ICGOO在线商城 > 传感器,变送器 > 运动传感器 - 加速计 > BMA220

- 型号: BMA220

- 制造商: BOSCH

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

BMA220产品简介:

ICGOO电子元器件商城为您提供BMA220由BOSCH设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 BMA220价格参考。BOSCHBMA220封装/规格:运动传感器 - 加速计, Accelerometer X,Y,Z Axis ±2g,4g,8g,16g 32Hz ~ 1kHz 12-LGA(2x2)。您可以下载BMA220参考资料、Datasheet数据手册功能说明书,资料中有BMA220 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

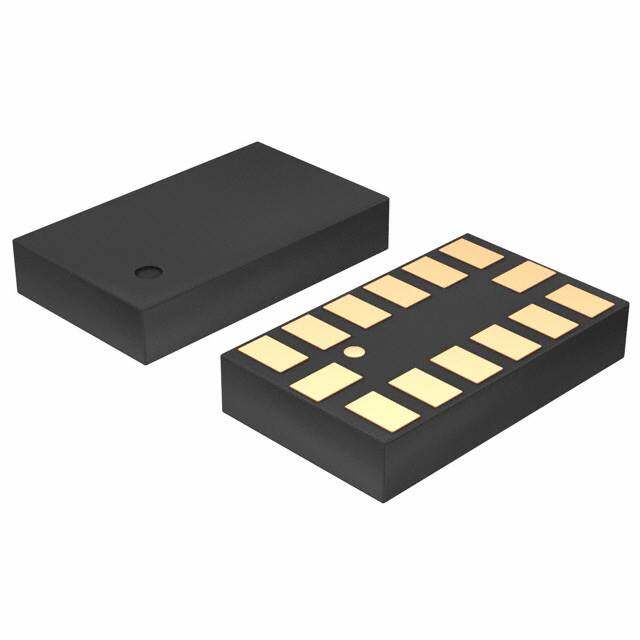

| 描述 | ACCELEROMETER 3-AXIS SPI/I2C SMD加速计 3-Axis 2x2mm LGA-12 2g-16g prog 8-bit |

| 产品分类 | 加速计运动与定位传感器 |

| 品牌 | Bosch Sensortec |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS不受无铅要求限制 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 加速计,Bosch Sensortec BMA220- |

| 数据手册 | |

| 产品型号 | BMA220 |

| 产品目录绘图 |

|

| 产品目录页面 | |

| 产品种类 | 加速计 |

| 传感轴 | X, Y, Z |

| 供应商器件封装 | 12-LGA(2x2) |

| 其它名称 | 828-1016-6 |

| 分辨率 | 6 bit |

| 加速 | 2 g, 4 g, 8 g, 16 g |

| 加速度范围 | ±2g, 4g, 8g, 16g |

| 商标 | Bosch Sensortec |

| 安装类型 | 表面贴装 |

| 安装风格 | SMD/SMT |

| 封装 | Reel |

| 封装/外壳 | 12-VFLGA |

| 封装/箱体 | LGA-12 |

| 工厂包装数量 | 10000 |

| 带宽 | 32Hz ~ 1kHz 可选 |

| 接口 | I²C, SPI |

| 数字输出-位数 | 6 bit |

| 数字输出-总线接口 | I2C, SPI |

| 最大工作温度 | + 85 C |

| 最小工作温度 | - 40 C |

| 标准包装 | 1 |

| 灵敏度 | 16LSB/g,8LSB/g,4LSB/g,2LSB/g |

| 电压-电源 | 1.62 V ~ 3.6 V |

| 电源电压-最大 | 3.6 V |

| 电源电压-最小 | 1.62 V |

| 电源电流 | 250 uA |

| 轴 | X,Y,Z |

| 输出类型 | I²C, SPI |

| 配用 | /product-detail/zh/BMA220-SHUTL/828-1018-ND/2330152 |

| 零件号别名 | 0273.141.102-1NV 828-1016-1-ND 828-1016-2-ND 828-1016-6-ND |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

