- 型号: GLAB20A1B

- 制造商: Honeywell Solid State Electronics

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

GLAB20A1B产品简介:

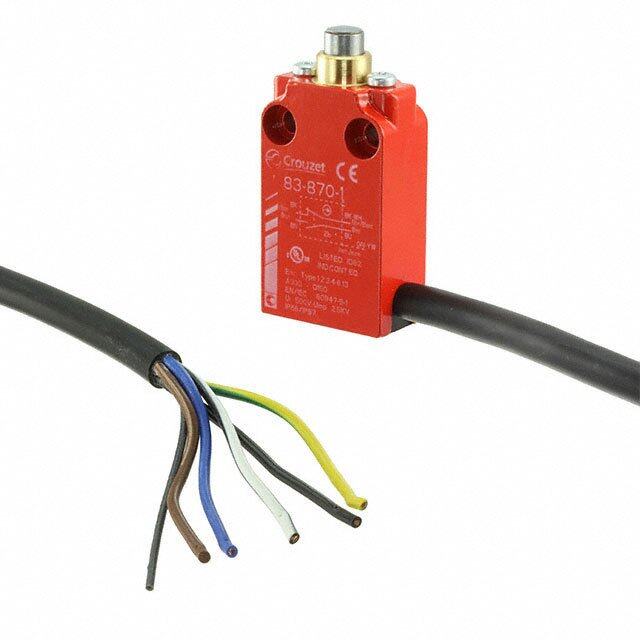

ICGOO电子元器件商城为您提供GLAB20A1B由Honeywell Solid State Electronics设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 GLAB20A1B价格参考¥1224.82-¥1224.82。Honeywell Solid State ElectronicsGLAB20A1B封装/规格:快动,限位开关, Switch DPDT Chassis Mount。您可以下载GLAB20A1B参考资料、Datasheet数据手册功能说明书,资料中有GLAB20A1B 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | SWITCH SIDE-ROTRY ROLL DPDT 120V限位开关 SW N.O./N.C. DPDT 6A Side Rotary w/Roller |

| 产品分类 | |

| IP等级 | IP 67 |

| 品牌 | Honeywell |

| 产品手册 | http://sensing.honeywell.com/product%20page?pr_id=11053 |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 开关,限位开关,Honeywell GLAB20A1BGLS |

| mouser_ship_limit | 该产品可能需要其他文件才能进口到中国。 |

| NEMA额定值 | 1, 4, 12, 13 |

| 数据手册 | |

| 产品型号 | GLAB20A1B |

| 产品种类 | |

| 侵入防护 | IP67 - 防尘,防水 |

| 其它名称 | 480-3496 |

| 包装 | 散装 |

| 商标 | Honeywell |

| 商标名 | Microswitch |

| 安装 | Screw |

| 安装类型 | 底座安装 |

| 工作位置 | 26° |

| 工作力 | 0.33 N |

| 工作温度 | -25°C ~ 85°C |

| 差动行程 | 12° |

| 开关功能 | 开-瞬时 |

| 开关类型 | Limit Switches |

| 执行器 | Lever |

| 操作力,扭矩 | 2.9 英寸‑磅 |

| 机械寿命 | 15,000,000 次循环 |

| 标准包装 | 1 |

| 特性 | 钢滚轮 |

| 电压额定值AC | 600 V |

| 电压额定值DC | 250 V |

| 电气寿命 | - |

| 电流额定值 | 10 A |

| 电路 | DPDT |

| 端子类型 | 螺丝端子 |

| 端接类型 | Screw |

| 类型 | Global Limit Switch |

| 致动器类型 | 侧旋,滚轴 |

| 触点形式 | DPDT - 2 NC / 2 NO |

| 超行程 | 59° |

| 释放力 | - |

| 预行程 | 26° |

| 额定电压-AC | 120V |

| 额定电压-DC | 125V |

| 额定电流 | 6A (AC), 550mA (DC) |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

MICRO SWITCH Global Limit Switches 002408 GLA Series Issue 4 Datasheet FEATURES • Designed to EN50041 standard, 30 mm x 60 mm mounting • Available as a standard body or plug-in body with same footprint • Wide range of actuator heads and levers • Side rotary switches factory set for CW and CCW actuation; field adjustable for CW only or CCW only • Certified for global applications; UL/CSA (Americas/Canada), CE (Europe), CCC (Asia-Pacific)1 • Conforms to IEC/EN 60947-5-1, EN45545-2 (GLA/GLF Series) • Sealed to IP67 and NEMA/UL 1, 4, 12, and 13 • Operating temperatures as low as -40 °C to 85 °C [-40 °F to 185 °F] • Multiple connectivity options to meet most applications: four DESCRIPTION different threaded conduits, micro-change connectors, mini- Honeywell’s MICRO SWITCH GLA Limit Switch Series is change connectors, Deutsch style 4-pin connector designed to global EN50041 standards and well suited for • One or two LED indicators available in switch body worldwide applications. The modular design (heads/actuators, • Single pole double throw, two pole single throw contact blocks bodies, and contact blocks) of the limit switch allows for rapid (1NC/1NO, 2NC, 2NO) are galvanically (electrically) isolated response to meet customer applications. The rugged die-cast (Zb) and designed with bifurcated contacts metal housing of the switch is ideal for indoor and outdoor • Two pole double throw contact block (2NC/2NO) has each applications where a degree of IP or NEMA enclosure sealing is pole galvanically (electrically) isolated (Zb) required. Normally closed snap-action contacts and normally • Normally closed contacts are positive opening , except closed slow-action contacts are positive opening . center neutral style • Contact blocks are available as snap action or slow action DIFFERENTIATION • Analog output available with side rotary actuator • Side rotary actuator incorporates dual bearing design which • Mechanical life up to 15 million operations prevents side loading during operation • Removable contact block allows for ease of wiring POTENTIAL APPLICATIONS • Modular design of limit switch (heads/actuators, bodies, and • Aerial lifts, boom lifts contact blocks) allows for rapid customization and delivery • Automotive assembly lines and machining centers • Optional 1 LED or 2 LED pilot lights in limit switch front • Agriculture equipment cover to indicate voltage present to switch and/or switch • Conveyors actuated • Doors and apertures • Specialty contact options, sequential (2-step style) action, • Material handling and center neutral action • Machine tools • Railroad locomotives and railroad signaling equipment PORTFOLIO • Transportation hubs The GLA Limit Switch Series with standard or plug-in • Valves housings (EN50041 design, with 30 mm x 60 mm mounting) complement the smaller GLC Series, GLD Series and GLE VALUE TO CUSTOMERS Series (EN50047 design, with 20 mm to 22 mm mounting). • Easy to install and maintain The GLA Series is part of the MICRO SWITCH Limit Switch • Rugged metal construction Series that includes the HDLS Series (Heavy Duty Limit Switch) and General Purpose Limit Switch (LS) Series. 1CCC certification is not available on the GL Series Switches sold within Europe, Middle East, and Africa. Option for CCC certification in these regions is available upon request. Sensing and Internet of Things

MICRO SWITCH Global Limit Switches, GLA Series Table 1. Specifications Characteristic Parameter Description EN50041 industrial grade limit switch, standard body or plug-in body with 30 mm x 60 mm mounting Certifications CE, CCC1, CSA, UL Conforming to standards IEC/EN 60947-5-1, EN45545-2 (GLA/GLF Series) Housing material Electrostatic epoxy coated zinc Side rotary, top pin plunger, top adjustable plunger, top roller plunger, top roller lever, Actuators wobble stick (multi-directional) actuator, cat whisker (multi-directional) actuator 0.5-14 NPT; PG 13,5; M20; G 1/2 (PF 1/2); Deutsch style 4-pin connector; Micro-change connector; Termination Mini-change connector; Pre-cabled Contact options* 1NC/1NO, 2NC, 2NO, 2NC/2NO, 2NC/2NO sequential, 2NC/2NO center neutral Contact type Snap action, slow action break-before-make (BBM), slow action make-before-break (MBB), slow action Contact material Silver alloy (standard), gold-plated (low-energy applications) Utilization category ac15, A300/A600; dc13, Q300 Rated operational voltage (Ue) 240 Vac, 600 Vac, 250 Vdc Rated operational current (Ie) 3 A, 1.2 A, 0.27 A Thermal current (Ith) 10 A, 2.5 A Rated insulation voltage (Ui) 300 V; 600 V Rated impulse withstand 2500 V voltage (Uimp) Short circuit protective device Class J fuse, rated 10A, 600 V (SCPD), type, and rating Pollution degree 3 Sealing IP67; NEMA/UL 1, 4, 12, and 13 -40 °C to 85 °C [-40 °C to 185 °F] side rotary actuator Operating temperature -25 °C to 85 °C [-13 °F to 185 °F] other actuators Mechanical life Up to 15 million operations Vibration (actuator not fitted) 10 g conforming to IEC 68-2-6 Shock (actuator not fitted) 50 g conforming to IEC 68-2-27 Standard limit switch with 1 LED pilot light (GLF Series) or 2 LED pilot lights (GLH Series) in front cover Options Plug-in limit switch with 1 LED pilot light (GLG Series) in front cover *Normally closed (NC) contacts are positive opening except for the center neutral limit switches 1CCC certification is not available on the GL Series Switches sold within Europe, Middle East, and Africa. Option for CCC certification in these regions is available upon request. Table 2. Electrical Ratings Electrical Rating ac dc A600 AC15 Q300 DC13 Gold-plated Ue Ie Ue Ie contacts (Volts) (Amps) (Volts) (Amps) 120 6 24 2.8 240 3 125 0.55 380 1.9 250 0.27 1 V 10 mA min. 480 1.5 50 V 100 mA max. 500 1.4 600 1.2 2 sensing.honeywell.com

