- 型号: F970J156KBA

- 制造商: AVX

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

F970J156KBA产品简介:

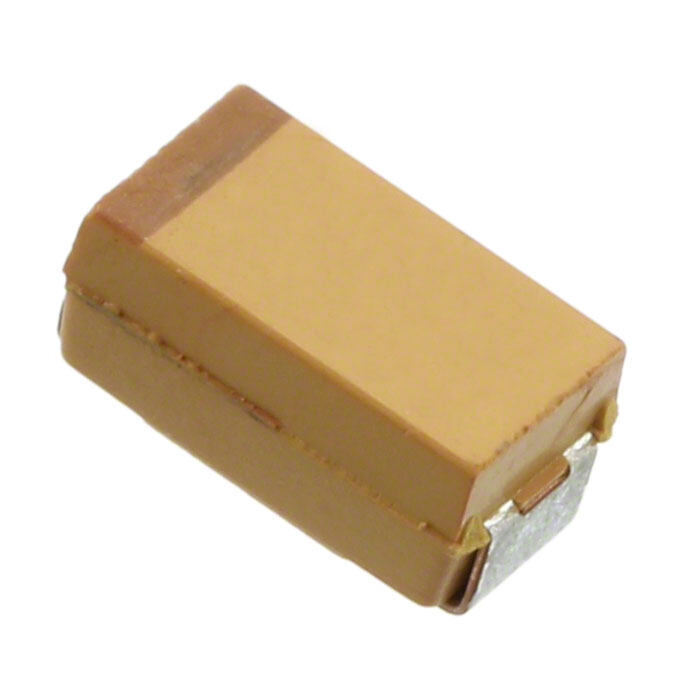

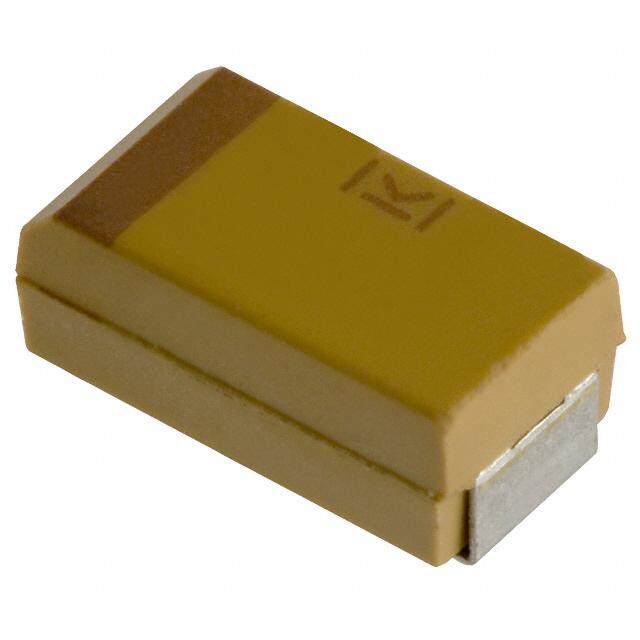

ICGOO电子元器件商城为您提供F970J156KBA由AVX设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 F970J156KBA价格参考。AVXF970J156KBA封装/规格:钽电容器, 15µF 模制 钽电容器 6.3V 1411(3528 公制) 2 欧姆。您可以下载F970J156KBA参考资料、Datasheet数据手册功能说明书,资料中有F970J156KBA 详细功能的应用电路图电压和使用方法及教程。

