ICGOO在线商城 > 射频/IF 和 RFID > RF 评估和开发套件,板 > CC2400DBK

- 型号: CC2400DBK

- 制造商: Texas Instruments

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

CC2400DBK产品简介:

ICGOO电子元器件商城为您提供CC2400DBK由Texas Instruments设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 CC2400DBK价格参考。Texas InstrumentsCC2400DBK封装/规格:RF 评估和开发套件,板, 。您可以下载CC2400DBK参考资料、Datasheet数据手册功能说明书,资料中有CC2400DBK 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

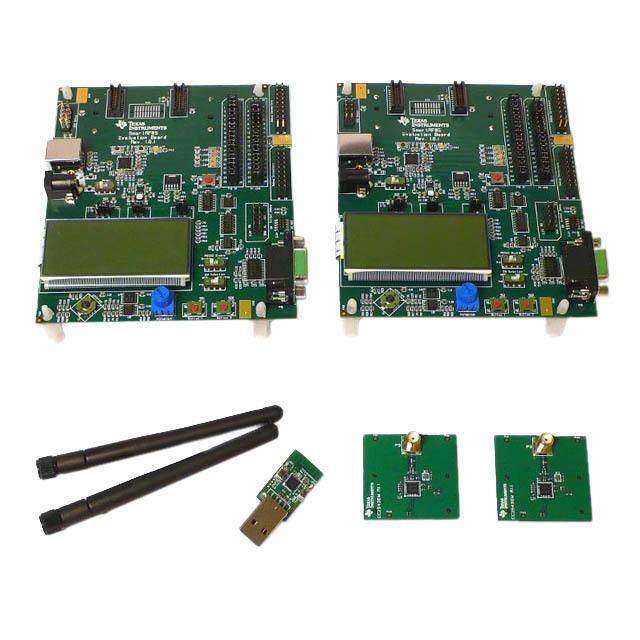

| 描述 | KIT DEMO BOARD FOR CC2400Zigbee/802.15.4开发工具 CC2400 2.4GHz DEMONSTRATION KIT |

| 产品分类 | |

| 品牌 | Texas Instruments |

| 产品手册 | |

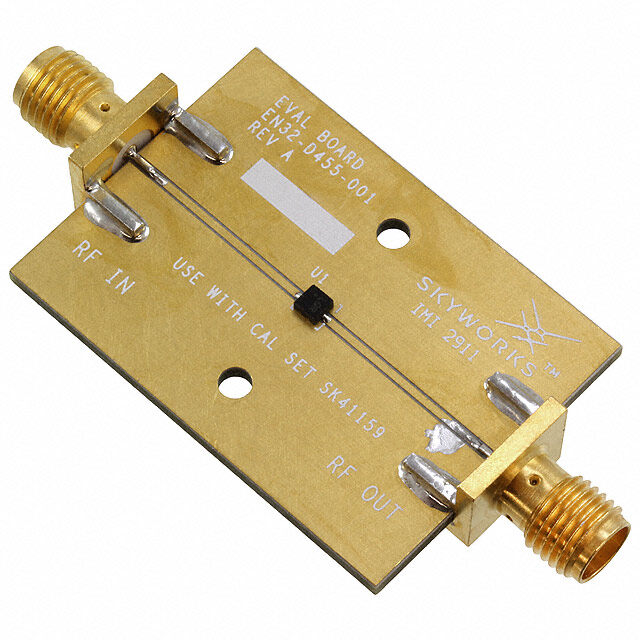

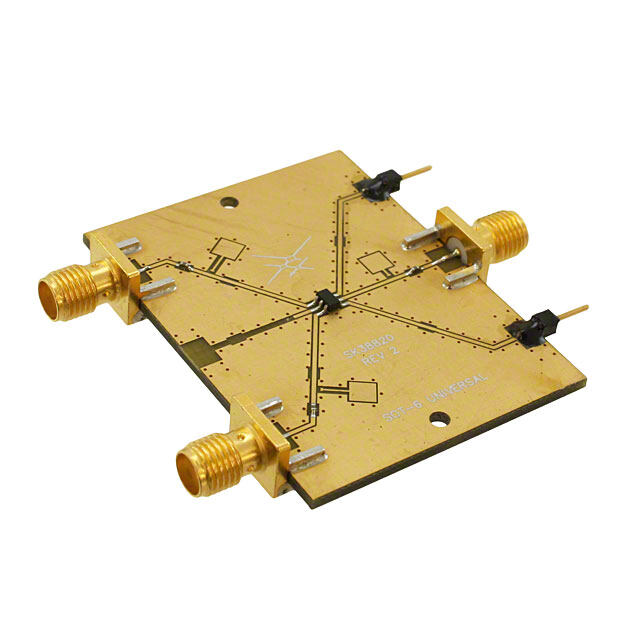

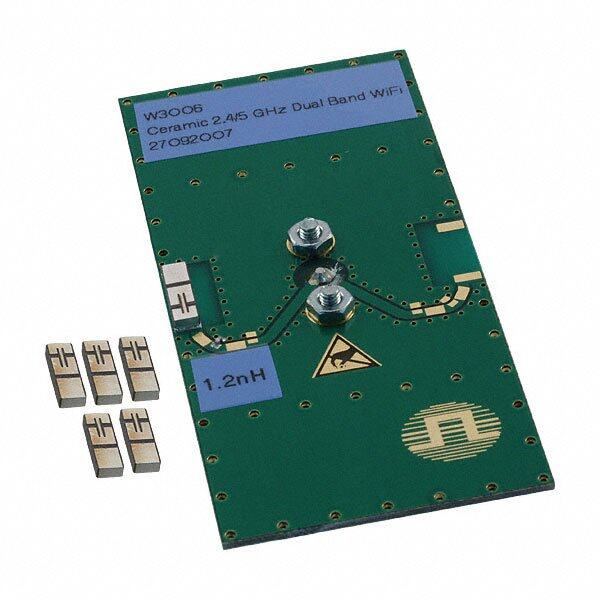

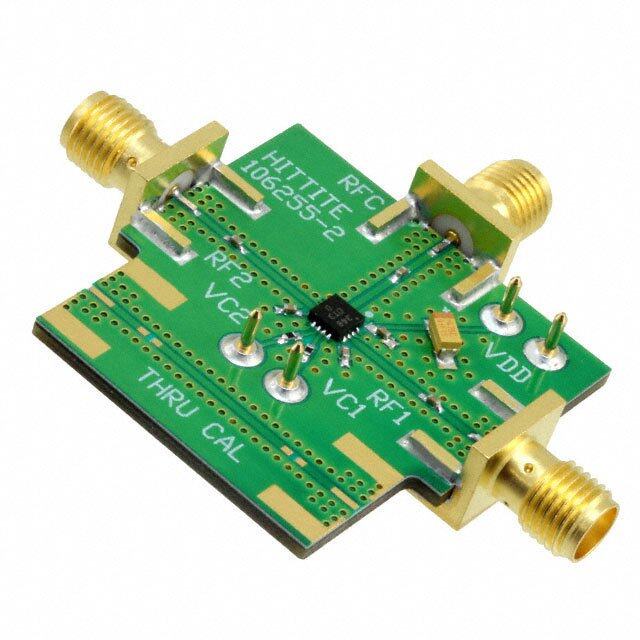

| 产品图片 | |

| rohs | 否含铅 / 不符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 射频/无线开发工具,Zigbee/802.15.4开发工具,Texas Instruments CC2400DBKSmartRF® |

| mouser_ship_limit | 此产品可能需要其他文件才能从美国出口。 |

| 数据手册 | |

| 产品型号 | CC2400DBK |

| 产品 | Demonstration Kits |

| 产品种类 | Zigbee/802.15.4开发工具 |

| 制造商产品页 | http://www.ti.com/general/docs/suppproductinfo.tsp?distId=10&orderablePartNumber=CC2400DBK |

| 商标 | Texas Instruments |

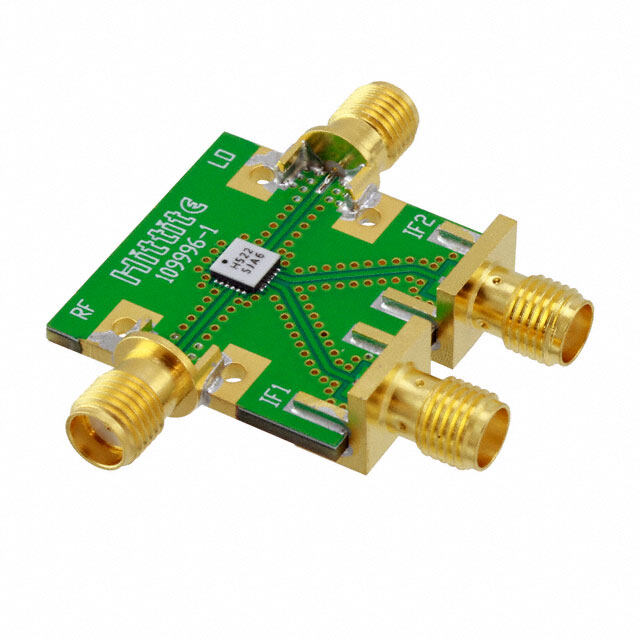

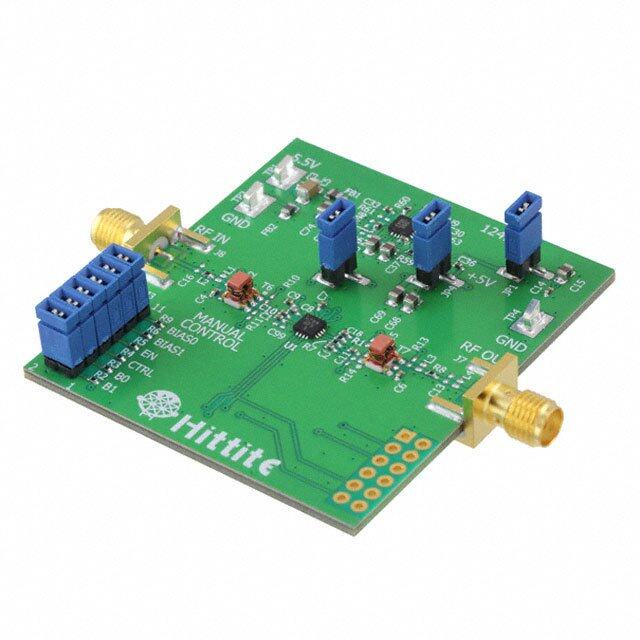

| 天线连接器类型 | SMA |

| 工作电源电压 | 4 V to 10 V |

| 工具用于评估 | CC2400 |

| 工厂包装数量 | 1 |

| 所含物品 | 2 个板,线缆,产品样品 |

| 接口类型 | RS-232 |

| 描述/功能 | Includes two CC2400DB Demonstration Boards |

| 标准包装 | 1 |

| 用于 | SmartRF04EB |

| 相关产品 | /product-detail/zh/CC2400-RTR1/CC2400-RTR1-ND/1690527/product-detail/zh/CC2400-RTB1/CC2400-RTB1-ND/1690526/product-detail/zh/CC2400RSU/296-32847-5-ND/1690525/product-detail/zh/CC2400RSUR/296-21512-1-ND/1304552/product-detail/zh/CC2400RTC/296-19466-ND/998339 |

