ICGOO在线商城 > 传感器,变送器 > 光学传感器 - 环境光,IR,UV 传感器 > ISL29038IROZ-T7

- 型号: ISL29038IROZ-T7

- 制造商: Intersil

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

ISL29038IROZ-T7产品简介:

ICGOO电子元器件商城为您提供ISL29038IROZ-T7由Intersil设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 ISL29038IROZ-T7价格参考。IntersilISL29038IROZ-T7封装/规格:光学传感器 - 环境光,IR,UV 传感器, Optical Sensor Ambient I²C 8-VFDFN Exposed Pad。您可以下载ISL29038IROZ-T7参考资料、Datasheet数据手册功能说明书,资料中有ISL29038IROZ-T7 详细功能的应用电路图电压和使用方法及教程。

ISL29038IROZ-T7 是一款由 Intersil(现已被 Renesas 收购)生产的高精度、低功耗的数字输出环境光传感器 (ALS) 和接近传感器。它广泛应用于各种需要检测环境光线强度和物体接近情况的设备中,尤其适合对功耗敏感的便携式电子设备。 应用场景 1. 智能手机和平板电脑: ISL29038IROZ-T7 可用于自动调节屏幕亮度,以适应不同的环境光条件,从而提高用户体验并延长电池寿命。此外,它还可以用于检测手机是否靠近耳朵,以便在通话时关闭触摸屏,防止误触。 2. 智能家居设备: 在智能灯具、智能窗帘等设备中,该传感器可以检测环境光线,实现自动开关或调光功能,提升家居自动化水平。同时,接近检测功能可用于触发其他智能家居设备的动作,如当有人靠近时自动开启灯光或显示面板。 3. 可穿戴设备: 对于智能手表、健身追踪器等可穿戴设备,ISL29038IROZ-T7 的低功耗特性使其成为理想选择。它可以用于检测手腕动作,唤醒设备或调整屏幕亮度,确保设备在不同光照条件下都能提供良好的可视性。 4. 工业自动化: 在工业环境中,该传感器可用于检测物体的存在或位置,帮助实现自动化控制。例如,在流水线上检测产品是否到达指定位置,或者在仓库中检测货物的存放情况。 5. 医疗设备: 在一些医疗设备中,ISL29038IROZ-T7 可用于监测患者的生理信号,如通过检测皮肤反射光来测量心率或血氧饱和度。其高精度和低功耗特性非常适合长时间佩戴的医疗监测设备。 6. 汽车电子: 该传感器可用于汽车内部的自动调光后视镜、仪表盘背光调节等功能,提升驾驶舒适性和安全性。此外,接近检测功能还可用于检测驾驶员是否靠近车辆,实现自动解锁或启动系统。 总之,ISL29038IROZ-T7 凭借其高精度、低功耗和多功能性,适用于多种应用场景,能够显著提升设备的智能化和用户体验。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | IC PROXIMITY SENSOR AMB LT 8ODFN |

| 产品分类 | |

| 品牌 | Intersil |

| 数据手册 | |

| 产品图片 | |

| 产品型号 | ISL29038IROZ-T7 |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | - |

| 供应商器件封装 | 8-ODFN(2.1x2) |

| 其它名称 | ISL29038IROZ-T7CT |

| 包装 | 剪切带 (CT) |

| 安装类型 | 表面贴装 |

| 封装/外壳 | 8-VFDFN |

| 工作温度 | -40°C ~ 85°C |

| 带接近传感器 | 是 |

| 标准包装 | 1 |

| 波长 | - |

| 电压-电源 | 2.25 V ~ 3.63 V |

| 类型 | 环境 |

| 输出类型 | I²C |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

DATASHEET ISL29038 FN7851 Low Power Ambient Light and Proximity Sensor with Enhanced Infrared Rejection Rev 1.00 January 23, 2015 The ISL29038 is a low power Ambient Light Sensor (ALS) and Features proximity (PROX) sensor. It has a built-in IR-LED driver for proximity function. The ALS function measures the amount of • Ideal for applications under dark or tinted glass light (in the visible spectrum) incident on the ISL29038. • Enhanced ambient sunlight rejection to 40k Lux The ALS function has a programmable ambient IR-rejection, • Programmable proximity sleep time between proximity which allows fine tuning of light source variations and is ideal measurements optimizes power consumption for light sensor applications under dark protective glass. The • Hardware interrupt - no polling required ALS provides a 12-bit measurement. A passive optical filter removes unwanted wavelengths (IR or Ultraviolet) to ensure • Programmable IR compensation to fine tune ALS accurate ALS measurement. performance for various glass compositions • Up to 4000 Lux, four selectable ALS ranges The proximity function includes a new offset adjustment to compensate for the IR light reflected off the inside of the • Programmable IR LED drive current to 250mA protective glass cover and back to the ISL29038 sensor. This • Operates from 2.25V to 3.63V VDD offset adjustment allows the sensor to compensate for these internal reflections and preserve the dynamic range of the • Power-down IDD, typical 0.2µADC proximity measurement. • Tiny 2.1x2.0x0.7 (mm) ODFN package The built-in current-driver pulses an external infrared LED at a Applications programmed current for 90µs. The infrared light that is reflected and received by ISL29038 is digitized by an 8-bit • Display dimming and adjustment ADC. The proximity sensor also has a passive optical filter - Mobile devices: smart phones, PDA, GPS designed to pass IR and reject visible wavelengths. - Computing: monitors, laptops, notebooks The ISL29038 provides a hardware pin to indicate an interrupt - Picture frames, tablet_PCs, LCD_TV event. The interrupt pin saves power as the host microcontroller can ‘wake-up’ on an interrupt event and does not need to poll • Object detection the device for an interrupt event. The interrupt generator is - Touchscreen disabling user configurable and provides several options for ALS and - Smart power-saving PROX trigger configurations. The ISL29038 supports an SMBus compatible I2C interface for configuration and control. 100 90 VDD_PULLUP 80 VDD_IRLED R2 C1 D1 IRLED SINCTL P, SUDLLA UAPNsD E (%) 70 250mA 100 1µF 1UG1NDIR IRDR 8 SMBus MASTER ANG 60 125mA VDD_ANALOG1CµF2 234 AARVGEDXNDTD SSIDNCALT 765 ISSNDCTAL SCALE R 4500 62.5mA R1 ISL29038 LL- 30 499k FU 31.25mA R1: 499k 1% RESISTOR 20 R2: 100Ω 5% RESISTOR C1, C2: 1µF CERAMIC 10V CAPACITOR 10 D1: OSRAM SFH4650 INFRARED LED 0 0 20 40 60 80 18% GREY CARD PROXIMITY DISTANCE (mm) FIGURE 1. TYPICAL APPLICATIONS CIRCUIT FIGURE 2. PROXIMITY SENSITIVITY FN7851 Rev 1.00 Page 1 of 15 January 23, 2015