MICRO SWITCH Global Limit Switches, GLA Series Figure 1. Product Nomenclature GL A A 01 A E7B Body Style Switch Type (EN50041) Conduit Basic Switch Heads Actuators or Levers* GGL lSoebraiels A Non plug-in A 0N.P5T-14 011snNaCp/ a1cNtOio,n SPDT 202DsnNPaCDp/T a2cNtOio,n A Side rotary 1A 31ro89ll emx r6m n fiyxloend , 3 3yroo8lkl emer, smno fixed 7A 1Øpl56a0,s4 tm imcm rmo xd 1 ConWly actuation SLwimitcith B Plug-in B PG 13,5 071gsnoNalCdp /c a1ocNntOitoa,n cStPs,D T, 222gsnoNalCdp /c a2ocNntOitoa,n cD tsP,D T, J Sceidnet erro ntaeruy,tral 1B 31ro89ll emx r6m s fitexeeld , 3A 3ynoy8kl omen, m 1ro9 fil lxxe e6rsd 7B 1Øco46i1l,7 s m pmrmimn xg 2 ConClWy actuation F Nwpiioltohnt 1pli lgLuhEgt-D in C 20 mm 021snNaCp/ a1cNtOio,n S*P*DT 242sLnENaDCp/ a2cNtOio,n D, PDT B Tpolupn pgienr (SST) 1C 32ro85ll emx r1m2 finxyelodn, 3B 3ysot8ek emel, mr1o9 lfil exxr e6sd 7C 1Øst54e3,e7 lm cmommil x s pring 3 Hleeveard t wo irtihg ht G Pwpililutohgt -1lii gnLhEtD D G(P 1F/ 12/2) 121s1nN LaCEp/D a1*cN*tOio,n S,PDT 322scnoNnaCpta/ a2cctNstOi,o L,n ED, DgPoDlTd, C Tp1ol2up nx r g5oe lmlre, rmSS rToller 1T 3189 mx 9m S fiSxTe rdo, ller 4J Aa2ld0uj0mu smitnamubm lme raoxd., 7D 1ØSS61T5,3 wm mirmem x 4 Hleeveard t wo iltehft Non plug-in 1NC/1NO, 2NC/2NO, DPDT, Top roller 38 mm fixed, Adjustable 140 mm x Head with lever H with 2 LED 03SPDT, BBM, 21snap action, D lever, nylon 1Y 50 x 10 rubber 4K aluminum rod, 8A Ø1,2 mm 5 to mounting pilot lights slow action sequential 19 x 8 mm roller roller 140 mm max. SST wire surface 1NC/1NO, SPDT, 2NC/2NO, DPDT, Top 38 to 93 mm Adjustable 190 mm x Roller plunger 33BBM, slow action, 28snap action, gold H adjustable 2A adjustable, 19 x 4N SST rod, 8B Ø1,2 mm 6 perpendicular gold contacts contacts, sequential plunger 6 nylon roller 318 mm max. SST wire to mtg. surface 041MNBCB/, 1sNloOw, aScPtDioTn, 252sLnENaDCp,/ sa2ecNqtOiuoe,n Dn, tPiaDlT, E Wobble stick 2B 3a6d8 sj tuteose t9la 3rbo lmlele,m r19 x 5A 3onfy8fl somentm ,r 1o fil9lxe xer d6 8C 1ØSS46T1,7 cmmomiml s xp ring 341MgoNBlCdB /,c 1soNlnoOtwa, caStcPstDioTn,, 312scsneoNqnaCupta/e a2cnctNtstiOia,o Ll,n ED, DgP,oDlTd, K Cwahtisker 2D 3a5d8 nj uytolso t9na3 br olmell,m e3r8 x 5B 3ostf8ef semel tmr,o 1 lfil9ex rxe d6 052slNowO ,action 262scneNnaCpte/ a2r cnNteOiou,n tDr, aPlDT, 2W 3a1d82j utruos bt9ab3be lmre r,m o3l8le rx 352sgloNolwOd ,ca octniotanc,ts 292sccnoeNnnaCpttea/ a2rc cntNsteOi,o u,n tDr, agPloDlTd, 2Y 3a1d80j utruos bt9ab3be lmre r,m o5l0le rx 062slNowC ,a ction 272scneNnaCpte/ a2r cnNteOiou,n tDr, aLPlEDDT,, *AA ccLtteuuvaaettroosrr bss ebbgeeiggniinnninnniignn ggw iwwthiitt hhco CCdooeddsee 1 78 t oaa rr5ee affoorerr EKfo ssr ttAyy llaeen wcdao tJb w bshtleyis lsekt esicridk h ehe reaoadtd ao ronynl yhl.ye.ads only. 362sgloNolwCd ,ca octniotanc,ts 302sccneoNnnaCpttea/ a2rc cntNsteOiou,n tDr, aLPlE,D gDTo,,ld **NOTE: Basic switch codes 02 and 12 may only be used with body styles B and G. Sensing and Internet of Things 3

MICRO SWITCH Global Limit Switches, GLA Series Table 3. MICRO SWITCH GLA Series Side Rotary Order Guide Catalog Listing* Head and Lever Type Contact Arrangement Contact Type Contact Material Operating Torque max. Nm [in-lb] Ba¢£r C c choonanrttata c(ctdt ce olgoprseeeneds) With LED Pilot Light/s 0.C5-o1n4d uNitPT C2o0n mdumit 26° 55°** 75° min. Silver 0,33 21-22 > 1NC/1NO Snap action 13-14 < – GLAA01A GLAC01A alloy [2.9] 12° Differential travel 26° 55°** 75° min. Silver 0,33 21-22 > 1 LED 1NC/1NO Snap action 13-14 < GLFA01A – alloy [2.9] (yellow) 12° Differential travel 26° 55°** 75° min. Gold- 0,33 21-22 > 1NC/1NO Snap action 13-14 < – GLAA07A GLAC07A plated [2.9] 12° Differential travel 1NC/1NO SlowB BacMtion, Sailllvoeyr [02,3.93] 1231--1242 26° ** 75° min. – – GLAC03A 38° Slow action, Silver 0,33 38° ** 75° min. Side 1NC/1NO MBB alloy [2.9] 1231--1242 – GLAA04A – rotary, 26° no lever Silver 0,33 26° ** 75° min. 2NC Slow action 11-12 – – GLAC06A alloy [2.9] 21-22 2NC/2NO Snap action Silver 0,33 1113--1124,, 2213--2224 26° 55°** 75° min><. – GLAA20A – alloy [2.9] 12° Differential travel 0° 16° 75° min. 2NC/2NO † 11-12 > Silver 0,33 13-14 < Center Snap action ‡ 21-22 > – GLAA26J – alloy [2.9] 23-24 < neutral 8° Differential travel 8° Differential travel 0° 16° 75° min. 2NC/2NO † 11-12 > Gold- 0,33 13-14 < Center Snap action ‡ 21-22 > – GLAA29J – plated [2.9] 23-24 < neutral 8° Differential travel 8° Differential travel 26° 55°** 75° min. Silver 0,33 21-22 > 1NC/1NO Snap action 13-14 < – GLAA01A1A GLAC01A1A alloy [2.9] 12° Differential travel 26° 55°** 75° min. 2 LEDs Gold- 0,33 21-22 > 1NC/1NO Snap action 13-14 < (green & GLHA07A1A – plated [2.9] 12° Differential travel yellow) 11NNCO/ SlowB BacMtion, Sailllvoeyr [02,3.93] 1231--1242 26° ** 75° min. – GLAA03A1A – 38° Sroidtaer y, 2NC/2NO Snap action Silver 0,33 1113--1124,, 2213--2224 26° 55°** 75° min><. – GLAA20A1A GLAC20A1A alloy [2.9] fixed 12° Differential travel lneyvleorn, 2NC/2NO Snap action Silver 0,33 1113--1124,, 2213--2224 26° 55°** 75° min><. ( g2r LeeEnD &s – GLHC24A1A roller alloy [2.9] 12° Differential travel yellow) 27° 42° 75° min. 2NC/2NO 11-12 > Silver 0,33 13-14 < Sequen- Snap action 21-22 > – GLAA21A1A – alloy [2.9] 23-24 < tial 8° Differential travel 8° Differential travel 0° 16° 75° min. 2NC/2NO † 11-12 > Silver 0,33 13-14 < Center Snap action ‡ 21-22 > – GLAA26J1A – alloy [2.9] 23-24 < neutral 8° Differential travel 8° Differential travel * Note: When conduit style G1/2 (PF1/2) is required, change the 4th digit in the catalog listing to the letter D. For example, GLAA01A1A would change to GLAD01A1A for G1/2 conduit. When conduit style PG13,5 is required, change the 4th digit in the cagalog listing to the letter B. For example, GLAA01A1A would change to GLA- B01A1A for PG13,5 conduit. ** Positive opening occurs. † Contacts 11-12, 13-14 operate in CCW direction. ‡ Contacts 21-22, 23-24 operate in CW direction. 4 sensing.honeywell.com

