- 型号: G3VM-61B1

- 制造商: Omron Electronics LLC

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

G3VM-61B1产品简介:

ICGOO电子元器件商城为您提供G3VM-61B1由Omron Electronics LLC设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 G3VM-61B1价格参考。Omron Electronics LLCG3VM-61B1封装/规格:固态继电器, 固体继电器 继电器 SPST-NO(1 Form A) 6-DIP(0.300",7.62mm)。您可以下载G3VM-61B1参考资料、Datasheet数据手册功能说明书,资料中有G3VM-61B1 详细功能的应用电路图电压和使用方法及教程。

Omron Electronics Inc-EMC Div 生产的固态继电器(Solid State Relay,SSR)型号 G3VM-61B1 是一款紧凑型、高性能的固态继电器,适用于多种工业和商业应用场景。以下是该型号的主要应用场景及特点: 1. 工业自动化控制 - 设备控制:用于控制各种工业设备中的电机、加热器、冷却风扇等负载。 - PLC接口:与可编程逻辑控制器(PLC)配合使用,实现对生产线中设备的开关控制。 - 传感器信号处理:将传感器检测到的信号转换为开关动作,用于监控和调节生产过程。 2. 温度控制 - 加热系统:在恒温箱、烤炉、热压机等设备中,通过精确控制加热元件的通断来维持设定温度。 - 制冷系统:用于空调、冰箱等制冷设备中,控制压缩机或风扇的运行状态。 3. 家用电器 - 家电开关控制:如微波炉、电饭煲、洗衣机等家用电器中,用于控制加热元件或电机的启动和停止。 - 节能模式:支持家电设备的节能模式切换,提高能源利用效率。 4. 医疗设备 - 精密仪器:在医疗诊断设备中,用于控制低电压、小电流电路的通断。 - 安全保护:确保设备在异常情况下能够快速切断电源,保障患者和操作人员的安全。 5. 通信与电子设备 - 信号切换:用于通信设备中的信号切换和隔离,确保信号传输的稳定性和安全性。 - 电源管理:在电子设备中实现电源的自动开启和关闭功能。 6. 照明控制 - LED灯具:用于控制LED灯的亮度调节或开关,支持智能照明系统的运行。 - 舞台灯光:在舞台灯光系统中,实现灯光效果的快速切换和调光。 特点总结: - 无触点设计:避免了机械继电器的磨损问题,寿命更长。 - 低功耗:工作时功耗较低,发热少,适合对能耗要求较高的场合。 - 高可靠性:具有较强的抗干扰能力和稳定性,能够在恶劣环境下正常工作。 - 小型化:体积小巧,便于安装在空间有限的设备中。 G3VM-61B1 的这些特点使其成为需要高效、可靠、安静开关控制的理想选择。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | RELAY SSR SPST 60V 500MA 6DIP固态继电器-PCB安装 60V, SPST-NO, DIP6 PCB 500mA 1ohm 130pF |

| 产品分类 | |

| 品牌 | Omron Electronics |

| 产品手册 | |

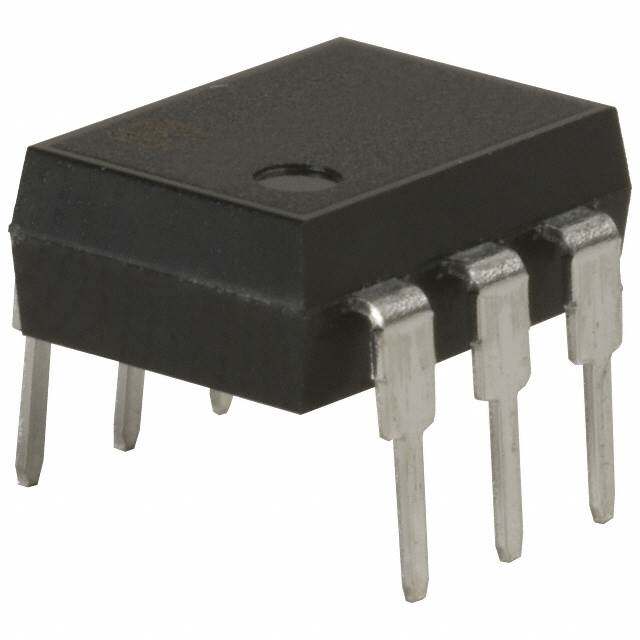

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 固态继电器,固态继电器-PCB安装,Omron Electronics G3VM-61B1G3VM |