ISL29038 VDD 2 ALS PHOTODIODE ARRAY COMMAND REGISTER PHOTODIODE DUAL CHANNEL AMPLIFIERS DATA (ALS AND IR) ADCs REGISTER 1 GNDIR IR PHOTODIODE I2C 5 SCL ARRAY 6 SDA IREF INTERRUPT 7 INT FOSC IR DRIVER 8 IRDR 4 3 REXT GND FIGURE 3. ISL29038 BLOCK DIAGRAM Pin Configuration Pin Description ISL29038 PIN# NAME DESCRIPTION (8 LD ODFN) TOP VIEW 1 GNDIR Ground for IRDR LED Current. 2 VDD Positive supply: 2.25V to 3.63V. GNDIR 1 8 IRDR 3 GND Ground. 4 REXT External Resistor, Connect to GND pin through a VDD 2 7 INT 499kΩ 1% resistor. THERMAL PAD 5 SCL I2C Serial Clock Input. GND 3 6 SDA 6 SDA I2C Serial Data Input/Output. REXT 4 5 SCL 7 INT Active Low, Open-Drain Output. 8 IRDR IR-LED Driver Sink - Connect to IR LED Cathode. - TPAD Thermal Pad - Connect to GND. Ordering Information PART NUMBER PART VDD RANGE TEMP RANGE PKG. (Notes1, 2, 3) MARKING (V) (°C) PACKAGE DWG. # ISL29038IROZ-T7 N/A 2.25 to 3.63 -40 to +85 8 Lead ODFN L8.2.1x2.0 ISL29038IROZ-EVALZ Evaluation Board NOTES: 1. Refer to TB347 for details on reel specifications. 2. These Intersil Pb-free plastic packaged products employ special Pb-free material sets; molding compounds/die attach materials and NiPdAu plate-e4 termination finish, which is RoHS compliant and compatible with both SnPb and Pb-free soldering operations. Intersil Pb-free products are MSL classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020. 3. For Moisture Sensitivity Level (MSL), see device information page for ISL29038. For more information on MSL see techbrief TB477. FN7851 Rev 1.00 Page 2 of 15 January 23, 2015

ISL29038 Absolute Maximum Ratings Thermal Information VDD Supply Voltage between VDD and GND. . . . . . . . . . . . . . . . . . . . . .4.0V Thermal Resistance (Typical) JA (°C/W) JC (°C/W) I2C Bus Pin Voltage (SCL, SDA). . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to 4.0V 8 Ld ODFN (Notes4, 5) . . . . . . . . . . . . . . . . 88 14 I2C Bus Pin Current (SCL, SDA). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <10mA Maximum Die Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+90°C REXT Pin Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.5V to VDD+0.5V Storage Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +100°C IRDR Pin Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.5V Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +85°C INT Pin Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.5V to 4.0V Pb-Free Reflow Profile (*) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . see TB477 INT Pin Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <10mA *Peak temperature during solder reflow +260°C max ESD Rating Human Body Model (Note6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2kV CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product reliability and result in failures not covered by warranty. NOTES: 4. JA is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See Tech Brief TB379. 5. For JC, the “case temp” location is the center of the exposed metal pad on the package underside. 6. Tested per JESD22-A114E, ESD on all pins is 2kV except IRDR, which is 1.5kV. Electrical Specifications VDD = 3.0V, TA = +25°C, REXT = 499kΩ 1% tolerance. MIN MAX PARAMETER DESCRIPTION TEST CONDITION (Note7) TYP (Note7) UNITS INPUT POWER VDD Power Supply Range 2.25 3.0 3.63 V IDD_OFF Supply Current when Powered Down ALS_EN = 0; PROX_EN = 0 0.2 1.0 µA IDD_NORM Supply Current for ALS+Prox in Sleep Time ALS_EN = 1; PROX_EN = 1 125 140 µA IDD_PRX_SLP Supply Current for Prox in Sleep Time ALS_EN = 0; PROX_EN = 1 95 µA IDD_ALS Supply Current for ALS ALS_EN = 1; PROX_EN = 0 95 µA ADC (ALS AND PROX) tINTGR_ALS 12-bit ALS Conversion Time 80 95 110 ms tINTGR_PROX 8-bit Prox Conversion Time 0.4 0.50 0.6 ms DATAALS_0 ALS Result when Dark EAMBIENT = 0 Lux, 2k range 1 Counts DATAALS_F Full-Scale ALS ADC Code EAMBIENT > selected range maximum Lux 4095 Counts ΔDATA1 Output Variation Over Light Sources: Ambient light sensing, no cover glass ±10 % DATA Fluorescent, Incandescent and Sunlight After programmable active IR compensation (Note8) ΔDATA2 Output Variation Over Light Sources: Ambient light sensing under cover glass ±10 % DATA Fluorescent, Incandescent and Sunlight After programmable active IR compensation (Note8) Linearity ALS ADC Data Linearity 20% - 80% of full range ±5 % DATAALS_0 Light Count, ALS_Range 125 Lux E = 50 Lux (Note9), 1555 1767 1979 Counts ALS_RANGE = 0 DATAALS_1 Light Count, ALS_Range 250 Lux E = 50 Lux (Note9), 771 876 981 Counts ALS_RANGE = 1 DATAALS_2 Light Count, ALS_Range 2000 Lux E = 300 Lux (Note9), 585 665 745 Counts ALS_RANGE = 2 DATAALS_3 Light Count, ALS_Range 4000 Lux E = 300 Lux (Note9), 292 331 371 Counts ALS_RANGE = 3 DATAPROX_0 Prox Data without Object in Path 1 Counts DATAPROX_F Full-Scale Prox ADC Code 255 Counts FN7851 Rev 1.00 Page 3 of 15 January 23, 2015