BMA220 Digital, triaxial accelerBaMAti2o20n sensor Bosch Sensortec Data sheet Data sheet Bosch Sensortec BMA220 data sheet Ordering code Please contact your Bosch Sensortec representative for the ordering code Package type 12-pin LGA Document revision 1.10 Document release date 13 April 2011 Document number BST-BMA220-DS003-07 Technical reference code(s) 0 273 141 102 Notes Specifications are subject to change without notice. Rev. 1.10 Page 1 13 April 2011 Product photos and pictures are for illustration purposes only and may © Bosch Sensortec GmbH reserves all righdtisf feevre fnr oinm th eth eev ernet aolf pinrdoudsturicatl ’psr oappeprtey arigrahtnsc. We.e reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet BMA220 Triaxial 2g to 16g acceleration sensor with on-chip motion- triggered interrupt controller Key features • Three-axis accelerometer • Ultra-Small package Mold package (LGA 12ld), Footprint 2mm x 2mm, height 0.98mm • Digital interface SPI (4-wire, 3-wire), I²C, interrupt pin I/O supply voltage range: 1.6V to 3.6V • Programmable functionality Acceleration ranges ±2g/±4g/±8g/±16g Bandwidth 1kHz . . . 32Hz Self test • On-chip interrupt controller Motion-triggered interrupt-signal generation for - orientation recognition - any-motion detection - tap/double tap sensing - low-g/high-g detection Stand-alone capability (no microcontroller needed) • Ultra-low power ASIC Low current consumption, short wake-up time, advanced features for system power management • RoHS compliant, halogen-free Typical applications • Display profile switching • Tap/double tap sensing • Menu scrolling • Gaming • Drop detection for warranty logging • Advanced system power management for mobile applications General description The BMA220 is a triaxial, low-g acceleration sensor with digital output for consumer market applications. It allows measurements of acceleration in three perpendicular axes. An evaluation circuitry (ASIC) converts the output of a micromechanical acceleration-sensing structure (MEMS) that works according to the differential capacitance principle. Package and interface have been defined to match a multitude of hardware requirements. Since the sensor features an ultra-small footprint and a flat package it is ingeniously suited for mobile applications. The sensor offers a variable I/O supply voltage range from 1.6V to 3.6V and can be programmed to optimize functionality, performance and power consumption in customer specific applications. In addition it features an on-chip interrupt controller enabling motion-based applications without use of a microcontroller. The BMA220 senses tilt, motion and shock vibration in cell phones, handhelds, computer peripherals, man-machine interfaces, virtual reality features and game controllers. Rev. 1.10 Page 2 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet CONTENT 1 SPECIFICATION.......................................................................................................................................5 2 ABSOLUTE MAXIMUM RATINGS...........................................................................................................7 3 BLOCK DIAGRAM...................................................................................................................................8 4 GLOBAL MEMORY MAP.........................................................................................................................9 4.1 CONTROL REGISTERS..........................................................................................................................10 4.2 SETTING REGISTERS............................................................................................................................13 4.3 DATA REGISTERS.................................................................................................................................14 4.4 INTERRUPT CONTROL REGISTERS.........................................................................................................15 5 INTERRUPT CONTROLLER..................................................................................................................16 5.1 LATCHED VS. NON-LATCHED MODES.....................................................................................................16 5.2 SUPPORTED TYPES OF INTERRUPTS......................................................................................................17 5.3 POWER-SAVING