ICGOO在线商城 > 传感器,变送器 > PMIC - 栅极驱动器 > HAFUHH0200L4AXT

- 型号: HAFUHH0200L4AXT

- 制造商: Honeywell Solid State Electronics

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

HAFUHH0200L4AXT产品简介:

ICGOO电子元器件商城为您提供HAFUHH0200L4AXT由Honeywell Solid State Electronics设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 HAFUHH0200L4AXT价格参考¥992.38-¥2617.63。Honeywell Solid State ElectronicsHAFUHH0200L4AXT封装/规格:PMIC - 栅极驱动器, 空气 Flow Sensor 200 SLPM 公型,0.8661"(22mm) 聚合物。您可以下载HAFUHH0200L4AXT参考资料、Datasheet数据手册功能说明书,资料中有HAFUHH0200L4AXT 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

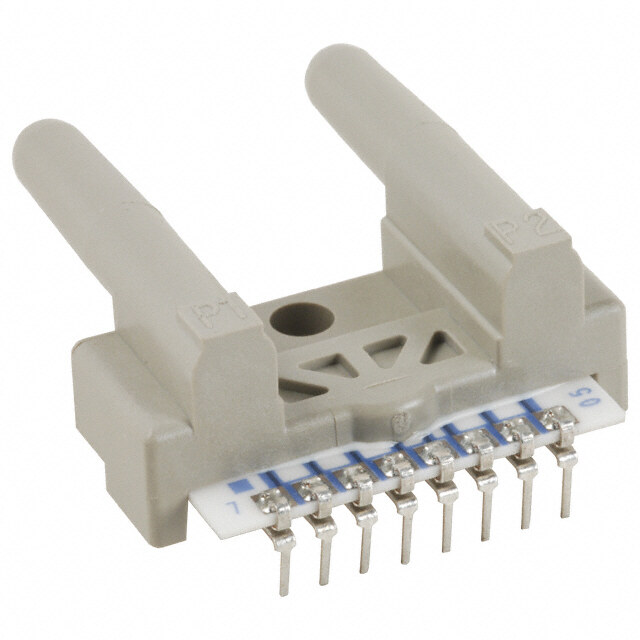

| 描述 | HONEYWELL ZEPHYR AIRFLOW SENSOR流量传感器 200LPM,DOI2,MISO5356 22mm OD PneumAdapt |

| 产品分类 | 流量传感器流量传感器 |

| 品牌 | Honeywell |

| 产品手册 | http://sensing.honeywell.com/index.php?ci_id=144883 |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | Honeywell HAFUHH0200L4AXTZephyr™ HAF |

| 数据手册 | |

| 产品型号 | HAFUHH0200L4AXT |

| 产品培训模块 | http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=25023http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=25863http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=30385 |