ISL29038 Electrical Specifications VDD = 3.0V, TA = +25°C, REXT = 499kΩ 1% tolerance. (Continued) MIN MAX PARAMETER DESCRIPTION TEST CONDITION (Note7) TYP (Note7) UNITS ProxWASH Washout Bit Activation Level Norwood Solar Emulator 40k Lux ProxOffsetMax Maximum PROX Offset, Referenced to 512 LSB Proximity ADC Range ProxOffsetInc Proximity Offset Adjust Increment Referenced 27 LSB to Proximity ADC Range LED DRIVER (IRDR PIN) tr Rise Time for IRDR Sink Current RLOAD = 15Ω at IRDR pin, 20% to 80% 25 ns tf Fall time for IRDR Sink Current RLOAD = 15Ω at IRDR pin, 80% to 20% 15 ns IIRDR_0 IRDR Sink Current PROX_DR = 0; VIRDR = 0.5V 31.25 mA IIRDR_1 IRDR Sink Current PROX_DR = 1; VIRDR = 0.5V 62.5 mA IIRDR_2 IRDR Sink Current PROX_DR = 2; VIRDR = 0.5V 125 mA IIRDR_3 IRDR Sink Current PROX_DR = 3; VIRDR = 0.5V 250 mA IIRDR_LEAK IRDR Leakage Current PROX_EN = 0; VIRDR = 3.63V 0.001 1 µA VIRDR IRDR Pin Voltage Compliance Register bit PROX_DR = 0 0.50 4.3 V tPULSE IIRDR On Time Per PROX Reading 90 µs MISCELLANEOUS VREF Voltage of REXT Pin ALS_EN = 1 or PROX_EN = 1 0.52 V 2 I C Electrical Specifications For SCL and SDA unless otherwise noted, VDD = 3V, TA = +25°C, REXT = 499kΩ 1% tolerance (Note11). MIN MAX SYMBOL PARAMETER TEST CONDITIONS (Note7) TYP (Note7) UNITS VI2C Supply Voltage Range for I2C Interface 1.7 3.63 V fSCL SCL Clock Frequency 400 kHz VIL SCL and SDA Input Low Voltage 0.55 V VIH SCL and SDA Input High Voltage 1.25 V Vhys Hysteresis of Schmitt Trigger Input 0.05VDD V VOL Low-level Output Voltage (open-drain) at 4mA Sink 0.4 V Current Ii Input Leakage for each SDA, SCL Pin -10 10 µA tSP Pulse Width of Spikes that must be Suppressed by 50 ns the Input Filter tAA SCL Falling Edge to SDA Output Data Valid 900 ns Ci Capacitance for each SDA and SCL Pin 10 pF tHD:STA Hold Time START Condition After this period, the first clock 600 ns pulse is generated tLOW LOW Period of the SCL Clock Measured at the 30% of VDD 1300 ns crossing tHIGH HIGH Period of the SCL Clock 600 ns tSU:STA Set-up Time for a START Condition 600 ns tHD:DAT Data Hold Time 30 ns tSU:DAT Data Set-up Time 100 ns FN7851 Rev 1.00 Page 4 of 15 January 23, 2015

ISL29038 2 I C Electrical Specifications For SCL and SDA unless otherwise noted, VDD = 3V, TA = +25°C, REXT = 499kΩ 1% tolerance (Note11). (Continued) MIN MAX SYMBOL PARAMETER TEST CONDITIONS (Note7) TYP (Note7) UNITS tR Rise Time of both SDA and SCL Signals (Note12) 20 + 0.1xCb ns tF Fall Time of both SDA and SCL Signals (Note12) 20 + 0.1xCb ns tSU:STO Set-up Time for STOP Condition 600 ns tBUF Bus Free Time Between a STOP and START Condition 1300 ns Cb Capacitive Load for Each Bus Line 400 pF Rpull-up SDA and SCL System Bus Pull-Up Resistor Maximum determined by tR and tF 1 kΩ tVD;DAT Data Valid Time 0.9 µs tVD:ACK Data Valid Acknowledge Time 0.9 µs VnL Noise Margin at the LOW Level 0.1VDD V VnH Noise Margin at the HIGH Level 0.2VDD V NOTES: 7. Parameters with MIN and/or MAX limits are 100% tested at +25°C, unless otherwise specified. Temperature limits established by characterization and are not production tested. 8. Cover glass assumes fixed infrared/visible light transmissivity ratio of 10. 9. The LED light source irradiance is calibrated to produce the same ALS count as a fluorescent light source of the same Lux level. 10. An 850nm infrared LED is used in production test for proximity/IR sensitivity testing. 11. All parameters in I2C Electrical Specifications table are guaranteed by design and simulation. 12. Cb is the capacitance of the bus in pF. FIGURE 4. I2C TIMING DIAGRAM FN7851 Rev 1.00 Page 5 of 15 January 23, 2015