MODES.......................................................................................................................17 5.4 ANY-MOTION (SLOPE) DETECTION.........................................................................................................18 5.5 TAP SENSING......................................................................................................................................21 5.6 ORIENTATION RECOGNITION.................................................................................................................24 5.7 LOW-G DETECTION..............................................................................................................................27 5.8 HIGH-G DETECTION..............................................................................................................................29 5.9 DATA READY DETECTION......................................................................................................................30 6 OPERATION MODES.............................................................................................................................31 6.1 DEDICATED MODES (µC-LESS / STAND ALONE)......................................................................................32 6.2 DIGITAL INTERFACE MODES..................................................................................................................33 6.3 LOW-POWER MODE AND SUSPEND MODE...............................................................................................34 6.4 MODE TRANSITION VIA INTERFACE........................................................................................................35 6.5 SELF TEST MODE.................................................................................................................................36 7 INTERFACES..........................................................................................................................................37 7.1 GENERAL DIGITAL INTERFACE DESCRIPTION..........................................................................................38 7.2 SPI INTERFACE...................................................................................................................................38 7.3 I²C INTERFACE....................................................................................................................................42 7.4 I²C WATCHDOG TIMER..........................................................................................................................46 7.5 SPI AND I²C ACCESS RESTRICTIONS.....................................................................................................46 8 PIN-OUT AND CONNECTING DIAGRAM.............................................................................................47 8.1 PIN-OUT..............................................................................................................................................47 8.2 CONNECTING DIAGRAMS......................................................................................................................48 9 PACKAGE...............................................................................................................................................51 9.1 OUTLINE DIMENSIONS..........................................................................................................................51 9.2 SENSING AXES ORIENTATION AND POLARITY OF THE ACCELERATION OUTPUT..........................................52 9.3 LANDING PATTERN RECOMMENDATION..................................................................................................53 9.4 MARKING............................................................................................................................................54 9.5 MOISTURE SENSITIVITY LEVEL AND SOLDERING.....................................................................................55 9.6 TAPE AND REEL SPECIFICATION............................................................................................................56 Rev. 1.10 Page 3 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 9.7 ORIENTATION......................................................................................................................................56 9.8 ROHS COMPLIANCY.............................................................................................................................57 