- 型号: ECW1J-C24-CC0024L

- 制造商: Bourns

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

ECW1J-C24-CC0024L产品简介:

ICGOO电子元器件商城为您提供ECW1J-C24-CC0024L由Bourns设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 ECW1J-C24-CC0024L价格参考。BournsECW1J-C24-CC0024L封装/规格:编码器, 。您可以下载ECW1J-C24-CC0024L参考资料、Datasheet数据手册功能说明书,资料中有ECW1J-C24-CC0024L 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

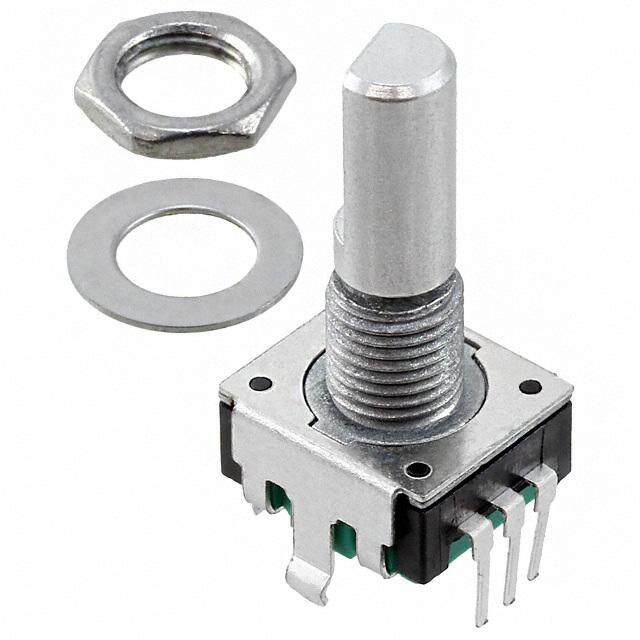

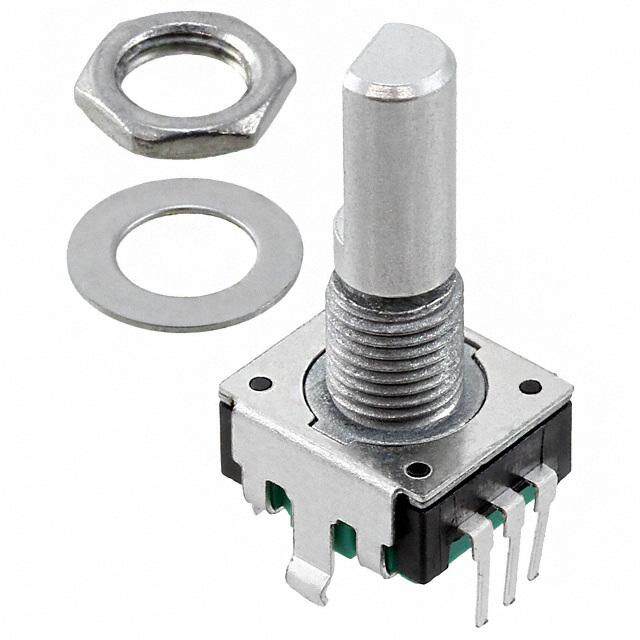

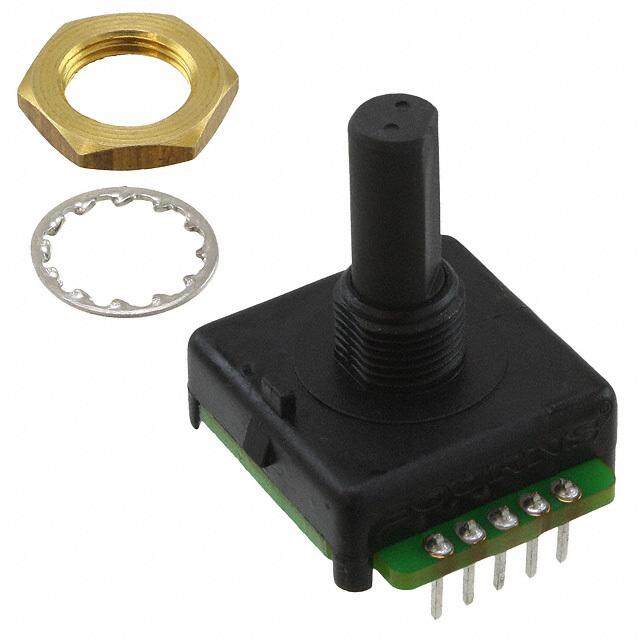

| 描述 | ENCODER DIGITAL CONT编码器 SLOT 24 DET 1/4" Bushing |

| 产品分类 | |

| 品牌 | Bourns |

| 产品手册 | |

| 产品图片 | |

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | Bourns ECW1J-C24-CC0024L* |