| 类型 | 收发器,ISM |

| 配套使用产品/相关产品 | CC2400 |

| 频率 | 2.4 GHz |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

CC2400 CC2400 2.4 GHz Low-Power RF Transceiver Applications • 2.4 GHz MHz ISM/SRD band systems • Wireless audio • Game controllers • PC peripherals • Sports and leisure equipment • Advanced toys Product Description The CC2400 is a true single-chip 2.4 GHz and error detection reducing the workload RF transceiver designed for low-power on the host microcontroller. and low-voltage wireless applications. The RF transceiver is integrated with a The main operating parameters of CC2400 baseband modem supporting data rates can be programmed via an SPI-bus. In a up to 1 Mbps. typical system CC2400 will be used together with a microcontroller and a few The CC2400 is a low-cost, highly integrated external, passive components. solution enabling robust wireless communication in the 2.4 - 2.4835 GHz CC2400 is based on Chipcon’s SmartRF®- unlicensed ISM band. It is intended for 03 technology in 0.18 µm CMOS. systems compliant with world-wide regulations covered by EN 300 440 (Europe), CFR47 Part 15 (US) and ARIB STD-T66 (Japan). Targeting a wide range of applications at 2.4 GHz, the CC2400 supports over-the-air data rates of 10 kbps, 250 kbps and 1 Mbps without requiring any modifications to the hardware. The CC2400 provides extensive hardware support for packet handling, data buffering, burst transmissions, data coding Key Features • True single-chip 2.4 GHz RF • Packet handling hardware transceiver with baseband modem • Data buffering • 10 kbps, 250 kbps and 1 Mbps over- • Digital RSSI output the-air data rates • Small size (QFN 48 package), 7x7 mm • Low current consumption (RX: 24 mA) • Reference design complies with EN • Low core supply voltage (1.8 V) 300 328, EN 300 440, FCC CFR47 part • Programmable output power 15 and ARIB STD-T66 • No external RF switch / filter needed • Powerful and flexible development • I/Q low-IF receiver tools available • I/Q direct up-conversion transmitter • Easy-to-use software for generating the • Few external components CC2400 configuration data • FIFO allows bursting of data This document contains information on a pre-production product. Specifications and information herein are subject to change without notice. SWRS042A Page 1 of 83

CC2400 Table of contents 1 ABBREVIATIONS..............................................................................................................4 2 FEATURES........................................................................................................................5 3 ABSOLUTE MAXIMUM RATINGS....................................................................................6 4 OPERATING CONDITIONS..............................................................................................6 5 ELECTRICAL SPECIFICATIONS.....................................................................................7 6 GENERAL CHARACTERISTICS......................................................................................7 7 RF TRANSMIT SECTION..................................................................................................8 8 RF RECEIVE SECTION.....................................................................................................9 9 AFC SECTION.................................................................................................................10 10 RSSI / CARRIER SENSE SECTION............................................................................11 11 IF SECTION..................................................................................................................11 12 FREQUENCY SYNTHESIZER SECTION....................................................................11 13 DIGITAL INPUTS/OUTPUTS.......................................................................................12 14 PIN ASSIGNMENT.......................................................................................................13 15 CIRCUIT DESCRIPTION.............................................................................................15 16 APPLICATION CIRCUIT..............................................................................................17 16.1 INPUT / OUTPUT MATCHING.......................................................................................17 16.2 BIAS RESISTOR........................................................................................................17 16.3 CRYSTAL.................................................................................................................17 16.4 DIGITAL I/O.............................................................................................................17 16.5 POWER SUPPLY DECOUPLING AND FILTERING............................................................17 16.6 POWER SUPPLY SWITCHING......................................................................................17 17 CONFIGURATION OVERVIEW...................................................................................20 18 CONFIGURATION SOFTWARE..................................................................................20 19 4-WIRE SERIAL CONFIGURATION INTERFACE......................................................21 20 OVERVIEW OF CONFIGURATIONS AND HARDWARE SUPPORT........................24 21 MICROCONTROLLER INTERFACE AND PIN CONFIGURATION...........................25 21.1 CONFIGURATION INTERFACE.....................................................................................25 21.2 SIGNAL INTERFACE IN UN-BUFFERED MODE................................................................25 21.3 GENERAL CONTROL AND STATUS PINS.......................................................................25 22 DATA BUFFERING......................................................................................................27 22.1 BUFFERED MODE.....................................................................................................27 22.2 BUFFERED MODE HARDWARE SUPPORT.....................................................................27 23 PACKET HANDLING HARDWARE SUPPORT..........................................................29 23.1 DATA PACKET FORMAT.............................................................................................29 23.2 ERROR DETECTION..................................................................................................29 23.3 HARDWARE INTERFACE............................................................................................31 24 DATA / LINE ENCODING............................................................................................31 24.1 DATA ENCODING IN BUFFERED MODE.........................................................................31 24.2 DATA ENCODING IN UN-BUFFERED MODE...................................................................32 25 RADIO CONTROL STATE MACHINE........................................................................34 26 POWER MANAGEMENT FLOW CHART...................................................................36 27 FSK MODULATION FORMATS..................................................................................38 28 BUILT-IN TEST PATTERN GENERATOR..................................................................38 29 RECEIVER CHANNEL BANDWIDTH.........................................................................39 30 DATA RATE PROGRAMMING....................................................................................40 31 DEMODULATOR, BIT SYNCHRONIZER AND DATA DECISION.............................41 32 AUTOMATIC FREQUENCY CONTROL.....................................................................42 33 LINEAR IF AND AGC SETTINGS...............................................................................43 34 RSSI..............................................................................................................................44 35 CARRIER SENSE........................................................................................................45 36 INTERFACING AN EXTERNAL LNA OR PA.............................................................45 37 GENERAL PURPOSE / TEST OUTPUT CONTROL PINS.........................................45 38 FREQUENCY PROGRAMMING..................................................................................47 38.1 TRANSMIT MODE......................................................................................................47 SWRS042A Page 2 of 83

CC2400 38.2 RECEIVE MODE........................................................................................................47 39 ALTERNATE TX IF SETTING.....................................................................................47 40 VCO..............................................................................................................................48 41 VCO SELF-CALIBRATION..........................................................................................48 42 OUTPUT POWER PROGRAMMING...........................................................................48 43 CRYSTAL OSCILLATOR............................................................................................49 44 INPUT / OUTPUT MATCHING.....................................................................................50 45 TYPICAL PERFORMANCE GRAPHS.........................................................................50 46 SYSTEM CONSIDERATIONS AND GUIDELINES.....................................................53 46.1 SRD REGULATIONS..................................................................................................53 46.2 FREQUENCY HOPPING AND MULTI-CHANNEL SYSTEMS................................................53 46.3 DATA BURST TRANSMISSIONS...................................................................................53 46.4 CONTINUOUS TRANSMISSIONS..................................................................................53 46.5 CRYSTAL DRIFT COMPENSATION...............................................................................53 46.6 SPECTRUM EFFICIENT MODULATION..........................................................................54 46.7 LOW LATENCY SYSTEMS...........................................................................................54 46.8 LOW COST SYSTEMS................................................................................................54 46.9 BATTERY OPERATED SYSTEMS..................................................................................54 46.10 INCREASING OUTPUT POWER....................................................................................54 47 PCB LAYOUT RECOMMENDATIONS.......................................................................56 48 ANTENNA CONSIDERATIONS..................................................................................57 49 CONFIGURATION REGISTERS.................................................................................58 50 PACKAGE DESCRIPTION (QFN48)...........................................................................76 51 RECOMMENDED LAYOUT FOR PACKAGE (/QFN48).............................................77 52 PACKAGE THERMAL PROPERTIES.........................................................................77 53 SOLDERING INFORMATION......................................................................................77 54 IC MARKING................................................................................................................78 55 PLASTIC TUBE SPECIFICATION...............................................................................80 56 CARRIER TAPE AND REEL SPECIFICATION..........................................................80 57 ORDERING INFORMATION........................................................................................80 58 GENERAL INFORMATION..........................................................................................81 58.1 DOCUMENT HISTORY...............................................................................................81 58.2 PRODUCT STATUS DEFINITIONS................................................................................82 58.3 DISCLAIMER.............................................................................................................82 58.4 TRADEMARKS..........................................................................................................82 58.5 LIFE SUPPORT POLICY.............................................................................................82 59 ADDRESS INFORMATION..........................................................................................83 SWRS042A Page 3 of 83

CC2400 1 Abbreviations ACP Adjacent Channel Power ACR Adjacent Channel Rejection ADC Analog-to-Digital Converter AFC Automatic Frequency Correction AGC Automatic Gain Control BER Bit Error Rate BOM Bill Of Materials bps bits per second BT Bandwidth-Time product (for GFSK) CRC Cyclic Redundancy Check CSMA Carrier Sense Multiple Access CSMA / CA Carrier Sense Multiple Access / Collision Avoidance DAC Digital-to-Analog Converter ESR Equivalent Series Resistance FH Frequency Hopping FHSS Frequency Hopping Spread Spectrum FIFO First In First Out (queue) FS Frequency Synthesizer FSK Frequency Shift Keying GFSK Gaussian Frequency Shift Keying IF Intermediate Frequency ISM Industrial Scientific Medical kbps kilo bits per second LNA Low Noise Amplifier Mbps Mega bits per second MCU Micro Controller Unit NRZ Non Return to Zero PA Power Amplifier PD Phase Detector PCB Printed Circuit Board PN9 Pseudo-random Bit Sequence (9-bit) PLL Phase Locked Loop PRN Pseudo Random Number PRNG Pseudo Random Number Generator RF Radio Frequency RSSI Received Signal Strength Indicator RX Receive (mode) SPI Serial Peripheral Interface SRD Short Range Device TBD To Be Decided/Defined TDMA Time Division Multiple Access TX Transmit (mode) VCO Voltage Controlled Oscillator VGA Variable Gain Amplifier SWRS042A Page 4 of 83

