ICGOO在线商城 > 传感器,变送器 > 光学传感器 - 测距 > GP2Y0D810Z0F

- 型号: GP2Y0D810Z0F

- 制造商: Sharp Microelectronics

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

GP2Y0D810Z0F产品简介:

ICGOO电子元器件商城为您提供GP2Y0D810Z0F由Sharp Microelectronics设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 GP2Y0D810Z0F价格参考。Sharp MicroelectronicsGP2Y0D810Z0F封装/规格:光学传感器 - 测距, Optical Sensor 10cm Digital Output。您可以下载GP2Y0D810Z0F参考资料、Datasheet数据手册功能说明书,资料中有GP2Y0D810Z0F 详细功能的应用电路图电压和使用方法及教程。

GP2Y0D810Z0F 是由 SHARP(夏普)和 Socle Technology 共同开发的一款光学传感器,主要用于测距应用。该传感器采用红外线技术,能够检测物体与传感器之间的距离,并输出数字信号。以下是 GP2Y0D810Z0F 的一些应用场景: 1. 机器人导航与避障 在机器人技术中,GP2Y0D810Z0F 可以用于检测前方障碍物的距离,帮助机器人进行路径规划和避障。它能够实时感知周围环境中的物体,确保机器人在移动过程中不会发生碰撞。由于其响应速度快、精度高,特别适合应用于小型机器人或自动化设备中。 2. 智能家居设备 该传感器可以集成到智能家居系统中,用于检测房间内的人员活动或物体位置。例如,在智能门锁、自动感应灯等设备中,GP2Y0D810Z0F 可以感知是否有物体靠近,从而触发相应的动作,如开锁或点亮灯光。此外,它还可以用于智能家电的防夹手功能,检测是否有物体靠近门缝,防止夹伤用户。 3. 工业自动化 在工业生产线上,GP2Y0D810Z0F 可以用于检测产品的位置或传送带上的物品是否到位。通过精确的距离测量,它可以确保生产线的正常运作,避免因物体位置不当而导致的故障。此外,它还可以用于自动化仓储系统中,帮助机器人叉车或其他搬运设备准确识别货架位置,提高物流效率。 4. 无人机与无人车 对于无人机和无人车来说,GP2Y0D810Z0F 可以作为近距离避障传感器,帮助设备在低空飞行或行驶时避开障碍物。它能够快速检测前方物体的距离,确保设备的安全运行。特别是在室内环境下,该传感器的应用可以大大提高无人设备的稳定性和安全性。 5. 医疗设备 在某些医疗设备中,GP2Y0D810Z0F 可以用于非接触式测量,例如检测患者与设备之间的距离,确保设备在使用过程中不会对患者造成伤害。此外,它还可以用于辅助手术机器人,帮助医生更精确地操作器械。 总之,GP2Y0D810Z0F 凭借其小巧的尺寸、快速的响应时间和较高的精度,适用于多种需要近距离测距的应用场景,尤其在机器人、智能家居、工业自动化等领域表现出色。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | SENSOR DIST MEASURE 10CM DIGITAL近程传感器 Distance Measuring Sensor 10cm |

