- 型号: EXB-38V472JV

- 制造商: Panasonic Corporation

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

EXB-38V472JV产品简介:

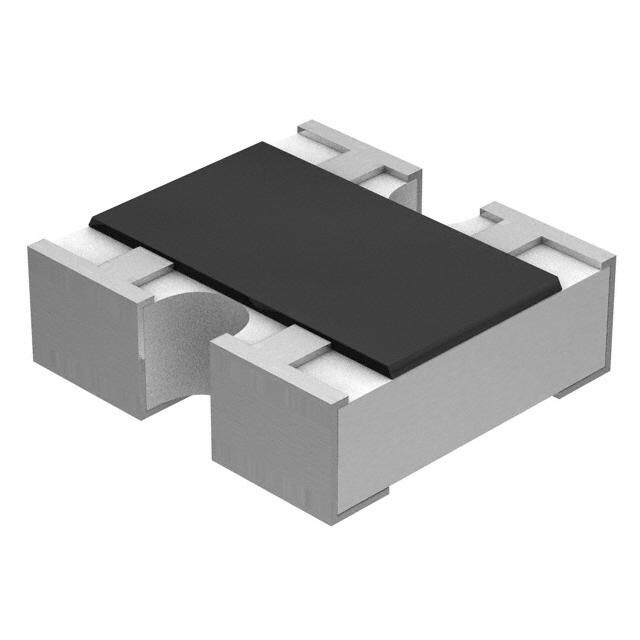

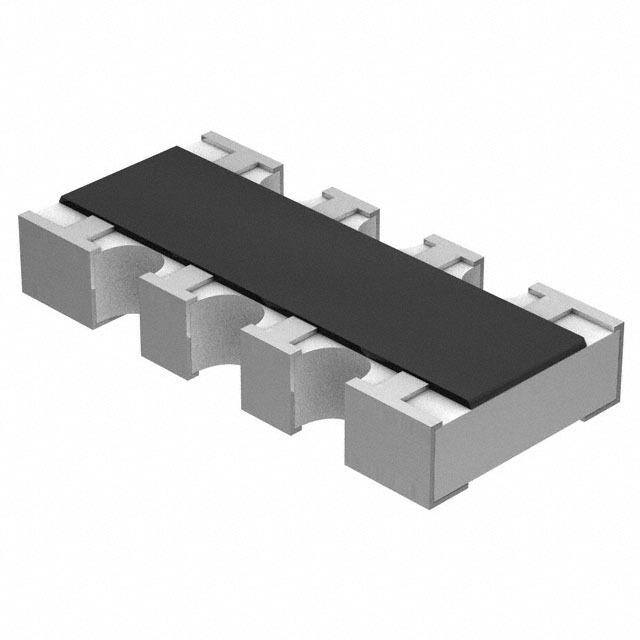

ICGOO电子元器件商城为您提供EXB-38V472JV由Panasonic Corporation设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 EXB-38V472JV价格参考。Panasonic CorporationEXB-38V472JV封装/规格:电阻器网络,阵列, 4.7k Ohm ±5% 62.5mW Power Per Element Isolated 4 Resistor Network/Array ±200ppm/°C 1206 (3216 Metric), Convex, Long Side Terminals。您可以下载EXB-38V472JV参考资料、Datasheet数据手册功能说明书,资料中有EXB-38V472JV 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | RES ARRAY 4.7K OHM 4 RES 1206电阻器网络与阵列 4.7K OHM 5% |

| 产品分类 | |

| 品牌 | Panasonic Electronic Components |

| 产品手册 | |

| 产品图片 |

|

| rohs | RoHS 合规性豁免无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 电阻器网络与阵列,Panasonic EXB-38V472JVEXB |

| 数据手册 | http://industrial.panasonic.com/www-cgi/jvcr13pz.cgi?E+PZ+3+AOC0001+EXB38V472JV+7+WW |