9.9 HALOGEN CONTENT.............................................................................................................................57 9.10 NOTE ON INTERNAL PACKAGE STRUCTURE..........................................................................................57 9.11 HANDLING INSTRUCTION....................................................................................................................57 10 LEGAL DISCLAIMER...........................................................................................................................58 10.1 ENGINEERING SAMPLES.....................................................................................................................58 10.2 PRODUCT USE...................................................................................................................................58 10.3 APPLICATION EXAMPLES AND HINTS....................................................................................................58 11 DOCUMENT HISTORY AND MODIFICATION....................................................................................59 Rev. 1.10 Page 4 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 1 Specification If not stated otherwise, the given values are maximum values over lifetime and full performance temperature and voltage ranges. Min/max. data represent 3-sigma values. Table 1: Operating conditions, output signal and mechanical characteristics Parameter Symbol Condition Min Typ Max Units OPERATING CONDITIONS g ±2.0 g FS2g g ±4.0 g FS4g switchable via Acceleration Range g serial digital interface ±8.0 g FS8g g ±16.0 g FS16g Supply Voltage 1.62 1.8 1.98 V V Analog Domain DDA Supply Voltage V 1.62 1.8 1.98 V DDD Digital Domain Supply Voltage V 1.62 3.6 V DDIO I/O Domain Voltage Input V SPI 0.1*V V IL SPI DDIO Low Level V I²C 0.3*V V IL I2C DDIO V Voltage Input IH SPI SPI 0.9*V V DDIO High Level V IH I2C I²C 0.7*V V DDIO V Voltage Output OH SPI & I²C V V DDIO High Level V Voltage Output OL SPI SPI GND V Low Level V OL I2C I²C, R ≥ 680 0.2*V V P DDIO Supply Current in I Nominal V supplies 250 A DD DD Normal Mode at T =25°C A Supply current in I Nominal V supplies < 10 A DDsl DD Low Power Mode T =25°C, BW = 1kHz A sleep dur. > 25ms Supply Current in I Nominal V supplies < 1 A DDsd DD Suspend Mode at T =25°C A Wake-Up Time t from sleep/suspend 1.2 ms w_up mode @1kHz bw Start-Up Time t POR @1kHz bw 1.5 ms s_up Operating T -40 +85 C A Temperature Rev. 1.10 Page 5 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet OUTPUT SIGNAL Device resolution D g 62.5 mg res FS2g S g , T =25°C 16 LSB/g 2g FS2g A S g ,T =25°C 8 LSB/g 4g FS4g A Sensitivity S g , T =25°C 4 LSB/g 8g FS8g A S g , T =25°C 2 LSB/g 16g FS16g A Sensitivity TCS -40°C T +85°C ±0.03 %/K A Temperature Drift Zero-g Offset Off T =25°C, V =1.8V, ±95 mg A DDA g FS2g Zero-g Offset TCO -40°C T +85°C, ±2 mg/K A Temperature Drift g FS2g Bandwidth bw 1st order filter, 32/64/ Hz switchable 125/250/ 500/1000 Nonlinearity NL best fit straight line ±2 %FS TSTx 0.7g*S LSB x depending on Self Test Response TSTy sensitivity/ 2.0g*Sy LSB acceleration range TSTz 0.6g*Sz LSB Output Noise n rms, 2 mg/Hz rms Nominal V supplies DD T =25°C, BW = 1kHz A MECHANICAL CHARACTERISTICS Cross Axis S relative contribution 2 % Sensitivity between 3 axes Alignment Error relative to package ±0.5 ° a outline Rev. 1.10 Page 6 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 2 Absolute maximum ratings All voltages below are given with respect to GND. Table 2: Absolute maximum ratings Parameter Condition Min Max Units Voltage at supply pad V and V -0.3 2.0 V DDD DDA V -0.3 4.25 V DDIO Voltage at any logic pad Non-supply pad -0.3 V +0.3 V DDIO Storage temperature range rel. humidity <=65% -50 +150 °C duration ≤ 200μs 10,000 g duration ≤ 1.0ms 2,000 g Mechanical shock free fall onto 1.8 m hard surfaces ESD HBM, at any pin 2 kV CDM 500 V Rev. 1.10 Page 7 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 3 Block diagram The following figure describes the functionality of the two basic parts of the sensor module, namely mechanical sensor element and evaluating ASIC. Sensor ASIC VDDA CAP0 VSS VDDD VDDIO Element C 1X PS C SDA 2X SDI C M FilterX M I2C SDO 1CYM ulitp C/U Gain & FilterY ulitp ADC Contaronld L ogic SPI SDO C2Y lexer Offset FilterZ lexer Interrupt Engines SSCCLK CSB C 1Z INT C 2Z Reference Clock Trimming OTP