| 产品分类 | |

| 品牌 | Sharp Microelectronics |

| 产品手册 | |

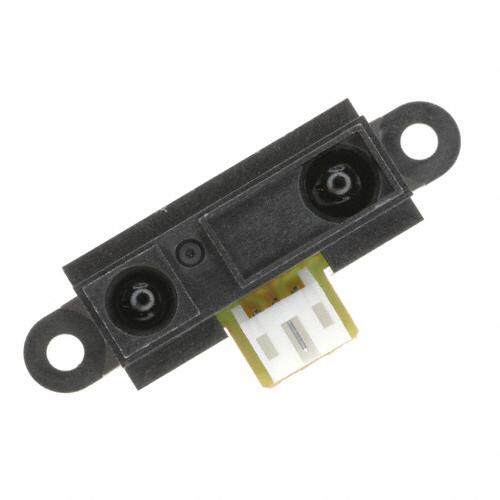

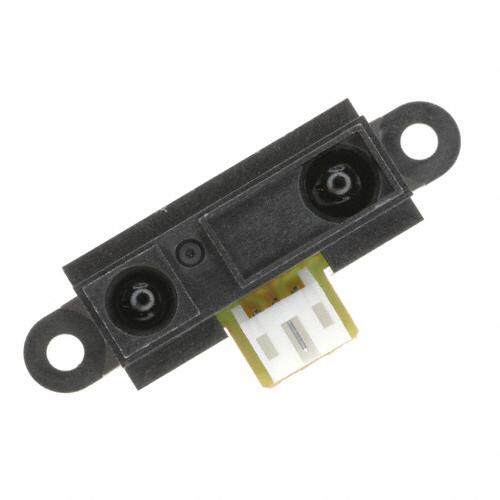

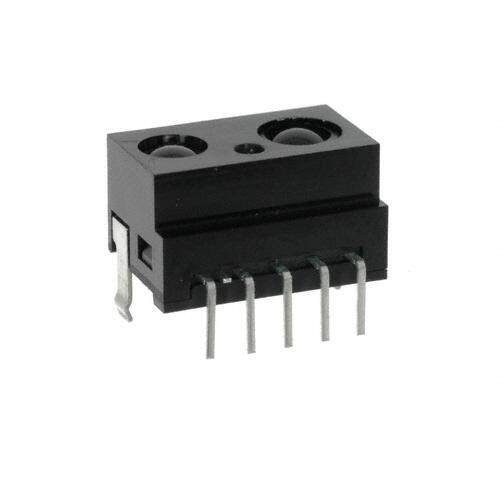

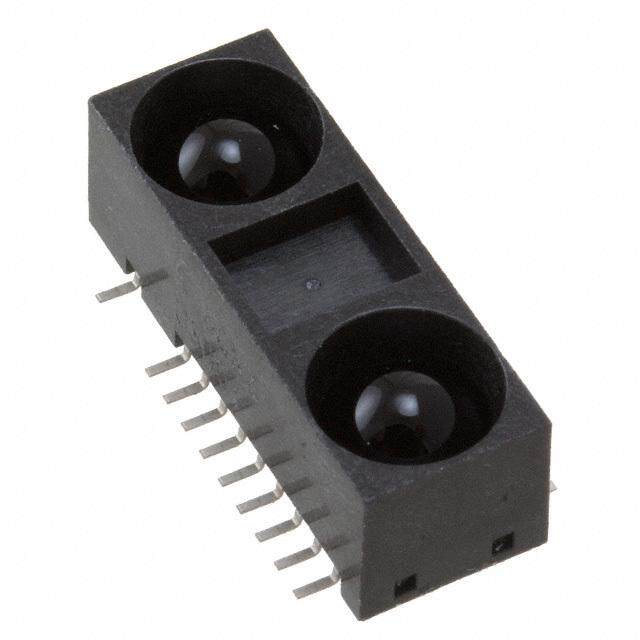

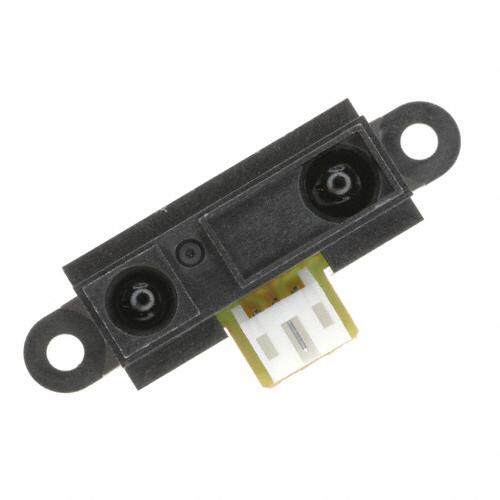

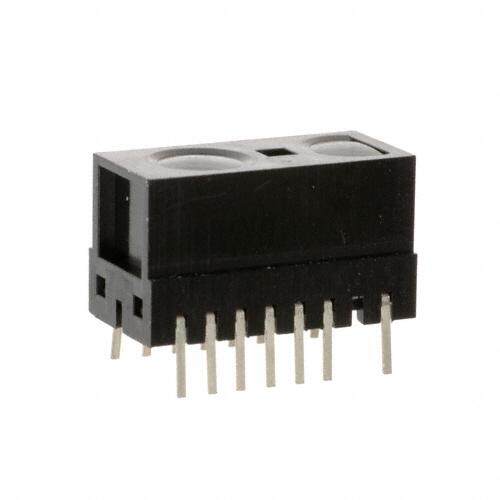