| mouser_ship_limit | 该产品可能需要其他文件才能进口到中国。 |

| 数据手册 | |

| 产品型号 | G3VM-61B1 |

| 产品 | Power Relays |

| 产品培训模块 | http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=25458http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=26145 |

| 产品目录绘图 |

|

| 产品目录页面 | |

| 产品种类 | 固态继电器-PCB安装 |

| 产品类型 | PCB Mount |

| 供应商器件封装 | 6-DIP |

| 其它名称 | G3VM61B1 |

| 其它有关文件 | |

| 包装 | 管件 |

| 商标 | Omron Electronics |

| 安装类型 | 通孔 |

| 安装风格 | Through Hole |

| 导通电阻 | 2 欧姆 |

| 封装/外壳 | 6-DIP(0.300",7.62mm) |

| 封装/箱体 | DIP-6 |

| 工厂包装数量 | 100 |

| 控制电压范围 | 1 V to 1.3 V |

| 标准包装 | 100 |

| 电压-负载 | 0 ~ 60 V |

| 电压-输入 | 1.15VDC |

| 电路 | SPST-NO(1 Form A) |

| 端子类型 | PC 引脚 |

| 端接类型 | Solder Pin |

| 系列 | G3VM |

| 继电器类型 | |

| 触点形式 | SPST (1 Form A) |

| 负载电压额定值 | 60 V |

| 负载电流 | 500mA |

| 负载电流额定值 | 500 mA |

| 输入电流 | 50 mA |

| 输入转输出绝缘方法 | Optocoupler |

| 输出类型 | AC,DC |

| 输出设备 | MOSFET |

| 零件号别名 | G3VM61B1NC |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

.jpg)

PDF Datasheet 数据手册内容提取

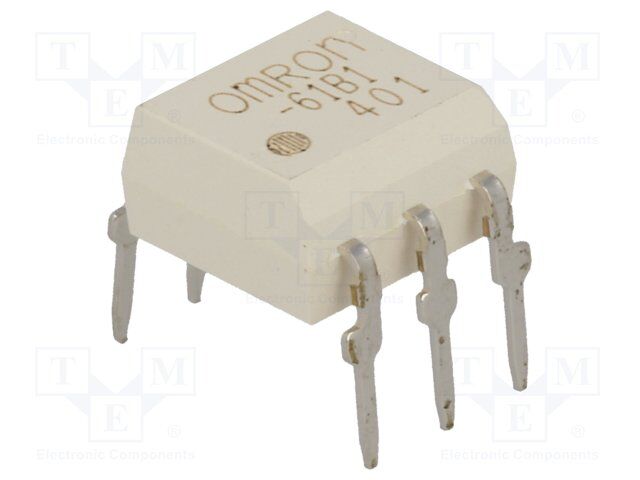

MOS FET Relays G3VM-61B1/E1 Analog-switching MOS FET Relays for High Switching Currents, with Dielectric Strength of 2.5 kVAC between I/O. (cid:127)Upgraded G3VM-61 B/E Series. (cid:127)Switches minute analog signals. (cid:127)Leakage current of 1 µA max. when output relay is open. RoHS compliant .! ■Application Examples Note: The actual product is marked differently from the image shown here. (cid:127)Measurement devices (cid:127)Security systems (cid:127)Amusement machines ■List of Models Contact form Terminals Load voltage (peak value) Model Number per stick Number per tape SPST-NO PCB terminals 60 VAC G3VM-61B1 50 --- Surface-mounting G3VM-61E1 terminals G3VM-61E1(TR) --- 1,500 ■Dimensions Note: All units are in millimeters unless otherwise indicated. G3VM-61B1 7.12±0.25 G3VM-61E1 7.12±0.25 6.4±0.25 6.4±0.25 0.8±0.25 7.62±0.25 7.62±0.25 3.65+−00..2155 3.65+−00..2155 1.0 4.0+−00..225 0.25+−00..015 min. Note: Tilysh fmero aamrck tetuhdae ld ipmifrfoeadrgeuenc tt- 2.5 min. 0.5±10..12±0.15 7.85 to 8.80 Note: Tilysh fmero aamrck tetuhdae ld ipmifrfoeadrgeuenc tt- 2.54±0.215.2±0.15 10.0 max. 1.0 min. shown here. 2.54±0.25 Weight: 0.38 g shown here. Weight: 0.38 g ■Terminal Arrangement/Internal Connections (Top View) G3VM-61B1 G3VM-61E1 6 5 4 6 5 4 1 2 3 1 2 3 ■PCB Dimensions (Bottom View) ■Actual Mounting Pad Dimensions (Recommended Value, Top View) G3VM-61B1 Six 0.8-dia. holes 2.54 (0.61) G3VM-61E1 2.54 2.54 2.54 8.3 to 8.8 (0.61) (1.52) (1.52) 1.3 1.5 12