CC2400 2 Features • 2400 – 2483 MHz RF transceiver • GFSK and FSK modulation • Packet handling hardware support • Very low current consumption (RX: • Preamble generator with 24 mA) programmable length • Over-the-air data rates of 10 kbps, • Programmable synchronization 250 kbps and 1 Mbps word insertion/detection • High sensitivity (-87 dBm @ 1Mbps, • CRC computation over the data BER=10-3) field • Agile frequency synthesizer (40 us • 8B/10B line coding option settling time) • On-chip VCO, LNA and PA • Data buffering • Low core supply voltage (1.6-2.0 V) • 32 byte FIFO • Flexible I/O supply voltage • Provides for flexible communication (1.6–3.6 V) to match the signal with the host controller. levels of the interfacing • Burst transmission reduces the microcontroller average power consumption. • Programmable output power • I/Q low-IF receiver • Powerful and flexible development • I/Q direct up-conversion transmitter tools available • Fully equipped development kit • Few external components • Demonstration board reference • Only reference crystal and a few design with microcontroller code passives needed • Easy-to-use SmartRF Studio • No external filters needed software for generating the CC2400 configuration data • Programmable baseband modem • 4-wire SPI interface • Small size (QFN 48 package) 7 x 7 mm • Serial clock up to 20 MHz • Digital RSSI output • Reference design complies with EN 300 328, EN 300 440, FCC CFR47 part 15 and ARIB STD-T66 SWRS042A Page 5 of 83

CC2400 3 Absolute Maximum Ratings Parameter Min. Max. Units Condition Supply voltage, chip core, −0.3 2.0 V AVDD/DVDD1.8=VDD Supply voltage (DVDD3.3=VDDIO), digital I/O −0.3 3.6 V Voltage on any pin, core −0.3 VDD+0.3, V max 2.0 Voltage on any pin, digital I/O (pin no. 27-35) −0.3 VDDIO+0.3, V max 3.6 Input RF level 10 dBm Storage temperature range −50 150 °C Reflow solder temperature 260 °C T = 10 s NOTE: The supply voltage to the chip core (AVDD/DVDD1.8) should not be switched off when the digital IO (DVDD3.3) supply voltage is still applied to the chip. If this is done, a large current will flow inside the CC2400 and the chip may be damaged as a result. If the core supply needs to be switched off to lower the power consumption, please see page 17 for a suggested solution. The absolute maximum ratings given the limiting values may cause permanent above should under no circumstances be damage to the device. violated. Stress exceeding one or more of Caution! ESD sensitive device. Precaution should be used when handling the device in order to prevent permanent damage. 4 Operating Conditions Parameter Min. Typ. Max. Unit Condition Supply voltage, chip core, 1.6 2.0 V AVDD/DVDD1.8 Supply voltage (DVDD3.3), digital 1.6 3.6 V The digital I/O voltage (DVDD3.3 I/O, VDDIO pin) must match the interfacing circuit. Recommended supply voltage, chip 1.8V core, AVDD/DVDD1.8 Recommended supply voltage 1.8V/ (DVDD3.3), digital I/O 3.3V Operating ambient temperature −40 85 °C range SWRS042A Page 6 of 83

CC2400 5 Electrical Specifications Parameter Min. Typ. Max. Unit Condition / Note Current Consumption, Power Down mode (OFF) 1.5 5 µA Oscillator core off Current Consumption, Idle mode (IDLE) 1.2 mA Current Consumption, Frequency synthesizer (FS_ON) 6.3 mA Current Consumption, 24 mA Receive mode Current Consumption, Transmit mode: P=−25 dBm 11 mA The output power is delivered differentially to a 50Ω single- P=−5 dBm 15 mA ended load through a balun, see also p. 50. P=0 dBm 19 mA Current Consumption, crystal 38 µA 16 MHz, 16 pF load crystal oscillator core Table 1 Electrical specifications 6 General Characteristics Tc = 25°C, AVDD/DVDD1.8 = 1.8 V, DVDD3.3 = 3.3V (digital I/O) if nothing else stated. Measured on Chipcon’s CC2400EM reference design. Parameter Min. Typ. Max. Unit Condition / Note RF Frequency Range 2400 2483 MHz Programmable in 1 MHz channel steps. Data rate 10 kbps Data rate is 250 kbps programmable/selectable, see 1 Mbps page 40 Table 2 General characteristics SWRS042A Page 7 of 83

CC2400 7 RF Transmit section Tc = 25°C, AVDD/DVDD1.8 = 1.8 V, DVDD3.3 = 3.3V (digital I/O) if nothing else stated. Measured on Chipcon’s CC2400EM reference design. Parameter Min. Typ. Max. Unit Condition / Note Binary FSK frequency deviation 0 250 500 ±kHz The frequency corresponding to the digital "0" is denoted f, while 0 f corresponds to a digital "1". 1 The frequency deviation is given by f=±(f−f)/2. The RF carrier d 1 0 frequency, f, is then given by c f=(f+f)/2. c 0 1 Nominal output power 0 dBm Default settings. Power delivered to a 50 Ω single- ended load through a balun. The output power is programmable in 8 steps. Programmable output power range 25 dB 20 dB bandwidth Maximum output power. Modulation is 1 Mbps, NRZ data, FSK 1.2 MHz ± 250 kHz frequency deviation. GFSK 1.0 MHz Adjacent Channel Power (ACP) Maximum output power. Modulation is 1 Mbps, NRZ data, FSK -30 dBc ± 250 kHz frequency deviation. GFSK -43 dBc Measured at 2 MHz offset. Harmonics At max output power delivered to 2nd order harmonic -41 dBm 50 Ω single-ended load through a 3rd order harmonic -54 dBm balun. Carrier modulated with pseudo-random data. See p.50. Spurious emission Maximum output power. 30 - 1000 MHz -65 -36 dBm Modulation is 1 Mbps FSK, NRZ 1– 12.75 GHz -41 -30 dBm data, ±250 kHz frequency 1.8 – 1.9 GHz -69 -47 dBm deviation. 5.15 – 5.3 GHz -65 -47 dBm Complying with EN 300 440, CFR47 Part 15 and ARIB STD- T66 Optimum load impedance 110 Ω Differential impedance as seen + j130 from the RF-port (RF_P and RF_N) towards the antenna. For matching details see “Input/ output matching” page 50 as well as the application circuit description on page 17. Table 3 Transmit characteristics SWRS042A Page 8 of 83

CC2400 8 RF Receive section Tc = 25°C, AVDD/DVDD1.8 = 1.8 V, DVDD3.3 = 3.3V (digital I/O) if nothing else stated. Measured on Chipcon’s CC2400EM reference design. Parameter Min. Typ. Max. Unit Condition / Note Receiver Sensitivity at BER = 10−3 Measured in a 50 Ohm single- ended load through a balun. FSK, NRZ mode used. 1 Mbps, 1 MHz channel BW -87 dBm ±250 kHz frequency deviation 250 kbps, 1 MHz channel BW -91 dBm ±250 kHz frequency deviation 10 kbps, 500 kHz channel BW -101 dBm ±125 kHz frequency deviation Saturation (maximum input level) 3 dBm Maximum gain in LNA. NRZ coded data, BER = 10−3 Co-channel rejection -10 dB 1 Mbps wanted signal 10 dB above the sensitivity level, interferer modulated like signal (pseudo-random FSK, ± 250 kHz deviation), interferer at operating frequency, BER = 10−3 Adjacent channel rejection (ACR) FSK wanted signal 10 dB above the sensitivity level, 1 MHz 1 Mbps 0 dB channel spacing, interferer 250 kbps 12 dB modulated like signal (pseudo- random FSK, ± 250 kHz deviation) at adjacent channel, BER = 10−3 Image channel rejection FSK wanted signal 10 dB above the sensitivity level, interferer 1 Mbps 21 dB modulated like signal (pseudo- 250 kbps 39 dB random FSK, ± 250 kHz deviation) at image frequency, BER = 10−3. The image channel is centered 2MHz below the center frequency of the desired channel. Selectivity (C/I) (In-band channel rejection) + 2MHz 20 dB 1Mbps FSK wanted signal at ± 3MHz 41 dB 2441 MHz, 3 dB above the ± 4MHz 50 dB sensitivity level (except + 2 MHz, ± 5MHz 52 dB which is 10 dB above the ± 10MHz 55 dB sensitivity limit), jammer ± 20 MHz 56 dB modulated like signal (pseudo- ± 50MHz 59 dB random, ± 250 kHz deviation) at ± 2-39 MHz in 1 MHz steps offset, BER = 10−3. Adjacent channels and image channel are excluded. + 2 MHz 48 dB 250 kbps FSK wanted signal at ± 3 MHz 50 dB 2441 MHz, 3 dB above the ± 4 MHz 55 dB sensitivity level (except + 2 MHz, ± 5 MHz 56 dB which is 10 dB above the ± 10 MHz 59 dB sensitivity limit), jammer ± 20 MHz 60 dB modulated like signal (pseudo- ± 50 MHz 64 dB random, ± 250 kHz deviation) at ± 2-39 MHz in 1 MHz steps offset, BER = 10−3. Adjacent channels and image channel are excluded. SWRS042A Page 9 of 83

CC2400 Parameter Min. Typ. Max. Unit Condition / Note Blocking / Desensitization* (*out-of-band spurious response rejection) 0.3 – 2.0 GHz 71 dB 1 Mbps FSK wanted signal 3 dB 2.0 – 2.399 GHz 50 dB above the sensitivity level, sine- 2.498 – 3.0 GHz 49 dB wave interfering signal, BER = 3 – 12.75 GHz 76 dB 10−3. Input IIP3 Measured directly by applying two Out of band -5 dBm tones and measuring the In band -17 dBm resulting difference tone amplitude. Image frequency suppression 56 dB Ratio between sensitivity for a signal at the image frequency and the sensitivity in the wanted channel with an inverted signal. The image frequency is centered -2 MHz from the center of the wanted channel. The signal source is 1Mbps, NRZ coded data, ±250 kHz frequency deviation, signal level for BER = 10−3 Spurious reception 80 dB Ratio between the sensitivity for an unwanted frequency and the sensitivity in the wanted channel. The signal source is a 1 Mbps, NRZ coded data, ±250 kHz frequency deviation, swept over all frequencies 2400 – 2483.5 MHz. Signal level for BER = 10−3 Adjacent channels and image channel are excluded. Spurious emission Complying with EN 300 440, < 1 GHz −70 -57 dBm CFR47 Part 15 and ARIB STD- 1 – 12.75 GHz −56 -47 dBm T66 Table 4 RF Receive characteristics 9 AFC section Parameter Min. Typ. Max. Unit Condition / Note For 1Mbps and 1 MHz channel width, AFC_SETTLING=4. AFC range ± 500 kHz Measured using an unmodulated carrier. AFC accuracy 5 kHz Table 5 AFC characteristics SWRS042A Page 10 of 83

