ICGOO在线商城 > 传感器,变送器 > 光学传感器 - 光断续器 - 槽型 - 晶体管输出 > EE-SX1109

- 型号: EE-SX1109

- 制造商: Omron Electronics LLC

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

EE-SX1109产品简介:

ICGOO电子元器件商城为您提供EE-SX1109由Omron Electronics LLC设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 EE-SX1109价格参考。Omron Electronics LLCEE-SX1109封装/规格:光学传感器 - 光断续器 - 槽型 - 晶体管输出, Optical Sensor Transmissive 0.118" (3mm) Phototransistor 4-SMD。您可以下载EE-SX1109参考资料、Datasheet数据手册功能说明书,资料中有EE-SX1109 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | OPTO SENSOR SLOT TYPE 3MM SMT光学开关(透射型,光电晶体管输出) TRANSMISSIVE |

| 产品分类 | |

| 品牌 | Omron Electronics |

| 产品手册 | |

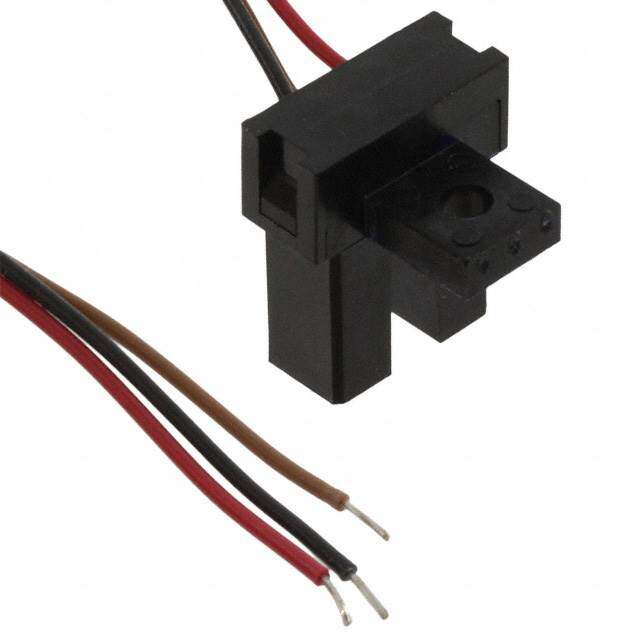

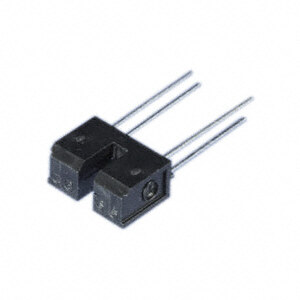

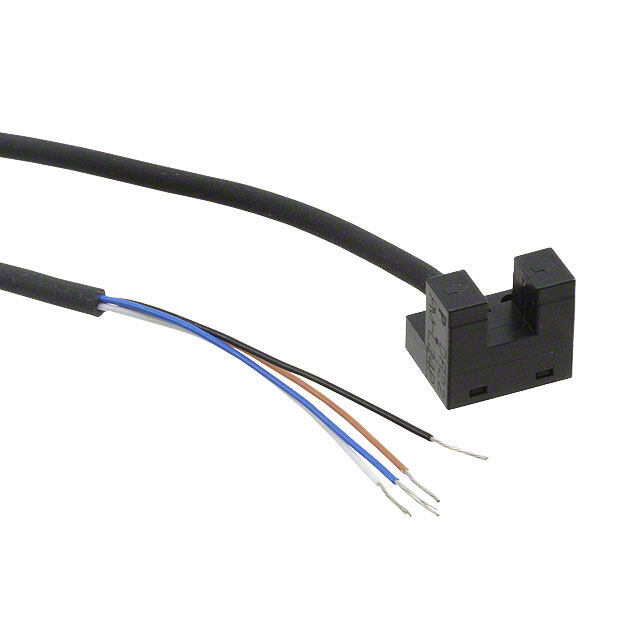

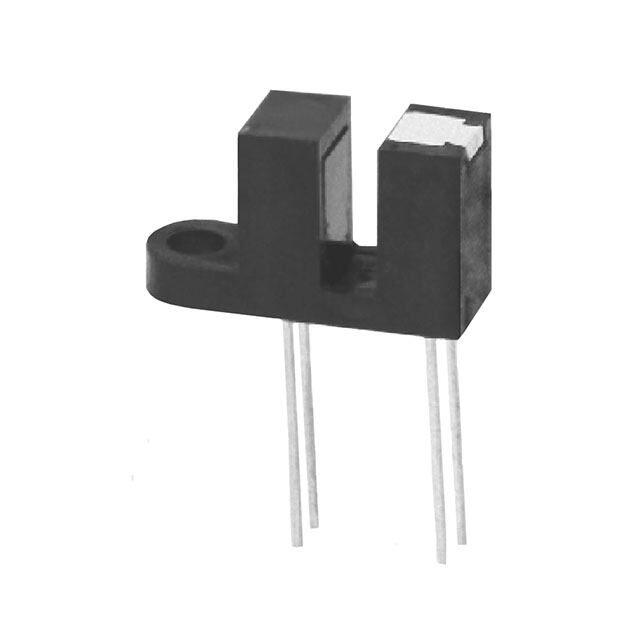

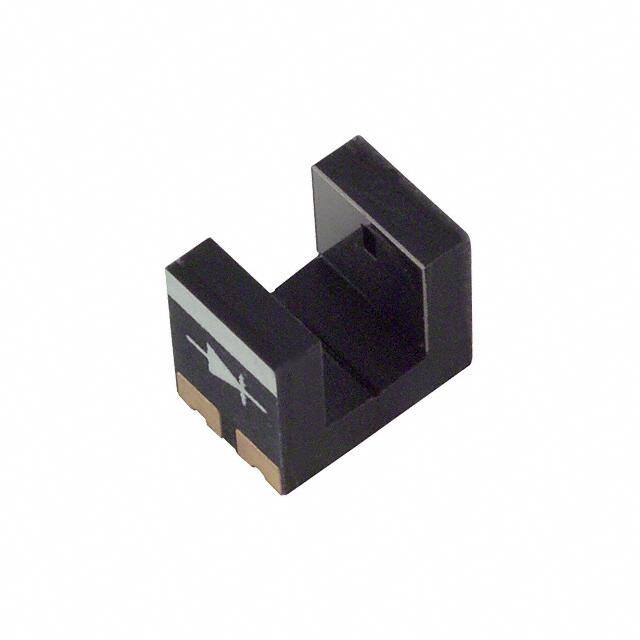

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 光学开关(透射型,光电晶体管输出),Omron Electronics EE-SX1109- |