| 产品型号 | EXB-38V472JV |

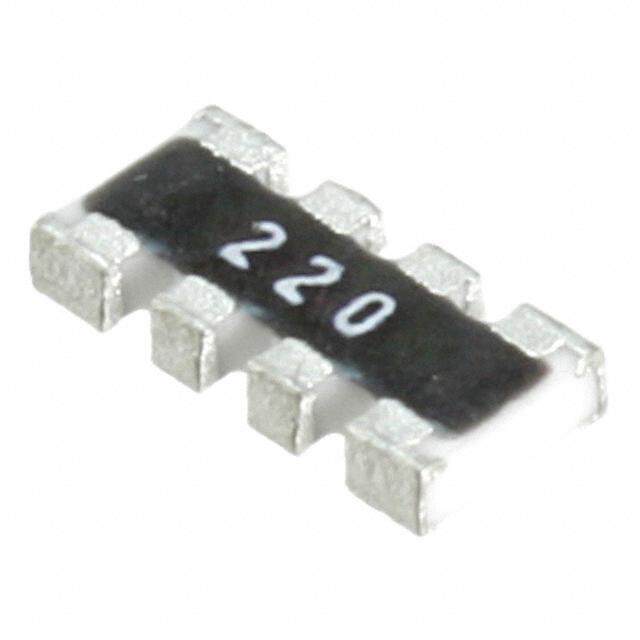

| 产品目录绘图 |

|

| 产品目录页面 | |

| 产品种类 | 电阻器网络与阵列 |

| 产品类型 | Arrays |

| 供应商器件封装 | 0603 |

| 其它名称 | Y9472DKR |

| 包装 | Digi-Reel® |

| 商标 | Panasonic |

| 外壳宽度 | 1.6 mm |

| 外壳长度 | 3.2 mm |

| 外壳高度 | 0.5 mm |

| 大小/尺寸 | 0.126" 长 x 0.063" 宽(3.20mm x 1.60mm) |

| 安装类型 | 表面贴装 |

| 容差 | ±5% |

| 封装 | Reel |

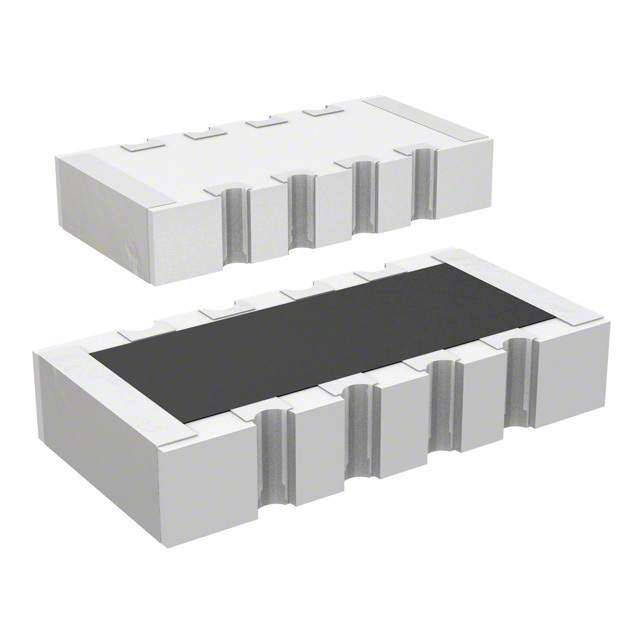

| 封装/外壳 | 1206(3216 公制),凸面,长边端子 |

| 工作温度 | -55°C ~ 125°C |

| 工作温度范围 | - 55 C to + 125 C |

| 工厂包装数量 | 5000 |

| 应用 | - |

| 引脚数 | 8 |

| 标准包装 | 1 |

| 每元件功率 | 62.5mW |

| 温度系数 | ±200ppm/°C |

| 电路类型 | 隔离 |

| 电阻(Ω) | 4.7k |

| 电阻器数 | 4 |

| 电阻器数量 | 4 |

| 电阻数值 | 4.7 kOhms |

| 端接类型 | SMD/SMT |

| 系列 | EXB3 |

| 高度 | 0.024"(0.60mm) |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

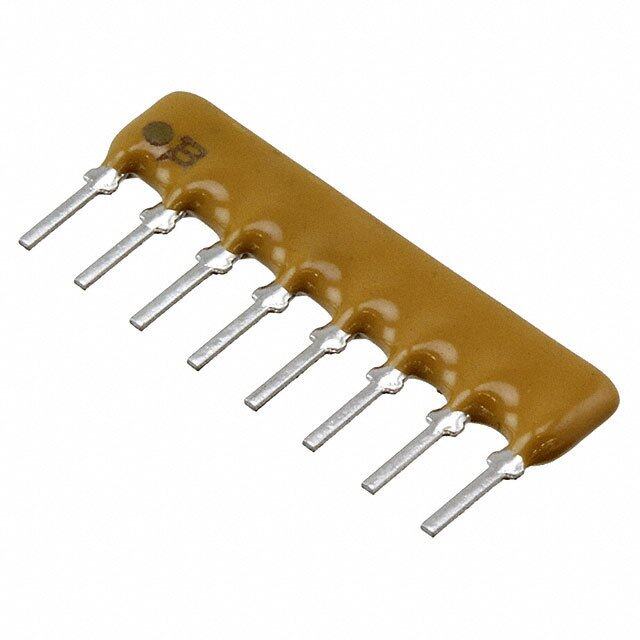

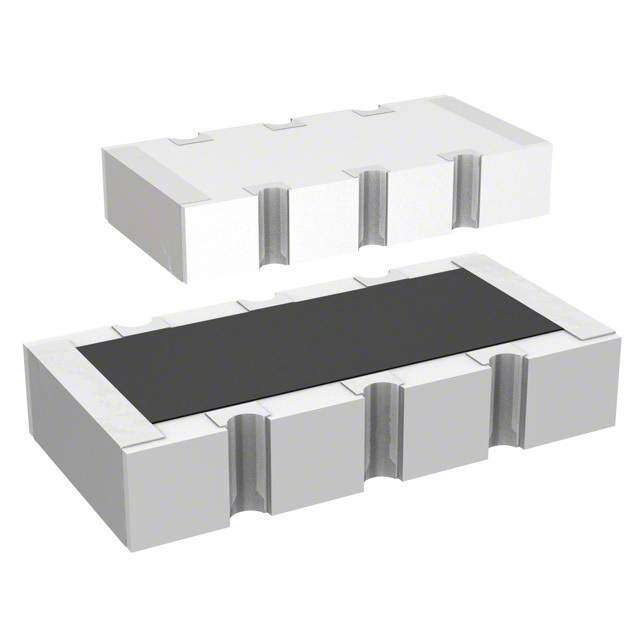

Chip Resistor Array Chip Resistor Array Type: EXB 14V, 18V, 24V, 28V, N8V, 2HV, 34V, V4V, 38V, V8V, S8V Features ● High density 2 resistors in 0.8 mm × 0.6 mm size / 0302 inch size : EXB14V 4 resistors in 1.4 mm × 0.6 mm size / 0502 inch size : EXB18V 2 resistors in 1.0 mm × 1.0 mm size / 0404 inch size : EXB24V 4 resistors in 2.0 mm × 1.0 mm size / 0804 inch size : EXB28V, EXBN8V 8 resistors in 3.8 mm × 1.6 mm size / 1506 inch size : EXB2HV 2 resistors in 1.6 mm × 1.6 mm size / 0606 inch size : EXB34V, EXBV4V 4 resistors in 3.2 mm × 1.6 mm size / 1206 inch size : EXB38V, EXBV8V 4 resistors in 5.1 mm × 2.2 mm size / 2009 inch size : EXBS8V ● Improvement of placement effi ciency Placement effi ciency of Chip Resistor Array is two, four or eight times of the fl at type chip resistor ● Reference Standard…IEC 60115-9, JIS