CC2400 10 RSSI / Carrier Sense section Parameter Min. Typ. Max. Unit Condition / Note For 1Mbps and 1 MHz channel width. RSSI range / Carrier sense range 80 dB (The range is from –100 dBm to –20 dBm typically) RSSI settling time 20 µs RSSI accuracy ± 4 dB See page 44 for details Table 6 RSSI / Carrier sense characteristics 11 IF section Parameter Min. Typ. Max. Unit Condition / Note Intermediate frequency (IF) 1 MHz Digital channel filter bandwidth 125 1000 kHz The digital channel filter 6dB- bandwidth is programmable in steps: 125, 250, 500 and 1000 kHz. See page 39 for details. Table 7 IF characteristics 12 Frequency Synthesizer section Parameter Min. Typ. Max. Unit Condition / Note Crystal oscillator frequency 16 MHz See page 49 for details. Crystal frequency accuracy 20 ±ppm The total crystal frequency requirement accuracy, i.e. initial tolerance plus aging and temperature dependency, will determine the frequency accuracy of the transmitted signal. 1 Mbps FSK, 250 kHz deviation. Crystal operation Parallel C4 and C5 are loading capacitors, see page 49 Crystal load capacitance 12 16 20 pF 16 pF recommended Crystal ESR 60 Ω Crystal oscillator start-up time 1.13 ms 16 pF load Note: This time can be reduced to 15 µs by enabling the XOSC core in power-down using the MANAND register. Phase noise Unmodulated carrier -108 dBc/Hz At ±1 MHz offset from carrier -114 dBc/Hz At ±2 MHz offset from carrier -114 dBc/Hz At ±5 MHz offset from carrier PLL loop bandwidth 50 kHz SWRS042A Page 11 of 83

CC2400 Parameter Min. Typ. Max. Unit Condition / Note PLL lock time (RX / TX turn-on 40 µs Until within ± 10 kHz time) Step size is 1MHz, no calibration. Note: Calibration should be performed for frequency changes > 8 MHz. PLL turn-on time from IDLE mode, 100 µs Crystal oscillator running. crystal oscillator on Calibration time included. Table 8 Frequency synthesizer characteristics 13 Digital Inputs/Outputs Parameter Min. Typ. Max. Unit Condition / Note Signal levels are referred to the voltage level at the pin DVDD3.3. Logic "0" input voltage 0 0.3* V DVDD Logic "1" input voltage 0.7* DVDD V DVDD Logic "0" output voltage 0 0.4 V Output current −8 mA, 3.3 V supply voltage Logic "1" output voltage 2.5 DVDD V Output current 8 mA, 3.3 V supply voltage Logic "0" input current NA −1 µA Input signal equals GND Logic "1" input current NA 1 µA Input signal equals DVDD DIO setup time 20 ns TX un-buffered mode, minimum time DIO must be ready before the positive edge of DCLK DIO hold time 10 ns TX un-buffered mode, minimum time DIO must be held after the positive edge of DCLK Serial interface (SCLK, SI, SO and See Table 12 page 22 CSn) timing specification Table 9 Digital input/output characteristics SWRS042A Page 12 of 83

CC2400 14 Pin Assignment 1 2 C AVDD_CHP ATEST1 ATEST2 R_BIAS AVDD_IF1 XOSC16_Q XOSC16_Q AVDD_XOS NC NC NC NC 8 7 6 5 4 3 2 1 0 9 8 7 4 4 4 4 4 4 4 4 4 3 3 3 VCO_GUARD 1 36 NC AVDD_VCO 2 35 GIO6 AVDD_PRE 3 34 SO AVDD_RF1 4 33 SI GND 5 32 SCLK QLP48 RF_P 6 CC2400 31 CSn 7x7 TXRX_SWITCH 7 30 DCLK/FIFO RF_N 8 29 DIO/PKT GND 9 28 TX AVDD_SW 10 27 RX NC 11 26 DVDD1.8 NC 12 25 DVDD3.3 13 14 15 16 17 18 19 20 21 22 23 24 AGND N A A A D D D B G D D D Exposed die C VDD VDD VDD VDD GND GUA T/GR IO1 GND SUB SUB attach pad _RF2 _IF2 _ADC _ADC _GUA RD _PAD _COR R S E D Figure 1 CC2400 Top View Pin no. Pin name Pin type Description - AGND Ground (analog) Exposed die attach pad. Must be connected to solid ground plane 1 VCO_GUARD Power (Analog) Connection of guard ring for VCO shielding 2 AVDD_VCO Power (Analog) Power supply for VCO 3 AVDD_PRE Power (Analog) Power supply for Prescaler 4 AVDD_RF1 Power (Analog) Power supply for RF front-end 5 GND Ground (Analog) Grounded pin for RF shielding 6 RF_P RF I/O Positive RF input/output signal to LNA/from PA in receive/transmit mode 7 TXRX_SWITCH Power (Analog) Common supply connection for RF front-end. Must be connected to RF_P and RF_N externally through a DC path. 8 RF_N RF I/O Negative RF input/output signal to LNA/from PA in receive/transmit mode 9 GND Ground (Analog) Grounded pin for RF shielding 10 AVDD_SW Power (Analog) Power supply connection SWRS042A Page 13 of 83

CC2400 Pin no. Pin name Pin type Description 11 NC --- No Connect 12 NC --- No Connect 13 NC --- No Connect 14 AVDD_RF2 Power (Analog) Power supply for receive and transmit mixers 15 AVDD_IF2 Power (Analog) Power supply for transmit IF chain 16 AVDD_ADC Power (Analog) Power supply connection of ADCs and DACs 17 DVDD_ADC Power (Digital) Power supply for digital part of receive ADCs 18 DGND_GUARD Ground (Digital) Ground connection for digital noise isolation 19 DGUARD Power (Digital) Power supply connection for digital noise isolation 20 BT/GR Digital Input Selection of Built-in-Test or Generic Radio (normal operation). Connect to ground for normal operation (NOTE: For Chipcon internal use only.) 21 GIO1 Digital I/O General digital I/O pin. Configure as output when not used. See Table 18 22 DGND Ground (Digital) Ground connection for digital modules 23 DSUB_PADS Ground (Digital) Substrate connection for digital I/O’s 24 DSUB_CORE Ground (Digital) Substrate connection for digital modules 25 DVDD3.3 Power (Digital) Power supply for digital I/O’s 26 DVDD1.8 Power (Digital) Power supply for digital modules 27 RX Digital Input Strobe signal for RX mode. Connect to ground when not used. 28 TX Digital I/O Strobe signal for TX mode. Connect to ground when not used. 29 DIO/PKT Digital I/O Data input/output in un-buffered mode or packet handling control signal. Configure as output when not used. 30 DCLK/FIFO Digital Output Data clock output signal in un-buffered mode or FIFO control signal. Leave open when not used. 31 CSn Digital Input SPI: Chip Select 32 SCLK Digital Input SPI: Serial data clock 33 SI Digital Input SPI: Slave Input 34 SO Digital Output SPI: Slave Output 35 GIO6 Digital Output General digital output pin. See Table 18 36 NC --- No Connect 37 NC --- No Connect 38 NC --- No Connect 39 NC --- No Connect 40 NC --- No Connect 41 AVDD_XOSC Power (Analog) Power supply for 16 MHz crystal oscillator 42 XOSC16_Q2 Analog output 16 MHz crystal oscillator 43 XOSC16_Q1 Analog input 16 MHz crystal oscillator or external clock input 44 AVDD_IF1 Power (Analog) Power supply connection of receive IF chain 45 R_BIAS Analog Output Connection for external precision bias resistor 46 ATEST2 Analog I/O Analog test I/O for prototype and production testing. Leave not connected when not used. 47 ATEST1 Analog I/O Analog test I/O for prototype and production testing. Leave not connected when not used. 48 AVDD_CHP Power (Analog) Power supply for phase detector and charge pump NOTES: The exposed die attach pad must be connected to a solid ground plane as this is the main ground connection for the chip. The digital inputs SCLK, SI and CSn are high-impedance inputs (no internal pull-up) and should have external pull- ups if not driven. RX and TX should have external pull-down if not driven (to prevent the state machine from being trigged). SO is high-impedance when CSn is high. External pull-up should be used at SO to prevent floating input at the microcontroller. SWRS042A Page 14 of 83

CC2400 15 Circuit Description ADC DIGITAL DEMODULATOR - Digital RSSI LNA - Gain Control - Image Suppression - Channel Filtering ADC - Demodulation R AGC CONTROL E TX/RX CONTROL GIC OLL C SmCa2rt4RF0 ®0 090 SFYRNETQH NTROL LO INTDEIFGRIFIFTOAACLE / ROCONTR O C C MI TX POWER CONTROL O T DAC DIGITAL Power MODULATOR Control PA Σ - Data Filtering - Modulation - Power Control DAC XOSC On-chip BIAS 16 MHz Figure 2. CC2400 simplified block diagram A simplified block diagram of CC2400 is programmable carrier sense indicator with shown in Figure 2. output on either GIO1 or GIO6. CC2400 features a low-IF receiver. The In transmit mode the baseband signal is received RF signal is amplified by the low- directly up-converted quadrature (I and Q) noise amplifier (LNA) and down-converted and then fed to the power amplifier (PA). in quadrature (I and Q) to the intermediate frequency (IF). At IF (1 MHz), the I/Q The TX IF signal is frequency shift keyed signal is filtered and amplified, and then (FSK). Optionally Gaussian filtering can be digitized by the ADCs. Automatic gain used enabling GFSK. The BT of the control, final channel filtering, Gaussian filter is 0.5 for a datarate of demodulation and bit synchronization is 1 Mbps. performed digitally. The internal T/R switch circuitry simplifies CC2400 outputs (in un-buffered mode only) the antenna interface and matching. The the digital demodulated data on the DIO antenna connection is differential. The pin. A synchronized data clock is then biasing of the PA and LNA is done by available at the DCLK pin. In buffered connecting TXRX_SWITCH to RF_P and mode the demodulated data is sent to a RF_N through an external DC path. FIFO and is accessible through the SPI interface. RSSI is available in digital The frequency synthesizer includes a format and can be read via the serial completely on-chip LC VCO and a 90 interface. The RSSI also features a degrees phase splitter for generating the SWRS042A Page 15 of 83