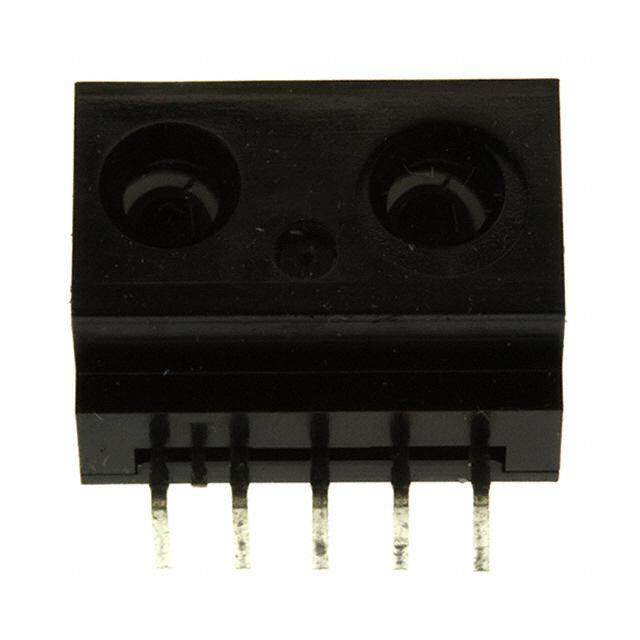

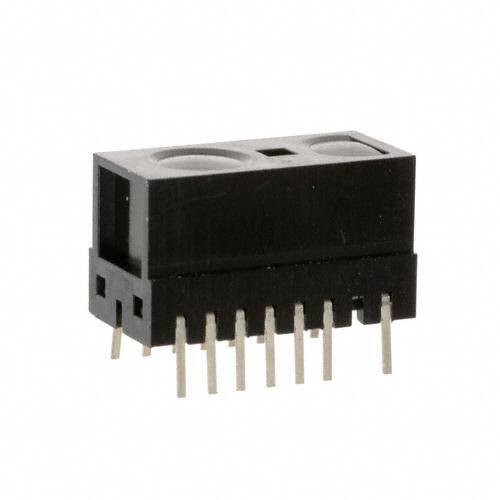

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | Sharp Microelectronics GP2Y0D810Z0F- |

| 数据手册 | http://www.sharpsma.com/webfm_send/1482http://www.sharpsma.com/webfm_send/1216 |