| mouser_ship_limit | 该产品可能需要其他文件才能进口到中国。 |

| 数据手册 | |

| 产品型号 | ECW1J-C24-CC0024L |

| PCN设计/规格 | |

| 产品 | Mechanical Encoders |

| 产品种类 | |

| 分辨率 | 24 PPR |

| 制动器数量 | 24 Detent |

| 商标 | Bourns |

| 大小/尺寸 | 28.5 mm x 22 mm |

| 套管材料 | Plastic |

| 套管螺纹 | M9 x 0.75 |

| 安装风格 | Panel |

| 封装 | Bulk |

| 工作温度范围 | - 40 C to + 85 C |

| 工厂包装数量 | 45 |

| 带开关 | No Switch |

| 技术 | Rotary |

| 标准包装 | 45 |

| 电源电压 | - |

| 端接类型 | Through Hole |

| 类型 | Incremental |

| 系列 | ECW |

| 衬套大小 | 9 mm x 6.35 mm |

| 轴直径 | 1/4 in |

| 轴类型 | Flatted |

| 轴长度 | 3/4 in |

| 输出 | Quadrature |

| 通道数量 | 2 Channel |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

Features n Incremental encoder / quadrature output n Exceptionally long operating life n Sturdy construction n Bushing mount n Available with PC board mounting bracket (optional) n RoHS compliant* ECW - Digital Contacting Encoder Electrical Characteristics Output ..................................................................................2-bit quadrature code, Channel A leads Channel B by 90 º electrically turning clockwise (CW) Closed Circuit Resistance ...........................................................................................................................................................................5 ohms maximum Open Circuit Resistance .......................................................................................................................................................................100 K ohms minimum Contact Rating ..................................................................................................................................................10 milliamp @ 10 VDC or 0.1 watt maximum Insulation Resistance (500 VDC) ...................................................................................................................................................1,000 megohms minimum Dielectric Withstanding Voltage (MIL-STD-202 Method 301) Sea Level ............................................................................................................................................................................................1,000 VAC minimum Electrical Travel .....................................................................................................................................................................................................Continuous Contact Bounce (15 RPM)................................................................................................................................................................5 milliseconds maximum RPM (Operating) ..............................................................................................................................................................................................120 maximum Phase Tolerance (CH A to CH B) ............................................................................................................................................................................90 ° ± 72 ° Environmental Characteristics Operating Temperature Range .........................................................................................................................................-40 ºC to +85 ºC (-40 °F to 185 °F) Storage Temperature Range ..........................................................................................................................................-40 ºC to +85 ºC (-40 °F to +185 °F) Humidity.................................................................................................................................................................MIL-STD-202, Method 103B, Condition B Vibration ..........................................................................................................................................................................................................................15 G Contact Bounce ...........................................................................................................................................................................0.1 millisecond maximum Shock...............................................................................................................................................................................................................................50 G Contact Bounce ...........................................................................................................................................................................0.1 millisecond maximum Rotational Life..................................................................................................................................................................................200,000 shaft revolutions IP Rating ..........................................................................................................................................................................................................................IP 40 Mechanical Characteristics Mechanical Angle ..................................................................................................................................................................................................Continuous Running Torque (Detented) ............................................................................................................................................0.5 to 1.5 N-cm (0.75 to 2.25 oz-in.) Undetented Torque ........................................................................................................................................................0.17 to 1.0 N-cm (0.25 to 1.50 oz-in) Mounting Torque .........................................................................................................................................................................79 N-cm (7 lb.-in.) maximum Shaft Side Load (Static)....................................................................................................................................................................4.5 kg (10 lbs.) minimum Weight ................................................................................................................................................................................Approximately 21 gms. (0.75 oz.) Terminals .................................................................................................................................................................................................PC pin or solder lug Soldering Condition Manual Soldering ...................................................................................................................96.5Sn/3.0Ag/0.5Cu solid wire or no-clean rosin cored wire 370 °C (700 °F) max. for 3 seconds Wave Soldering ...........................................................................................................................................96.5Sn/3.0Ag/0.5Cu solder with no-clean flux 260 °C (500 °F) max. for 5 seconds Wash processes ....................................................................................................................................................................................Not recommended Marking ...........................................................................................................................Manufacturer’s name and trademark, part number, and date code. Hardware .................................................One lockwasher and one mounting nut are shipped with each encoder, except where noted in the part number. Quadrature Output Table – This table is intended to show available outputs as currently defined. 1/4 CYCLE PER DETENT FULL CYCLE PER DETENT (Normally Open in Detent Shown) CW Channel A CW Channel A Closed Circuit Closed Circuit Open Circuit Open Circuit Closed Circuit Closed Circuit Open Circuit Open Circuit D D D D D D D D D D D D D D D D D D D D D D Channel B CCW Channel B CCW RECOMMENDED INCREMENTAL CONTROL DIAGRAM FOR USE WITH A DEBOUNCE CIRCUIT (CUSTOMER LOGIC CIRCUITRY) 7 9 DIRECTION 5 ms DELAY DEBOUNCE DECODE UP/DOWN BINARY (MC 14490) LOGIC COUNTER OUTPUT MAGNITUDE *RoHS Directive 2015/863, Mar 31, 2015 and Annex. Specifications are subject to change without notice. Users should verify actual device performance in their specific applications. WARNING Cancer and Reproductive Harm The products described herein and this document are subject to specific legal disclaimers as set forth www.P65Warnings.ca.gov on the last page of this document, and at www.bourns.com/docs/legal/disclaimer.pdf.