VSS Figure 1: Block diagram BMA220 Rev. 1.10 Page 8 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 4 Global memory map The memory map below shows all externally accessible data registers which are needed to operate BMA220.The left columns show the memory addresses. The columns in the middle depict the content of each register bit. The colors of the bits indicate whether they are read-only, write-only or read- and writable. The memory is volatile so that the writable content has to be re- written after each power-on. The extended address space greater than 0x19 (SPI) / 0x32 (I2C) is not shown. These registers are reserved for further Bosch factory testing and trimming. Register Register default after Address Address bit7 bit6 bit5 bit4 bit3 bit2 bit1 bit0 power-up (I²C) (SPI) 0x32 0x19 softreset 0x00 0x30 0x18 suspend 0x00 0x2E 0x17 unused WDT_TO_en WDT_TO_sel SPI3 0x00 0x2C 0x16 reserved 0x00 0x2A 0x15 reserved 0x00 0x28 0x14 reserved 0x00 0x26 0x13 reserved 0x00 0x24 0x12 reserved 0x10 0x22 0x11 unused sbist_sign sbist (off,x,y,z) range[1:0] 0x00 0x20 0x10 serial_high_bw unused filt_config[3:0] 0x00 0x1E 0x0F unused sleep_en sleep_dur[2:0] en_x_channel en_y_channel en_z_channel 0x07 0x1C 0x0E reset_int lat_int[2:0] en_low en_high_x en_high_y en_high_z 0x00 0x1A 0x0D en_data en_orient en_slope_x en_slope_y en_slope_z en_tt_x en_tt_y en_tt_z 0x00 0x18 0x0C unused tt_int low_int high_int data_int slope_int 0x00 0x16 0x0B orient_int orient[2:0] int_first_x int_first_y int_first_z int_sign 0x00 0x14 0x0A unused tip_en orient_blocking [1:0] tt_samp[1:0] 0x08 0x12 0x09 orient_ex slope_filt slope_th[3:0] slope_dur[1:0] 0x45 0x10 0x08 tt_filt tt_th[3:0] tt_dur[2:0] 0xB5 0xE 0x07 low_hy[1:0] low_dur[5:0] 0x7F 0xC 0x06 low_th[3:0] high_th[3:0] 0x4E 0xA 0x05 high_hy[1:0] high_dur[5:0] 0x7F 0x8 0x04 acc_z<5:0> 0 0 0x00 0x6 0x03 acc_y<5:0> 0 0 0x00 0x4 0x02 acc_x<5:0> 0 0 0x00 0x2 0x01 Revision ID 0x00 0x0 0x00 Chip ID 0xDD Figure 2: Memory map Note: From SPI I²C use burst address increment in 0x02h steps. Rev. 1.10 Page 9 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 4.1 Control registers 4.1.1 3-wire SPI mode selection The BMA220 supports both 4-wire and 3-wire SPI. The protocols are exactly the same except for the fact that in 3-wire mode, the SDI pin is also used for data output. The default mode is 4-wire SPI. If 3-wire SPI should be used, the SPI3 bit in register 0x17 (SPI) must be set to ‘1’. 4.1.2 Low-power mode configuration The BMA220 supports a low-power mode. In this low-power mode, the chip wakes up periodically, enables the interrupt controller and goes back to sleep if no interrupt has occurred. The procedure is the following: 1. Wake-up 2. Enable analog front-end and convert acceleration data until the low-pass filters have settled. 3. Enable integrated interrupt controller and evaluate interrupt conditions. Once the interrupt conditions have been evaluated and no interrupt has occurred, the chip goes back to sleep. If no interrupt is enabled, the acceleration for x-, y- and z-axes are converted once and then the chip goes back to sleep. 4. Sleep for the programmed duration Figure 3: sleep and awake phases The low-power mode can be enabled by setting the sleep_en bit in Reg. 0x0F (SPI) / 0x1E (I2C) and by enabling the data ready interrupt (or any other interrupt, see chapter 5). The sleep duration can be configured via the sleep_dur bits in Reg 0x0F (SPI) / 0x1E (I2C). sleep_dur setting Sleep Duration 000 2ms 001 10ms 010 25ms 011 50ms 100 100ms 101 500ms 110 1s 111 2s Table 3: Sleep durations for low-power mode Rev. 1.10 Page 10 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 4.1.3 Low-power mode dimensioning The power saving that can be achieved depends on the programmed sleep duration and the configured bandwidth. Figure 4 explains the power consumption in relation to the different ASIC states (sleep and awake phases). Figure 4: Sleep and awake phase If a low bandwidth is selected, the time required for filter settling might be the dominating time. Refer to table 2 for the appropriate dimensioning of the attainable current saving. Filter cut-off Settling time 32 Hz 16690µs 64 Hz 8690µs 125 Hz 4690µs 250 Hz 2690µs 500 Hz 1690µs 1000 Hz 1190µs Table 4: Approximate awake phase times for 1 data sample 4.1.4 Channel activation / de-activation In order to optimize further power consumption of the BMA220, data evaluation of individual axes can be deactivated. Per default, all three axes are active. If the user wants to disable one or more axes, the appropriate en_?