ISL29038 ISL29038 Configuration and Each I2C transaction ends with the master asserting a stop condition (SDA rising while SCL remains high). For more Control information about the I2C standard, consult the Philips™ I2C 2 specification documents. I C Interface Timing specifications are included in “I2C Electrical ISL29038 configuration and control is performed using the I2C Specifications” on page4. The timing parameters are defined in or SMBus. The ISL29038’s I2C interface slave address is Figure4. internally hard wired as 8’b1000100x, where x denotes the R/W bit. The I2C interface on the ISL29038 supports single and multiple byte read and write transfers using the random-read/write Every I2C transaction begins with the master asserting a start protocol. The ISL29038 does not support I2C ‘Repeat Start’ condition (SDA falling while SCL remains high). The first protocol. transmitted byte is initiated by the master and includes 7 address bits and a R/W bit. The slave is responsible for pulling NOTE: That in most system implementations, the ISL29038 is connected SDA low during the ACK time after every transmitted byte. to a single I2C master with one or more slave devices, consequently, absence of ‘Repeat Start’ function does not adversely affect I2C bus Figure5 shows a sample one-byte read. The I2C bus master system performance. always drives the SCL (clock) line, while either the master or the slave can drive the SDA (data) line. I2C DATA START DEVICE ADDRESS W A REGISTER ADDRESS STOPSTART DEVICE ADDRESS A DATA BYTE0 I2C SDA A6 A5 A4 A3 A2 A1 A0 W A R7 R6 R5 R4 R3 R2 R1 R0 A A6 A5 A4 A3 A2 A1 A0 W A SDA DRIVEN BY ISL29038 MASTER I2C SDA SLAVE(ISL29038) SDA DRIVEN BY MASTER A SDA DRIVEN BY MASTER A SDA DRIVEN BY MASTER A D7 D6 D5 D4 D3 D2 D1 D0 I2C CLK 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 FIGURE 5. I2C DRIVER TIMING DIAGRAM FOR MASTER AND SLAVE CONNECTED TO COMMON BUS FN7851 Rev 1.00 Page 6 of 15 January 23, 2015

ISL29038 Typical Performance Curves 100 100 ALS RESPONSE (BLUE) 90 90 RANGE: 2k Lux 80 80 %) 250mA %) GE ( 70 GE ( 70 CIE 1924 PHOTOPIC CURVE AN 60 125mA AN 60 R R FULL-SCALE 345000 62.5m3A1.25mA FULL-SCALE 23450000 20 10 10 0 0 0 20 40 60 80 300 400 500 600 700 800 900 1000 1100 18% GREY CARD PROXIMITY DISTANCE (mm) WAVELENGTH (nm) FIGURE 6. PROXIMITY SENSITIVITY (Note13) FIGURE 7. ALS SENSITIVITY (Note14) 15 100 90 %) 80 R) Y ( % FS 10 TIVIT 70 E ( NSI 60 NG 50% SE 50 A D CH ZE 40 E LI U 5 A 30 L M A R V O 20 N 10% 10 0 0 0 8k 16k 24k 32k 40k -90 -60 -30 0 30 60 90 AMBIENT LIGHT LEVEL (LUX) ANGLE (°) FIGURE 8. PROXIMITY AMBIENT LIGHT REJECTION (Note15) FIGURE 9. ALS ANGULAR SENSITIVITY (Note16) NOTES: 13. The ISL29038 Proximity distance sweeps with different IRDR LED current settings using an 18% Grey card reflector. 14. The ISL29038 Ambient Light Sensor Spectral response when compared to a theoretical CIE 1924 Photopic curve. The ‘Blue’ line shows the ISL29038 response and the ‘Red’ line depicts the CIE 1924 Photopic curve. 15. The ISL29038 Proximity Ambient Light Rejection using a Norwood Solar Emulator. At 40k lux ambient light level, the Proximity Washout Count (Reg 0x0D[7:1]) is 127 indicating a saturation in Proximity Signal processing path. The Proximity Washout bit 0x0D[0] is active at approximately 90% of the maximum level. At 10% initial PROX count (due to optical leakage from IR LED to the ISL29038), the PROX data error is under 2%. At 50% initial PROX count (severe optical leakage), the PROX data error is about 7%. 16. The Ambient Light Sensor Angular Sensitivity of the ISL29038 using a white LED light source. FN7851 Rev 1.00 Page 7 of 15 January 23, 2015

ISL29038 ISL29038 Register Set TABLE 1. CONFIGURATION AND CONTROL REGISTERS ADDRESS POWER-ON REGISTER BIT FUNCTION (HEX) REGISTER NAME DEFAULT ACCESS FIELDS NAME/VALUE FUNCTION 0x00 Device ID b11000xxx RO [7:0] Device Identification [7:3] [11000] ISL29038 Device ID [2:0] Reserved 0x01 Config0 0x00 RW [7:0] Proximity Configuration [7:6] Reserved RW [5] PROX_EN Proximity Enable/Disable [1] Enable [0] Disable RW [4:2] PROX_SLP Proximity Sleep Time Select [000] 400ms [001] 100ms [010] 50ms [011] 25ms [100] 12.5ms [101] 6.25ms [110] 3.125ms [111] 0ms RW [1:0] IRDR_DRV IR LED Current [00] 31.25mA [01] 62.5mA [10] 125mA [11] 250mA 0x02 Config1 0x00 RW [7:0] Proximity/ALS Configuration RW [7] INT_ALG Interrupt Algorithm [1] Window Comparator [0] Hysteresis Window RW [6:3] PROX_OFFSET Proximity Offset Compensation RW [2] ALS_EN Ambient Light Sensing Enable/Disable [1] Enable [0] Disable RW [1:0] ALS_RANGE Ambient Light Sensor Range Select [00] 125 Lux [01] 250 Lux [10] 2000 Lux [11] 4000 Lux 0x03 Config2 0x00 RW [7:0] ALS_IR_COMP Ambient Light Sensor IR Compensation RW [7:5] Reserved RW [4:0] ALSIRComp ALS Infra Red Compensation (Unsigned Binary) 0x04 INTConfig 0x10 RW [7:0] INTConfig Interrupt Configuration, Status and Control FN7851 Rev 1.00 Page 8 of 15 January 23, 2015

