ICGOO在线商城 > HL10006Z50R00JJ

- 型号: HL10006Z50R00JJ

- 制造商: Vishay

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

HL10006Z50R00JJ产品简介:

ICGOO电子元器件商城为您提供HL10006Z50R00JJ由Vishay设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 提供HL10006Z50R00JJ价格参考以及VishayHL10006Z50R00JJ封装/规格参数等产品信息。 你可以下载HL10006Z50R00JJ参考资料、Datasheet数据手册功能说明书, 资料中有HL10006Z50R00JJ详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

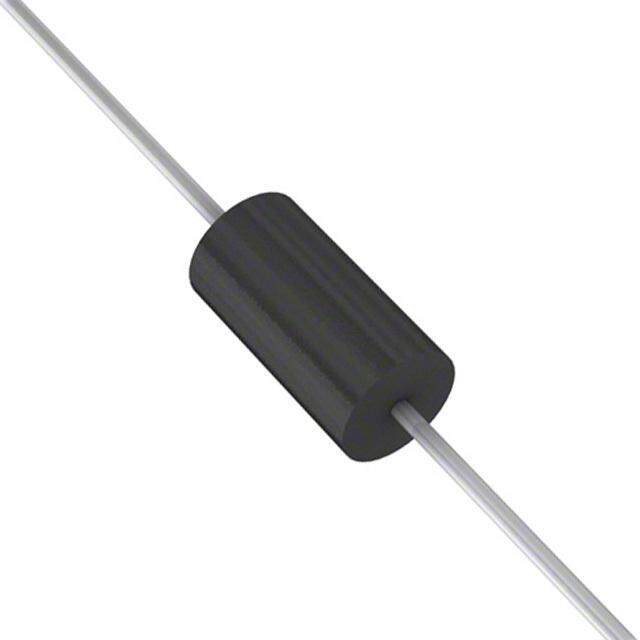

| 描述 | RES CHAS MNT 50 OHM 5% 100W线绕电阻器 - 底架安装 100watts 50ohms 5% |

| 产品分类 | |

| 品牌 | Vishay DaleVishay / Dale |

| 产品手册 | http://www.vishay.com/doc?30208 |

| 产品图片 |

|

| rohs | 否含铅 / 不符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 线绕电阻器,线绕电阻器 - 底架安装,Vishay / Dale HL10006Z50R00JJHL |

