 – 0,75 Pin 430-8560-404 430-8560-411 430-8560-410 Socket 430-8588-031 - - 20 - 0,5 – 1,0 Pin 430-8588-030 - - Socket 031-8704-502 - - 16 20– 14 0,5 – 2,0 Pin 430-8560-406 - - KPSE / VG95328 Termination Contact order reference Contact size Contact type AWG mm² KPSE version VG95328 version Socket with insulation support 031-8704-203 031-8704-203 20 24 - 18 0,2 - 0,75 Pin with insulation support 430-8560-006 430-8560-006 Socket 031-8704-000 031-8704-000 16 20 - 14 0,5 - 2,0 Pin 430-8560-004 430-8560-004 Socket 031-8704-012 - 12 14 - 12 2,0 Pin 430-8560-016 - Grounding Pin 430-8560-020 - KPT14A4 Termination Contact order Contact size Contact type Cable type reference Receptacle DM 53742-5001 Coaxial RG187/U, RG188/U Plug DM 53740-5001 Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 39

PRODUCT SAFETY INFORMATION 1. MATERIAL CONTENT AND PHYSICAL FORM to be damaged. Electrical connectors do not usually contain hazardous materials. 4. DISPOSAL They contain conducting and non-conducting materials and can be Incineration of certain materials may release noxious or even divided into two groups. toxic fumes. a) Printed circuit types and low cost audio types which employ all plastic insulators and casings. 5. APPLICATION b) Rugged, Fire Barrier and High Reliability types with metal casings Connectors with exposed contacts should not be selected for use on and either natural rubber, synthetic rubber, plastic or glass the current supply side of an electrical circuit, because an electric insulating materials. Contact materials vary with type of connector shock could result from touching exposed contacts on an unmated and also application and are usually manufactured from either: connector. Voltages in excess of 30 V ac or 42.5 V DC are Copper, copper alloys, nickel, alumel, chromel or steel. In special potentially hazardous and care should be taken to ensure that such applications, other alloys may be specified. voltages cannot be transmitted in any way to exposed metal parts of the connector body. The connector and wiring should be checked, before making live, to have no damage to metal parts or insulators, no solder blobs, loose strands, conducting lubricants, swarf, or any other undesired conducting particles. Circuit resistance and continuity check should be made to make certain 2. FIRE CHARACTERISTICS AND ELECTRIC SHOCK HAZARD that there are no high resistance joints or spurious conducting There is no fire hazard when the connector is correctly wired and paths. Always use the correct application tools as specified in the used within the specified parameters. Data Sheet/Catalog. Do not permit untrained personnel to wire, assemble or tamper with connectors. For operation voltage please Incorrect wiring or assembly of the connector or careless use of see appropriate national regulations. metal tools or conductive fluids, or transit damage to any of the component parts may cause electric shock or burns. Live circuits must not be broken by separating mated connectors as this may IMPORTANT GENERAL INFORMATION cause arcing, ionization and burning. Heat dissipation is greater at (i) Air and creepage paths/Operating voltage. The admissible maximum resistance in a circuit. Hot spots may occur when operating voltages depend on the individual applications and the resistance is raised locally by damage, e.g. cracked or deformed valid national and other applicable safety regulations. For this contacts, broken strands of wire. Local overheating may also result reason the air and creepage path data are only reference values. from the use of the incorrect application tools or from poor quality Observe reduction of air and creepage paths due to PC board and/ soldering or slack screw terminals. or harnessing. Overheating may occur if the ratings in the product Data Sheet/ (ii) Temperature Catalog are exceeded and can cause breakdown of insulation and hence electric shock. If heating is allowed to continue it intensifies All information given are temperature limits. The operation by further increasing the local resistance through loss of temper of temperature depends on the individual application. spring contacts, formation of oxide film on contacts and wires and (iii) Other important information leakage currents through carbonization of insulation and tracking Cannon continuously endeavors to improve their products. paths. Fire can then result in the presence of combustible materials Therefore, Cannon products may deviate from the description, and this may release noxious fumes. Overheating may not be technical data and shape as shown in this catalog and data sheets. visually apparent. Burns may result from touching overheated ITT Cannon manufactures the highest quality products available in components. the marketplace; however these products are intended to be used in accordance with the specifications in this publication. Any use or 3. HANDLING application that deviates from the stated operating specifications is Care must be taken to avoid damage to any component parts of not recommended and may be unsafe. No information and data electrical connectors during installation and use. Although there are contained in this publication shall be construed to create any normally no sharp edges, care must be taken when handling certain liability on the part of Cannon. Any new issue of this publication components to avoid injury to fingers. shall automatically invalidate and supersede any and all previous issues. Electrical connectors may be damaged in transit to the customers, and damage may result in creation of hazards. Products should therefore be examined prior to installation/use and rejected if found Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 40 www.ittcannon.com

Amazing things happen when great things connect www.ittcannon.com 41

Notes _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products 42 www.ittcannon.com

Notes _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ _____________________________________________________________________________________________________________________ Dimensions shown in mm | Specifications and dimensions subject to change This document solely applies to European manufactured KPT / KPSE / KPTC products www.ittcannon.com 43

Connect with your ITT Cannon representative today or visit us at www.ittcannon.com Connect with the experts ITT's Cannon brand is a world leader in the design and manufacture of highly engineered connector solutions for multiple end markets. North America Europe Asia 56 Technology Drive Corso Europa 41/43 Cannonstrasse 1 Tuopandun Industrial Area, Jinda Cheng, Irvine, CA 92618 USA 20020 Lainate (MI), Italy 71384 Weinstadt, Germany Xiner Village, Shajing Town, Boan District, Phone: +1.800.854.3028 Phone: +39.02938721 Phone: +49.7151.699.0 Shenzhen City, Guangdong Province, China 518215 Phone: +86.755.2726.7888 The “ITT Engineered Blocks“ symbol, “Engineered for life”, “ITT” and “Cannon“ are registered trademarks of ITT Inc. © 2019 ITT Inc. Specification and other data are based on information available at the time of printing, and are subject to change without notice. ITT Cannon KPx Catalog 022019

Datasheet下载

Datasheet下载