C 5201-9, EIAJ RC-2129 ● AEC-Q200 qualifi ed (EXB2, EXB3) ● RoHS compliant ■ As for Packaging Methods, Land Pattern, Soldering Conditions and Safety Precautions, Please see Data Files Explanation of Part Numbers 1 2 3 4 5 6 7 8 9 10 11 E X B V 8 V 4 7 2 J V Product Code Code Inch Construction Schematics Resistance Value Resistance Packaging Methods Thick Film 14 0201×2 Convex Terminal Isolated The first two digits are Tolerance Code Packaging Part No. V Chip Resistor 18 0201×4 Flat Terminal type significant figures of J ±5 % Embossed Carrier Taping Networks 24 0402×2 Convex Terminal resistance value and 0 Jumper Nil 4 mm pitch, 2,500 pcs. EXBS8V 22H8 00460022××48 CCoonnvveexx TTeerrmmiinnaall ttfhhoeello tnwhuiirnmdgb o. enJrue om df pezeenrroo tisses X P2 umnmch peidtc Ch,a 1rr0ie,0r 0Ta0p pincgs.E24XVB, 1248VV,, 1N88V,V 34 0603×2 Convex Terminal expressed by R00 Punched Carrier Taping EXB2HV, 34V, 38 0603×4 Convex Terminal Example : 222 → 2.2k Ω V 4 mm pitch, 5,000 pcs. 38V, V4V, V8V N8 0402×4 Concave Terminal V4 0603×2 Concave Terminal V8 0603×4 Concave Terminal S8 0805×4 Concave Terminal Construction (Example : Concave Terminal) Schematics ● Isolated type 14V, 24V, 18V, 28V, N8V, 2HV Protective coating 34V, V4V 38V, V8V, S8V 2 resistors 4 resistors 8 resistors 4 3 8 7 6 5 16 15 14 13 12 11 10 9 Alumina substrate Electrode (Outer) Thick film resistive element Electrode (Between) Electrode (Inner) 1 2 1 2 3 4 1 2 3 4 5 6 7 8 Design and specifications are each subject to change without notice. Ask factory for the current technical specifications before purchase and/or use. Should a safety concern arise regarding this product, please be sure to contact us immediately. 05 Feb. 2018