| 数据手册 | |

| 产品型号 | HL10006Z50R00JJHL10006Z50R00JJ |

| 产品 | Power Resistors Wirewound Silicon Coated |

| 产品目录绘图 |

|

| 产品目录页面 | |

| 产品种类 | 线绕电阻器 - 底架安装 |

| 其它名称 | HLC-50 |

| 功率(W) | 100W |

| 功率额定值 | 100 W |

| 包装 | 散装 |

| 商标 | Vishay / Dale |

| 外壳直径 | 23.02 mm |

| 外壳长度 | 165.1 mm |

| 大小/尺寸 | 0.750" 直径 x 6.500" 长(19.05mm x 165.10mm) |

| 安装特性 | 支架(不包括) |

| 容差 | ±5%5 % |

| 封装 | Bulk |

| 封装/外壳 | 径向,管状 |

| 工作温度范围 | - 55 C to + 350 C |

| 引线形式 | 焊片 |

| 成分 | 绕线 |

| 标准包装 | 1 |

| 涂层,外壳类型 | 硅酮涂层 |

| 温度系数 | ±30ppm/°C30 PPM / C |

| 特性 | - |

| 电阻 | 50 Ohms |

| 电阻(Ω) | 50 |

| 相关产品 | /product-detail/zh/BRACKET206/BRACKET206-ND/713758 |

| 端接类型 | Solder Lug |

| 类型 | Wirewound Resistors, Industrial Power, Tubular |

| 系列 | HL |

| 高度 | - |

PDF Datasheet 数据手册内容提取

Product is End of Life Mar-2016 and Replaced by FST HL, NHL www.vishay.com Vishay Dale Wirewound Resistors, Industrial Power, Tubular (HL), Non-Inductive Tubular (NHL) FEATURES • High temperature silicon coating • Complete welded construction Available • Available in non-inductive styles (model NHL) with Ayrton-Perry winding • Tight tolerance of 5 % for values above 1 W • Excellent stability in operation (< 3 % change in Available Note resistance) * This datasheet provides information about parts that are • Material categorization: RoHS-compliant and / or parts that are non-RoHS-compliant. For Available example, parts with lead (Pb) terminations are not RoHS-compliant. for definitions of compliance please see Please see the information / tables in this datasheet for details. www.vishay.com/doc?99912 Available STANDARD ELECTRICAL SPECIFICATIONS GLOBAL HISTORICAL POWER RATING RESISTANCE RANGE RESISTANCE RANGE WEIGHT (typical) MODEL MODEL P25 °C W ± 5 % ± 10 % g HL011 HL-11 1.0 to 70K 0.10 to 70K 11 10.50 NHL011 NHL-11 1.0 to 4.7K 1.0 to 4.7K HL012 HL-12 1.0 to 58K 0.10 to 58K 12 6.69 NHL012 NHL-12 1.0 to 3.9K 1.0 to 3.9K HL015 HL-15 1.0 to 60K 0.10 to 60K 15 8.64 NHL015 NHL-15 1.0 to 4.3K 1.0 to 4.3K HL020 HL-20 1.0 to 95K 0.10 to 95K 20 12.57 NHL020 NHL-20 1.0 to 6.8K 1.0 to 6.8K HL025 HL-25 1.0 to 115K 0.10 to 115K 25 20.72 NHL025 NHL-25 1.0 to 8.8K 1.0 to 8.8K HL026 HL-26 1.0 to 170K 0.10 to 170K 26 15.34 NHL026 NHL-26 1.0 to 11.8K 1.0 to 11.8K HL050 HL-50 1.0 to 112K 0.10 to 112K 50 42.08 NHL050 NHL-50 1.0 to 21.5K 1.0 to 21.5K HL051 HL-51 1.0 to 124K 0.10 to 124K 51 51.96 NHL051 NHL-51 1.0 to 22.9K 1.0 to 22.9K HL060 HL-60 1.0 to 145K 0.10 to 145K 60 65.64 NHL060 NHL-60 1.0 to 27.2K 1.0 to 27.2K HL065 HL-65 1.0 to 170K 0.10 to 170K 65 64.82 NHL065 NHL-65 1.0 to 31.4K 1.0 to 31.4K HL080 HL-80 1.0 to 190K 0.10 to 190K 80 121.58 NHL080 NHL-80 1.0 to 38.3K 1.0 to 38.3K HL100 HL-100 1.0 to 260K 0.10 to 260K 100 91.37 NHL100 NHL-100 1.0 to 48.5K 1.0 to 48.5K HL120 HL-120 1.0 to 330K 0.10 to 330K 120 183.82 NHL120 NHL-120 1.0 to 64.1K 1.0 to 64.1K HL130 HL-130 1.0 to 380K 0.10 to 380K 130 192.36 NHL130 NHL-130 1.0 to 70.2K 1.0 to 70.2K HL160 HL-160 1.0 to 470K 0.10 to 470K 160 245.86 NHL160 NHL-160 1.0 to 105K 1.0 to 105K HL175 HL-175 1.0 to 500K 0.10 to 500K 175 250.80 NHL175 NHL-175 1.0 to 112K 1.0 to 112K HL225 HL-225 1.0 to 645K 0.10 to 645K 225 309.97 NHL225 NHL-225 1.0 to 121K 1.0 to 121K GLOBAL PART NUMBER INFORMATION Global Part Numbering example: NHL10006Z10R00JJ N H L 1 0 0 0 6 Z 1 0 R 0 0 J J GLOBAL TERMINAL TERMINAL RESISTANCE TOLERANCE PACKAGING CODE SPECIAL MODEL DESIGNATION FINISH VALUE NHL100 02 E = lead R = decimal J = ± 5.0 % E = lead (Pb)-free skin pack (dash (see “Standard Electrical 05 (Pb)-free K = thousand K = ± 10.0 % J (1) = skin pack (J01) number) Specifications” 06 10R00 = 10.0 (up to table above for 07 Z = tin / lead 1K000 = 1 k Note 2 digits) additional P/N’s) 14 N = nickel (1) Tin / lead for type “Z”, lead (Pb)-free for type “N” from 1 to 99 15 as applicable Historical Part Numbering