| 产品型号 | GP2Y0D810Z0F |

| 不同距离时的电压-输出差异(典型值) | - |

| 不同距离时的电压-输出(典型值) | - |

| 产品目录页面 | |

| 产品种类 | 近程传感器 |

| 其它名称 | 425-2616-5 |

| 商标 | Sharp Microelectronics |

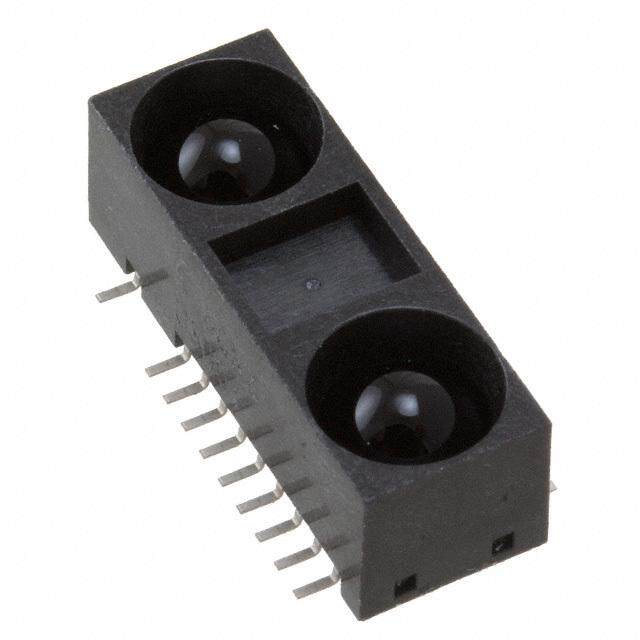

| 封装/箱体 | DIP-14 |

| 工厂包装数量 | 1000 |

| 应用说明 | http://www.sharpsma.com/webfm_send/1604 |

| 感应方式 | Optical |

| 感应距离 | 10cm |

| 最大工作温度 | + 60 C |

| 最小工作温度 | - 10 C |

| 标准包装 | 40 |

| 电压-电源 | 2.7 V ~ 6.2 V |

| 电流-电源 | 10.5mA |

| 输出类型 | 数字 |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

GP2Y0D810Z0F GP2Y0D810Z0F Distance Measuring Sensor Unit Digital output (100 mm) type ■ ■Agency approvals/Compliance Description 1. Compliant with RoHS directive (2002/95/EC) GP2Y0D810Z0F is distance measuring sensor unit, composed of an integrated combination of PSD (position sensitive detector) , IRED (infrared emitting diode) and signal processing circuit. The variety of the reflectivity of the object, the ■Applications environmental temperature and the operating duration 1. Touch-less switch are not influenced easily to the distance detection (Sanitary equipment, Control of illumination, etc.) because of adopting the triangulation method. 2. Robot cleaner The output voltage of this sensor stays high in case an object exists in the specified distance range. So this sensor can also be used as proximity sensor. ■Features 1. Digital output type 2. Short distance type Detecting distance : Typ. 100 mm 3. Low profile Package size : 13.6×7×7.95 mm 4. Consumption current : Typ. 5 mA 5. Battery drive compatible Supply voltage : 2.7 to 6.2 V 6. Sunlight tolerance 7. Add Vin terminal, and an external transistor of Vcc line is unnecessary at intermittent operating. Notice The content of data sheet is subject to change without prior notice. In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that may occur in equipment using any SHARP devices shown in catalogs, data books, etc. Contact SHARP in order to obtain the latest device specification sheets before using any SHARP device. 1 Sheet No.: E4-A01101EN Date Dec.01.2006 ©SHARP Corporation

GP2Y0D810Z0F ■Block diagram GND④ V ⑪ CC C 2 ⑫V in PD Signal VCC processing circuit Voltage regulator C REG⑦ 1 ⑭Anode V Oscillation circuit LED ⑬V O LED drive circuit Output circuit ①Cathode R 1 Distance measuring IC LED_FB② LED③ R1 (LED current adjustment resistance = 4.3 Ω) (LED Pulse current Typ. 70 mA) C1·C2=0.1μF ■Outline Dimensions (Unit : mm) 7.95 Light emitter Light detector 4.7 13.6 (3°) ot) o minal r6.5 6.2 7 (ter 0.2 2.5 A B (3°) Symbol ① Cathode S 8 1 0 ② LED_FB U 4 0 0 1 Stamp (Example) ③ LED SHARP「S」 ④ GND S 8 1 0 C GP2Y0D810Z0F ⑤ ― U 4 0 0 1 LOT No. ⑥ ― Month(1 to 9‚ O, N, D) 0.40 (DIN Standard symbol) ⑦ REG 3 P1.5-5 Year(DIN Standard symbol) ⑧ ― (terminal root) ⑨ ― DIN Standard year production ⑩ ― 3 5 7 (Remove G, I, O, Q, Y, Z) 1 2 4 6 (It repeats itself by a period for 20 years) ⑪ VCC Material year Mark ⑫ V D 2006 U in A Case PC (Color:Black) ⑬ V 2007 V O B Lens PC(Visible light cut type) 2008 W ⑭ Anode C Device coating PPS(Color:Black) 2009 X ー : No contact D Lead pin 42ALLOY(Pd-Au plating) .... .... 2025 T 14 12 10 8 2026 U (Note1) Unspecified tolerances shall be ±0.3mm. 13 11 9 Product mass : approx. 0.7g (Note2) ( ) : Reference value Sheet No.: E4-A01101EN 2