ISL29038 TABLE 1. CONFIGURATION AND CONTROL REGISTERS (Continued) ADDRESS POWER-ON REGISTER BIT FUNCTION (HEX) REGISTER NAME DEFAULT ACCESS FIELDS NAME/VALUE FUNCTION RO [7] PROX_INT_FLG Proximity Interrupt Flag [1] Proximity Interrupt Event [0] No Proximity Interrupt Event RW [6:5] PROX_PRST Proximity Interrupt Reporting Persistency [00] INT after 1 Proximity Flag Event [01] INT after 2 Consecutive Proximity Flag Event [10] INT after 4 Consecutive Proximity Flag Event [11] INT after 8 Consecutive Proximity Flag Event RO [4] PWR_FAIL Power Failure (Brown-out) Alarm [1] Brown-Out Detected [0] Normal Operation RO [3] ALS_INT_FLG Ambient Light Sensor Interrupt Flag [1] ALS Interrupt Flag Event [0] No ALS Interrupt Flag Event RW [2:1] ALS_INT_PRST ALS Interrupt Reporting Persistency [00] INT after 1 ALS Flag Event [01] INT after 2 Consecutive ALS Flag Event [10] INT after 4 Consecutive ALS Flag Event [11] INT after 8 Consecutive ALS Flag Event RW [0] INT_CFG Interrupt Output (Pin) Configuration [1] Interrupt if ALS and PROX Event [0] Interrupt if ALS or PROX Event 0x05 PROX_INT_TL 0x00 RW [7:0] PROX_INT_TL Proximity Interrupt LOW threshold 0x06 PROX_INT_TH 0xFF RW [7:0] PROX_INT_TH Proximity Interrupt HIGH threshold 0x07 ALS_INT_TL 0x00 RW [7:0] ALS_INT_TL1 ALS Interrupt LOW threshold bit[11:4] 0x08 ALS_INT_TLH 0x0F RW [7:0] ALS Interrupt LOW/HIGH threshold bits [7:4] ALS_INT_TL0 ALS Interrupt LOW threshold bit[3:0] [3:0] ALS_INT_TH1 ALS Interrupt HIGH threshold bit[11:8] 0x09 ALS_INT_TH 0xFF RW [7:0] ALS_INT_TH0 ALS Interrupt HIGH threshold bit[7:0] 0x0A PROX_DATA RO [7:0] PROX_DATA Proximity Data (Unsigned Binary) 0x0B ALS_DATA_HB RO [7:0] ALS_DATA_HB ALS Data HIGH Byte [7:4] Set to 0000 [3:0] ALS Data Bit[11:8] 0x0C ALS_DATA_LB RO [7:0] ALS_DATA_LB ALS Data Bit[7:0] 0x0D PROX_AMBIR RO [7:0] PROX_AMBIR Proximity Mode Ambient IR Measurement [7:1] Proximity Mode Ambient IR Component RO [0] PROX_WASH Proximity Washout Status [1] Proximity Washout Detected [0] Normal Proximity Operation 0x0E Config3 0x00 [7:0] SoftReset Software Reset 0x38 Initiate Soft Reset 0x00 Normal operation FN7851 Rev 1.00 Page 9 of 15 January 23, 2015

ISL29038 Registers 0x01, 0x02 are used to configure the primary proximity The ALS runs continuously with new data available every 90ms. and ALS parameters. Register 0x03 is used for optimizing IR The proximity sensor runs continuously with a time between compensation in ALS measurements. A procedure to optimize IR conversions controlled by PROX_SLP (Reg 0x01[6:4]). compensation is described in “ALS IR Compensation” on page11. Ambient Light Sensing Register 0x04 is the Interrupt Configuration and Status Register, and is used primarily to indicate interrupt events from proximity The ISL29038 is set for ambient light sensing when Register bit ALS_EN = 1. Four measurement ranges from 125 Lux to 4000 Lux and ALS measurements. A PWR_FAIL bit to indicate a are available. The ALS measurement range is configured via Reg ‘Brown-Out’ event is available and is set in case of a power supply interruption. A ‘Brown-Out’ event does not generate a hardware 0x02[1:0]. interrupt. The host micro-controller must clear this bit by writing a Proximity Sensing ‘0’ to Reg 0x04[4]. When proximity sensing is enabled (PROX_EN = 1), the external Register 0x04 is also used to configure ALS and Proximity IR LED is driven for 100µs by the built-in IR LED driver through interrupt persistency and the operation of the INT pin. the IRDR pin. Registers 0x05 and 0x06 are used to set the proximity ‘LOW’ and ‘HIGH’ threshold for proximity interrupt event generation. ALS CONVERSION TIME = 90ms SEVERAL s BETWEEN (FIXED) CONVERSIONS Registers 0x07, 0x08 and 0x09 are used to set the ALS ‘LOW’ and ‘HIGH’ threshold. Two 12-bit numbers span three address ALS ACTIVE locations as shown in Table1. 90ms 90ms 90ms 90ms 90ms TIME Data registers 0x0A holds result of proximity conversion. The proximity result should be validated by ‘Washout’ bit in Reg 0.50ms FOR PROX CONVERSION 0x0D[0]. Registers 0x0B and 0x0C hold results of an ALS PROX measurement. SENSOR ACTIVE TIME The ALS data is 12 bits wide. Least Significant Byte of the ALS data is available at address 0x0C and Most Significant Byte (MSB) of ALS data is available at address 0x0B. The MSB is right SERIES OF IRDR CURRENT PULSES justified, i.e., the upper nibble is always zero and lower nibble (CURRENT TOTALING 0.09ms contains four data bits. DRIVER) TIME Register 0x0D[7:1] contains ambient IR measurement in proximity measurement phase. This measurement is for SLEEP TIME detecting ambient Washout condition, which is indicated by Reg (PROX_SLP) 0x0D[0] being ‘HIGH’. Proximity ‘Washout’ is described in FIGURE 10. TIMING DIAGRAM FOR PROX/ALS EVENTS - NOT TO SCALE “Proximity Ambient Washout Detection” on page11. The IR LED current depends on PROX_DRV (Reg 0x01[1:0]). Drive A software reset can be initiated by writing 0x38 to Reg 0x0E. current settings are as shown in Table1. IR LED drive is in high ISL29038 Operation impedance state when not active. When the IR from the LED reaches an object and gets reflected Photodiodes and ADCs back to the ISL29038, the reflected IR light is converted into a current. This current is converted to digital data using an 8-bit The ISL29038 contains two photodiode arrays, which convert ADC. The proximity measurement takes 0.5ms for one photons (light) into current. The ALS photodiodes are designed to conversion including the 90μs LED drive time. The period mimic the human eye’s wavelength response curve to visible light. between proximity measurements is determined by PROX_SLP The ALS photodiodes’ current output is digitized by a 12-bit ADC. (sleep time) in Reg 0x01[4:2]. The ALS ADC output is accessed by reading from Reg 0x0B and Average LED driving current consumption is given by Equation1. 0x0C when the ADC conversion is completed. I 90s The ALS ADC converter uses a charge-balancing architecture. I = --l--R----D----R-----;-P----E----A----K----------------------- (EQ. 1) Charge-balancing is best suited for converting small current signals lRDR;AVE TSLEEP in the presence of periodic AC noise. The ISL29038 targets an A typical IRDR scheme is 250mA pulses every 400ms, averaging integration time of 90ms, which can vary ±15% from nominal. The about 56μA DC. ALS integration time is intended to minimize 60Hz flicker. The proximity sensor uses an 8-bit ADC, which operates in a Total Current Consumption similar fashion. The IRDR pin drives (pulses) an infrared LED, the Total current consumption is the sum of IDD and IIRDR. The IRDR emitted IR reflects off an object back into the ISL29038, and the pin sinks current and the average IRDR current is calculated using photo diodes convert the reflected IR to a current signal in Equation1. The IDD depends on voltage and the mode of 0.5ms. The ADC subtracts the IR reading before and after the operation. For simplicity, Equation1 ignores proximity ADC LED is driven to remove ambient IR contribution. conversion time since it is much smaller than the sleep time. FN7851 Rev 1.00 Page 10 of 15 January 23, 2015