AVX Corporation的钽电容器型号F970J156KBA是一款固态钽电容器,其主要应用场景包括但不限于以下几个方面: 1. 电源管理电路 在电源管理系统中,F970J156KBA可以用于滤波、去耦和储能。它能够有效减少电源噪声,确保电压稳定,特别适用于需要高可靠性和低噪声的电源设计。例如,在开关电源、线性稳压器等设备中,该电容器可以提供稳定的电压输出,防止电压波动对系统的影响。 2. 通信设备 钽电容器广泛应用于通信设备中的信号处理和传输模块。F970J156KBA具有良好的高频特性,能够在高速数据传输和信号调理电路中发挥重要作用。例如,在基站、路由器、交换机等通信设备中,它可以用于滤除高频干扰,保证信号的完整性和稳定性。 3. 消费电子 在智能手机、平板电脑、笔记本电脑等消费电子产品中,F970J156KBA可用于音频放大器、摄像头模块、触摸屏控制器等关键组件的电源滤波和去耦。它的高容值和小体积使其成为这些紧凑型设备的理想选择,能够有效减少电磁干扰(EMI),提升产品的性能和用户体验。 4. 工业自动化 在工业自动化控制系统中,如PLC(可编程逻辑控制器)、变频器、伺服驱动器等,F970J156KBA可以用于电源滤波、信号调理和瞬态电压抑制。它能够承受较大的温度变化和机械振动,确保系统的稳定运行,特别是在恶劣的工作环境下,如高温、潮湿或强电磁干扰的环境中。 5. 汽车电子 在汽车电子系统中,如发动机控制单元(ECU)、车身控制系统、安全气囊系统等,F970J156KBA可用于电源滤波和去耦。它具备出色的抗振性和耐温性,能够在极端条件下保持稳定工作,确保汽车电子系统的可靠性和安全性。 6. 医疗设备 在医疗设备中,如心电图仪、超声波设备、监护仪等,F970J156KBA可以用于电源滤波和信号调理,确保设备的精度和可靠性。其高可靠性使得它在对精度要求极高的医疗应用中表现优异。 总之,AVX Corporation的F970J156KBA钽电容器凭借其高可靠性、低ESR(等效串联电阻)和长寿命等特点,广泛应用于各种需要高性能电容器的场景,尤其是在对稳定性、可靠性和小型化有较高要求的应用中。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | CAP TANT 15UF 6.3V 10% 1411 |

| ESR(等效串联电阻) | 2 欧姆 |

| 产品分类 | |

| 品牌 | AVX Corporation |

| 数据手册 | |

| 产品图片 |

|

| 产品型号 | F970J156KBA |

| PCN制造商信息 | |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | F97 |

| 不同温度时的使用寿命 | - |

| 其它名称 | 478-8521-6 |

| 制造商尺寸代码 | B |

| 包装 | Digi-Reel® |

| 大小/尺寸 | 0.138" 长 x 0.110" 宽(3.50mm x 2.80mm) |

| 安装类型 | 表面贴装 |

| 容差 | ±10% |

| 封装/外壳 | 1411(3528 公制) |

| 工作温度 | -55°C ~ 125°C |

| 引线间距 | - |

| 标准包装 | 1 |

| 特性 | 高可靠性 |

| 电压-额定 | 6.3V |

| 电容 | 15µF |

| 类型 | 模制 |

| 高度-安装(最大值) | 0.091"(2.30mm) |

PDF Datasheet 数据手册内容提取

F97 Series Resin-Molded Chip, Improved Reliability J-Lead FEATURES • Compliant to the RoHS2 directive 2011/65/EU • Compliant to AEC-Q200 • Improved reliability - FR=0.5%/1000hrs LEAD-FREE COMPATIBLE • SMD J-lead COMPONENT APPLICATIONS • Automotive electronics(Engine ECU) • Industrial equipment CASE DIMENSIONS:millimeters (inches) Code EIA Code EIA Metric L W1 W2 H S 3.20 ± 0.20 1.60 ± 0.20 1.20 ± 0.10 1.60 ± 0.20 0.80 ± 0.20 A 1206 3216-18 (0.126 ± 0.008) (0.063 ± 0.008) (0.047 ± 0.004) (0.063 ± 0.008) (0.031 ± 0.008) 3.50 ± 0.20 2.80 ± 0.20 2.20 ± 0.10 1.90 ± 0.20 0.80 ± 0.20 B 1210 3528-21 (0.138 ± 0.008) (0.110 ± 0.008) (0.087 ± 0.004) (0.075 ± 0.008) (0.031 ± 0.008) 6.00 ± 0.20 3.20 ± 0.20 2.20 ± 0.10 2.50 ± 0.20 1.30 ± 0.20 C 2312 6032-27 (0.236 ± 0.008) (0.126 ± 0.008) (0.087 ± 0.004) (0.098 ± 0.008) (0.051 ± 0.008) 7.30 ± 0.20 4.30 ± 0.20 2.40 ± 0.10 2.80 ± 0.20 1.30 ± 0.20 N 2917 7343-30 (0.287 ± 0.008) (0.169 ± 0.008) (0.094 ± 0.004) (0.110 ±0.008) (0.051 ± 0.008) A, B CASE C, N CASE MARKING L W1 L W1 A CASE B CASE C CASE N CASE H H Capacitance Capacitance Capacitance Capacitance Code (µF) (µF) Month (µF) Code Month W2 W2 C 475 1160r MCoondteh 1016r 4710r Code S S S S Rated Voltage Rated Voltage Rated Voltage Rated Voltage Code (V) (V) (V) HOW TO ORDER F97 1C 335 M A (cid:2) Type Rated Capacitance Tolerance Case Packaging Voltage Code K = ±10% Size See Tape & Reel pF code: 1st two digits M = ±20% See Packaging Section represent significant figures, table 3rd digit represents multiplier above (number of zeros to follow) TECHNICAL SPECIFICATIONS Category Temperature Range: -55 to +125°C Rated Temperature: +85°C Capacitance Tolerance: ±20%, ±10% at 120Hz Dissipation Factor: Refer to next page ESR 100kHz: Refer to next page Leakage Current: After 1 minute’s application of rated voltage, leakage current at 20°C is not more than 0.01CV or 0.5μA, whichever is greater. After 1 minute’s application of rated voltage, leakage current at 85°C is not more than 0.1CV or 5μA, whichever is greater. After 1 minute’s application of derated voltage, leakage current at 125°C is not more than 0.125CV or 6.3μA, whichever is greater. Capacitance Change By Temperature +15% Max. at +125°C +10% Max. at +85°C -10% Max. at -55°C 108 071119

