ICGOO在线商城 > 连接器,互连器件 > FFC,FPC(扁平柔性)连接器 > FH40-40S-0.5SV

- 型号: FH40-40S-0.5SV

- 制造商: Hirose Electric

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

FH40-40S-0.5SV产品简介:

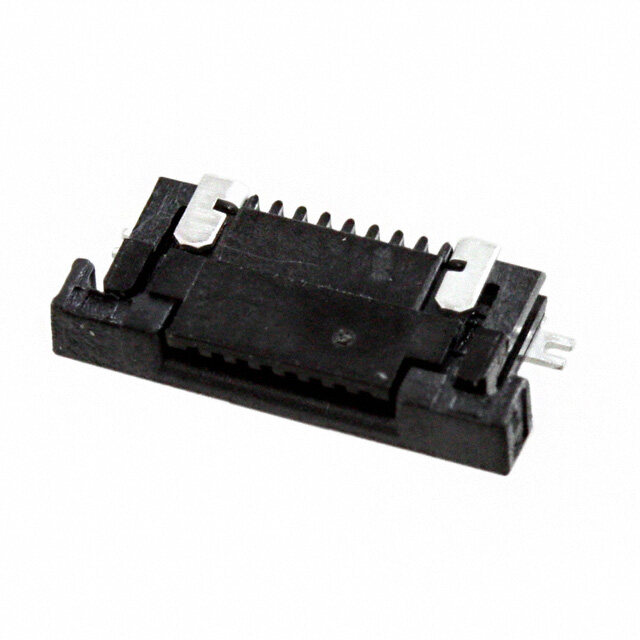

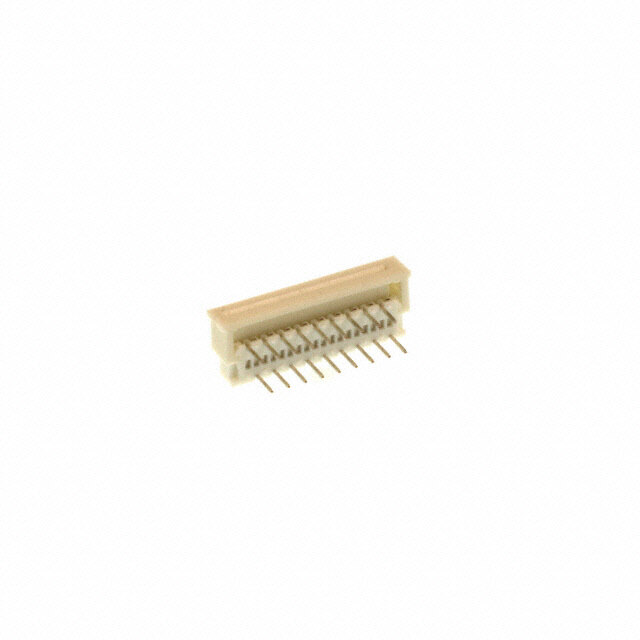

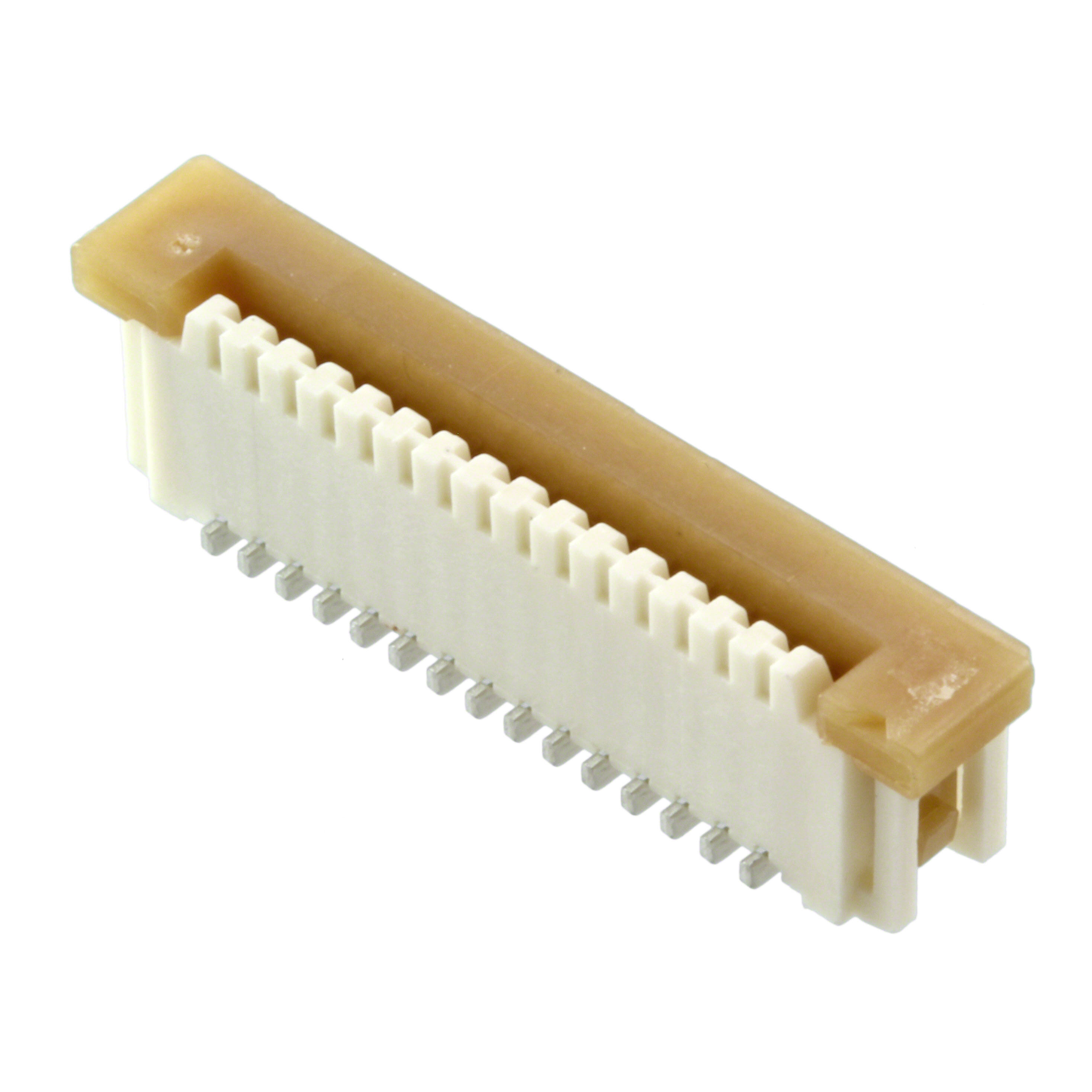

ICGOO电子元器件商城为您提供FH40-40S-0.5SV由Hirose Electric设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 FH40-40S-0.5SV价格参考。Hirose ElectricFH40-40S-0.5SV封装/规格:FFC,FPC(扁平柔性)连接器, 40 位置 FPC 连接器 触头,垂直,1 面 0.020"(0.50mm) 表面贴装。您可以下载FH40-40S-0.5SV参考资料、Datasheet数据手册功能说明书,资料中有FH40-40S-0.5SV 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | CONN FPC/FFC 40POS .5MM VERT SMDFFC & FPC连接器 0.5mm 40P VERT FPC SMT GOLD |

| 产品分类 | |

| FFC,FCB厚度 | 0.30mm |