| 产品种类 | 流量传感器 |

| 传感器类型 | Digital Airflow |

| 其它名称 | 480-5674 |

| 商标 | Honeywell |

| 商标名 | Zephyr |

| 开关功能/额定值 | - |

| 感应范围 | 200 SLPM |

| 材料-本体 | 聚合物 |

| 标准包装 | 1 |

| 流量传感器类型 | 空气 |

| 电压-输入 | 3 V ~ 10 V |

| 电源电压 | 3 V to 10 V |

| 端口尺寸 | 公型,0.8661"(22mm) |

| 类型 | High Accuracy Air Flow Sensor |

| 精度/可靠性 | 3.5 % |

| 系列 | HAF |

| 额定范围 | 200 SLPM |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

Honeywell ZephyrTM Digital Airflow Sensors 008268 Issue 5 HAF Series—High Accuracy: 10 SLPM, 15 SLPM, 20 SLPM, 50 SLPM, 100 SLPM, 200 SLPM, 300 SLPM Datasheet FEATURES • Fast response time (1 ms) allows the customer’s application to respond quickly to a change in airflow, important in critical medical (e.g., anesthesia) and industrial (e.g., fume hood) applications. • High stability reduces errors due to thermal effects and null shift, providing accurate readings over time and often eliminating the need for system calibration after PCB mount and periodically over time. • High sensitivity at very low flows provides a fast response time at the onset or cessation of flow. • High 12-bit resolution increases the ability to sense small airflow changes, allowing customers to more precisely control their application. • Wide airflow range: The industry’s broadest airflow range measures mass flow with standard flow ranges of 0 to10, 0 to 15, 0 to 20, 0 to 50, 0 to 100, 0 to 200 and 0 SLPM to DESCRIPTION 300 SLPM, or custom flow ranges, increasing the options to Honeywell Zephyr™ HAF Series sensors provide a digital integrate the sensor into the application. interface for reading airflow over specified full-scale flow and • Choice of port styles: Manifold mount, 22 mm OD tapered compensated temperature ranges. The thermally isolated male fitting, and G 3/8 female threaded fitting provide heater and temperature sensing elements help these sensors flexibility to choose the pneumatic connection that is best provide a fast response to air or gas flow. Zephyr sensors are for the customer’s application. designed to measure mass flow of air and other non-corrosive • Linear output provides a more intuitive sensor signal than gases. Standard flow ranges are 10 SLPM, 15 SLPM, 20 the raw output of basic airflow sensors, which can help SLPM, 50 SLPM, 100 SLPM, 200 SLPM and 300 SLPM, reduce production costs, design, and implementation time. with custom flow ranges available. The sensors are fully • Wide supply voltage range (3 Vdc to 10 Vdc) provides a calibrated and temperature compensated with an onboard flexible regulated power circuit which allows the designer the Application Specific Integrated Circuit (ASIC). The HAF Series flexibility to choose the supply voltage that works best in the >10 SLPM is compensated over the calibrated temperature system. range of 0°C to 50°C [32°F to 122°F]. The state-of-the-art • ASIC-based I2C digital output simplifies integration ASIC-based compensation provides digital (I2C) outputs with to microprocessors or microcontrollers, reducing PCB a response time of 1 ms. These sensors operate on the heat complexity and component count. transfer principle to measure mass airflow. They consist of • RoHS-compliant materials Meet Directive 2002/95/EC. a microbridge Microelectronic and Microelectromechanical System (MEMS) with temperature-sensitive resistors POTENTIAL APPLICATIONS deposited with thin films of platinum and silicon nitride. • Medical: Anesthesia delivery machines, ventilators, The MEMS sensing die is located in a precise and carefully ventricular assist devices (heart pumps), spirometers, designed airflow channel to provide repeatable response to laparoscopy flow. Zephyr sensors provide the customer with enhanced • Industrial: Analytic instrumentation (spectrometry, reliability, high accuracy, repeatable measurements and the chromatrography), air-to-fuel ratio, fuel cells, fume hoods, ability to customize sensor options to meet many specific gas leak detection, process control gas monitoring, vacuum application needs. The combination of rugged housings with pump monitoring a stable substrate makes these products extremely robust. They are designed and manufactured according to ISO 9001 PORTFOLIO standards. The Honeywell Zephyr Digital Airflow Sensors join an extensive line of airflow sensors for potential use in medical, VALUE TO CUSTOMERS • Precise measurement: The industry’s smallest Total Error industrial, and consumer applications. Band, fast response time, and high accuracy provide precise measurement and high performance in the customer’s application. • Saves time: Configurable and customizable with a choice of port styles simplifies design and reduces production time. • Cost-effective: Reduces printed circuit board (PCB) size and overall design and production costs. Sensing and Internet of Things