F97 Series Resin-Molded Chip, Improved Reliability J-Lead CAPACITANCE AND RATED VOLTAGE RANGE (LETTER DENOTES CASE SIZE) Capacitance Rated Voltage μF Code 6.3V (0J) 10V (1A) 16V (1C) 20V (1D) 25V (1E) 35V (1V) 0.33 334 A 0.47 474 A 0.68 684 A A A 1.0 105 A A A B 1.5 155 A A B 2.2 225 A A A B B 3.3 335 A A A B B C 4.7 475 A A/B A/B A/B C C 6.8 685 A/B B B C C N 10 106 A/B A/B/C C C/N N 15 156 B B A/C N N 22 226 A/B A/B B/C/N C/N N 33 336 A/C B/C/N B/C/N 47 476 B/C B/C/N C/N 68 686 N N 100 107 N C 150 157 C Released ratings Please contact to your local AVX sales office when these series are being designed in your application. Voltage vs Temperature Rating 100% 100% 100% 90% 80% 70% 60% 67% 67% 63% 50% 50% 50% 40% 42% 30% 32% 20% 10% 0% -55ºC 85ºC 125ºC Rated Voltage Recommended Applications Voltage in General Circuit Recommended Applications Voltage in Low Impedance Circuit 071119 109

F97 Series Resin-Molded Chip, Improved Reliability J-Lead RATINGS & PART NUMBER REFERENCE Rated DF ESR 100kHz RMS Current (mA) *1 AVX Case Capacita n c e Voltage DCL @ 120Hz @ 100kHz ΔC/C MSL P a r t N o . S i z e ( μ F ) (V) ( μ A ) (%) (Ω) 2 5 º C 8 5 º C 1 2 5 º C (%) 6.3 Volt F970J335#AA A 3.3 6.3 0.5 4 4.5 129 116 52 * 3 F970J475#AA A 4.7 6.3 0.5 6 4.0 137 123 55 * 3 F970J685#AA A 6.8 6.3 0.5 6 3.5 146 132 59 * 3 F970J685#BA B 6.8 6.3 0.5 6 2.5 184 166 74 * 3 F970J156#BA B 15 6.3 0.9 6 2.0 206 186 82 * 3 F970J226#AA A 22 6.3 1.4 12 2.5 173 156 69 * 3 F970J226#BA B 22 6.3 1.4 8 1.9 212 190 85 * 3 F970J336#AA A 33 6.3 2.1 12 2.5 173 156 69 * 3 F970J336#CC C 33 6.3 2.1 6 1.1 316 285 126 * 3 F970J476#BA B 47 6.3 3.0 8 1.0 292 262 117 * 3 F970J476#CC C 47 6.3 3.0 6 0.9 350 315 140 * 3 F970J686#NC N 68 6.3 4.3 6 0.6 500 450 200 * 3 F970J107#NC N 100 6.3 6.3 8 0.6 500 450 200 * 3 F970J157#CC C 150 6.3 9.5 12 0.7 396 357 159 * 3 10 Volt F971A225#AA A 2.2 10 0.5 4 5.0 122 110 49 * 3 F971A335#AA A 3.3 10 0.5 4 4.5 129 116 52 * 3 F971A475#AA A 4.7 10 0.5 6 4.0 137 123 55 * 3 F971A475#BA B 4.7 10 0.5 6 2.8 174 157 70 * 3 F971A685#BA B 6.8 10 0.7 6 2.5 184 166 74 * 3 F971A106#AA A 10 10 1.0 6 3.0 158 142 63 * 3 F971A106#BA B 10 10 1.0 6 2.0 206 186 82 * 3 F971A156#BA B 15 10 1.5 6 2.0 206 