MICRO SWITCH Global Limit Switches, GLA Series Table 3. MICRO SWITCH GLA Series Side Rotary Order Guide, continued Catalog Listing* Head and Lever Type Contact Arrangement Contact Type Contact Material Operating Torque max. Nm [in-lb] Ba¢£r C c choonanrttata c(ctdt ce olgoprseeeneds) With LED Pilot Light/s 0.C5-o1n4d uNitPT C2o0n mdumit 26° 55°** 75° min. Silver 0,33 21-22 > 1NC/1NO Snap action 13-14 < – GLAA01A1B GLAC01A1B alloy [2.9] 12° Differential travel 26° 55°** 75° min. Silver 0,33 21-22 > 1 LED 1NC/1NO Snap action 13-14 < GLFA01A1B – alloy [2.9] (yellow) 12° Differential travel 26° 55°** 75° min. 2 LEDs Silver 0,33 21-22 > 1NC/1NO Snap action 13-14 < (green & GLHA01A1B GLHC01A1B alloy [2.9] 12° Differential travel yellow) 26° 55°** 75° min. Gold- 0,33 21-22 > 1NC/1NO Snap action 13-14 < – GLAA07A1B GLAC07A1B plated [2.9] 12° Differential travel 1NC/1NO SlowB BacMtion, Sailllvoeyr [02,3.93] 1231--1242 26° ** 75° min. – GLAA03A1B – 38° Slow action, Silver 0,33 38° ** 75° min. 1NC/1NO MBB alloy [2.9] 1231--1242 – GLAA04A1B – 26° Silver 0,33 26° ** 75° min. 2NC Slow action 11-12 – GLAA06A1B GLAC06A1B alloy [2.9] 21-22 Side 2NC/2NO Snap action Silver 0,33 1113--1124,, 2213--2224 26° 55°** 75° min><. – GLAA20A1B GLAC20A1B alloy [2.9] rotary, 12° Differential travel fixed lever, 2NC/2NO Snap action Gold- 0,33 1113--1124,, 2213--2224 26° 55°** 75° min><. – GLAA22A1B – steel plated [2.9] 12° Differential travel roller 2NC/2NO Snap action Silver 0,33 1113--1124,, 2213--2224 26° 55°** 75° min><. 1 LED GLFA24A1B – alloy [2.9] (yellow) 12° Differential travel 2NC/2NO Snap action Silver 0,33 1113--1124,, 2213--2224 26° 55°** 75° min><. (2g rLeEenD s& – – alloy [2.9] 12° Differential travel yellow) 2NC/2NO Snap action Gold- 0,33 1113--1124,, 2213--2224 26° 55°** 75° min><. ( g2r LeeEnD &s GLHA32A1B – plated [2.9] 12° Differential travel yellow) 27° 42° 75° min. 11-12 > 2NC/2NO Silver 0,33 13-14 < Snap action 21-22 > – – GLAC21A1B Sequential alloy [2.9] 23-24 < 8° Differential travel 8° Differential travel 0° 16° 75° min. 2NC/2NO † 11-12 > Silver 0,33 13-14 < Center Snap action ‡ 21-22 > – GLAA26J1B – alloy [2.9] 23-24 < neutral 8° Differential travel 8° Differential travel 0° 16° 75° min. 2NC/2NO † 11-12 > Gold- 0,33 13-14 < Center Snap action ‡ 21-22 > – GLAA29J1B – plated [2.9] 23-24 < neutral 8° Differential travel 8° Differential travel * Note: When conduit style G1/2 (PF1/2) is required, change the 4th digit in the catalog listing to the letter D. For example, GLAA01A1A would change to GLAD01A1A for G1/2 conduit. When conduit style PG13,5 is required, change the 4th digit in the cagalog listing to the letter B. For example, GLAA01A1A would change to GLA- B01A1A for PG13,5 conduit. ** Positive opening occurs. † Contacts 11-12, 13-14 operate in CCW direction. ‡ Contacts 21-22, 23-24 operate in CW direction. Sensing and Internet of Things 5

MICRO SWITCH Global Limit Switches, GLA Series Table 3. MICRO SWITCH GLA Series Side Rotary Order Guide, continued Catalog Listing* pe ent max. ht/s Head and Lever Ty Contact Arrangem Contact Type Contact Material Operating Torque Nm [in-lb] Ba¢£r C c choonanrttata c(ctdt ce olgoprseeeneds) With LED Pilot Lig 0.C5-o1n4d uNitPT C2o0n mdumit 26° 55°** 75° min. Snap ac- Silver 0,33 21-22 > 1NC/1NO 13-14 < – GLAA01A2A GLAC01A2A tion alloy [2.9] 12° Differential travel 26° 55°** 75° min. Snap ac- Gold- 0,33 21-22 > 1NC/1NO 13-14 < – GLAA07A2A – tion plated [2.9] 12° Differential travel Silver 0,33 26° ** 75° min. Side 2NC Slow action 11-12 – GLAA06A2A – alloy [2.9] 21-22 rotary, aadbjlue st- 2NC/2NO Sntaiopn ac- Sailllvoeyr [02,3.93] 1113--1124,, 2213--2224 26° 55°** 75° min><. – GLAA20A2A – 12° Differential travel lever, nroyllloenr 2NC/2NO Sntaiopn ac- pGlaotlded- [02,3.93] 1113--1124,, 2213--2224 26° 55°** 75° min><. – GLAA22A2A – 12° Differential travel 2NC/2NO Snap ac- Silver 0,33 1113--1124,, 2213--2224 26° 55°** 75° min><. 1 LED GLFA24A2A – tion alloy [2.9] (yellow) 12° Differential travel 0° 16° 75° min. 2NC/2NO † 11-12 > Snap ac- Silver 0,33 13-14 < Center ‡ 21-22 > – GLAA26J2A – tion alloy [2.9] 23-24 < neutral 8° Differential travel 8° Differential travel 26° 55°** 75° min. Snap ac- Silver 0,33 21-22 > 1NC/1NO 13-14 < – GLAA01A2B GLAC01A2B tion alloy [2.9] 12° Differential travel 26° 55°** 75° min. Snap ac- Gold- 0,33 21-22 > 1NC/1NO 13-14 < – GLAA07A2B GLAC07A2B tion plated [2.9] 12° Differential travel 26° 55°** 75° min. Snap ac- Silver 0,33 21-22 > 1 LED 1NC/1NO 13-14 < GLFA01A2B GLFC01A2B tion alloy [2.9] (yellow) 12° Differential travel Sroidtaer y, 1NC/1NO tSiolonw, B aBcM- Sailllvoeyr [02,3.93] 1231--1242 26° ** 75° min. – GLAA03A2B – 38° adjust- alebvleer , 1NC/1NO tSiolonw, B aBcM- Sailllvoeyr [02,3.93] 1231--1242 26° **38° 75° min. ( y1e LlloEwD) GLFA03A2B – steel roller 1NC/1NO tSiolonw, B aBcM- pGlaotlded- [02,3.93] 1231--1242 26° ** 75° min. ( y1e LlloEwD) GLFA33A2B – 38° Silver 0,33 26° ** 75° min. 2NC Slow action 11-12 – – GLAC06A2B alloy [2.9] 21-22 2NC/2NO Snap ac- Silver 0,33 1113--1124,, 2213--2224 26° 55°** 75° min><. – GLAA20A2B GLAC20A2B tion alloy [2.9] 12° Differential travel 0° 16° 75° min. 2NC/2NO † 11-12 > Snap ac- Silver 0,33 13-14 < Center ‡ 21-22 > – GLAA26J2B – tion alloy [2.9] 23-24 < neutral 8° Differential travel 8° Differential travel * Note: When conduit style G1/2 (PF1/2) is required, change the 4th digit in the catalog listing to the letter D. For example, GLAA01A1A would change to GLAD01A1A for G1/2 conduit. When conduit style PG13,5 is required, change the 4th digit in the cagalog listing to the letter B. For example, GLAA01A1A would change to GLA- B01A1A for PG13,5 conduit. ** Positive opening occurs. † Contacts 11-12, 13-14 operate in CCW direction. ‡ Contacts 21-22, 23-24 operate in CW direction. 6 sensing.honeywell.com