ISL29038 ALS IR Compensation Proximity Ambient Washout Detection The ISL29038 is designed for operation under dark glass cover. Optical proximity sensor can saturate when illuminated with Glass or plastic covers can significantly attenuate visible light excessive ambient light. The ISL29038 provides a warning flag and pass the Infrared light without much attenuation. when the proximity measurement may be erroneous due to Consequently, the ISL29038 under a glass cover experiences an excessive ambient light. The PROX_WASH register (Reg 0x0D[0]) IR rich environment. reports this condition. The on-chip ALS passive optical filter on the ISL29038 is designed Interrupts Events to block most of the IR incident on the ALS photo diodes. In addition, the ISL29038 provides a programmable active IR The ISL29038 interrupts are designed to minimize host compensation that subtracts residual IR still reaching the sensor. microcontroller overhead of continuous polling. The ISL29038 can generate interrupts on the results of an ALS measurement or The ALS_IR_COMP register (Reg 0x03[4:0]) allows fine tuning of proximity measurement. the residual infrared component from the ALS output. The ALS interrupt event ALS_FLAG (Reg 0x04[3]) is governed by The recommended procedure for determining ALS IR Reg 0x07 through 0x09. Two-12 bit high and low threshold compensation is as follows: values are written to these registers. The ISL29038 will set the ALS interrupt flag if the ADC conversion count in Registers 0x0B • Illuminate the ISL29038 based product with a light source and 0x0C are outside the programmed thresholds. The without IR, such as a white LED. Record the ALS measurement ALS_FLAG is cleared by writing a ‘0’ to Reg 0x04[3]. and the Lux level. • Illuminate the device with an IR LED and the White LED. Take A proximity interrupt event (PROX_FLAG) is governed by the high an ALS measurement and Lux level measurement. and low thresholds in Reg 0x05 and 0x06 (PROX_LT and PROX_HT) and is indicated by Reg 0x04[7]. PROX_FLAG is set • Adjust the ALS_IR_COMP register (Reg 0x03, bits 4:0) to when the measured proximity data is more than the higher compensate for the IR contribution. threshold. The proximity interrupt flag is cleared when the • Repeat steps above until the IR light source contribution to the proximity data is lower than the low proximity threshold or by ALS measurement is under 10 percent assuming no change in writing a ‘0’ to Reg 0x04[7]. Lux level due to IR light source. The Proximity interrupt generation can be selected between ‘out-of-window’ threshold and hysteresis schemes. When the Proximity Offset PROX_INT_ALG register (Reg 0x02, Bit 7) is set to 0, proximity Systems built with a protective glass cover over the ISL29038 uses a window comparator scheme; when set to 1, proximity can provide light ‘leakage’ or ‘crosstalk’ from the IR LED by uses a hysteresis scheme. reflection from the glass saturating the proximity sensor In hysteresis mode, the interrupt event is generated if the measurement system (Figure11). proximity ADC count is higher than the PROX_HT threshold and Saturation can occur when the reflection from the glass with no the interrupt event is cleared when the proximity ADC count is object in the proximity detection space exceeds the full scale of less than the PROX_LT threshold. The interrupt event flag can the measurement system. The ISL29038 proximity system also be cleared by writing a ‘0’ to Reg 0x04[7]. provides a user programmable proximity offset correction to compensate for this reflection. INTERRUPT PERSISTENCE To minimize interrupt events due to ‘transient’ conditions, an interrupt persistency option is available for both ALS and proximity measurements. Persistency requires ‘X-consecutive’ interrupt flags GLASS COVER before the INT pin is driven low. Both ALS and PROX have their own independent interrupt persistency options. ALS_PRST and PROX_PRST configuration are controlled from Reg 0x04. Power-Up and ‘Brown-Out’ Reset SENSOR LED The ISL29038 has an enhanced power-on-reset system. A ‘Brown-Out’ detector flag in Reg 0x04[4] informs the system that PCB the device has powered-up properly. This flag should be reset as FIGURE 11. PROXIMITY SET-UP HIGHLIGHTING CROSSTALK part of the initialization sequence. REFLECTED FROM COVER GLASS A ‘Brown-Out’ condition is defined as an operating condition when the power supply voltage is not within the specified limits. The PROX_IR_COMP register (Reg 0x02[6:3]) applies a corrective offset to the received signal prior to ADC conversion, which During the brown-out period at power-up, the I2C interface and allows the signal to be brought within the usable range of the the IR LED driver are inactive. Following brown-out, the I2C proximity measurement system. interface is re-initialized and the configuration registers are set to power-up default values. After power-up and during device initialization, host should examine that the PWR_FAIL flag FN7851 Rev 1.00 Page 11 of 15 January 23, 2015