Chip Resistor Array Ratings [For Resistor] Power Rating Limiting Element Maximum Overload Resistance Resistance Category Part No. T.C.R. AEC-Q200 at 70 °C Voltage (1) Voltage (2) Tolerance Range Temperature Range (inch size) (×10–6/°C) Grade (W / element) (V) (V) (%) (Ω) (°C) EXB14V (0201×2) 0.031 12.5 25 ±5 10 to 1M (E24) –55 to +125 – EXB18V 0.031 (0201×2) (0.1 W / package) 12.5 25 ±5 10 to 1M (E24) –55 to +125 – EXB24V (0402×2) 0.063 50 100 ±5 1 to 1M (E24) –55 to +125 Grade 1 EXB28V (0402×4) 0.063 50 100 ±5 1 to 1M (E24) –55 to +125 Grade 1 EXB2HV 0.063 <10 Ω : (0602×8) (0.25 W / package) 25 50 ±5 10 to 1M (E24) –200 to +600 –55 to +125 Grade 1 EXB34V (0603×2) 0.063 50 100 ±5 1 to 1M (E24) –55 to +125 Grade 1 10 Ω to1M Ω : EXB38V (0603×4) 0.063 50 100 ±5 1 to 1M (E24) ±200 –55 to +125 Grade 1 EXBN8V (0402×4) 0.031 50 100 ±5 10 to 1M (E24) –55 to +125 – EXBV4V (0603×2) 0.063 50 100 ±5 10 to 1M (E24) –55 to +125 – EXBV8V (0603×4) 0.063 50 100 ±5 10 to 1M (E24) –55 to +125 – EXBS8V (0805×4) 0.1 100 200 ±5 10 to 1M (E24) –55 to +125 – (1) Rated Continuous Working Voltage (RCWV) shall be det er mined from RCWV=√Power Rating × Re sis tance Values, or Limiting Element Voltage liste d above, whichever less. (2) Overload Test Voltage (OTV) shall be determined from OTV=Specified Magnification (refer to performance) × RCWV or Maximum Overload Voltage listed above, whichever less. [For Jumper] Power Derating Curve Part No. Rated Current Maximum Over load Current (1) For resistors operated in ambient temperatures above 70 °C, power rating shall be derated in accordance (inch size) (A / element) (A) with the figure below. EXB14V (0201×2) 0.5 1 EXB18V (0201×4) 0.5 1 100–55 °C 70 °C EXB24V (0402×2) 1 2 %) 80 d ( 60 EXB28V a (0402×4) 1 2 d Lo 40 e (E0X60B22×H8V) 1 2 Rat 20 125 °C 0 EXB34V (0603×2) 1 2 –60–40–20 0 20 40 60 80 100120140160180 Ambient Temperature (°C) EXB38V (0603×4) 1 2 EXBN8V (0402×4) 1 2 EXBV4V (0603×2) 1 2 EXBV8V (0603×4) 1 2 EXBS8V (0805×4) 2 4 (1) Overload test current Design and specifications are each subject to change without notice. Ask factory for the current technical specifications before purchase and/or use. Should a safety concern arise regarding this product, please be sure to contact us immediately. 05 Feb. 2018