MICRO SWITCH Global Limit Switches, GLA Series Table 3. MICRO SWITCH GLA Series Side Rotary Order Guide, continued Catalog Listing* Head and Lever Type Contact Arrangement Contact Type Contact Material Operating Torque max. Nm [in-lb] Ba¢£r C c choonanrttata c(ctdt ce olgoprseeeneds) With LED Pilot Light/s 0.C5-o1n4d uNitPT C2o0n mdumit Side rotary, adjust- able 26° 55°** 75° min. Silver 0,33 21-22 > lever, 1NC/1NO Snap action 13-14 < – GLAA01A2Y – alloy [2.9] Ø 50 12° Differential travel mm rubber roller 26° 55°** 75° min. Silver 0,33 21-22 > 1NC/1NO Snap action 13-14 < – GLAA01A4J GLAC01A4J alloy [2.9] 12° Differential travel 26° 55°** 75° min. Silver 0,33 21-22 > 1 LED 1NC/1NO Snap action 13-14 < – GLFC01A4J alloy [2.9] (yellow) 12° Differential travel 26° 55°** 75° min. 2 LEDs Silver 0,33 21-22 > 1NC/1NO Snap action 13-14 < (green & GLHA01A4J – alloy [2.9] 12° Differential travel yellow) 1NC/1NO SlowB BacMtion, Sailllvoeyr [02,3.93] 1231--1242 26° ** 75° min. – GLAA03A4J – 38° Slow action, Silver 0,33 38° ** 75° min. 1NC/1NO MBB alloy [2.9] 1231--1242 – GLAA04A4J – Side 26° raodtjaursyt,- 2NC/2NO Snap action Silver 0,33 1113--1124,, 2213--2224 26° 55°** 75° min><. – GLAA20A4J – alloy [2.9] able alu- 12° Differential travel mroidnum 2NC/2NO Snap action pGlaotlded- [02,3.93] 1113--1124,, 2213--2224 26° 55°** 75° min><. – GLAA22A4J – 12° Differential travel 2NC/2NO Snap action Silver 0,33 1113--1124,, 2213--2224 26° 55°** 75° min><. 1 LED GLFA24A4J – alloy [2.9] (yellow) 12° Differential travel 2NC/2NO Snap action Gold- 0,33 1113--1124,, 2213--2224 26° 55°** 75° min><. 1 LED – GLFC32A4J plated [2.9] (yellow) 12° Differential travel 2NC/2NO Snap action Silver 0,33 1113--1124,, 2213--2224 26° 55°** 75° min><. ( g2r LeeEnD &s GLHA24A4J – alloy [2.9] 12° Differential travel yellow) 27° 42° 75° min. 2NC/2NO 11-12 > Silver 0,33 13-14 < Sequen- Snap action 21-22 > – GLAA21A4J – alloy [2.9] 23-24 < tial 8° Differential travel 8° Differential travel * Note: When conduit style G1/2 (PF1/2) is required, change the 4th digit in the catalog listing to the letter D. For example, GLAA01A1A would change to GLAD01A1A for G1/2 conduit. When conduit style PG13,5 is required, change the 4th digit in the cagalog listing to the letter B. For example, GLAA01A1A would change to GLA- B01A1A for PG13,5 conduit. ** Positive opening occurs. Sensing and Internet of Things 7

MICRO SWITCH Global Limit Switches, GLA Series Table 3. MICRO SWITCH GLA Series Side Rotary Order Guide, continued Catalog Listing* Head and Lever Type Contact Arrangement Contact Type Contact Material Operating Torque max. Nm [in-lb] Ba¢£r C c choonanrttata c(ctdt ce olgoprseeeneds) With LED Pilot Light/s 0.C5-o1n4d uNitPT C2o0n mdumit Side Silver 0,33 26° ** 75° min. rotary, 2NC Slow action 11-12 – GLAA06A5A – alloy [2.9] 21-22 fixed offset lneyvleorn, 2NC/2NO Snap action Silver 0,33 1113--1124,, 2213--2224 26° 55°** 75° min><. – GLAA20A5A – alloy [2.9] roller 12° Differential travel * Note: When conduit style G1/2 (PF1/2) is required, change the 4th digit in the catalog listing to the letter D. For example, GLAA01A1A would change to GLAD01A1A for G1/2 conduit. When conduit style PG13,5 is required, change the 4th digit in the cagalog listing to the letter B. For example, GLAA01A1A would change to GLA- B01A1A for PG13,5 conduit. ** Positive opening occurs. Table 4. MICRO SWITCH GLA Series Plunger Order Guide Catalog Listing* /s nt x. ht e a g Head Type Contact Arrangem Contact Type Contact Material Operating Force mN [lb] Bar¢ C£h c acorontn t(tamacctit lc loilompseeentders) With LED Pilot Li 0.C5-o1n4d uNitPT C2o0n mdumit 37.5 35 33** 30.5 Silver 16 21-22 > 1NC/1NO Snap action 13-14 < – GLAA01B GLAC01B alloy [3.6] 0.9 Differential travel 37.5 35 33** 30.5 Silver 16 21-22 > 1 LED 1NC/1NO Snap action 13-14 < GLFA01B GLFC01B alloy [3.6] (yellow) 0.9 Differential travel 37.5 35 33** 30.5 Gold- 16 21-22 > 1NC/1NO Snap action 13-14 < – – GLAC07B plated [3.6] 0.9 Differential travel Slow action, Silver 16 37.5 35** 30.5 1NC/1NO BBM alloy [3.6] 1231--1242 >< – GLAA03B – 34 Top pin 37.5 35 33** 30.5 plunger 2NC/2NO Snap action Silver 16 1113--1124,, 2213--2224 >< – GLAA20B GLAC20B alloy [3.6] 0.9 Differential travel 37.5 35 33** 30.5 2NC/2NO Snap action Silver 16 1113--1124,, 2213--2224 >< 1 LED GLFA24B – alloy [3.6] (yellow) 0.9 Differential travel 37.5 35 33** 30.5 2NC/2NO Snap action Gold- 16 1113--1124,, 2213--2224 >< – GLAA22B GLAC22B plated [3.6] 0.9 Differential travel 37.5 35 33.8 30.5 11-12 > Gold- 16 13-14 < 1 LED 2NC/2NO Snap action 21-22 > GLFA32B – plated [3.6] 23-24 < (yellow) 0.8 Differential travel 0.8 Differential travel * Note: When conduit style G1/2 (PF1/2) is required, change the 4th digit in the catalog listing to the letter D. For example, GLAA01A1A would change to GLAD01A1A for G1/2 conduit. When conduit style PG13,5 is required, change the 4th digit in the cagalog listing to the letter B. For example, GLAA01A1A would change to GLA- B01A1A for PG13,5 conduit. ** Positive opening occurs. 8 sensing.honeywell.com