CC2400 LO_I and LO_Q signals to the down- synthesizer. A PLL lock signal is available conversion mixers in receive mode and via the GIO pins. up-conversion mixers in transmit mode. The VCO operates in the frequency range The digital baseband includes support for 4800 – 4966 MHz, and the frequency is packet handling and data buffering. divided by two when split in I and Q. The 4-wire SPI serial interface is used for A crystal must be connected to configuration (and data interface in XOSC16_Q1 and XOSC16_Q2 and buffered mode). A few digital I/O lines can generates the reference frequency for the be configured for use with packet handling strobe and interrupt signals. SWRS042A Page 16 of 83

CC2400 16 Application Circuit Few external components are required for the operation of CC2400. A typical 16.3 Crystal application circuit is shown in Figure 3. A An external crystal with input and output description of the external components loading capacitors (C421 and C431) is referring to Figure 3 are described in used for the crystal oscillator. See page 49 Table 10. The bill of materials (BOM) is for details. given in Table 11. 16.4 Digital I/O Good PCB layout is vital for proper The supply voltage for the digital I/O must operation, please see the section on PCB match the interfacing microcontroller. The Layout Recommendations on page 56 for digital I/Os of CC2400 can interface more details. microcontrollers with supply voltages in the range 1.6 – 3.6 V. 16.1 Input / output matching The RF input/output is high impedance 16.5 Power supply decoupling and and differential. The optimum differential filtering load for the RF port is listed on page 8. Proper power supply decoupling must be used for optimum performance. The When using an unbalanced antenna like a placement and size of the decoupling monopole, a balun should be used in capacitors and the power supply filtering order to get optimum performance. The are very important to achieve the best balun can be implemented using low-cost performance in an application. Chipcon discrete inductors and capacitors. The provides a compact reference design that balun consists of C61, C62, C71, C81, should be followed very closely. L61, L62 and L72, and will match the RF input/output to 50 Ω, see Figure 3. L61 16.6 Power supply switching and L62 also provide DC biasing of the As described in a note in the Absolute LNA/PA input/output. L71 is used to Maximum Ratings section, the voltage isolate the TXRX_SWITCH pin. An supply to the chip core should not be internal T/R switch circuit is used to switch switched off separately from the I/O supply between the LNA and the PA. See voltage. “Input/output matching” on page 50 for more details. If it is necessary to switch the core power supply off, for instance to save the power If a balanced antenna, like a folded dipole, dissipated in the 1.8V regulator, the I/O is used, the balun can be omitted. If the supply should be turned off as well. This antenna also provides a DC path from the can be done quite easily by running the TXRX_SWITCH pin to the RF pins, I/O supply from a microcontroller I/O pin. inductors are not needed for DC biasing. Current drawn on the I/O supply is just a The L71 isolation inductor should still be few milliamps, so an ordinary I/O pin used to avoid antenna reflections. Figure 4 should have no problems in sourcing this shows a typical application circuit with current. Power sequencing should be differential antenna. The dipole has a performed so that both supplies are turned virtual ground point, hence bias is on and off simultaneously. provided without degradation in antenna performance. Please note that a differential antenna is generally larger than an equivalent single-ended antenna. 16.2 Bias resistor The bias resistor R451 is used to set an accurate bias current for the chip. SWRS042A Page 17 of 83

CC2400 Ref Description C71 Front-end bias decoupling and match, see page 50 C61 Discrete balun and match, see page 50 C81 Discrete balun and match, see page 50 C62 DC block to antenna and match C421 16MHz crystal load capacitor, see page 49 C431 16MHz crystal load capacitor, see page 49 L61 DC bias and match, see page 50 L62 DC bias and match, see page 50 L71 RF blocking inductor, see page 50 L81 Discrete balun and match, see page 50 R451 Precision resistor for current reference generator XTAL 16MHz crystal, see page 49 Table 10. Overview and description of external components for an unbalanced antenna (balun implemented with low cost discrete components) AVDD=1.8V AVDD=1.8V C431 C421 R451 XTAL AVDD=1.8V 48 47 46 45 44 43 42 41 40 39 38 37 12 VACVOD_DG__CHPUVACAVDDROD ATEST1 ATEST2 R_BIAS AVDD_IF1 XOSC16_Q1 XOSC16_Q2 AVDD_XOSC NC NC NC NC GNIOC6 3365 3 34 AVDD_PRE SO (5A0n Otehnmna) C61 4 AVDD_RF1 SI 33 SPI-bus 5 GND SCLK 32 C71L62 6 RF_P CC2400 CSn 31 7 TXRX_SWITCH DCLK/FIFO 30 C62 L61 L718 RF_N DIO/PKT 29 Odipgtiitoaln al L81 9 GND TX 28 interface C81 10 AVDD_SW D RX 27 1112 NNCC NC AVDD_RF2 AVDD_IF2 AVDD_ADC DVDD_ADC GND_GUARD DGUARD BT/GR GIO1 DGND DSUB_PADS DSUB_CORE DDVVDDDD31..38 2265 DD=1VV.8DD /DD 3= .D31Vi.g8iVtal I/O 13 14 15 16 17 18 19 20 21 22 23 24 AVDD=1.8V DVDD=1.8V Figure 3 Typical application circuit with discrete balun for interfacing single-ended antenna SWRS042A Page 18 of 83

CC2400 AVDD=1.8V AVDD=1.8V C431 C421 R451 XTAL AVDD=1.8V 48 47 46 45 44 43 42 41 40 39 38 37 12 VACVOD_DG__CHPUVACAVDDROD ATEST1 ATEST2 R_BIAS AVDD_IF1 XOSC16_Q1 XOSC16_Q2 AVDD_XOSC NC NC NC NC GNIOC6 3365 3 34 AVDD_PRE SO 4 AVDD_RF1 SI 33 SPI-bus 5 GND SCLK 32 Fdioplodleed L61 L71 67 RTXF_RPX_SWITCH CC2400 DCLK/FCISFnO 3310 antenna Optional 8 RF_N DIO/PKT 29 digital 9 GND TX 28 interface 10 AVDD_SW D RX 27 1112 NNCC NC AVDD_RF2 AVDD_IF2 AVDD_ADC DVDD_ADC GND_GUARD DGUARD BT/GR GIO1 DGND DSUB_PADS DSUB_CORE DDVVDDDD31..38 2265 DD=1VV.8DD /DD 3= D.13i.Vg8iVtal I/O 13 14 15 16 17 18 19 20 21 22 23 24 AVDD=1.8V DVDD=1.8V Figure 4 Typical application circuit with differential antenna (folded dipole) Item Single ended output, discrete Differential antenna balun C62 5.6 pF, +/- 0.25pF, NP0, 0402 Not used C61 0.5 pF, +/- 0.25pF, NP0, 0402 Not used C81 0.5 pF, +/- 0.25pF, NP0, 0402 Not used C71 100 nF, 10%, X5R, 0402 100 nF, 10%, X5R, 0402 C421 18 pF, 5%, NP0, 0402 18 pF, 5%, NP0, 0402 C431 18 pF, 5%, NP0, 0402 18 pF, 5%, NP0, 0402 L61 7.5 nH, 5%, Monolithic/multilayer, 0402 27 nH, 5%, Monolithic/multilayer, 0402 L62 5.6 nH, 5%, Monolithic/multilayer, 0402 Not used L71 27 nH, 5%, Monolithic/multilayer, 0402 27 nH, 5%, Monolithic/multilayer, 0402 L81 7.5 nH, 5%, Monolithic/multilayer, 0402 Not used R451 43 kΩ, 1%, 0402 43 kΩ, 1%, 0402 XTAL 16 MHz crystal, 16 pF load (C) 16 MHz crystal, 16 pF load (C) L L NOTE: Decoupling components are not included. Table 11. Bill of materials for the application circuits SWRS042A Page 19 of 83

CC2400 17 Configuration Overview CC2400 can be configured to achieve • Crystal oscillator power-up / power optimum performance for different down applications. Through the programmable • Data rate and line coding (NRZ, configuration registers the following key 8B/10B coding) parameters can be programmed: • Synthesizer lock indicator mode • Digital RSSI • Receive / transmit mode • FSK / GFSK modulation • RF frequency • Data buffering • RF output power • Packet handling hardware support • FSK frequency deviation • Power-down / power-up mode 18 Configuration Software Chipcon provides users of CC2400 with a microcontroller for the configuration of software program, SmartRF® Studio CC2400. (Windows interface) that generates all necessary CC2400 configuration data, Figure 5 shows the user interface of the based on the user's selections of various CC2400 configuration software. parameters. These hexadecimal numbers will then be the necessary input to the Figure 5. SmartRF® Studio user interface SWRS042A Page 20 of 83

CC2400 19 4-wire Serial Configuration Interface CC2400 is configured via a simple 4-wire The data word is loaded into the internal SPI-compatible interface (SI, SO, SCLK configuration register, when the last bit, and CSn) where CC2400 is the slave. This D0, of the 16 data bits has been written. interface is also used as data interface in buffered mode (see page 27). The configuration data will be retained during a programmed power-down mode, There are 44 16-bit configuration registers, but not when the power-supply is turned 9 Command Strobe Registers, and one off. The registers can be programmed in register to access the FIFO. Each register any order. has a 7-bit address. The FIFO (32 bytes) is 8 bits wide. A Read/Write bit indicates a The configuration registers can also be read or a write operation and forms the 8- read by the microcontroller via the same bit address field together with the 7-bit configuration interface. The R/W bit must address. be set high to initiate the data read-back, then the seven address bits are sent. Some registers are termed Command CC2400 then returns the data from the Strobe Registers. By addressing a addressed register. SO is used as the Command Strobe register internal data output and must be configured as an sequences will be started. These input by the microcontroller. commands can be used to quickly change from RX mode to TX mode, for example. The command strobe register is accessed in the same way as for a write operation, A full configuration of CC2400 requires but no data is transferred. That is, only the sending 44 data frames of 24 bits each (7 R/W bit and the seven address bits are address bits, R/W bit and 16 data bits). written before CSn should be set high. The time needed for a full configuration depend on the SCLK frequency. With a Figure 7 shows a summary of read and SCLK frequency of 20 MHz the full write operations. A register read/write can configuration is done in less than 5 µs. be terminated after one byte if only the Setting the device in power down mode most significant byte is required. A register requires addressing one command strobe can also be accessed repeatedly without register only, and will in this case take less writing the address again. The buffer FIFO than 0.4 µs. All registers except the strobe (8 bit wide, 32 bytes) can be written registers are also readable. continuously by simply writing new bytes over and over. The internal data pointer is then updated for every written byte. The In each write-cycle, 24 bits are sent on the session is terminated when the CSn is set SI-line. The bit to be sent first is the R/W high. bit (0 for write, 1 for read). The next seven bits are the address-bits (A6:0). A6 is the Please note that a longer hold time, t , is MSB (Most Significant Bit) of the address ps needed before setting CSn high when and is sent first. The 16 data-bits are then accessing the FIFO in buffered mode. transferred (D15:0). During address and data transfer the CSn (Chip Select, active During the transfer of the address, the low) must be kept low. See Figure 6. CC2400 returns a status byte on the SO The timing for the programming is shown line containing some important flags. This in Figure 6 with reference to Table 12. The is shown in Table 13. clocking of the data on SI into the CC2400 is performed on the positive edge of SCLK. SWRS042A Page 21 of 83