| 数据手册 | |

| 产品型号 | EE-SX1109 |

| 上升时间 | 10 us |

| 下降时间 | 10 us |

| 产品目录页面 | |

| 产品种类 | 光学开关(透射型,光电晶体管输出) |

| 光圈宽度 | 0.5 mm |

| 其它名称 | OR638DKR |

| 其它有关文件 | |

| 功率耗散 | 75 mW |

| 包装 | Digi-Reel® |

| 响应时间 | 10µs, 10µs |

| 商标 | Omron Electronics |

| 安装类型 | 表面贴装 |

| 安装风格 | Through Hole |

| 封装 | Reel |

| 封装/外壳 | 4-SMD |

| 工作温度 | -30°C ~ 85°C |

| 工厂包装数量 | 1000 |

| 感应方式 | Transmissive, Slotted |

| 感应方法 | 可传导的 |

| 感应距离 | 3 mm |

| 最大工作温度 | + 85 C |

| 最大集电极电流 | 20 mA |

| 最小工作温度 | - 30 C |

| 标准包装 | 1 |

| 槽宽 | 3 mm |

| 波长 | 940 nm |

| 特色产品 | http://www.digikey.cn/product-highlights/zh/nonamplified-photomicrosensors/52959 |

| 电压-集射极击穿(最大值) | 20V |

| 电流-DC正向(If) | 25mA |

| 电流-集电极(Ic)(最大值) | 20mA |

| 类型 | 无放大 |

| 系列 | EE-SX1109 |

| 输出设备 | Phototransistor |

| 输出配置 | 光电晶体管 |

| 集电极—发射极最大电压VCEO | 20 V |

| 零件号别名 | 1461616 367412 EESX1109NC |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