MICRO SWITCH Global Limit Switches, GLA Series Table 5. MICRO SWITCH GLA Series Roller Plunger Order Guide Catalog Listing* nt x. ht/s e a g m m Li Head Type Contact Arrange Contact Type Contact Material Operating Force N [lb] Bar¢ C£h c acorontn t(tamacctit lc loilompseeentders) With LED Pilot 0.C5-o1n4d uNitPT C2o0n mdumit 50.5 48 46** 43.5 Silver 16 21-22 > 1NC/1NO Snap action 13-14 < – GLAA01C GLAC01C alloy [3.6] 0.9 Differential travel 50.5 48 46** 43.5 Silver 16 21-22 > 1 LED 1NC/1NO Snap action 13-14 < GLFA01C – alloy [3.6] (yellow) 0.9 Differential travel 50.5 48 46** 43.5 2 LEDs Silver 16 21-22 > 1NC/1NO Snap action 13-14 < (green & GLHA01C – alloy [3.6] 0.9 Differential travel yellow) 50.5 48 46** 43.5 Gold- 16 21-22 > 1NC/1NO Snap action 13-14 < – GLAA07C GLAC07C plated [3.6] 0.9 Differential travel 50.5 48 46** 43.5 Gold- 16 21-22 > 1 LED 1NC/1NO Snap action 13-14 < GLFA07C – plated [3.6] (yellow) 0.9 Differential travel Slow action, Silver 16 50.5 48** 43.5 1NC/1NO BBM alloy [3.6] 1231--1242 >< – GLAA03B – 47 Slow action, Silver 16 50.5 47** 43.5 Top 1NC/1NO MBB alloy [3.6] 1231--1242 >< – GLAA04B – roller 48 plunger Silver 16 50.5 48** 43.5 2NC Slow action 11-12 > – GLAA06C GLAC06C alloy [3.6] 21-22 < 50.5 48 46** 43.5 Silver 16 11-12, 21-22 > 2NC/2NO Snap action 13-14, 23-24 < – GLAA20C GLAC20C alloy [3.6] 0.9 Differential travel 50.5 48 46** 43.5 Gold- 16 11-12, 21-22 > 2NC/2NO Snap action 13-14, 23-24 < – GLAA22C – plated [3.6] 0.9 Differential travel 50.5 48 46** 43.5 Silver 16 11-12, 21-22 > 1 LED 2NC/2NO Snap action 13-14, 23-24 < GLFA24C – alloy [3.6] (yellow) 0.9 Differential travel 50.5 48 46** 43.5 2 LEDs Gold- 16 11-12, 21-22 > 2NC/2NO Snap action 13-14, 23-24 < (green & – GLHC32C plated [3.6] 0.9 Differential travel yellow) 50.5 48 45.8 43.5 2NC/2NO 11-12 > Silver 16 13-14 < Sequen- Snap action 21-22 > – GLAA21C – alloy [3.6] 23-24 < tial 0.8 Differential travel 0.8 Differential travel * Note: When conduit style G1/2 (PF1/2) is required, change the 4th digit in the catalog listing to the letter D. For example, GLAA01A1A would change to GLAD01A1A for G1/2 conduit. When conduit style PG13,5 is required, change the 4th digit in the cagalog listing to the letter B. For example, GLAA01A1A would change to GLA- B01A1A for PG13,5 conduit.. ** Positive opening occurs. Sensing and Internet of Things 9

MICRO SWITCH Global Limit Switches, GLA Series Table 6. MICRO SWITCH GLA Series Wobble Order Guide Catalog Listing* ent ax. ht/s m m g Head Type Contact Arrange Contact Type Contact Material Operating Force N [lb] Ba¢£r C c choonanrttata c(ctdt ce olgoprseeeneds) With LED Pilot Li 0.C5-o1n4d uNitPT C2o0n mdumit Wobble stick, 18° 35° Silver 0,2 21-22 > 150 mm 1NC/1NO Snap action 13-14 < – GLAA01E7A – alloy [1.8] plastic 8° Differential travel rod 18° 35° Silver 0,2 21-22 > 1NC/1NO Snap action 13-14 < – GLAA01E7B GLAC01E7B alloy [1.8] 8° Differential travel 18° 35° Silver 0,2 21-22 > 1 LED 1NC/1NO Snap action 13-14 < GLFA01E7B GLFC01E7B alloy [1.8] (yellow) 8° Differential travel 18° 35° 2 LEDs Silver 0,2 21-22 > 1NC/1NO Snap action 13-14 < (green & GLHA01E7B – alloy [1.8] Wobble 8° Differential travel yellow) stick, 18° 35° 141 mm Gold- 0,2 21-22 > 1NC/1NO Snap action 13-14 < – – GLAC07E7B sst coil plated [1.8] 8° Differential travel spring 1NC/1NO SlowB BacMtion, Sailllvoeyr [01,.28 ] 1231--1242 18° 35°>< – – – 25° 2NC/2NO Snap action Silver 0,2 1113--1124,, 2213--2224 18° 35°>< – GLAA20E7B GLAC20E7B alloy [1.8] 8° Differential travel 2NC/2NO Snap action Silver 0,2 1113--1124,, 2213--2224 18° 35°>< 1 LED GLFA24E7B – alloy [1.8] (yellow) 8° Differential travel Wobble 18° 35° stick, Silver 0,2 21-22 > 1NC/1NO Snap action 13-14 < – GLAA01E7D – 165 mm alloy [1.8] 8° Differential travel sst wire * Note: When conduit style G1/2 (PF1/2) is required, change the 4th digit in the catalog listing to the letter D. For example, GLAA01A1A would change to GLAD01A1A for G1/2 conduit. When conduit style PG13,5 is required, change the 4th digit in the cagalog listing to the letter B. For example, GLAA01A1A would change to GLA- B01A1A for PG13,5 conduit. 10 sensing.honeywell.com

MICRO SWITCH Global Limit Switches, GLA Series Table 6. MICRO SWITCH GLA Series Wobble Order Guide, continued Catalog Listing* ent ax. ht/s m m g Head Type Contact Arrange Contact Type Contact Material Operating Force N [lb] Ba¢£r C c choonanrttata c(ctdt ce olgoprseeeneds) With LED Pilot Li 0.C5-o1n4d uNitPT C2o0n mdumit Cat 18° whisker, Silver 0,1 21-22 > 1NC/1NO Snap action 13-14 < – GLAA01K8A – 140 mm alloy [0.9] 8° Differential travel sst wire 18° Silver 0,1 21-22 > 1NC/1NO Snap action 13-14 < – GLAA01K8B – alloy [0.9] 8° Differential travel Cat whisker, 190 mm sst wire 2NC/2NO Snap action Silver 0,1 1113--1124,, 2213--2224 18° >< – GLAA20K8B GLAC20K8B alloy [0.9] 8° Differential travel 18° Silver 0,1 21-22 > 1NC/1NO Snap action 13-14 < – GLAA01K8C – alloy [0.9] 8° Differential travel Cat whisker, 141 mm sst coil spring 2NC/2NO Snap action Silver 0,1 1113--1124,, 2213--2224 18° >< – GLAA20K8C – alloy [0.9] 8° Differential travel * Note: When conduit style G1/2 (PF1/2) is required, change the 4th digit in the catalog listing to the letter D. For example, GLAA01A1A would change to GLAD01A1A for G1/2 conduit. When conduit style PG13,5 is required, change the 4th digit in the cagalog listing to the letter B. For example, GLAA01A1A would change to GLA- B01A1A for PG13,5 conduit. Sensing and Internet of Things 11

MICRO SWITCH Global Limit Switches, GLA Series Table 7. MICRO SWITCH GLA Series Top Roller Lever Order Guide Catalog Listing* /s nt ht e g m Li Head Type Contact Arrange Contact Type Contact Material Operating Forcemax. N [lb] Bar¢ C£h c acorontn t(tama cctit lc loilompseeentders) With LED Pilot 0.C5-o1n4d uNitPT C2o0n mdumit 65,2 61 56,9** 52 1NC/1NO Snap action Silver 9,5 1231--1242 >< – GLAA01D GLAC01D alloy [2.1] 1,7 Differential travel 65,2 61 56,9** 52 1NC/1NO Snap action Silver 9,5 1231--1242 >< 1 LED GLFA01D – alloy [2.1] (yellow) 1,7 Differential travel Top Slow action, Silver 9,5 65,2 59,1** 52 roller 1NC/1NO MBB alloy [2.1] 1231--1242 >< – GLAA04D – lever 61 2NC/2NO Snap action Silver 9,5 1113--1124,, 2213--222465,2 61 56,9** 52>< – GLAA20D GLAC20D alloy [2.1] 1,7 Differential travel 2NC/2NO Snap action Gold- 9,5 1113--1124,, 2213--222465,2 61 56,9** 52>< – GLAA22D GLAC22D plated [2.1] 1,7 Differential travel * Note: When conduit style G1/2 (PF1/2) is required, change the 4th digit in the catalog listing to the letter D. For example, GLAA01A1A would change to GLAD01A1A for G1/2 conduit. When conduit style PG13,5 is required, change the 4th digit in the cagalog listing to the letter B. For example, GLAA01A1A would change to GLAB01A1A for PG13,5 conduit. ** Positive opening occurs. 12 sensing.honeywell.com