| 品牌 | Hirose Connector |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | FFC & FPC连接器,Hirose Connector FH40-40S-0.5SVFH40 |

| 数据手册 | |

| 产品型号 | FH40-40S-0.5SV |

| 产品目录绘图 |

|

| 产品目录页面 | |

| 产品种类 | FFC & FPC连接器 |

| 产品类型 | Board Mount |

| 位置数量 | 40 |

| 其它名称 | HFW40DKR |

| 包装 | Digi-Reel® |

| 商标 | Hirose Connector |

| 外壳材料 | 液晶聚合物(LCP) |

| 安装类型 | 表面贴装 |

| 安装角 | Vertical |

| 封装 | Reel |

| 工作温度 | -40°C ~ 85°C |

| 工厂包装数量 | 1000 |

| 扁平柔性类型 | FPC |

| 材料可燃性等级 | UL94 V-0 |

| 板上高度 | 0.228"(5.80mm) |

| 标准包装 | 1 |

| 特性 | - |

| 特色产品 | http://www.digikey.com/cn/zh/ph/hirose/fh40.html |

| 电缆端类型 | 焊片式 |

| 端接 | |

| 端接类型 | SMD |

| 系列 | FH40 |

| 致动器材料 | 液晶聚合物(LCP) |

| 节距 | 0.5 mm |

| 触头材料 | 磷青铜 |

| 触头镀层 | 金 |

| 连接器/触头类型 | 触头,垂直,1 面 |

| 针脚数 | 40 |

| 锁定功能 | 触发锁 |

| 间距 | 0.020"(0.50mm) |

| 额定电压 | 50V |

| 额定电流 | 0.5A |

.jpg)