CC2400 tps tsp tch tcl tsd thd tns SCLK: CSn: Write to register: SI 0 A6 A5 A4 A3 A2 A1 A0 X DW15 DW14 DW13 DW12 DW11 DW10 DW9 DW8 X DW7 DW6 DW5 DW4 DW3 DW2 DW1 DW0 X SO S7 S6 S5 S4 S3 S2 S1 S0 X Read from register: SI 1 A6 A5 A4 A3 A2 A1 A0 X SO S7 S6 S5 S4 S3 S2 S1 S0 DR15 DR14 DR13 DR12 DR11 DR10 DR9 DR8 DR7 DR6 DR5 DR4 DR3 DR2 DR1 DR0 DR15 Figure 6. SPI timing diagram CSn: Command strobe: ADDR Read or write a whole register (16 bit): ADDR DATA8MSB DATA8LSB Read or write 8 MSB of a register: ADDR DATA8MSB Read or write a whole register continuously: ADDR DATA8MSB DATA8LSB DATA8MSB DATA8LSB ... DATA8MSB DATA8LSB Read or write n bytes from/to RF FIFO: ADDRFIFO DATAbyte0 DATAbyte1 DATAbyte2 DATAbyte3 ... DATAbyte n-2 DATAbyte n-1 Figure 7. Configuration registers write and read operations via SPI Parameter Symbol Min Max Units Conditions SCLK, clock f 20 MHz SCLK frequency SCLK low t 25 ns The minimum time SCLK must be low. cl,min pulse duration SCLK high t 25 ns The minimum time SCLK must be high. ch,min pulse duration CSn setup t 25 ns The minimum time CSn must be low before sp time positive edge of SCLK. CSn hold t 25 ns The minimum time CSn must be held low after the ns time 1 last negative edge of SCLK. CSn hold t 300 ns In buffered mode: The minimum time CSn must be ps time 2 held low after the last positive edge of SCLK. This only applies to FIFO accesses. SI setup time t 25 ns The minimum time data on SI must be ready sd before the positive edge of SCLK. SI hold time t 25 ns The minimum time data must be held at SI, after hd the positive edge of SCLK. Rise time t 100 ns The maximum rise time for SCLK and CSN rise Fall time t 100 ns The maximum fall time for SCLK and CSn fall Note: The set-up- and hold-times refer to 50% of VDD. Table 12. SPI timing specification SWRS042A Page 22 of 83

CC2400 Bit # Name Description 7 - Reserved, ignore value 6 XOSC16M_STABLE Indicates whether the 16 MHz oscillator is running ('1') or not 5 RESERVED Reserved 4 SYNC_RECEIVED Indicates whether a sync word has been received or not so far in the RX operation 3 CRC_OK Indicates whether the next two bytes in the FIFO will make the CRC calculation successful or not: 0: CRC not OK or CRC off 1: CRC OK 2 FS_LOCK Indicates whether the frequency synthesiser is in lock ('1') or not. 1:0 RESERVED[1:0] Reserved Table 13. Status byte returned during address transfer SWRS042A Page 23 of 83

CC2400 20 Overview of Configurations and Hardware Support The CC2400 can be configured for different Table 14 below gives a summary of the data interfaces, coding schemes and possibilities. packet handling hardware support. Data Data coding Packet handling support interface Buffered NRZ TX: • Preamble generation (32 byte FIFO • Sync word insertion accessed • CRC computation and insertion through the SPI interface) RX: • Sync Word detection 8/10 code • CRC computation and check Manchester Un-buffered NRZ RX: • Sync Word detection (DIO and DCLK synchronous interface) Manchester Table 14. Configurations and hardware support SWRS042A Page 24 of 83

CC2400 21 Microcontroller Interface and Pin Configuration Used in a typical system, CC2400 will interface to a microcontroller. This 21.2 Signal interface in un-buffered microcontroller must be able to: mode A bi-directional pin (DIO) is used for data • Program CC2400 into different modes to be transmitted and received. DCLK and read back status information via providing the data timing should be the 4-wire SPI-bus configuration connected to a microcontroller input. interface (SI, SO, SCLK and CSn). In buffered mode the data signal is also The data is clocked in/out at the positive transmitted through the SPI-bus edge of DCLK. • Interface to the bi-directional synchronous data signal interface (DIO 21.3 General control and status pins and DCLK) if un-buffered data Optionally, in buffered mode, the FIFO pin transmission is to be used can be used to interrupt the • Optionally interface to the general microcontroller at full/empty FIFO. This pin control and status pins (RX, TX, FIFO, should then be connected to a PKT, GIO1 and GIO6) if the hardware microcontroller interrupt pin. supported packet handling functions are to be used Optionally, using the packet handling • Optionally the microcontroller can support, the PKT pin can be used in monitor the general I/O pins (GIO1, buffered mode to interrupt the GIO6) for frequency lock status, carrier microcontroller when a sync word is sense status, or other status detected (RX mode) and packet is information transmitted (TX mode). This pin should then be connected to a microcontroller • Optionally, the microcontroller can read interrupt pin. back digital RSSI value and other status information via the 4-wire SPI The polarity of FIFO and PKT can be interface controlled by the INT register (address 0x23). 21.1 Configuration interface The microcontroller interface is shown in Optionally, the RX and TX pins can be Figure 8. The microcontroller uses a used to change the operating mode of minimum of 4 I/O pins for the SPI CC2400 as an alternative to using the SPI configuration interface (SI, SO, SCLK and interface strobe commands. These pins CSn). All other pins are optional. SO should then be connected to should be connected to an input at the microcontroller output pins. If the RX and microcontroller. SI, SCLK and CSn must TX pins are not used, they should be be microcontroller outputs. grounded in order to prevent accidental change of mode. The microcontroller pins connected to SI, SO and SCLK can be shared with other Optionally, the GIO1 and GIO6 can be SPI-interface devices. SO is a high used to monitor several status signals as impedance output as long as CSn is not activated (active low). selected by the IOCFG register. The GIO6 pin should be connected to a CSn should have an external pull-up microcontroller input pin. See Table 18 for resistor or be set to a high level during available signals. power down mode in order to prevent the input from floating. SI and SCLK should be Table 15 gives a summary of the possible set to a defined level to prevent the input pin configurations in the different operation from floating. modes. SWRS042A Page 25 of 83

CC2400 Pin name SCLK SI SO CSn DIO/ DCLK/ RX TX GIO1* GIO6* PKT FIFO Pin number 32 33 34 31 29 30 27 28 21 35 Direction I I O I I/O O I I O O Buffered SCLK SI SO CSn - FIFO (RX) (TX) (GIO1) (GIO6) mode Buffered SCLK SI SO CSn PKT FIFO (RX) (TX) (GIO1) (GIO6) mode with Packet handling Un-buffered SCLK SI SO CSn DIO DCLK (RX) (TX) (GIO1) (GIO6) mode NOTE: Pin functions in parentheses are optional * The use of GIO1 and GIO6 are selected in register IOCFG (address 0x08) Table 15. Pin configuration Buffered RF Mode: Unbuffered RF Mode: CC2400 Data & µC CC2400 µC Control Control CSn GIO1 CSn GIO1 SI MOSI SI MOSI SO MISO SO MISO SCLK SCLK SCLK SCLK DIO/PKT Other Circuit DCLK/FIFO CSn GIO2 Data SI SO SCLK Full hardware support for packet handling : Data & CC2400 µC Control CSn GIO1 SI MOSI SO MISO SCLK SCLK DIO/PKT GIO2 DCLK/FIFO GIO3 RX GIO4 TX GIO5 GIO1 GIO6 GIO6 GIO7 Control Figure 8. Microcontroller interface SWRS042A Page 26 of 83

CC2400 22 Data Buffering The CC2400 can be used with a buffered or mode. The threshold (FIFO_THRESHOLD) un-buffered data interface. The data is set in INT.FIFO_THRESHOLD[4:0]. buffering mode is controlled by the GRMDM.PIN_MODE[1:0] bits (register In receive mode there will be an interrupt address 0x20). when the number of received bytes in the FIFO reaches FIFO_THRESHOLD. The In un-buffered mode a synchronous data default value is 30, giving an interrupt clock is provided by CC2400 at the DCLK when 30 bytes are received. If the FIFO pin, and the DIO pin is used as data becomes full (32 bytes) before it is read, input/output (see Figure 8). the reception will be terminated (goes to the FS_ON state). 22.1 Buffered mode In the buffered mode a 32-byte First-in In transmit mode there will be an interrupt First-Out (FIFO) register block is used for when the number of bytes left in the FIFO data to be transmitted and data received. reaches 32 - FIFO_THRESHOLD. For the The FIFO is accessed through the default value this will happen when there FIFOREG register (address 0x70) using are 2 bytes left. The transmission is the SPI interface. Multiple bytes can be terminated when the FIFO runs empty written to the FIFO without repeating the (goes to the FS_ON state). Note that in address if the CSn line is held low. order for the FIFO pin to give an interrupt in transmit mode the number of bytes The crystal oscillator must be running must first exceed 32 - FIFO_THRESHOLD. when accessing the FIFO. The FIFO pin activity is illustrated in By using the FIFO buffer the data can be Figure 10. transmitted in bursts. The buffered mode will therefore offload the host controller The INT.FIFO_POLARITY bit sets the keeping the SPI data rate much lower than polarity of the interrupt signal. the data rate on the air. This gives also a great advantage in reducing the current In TX mode, the FIFO pin goes low when consumption as the transmitter and a transmission starts and the preamble is receiver are enabled only in short periods. sent. It will stay low as long as the FIFO is It also allows the SPI to operate faster empty. When data is written to the FIFO, it than the data rate, providing more time for will go high. If the number of bytes in the the MCU to work between data transfers. FIFO goes below the FIFO_THRESHOLD, the FIFO pin will go low again. If the FIFO More than 32 bytes can be received if the pin goes low, it will stay low until the CRC FIFO is read during reception. In the same has been transmitted. way more than 32 bytes can be transmitted if new data is written into the FIFO_FULL and FIFO_EMPTY signals are FIFO during transmission. Figure 9 shows available on the general-purpose I/O pins. the ways the FIFO can be used during These two signals are affected by transmission. FIFO_THRESHOLD. 22.2 Buffered mode hardware support In transmit mode, FIFO_EMPTY is low if In the buffered mode the FIFO pin can be the number of bytes in the FIFO is more used as an interrupt output to assist the than 32-FIFO_THRESHOLD. In receive microcontroller in supervising the FIFO. mode, FIFO_EMPTY goes low when there is more than 1 byte in the FIFO. The FIFO pin can be programmed to give an interrupt when the FIFO is nearly FIFO_FULL is high if the number of bytes empty in TX mode, and nearly full in RX in the FIFO is greater or equal to FIFO_THRESHOLD. SWRS042A Page 27 of 83