MICRO SWITCH Global Limit Switches, GLA Series Table 8. MICRO SWITCH GLB Series Side Rotary Order Guide (Plug-in Body) Catalog Listing* ent max. ght/s Head Type Contact Arrangem Contact Type Contact Material Operating Torque Nm [in-lb] Ba¢£r C c choonanrttata c(ctdt ce olgoprseeeneds) With LED Pilot Li 0.C5-o1n4d uNitPT C2o0n mdumit Side 26° 55°** 75° min. Snap ac- Silver 0,33 21-22 > rotary, 1NC/1NO 13-14 < – GLBA02A GLBC02A tion alloy [2.9] no lever 12° Differential travel Side rotary, 26° 55°** 75° min. fixed Snap ac- Silver 0,33 21-22 > 1NC/1NO 13-14 < – GLBA02A1A – lever, tion alloy [2.9] 12° Differential travel nylon roller Side 26° 55°** 75° min. Snap ac- Silver 0,33 21-22 > rotary, 1NC/1NO 13-14 < – GLBA02A1B GLBC02A1B tion alloy [2.9] fixed 12° Differential travel lever, 26° 55°** 75° min. steel 1NC/1NO Snap ac- Silver 0,33 1231--1242 >< 1 LED GLGA12A1B GLGC12A1B tion alloy [2.9] (yellow) roller 12° Differential travel Side rotary, adjust- 26° 55°** 75° min. Snap ac- Silver 0,33 21-22 > able 1NC/1NO 13-14 < – GLBA02A2A GLBC02A2A tion alloy [2.9] lever, 12° Differential travel nylon roller Side 26° 55°** 75° min. rotary, 1NC/1NO Snap ac- Silver 0,33 1231--1242 >< – GLBA02A2B GLBC02A2B tion alloy [2.9] adjust- 12° Differential travel able lever, 26° 55°** 75° min. Snap ac- Silver 0,33 21-22 > 1 LED steel 1NC/1NO 13-14 < GLGA12A2B – tion alloy [2.9] (yellow) roller 12° Differential travel Side 26° 55°** 75° min. Snap ac- Silver 0,33 21-22 > rotary, 1NC/1NO 13-14 < – GLBA02A4J GLBC02A4J tion alloy [2.9] adjust- 12° Differential travel able alumi- 26° 55°** 75° min. Snap ac- Silver 0,33 21-22 > 1 LED num 1NC/1NO 13-14 < GLGA12A4J – tion alloy [2.9] (yellow) rod 12° Differential travel * Note: When conduit style G1/2 (PF1/2) is required, change the 4th digit in the catalog listing to the letter D. For example, GLAA01A1A would change to GLAD01A1A for G1/2 conduit. When conduit style PG13,5 is required, change the 4th digit in the cagalog listing to the letter B. For example, GLAA01A1A would change to GLA- B01A1A for PG13,5 conduit. ** Positive opening occurs. Sensing and Internet of Things 13

MICRO SWITCH Global Limit Switches, GLA Series Table 9. MICRO SWITCH GLB Series Top Plunger Order Guide (Plug-in Body) Catalog Listing* gement ce max. ot Light/s 0.5-14 NPT 20 mm Head Type Contact Arran Contact Type Contact Mtl Operating ForN [lb] Bar¢ C£h c acorontn t(tamacctit lc loilompseeentders) With LED Pil Conduit Conduit 1NC/1NO Snap action Silver 16 1231--124237.5 35 33** 30.5>< – GLBA02B GLBC02B alloy [3.6] Top pin 0.9 Differential travel plunger 1NC/1NO Snap action Silver 16 1231--124237.5 35 33** 30.5>< 1 LED GLGA12B GLGC12B alloy [3.6] (yellow) 0.9 Differential travel 1NC/1NO Snap action Silver 16 1231--124237.5 35 33** 30.5>< – GLBA02C GLBC02C Top alloy [3.6] 0.9 Differential travel roller plunger 1NC/1NO Snap action Silver 16 1231--124237.5 35 33** 30.5>< 1 LED GLGA12C – alloy [3.6] (yellow) 0.9 Differential travel Table 10. MICRO SWITCH GLB Series Top Roller Lever Order Guide (Plug-in Body) Catalog Listing* Head Type Contact Arrangement Contact Type Contact Mtl Operating Force max. N [lb] Bar¢ C£h c acorontn t(tamacctit lc loilompseeentders) With LED Pilot Light 0.C5-o1n4d uNitPT C2o0n mdumit 1NC/1NO Snap action Silver 9.5 1113--1124,, 2213--222465,2 61 56,9** 52>< – GLBA02D GLBC02D alloy [2.1] Top 1,7 Differential travel roller lever 1NC/1NO Snap action Silver 9.5 1113--1124,, 2213--222465,2 61 56,9** 52>< 1 LED GLGA12D – alloy [2.1] (yellow) 1,7 Differential travel * Note: When conduit style G1/2 (PF1/2) is required, change the 4th digit in the catalog listing to the letter D. For example, GLAA01A1A would change to GLAD01A1A for G1/2 conduit. When conduit style PG13,5 is required, change the 4th digit in the cagalog listing to the letter B. For example, GLAA01A1A would change to GLA- B01A1A for PG13,5 conduit. ** Positive opening occurs. 14 sensing.honeywell.com

MICRO SWITCH Global Limit Switches, GLA Series Table 11. MICRO SWITCH GLB Series Wobble Order Guide (Plug-in Body) Catalog Listing* gement ce max. ot Light/s 0.5-14 NPT 20 mm Head Type Contact Arran Contact Type Contact Mtl Operating ForN [lb] Ba¢£r C c choonanrttata c(ctdt ce olgoprseeeneds) With LED Pil Conduit Conduit Wobble stick, 18° 35° 150 1NC/1NO Snap ac- Silver 0,1 1231--1242 >< – GLBA02E7A – mm tion alloy [0.9] 8° Differential travel plastic rod 18° 35° Wobble 1NC/1NO Snap ac- Silver 0,1 1231--1242 >< – GLBA02E7B GLBC02E7B stick, tion alloy [0.9] 8° Differential travel 141 mspmrin cgoil 1NC/1NO Sntaiopn ac- Sailllvoeyr [00,.19 ] 1231--1242 18° 35°>< ( y1e LlloEwD) GLGA12E7B – 8° Differential travel Cat Whis- 18° 35° ker, 190 1NC/1NO Snap ac- Silver 0,1 1231--1242 >< – GLBA02K8B – tion alloy [0.9] mm sst 8° Differential travel wire Cat whisker, 18° 35° 141 1NC/1NO Snap ac- Silver 0,1 1231--1242 >< – GLBA02K8C – mm tion alloy [0.9] 8° Differential travel sst coil spring * Note: When conduit style G1/2 (PF1/2) is required, change the 4th digit in the catalog listing to the letter D. For example, GLAA01A1A would change to GLAD01A1A for G1/2 conduit. When conduit style PG13,5 is required, change the 4th digit in the cagalog listing to the letter B. For example, GLAA01A1A would change to GLA- B01A1A for PG13,5 conduit.. Sensing and Internet of Things 15

MICRO SWITCH Global Limit Switches, GLA Series Product Dimensions: GLA Series Figure 2. Fixed Lever, Side Rotary Switch - Non-plug-in Body Style, GLZ51 Style Lever, and GLA Body Y Ø X Z 70,00 2M,7A5X6 38,1 mm 1.50 in 20,0 mm 0.79 in LEVER ROLLER X DIM Y DIM Z DIM (catalog listing) MATL GLZ51A NYLON 1.795,1 525.2,90 6.2,45 GLZ51B STEEL 1.795,1 525.2,90 6.2,45 60,0 mm 622.,404 m inm 82,0 mm1042.0,95 minm GLZ51C NYLON 12.40,05 529.3,13 1.520,7 2.36 in 75,8 mm 3.23 in GLZ51Y RUBBER 15.09,70 626.6,10 1.309,0 7,3 mm 2.99 in GLZ51T STASTINELEELSS 1.795.1 526.2.84 .83.485 0.29 in CONDUIT ENTRY Ø 5,3 mm Ø 0.21 in 5,3 mm 0.21 in 16,0 mm 310.,108 m inm 31,5 mm 0.63 in 1.24 in 42,0 mm 1.65 in 42,0 mm 1.65 in Figure 3. Fixed Lever, Side Rotary Switch - Plug-in Body Style, GLZ51 Style Lever, and GLB Body 6,4 mm [0.25 in] 55,9 mm [2.20 in] 50,0 mm Ø 19,1 mm [1.97 in] [Ø 0.75 in] 38,1 mm 70,00 mm max. [1.50 in] [2,756 in max.] 20,0 mm [0.79 in] 102,9 mm [4.05 in] 60,0 mm 69,7 mm [2.36 in] [2.74 in] 75,8 mm 62,0 mm [2.99 in] [2.44 in] 7,3 mm [0.29 in] CONDUIT ENTRY Ø 5,3 mm [Ø 0.21 in] 5,3 16,0 mm [0.63 in] 31,5 mm 30,0 mm [1.24 in] [1.18 in] 42,0 mm 41,5 mm [1.65 in] [1.63 in] 16 sensing.honeywell.com