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

0.5mm Pitch, 5.8mm above the board, vertical connectors for FPC FH40 Series ●Strong actuator construction d. e v r e s e R s ht g Ri All D. Fig.1 T L O., ■Features ●Simple FPC insertion C C 1. Reduction in connection man-hours (30% RI T reduction compared to our conventional C E item) L E Our unique actuator form enables the completion of E S both FPC insertion ~ joint in the same motion. O R 2. Prevention of half and diagonal joints HI 8 The side catcher for FPC positioning ensures accurate 1 0 FPC insertion. 2 ht 3. Durable structure and no lost actuator g ri y The unique terminal form means the actuator is p o C retained, even under rough operation conditions. 8 1 4. One-finger operation of the actuator 0 Fig.2 2 1. Proven (in several other Hirose's connectors!) Flip- c. Lock rotating actuator assures reliable mechanical and e ●Lock D electrical connection with FPC, confirming it with a definite tactile feel. 5. Accepts standard FPC thickness 0.3mm thick standard Flexible Printed Circuit (FPC) can be used. 6. Board placement with automatic equipment Flat upper surface and tape and reel packaging facilitate vacuum pick-up and placement. Standard reel packaging contains 1,000 connectors. 7. Halogen-free * *As defined by IEC61249-2-21 Br-900ppm maximum, Cl-900ppm maximum, Cl + Br combined-1,500ppm maximum Fig.3 Ipnl ecaassee sc ownhtaecret ath ceo ampppalincya trieopnr ewsielln dteamtivaen fdo ar fhuirgthh eler vineflo orfm raetliiaobni.lity, such as automotive, 2016.3③ 1

FH40 Series●0.5mm Pitch, 5.8mm above the board, vertical connectors for FPC ■Product Specifications Current rating : 0.5A DC(Note 1) Operating Temperature Range : −40 to +105ç (Note 2) Storage Temperature Range : −10 to +50ç (Note 2) Ratings Voltage rating : 50Vrms AC Operating Humidity Range : Relative humidity 90% max. Storage Humidity Range : Relative humidity 90% max. (No condensation) (No condensation) Recommended FPC Thickness 0.3±0.05mm, Gold plated contact pads Item Specifi cation Conditions 1. Insulation resistance 500Mø min. 100V DC 2. Withstanding voltage No fl ashover or insulation breakdown 150Vrms AC / 1 minute 50mø max. 3. Contact resistance 1mA, (DC or 1000Hz) Including FPC and FFC conductor resistance d. Contact resistance : 50mø max. e 4. Durability 20 cycles v No damage, cracks, or parts dislocation r e s No electrical discontinuity of 1µs or longer e Frequency : 10 to 55Hz, single amplitude of 0.75mm, R 5. Vibration Contact resistance: 50mø max. s 10 cycles in each of the 3 axis. ht No damage, cracks, or parts dislocation Rig No electrical discontinuity of 1µs or longer Acceleration of 981m/s2, 6ms duaration, sine All 6. Shock No damage, cracks, or parts dislocation half-wave wavefrom 3 cycles in each of the 3 D. Contact resistance : 50mø max. axis T Contact resistance : 50mø max. L O., 7. Humidity(Steady state) INnos udlaatmioang ree,s cisratacnkcse, o: r5 p0aMrtøs mdisinlo.cation 96 hours at 40ç and humidity of 90 to 95% C C Contact resistance : 50mø max. Temperature : −40ç → +15ç to +35ç → +105ç → +15ç to +35ç RI 8. Temperature Cycle Insulation resistance : 50Mø min. Time : 30 → 2 to 3 → 30 → 2 to 3(minutes) T C No damage, cracks, or parts dislocation 5 cycles E L No deformation of Refl ow : At the recommended temperature profi le E 9. Resistance to Soldering heat E components affecting performance Manual soldering : 350ç±5ç for 5 seconds S Note 1 : When passing the current through all of the contacts, use 70% of the rated current. O R Note 2 : Includes temperature rise caused by current fl ow. HI Note 3 : The term "storage" refers to products stored for a long period prior to mounting and use. 8 The operating temperature and humidity range covers the non-conducting condition of installed connectors in storage, 1 0 shipment or during transportation after board mounting. 2 ht g yri ■Materials / Finish p o C 8 Part Material Finish Remarks 1 Color : Beige 0 Insulator LCP UL94V-0 2 Color : Black 1. c. Contact Phosphor bronze Gold plated ––––––– e D ■Product Number Structure Refer to the chart below when determining the product specifications from the product number. Please select from the product numbers listed in this catalog when placing orders. FH 40 - 50S - 0.5 SV (99) q w e r t y q Series Name : FH w Series No. : 40 e Number of positions : 10 to 80 r Contact pitch : 0.5mm t SV : SMT vertical mounting type y Specifi cations standard...Partial gold plating 1,000pcs/reel (99)...Partial gold plating 500pcs/reel 2