GP2Y0D810Z0F ■Absolute Maximum Ratings Parameter Symbol Rating Unit Supply voltage V -0.3 to +7 V CC Output terminal voltage V -0.3 to V +0.3 V O CC Input terminal voltage V -0.3 to V +0.3 V in CC Operating temperature T -10 to +60 ℃ opr Storage temperature T -20 to +70 ℃ stg * Soldering temperature T 260 ℃ sol ■Electro-optical Characteristics (Ta=25℃,VCC=5V) Parameter Symbol Rating MIN. TYP. MAX. Unit Average supply current I V =5V, V =5V, R =4.3Ω (*1) ― 5 6.5 mA CC1 CC in 1 Average supply current I V =5V, V =5V, R =4.3Ω (*1) ― 9 10.5 mA CC2 CC in 1 Stand-by supply current I V =5V, V =0V ― 5 8 μA CC3 CC in V Output voltage at high level V -0.6 ― ― V OH CC Output voltage V Output voltage at low level ― ― 0.6 V OL Detecting distance L (*2)(*3) 80 100 130 mm (*1) ICC1 : (LED Emitting time : Typ. 20 μs × 8 times), ICC2 : (Emitting time : Typ. 20 μs × 15 times), LED Pulse Current : Typ. 70 mA (*2) Using reflective object : White paper (Made by Kodak Co., Ltd. gray cards R-27·white face, reflectance ; 90%) (*3) Output voltage switch has a hysteresis width. The distance specified by L should be the distance which the output turns from L to H in case an object moves to the sensor. ■Recommended operating conditions Parameter Symbol Conditions Rating Unit Supply voltage V 2.7 to 6.2 V CC High level input voltage V CMOS level signal. Operating MIN V -0.2 V inH CC Low level input voltage V CMOS level signal. Standby state MAX 0.2 V inL Sheet No.: E4-A01101EN 3

GP2Y0D810Z0F Fig. 1 Timing chart Vcc (Power supply) Vin (Input) Stand-by MAX 1.88 ms (TYP 1.28 ms) Distance measuring operating First Second nth Stand-by measurement measurement measurement First Second nth Vo (Output) Unstable output output output output MAX 5.65 ms (MAX 3.77 ms) (TYP 3.84 ms) (TYP 2.56 ms) Sheet No.: E4-A01101EN 4

GP2Y0D810Z0F Fig. 2 Example of distance measuring characteristics (output) H→L H ] V [ ut Hysteresis width p ut O L L→H 0 20 40 60 80 100 120 140 160 180 200 Distance to reflective object L [mm] Set-up detection distance L = 100 mm (TYP) Sheet No.: E4-A01101EN 5

GP2Y0D810Z0F ■Notes ● Advice for the optics • The lens of this device needs to be kept clean. There are cases that dust, water or oil and so on deteriorate the characteristics of this device. Please consider in actual application. • Please don’t do washing. Washing may deteriorate the characteristics of optical system and so on. Please confirm resistance to chemicals under the actual usage since this product has not been designed against washing. ● Advice for the characteristics • In case that an optical filter is set in front of the emitter and detector portion, the optical filter which has the most efficient transmittance at the emitting wavelength range of LED for this product (λ = 870 ± 70nm), shall be recommended to use. Both faces of the filter should be mirror polishing. Also, as there are cases that the characteristics may not be satisfied according to the distance between the protection cover and this product or the thickness of the protection cover, please use this product after confirming the operation sufficiently in actual application. • In case that there is an object near to emitter side of the sensor between sensor and a detecting object, please use this device after confirming sufficiently that the characteristics of this sensor do not change by the object. • When the detector is exposed to the direct light from the sun, tungsten lamp and so on, there are cases that it can not measure the distance exactly. Please consider the design that the detector is not exposed to the direct light from such light source. • Distance to a mirror reflector can not be sometimes measured exactly. In case of changing the mounting angle of this product, it may measure the distance exactly. • In case that reflective object has boundary line which material or color etc. are excessively different, in order to decrease deviation of measuring distance, it shall be recommended to set the sensor that the direction of boundary line and the line between emitter center and detector center are in parallel. (Incorrect) (Correct) • In order to decrease deviation of measuring distance by moving direction of the reflective object, it shall be recommended to set the sensor that the moving direction of the object and the line between emitter center and detector center are vertical. (Incorrect) (Correct) (Moving direction) (Moving direction) ● Notes on handling • There are some possibilities that the internal components in the sensor may be exposed to the excessive mechanical stress. Please be careful not to cause any excessive pressure on the sensor package and also on the PCB while assembling this product. • Soldering shall be done with a soldering iron and below 260℃, less than 5s and maximum 2 times. Also, please pay attention not to put outer force on lead terminals while soldering. Please do not apply flow soldering because it may damage optical lens of the device. Sheet No.: E4-A01101EN 6