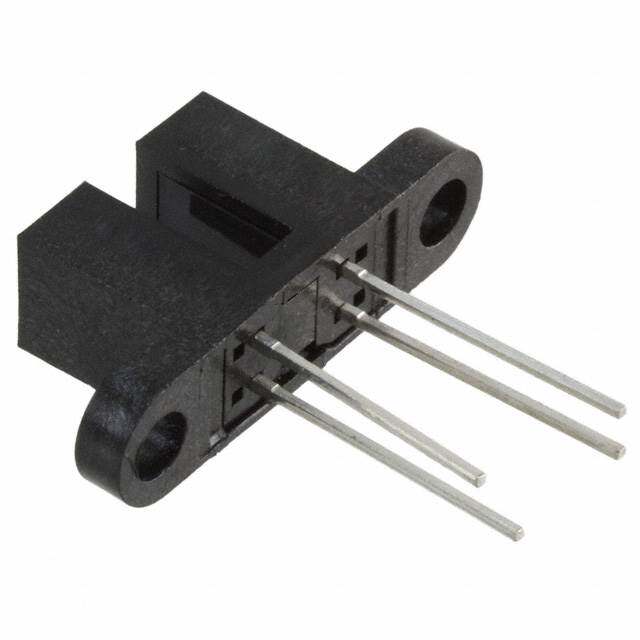

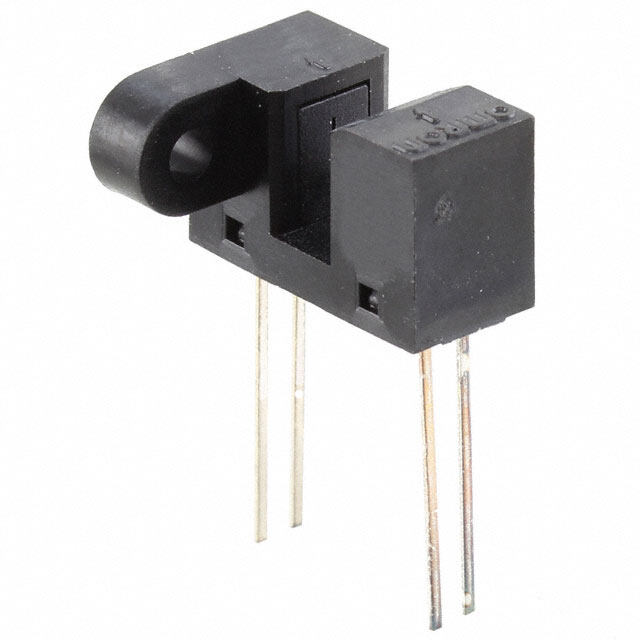

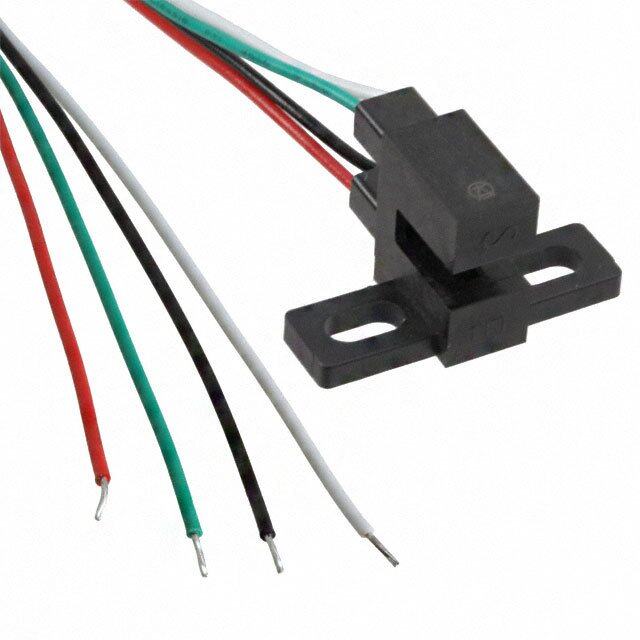

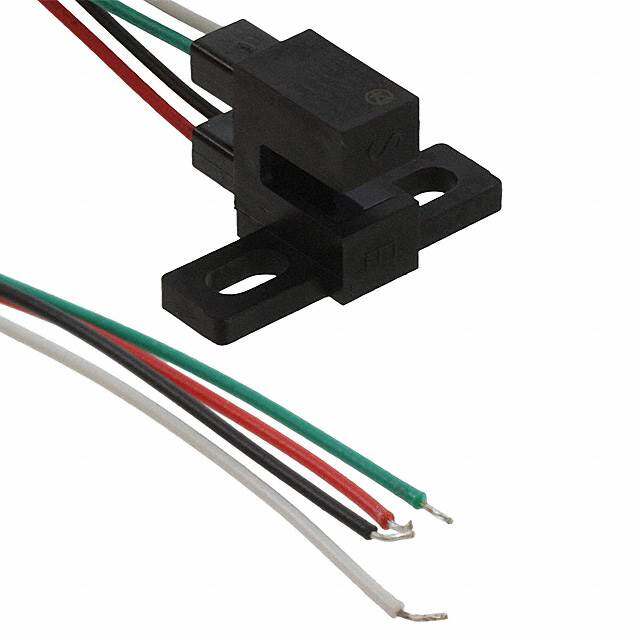

Photomicrosensor (Transmissive) EE-SX1109 Be sure to read Precautions on page25. ■ ■ Dimensions Features Note:All units are in millimeters unless otherwise indicated. (cid:129)Ultra-compact with a 6-mm-wide sensor and a 3-mm-wide slot. (cid:129)PCB surface mounting type. (cid:129)High resolution with a 0.5-mm-wide aperture. ■ Absolute Maximum Ratings ° (Ta = 25 C) Item Symbol Rated value Emitter Forward current I 25 mA F (seenote 1) Pulse forward cur- I 100 mA FP rent (seenote2) Optical axis Reverse voltage V 5 V R Detector Collector–Emitter V 20 V CEO voltage Emitter–Collector V 5 V ECO voltage Cross section AA Collector current I 20 mA Recommended C Internal Circuit Soldering Pattern Collector dissipa- P 75 mW C tion (seenote 1) Ambient tem- Operating Topr –30°C to 85°C perature Storage Tstg –40°C to 90°C Reflow soldering Tsol 255°C (see note 3) Manual soldering Tsol 350°C Terminal No. Name (see note 3) A Anode Note:1. Refer to the temperature rating chart if the ambient temper- K Cathode ature exceeds 25°C. Unless otherwise specified, the C Collector tolerances are ±0.15 mm. 2. Duty: 1/100; Pulse width: 0.1 ms E Emitter 3. Complete soldering within 10 seconds for reflow soldering and within 3 seconds for manual soldering. ■ ° Electrical and Optical Characteristics (Ta = 25 C) Item Symbol Value Condition Emitter Forward voltage V 1.1 V typ., 1.3 V max. I = 5 mA F F Reverse current I 10 μA max. V = 5 V R R Peak emission wavelength λ 940 nm typ. I = 20 mA P F Detector Light current I 50 μA min., 150 μA typ., I = 5 mA, V = 5 V L 500 μA max. F CE Dark current I 100 nA max. V = 10 V, 0 lx D CE Leakage current I --- --- LEAK Collector–Emitter saturated volt- V (sat) 0.1 V typ., 0.4 V max. I = 20 mA, I = 50 μA CE F L age Peak spectral sensitivity wave- λ 900 nm typ. --- P length Rising time tr 10 μs typ. V = 5 V, R = 1 kΩ, CC L I = 100μA L Falling time tf 10 μs typ. V = 5 V, R = 1 kΩ, CC L I = 100μA L 70 EE-SX1109 Photomicrosensor (Transmissive)