FH40 Series●0.5mm Pitch, 5.8mm above the board, vertical connectors for FPC ■Connector Dimensions A (FPC insertion slot dimension) Pin No.1 1 (0.12) 1 (0.12) d. e B v (5.65) r se Number of contacts indicator 4.65 e R s D. All Right 5.8 (2.3) (1.45)(4.35)5.8 T L 1 O., 0.5 3.55 C C C RI T C E Note 1 : The coplanarity of each terminal lead within specified dimension is 0.1mm Max. EL Note 2 : Packaged on tape and reel only. Check packaging specification. E Note 3 : Slight variations in color of the plastic compounds do not affect form, fit or function of the connector. S O Note 4 : After reflow, the terminal plating may change color, however this does not represent a quality issue. R HI 8 1 0 Unit : mm 2 ht Part No. HRS No. No. of Contacts A B C g ri FH40-10S-0.5SV 580-2104-6 10 5.57 8.2 4.5 y p FH40-20S-0.5SV 580-2105-9 20 10.57 13.2 9.5 o C FH40-24S-0.5SV 580-2106-1 24 12.57 15.2 11.5 8 FH40-30S-0.5SV 580-2108-7 30 15.57 18.2 14.5 1 0 FH40-40S-0.5SV 580-2107-4 40 20.57 23.2 19.5 2 1. FH40-45S-0.5SV 580-2101-8 45 23.07 25.7 22 c. FH40-50S-0.5SV 580-2100-5 50 25.57 28.2 24.5 e D FH40-60S-0.5SV 580-2109-0 60 30.57 33.2 29.5 FH40-64S-0.5SV 580-2102-0 64 32.57 35.2 31.5 FH40-80S-0.5SV 580-2103-3 80 40.57 43.2 39.5 Note 1 : Tape and reel packaging (1,000 pcs/reel, 500 pcs/reel). Order by number of reels. 3

FH40 Series●0.5mm Pitch, 5.8mm above the board, vertical connectors for FPC BRecommended PCB mounting pattern and metal mask dimensions n) patter mask) and etal L M Pin No.1 ±0.1 ( 0.05 ( 2 ± 1. 1 1 0. 1 ± 0. 2 ± 1. 5 2 4. d. e v er 0.5±0.05 0.35±0.1 (Land pattern) s 1±0.05 e 0.25±0.05 (Metal mask) R s C±0.05 ht g Recommended metal mask thickness : t=0.15 Ri All D. BRecommended FPC Dimensions T L O., It is not recommended to mate FPC without tabs to this connector. C C RI X) T ( ELEC R0.2MAXR0.2MAX 4±0.1 8±0.1 HIROSE 3.5MIN R 0.2 M A X 1. 2. 4.5MIN (stiffener) 018 R0.2 0.5±0.05 0.35±0.03 CC00..55MMMAAAXXX 0.3±0.05 2 0.5±0.1 C±0.05 0.5±0.1 ht D±0.07 g E±0.1 ri y p o C Note 1 : Stiffener dimension should be 3.5mm min., and X dimension should be 0.5mm for improved 8 flexibility of FPC. 1 0 2 c.1. Unit : mm e D Part No. HRS No. No. of Contacts C D E FH40-10S-0.5SV 580-2104-6 10 4.5 5.5 7.1 FH40-20S-0.5SV 580-2105-9 20 9.5 10.5 12.1 FH40-24S-0.5SV 580-2106-1 24 11.5 12.5 14.1 FH40-30S-0.5SV 580-2108-7 30 14.5 15.5 17.1 FH40-40S-0.5SV 580-2107-4 40 19.5 20.5 22.1 FH40-45S-0.5SV 580-2101-8 45 22 23 24.6 FH40-50S-0.5SV 580-2100-5 50 24.5 25.5 27.1 FH40-60S-0.5SV 580-2109-0 60 29.5 30.5 32.1 FH40-64S-0.5SV 580-2102-0 64 31.5 32.5 34.1 FH40-80S-0.5SV 580-2103-3 80 39.5 40.5 42.1 4