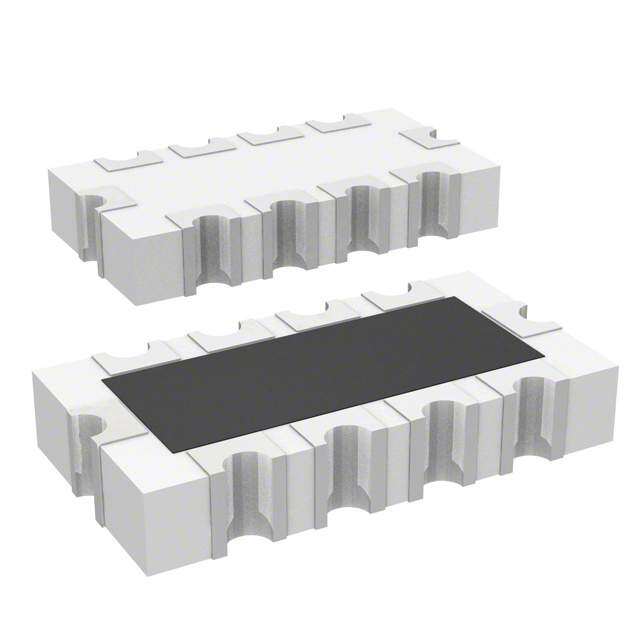

Chip Resistor Array Dimensions in mm (not to scale) (1) Convex Terminal type EXB14V, 24V, 34V EXB28V, 38V A1 A1 A2 B G B G W W B G B G P T P T L L A1 A2 EXB2HV B G W B G P L T Part No. Dimensions (mm) Mass (Weight) (inch size) L W T A1 A2 B P G [g/1000 pcs.] EXB14V (0201×2) 0.80 ±0.10 0.60±0.10 0.35±0.10 0.35±0.10 — 0.15±0.10 (0.50) 0.15±0.10 0.5 EXB24V (0402×2) 1.00±0.10 1.00±0.10 0.35±0.10 0.40±0.10 — 0.18±0.10 (0.65) 0.25±0.10 1.2 EXB28V (0402×4) 2.00±0.10 1.00±0.10 0.35±0.10 0.45±0.10 0.35±0.10 0.20±0.10 (0.50) 0.25±0.10 2.0 EXB2HV (0602×8) 3.80±0.10 1.60±0.10 0.45±0.10 0.35±0.10 0.35±0.10 0.30±0.10 (0.50) 0.30±0.10 9.0 EXB34V (0603×2) 1.60±0.20 1.60±0.15 0.50±0.10 0.65±0.15 — 0.30±0.20 (0.80) 0.30±0.20 3.5 EXB38V (0603×4) 3.20±0.20 1.60±0.15 0.50±0.10 0.65±0.15 0.45±0.15 0.30±0.20 (0.80) 0.35±0.20 7.0 ( ) Reference (2) Concave Terminal type EXBV4V EXBN8V, V8V, S8V A1 A1 A2 B G B G W W B G B G P P L T L T Part No. Dimensions (mm) Mass (Weight) (inch size) L W T A1 A2 B P G [g/1000 pcs.] EXBN8V (0402×4) 2.00 ±0.10 1.00±0.10 0.45±0.10 0.30 ±0.10 0.30 ±0.10 0.20±0.15 (0.50) 0.30±0.15 3.0 EXBV4V (0603×2) 1.60+–00..2100 1.60+–00..2100 0.60±0.10 0.60 ±0.10 — 0.30±0.15 (0.80) 0.45±0.15 5.0 EXBV8V (0603×4) 3.20+–00..2100 1.60+–00..2100 0.60±0.10 0.60 ±0.10 0.60 ±0.10 0.30±0.15 (0.80) 0.45±0.15 10 EXBS8V (0805×4) 5.08+–00..2100 2.20+–00..2100 0.70±0.20 0.80±0.15 0.80±0.15 0.50±0.15 (1.27) 0.55±0.15 30 ( ) Reference (3) Flat Terminal type A1 A2 EXB18V B G W G B P T L Part No. Dimensions (mm) Mass (Weight) (inch size) L W T A1 A2 B P G [g/1000 pcs.] EXB18V (0201×4) 1.40±0.10 0.60±0.10 0.35±0.10 0.20±0.10 0.20±0.10 0.10±0.10 (0.40) 0.20±0.10 1.0 ( ) Reference Design and specifications are each subject to change without notice. Ask factory for the current technical specifications before purchase and/or use. Should a safety concern arise regarding this product, please be sure to contact us immediately. 05 Feb. 2018