CC2400 FIFO 0 # et k Data to c Data a packet P from engine MCU a) Single packet in FIFO FIFO 0 # et k c Data a Data already sent P pending to packet engine from MCU b) Packet longer than FIFO Figure 9. Ways in which the FIFO can be used during transmit mode FSON strPoLbLSe lRoXc ksterdo,be Sync word detected FItFhOr ebsytheols dreach FItFhOr ebsytheols dgo under RF data Preamble Sync word Data PKT RX mode: FIFO FSON stroPbLeLS lToXc ksterdo,be FItFhOr ebsytheols dreach FIFO emptPyacckoetm ptlreatnesmission MCU data TX mode: PKT FIFO Figure 10. FIFO and PKT timing diagram SWRS042A Page 28 of 83

CC2400 23 Packet Handling Hardware Support The CC2400 has built-in hardware support GRMDM. Number of bytes for packet oriented radio protocols. (8 bits) PRE_BYTES[2:0] 000 0* The buffered mode packet handling 001 1 support can in transmit mode be used to 010 2 construct the data packet: 011 4 • Add a programmable number of 100 8 preamble bytes 101 16 110 32 • Add a synchronization word 111 Infinitely until TX • Compute and add a CRC GRMDM.PRE_BYTES computed over the data field [2:0] is set to 000 * Should not be used if packet reception is to be used. Use to terminate infinite transmission (111). In receive mode the packet handling support can be used to de-construct the The length of the synchronization word is data packet: programmable as shown below. • Synchronization word detection • Compute and check the received GRMDM. Number of bits CRC SYNC_WORD_SIZE The packet handling support can be [1:0] combined with the 8/10 line-encoding 00 8 scheme. The 8/10 coding will apply to the 01 16 data field (FIFO data) of the packet only 10 24 (and CRC). 11 32 In un-buffered mode the synchronization The synchronization word is word detection can be used to mute DCLK programmable in the SYNCL and SYNCH until a valid sync word is received. registers. The default (and recommended) synchronization word length is 32 bits, 23.1 Data packet format which gives high immunity against false The format of the data packet can be synchronization word indication. If lower configured, and can consist of the immunity can be accepted, one can following items: reduce the length to 16 bits. (However, using 8 bits will typically give too many • Preamble false synchronization word indications.) • Synchronization word A threshold on the number of bits in error • Data when receiving the synchronization word • CRC can be programmed in GRMDM.SYNC_ERRBITS_ALLOWED[1:0] See Table 16 and Figure 11 for details. in the range 0 – 3. (A threshold of 0 is default.) The preamble pattern is ‘(0)101010…’. The first bit in the preamble is always the 23.2 Error detection same as the first bit in the synchronization When the CRC is enabled it will be word. The length of the preamble is calculated based on the data field of the programmable. The default and packet, i.e. not including the preamble or recommended length is 4 bytes. the synchronization word. When transmitting the packet the CRC is When using GFSK modulation at 1 Mbps, appended after the last data byte in the Chipcon recommends using a preamble data field, i.e. when the FIFO becomes length of 32 bytes in order to avoid a high empty. level of bit errors. If low packet overhead is required, Chipcon recommends that When a packet is being received the CRC FSK be used at 1 Mbps instead of GFSK. is calculated as the data is read out of the SWRS042A Page 29 of 83

CC2400 FIFO. When all data is read, the next two The CRC polynomial is: bytes in the FIFO are the CRC. x16 + x15 + x2 + 1 If the reception of the packet is error free, the PKTSTATUS.CRC_OK flag is set (also available on the GIO1 and GIO6 pins). Packet field Preamble Synchronisation word Data field CRC Use Mandatory Mandatory Mandatory Optional Length ≥ 1 byte 1, 2, 3 or 4 bytes ≥ 1 byte 2 bytes GRMDM register PRE_BYTES[2:0] SYNC_WORD_SIZE[1:0] CRC_ON configuration bits Table 16. Data packet format Optional 8/10 coding Legend: Optional CRC-16 calculation Inserted automatically in TX, processed and removed in RX. P(1r0e1a0m..b.1le0 b1i0ts) c word Data field RC-16 Unprocessed user data yn C S 32 bits 16/32 bits 8 x n bits 16 bits Figure 11. Packet format details (with recommended lengths of preamble and synchronization word) SWRS042A Page 30 of 83

CC2400 Outside of the TX and RX modes, the PKT 23.3 Hardware interface pin provides an indication of whether the In the buffered mode the PKT pin can be PLL is in lock or not. For example, in the used as an interrupt output to assist the FSON state, the PKT pin will be high if the microcontroller in supervising the PLL is in lock. transmission and reception of data packets. The PKT pin activity is illustrated in Figure 10. The PKT pin can be programmed to give an interrupt when the synthesizer has The polarity of the interrupt signal is set by locked and is ready to receive / transmit a the INT.PKT_POLARITY bit. data packet. Receive mode or transmit mode can then be activated. In transmit mode, the PKT pin will go low for a short while when the transmission is In receive mode there will be an interrupt completely over (the CRC has been sent). when the synchronization word is found. Incoming data will then be written to the In receive mode, the PKT pin will go low FIFO. when a sync word is found. It will stay low for the period of time it would take to In transmit mode there will be an interrupt receive 32 bytes, no matter how long the when the FIFO has run empty, the two received packet is (the CC2400 does not CRC bytes have been transmitted and the know how long incoming packets are). transmitter has been turned off. 24 Data / Line Encoding The CC2400 can operate with the following 8/10 coding means that 8 bits are coded line-encoding formats: into 10 chips using the original IBM • NRZ (Non-Return-to-Zero) 8B/10B-coding scheme. The effective bit • Manchester coding (also known rate is 80 % of the baud rate using 8/10 as bi-phase-level) coding and is therefore more efficient that the Manchester coding. • 8/10 coding The benefit of the Manchester coding and The data format is controlled by the 8/10 coding is the whitening of the GRMDM.DATA_FORMAT[1:0] bits. transmission spectrum even when rows of Manchester coding and 8/10 coding equal bits are to be transmitted, improved reduce the effective bit rate but are in clock recovery properties and DC balance. some applications used for spectral properties and error detection. Setting the MDMTST0.INVERT_DATA bit the data is inverted before transmission in Manchester coding means coding each bit TX mode and inverted after reception in into two chips of opposite polarity. The RX mode. Manchester code is based on transitions; a “0” is encoded as a low-to-high transition, a “1” is encoded as a high-to- 24.1 Data encoding in buffered mode low transition. See Figure 14. The In the buffered mode, using the internal Manchester code ensures that the signal FIFO, all three line-encoding schemes can has a constant DC component, which is be used. necessary in some FSK demodulators. The encoding/decoding takes place as the This is not required by the CC2400 data is sent from the FIFO to the demodulator, but the coding option is modulator, and from the demodulator to included for compatibility reasons. The the FIFO. The line encoding is therefore effective bit rate is half the baud rate using invisible to the user. Manchester coding. SWRS042A Page 31 of 83

CC2400 If 8/10 coding is selected when using the into the interfacing circuit at the rising packet mode support, it should be noted edge of DCLK. See Figure 12. that the preamble and the sync words are not encoded. Synchronous Manchester encoded mode. In transmit mode CC2400 provides the data clock at DCLK, and DIO is used as data 24.2 Data encoding in un-buffered input. Data is clocked into CC2400 at the mode rising edge of DCLK and should be in NRZ When data buffering is not used, but the format. The data is modulated at RF with DIO/DCLK interface, the CC2400 can be Manchester code. The encoding is done configured for two different data formats: by CC2400. In this mode the effective bit rate is half the baud rate due to the Synchronous NRZ mode. In transmit coding. This limits the maximum bit rate to mode CC2400 provides the data clock at 500 kbps. In receive mode CC2400 does DCLK, and DIO is used as data input. the synchronization and provides received Data is clocked into CC2400 at the rising data clock at DCLK and data at DIO. edge of DCLK. The data is modulated at CC2400 does the decoding and NRZ data RF without encoding. In receive mode is presented at DIO. The data should be CC2400 does the synchronization and clocked into the interfacing circuit at the provides received data clock at DCLK and rising edge of DCLK. See Figure 13. data at DIO. The data should be clocked Transmitter side: DCLK Clock provided by CC2400 DIO Data provided by microcontroller(NRZ) “RF” FSK modulating signal (NRZ), internal in CC2400 Receiver side: “RF” Demodulated signal (NRZ), internal in CC2400 DCLK Clock provided by CC2400 DIO Data provided by CC2400(NRZ) Figure 12. Synchronous NRZ mode SWRS042A Page 32 of 83

CC2400 TTrraannssmmiitttteerr ssiiddee:: DDCCLLKK CClloocckk pprroovviiddeedd bbyy CCCC22440000 DDIIOO DDaattaa pprroovviiddeedd bbyy mmiiccrrooccoonnttrroolllleerr ((NNRRZZ)) ““RRFF”” FFSSKK mmoodduullaattiinngg ssiiggnnaall ((MMaanncchheesstteerr eennccooddeedd)),, iinntteerrnnaall iinn CCCC22440000 RReecceeiivveerr ssiiddee:: ““RRFF”” DDeemmoodduullaatteedd ssiiggnnaall ((MMaanncchheesstteerr eennccooddeedd)),, iinntteerrnnaall iinn CCCC22440000 DDCCLLKK CClloocckk pprroovviiddeedd bbyy CCCC22440000 DDIIOO DDaattaa pprroovviiddeedd bbyy CCCC22440000 ((NNRRZZ)) Figure 13. Synchronous Manchester encoded mode 11 00 11 11 00 00 00 11 11 00 11 TTXX ddaattaa TTiimmee Figure 14. Manchester encoding SWRS042A Page 33 of 83