ECW - Digital Contacting Encoder Dimensional Drawings BUSHING MOUNTED - HOUSING A PANEL HOLE DIMENSIONS “L” ± 0.38 Rear-Facing Terminals (“L” ± .015) Bushing Mounted 22.2 ± 0.25 8.51 6.35 (.874 ± .010) (.335) (.250) 9.52 9.14 (1.413.17) 27.68 ± 0.25 (.375) (.360)DIA. (1.090 ± .010) 9.0 DIA. (.1547.87 ±± .00.250)DIA. 28.49 ± 0.25 (3.1.1275)DIA. (.354) (1.122 ± .010) 1.52 M9 X 0.75-6g SPL ACB 5.69 ± 0.25 (.224 ± .010) (.060) CHANNEL A COMMONCHANNEL B PCB BRACKET MOUNTED - HOUSING B PCB MOUNTING DIMENSIONS SOLDER HOLES - HOUSING C Dimensions not given are the same as Bushing Mounted. (Housing Styles B and E) Dimensions not given are the same as Bushing Mounted. 28.499 ± .254 6.12 ± 0.25 9.02 23.37 ± 0.51 CL (1.122 ± .010) (.241 ± .010) (.355) (.920 ± .020) 11.4 15.2 (.450) .762 (.600) 2.54 (.030) 17.069 23.6 (.100)TYP. 16.002 4 PLCS. (.672) (.930) 1.2 (.630) (.047)DIA. 7 PLCS. 2.54 A C B (6.2.3550 ±± 0.0.2150) CHANNEL A COAMCMBONCHANNEL B (1.0.5672) (.1(05.02.)0080) 3( ..P10L04C72S)D.IA. SNAP-IN MOUNT - Housing G PCB MOUNTING DIMENSIONS 13.08 “L” ± 0.38 22.68 (.515) (“L” ± .015) (.893) (8.3.5315)6.35 (2.28.7240 ±± .00.1205) 9.53 (104.5.6788 ±± 50..0280)DIA. (1.14.4363) (.375) (.250) 27.69 ± 0.25 (1.090 ± .010) 21.11 11.10 28.50 ± 0.25 .97 (.831) 8.99 (.437) (1.122 ± .010) 8 X(.038)R (.354) 3 X .635 (7.2.2845 ±± 0.0.2150) (1.0.5620) DIA. CHANNEL A COMMONCHANNEL B ((5..20.002805)) (2.1.5040) 2 X(2.1.5040)3 X(01..00472)(1.04.2990) (1.24.8224) (1.97.7786) Shaft Style B Shaft Style C Shaft Style J Shaft Style R Shaft Style Y 4.75 ± .006/-.051 (6.2.3429 ++ 0.0.0031//–– 0.0.0063)DIA. (5.2.5148 ±± ..007063) (4.1.0518 ++ ..005012// –– ..002051) (.187 + .003/-.002)DIA. (0.0.9442) (6.2.0306 ±± ..102075) (1.0.5672) (.41.875) DIA. DIA. DIA. (.10.663) (1.0.1497) ""DD"" D= I(MSHENA"DSF"TIO LNE NEXGTTEHN, D(F6.2MS.34 SF29)R ++ –O 0. 0M(.00B 31US//HS–– HA0.0F.I00NT63G )E NLEDN TGOT HBU)SHIN"GD" FACE (0.0.7381) (.10.663) (1.0.1497) S< L1O "T L DEENPGTTHH ( " (Y 1. 5" 4 7S . 78 H ) A FFTO)R ( S 9. 3 H. 68 A 50 F ) T SF O≥R 1 S "H LAEFNTGST H BUSHING MOUNTED - HOUSING H 23.87 Front-Facing Terminals (.940) 15.87 ±.038 .25 .13 22.2 ±.025 (.625 ±.015) (.010) (.005) (.874 ±.010) 9.01 ±.020 6.35 8.50 ±.025 1.52 (.355 ±.008) 4.01 +.050/-.025 (.250) (.335 ±.010) MM (.060) 1.19 11.09 (.158 +.002/-.001) (IN) (1.548.97 ±±..005200)D(.I0A4.7) (.437) (3.1.1275)DIA. (9.3.5725) (9.3.9931)DIA. .635 3 PLCS. (.025) 2.54 3/8–32 UNEF 2A 2.54 16.0 2 PLCS. 1.19 (.100) (2.1.7190) (1.678.45 ±±..002150) 1.57 (.047)D4 IPAL.CS. 2( .P10L0C)S. (.630) (.062) 4.75 +.076/-.050 3.55 CHANNEL A CHANNEL B (.187 +.003/-.002)DIA. (.140) COMMON Specifications are subject to change without notice. Users should verify actual device performance in their specific applications. The products described herein and this document are subject to specific legal disclaimers as set forth on the last page of this document, and at www.bourns.com/docs/legal/disclaimer.pdf.