MICRO SWITCH Global Limit Switches, GLA Series Figure 4. Adjustable Lever Dimensions, GLZ52 Y Ø X Z LEVER ROLLER X DIM Y DIM Z DIM MATL 19,1 65,9 6,4 38,1 mm to 91,5 mm adjustment GLZ52A NYLON .75 2.59 .25 1.50 in to 3.60 in adjustment 19,1 65,9 6,4 GLZ52B STEEL .75 2.59 .25 38,1 65,9 6,4 GLZ52D NYLON 1.5 2.59 .25 19,1 79,37 33,07 GLZ52E NYLON .75 3.125 1.300 40,0 71,5 12,7 GLZ52W RUBBER 1.6 2.81 .5 50,0 68,8 10,0 GLZ52Y RUBBER 1.97 2.71 .39 Figure 5. Aluminum Rod Lever Dimensions, GLZ54 6,5 mm [0.26 in] Ø 3,2 mm [Ø 0.13 in] GLZ54J: 200,0 mm [7.87 in] GLZ54K: 140,0 mm [5.51] Aluminum Rod GLZ54J: 201,5 mm [7.93 in] GLZ54K: 141,0 mm [5.56] 59,2 mm [2.33 in] Sensing and Internet of Things 17

MICRO SWITCH Global Limit Switches, GLA Series Figure 6. Pin Plunger Dimensions Figure 7. Roller Plunger Dimensions 16,0 16,0 Ø 10,0 [Ø 0.39] [0.63] 4,7 [0.63] Steel roller [0.19] Ø 12,4 37,5 [Ø 0.49] [1.48] 50,5 [1.99] Top Pin Plunger Refer to Figure 2 or 3 for other dimensions Top Roller Plunger Refer to Figure 2 or 3 for other dimensions Figure 8. Roller Lever Dimensions 16,0 7,9 [0.63] 13,0 [0.31] [0.51] 14,0 [0.55] 65,2 Ø 18,7 [2.57] [Ø 0.74] 35,0 [1.38] Top Roller Lever Refer to Figure 2 or 3 for other dimensions 18 sensing.honeywell.com

MICRO SWITCH Global Limit Switches, GLA Series Head Code: E • WOBBLE AND CAT WHISKER ACTUATOR DIMENSIONS Figure 9. Coil Actuator Figure 10. Plastic Rod and Flexible Cable Plastic tip 16,0 mm Ø6,4 mm [0.63 in] [Ø0.25 in] Cable Plastic 141,1 mm [5.55 in] 150,3 mm 153,5 mm [5.92 in] [6.04 in] Refer to Figure 2 or 3 for other dimensions Refer to Figure 2 or 3 for other dimensions Figure 11. Cat Whisker Wobbles 5.5 inches (stainless 6.5 inches (stainless steel) 7.5 inches (stainless steel) steel) Ø1,2 mm [Ø0.05 in] Ø1,3 mm [Ø0.05 in] Ø1,2 mm [Ø0.05 in] 190,5 mm [7.5 in] 165,1 mm [6.50 in] 139,7 mm [5.50 in] Refer to Figure 2 or 3 for other dimensions Sensing and Internet of Things 19

MICRO SWITCH Global Limit Switches, GLA Series APPLICATION INFORMATION Figure 14. Actuation Adjustment Side Rotary Assemblies The side rotary assemblies incorporate a feature for adjusting the free position of the side rotary lever. The EN 50041 body style allows infinite adjustment and reclamp. See the following dia- grams for details of the mechanism in each case. Figure 12. Standard EN 50041 Body Style REPLACEMENT INSTRUCTIONS All levers for side rotary assemblies are available as replacment parts. All basics, except the plug-in, can be replaced. All EN 50041 heads can be replaced. The replacement procedures for these components are straightforward in nature. Side Rotary Levers Remove the lever from the product being replaced. On EN 50041 product this is achieved by loosening the Allen screw holding the There are two lever mounting options: lever on the shaft. Replace the lever and tighten the Allen screw 1. By fully seating the lever in one of the four 90° detent posi- or combination screw. Re-test the switch in its application. tions on the shaft hub which provides positive lever retention. 2. By mounting the lever on the serrated portion of the shaft Heads (which enables the lever to be mounted in any position). All EN 50041 style switch heads can be removed and replaced. To change the rotary lever’s free position: 1. Remove the head by unscrewing the four retaining screws on 1. Use a 3 mm hex Allen wrench to loosen the Allen screw, as the head assembly. shown in Figure 13, below. 2. Ensure replacement part is identical to one being removed. 2. Back off the lever 2 mm and move it to the desired free 3. Re-test the assembly and ensure correct operation. position. Basic Switches 3. Retighten the Allen screw. Non-plug-in 4. Check to see if the free position is satisfactory for the Basic switches can be removed and replaced by following this application. procedure: 5. Repeat the adjustment procedure if necessary. 1. Remove the cover from the body. A teller tab located at the bottom of the lever (see diagram below) 2. Before disconnecting the switch wiring, carefully note the wir- helps prevent lever slippage. It enables the installer to detect the ing arrangement for your application, particularly the safety correct tightening torque. When this tab cannot be moved, the ground connection. Allen screw has been tightened properly. 3. Remove the basic switch retaining screw. 4. Remove the basic switch and install the replacement basic Figure 13. Allen Screw and Teller Tab Location switch. 5. Use the retaining screw to install the new basic switch – ensure that it is correctly seated in the switch body. 6. Wire the switch terminals as before. 7. Before replacing the cover – ensure that the basic switch wires are not twisted or otherwise lifted from the basic switch EN 50041 Side Rotary Actuator Direction Adjustment (to prevent them from becoming trapped when the cover is As furnished, GLS rotary switches will operate when the lever is replaced). rotated from either the left or right. They can be field modified to 8. Test the switch in its application. operate in one direction only (Clockwise CW; Counter clockwise Figure 15. Retaining screw location CCW) by following these steps: 1. Carefully remove the complete head assembly. 2. Turn the head assembly upside down as shown in Figure 14. 3. Pull the plunger mechanism out and rotate it through 90° increments until the alignment tab points to the desired func- tion (CW, CCW, or CW and CCW). 4. Push plunger mechanism in. 5. Reassemble the head assembly and re-test the switch in its application. 20 sensing.honeywell.com

MICRO SWITCH Global Limit Switches, GLA Series Basic Switches Plug-in EN50041 body style Figure 17. Wiring Diagram 2 The switch enclosure portion of this two-piece body style plugs into a pre-wired terminal block mounted in the application. Replacement is accomplished by unplugging the old switch enclosure and plugging-in a new switch enclosure (basics are permanently staked in the switch enclosure). LED WIRING The GLF, GLG, and GLH versions of GLS (EN 50041) come complete with LED indicators. These indicators can be wired in a variety of ways. Operation can indicate switch free or switch In Figure 17, Wiring Diagram 2, the basic switch contact is operated depending on the wiring arrangement employed. The closed. The current for the LED cannot flow through the LED table below indicates the body styles and indicators offered. and the LED will not illuminate. Table 12. LED Series Figure 18. Wiring Diagram 3 Body Function Specification GLF 1 LED 12 Æ 250 Vac and dc less than 1.5 mA draw GLG 1 LED plug- 12 Æ 250 Vac and dc less than 1.5 mA draw in GLH 2 LED 18 Æ 30 Vdc 7 mA typ. current draw The following wiring diagrams show possible configurations that can be used for the LEDs. Combinations of these arrange- ments can be used where the dual LED versions of GLS are employed. Figure 16. Wiring Diagram 1 In Figure 18, Wiring Diagram 3, regardless of the position of the basic switch, the current for the LED can flow through the LED and the LED will illuminate indicating power available. Figure 19. Wiring Diagram 4 In Figure 16, Wiring Diagram 1, the basic switch contact is open. The current for the LED can flow through the LED (via the load) and the LED illuminates. In Figure 19, Wiring Diagram 4, when the load is energized the LED will illuminate. The above examples suggest options with these versions of GLS. The LED pilot lights should be treated as ’’for indication only’’ devices. Note: While every effort is made to ensure that the above guidelines are accurate, no responsibility can be accepted for failure to apply good engineering practice to machinery design and use of Honeywell products. Never apply any of the procedures outlined above on live circuits. Ensure that testing of changes is carried out with no risk of injury during tests. These guidelines are produced to help our customers make the right choices in applying our Limit Switches to general applications. Contact your local Honeywell representative if you have any difficulties. Sensing and Internet of Things 21