FH40 Series●0.5mm Pitch, 5.8mm above the board, vertical connectors for FPC BRecommended FPC construction 1. Using Single-sided FPC FPC : Flexible Printed Circuit Material Thickness Material Name Material (µm) Covering fi lm layer Polyimide 1 mil thick. (25) Cover adhesive (25) Surface treatment 0.2µm thick gold plated over 1 to 3 5µm nickel underplating Copper foil Cu 1oz 35 Base adhesive Thermosetting adhesive 25 Base fi lm Polyimide 1 mil thick 25 d. ve Reinforcement material adhesive Thermosetting adhesive 40 r e s Stiffene Polyimide 7 mil thick 175 e R Total 303 s ht g Ri All 2. Using Double-sided FPC FPC : Flexible Printed Circuit D. T L Material Thickness O., Material Name Material (µm) C Covering film layer Polyimide 1 mil thick. (25) C RI Cover adhesive (25) CT Surface treatment 05.µ2mµ mn icthkieclk u gnodlde rppllaatteindg over 1 to 3 E L Through-hole copper Cu 15 E E Copper foil Cu 1/2oz 18 S O Base adhesive Thermosetting adhesive 18 R HI Base film Polyimide 1 mil thick 25 8 Base adhesive Thermosetting adhesive 18 1 0 Copper foil Cu 1/2oz (18) 2 ht Cover adhesive Thermosetting adhesive 25 g yri Covering film layer Polyimide 1 mil thick. 25 p o Reinforcement material adhesive Thermosetting adhesive 50 C 8 Stiffener Polyimide 4 mil thick 100 1 20 * To prevent release of the FPC due to its bending, use of the double sided FPC Total 297 1. with copper foil on the back side is NOT RECOMMENDED. c. e D 3. Using FFC FFC : Flexible Flat Cable Material Name Material Thickness (µm) Polyester fi lm 12 Adhesive Polyester thermoplastic type 30 Annealed copper foil 35 (Gold plating over nickel under plating) Adhesive Polyester 30 Polyester 12 Adhesive Polyester 30 Stiffener Polyester 188 Total 295 * Actual tolerance of the thickness is approximately ±20µm. 1. This specifi cation is a recommendation for the material confi guration of the FPC/FFC (t=0.3 ±0.05mm) for the FH40 series connectors. 2. Please contact the FPC/FFC manufacturer for the material confi gurations of their FPC/FFC. 5

FH40 Series●0.5mm Pitch, 5.8mm above the board, vertical connectors for FPC BPackaging Specification ● Embossed Carrier Tape Dimensions ● Embossed Carrier Tape Dimensions (Tape width to 24mm max.) (Tape width 32mm min.) 1 4±0.1 2±0.1512±0.1 Ø1.5+0.10 1.75±0.1 (0.5) (6) 4±0.1 2±0.1512±0.1 Ø1.5+0.01 1.75±0. (0.5) (6) 1 ±0.1 H±0. (J) H ±0.3 (J) ±0.1±0.3 F GF ed. +0.150 v (3.25) 7 er (0.45) (2.05) Flat surface, 1. es (6.25) for placement with ghts R Unreeling direction automatic equipment. (3.25)(6.25) (0.45) (2.051).5+Ffo00lar.1 tp slaucrefamcee,n t with Ri automatic equipment. All Unreeling direction D. LT ● Reel Dimensions O., Ø13) ( C C (K: INSIDE) RI T C E ELE (Ø380)(Ø80) S O R (L: OUTSIDE) HI 8 1 0 2 End portion Mounting portion Lead portion (400mm min.) ht g ri y p o C 8 01 Noi ncsoenrnteedctor Embossed carrier tape Noi ncsoenrnteedctor Top cover tape 2 1. (10 pockets min.) (10 pockets min.) c. e D BPackaging Specification Dimensions Unit : mm Part No. HRS No. No. of Contacts F G H J K L FH40-10S-0.5SV 580-2104-6 10 16 --- 7.5 8.4 17.4 21.4 FH40-20S-0.5SV 580-2105-9 20 --- 13.4 24 11.5 25.4 29.4 FH40-24S-0.5SV 580-2106-1 24 --- 15.4 FH40-30S-0.5SV 580-2108-7 30 32 28.4 14.2 18.4 33.4 37.4 FH40-40S-0.5SV 580-2107-4 40 23.4 FH40-45S-0.5SV 580-2101-8 45 44 40.4 20.2 25.9 45.4 49.4 FH40-50S-0.5SV 580-2100-5 50 28.4 FH40-60S-0.5SV 580-2109-0 60 33.4 FH40-64S-0.5SV 580-2102-0 64 56 52.4 26.2 35.4 57.4 61.4 FH40-80S-0.5SV 580-2103-3 80 43.4 Note 1 : Tape and reel packaging (1,000 pcs/reel). 6