example: NHL-100-06Z 10 5 % J01 NHL-100 06Z 10 5 % J01 HISTORICAL MODEL TERMINAL/FINISH RESISTANCE VALUE TOLERANCE PACKAGING Revision: 26-Feb-16 1 Document Number: 30208 For technical questions, contact: ww2dresistors@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Product is End of Life Mar-2016 and Replaced by FST HL, NHL www.vishay.com Vishay Dale DIMENSIONS in inches [millimeters] TERMINAL SETBACK A O.D. I.D. LENGTH (Includes Coating and Terminal Band) DIMENSIONS in inches [millimeters] CORE DIMENSIONS TERMINAL DISTANCE TERMINAL DESIGNATION GLOBAL MODEL A LENGTH I.D. SETBACK BETWEEN BRACKET (MAX.) ± 0.062 O.D. ± 0.031 ± 0.31 TERMINALS STANDARD OPTIONAL TYPES (1) [± 1.59] [± 0.79] [± 0.79] (REF.) HL011 0.469 1.750 0.375 0.188 0.094 1.187 02 - 101, 204, 301 NHL011 [11.91] [44.45] [9.53] [4.76] [2.38] HL012 0.406 1.750 0.313 0.188 0.094 1.187 05 14 101, 204, 301 NHL012 [10.32] [44.45] [7.94] [4.76] [2.38] HL015 0.563 1.500 0.438 0.313 0.094 0.937 02 14 101, 203, 301 NHL015 [14.29] [38.10] [11.11] [7.94] [2.38) HL020 0.563 2.000 0.438 0.313 0.094 1.437 02 14 101, 203, 301 NHL020 [14.29] [50.8] [11.11] [7.94] [2.38] HL025 0.688 2.000 0.563 0.313 0.094 1.312 06 15 101, 203, 301 NHL025 [17.46] [50.8] [14.29] [7.94] [2.38] HL026 0.563 3.000 0.438 0.313 0.094 2.437 02 14 101, 203, 301 NHL026 [14.29] [76.2] [11.11] [7.94] [2.38] HL050 0.688 4.000 0.563 0.313 0.094 3.312 06 15 101, 203, 301 NHL050 [17.46] [101.6] [14.29] [7.94] [2.38] HL051 0.906 3.500 0.750 0.500 0.125 2.75 06 15 102, 206, 303 NHL051 [23.02] [88.9] [19.05] [12.70] [3.18] HL060 0.906 4.000 0.750 0.500 0.125 3.250 06 15 102, 206, 303 NHL060 [23.02] [101.6] [19.05] [12.70] [3.18] HL065 0.906 4.500 0.750 0.500 0.125 3.750 06 15 102, 206, 303 NHL065 [23.02] [114.3] [19.05] [12.70] [3.18] HL080 1.313 4.000 1.125 0.750 0.219 2.812 07 15 103, 205, 303 NHL080 [33.34] [101.6] [28.58] [19.05] [5.56] HL100 0.906 6.500 0.750 0.500 0.125 5.750 06 15 102, 206, 303 NHL100 [23.02] [165.1] [19.05] [12.70] [3.18] HL120 1.313 6.000 1.125 0.750 0.219 4.812 07 15 103, 205, 303 NHL120 [33.34] [152.4] [28.58] [19.05] [5.56] HL130 1.313 6.500 1.125 0.750 0.219 5.312 07 15 103, 205, 303 NHL130 [33.34] [165.1] [28.58] [19.05] [5.56] HL160 1.313 8.000 1.125 0.750 0.219 6.812 07 15 103, 205, 303 NHL160 [33.34] [203.2] [28.58] [19.05] [5.56] HL175 1.313 8.500 1.125 0.750 0.219 7.312 07 15 103, 205, 303 NHL175 [33.34] [215.9] [28.58] [19.05] [5.56] HL225 1.313 10.500 1.125 0.750 0.219 9.312 07 15 103, 205, 303 NHL225 [33.34] [266.7] [28.58] [19.05] [5.56] Note (1) Brackets are available for mounting HL series resistors - see Mounting Hardware section. TERMINAL DIMENSIONS TERMINAL STYLE DIMENSION A D A D 02 05 06 07 14 15 C C A 0.188 0.188 0.250 0.375 0.188 0.250 [4.76] [4.76] [6.35] [9.53] [4.76] [6.35] Sthtryule 0 072 B Styles 14 and 15 B B [01.04.0362] [01.14.3181] [01.45.6239] [01.56.2858] [104.5.2693] [01.55.9048] 0.093 0.104 0.166 0.173 0.050 0.065 TERMINAL FINISH C [2.36] [2.64] [4.22] [4.39] [1.27] [1.65] “E” Finish - 100 % Sn coated steel. “Z” Finish - 60/40 SnPb 0.020 0.020 0.020 0.020 0.020 0.031 coated steel. “N” Finish - Nickel coated steel. Finish for D [0.51] [0.51] [0.51] [0.51] [0.51] [0.79] terminal style 14 and 15 limited to nickel plated steel (N). Revision: 26-Feb-16 2 Document Number: 30208 For technical questions, contact: ww2dresistors@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Product is End of Life Mar-2016 and Replaced by FST HL, NHL www.vishay.com Vishay Dale MOUNTING HARDWARE Mounting hardware is available for HL resistors, see HL Brackets and Sliders datasheet for more information: www.vishay.com/doc?30279 TECHNICAL SPECIFICATIONS PARAMETER UNIT HL, NHL RESISTOR CHARACTERISTICS Temperature Coefficient ppm/°C ± 30 for 10 and above; ± 50 for 1 to 9.9 ; ± 90 for 0.1 to 0.99 Short Time Overload - 10 