MICRO SWITCH Global Limit Switches, GLA Series REPLACEMENT PARTS - Levers REPLACEMENT PARTS - Basic Switches Rod/Roll- Rod/ Roller GLF GLH Catalog GLA er Mate- Roller Dia. Width mm Basic Switch Code Body Body Listing Body rial mm [in] [in] (1 LED) (2 LEDs) Fixed length lever; 38,1 mm [1.5 in] radius 01; 1NC/1NO, snap action GLZ301 GLZ301 GLZ301 GLZ51A Nylon 19,0 [0.75] 6,35 [0.25] 03; 1NC/1NO, slow action GLZ51B Steel 19,0 [0.75] 6,35 [0.25] GLZ303 GLZ303 GLZ303 BBM GLZ51C Nylon 25,4 [1.00] 12,7 [0.50] 04; 1NC/1NO, slow action GLZ51E Bronze 19,0 [0.75] 6,35 [0.25] MBB GLZ304 GLZ304 GLZ304 GLZ51T SST 19,0 [0.75] 9,5 [0.38] 06; 2NC, Slow action GLZ306 GLZ306 GLZ306 GLZ51Y Rubber 50,0 [1.97] 10,0 [0.39] 07; 1NC/1NO, snap action, Adjustable length lever; 38,1 to 89,0 mm [1.5 to 3.5 in] gold contacts GLZ307 GLZ307 GLZ307 radius 20; 2NC/2NO, snap action GLZ320 – – GLZ52A Nylon 19,0 [0.75] 6,35 [0.25] 21; 2NC/2NO, snap action, GLZ52B Steel 19,0 [0.75] 6,35 [0.25] sequence GLZ321 – – GLZ52D Nylon 38,1 [1.50] 6,35 [0.25] 22; 2NC/2NO, snap action, GLZ322 – – gold contacts GLZ52E Nylon 19,0 [0.75] 33,1 [1.30] 24; 2NC/2NO, snap action, – GLZ324 GLZ324 GLZ52W Rubber 40.7 [1.60] 12,7 [0.50] use with LED body 26; 2NC/2NO, snap action, GLZ52Y Rubber 50,0 [1.97] 10,0 [0.39] GLZ326 – – center neutral Fixed length yoke lever; 38,1 mm [1.5in] radius 32; 2NC/2NO, snap action, GLZ53 No rollers n/a n/a gold-plated contacts, use – GLZ332 GLZ332 GLZ53A Nylon 19,0 [0.75] 6,35 [0.25] with LED body GLZ53B Steel 19,0 [0.75] 6,35 [0.25] 33; 1NC/1NO, slow action GLZ333 GLZ333 GLZ333 GLZ53E Bronze 19,0 [0.75] 6,35 [0.25] BBM, gold-plated contacts Adjustable rod levers 34; 1NC/1NO, slow action, GLZ334 GLZ334 GLZ334 MBB, gold plated contacts GLZ54 Hub only n/a n/a 36; 2NC, slow action, gold- GLZ336 GLZ336 GLZ336 plated contacts Alum. rod 3,17 mm GLZ54J 200 mm n/a [0.125 in] [7.9 in] Alum. rod 3,17 mm GLZ54K 140 mm n/a [0.125 in] [5.51 in] SST rod 3,17 mm GLZ54N 318 mm n/a [0.125 in] [12.5 in] Fixed length offset lever; 38,1 mm [1.5 in] radius GLZ55A Nylon 19,0 [0.75] 6,35 [0.25] GLZ55B Steel 19,0 [0.75] 6,35 [0.25] GLZ55E Bronze 19,0 [0.75] 6,35 [0.25] Fixed length spring rod Delrin rod, GLZ68 305 mm 6,35 [0.25] n/a [12.0 in] 22 sensing.honeywell.com

MICRO SWITCH Global Limit Switches, GLA Series REPLACEMENT PARTS - Heads Head type GLA GLB GLF GLG GLH A; Side rotary, less lever GLZ1AA GLZ1AA GLZ1AA GLZ1AA GLZ1AA B; Top pin plunger GLZ1AB GLZ1AB GLZ1AB GLZ1AB GLZ1AB C; Top roller plunger GLZ1AC GLZ1AC GLZ1AC GLZ1AC GLZ1AC D; Top roller lever GLZ1AD GLZ1AD GLZ1AD GLZ1AD GLZ1AD E7A; Wobble plastic rod, 150 mm GLZ1AE7A GLZ1AE7A GLZ1AE7A GLZ1AE7A GLZ1AE7A E7B; Wobble sst coil spring, 141 mm GLZ1AE7B GLZ1AE7B GLZ1AE7B GLZ1AE7B GLZ1AE7B E7D; Wobble sst wire, 165 mm GLZ1AE7D GLZ1AE7D GLZ1AE7D GLZ1AE7D GLZ1AE7D K8A; Cat whisker, 140 mm sst wire GLZ1AK8A GLZ1AK8A GLZ1AK8A GLZ1AK8A GLZ1AK8A K8B; Cat whisker, 190 mm sst wire GLZ1AK8B GLZ1AK8B GLZ1AK8B GLZ1AK8B GLZ1AK8B K8C; Cat whisker, sst coil spring GLZ1AK8C GLZ1AK8C GLZ1AK8C GLZ1AK8C GLZ1AK8C Sensing and Internet of Things 23

m WARNING ADDITIONAL MATERIALS PERSONAL INJURY The following associated literature is available at DO NOT USE these products as safety or emergency stop sensing.honeywell.com: devices or in any other application where failure of the • Product range guide product could result in personal injury. • Product application-specific information Failure to comply with these instructions could result in – Sensors and switches in front loaders death or serious injury. – Sensors and switches in mobile cranes – Sensors and switches in oil rig applications m WARNING MISUSE OF DOCUMENTATION • The information presented in this product sheet is for reference only. Do not use this document as a product installation guide. • Complete installation, operation, and maintenance information is provided in the instructions supplied with each product. Failure to comply with these instructions could result in death or serious injury. Warranty/Remedy Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship during the appli- cable warranty period. Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please refer to your order acknowledgment or consult your local sales office for specific warranty details. If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace, at its option, without charge those items that Honeywell, in its sole discretion, finds defec- tive. The foregoing is buyer’s sole remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. In no event shall Honeywell be liable for consequential, special, or indirect damages. While Honeywell may provide application assistance personally, For more information through our literature and the Honeywell web site, it is buyer’s Honeywell Sensing and Internet of sole responsibility to determine the suitability of the product in Things services its customers through a the application. worldwide network of sales offices and Specifications may change without notice. The information we distributors. For application assistance, supply is believed to be accurate and reliable as of this writing. current specifications, pricing or the However, Honeywell assumes no responsibility for its use. nearest Authorized Distributor, visit sensing.honeywell.com or call: Asia Pacific +65 6355-2828 Europe +44 (0) 1698 481481 USA/Canada +1-800-537-6945 Honeywell Sensing and Internet of Things 9680 Old Bailes Road Fort Mill, SC 29707 002408-4-EN | 4 | 02/18 www. honeywell.com © 2018 Honeywell International Inc. All rights reserved.

Mouser Electronics Authorized Distributor Click to View Pricing, Inventory, Delivery & Lifecycle Information: H oneywell: GLAA20K8B GLAA21A GLAA21A1A GLAA21A1B GLAA22A1B GLAA22A4J GLAA22B GLAA22D GLAA01A GLAB01A GLAB01A1A GLAB01A1B GLAB01A2A GLAB01A5A GLAB01A5B GLAB01C GLAB01E7B GLAB03A1A GLAB03A1B GLAB03A2A GLAB03A2B GLAB03A4J GLAB03B GLAB03C GLAB03D GLAB04A1A GLAB04A1B GLAB07A1B GLAB07A2B GLAB07A4J GLAB07B GLAB07C GLAB07E7B GLAB20A1A GLAB20A1B GLAB20A2A GLAB20A2B GLAB20A4J GLAB20A5B GLAB20B GLAB20C GLAB20D GLAB20E7B GLAB21C GLAB22A1A GLAB22A1B GLAB22A2B GLAB22B GLAB22C GLAB34B GLAC01A GLAC01A1A GLAC01A1B GLAC01A2A GLAC01A2B GLAC01A4J GLAC01A5B GLAC01C GLAC01E7B GLAC03A GLAC03A1B GLAC04C GLAC04D GLAC06A1B GLAC06B GLAC06C GLAC07A4J GLAC07C GLAC07E7B GLAC20A1A GLAC20A1B GLAC20A2B GLAC20A4J GLAC20C GLAC20D GLAC20E7B GLFB01A1A GLFB01A1B GLFB01A2A GLFB01A2B GLFB01A4J GLFB01C GLFB01D GLFB01E7B GLFB24A1B GLFB24A4J GLFB24C GLFC01A1B GLFC01A2B GLFC01B GLFC01C GLFC01D GLFC24A2B GLFC32A4J GLFD01A1B GLFD01A2B GLFA01A GLFA01A1A GLFA01A1B GLFA01A2B

Datasheet下载

Datasheet下载