Chip Resistor Array Perfomance Performance Test Item Test Conditions Requirements Within Specifi ed Resistance 20 °C Tolerance Within Specifi ed T. C. R. +25 °C/+125 °C T. C. R. Rated Voltage × 2.5, 5 s Overload ±2% Jumper type : Max. Overload Current, 5 s Resistance to Soldering Heat ±1% 270 °C, 10 s Rapid Change of Temperature ±1% –55 °C (30min.) / +125 °C (30min.), 100 cycles High Temperature Exposure ±1% +125 °C , 1000 h Damp Heat, Steady State ±1% 60 °C, 90% to 95 %RH, 1000 h 60 °C, 90% to 95 %RH, Rated Voltage (Jumper type: Rated Current), Load Life in Humidity ±3% 1.5 h ON/0.5 h OFF cycle, 1000 h 70 °C, Rated Voltage(Jumper type: Rated Current), Endurance at 70 °C ±3% 1.5 h ON/0.5 h OFF cycle, 1000 h Design and specifications are each subject to change without notice. Ask factory for the current technical specifications before purchase and/or use. Should a safety concern arise regarding this product, please be sure to contact us immediately. 05 Feb. 2018

Surface Mount Resistors Safety precautions Safety Precautions (Common precautions for Surface Mount Resistors) The following are precautions for individual products. Please also refer to the common precautions for Fixed Resistors in this catalog. 1. Take measures against mechanical stress during and after mounting of Surface Mount Resistors (hereafter called the resistors) so as not to damage their electrodes and protective coatings. Be careful not to misplace the resistors on the land patterns. Otherwise, solder bridging may occur. 2. Keep the rated power and ambient temperature within the specified derating curve. Some circuit boards, wiring patterns, temperatures of heat generated by adjacent components, or amb ie nt tem per a tures can become factors in the rise of the temperature of the res is tors, regardless of the level of power applied. Therefore, check the conditions before use and op ti mize them so as not to damage the boards and peripheral components. Make sure to contact us before using the resistors under special conditions. 3. If a transient load (heavy load in a short time) like a pulse is expected to be applied, check and evaluate the operations of the resistors when installed in your products before use. Never exceed the rated power. Otherwise, the performance and/or reliability of the resistors may be impaired. 4. Before using halogen-based or other high-activity flux, check the possible effects of the flux residues on the per for mance and reliability of the resistors. 5. When soldering with a soldering iron, never touch the resistors'bodies with the tip of the soldering iron. When using a soldering iron with a high temperature tip, finish soldering as quickly as possible (within three seconds at 350 °C max.). 6. As the amount of applied solder becomes larger, the mechanical stress applied to the resistors increases, causing problems such as cracks and faulty characteristics. Avoid applying an excessive amounts of solder. 7. When the resistors' protective coatings are chipped, flawed, or removed, the characteristics of the resistors may be impaired. Take special care not to apply mechanical shock during automatic mounting or cause damage during handling of the boards with the resistors mounted. 8. Do not apply shock to the resistors or pinch them with a hard tool (e.g. pliers and tweezers). Otherwise, the resistors' protective coatings and bodies may be chipped, affecting their performance. 9. Avoid excessive bending of printed circuit boards in order to protect the resistors from abnormal stress. 10. Do not immerse the resistors in solvent for a long time. Before using solvent, carefully check the effects of imm er sion. 11. Transient voltage If there is a possibility that the transient phen om e non (significantly high voltage ap plied in a short time) may occ ur or that a high voltage pulse may be applied, make sure to evaluate and check the chara ct er is tics of Fixed Metal (Oxide) Film Resistors mounted on your product rather than only depending on the calculated pow er limit or steady-state conditions to complete the des ign or decide to use the resistors. 12. Do not apply excessive tension to the terminals. Design and specifications are each subject to change without notice. Ask factory for the current technical specifications before purchase and/or use. Should a safety concern arise regarding this product, please be sure to contact us immediately. 02 Sep. 2014