FH40 Series●0.5mm Pitch, 5.8mm above the board, vertical connectors for FPC BTemperature Profile MAX 250ç HRS test conditions 250 Solder method : Reflow, IR/hot air 230ç Environment: : Room air Solder composition : Paste, 96.5%Sn/3%Ag/0.5%Cu e 200 200ç (Senju Metal Industry, Co., Ltd.’s atur Part Number : M705-GRN360-K2-V) per Test board : Glass epoxy 30mm∞66mm∞0.8mm thick m Te 150 150ç Land dimensions : 0.35mm∞1.2mm Metal mask : 0.25∞1.0∞0.15mm thick (ç) d. 100 The temperature profiles shown are based on the above e v conditions. r e s In individual applications the actual temperature may vary, Re 50 depending on solder paste type, volume / thickness and s 25ç board size / thickness. Consult your solder paste and ht (60 seconds) 90 to 120 seconds 60 seconds g equipment manufacturer for specific recommendations. Ri 0 Preheating Soldering All Start D. Time (Seconds) T L O., C C RI T C E L E E S O R HI 8 1 0 2 ht g ri y p o C 8 1 0 2 1. c. e D 7

FH40 Series●0.5mm Pitch, 5.8mm above the board, vertical connectors for FPC BConnector Operation and Precautions Operation Precautions 1. FPC Termination procedure. q Avoid forcing the actuator up or down without q Verify that the actuator is positioned upright. If the FPC inserted. the actuator has rotated to the side, carefully rotate it upright. d. e v er w Insert the FPC vertically in the connector slot w Application of excessive force to the inserted s e assuring that the conductive traces of the FPC FPC may cause damage to connector and may R s are facing away from the actuator. affect the reliability of electrical connection. ht g Ri All FPC conductive traces D. T L O., C C RI T C E L E E Do not insert the FPC diagonally. S e Press down the actuator in the direction shown. Doing so will result in the corners of the FPC O R catching on the contacts and will cause HI deformation of the contacts. 8 1 0 2 e Disengage the actuator to release the lock and ht extract the FPC/FFC (refer to the picture g ri below). By utilizing your thumb and index y p finger, you can easily manipulate the actuator o C to disengage the lock. 8 1 0 2. FPC Removal 2 c.1. q Rotate the actuator upward and withdraw the e FPC. D During the design phase of the PCB layout, make sure to incorporate enough space to engage/ disengage the actuator on this connector when inserting or removing the FPC. ® 2-6-3,Nakagawa Chuoh,Tsuzuki-Ku,Yokohama-Shi 224-8540,JAPAN TEL: +81-45-620-3526 Fax: +81-45-591-3726 http://www.hirose.com http://www.hirose-connectors.com The characteristics and the specifications contained herein are for reference purpose. Please refer to the latest customer drawings prior to use. 8 The contents of this catalog are current as of date of 03/2016. Contents are subject to change without notice for the purpose of improvements. Powered by TCPDF (www.tcpdf.org)

Mouser Electronics Authorized Distributor Click to View Pricing, Inventory, Delivery & Lifecycle Information: H irose Electric: FH40-10S-0.5SV FH40-20S-0.5SV FH40-24S-0.5SV FH40-30S-0.5SV FH40-40S-0.5SV FH40-45S-0.5SV FH40- 50S-0.5SV FH40-60S-0.5SV FH40-64S-0.5SV FH40-80S-0.5SV FH40-60(30)SB-1SV FH40-80(40)SB-1SV FH40- 30S-0.5SV(99) FH40-80(40)SB-1SV(99) FH40-10S-0.5SV(99) FH40-80S-0.5SV(99) FH40-24S-0.5SV(99) FH40- 45S-0.5SV(99) FH40-60S-0.5SV(99) FH40-64S-0.5SV(99) FH40-50S-0.5SV(99) FH40-20S-0.5SV(99) FH40-40S- 0.5SV(99) FH40-60(30)SB-1SV(99)

Datasheet下载

Datasheet下载

.jpg)

.jpg)