■ Engineering Data Forward Current vs. Collector Dis- Forward Current vs. Forward Light Current vs. Forward Current sipation Temperature Rating Voltage Characteristics (Typical) Characteristics (Typical) A) mW) mA) TVaC E= = 2 55 °VC Forward current I (mF ollector dissipation P (C (Forward current IF μLight current I (A)L C Ambient temperature Ta (°C) Forward voltage VF (V) Forward current IF (mA) Light Current vs. Collector−Emitter Relative Light Current vs. Ambient Dark Current vs. Ambient Temper- Voltage Characteristics (Typical) Temperature Characteristics (Typical) ature Characteristics (Typical) A) Ta = 25°C (%)L IVFC =E 5= m5 AV A) μcurrent I (L IF = 10 mA ght current I urrent I (nD VCE = 10 V ht e li k c VCE = 2 V Lig IF = 5 mA ativ Dar el R Collector−Emitter voltage VCE (V) Ambient temperature Ta (°C) Ambient temperature Ta (°C) Response Time vs. Load Resist- Sensing Position Characteris- Sensing Position Characteris- ance Characteristics (Typical) tics (Typical) tics (Typical) μe tr, tf (s) TVaC C= = 2 55° VC (%)ent IL VIFC =E 5= m5 AV ent I (%)L VIFC =E 5= m5 AV sponse tim e light curr e light curr e v v R ati ati el el R R Load resistance RL (kΩ) Distance d (mm) Distance d (mm) Response Time Measurement Circuit Input 90 % Output 10 % Input Output EE-SX1109 Photomicrosensor (Transmissive) 71

Unit: mm (inch) ■ Tape and Reel Reel 21±0.8 dia. 2±0.5 330+2 dia. 13± 0.5 dia. 80±1 dia. Product name Quantity Lot No. 12.4+02 18.4 max. Tape 1.5 dia. Tape configuration Terminating part Parts mounted Leading part (40 mm min.) (400 mm min.) Empty Pull-out direction (40 mm min.) Tape quantity 1,000 pcs./reel 72 EE-SX1109 Photomicrosensor (Transmissive)

Precautions ■ Soldering Information Reflow soldering (cid:129)The following soldering paste is recommended: Melting temperature: 216 to 220°C Composition: Sn 3.5 Ag 0.75 Cu (cid:129)The recommended thickness of the metal mask for screen printing is between 0.2 and 0.25 mm. (cid:129)Set the reflow oven so that the temperature profile shown in the following chart is obtained for the upper surface of the product being soldered. 260°C max. 1 to 5°C/s 255°C max. 230°C max. ure 1 to 5°C/s 150 to 180°C at er p m Te 10 sec max. 120 sec 40 sec max. Time Manual soldering (cid:129)Use ”Sn 60” (60% tin and 40% lead) or solder with silver content. (cid:129)Use a soldering iron of less than 25 W, and keep the temperature of the iron tip at 300°C or below. (cid:129)Solder each point for a maximum of three seconds. (cid:129)After soldering, allow the product to return to room temperature before handling it. Storage To protect the product from the effects of humidity until the package is opened, dry-box storage is recommended. If this is not possible, store the product under the following conditions: Temperature: 10 to 30°C Humidity: 60% max. The product is packed in a humidity-proof envelope. Reflow soldering must be done within 48 hours after opening the envelope, during which time the product must be stored under 30°C at 80% maximum humidity. If it is necessary to store the product after opening the envelope, use dry-box storage or reseal the envelope. Baking If a product has remained packed in a humidity-proof envelope for six months or more, or if more than 48 hours have lapsed since the envelope was opened, bake the product under the following conditions before use: Reel: 60°C for 24 hours or more Bulk: 80°C for 4 hours or more EE-SX1109 Photomicrosensor (Transmissive) 73

Datasheet下载

Datasheet下载