ECW - Digital Contacting Encoder How to Order PART NUMBERING SYSTEM E C W 1 J - B 2 4 - B C 0 0 2 4 L RoHS IDENTIFIER Code Description L Compliant Code Rotational Life PERFORMANCE CODE C 200,000 Revolutions Code Detents Cycles/Rev. E0006 0 6 E0009 0 9 BUSHING CONFIGURATION E0012 0 12 Code Description E0024 0 24 W 9 mm x 1/4 " Length. Threaded M9x0.75 E0036 0 36 L 9 mm x 3/8 " Length. Threaded M9x0.75 B0012 12 12 (Use B shaft only.) C0006 6 24 T 9 mm x 1/4 ". No Thread. C0024 24 D0009 36 9 SWITCHING CONFIGURATION (In Detent Position) HOUSING TERMINAL CONFIGURATION Applies to performance codes B0012 and C0024 (X indicates “Equipped With” only, use code "0" for all other performance codes. Code Code Description Features A B C D E F G* H K 0 Not Applicable Terminal Cover X X X X 1 Normally Open Rear-Facing Terminals X X X X Solder Holes X X X PCB Bracket X X X X ANTI-ROTATION LUG POSITION Hardware Included X X X X X Code Description Snap-In Mount X J 9:00 Position Forward-Facing Terminals X X D None *Bushing code T only. SHAFT LENGTH (FMS) SHAFT STYLE (See Outline Drawing for Details) Available Code Description Code Description Shaft Styles B Plain with Inserted Slot (1/4 " Dia.) 16 1/2 " Length B C Single Flatted (1/4 " Dia.) 20 5/8 " (15.9 mm) Length J R Plain with Cross Slot (6 mm Dia.) 24 3/4 " (19 mm) Length B, C, J, Y Y Split Shaft Version (.185 " Dia.) 28 7/8 " (22.2 mm) Length B, C, J, Y J Flatted Shaft (3/16 " Dia.) 32 1 " (25.4 mm) Length B, C, J, Y 36 1-1/8 " (28.6 mm) Length B, C, J, Y Metric The sample part number demonstrates the identification code for Bourns contacting encoders. 19 19 mm Length R 22 22 mm Length R Boldface features are Bourns standard options. All others 24 24 mm Length R are available with higher minimum order quantities. REV. 04/15/20 Specifications are subject to change without notice. Users should verify actual device performance in their specific applications. The products described herein and this document are subject to specific legal disclaimers as set forth on the last page of this document, and at www.bourns.com/docs/legal/disclaimer.pdf.