Honeywell ZephyrTM Digital Airflow Sensors HAF Series—High Accuracy: 10, 15, 20, 50, 100, 200, 300 SLPM Figure 1. Total Error Band vs. Accuracy Other airflow sensor manufacturers only report on accuracy, while Honeywell reports Total Error Band. Sources of Error Offset Full Scale Span Pressure Non-Linearity Accuracy Total Pressure Hysteresis BFSL Error Pressure Non-Repeatability Band Thermal Effect on Offset Thermal Effect on Span Thermal Hysteresis HIGH ACCURACY TOTAL ERROR BAND (TEB)* Ideal for use in demanding applications that require high Honeywell specifies TEB, the most comprehensive, clear, accuracy. and meaningful measurement that provides the sensor’s – 0%FS to 14.3%FS = 0.5%FS true accuracy (see Figure 1). TEB allows for precise airflow – 14.3%FS to 100%FS = 3.5%reading measurement, often ideal for demanding applications with high accuracy requirements for precise airflow measurement. • 10, 15, 20, 50, 100, 200 SLPM: – 0%FS to 12.5%FS = 0.5%FS – 12.5%FS to 100%FS = 4.0%reading • 300 SLPM only: – 0%FS to 12.5%FS = 0.5%FS – 12.5%FS to 66.7%FS = 4.0%reading – 66.7%FS to 100%FS = 7.0%reading Table 1. Absolute Maximum Ratings1 Characteristic Parameter Supply voltage -0.3 Vdc to 11.0 Vdc Voltage on digital I/O output pins -0.3 Vdc to 3.0 Vdc2 Storage temperature range -40°C to 100°C [-40°F to 212°F] Maximum flow change 10,000 SLPM/s Maximum common mode pressure 4 bar | 60 psi at 25°C [77°F] Maximum flow 350 SLPM 1Absolute maximum ratings are the extreme limits that the device will withstand without damage to the device. However, the electrical and mechanical characteristics are not guaranteed as the maximum limits (above recommended operating conditions) are approached, nor will the device necessarily operate at absolute maximum ratings. 2Digital I/O pins are diode protected at this voltage up to 2 mA. Digital bus voltage may exceed this value if the maximum digital bus current is limited to 2 mA or less. The maximum bus current is generally determined by the bus pull-up resistors CAUTION CAUTION IMPROPER USE PRODUCT DAMAGE Do not use these products to sense liquid flow. Do not dissamble these products. Failure to comply with these instructions may result in Failure to comply with these instructions may result in product damage. product damage. 2 Sensing and Internet of Things

Honeywell ZephyrTM Digital Airflow Sensors HAF Series—High Accuracy: 10, 15, 20, 50, 100, 200, 300 SLPM Table 2. Operating Specifications Characteristic Parameter Supply voltage 3 Vdc to 10 Vdc Supply current 20 mA max. Power: 3 Vdc 60 mW max. 10 Vdc 200 mW max. Calibrated temperature range1 0°C to 50°C [32°F to 122°F] Operating temperature range -20°C to 70°C [-4°F to 158°F] Full scale (FS) flow2 10, 15, 20, 50, 100, 200, 300 SLPM Calilbrated flow range 0 to 10, 0 to 15, 0 to 20, 0 to 50, 0 to 100, 0 to 200, 0 SLPM to 300 SLPM Calibration gas clean, dry air Accuracy3 0%FS to 14.3%FS 0.5%FS 14.3%FS to 100%FS 3.5%reading Total Error Band:4 10, 15, 20, 50, 100, 200 SLPM: 0%FS to 12.5%FS 0.5%FS 12.5%FS to 100%FS 4.0%reading 300 SLPM only: 0%FS to 12.5%FS 0.5%FS 12.5%FS to 66.7%FS 4.0%reading 66.7%FS to 100%FS 7.0%reading Null accuracy5 ±0.5%FS Flow response time6 1 ms Warm up time7 35 ms Resolution: 10 SLPM 0.002 SLPM 15 SLPM 0.003 SLPM 20 SLPM 0.003 SLPM 50 SLPM 0.008 SLPM 100 SLPM 0.015 SLPM 200 SLPM 0.029 SLPM 300 SLPM 0.043 SLPM Proof pressure 10.3 bar | 150 psig Burst pressure 13.7 bar | 200 psig Bus standards8 I2C fast mode (up to 400 kHz) Reverse polarity protection no 1 Custom and extended temperature compensated ranges are possible. Contact Honeywell for details. 2 Honeywell standard for mass flow rate units is SLPM, which has reference conditions of 0°C and 1 atm. Custom units are given as LPM with listed reference conditions at the first mention. 3 Accuracy is the maximum deviation in output from nominal over the entire calibrated flow range at 25ºC. Errors include Offset, Full Scale Span, Linearity, Flow Hysteresis, and Repeatability. 4 Total Error Band (TEB) is the maximum deviation in output from nominal over the entire calibrated flow range and temperature range. Total Error Band includes all Accuracy errors, as well as all temperature effects over the compensated temperature range, including Temperature Offset, Temperature Span and Thermal Hysteresis. 5 Null Accuracy is the maximum deviation in output from nominal at null flow over the entire calibrated temperature range. 6 Response time: time to electrically respond to any mass flow change at the microbridge airflow transducer (response time of the transducer may be affected by the pneumatic interface). 7 Warm-up time: time to the first valid flow measurement after power is applied. 8 Refer to the Technical Note “I2C Communications with Honeywell Digital Airflow Sensors” for I2C protocol information. Sensing and Internet of Things 3