GP2Y0D810Z0F ● Presence of ODC etc. This product shall not contain the following materials. And they are not used in the production process for this product. Regulation substances : CFCs, Halon, Carbon tetrachloride, 1.1.1-Trichloroethane (Methylchloroform) Specific brominated flame retardants such as the PBB and PBDE are not used in this product at all. This product shall not contain the following materials banned in the RoHS Directive (2002/95/EC). • Lead, Mercury, Cadmium, Hexavalent chromium, Polybrominated biphenyls (PBB), Polybrominated diphenyl ethers (PBDE). Sheet No.: E4-A01101EN 7

GP2Y0D810Z0F ■Package specification Sleeve Product Put products of 40 pieces in sleeve. Sheet No.: E4-A01101EN 8

GP2Y0D810Z0F ■Important Notices · The circuit application examples in this publication are with equipment that requires higher reliability such as: provided to explain representative applications of --- Transportation control and safety equipment (i.e., SHARP devices and are not intended to guarantee any circuit aircraft, trains, automobiles, etc.) design or license any intellectual property rights. SHARP --- Traffic signals takes no responsibility for any problems related to any --- Gas leakage sensor breakers intellectual property right of a third party resulting from the use --- Alarm equipment of SHARP's devices. --- Various safety devices, etc. (iii) SHARP devices shall not be used for or in · Contact SHARP in order to obtain the latest device specifi- connection with equipment that requires an extremely high cation sheets before using any SHARP device. SHARP level of reliability and safety such as: reserves the right to make changes in the specifications, --- Space applications characteristics, data, materials, structure, and other --- Telecommunication equipment [trunk lines] contents described herein at any time without notice in --- Nuclear power control equipment order to improve design or reliability. Manufacturing --- Medical and other life support equipment (e.g., locations are also subject to change without notice. scuba). · Observe the following points when using any devices in this · If the SHARP devices listed in this publication fall publication. SHARP takes no responsibility for damage within the scope of strategic products described in the caused by improper use of the devices which does not meet the Foreign Exchange and Foreign Trade Law of Japan, it is conditions and absolute maximum ratings to be used specified necessary to obtain approval to export such SHARP devices. in the relevant specification sheet nor meet the following condi- tions: · This publication is the proprietary product of SHARP and (i) The devices in this publication are designed for use in is copyrighted, with all rights reserved. Under the copy- general electronic equipment designs such as: right laws, no part of this publication may be repro- --- Personal computers duced or transmitted in any form or by any means, --- Office automation equipment electronic or mechanical, for any purpose, in whole or in --- Telecommunication equipment [terminal] part, without the express written permission of SHARP. --- Test and measurement equipment Express written permission is also required before any use --- Industrial control of this publication may be made by a third party. --- Audio visual equipment --- Consumer electronics · Contact and consult with a SHARP representative if there (ii) Measures such as fail-safe function and redundant design are any questions about the contents of this publication. should be taken to ensure reliability and safety when SHARP devices are used for or in connection Sheet No.: E4-A01101EN 9

Datasheet下载

Datasheet下载