186 82 * 3 F971A226#AA A 22 10 2.2 15 3.0 158 142 63 * 3 F971A226#BA B 22 10 2.2 8 1.9 212 190 85 * 3 F971A336#BA B 33 10 3.3 8 1.9 212 190 85 * 3 F971A336#CC C 33 10 3.3 6 1.1 316 285 126 * 3 F971A336#NC N 33 10 3.3 6 0.7 463 417 185 * 3 F971A476#BA B 47 10 4.7 10 1.0 292 262 117 * 3 F971A476#CC C 47 10 4.7 8 0.9 350 315 140 * 3 F971A476#NC N 47 10 4.7 6 0.7 463 417 185 * 3 F971A686#NC N 68 10 6.8 6 0.6 500 450 200 * 3 F971A107#CC C 100 10 10.0 10 0.7 396 357 159 * 3 16 Volt F971C105#AA A 1 16 0.5 4 7.5 100 90 40 * 3 F971C155#AA A 1.5 16 0.5 4 6.3 109 98 44 * 3 F971C225#AA A 2.2 16 0.5 4 5.0 122 110 49 * 3 F971C335#AA A 3.3 16 0.5 4 4.5 129 116 52 * 3 F971C475#AA A 4.7 16 0.8 8 4.0 137 123 55 * 3 F971C475#BA B 4.7 16 0.8 6 2.8 174 157 70 * 3 F971C685#BA B 6.8 16 1.1 6 2.5 184 166 74 * 3 F971C106#AA A 10 16 1.6 8 3.5 146 132 59 * 3 F971C106#BA B 10 16 1.6 6 2.1 201 181 80 * 3 F971C106#CC C 10 16 1.6 6 1.5 271 244 108 * 3 F971C156#AA A 15 16 2.4 12 3.5 146 132 59 ±10 3 F971C156#CC C 15 16 2.4 6 1.2 303 272 121 * 3 F971C226#BA B 22 16 3.5 8 1.9 212 190 85 * 3 F971C226#CC C 22 16 3.5 8 1.1 316 285 126 * 3 F971C226#NC N 22 16 3.5 6 0.7 463 417 185 * 3 F971C336#BA B 33 16 5.3 10 2.1 201 181 80 * 3 F971C336#CC C 33 16 5.3 8 1.1 316 285 126 * 3 F971C336#NC N 33 16 5.3 6 0.7 463 417 185 * 3 F971C476#CC C 47 16 7.5 10 1.1 316 285 126 * 3 F971C476#NC N 47 16 7.5 8 0.7 463 417 185 * 3 20 Volt F971D684#AA A 0.68 20 0.5 4 7.6 99 89 40 * 3 F971D105#AA A 1 20 0.5 4 7.5 100 90 40 * 3 F971D155#AA A 1.5 20 0.5 4 6.7 106 95 42 * 3 F971D225#AA A 2.2 20 0.5 6 6.3 109 98 44 * 3 F971D335#BA B 3.3 20 0.7 4 3.1 166 146 66 * 3 F971D475#AA A 4.7 20 0.9 8 4.0 137 123 55 * 3 F971D475#BA B 4.7 20 0.9 6 2.8 174 157 70 * 3 F971D685#CC C 6.8 20 1.4 6 1.8 247 222 99 * 3 F971D106#CC C 10 20 2.0 6 1.5 271 244 108 * 3 F971D156#NC N 15 20 3.0 6 0.7 463 417 185 * 3 F971D226#CC C 22 20 4.4 8 1.1 316 285 126 * 3 F971D226#NC N 22 20 4.4 6 0.7 463 417 185 * 3 25 Volt F971E684#AA A 0.68 25 0.5 4 7.6 99 89 40 * 3 F971E105#AA A 1 25 0.5 4 7.5 100 90 40 * 3 F971E225#BA B 2.2 25 0.6 4 3.8 150 135 60 * 3 F971E335#BA B 3.3 25 0.8 4 3.5 156 140 62 * 3 F971E475#CC C 4.7 25 1.2 6 1.8 247 222 99 * 3 110 071119