Honeywell ZephyrTM Digital Airflow Sensors HAF Series—High Accuracy: 10, 15, 20, 50, 100, 200, 300 SLPM Table 3. Environmental Specifications Characteristic Parameter Humidity 0% to 95% RH, non-condensing Shock 30 g, 6 ms Vibration 1,33 g at 10 Hz to 500 Hz ESD ESD IEC6100-4-2 air discharge up to 8 kV, or direct contact discharge up to 4 kV Radiated immunity: Level 3 from 80 MHz to 1000 MHz per IEC61000-4-3 20 , 50, 100 , 200, 300 SLPM 1 m shielded cable with 3 cm exposed leads at connector 10, 15 SLPM 1 m shielded cable with 3 cm exposed leads at connector and 280 Ohm at MHz ferrite bead Table 4. Materials Specifications Characteristic Parameter glass reinforced (GR) thermoplastic polymer, gold, silicon, silicon dioxide, silicon nitride, epoxy, Wetted materials PCB epoxy composite Housing GR thermoplastic polymer Substrate PCB Adhesives epoxy Electronic components silicon, gold Compliance RoHS, WEEE Table 5. Recommended Mounting and Implementation Characteristic Parameter Mounting screw size 10-32 Mounting screw torque 1,13 N m [20 in-lb] Electrical connection 6 pin SIP connector Pneumatic connection manifold mount, 22 mm OD tapered male fitting, G 3/8 female threaded fitting 4 Sensing and Internet of Things

Honeywell ZephyrTM Digital Airflow Sensors HAF Series—High Accuracy: 10, 15, 20, 50, 100, 200, 300 SLPM Figure 2. Nomenclature and Order Guide1 For example, HAFUHM0020L4AXT defines a Honeywell ZephyrTM Airflow Sensor, unidirectional flow, long port, manifold mount, 20 SLPM, I2C output with custom 0x49 address, 10% to 90% transfer function, 3 Vdc to 10 Vdc supply voltage. HAF U HM 0020 L 4 A X T Product Series Flow Direction Port Style Flow Range Unit Output Format Transfer Reserved for Supply Voltage Function Future Use HAF Series— High Accuracy U Unidirectional 0010 10 L SLPM 2 Digital I2C address: A 10% to 90% of input X XXXXX T 3 Vdc to 10 Vdc Airflow Sensor HM Manifold 0x29 mount 0015 15 3 Digital I2C address: 0x39 2ta2p mermed O mDa le 0020 20 4 D0xig4i9tal I2C address: HH fitting per ISO 5356 0050 50 5 Digital I2C address: 0x59 HT Gth 3re/a8d feedmale 0100 100 6 D0xig6i9tal I2C address: fitting per ISO 1179 0200 200 7 Digital I2C address: 0x79 0300 300 1Apart from the general configuration required, other customer-specific requirements are also possible. Please contact Honeywell. Figure 3. All Available Standard Configurations Manifold mount 22 mm OD tapered male fitting G 3/8 female threaded fitting Sensing and Internet of Things 5