Legal Disclaimer Notice This legal disclaimer applies to purchasers and users of Bourns® products manufactured by or on behalf of Bourns, Inc. and its affiliates (collectively, “Bourns”). Unless otherwise expressly indicated in writing, Bourns® products and data sheets relating thereto are subject to change without notice. Users should check for and obtain the latest relevant information and verify that such information is current and complete before placing orders for Bourns® products. The characteristics and parameters of a Bourns® product set forth in its data sheet are based on laboratory conditions, and statements regarding the suitability of products for certain types of applications are based on Bourns’ knowledge of typical requirements in generic applications. The characteristics and parameters of a Bourns® product in a user application may vary from the data sheet characteristics and parameters due to (i) the combination of the Bourns® product with other components in the user’s application, or (ii) the environment of the user application itself. The characteristics and parameters of a Bourns® product also can and do vary in different applications and actual performance may vary over time. Users should always verify the actual performance of the Bourns® product in their specific devices and applications, and make their own independent judgments regarding the amount of additional test margin to design into their device or application to compensate for differences between laboratory and real world conditions. Unless Bourns has explicitly designated an individual Bourns® product as meeting the requirements of a particular industry standard (e.g., ISO/TS 16949) or a particular qualification (e.g., UL listed or recognized), Bourns is not responsible for any failure of an individual Bourns® product to meet the requirements of such industry standard or particular qualification. Users of Bourns® products are responsible for ensuring compliance with safety-related requirements and standards applicable to their devices or applications. Bourns® products are not recommended, authorized or intended for use in nuclear, lifesaving, life-critical or life-sustaining ap- plications, nor in any other applications where failure or malfunction may result in personal injury, death, or severe property or environmental damage. Unless expressly and specifically approved in writing by two authorized Bourns representatives on a case-by-case basis, use of any Bourns® products in such unauthorized applications might not be safe and thus is at the user’s sole risk. Life-critical applications include devices identified by the U.S. Food and Drug Administration as Class III devices and generally equivalent classifications outside of the United States. Bourns expressly identifies those Bourns® standard products that are suitable for use in automotive applications on such products’ data sheets in the section entitled “Applications.” Unless expressly and specifically approved in writing by two authorized Bourns representatives on a case-by-case basis, use of any other Bourns® standard products in an automotive application might not be safe and thus is not recommended, authorized or intended and is at the user’s sole risk. If Bourns expressly identifies a sub-category of automotive application in the data sheet for its standard products (such as infotainment or lighting), such identification means that Bourns has reviewed its standard product and has determined that if such Bourns® standard product is considered for potential use in automotive applications, it should only be used in such sub-category of automotive applications. Any reference to Bourns® standard product in the data sheet as compliant with the AEC-Q standard or “automotive grade” does not by itself mean that Bourns has approved such product for use in an automotive application. Bourns® standard products are not tested to comply with United States Federal Aviation Administration standards generally or any other generally equivalent governmental organization standard applicable to products designed or manufactured for use in aircraft or space applications. Bourns expressly identifies Bourns® standard products that are suitable for use in aircraft or space applications on such products’ data sheets in the section entitled “Applications.” Unless expressly and specifically approved in writing by two authorized Bourns representatives on a case-by-case basis, use of any other Bourns® standard product in an aircraft or space application might not be safe and thus is not recommended, authorized or intended and is at the user’s sole risk. The use and level of testing applicable to Bourns® custom products shall be negotiated on a case-by-case basis by Bourns and the user for which such Bourns® custom products are specially designed. Absent a written agreement between Bourns and the user regarding the use and level of such testing, the above provisions applicable to Bourns® standard products shall also apply to such Bourns® custom products. Users shall not sell, transfer, export or re-export any Bourns® products or technology for use in activities which involve the design, development, production, use or stockpiling of nuclear, chemical or biological weapons or missiles, nor shall they use Bourns® products or technology in any facility which engages in activities relating to such devices. The foregoing restrictions apply to all uses and applications that violate national or international prohibitions, including embargos or international regulations. Further, Bourns® products and Bourns technology and technical data may not under any circumstance be exported or re-exported to countries subject to international sanctions or embargoes. Bourns® products may not, without prior authorization from Bourns and/or the U.S. Government, be resold, transferred, or re-exported to any party not eligible to receive U.S. commodities, software, and technical data. To the maximum extent permitted by applicable law, Bourns disclaims (i) any and all liability for special, punitive, consequential, incidental or indirect damages or lost revenues or lost profits, and (ii) any and all implied warranties, including implied warranties of fitness for particular purpose, non-infringement and merchantability. For your convenience, copies of this Legal Disclaimer Notice with German, Spanish, Japanese, Traditional Chinese and Simplified Chinese bilingual versions are available at: Web Page: http://www.bourns.com/legal/disclaimers-terms-and-policies PDF: http://www.bourns.com/docs/Legal/disclaimer.pdf C1753 05/17/18R

Datasheet下载

Datasheet下载