CC2400 25 Radio control state machine CC2400 has a built-in state machine that is command strobe registers, or by using the used to switch between different operation RX and TX control pins. It is possible to states (modes). The change of state is change quickly between TX and RX by done either by writing to command strobe way of the FS On state. registers, or using dedicated pins. Turning off RF can be accomplished by Before using the radio in either RX or TX either accessing the command strobe mode, the main crystal oscillator must be register SRFOFF or by using the RX and turned on and become stable. The crystal TX control pins. When using the RX and oscillator has a start-up time given in TX pins to go from the FS On to Radio Off Table 8, during which its output is gated it is important that TX is set to 0 before RX internally to avoid timing problems is set to 0. stemming from too narrow clock pulses. The crystal oscillator is controlled by The state transitions using the RX and TX accessing the SXOSCON/SXOSCOFF pins are illustrated in Figure 15. command strobe registers. The XOSC16M_STABLE bit in the status Note that to switch between RX and TX, register returned during address transfer the FSDIV register must be updated. This indicates whether the oscillator is running is because direct conversion is used in TX and stable or not (See Table 13). This mode, while an IF frequency of 1 MHz is status register can be polled when waiting used in RX mode. Please see page 47 for for the oscillator to start. more information about frequency programming. The frequency synthesizer (FS) can be started by either accessing the command Also note that the FSDIV register should strobe register SFSON or by using the RX only be changed when the radio is in IDLE and TX control pins. The FS will then enter mode, otherwise the PLL can go out of its self-calibration mode. After the lock. calibration is performed, the FS needs to lock onto the right LO frequency. The calibration and lock acquisition time is given in Table 8. When the FS is in lock it is possible to go into RX or TX mode. That can be done either by accessing the SRX/STX SWRS042A Page 34 of 83

CC2400 SXOSCOFF OFF [0] SXOSCON & Osc. settled IDLE [1] RX=TX=1 SRX | STX | SFSON PIN STROBE RXTX_CAL RXTX_CAL [8] [14] All calib done & All calib done & fs in lock fs in lock PIN STROBE RRXX==TTXX==10 | FS[9_]O N TX=0 SFSON FS[1_5O]N SFSON | packet done RX=0 RX=TX=0 | STX SRX RX=TX=0 RX=TX=1 PIN PIN STROBE STROBE TX RX TX RX [12] [10] [17] [16] TX=0 | TX=1 | SRFOFF| RX=0 | packet done SFSON | packet RX=1 | packet done done PIN PIN STROBE TX_OFF RX_OFF TX_OFF [13] [11] [18] Immediately SRFOFF BEFORE_IDLE [24] Figure 15. Radio control state diagram (FSMSTATE.FSM_CUR_STATE[4:0] value in brackets) Figure 15 shows a state transition diagram CC2400 will get stuck in the for the radio control state machine. This STROBE_RXTX_CAL state. The chip figure shows the possibilities that exist for must then be reset to exit this state. This changing between states. Note for should never happen in an actual example that it is not possible to go from application as long as recommended IDLE mode back to OFF. This diagram register settings are used. can be very useful for debugging what is happening within the CC2400 by reading Also note that the frequency register FSMSTATE.FSM_CUR_STATE[4:0]. FSDIV should only be modified when the CC2400 is in IDLE mode, otherwise the If invalid parameters are used during PLL may go out of lock since calibration is development or testing, the PLL may not only performed when exiting the IDLE lock after calibration. If this happens, the state SWRS042A Page 35 of 83

CC2400 26 Power Management Flow Chart CC2400 offers great flexibility for power with very low power consumption and the management in order to meet strict power crystal oscillator is not running. consumption requirements in battery- operated applications. Figure 17 shows the sequence for entering RX or TX mode. The flow chart After reset the CC2400 is in Power Down illustrates the simplest way to send a data mode. All configuration registers can then packet using the strobe command be programmed in order to make the chip registers. After one or more data packets ready to operate at the correct frequency, are transmitted or received, the chip is data rate and mode. Due to the very fast again set to Power Down mode. start-up time, the CC2400 can remain in Power Down until a transmission session During chip initialization a few registers is requested. need to be programmed to other values than their reset values. SmartRF® Studio Figure 16 shows a typical power-on and should be used to find/generate the initializing sequence. After this initializing required configuration data for these sequence the chip is in Power Down mode registers. Power off Supply power turned on Reset: MAIN = 0x0000 MAIN = 0x8000 Program all registers that are different from reset value Power Down Figure 16. Initializing sequence SWRS042A Page 36 of 83

CC2400 PD (Power Down) SXOSCON Wait for the specified crystal Wait until crystal oscillator is oscillator start-up time, or poll the stable XOSC16M_STABLE bit IDLE (XOSC is running) SFSON The PLL and filters are calibrated FSON (XOSC and PLL is running) RX: SRX TX RX or TX? Write data to FIFO TX: STX Data is received. FIFO should be read if buffered mode is Data is transmitted. FIFO used should be filled if buffered mode is used Go to Go to NO: SFSON YES: SXOSCOFF YES: SXOSCOFF NO: SFSON power power down?* down?* NO: SRFOFF NO: SRFOFF Power Down *Go to PD state if the crystal oscillator should be shut off in order to save power. Go back to IDLE if a new packet shall be received/transmitted quickly. Or go back to FSON if changing fast between RX and TX mode. Figure 17. Sequence for activating RX or TX mode SWRS042A Page 37 of 83

CC2400 27 FSK Modulation Formats The data modulator can modulate 2FSK, which is two level FSK, and GFSK, which However, if GFSK modulation is used is a Gaussian filtered FSK with BT=0.5 at together with a data rate of 1 Mbps, it is 1 Mbps (for lower data rates BT will be recommended to use a preamble length of higher). 32 bytes as otherwise packet error performance can be affected. The purpose of the GFSK is to make a more bandwidth efficient system. The Figure 18 shows a plot of the spectrum for modulation and the Gaussian filtering is FSK and GFSK modulation. Input data performed internally. The was a PN9 sequence. The plot was GRMDM.TX_GAUSSIAN_FILTER bit captured using a spectrum analyzer set to enables the GFSK. 5 MHz span and 300 kHz RBW. 0 -10 -20 m) -30 B d FSK er ( GFSK w Po -40 -50 -60 -70 2,438 2,439 2,440 2,441 2,442 2,443 Frequency [GHz] Figure 18. Modulated spectrum 28 Built-in Test Pattern Generator The CC2400 has a built-in test pattern generator that can generate a PN9 The PN9 generator can be used for pseudo random sequence. The transmission of ‘real-life’ data when MDMTST0.TX_PRNG bit enables the PN9 measuring modulation bandwidth or generator. occupied bandwidth. The PN9 pseudo random sequence is defined by the polynomial x9 + x5 + 1. SWRS042A Page 38 of 83

CC2400 29 Receiver Channel Bandwidth In order to meet different channel width There is a tradeoff between selectivity and and channel spacing requirements, the accepted frequency tolerance. In receiver’s digital channel filter bandwidth applications where larger frequency drift is is programmable. It can be programmed expected (depends on the accuracy of the from 125 to 1000 kHz. crystal), the filter bandwidth should be increased, at the expense of reduced The GRDEC.CHANNEL_DEC[1:0] register adjacent channel rejection (ACR). bits control the bandwidth. It is strongly recommended to use one of The table below summarizes the the three settings for over-the-air data selectable channel bandwidths. rates and channel bandwidths as described in the section “Data Rate Channel filter GRDEC.CHANNEL_DEC[1:0] Programming” on page 40. bandwidth [binary] [kHz] 1000 00 500 01 250 10 125 11 SWRS042A Page 39 of 83

CC2400 30 Data Rate Programming The supported over-the-air data rates are 1Mbps, 250kbps and 10kbps. The data CHANNEL BW DEC_ Data rate rate is programmable via the GRDEC _DEC [kHz] VAL [kbps] register. [binary] [decimal] 00 1000 0 1000 00 1000 3 250 Supported channel filter bandwidths and 01 500 49 10 data rates are shown in the following table. Figure 19 shows how sensitivity varies as a function of frequency offset between the transmitter and the receiver for various data rates. It is possible to tolerate even larger offsets by making use of the AFC feature; please see page 42 for further details. -10 -30 m) B vity (d -50 215 M0 bkpbsps siti 10 kbps n e S -70 -90 -110 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 5 2 9 6 3 0 7 4 1 8 5 2 9 6 3 3 6 9 2 5 8 1 4 7 0 3 6 9 2 4 4 3 3 3 3 2 2 2 1 1 1 - - - 1 1 1 2 2 2 3 3 3 3 4 - - - - - - - - - - - - Offset (kHz) Figure 19. Sensitivity as a function of frequency offset SWRS042A Page 40 of 83

CC2400 31 Demodulator, Bit Synchronizer and Data Decision The block diagram for the demodulator, signal. Once a shift in the received data slicer and bit synchronizer is shown frequency larger than half the expected in Figure 20. The built-in bit synchronizer separation is detected, a bit transition is extracts the data rate and performs data recorded and the average value to be decision. The data decision is done using used by the data slicer is calculated. over-sampling and digital filtering of the incoming signal. This improves the The actual number of samples used to find reliability of the data transmission and the averaging value can be programmed provides a synchronous clock in the un- and set higher for better data decision buffered mode. Using the buffered mode accuracy. This is controlled by the simplifies the data interface further, as AFC_SETTLING[1:0] bits. If RX data is data can be written and read byte-for-byte present in the channel when the RX chain in bursts from the FIFO. is turned on, then the data slicing estimate will usually give correct results after 4 bits. The suggested preamble is a 32 bit The data slicing accuracy will increase ‘(0)10101…’ bit pattern, the same as used after this, depending on the by the packet handling support, see page AFC_SETTLING[1:0] bits. If the start of 29. This is necessary for the bit a transmission occurs after the RX chain synchronizer to synchronize with the is turned on, the minimum number of bit coding correctly. transitions (or preamble bits) before correct data slicing will depend on the The data slicer performs the bit decision. AFC_SETTLING[1:0] bits, as shown in Ideally the two received FSK frequencies Table 17. The recommended setting is are placed symmetrically around the IF 11b, requiring 16 data bits of preamble to frequency. However, if there is some fill the averaging filter completely. frequency error between the transmitter and the receiver, the bit decision level The internally calculated average FSK should be adjusted accordingly. In CC2400 frequency value gives a measure for the this is done automatically by measuring frequency offset of the receiver compared the two frequencies and by using the to the transmitter. The frequency offset average value as the decision level. can be read from RSSI.RX_FREQ_OFFSET[7:0]. This The digital data slicer in CC2400 uses an information can also be used for an average value of the minimum and automatic frequency control, as described maximum frequency deviation detected as at page 43. the comparison level. The MDMTST0.AFC_DELTA register is used to set the expected deviation of the incoming Average filter Bit Digital IF Frequency Data Data slicer synchronizer Decimator filtering detector filter comparator and data decoder Figure 20. Demodulator block diagram SWRS042A Page 41 of 83