x rated power for 5 s Dielectric Withstanding Voltage V 1000, from terminal to mounting hardware AC Maximum Working Voltage V (P x R)1/2 Insulation Resistance 1000 M minimum dry, 100 M minimum after moisture test Operating Temperature Range °C -55 to +350 MATERIAL SPECIFICATIONS NHL NON-INDUCTIVE Element: copper-nickel alloy of nickel-chrome alloy, Models of equivalent physical and electrical specifications depending on resistance value are available with non-inductive (Ayrton-Perry) winding. They are identified by adding the letter N to the front of the Core: ceramic, steatite HL type designation (NHL225 for example). For NHL models Coating: special high temperature silicone maximum resistance values are lower, see Standard Standard Terminals: model “E” terminals are tinned steel Electrical Specifications table. Terminal Bands: steel Part Marking: Vishay Dale, model, wattage, value, tolerance, date code DERATING % 120 N ER I 100 W O D P 80 E T A R 60 40 20 0 - 65- 50 0 50 150 250 350 25 AMBIENT TEMPERATURE IN °C PERFORMANCE TEST CONDITIONS OF TEST TEST LIMITS Rated power applied until thermally stable, then a minimum of Thermal Shock ± (2.0 % + 0.05 ) R 15 min at -55 °C Short Time Overload 10x rated power for 5 s ± (2.0 % + 0.05 ) R Dielectric Withstanding Voltage 1000 VRMS for 1 min ± (0.1 % + 0.05 ) R Low Temperature Storage -55 °C for 24 h ± (2.0 % + 0.05 ) R High Temperature Exposure 250 h at + 350 °C ± (2.0 % + 0.05 ) R Humidity 75 °C, 90 % to 100 % RH, 240 h ± (5.0 % + 0.05 ) R Load Life 1000 h at rated power, + 25 °C, 1.5 h “ON”, 0.5 h “OFF” ± (3.0 % + 0.05 ) R Moisture Resistance MIL-STD-202 Method 106, 7b not applicable ± (2.0 % + 0.05 ) R Shock, Specified Pulse MIL-STD-202 Method 213, 100 g’s for 6 ms, 10 shocks ± (0.2 % + 0.05 ) R Vibration, High Frequency Frequency varied 10 Hz to 2000 Hz, 20 g peak, 2 directions 6 h each ± (0.2 % + 0.05 ) R Revision: 26-Feb-16 3 Document Number: 30208 For technical questions, contact: ww2dresistors@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice www.vishay.com Vishay Disclaimer ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROV E RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE. Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively, “Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other disclosure relating to any product. Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose o r the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special, consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular purpose, non-infringement and merchantability. Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of typical requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements about the suitability of products for a particular application. It is the customer’s responsibility to validate that a particular product with the properties described in the product specification is suitable for use in a particular application. Parameters provided in datasheets and / or specifications may vary in different applications and performance may vary over time. All operating parameters, including typical parameters, must be validated for each customer application by the customer’s technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase, including but not limited to the warranty expressed therein. Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustainin g applications or for any other application in which the failure of the Vishay product could result in personal injury or death. Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk . Please contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this documen t or by any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners. © 2019 VISHAY INTERTECHNOLOGY, INC. ALL RIGHTS RESERVED Revision: 01-Jan-2019 1 Document Number: 91000

Datasheet下载

Datasheet下载