Honeywell ZephyrTM Digital Airflow Sensors HAF Series—High Accuracy: 10, 15, 20, 50, 100, 200, 300 SLPM Figure 4. Nominal Digital Output: 10, 15, 20, 50, 100, 200, 300 SLPM 18018 16380 14742 ts) 13104 n u o 11466 C t ( 9828 u p ut 8190 O al 6552 t gi 4914 Di 3276 1638 0 0 100 Full Scale Flow (%) Figure 5. Accuracy and Total Error Band 10, 15, 20, 50, 100, 200 SLPM 300 SLPM only 8.00% 4.00% TEB = 7.00% 3.00% 7.00% TEB = 4.67% at 300 SLPM at 200 SLPM 6.00% 2.00% ) S 5.00% F 1.00% TEB = 2.65% % at 200 SLPM 4.00% ( 0 r rro-1.00% 3.00% TaEt 4B3 = S 0L.5P%M E 2.00% -2.00% ) S 1.00% -3.00% F % 0 -4.00% r ( 0 10 20 30 40 50 60 70 80 90 100 o-1.00% r %FS Er -2.00% Ideal -3.00% Accuracy: 0%FS to 14.3%FS = 0.5% -4.00% 14.3%FS to 100%FS = 3.5% -5.00% Total Error Band: 0%FS to 12.5%FS = 0.5% -6.00% 12.5%FS to 100%FS = 4.0% -7.00% -8.00% 0 10 20 30 40 50 60 70 80 90 100 %FS Ideal Accuracy: 0%FS to 14.3%FS (0 SLPM to 43 SLPM) = 0.5% 14.3%FS to 100%FS (43 SLPM to 300 SLPM) = 3.5% Total Error Band: 0%FS to 14.3%FS (0 SLPM to 43 SLPM) = 0.5% 14.6%FS to 66.7%FS (44 SLPM to 200 SLPM) = 4.0% 66.7%FS to 100%FS (200 SLPM to 300 SLPM) = 7.0% 6 Sensing and Internet of Things

Honeywell ZephyrTM Digital Airflow Sensors HAF Series—High Accuracy: 10, 15, 20, 50, 100, 200, 300 SLPM Figure 6. Flow vs Pressure Drop: 10, 15, 20, 50, 100, 200, 300 SLPM Flow Typical Pressure Drop (SLPM) mbar inH O kPa 2 0 0.000 0.000 0.000 1 0.103 0.042 0.010 2 0.206 0.082 0.021 4 0.396 0.159 0.040 8 0.803 0.322 0.080 20.684 10 1.027 0.412 0.103 ) 12 1.279 0.513 0.128 a 17.237 P 14 1.549 0.621 0.155 k ( p 13.790 15 1.686 0.676 0.169 o Dr 10.342 16 1.820 0.730 0.182 e r 18 2.126 0.853 0.213 u 6.895 s 20 2.444 0.980 0.244 s e r 3.447 25 3.320 1.332 0.332 P 50 9.314 3.736 0.931 0.000 0 50 100 150 200 250 300 350 75 17.553 3.736 1.755 Flow (SLPM) 100 27.979 3.736 2.798 125 40.533 3.736 4.053 150 54.881 22.017 5.488 175 71.158 28.546 7.116 200 89.506 35.907 8.951 225 109.363 43.873 10.936 250 131.037 52.568 13.104 275 154.389 61.936 15.439 300 179.235 71.904 17.924 Table 6. Ideal Transfer Function Item Equation Digital Output Code 16384 * [0.1 + 0.8 * (Flow Applied/Full Scale Flow)] Flow Applied Full Scale Flow * [(Digital Output Code/16384) - 0.1]/0.8 Digital Interface For additional details on the use of Zephyr with digital output see the Technical Note “I2C Communications with Honeywell Digital Airflow Sensors”. The sensor uses the I2C standard for digital communication with a slave address specified in the Nomenclature and Order Guide in Figure 2. Following sensor power-up, each of the first two read sequences shown in Figure 7 will respond with 2 bytes of the unique 4-byte Serial Number. The first read after power-up will respond with the two most significant bytes of the Serial Number, while the second read will respond with the two least significant bytes of the Serial Number. For reliable performance, allow sensor to be powered for the sensor startup time before performing the first read, then allow a 10 ms command response time before performing the second read. Sensing and Internet of Things 7