Safety Precautions (Common precautions for Fixed Resistors) • When using our products, no matter what sort of equipment they might be used for, be sure to make a written agreement on the specifications with us in advance. The design and specifications in this catalog are subject to change without prior notice. • Do not use the products beyond the specifications described in this catalog. • This catalog explains the quality and performance of the products as individual components. Before use, check and evaluate their operations when installed in your products. • Install the following systems for a failsafe design to ensure safety if these products are to be used in equipm ent where a defect in these products may cause the loss of human life or other significant dam age, such as damage to vehicles (automobile, train, vessel), traffic lights, medical equipment, aerospace equipment, electric heating appliances, combustion/gas equipment, rotating equipment, and disaster/crime prevention equipment. ✽ Systems equipped with a protection circuit and a protection device ✽ Systems equipped with a redundant circuit or other system to prevent an unsafe status in the event of a sing le fault (1) Precautions for use • These products are designed and manufactured for general and standard use in general elect ron ic equipment (e.g. AV equipment, home electric appliances, office equipment, information and communication equipment) • These products are not intended for use in the following special conditions. Before using the products, carefully check the effects on their quality and performance, and determine whether or not they can be used. 1. In liquid, such as water, oil, chemicals, or organic solvent 2. In direct sunlight, outdoors, or in dust 3. In salty air or air with a high concentration of corrosive gas, such as Cl, H S, NH , SO , or NO 2 2 3 2 2 4. Electric Static Discharge (ESD) Environment These components are sensitive to static electricity and can be damaged under static shock (ESD). Please take measures to avoid any of these environments. Smaller components are more sensitive to ESD environment. 5. Electromagnetic Environment Avoid any environment where strong electromagnetic waves exist. 6. In an environment where these products cause dew condensation 7. Sealing or coating of these products or a printed circuit board on which these products are mounted, with resin or other materials • These products generate Joule heat when energized. Carefully position these products so that their heat will not affect the other components. • Carefully position these products so that their temperatures will not exceed the category temperature range due to the effects of neighboring heat-generating components. Do not mount or place heat-generating components or inflammables, such as vinyl-coated wires, near these products. • Note that non-cleaning solder, halogen-based highly active flux, or water-soluble flux may deteriorate the performance or reliability of the products. • Carefully select a flux cleaning agent for use after soldering. An unsuitable agent may deteriorate the performance or reliability. In particular, when using water or a water-soluble cleaning agent, be careful not to leave water residues. Otherwise, the insulation performance may be deteriorated. (2) Precautions for storage The performance of these products, including the solderability, is guaranteed for a year from the date of arr iv al at your company, provided that they remain packed as they were when delivered and stored at a temp er a ture of 5 °C to 35 °C and a relative humidity of 45 % to 85 %. Even within the above guarantee periods, do not store these products in the following conditions. Otherwise, their electrical performance and/or solderability may be deteriorated, and the packaging materials (e.g. taping materials) may be deformed or deteriorated, resulting in mounting failures. 1. In salty air or in air with a high concentration of corrosive gas, such as Cl, H S, NH , SO , or NO 2 2 3 2 2 2. In direct sunlight <Package markings> Package markings include the product number, quantity, and country of origin. In principle, the country of origin should be indicated in English. 01 Sep. 2014

Datasheet下载

Datasheet下载