ISL29038 (Reg 0x04[4]) is set and then clear the flag by writing ‘0’ to Reg Typical Application Circuit 0x04[4]. A typical application circuit for the ISL29038 is shown in Following power-up, a ‘Brown-Out’ condition, if detected, is Figure12. The ISL29038’s I2C address is internally hard wired as reported by PWR_FAIL flag by Reg 0x04[4]. Device configuration ‘1000100x’, with x representing the R/W bit. The device can be registers are not set to their power-up default after ‘Brown-Out’. connected to a system’s I2C bus together with other I2C PWR_FAIL flag should be periodically monitored to detect post compliant devices. It is important to ensure that there is no power-up power supply interruption. address conflict with other I2C devices on the bus. Power-Down The SCL, SDA and INT pins on ISL29038 are open drain and Setting ALS_EN (Reg 0x02[2]) and PROX_EN (Reg 0x01[5]) to ‘0’ require pull-up resistors for proper system operation. Values of puts the ISL29038 into a power-down state with power supply the pull-up resistors is system dependent and can range from current dropping to less than 1µA. All configuration registers are 2.2k to 10k depending upon the number of I2C devices on the maintained in power-down mode. bus. The proximity sensing system can be powered using a dual power Soft Reset supply or using a single power supply. In dual supply A software reset to ISL29038 can be initiated by writing 0x38 to configuration, the IR LED and the ISL29038 are powered from Reg 0x0E. Following reset, all configuration registers are set to separate power supplies. The VDD IRLED can range from 2.25V to their default power-up state. After soft reset, the ISL29038 5.0V and the VDD_ANALOG can range from 2.25V to 3.63V. In defaults to the power-down configuration. dual supply configuration, resistor R2 should not be installed. ALS Data Count Read Out In single supply configuration, the IR LED and the ISL29038 are A 2 byte I2C read from ALS_DATA_HB outputs MSB 1st data on pfroowme r2e.2d 5frVo mto t3h.6e 3sVa maned p tohwee Vr DsDou_Arcnea. lTohge i sV DdDer_iIvReLdE fDro cman range SDA. This data is LSB justified with a zero fill for unused bits. VDD_IRLED using resistor R2. NOTE: That the MSB byte address precedes the LSB byte address. The In either power supply configuration, a 1µF decoupling capacitor ALS count is 256*(ALS_DATA_HB) + ALS_DATA_LB. should be installed close to the AVDD pin, and another 1µF Proximity Detection of Various Objects decoupling capacitor should be placed close to the IR LED anode. Proximity sensing relies on the amount of IR reflected back from objects. A perfect black object would absorb all incident light and reflect no photons. The ISL29038 is sensitive enough to detect black ESD foam, which reflects only 1% of IR. Blonde hair typically reflects more than brown hair and skin tissue is more reflective than human hair. IR penetrates into the skin and is reflected from within. As a result, the proximity count generally peaks at contact and monotonically decreases as skin moves away. The reflective characteristics of skin are very different from that of a inanimate object such as paper. VDD_PULLUP VDD_IRLED D1 IRLED SCL, SDA AND R2 C1 INT PULL UPs 100 1µF U1 1 8 SMBus MASTER GNDIR IRDR 2 7 VDD_ANALOG AVDD INT INT 3 6 C2 4 AGND SDA 5 SDA 1µF RExt SCL SCL R1 ISL29038 499k R1: 499k 1% RESISTOR R2: 100Ω 5% RESISTOR C1, C2: 1µF CERAMIC 10V CAPACITOR D1: OSRAM SFH4650 INFRARED LED FIGURE 12. TYPICAL APPLICATIONS CIRCUIT FN7851 Rev 1.00 Page 12 of 15 January 23, 2015