G3VM-61B1/E1 G3VM-61B1/E1 ■Absolute Maximum Ratings (Ta = 25°C) Item Symbol Rating Unit Measurement Conditions Input LED forward current IF 50 mA Note: 1. Touhtep udti ewleacstr icch setcreknegdt hb yb eatpwpelyeinn gth veo ilntapguet abned- Repetitive peak LED forward IFP 1 A 100 µs pulses, 100 pps tween all pins as a group on the LED side and current all pins as a group on the light-receiving side. LraEteD forward current reduction ∆ IF/°C −0.5 mA/°C Ta ≥ 25°C Connection Diagram LED reverse voltage VR 5 V Connection temperature Tj 125 °C 1 6 Load Output Output dielectric strength VOFF 60 V ConnAection 2 5 o r DACC 3 4 Continuous Connection A IO 500 mA load current Connection B 500 Connection C 1,000 1 6 Load OrreaNdteu ccutirorenn t CCoonnnneeccttiioonn AB ∆ ION/°C −−55 mA/°C Ta ≥ 25°C ConnBection 23 54 DC Connection C −10.0 Connection temperature Tj 125 °C Dielectric strength between input and VI-O 2,500 Vrms AC for 1 min 1 6 Load output (See note 1.) Connection 2 5 DC Operating temperature Ta −40 to +85 °C With no icing or condensation C 3 4 Storage temperature Tstg −55 to +125 °C With no icing or condensation Soldering temperature (10 s) --- 260 °C 10 s ■Electrical Characteristics (Ta = 25°C) Item Symbol Mini- Typical Maxi- Unit Measurement mum mum conditions Input LED forward voltage VF 1.0 1.15 1.3 V IF = 10 mA Note: 2. TTuimrne-sON and Turn-OFF Reverse current IR --- --- 10 µA VR = 5 V Capacity between terminals CT --- 30 --- pF V = 0, f = 1 MHz IF 1 6 RL VDD Trigger LED forward current IFT --- 1.6 3 mA IO = 500 mA 2 4 VOUT Output Maximum resistance Connection A RON --- 1 2 Ω IF = 5 mA, with output ON IO = 500 mA Connection B --- 0.5 1 Ω IF = 5 mA, IO = 500 mA IF Connection C --- 0.25 --- Ω IF = 5 mA, Copuerrnent leakage when the relay is ILEAK --- --- 1.0 µA IVOO =F F1 =,0 6000 Vm A VOUTtON 10% 9t0O%FF Capacity between I/O terminals CI-O --- 0.8 --- pF f = 1 MHz, Vs = 0 V Insulation resistance RI-O 1,000 --- --- MΩ VI-O = 500 VDC, RoH ≤ 60% Turn-ON time tON --- 0.8 2.0 ms IF = 5 mA, RL = 200 Ω, Turn-OFF time tOFF --- 0.1 0.5 ms VDD = 20 V (See note 2.) ■Recommended Operating Conditions Use the G3VM under the following conditions so that the Relay will operate properly. Item Symbol Minimum Typical Maximum Unit Output dielectric strength VDD --- --- 48 V Operating LED forward current IF 5 7.5 25 mA Continuous load current IO --- --- 500 mA Operating temperature Ta − 20 --- 65 °C ■Engineering Data ■Safety Precautions Load Current vs. Ambient Temperature Refer to “Common Precautions” for all G3VM models. G3VM-61B1(E1) A)1,200 m nt ( Connection C urre1,000 d c a Lo 800 600 Connection A or connection B 400 200 0 −20 0 20 40 60 80 100 Ambient temperature (°C) 13