F97 Series Resin-Molded Chip, Improved Reliability J-Lead RATINGS & PART NUMBER REFERENCE Rated DF ESR 100kHz RMS Current (mA) *1 AVX Case Capacita n c e Voltage DCL @ 120Hz @ 100kHz ΔC/C MSL P a r t N o . S i z e ( μ F ) (V) ( μ A ) (%) (Ω) 2 5 º C 8 5 º C 1 2 5 º C (%) F971E685#CC C 6.8 25 1.7 6 1.8 247 222 99 * 3 F971E106#CC C 10 25 2.5 6 1.6 262 236 105 * 3 F971E106#NC N 10 25 2.5 6 1.0 387 349 155 * 3 F971E156#NC N 15 25 3.8 6 0.7 463 417 185 * 3 F971E226#NC N 22 25 5.5 6 0.7 463 417 185 * 3 35 Volt F971V334#AA A 0.33 35 0.5 4 12.0 79 71 32 * 3 F971V474#AA A 0.47 35 0.5 4 10.0 87 78 35 * 3 F971V684#AA A 0.68 35 0.5 4 7.6 99 89 40 * 3 F971V105#BA B 1 35 0.5 4 4.0 146 131 58 * 3 F971V155#BA B 1.5 35 0.5 4 4.0 146 131 58 * 3 F971V225#BA B 2.2 35 0.8 4 3.8 150 135 60 * 3 F971V335#CC C 3.3 35 1.2 4 2.0 235 211 94 * 3 F971V475#CC C 4.7 35 1.6 6 1.8 247 222 99 * 3 F971V685#NC N 6.8 35 2.4 6 1.0 387 349 155 * 3 F971V106#NC N 10 35 3.5 6 1.0 387 349 155 * 3 *1: ΔC/C Marked “*” #: "M" for ±20% tolerance, "K" for ± 10% tolerance. Moisture Sensitivity Level (MSL) is defined according to J-STD-020. Item All Case (%) Damp Heat ±10 Temperature cycles ±5 Resistance soldering heat ±5 Surge ±5 Endurance ±10 Load Humidity ±10 QUALIFICATION TABLE F97 series (Temperature range -55ºC to +125ºC) TEST Condition At 85°C, 85% R.H., 1000 hours (No voltage applied) D a m p H e a t Capacitance Change ........... Refer to page 110 (*1) ( S t e a d y S t a t e ) Dissipation Factor ................ Initial specified value or less Leakage Current .................. 125% or less than the initial specified value After 1000 hour’s application of rated voltage in series with a 33Ω resistor at 85°C, 85% R.H., capacitors meet the characteristics requirements table below. L o a d H u m i d i t y Capacitance Change ........... Refer to page 110 (*1) Dissipation Factor ................ 120% or less than the initial specified value Leakage Current .................. 200% of less than the initial specified value At -55°C / +125°C, 30 minutes each, 1000 cycles T e m p e r a t u r e C y c l e s Capacitance Change ........... Refer to page 109 (*1) Dissipation Factor ................ Initial specified value or less Leakage Current .................. Initial specified value or less 10 seconds reflow at 260°C, 5 seconds immersion at 260°C. R e s i s t a n c e t o Capacitance Change ........... Refer to page 110 (*1) S o l d e r i n g H e a t Dissipation Factor ................ Initial specified value or less Leakage Current .................. Initial specified value or less S o l d e r a b i l i t y After immersing capacitors completely into a solder pot at 245ºC for 2 to 3 seconds, more than 3/4 of their electrode area shall remain covered with new solder. After application of surge voltage in series with a 33Ω resistor at the rate of 30 seconds ON, 30 seconds OFF, for 1000 successive test cycles at 85ºC, capacitors shall meet the characteristic requirements in the table above. S u r g e Capacitance Change ........... Refer to page 110 (*1) Dissipation Factor ................ Initial specified value or less Leakage Current .................. Initial specified value or less After 2000 hours’ application of rated voltage in series with a 3Ω resistor at 85°C, or derated voltage in series with a 3Ω resistor at 125°C, capacitors shall meet the characteristic requirements in the table above. E n d u r a n c e Capacitance Change ........... Refer to page 110 (*1) Dissipation Factor ................ Initial specified value or less Leakage Current .................. Initial specified value or less After applying the pressure load of 17.7N for 60 seconds horizontally to the center of capacitor side Shear Test body which has no electrode and has been soldered beforehand on a substrate, there shall be found neither exfoliation nor its sign at the terminal electrode.. Keeping a capacitor surface-mounted on a substrate upside down and supporting the substrate at both of the opposite bottom points 45mm apart from the center of capacitor, the pressure strength is Terminal Strength applied with a specified jig at the center of the substrate so that substrate may bend by1mm as illustrated. Then, there shall be found no remarkable abnormality on the capacitor terminals. 0.5% per 1000 hours at 85°C, V with 0.1Ω/V series impedance, Failure Rate R 60% confidence level. 071119 111

F97 Series Resin-Molded Chip, Improved Reliability J-Lead AVX SOLID ELECTROLYTIC CAPACITOR ROADMAP SERIES LINE UP: CONVENTIONAL SMD MnO 2 112 071119

Datasheet下载

Datasheet下载