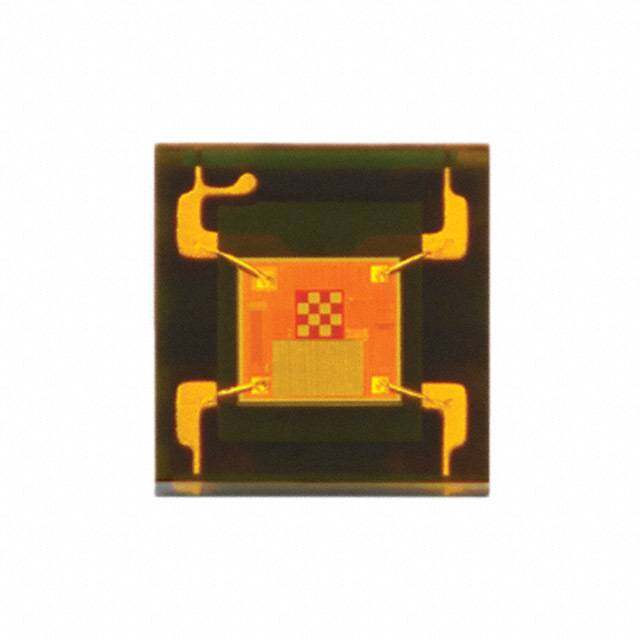

ISL29038 Soldering Considerations ISL29038 pins IRGND and AGND should connect to a low impedance ground with low resistance and low inductance Convection heating is recommended for reflow soldering; traces. Ferrite beads and inductors should be avoided in the direct-infrared heating is not recommended. The plastic ODFN ground path. If necessary, due to RF consideration, the effects of package does not require a custom reflow soldering profile. A DCR (DC resistance) should be evaluated on ALS and Proximity standard reflow soldering profile with a +260°C maximum is system performance. recommended. Additional information regarding soldering A 1µF ceramic decoupling capacitor should be placed as close to ISL29038 is included in Intersil Technical Brief TB477. the AVDD pin as possible. Suggested PCB Footprint The ISL29038 drives the IR LED with 0.09ms current pulses. To Refer to TB477,“Surface Mount Assembly Guidelines for Optical supply this pulsed current, a 1 to 10µF bulk decoupling capacitor Dual FlatPack No Lead (ODFN) Package” before starting ODFN (C1) must be connected from the IR LED anode to the GNDIR pin product board mounting. to minimize instantaneous resistive voltage drop. The connection from IR LED cathode to the IRDR pin should be short and with Additional information regarding soldering is also included in minimal inductance. Similarly, connection from the IR LED to Intersil Technical Brief TB477. VDD must be made with a low impedance trace. PCB Layout Considerations For most applications, a single power supply may be used to power the IR LED and the ISL29038. Use of resistor R2 and The ISL29038 is relatively insensitive to PCB layout. Adherence capacitor C2 (Figure13) to help filter out the power supply noise to the following guidelines will ensure first pass success and best generated from IR LED switching is recommended for best performance. ISL29038 performance when using a single power supply. For Route the I2C/SMBus SCL, SDA and the INT traces away from dual supply operation, resistor R2 should not be installed. sources of switching noise. A 499k 1% tolerance resistor must be connected from the REXT pin to AGND. This node also needs to be isolated from any switching noise. 2.10 1 8 2 7 2.00 3 6 ALS SENSOR OFFSET 0.03mm ALS SENSOR AREA 0.66mm x 0.24mm PROX SENSOR OFFSET 0.42mm 4 5 PROX SENSOR AREA 0.57mm x 0.16mm 0.57 FIGURE 13. 8 LD ODFN SENSOR LOCATION OUTLINE - DIMENSIONS IN mm FN7851 Rev 1.00 Page 13 of 15 January 23, 2015

ISL29038 Revision History The revision history provided is for informational purposes only and is believed to be accurate, but not warranted. Please go to web to make sure you have the latest revision. DATE REVISION CHANGE January 23, 2015 FN7851.1 Thermal Information table on page3: changed theta JC value from 10 to 14. Configuration and control registers on page8; under Reg2 configure1 section: changed Window Comparator from 0 to 1 and Hysteresis Window from 1 to 0. October 12, 2012 FN7851.0 Initial Release. About Intersil Intersil Corporation is a leading provider of innovative power management and precision analog solutions. The company's products address some of the largest markets within the industrial and infrastructure, mobile computing and high-end consumer markets. For the most updated datasheet, application notes, related documentation and related parts, please see the respective product information page found at www.intersil.com. You may report errors or suggestions for improving this datasheet by visiting www.intersil.com/ask. Reliability reports are also available from our website at www.intersil.com/support © Copyright Intersil Americas LLC 2012-2015. All Rights Reserved. All trademarks and registered trademarks are the property of their respective owners. For additional products, see www.intersil.com/en/products.html Intersil products are manufactured, assembled and tested utilizing ISO9001 quality systems as noted in the quality certifications found at www.intersil.com/en/support/qualandreliability.html Intersil products are sold by description only. Intersil may modify the circuit design and/or specifications of products at any time without notice, provided that such modification does not, in Intersil's sole judgment, affect the form, fit or function of the product. Accordingly, the reader is cautioned to verify that datasheets are current before placing orders. Information furnished by Intersil is believed to be accurate and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries. For information regarding Intersil Corporation and its products, see www.intersil.com FN7851 Rev 1.00 Page 14 of 15 January 23, 2015

ISL29038 Package Outline Drawing L8.2.1x2.0 8 LEAD OPTICAL DUAL FLAT NO-LEAD PLASTIC PACKAGE (ODFN) Rev 3, 1/11 2.10 A 0.15 6 B PIN 1 INDEX AREA 0.25 6 0.50 PIN 1 INDEX AREA 2.00 1.50 1.50 0.20±0.05 4 (2X) 0.10 0.10 M CAB TOP VIEW 8X 0 . 35 ± 0 . 05 0.75 BOTTOM VIEW SEE DETAIL "X" 2.50 0.10C 2.10 0.70±0.05 C BASE PLANE SEATING PLANE SIDE VIEW 0.08C (6x0.50) (1.50) (8x0.20) C 0 . 2 REF 5 (8x0.20) 0 . 00 MIN. 0 . 05 MAX. (8x0.55) DETAIL "X" (0.75) TYPICAL RECOMMENDED LAND PATTERN NOTES: 1. Dimensions are in millimeters. Dimensions in ( ) for Reference Only. 2. Dimensioning and tolerancing conform to ASME Y14.5m-1994. 3. Unless otherwise specified, tolerance : Decimal ± 0.05 4. Dimension applies to the metallized terminal and is measured between 0.25mm and 0.35mm from the terminal tip. 5. Tiebar shown (if present) is a non-functional feature. 6. The configuration of the pin #1 identifier is optional, but must be located within the zone indicated. The pin #1 indentifier may be either a mold or mark feature. FN7851 Rev 1.00 Page 15 of 15 January 23, 2015

Datasheet下载

Datasheet下载