G3VM Series G3VM Series Common Precautions Protection from Surge Voltage on the Input !WARNING Terminals Be sure to turn OFF the power when wiring the Relay, other- wise an electric shock may be received. If any reversed surge voltage is imposed on the input terminals, insert a diode in parallel to the input terminals as shown in the fol- !WARNING lowing circuit diagram and do not impose a reversed voltage value of 3V or more. Do not touch the charged terminals of the SSR, otherwise an electric shock may be received. Surge Voltage Protection Circuit Example !Caution Do not apply overvoltage or overcurrent to the I/O circuits of the SSR, otherwise the SSR may malfunction or burn. !Caution Protection from Spike Voltage on the Output Terminals Be sure to wire and solder the Relay under the proper soldering conditions, otherwise the Relay in operation may generate ex- If a spike voltage exceeding the absolute maximum rated value is cessive heat and the Relay may burn. generated between the output terminals, insert a C-R snubber or clamping diode in parallel to the load as shown in the following Typical Relay Driving Circuit Examples circuit diagram to limit the spike voltage. C-MOS Spike Voltage Protection Circuit Example Load Unused Terminals (6-pin models only) Transistor Terminal 3 is connected to the internal circuit. Do not connect anything to terminal 3 externally. 10 to 100 kΩ Load Pin Strength for Automatic Mounting In order to maintain the characteristics of the relay, the force imposed on any pin of the relay for automatic mounting must not exceed the following. Use the following formula to obtain the LED current limiting resis- tance value to assure that the relay operates accurately. R = VCC − VOL − VF (ON) In direction A: 1.96 N 1 5 to 20 mA In direction B: 1.96 N Use the following formula to obtain the LED forward voltage value to assure that the relay releases accurately. V = V − V < 0.8 V F (OFF) CC OH 4

G3VM Series G3VM Series Load Connection Solder Mounting Do not short-circuit the input and output terminals while the relay Perform solder mounting under the following recommended con- is operating or the relay may malfunction. ditions to prevent the temperature of the Relays from rising. AC Connection <Flow Soldering> Through-hole Mounting (Once Only) Load Solder type Preheating Soldering Lead solder 150°C 230 to 260°C SnPb 60 to 120 s 10 s max. DC Single Connection Lead-free solder 150°C 245 to 260°C SnAgCu 60 to 120 s 10 s max. Load Note: We recommend that the suitability of solder mounting be verified under actual conditions. <Reflow Soldering> Surface Mounting DIP or SOP Packages (Twice Max.) Load Solder type Preheating Soldering Lead solder 140→160°C 210°C Peak DC Parallel Connection SnPb 60 to 120 s 30 s max. 240°C max. Load Lead-free solder 180→190°C 230°C Peak SnAgCu 60 to 120 s 30 to 50 s 260°C max. Surface Mounting SSOP Packages (Twice Max.) Solder type Preheating Soldering Lead solder 140→160°C 210°C Peak SnPb 60 to 120 s 30 s max. 240°C max. Lead-free solder 150→180°C 230°C Peak SnAgCu 120 s max. 30 s max. 250°C max. Note: 1. We recommend that the suitability of solder mounting be verified under actual conditions. 2. Tape cut SSOPs are packaged without humidity resis- tance. Use manual soldering to mount them. Manual Soldering (Once Only) Manually solder at 350°C for 3 s or less or at 260°C for 10 s or less. SSOP Handling Precautions <Humidity-resistant Packaging> Component packages can crack if surface-mounted components that have absorbed moisture are subjected to thermal stress when mounting. To prevent this, observe the following precau- tions. 1. Unopened components can be stored in the packaging at 5 to 30°C and a humidity of 90% max., but they should be used within 12 months. 2. After the packaging has been opened, components can be stored at 5 to 30°C and a humidity of 60% max., but they should be mounted within 168 hours. 3. If, after opening the packaging, the humidity indicator turns pink to the 30% mark or the expiration data is exceeded, bake the components while they are still on the taping reel, and use them within 72 hours. Do not bake the same com- ponents more than once. Baking conditions: 60±5°C, 64 to 72 h Expiration date: 12 months from the seal date (given on the label) 4. If the same components are baked repeatedly, the tape detachment strength will change, causing problems when mounting. When mounting using dehumidifying measures, always take countermeasures against component damage from static electricity. 5. Do not throw or drop components. If the laminated packag- ing material is damaged, airtightness will be lost. 6. Tape cut SSOPs are packaged without humidity resistance. Use manual soldering to mount them. 5

Mouser Electronics Authorized Distributor Click to View Pricing, Inventory, Delivery & Lifecycle Information: O mron: G3VM-61B1 G3VM-61E1 G3VM-61B G3VM-61E1(TR) G3VM-61D1(TR)

Datasheet下载

Datasheet下载