Honeywell ZephyrTM Digital Airflow Sensors HAF Series—High Accuracy: 10, 15, 20, 50, 100, 200, 300 SLPM Figure 7. Sensor I2C Read and Write Sequences I2C Read: Slave responds to Master with data Data Byte 0 (Most Significant) Data Byte 1 (Least Significant) SDA S A6 A5 A4 A3 A2 A1 A0 1 SA D7 D6 D5 D4 D3 D2 D1 D0 MAD7 D6 D5 D4 D3 D2 D1 D0MN S SCL I2C Read: Master sends data to Slave Command Byte SDA S A6 A5 A4 A3 A2 A1 A0 1 SA D7 D6 D5 D4 D3 D2 D1 D0 SA S SCL Bit Name Description S Start condition Master pulls SDA from high to low while SCL remains high S Stop condition Master allows SDA to float from low to high while SCL remains high A6 Address bit I2C Slave Address is the 7 Most Significant Bits for the first transmitted byte 1 Read/write bit Read = 1, Write = 0 D7 Data bit Read = 1, Write = 0 SA Slave ACK Slave pulls SDA low MA Master ACK Master pulls SDA low MN Master NACK Master allows SDA to float high After the power-up read sequence described above, the sensor will respond to each I2C read request with a 16-bit (2 byte) digital flow reading. Read requests taken faster than the Response Time (1 ms) are not guaranteed to return fresh data. The first two bits of each flow reading will be ‘00’, while non-flow responses (such as error and status codes) will begin with ‘11’. There are several user commands available as shown in Table 8. Following an I2C write sequence of a user command, the sensor will respond to the next I2C read request with a 16-bit response. Possible responses to user commands can be seen in Table 9. Table 8. User Command Descriptions Command Byte Command Response Time Command Name Command Description (Hexadecimal) (Max.) Next two read requests will each return two bytes of 0x01 GetSerialNumber 10 ms the sensor’s unique 4-byte Serial Number. 0x02 PowerOnReset Force Power-On reset of sensor microcontroller. 20 ms Calculates EEPROM Checksum and compares to production Checksum value. If the values match, 0x03 Checksum 1 s the next read request will respond with 0xCCA5. Otherwise, the next read will respond with 0xCC90. 1 Table 9. Sensor Response Descriptions Sensor Response Response Name Response Description (Hexadecimal) 0xCCA5 POSACK non-response command was executed successfully 0xCC99 BadCommand command byte was not recognized 0xCC9A BadParam command sent with incorrect parameter bytes 0xCC9B Failure command failed during execution 0xCC90 BadChecksum checksum did not match stored value 0xCCBB Busy sensor is busy calculating the checksum value The maximum sink current on SCL or SDA is 2 mA. Therefore, if the pull-up resistors are biased by VDD, and if VDD reaches the maximum supply voltage of 6 V, then the pull-up resistors for SCL and SDA must be greater than 3.0 kOhm to limit the sink current to 2 mA. The typical value for SCL and SDA pull-up resistors is 4.7 kOhm (this value depends on the bus capacitance and the bus speed). 8 Sensing and Internet of Things

Honeywell ZephyrTM Digital Airflow Sensors HAF Series—High Accuracy: 10, 15, 20, 50, 100, 200, 300 SLPM Figure 8. Mounting Dimensions (For reference only: mm [in].) Port Style: Manifold Mount 8 71,2 Mounting Footprint [0.3] [2.80] 55,2 [2.17] 71,2 16,0 [2.80] [0.63] 30,0 55,2 [1.2] [2.17] 4X 5,60 [104.5,68] [0.220] [310.2,60] 4X 15,0 4X 5,20 16,0 [0.59] A [0.205] [0.63] A 22,0 54,4 [0.87] 44,0 14,5 [2.14] 33,0 [1.73] [0.57] [414.7,03] [1.30] [524.1,44] B 8 [0.3] 51,5 [04.1,06] [623.4,29] 87 2 X [103.5,01 ]DIA. [2.03] [3.4] D 54 34,5 [2.1] [1.36] A Pin 1. 33 [1.3] 4X 4,50 B 4X 10-32 pan head screws 1,13 N m [20 in-lb] torque. 42,4 [0.177] [1.67] C 2X Gland for O-Ring AS568-113, 13,94 mm ID x 2,62 mm [0.549 in ID x 0.103 in W. Two O-rings, AS568A-113 Durometer 22,0 A65 to A80 Silicon or Viton, are required to seal sensor to [0.87] C manifold. O-rings are not included. 4,0 63,2 [0.16] [2.49] D Flow channel. 87 [3.4] Port Style: 22 mm OD Tapered Male Fitting per ISO 5356 14 39,5 [0.6] [1.56] 18,3 [0.72] Mounting Footprint 21,0 2X 5,70 [0.83] [0.22] 14 39.5 [0.6] [1.56] 14,8 [0.58] 14,8 [0.58] 2X 5,20 A [0.205] 14,5 A [0.57] 54,4 [2.14] 44,0 14,5 35,1[1.73] [0.57] 44,0 [1.38] [1.73] 54,4 [2.14] 2X 18,3 [0.72] B 2X 21,0 68 [0.83] [2.7] C 54 [2.1] 18,0 51,5 [0.71] [2.03] A Pin 1. B 2X 10-32 pan head screws 1,13 N m [20 in-lb] torque. C 15 mm ID/22 mm OD tapered fitting per ISO 5356. 30 35 [1.2] [1.4] 2X 4,50 [0.177] 68 42,4 [2.7] [1.67] 110 [4.3] Sensing and Internet of Things 9

Honeywell ZephyrTM Digital Airflow Sensors HAF Series—High Accuracy: 10, 15, 20, 50, 100, 200, 300 SLPM Figure 8. Mounting Dimensions (For reference only: mm [in], continued.) Port Style: G 3/8 Female Threaded Fitting per ISO 1179 16 39,5 [0.63] [1.56] Mounting Footprint 2X 18,3 16 39,5 2X 1,5 [0.72] [0.63] [1.56] [0.06] 2X 5,70 2X 1.5 14,8 [0.22] [0.06] [0.58] 14,8 A [0.58] A 44,0 14,5 35,1 [1.73] 2X 5,20 [0.57] [1.38] [0.205] 44,0 54,4 [1.73] [2.14] 54,4 14,5 [2.14] [0.57] 2X 18,3 71 [0.72] [2.8] B C A Pin 1. 51,5 B 2X 10-32 pan head screws 1,13 N m [20 in-lb] torque. [2.03] 18,0 [0.71] 54 C ISO 1179 G3/8, recommended torque is 1,7 ±0,6 N m 34,5 [2.1] [1.36] [15 ±5 in lb]. Electrical connector part number is JST (Japan Solderless Terminals) B6B-PH-K-S. Mating 30,0 connector part numbers are JST PHR-6 (socket) and [1.18] 35 2X 4,50 [1.4] [0.177] JST SPH-002T-P0.5L (crimp terminal). 71,4 [2.81] 42,4 [1.67] Table 7. Pinout (Digital Function) Pin 1 Pin 2 Pin 3 Pin 4 Pin 5 Pin 6 NC SCL VVDD ground SDA NC 10 Sensing and Internet of Things

ADDITIONAL INFORMATION WARNING The following associated literature is available on the Honeywell web site at sensing.honeywell.com: PERSONAL INJURY DO NOT USE these products as safety or emergency stop • Product line guide devices or in any other application where failure of the • Product range guide product could result in personal injury. • Technical Information Failure to comply with these instructions could result in – I2C Communications with Honeywell Digital Airflow death or serious injury. Sensors – Gas Media Compatibility and Correction Factors WARNING • Application Specific Information MISUSE OF DOCUMENTATION • The information presented in this datasheet is for reference only. Do not use this document as a product installation guide. • Complete installation, operation, and maintenance information is provided in the instructions supplied with each product. Failure to comply with these instructions could result in death or serious injury. Warranty/Remedy Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship during the applicable warranty period. Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please refer to your order acknowledgment or consult your local sales office for specific warranty details. If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace, at its option, without charge those items that Honeywell, in its sole discretion, finds defective. The foregoing is buyer’s sole remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. In no event shall Honeywell be liable for consequential, special, or indirect damages. For more information Honeywell Sensing and Internet of While Honeywell may provide application assistance personally, Things services its customers through a through our literature and the Honeywell web site, it is buyer’s worldwide network of sales offices and sole responsibility to determine the suitability of the product in distributors. For application assistance, the application. current specifications, pricing or the Specifications may change without notice. The information we nearest Authorized Distributor, visit sensing.honeywell.com or call: supply is believed to be accurate and reliable as of this writing. Asia Pacific +65 6355-2828 However, Honeywell assumes no responsibility for its use. Europe +44 (0) 1698 481481 USA/Canada +1-800-537-6945 Honeywell Sensing and Internet of Things 9680 Old Bailes Road Fort Mill, SC 29707 008268-5-EN | 5 | 02/18 www.honeywell.com © 2018 Honeywell International Inc.

Datasheet下载

Datasheet下载