_channel bits at address 0x0F (SPI) / 0x1E (I2C) must be set to ‘0’. 4.1.5 Soft-reset The BMA220 can be put into a soft-reset state by performing a read from the soft-reset address. To bring the chip back into operation, another read must be performed from the same memory address. The reading returns value 0xFF if the system was in soft reset mode; otherwise it returns value 0x00. Please note that all internal configuration data programmed by the user will be lost. Rev. 1.10 Page 11 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 4.1.6 Suspend mode The BMA220 can be put into a suspend mode e.g. to easily achieve a power consumption below 1μA by performing a read from the suspend address. To bring the chip back into normal mode operation, another read must be performed from the same memory address. The reading returns value 0xFF if the system was in suspend mode, otherwise it returns value 0x00. Please note, that during suspend, all analog modules expect for power-on-reset will be disabled. Only reads through the serial interface are supported during suspend. Rev. 1.10 Page 12 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 4.2 Setting registers 4.2.1 Acceleration range and sensitivity setting The BMA220 has four different range settings for the full scale acceleration range. In dependence of the use case always the lowest full scale range with the maximum resolution should be selected. Please refer to literature to find out, which full scale acceleration range, which sensitivity or which resolution is the ideal one. This can be configured via the register bits range[1:0] at address 0x11 (SPI) / 0x22 (SPI). The following table shows the range bits with corresponding scale and resolution. range[1:0] Full Scale Sensitivity Resolution Example use case ‘00’ ±2g 16 LSB / g 62.5mg / LSB Orientation recognition ‘01’ ±4g 8 LSB / g 125mg / LSB Gaming ‘10’ ±8g 4 LSB / g 0.25g / LSB ‘11’ ±16g 2 LSB / g 0.5g / LSB Shock vibration detection Table 5: Acceleration resolution 4.2.2 Filter and bandwidth configuration The BMA220 has a digital filter that can be configured by setting the corresponding register bits filter_config[3:0] at address 0x10 (SPI) / 0x20 (I2C). For compatibility reasons the settings are defined based on BMA120. To always ensure an ideal cut off frequency of the filter the BMA220 is adjusting the sample rate automatically. filter_config[3:0] 0x5 0x4 0x3 0x2 0x1 0x0 digital filter cut-off frequency 32Hz 64Hz 125Hz 250Hz 500Hz 1kHz Table 6: Digital filter configuration The internal SC-filter has a fix cut-off frequency at 1 KHz. In addition to the internal SC-filter a digital filter is available which is providing a filtered and an unfiltered data stream for all of the 3 axes of acceleration. If application specific reasons require a bandwidth configuration <32Hz, please contact your Bosch Sensortec representative. Rev. 1.10 Page 13 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 4.3 Data registers 4.3.1 Acceleration data read-out The acceleration data can be read-out through addresses 0x02 (SPI) / 0x04 (I2C) through 0x04 (SPI) / 0x08 (I2C). The acceleration data is in 2’s complement according to the table below. An efficient way to read out the acceleration data in I²C or SPI mode is the burst-accesses. During such an access, the BMA220 automatically increments the read address after each byte. By using this kind of access, the data transferred over the I²C bus can be reduced by up to 50%. Decimal value Acceleration (in 2g range mode) + 31 + 1.94g … … 0 0g … … -32 - 2.0g Table 7: Acceleration register content Per default, the bandwidth of the data being read-out is limited by the internal low-pass filters according to the filter configuration. However, it is possible to read-out data only 1st order filtered (1 kHz) even though the internal filters are configured differently. The reason for this feature is that the interrupt controller may operate on low-bandwidth data while the external master still needs to operate on high-bandwidth data. Unfiltered (1kHz high-bandwidth) data can be read-out through the serial interface when the serial_high_bw bit is set to ‘1’. Per default, filtered data is read-out through the serial interface. 4.3.2 Chip / revision ID The chip ID and the revision ID can be read-out through addresses 0x00 (SPI & I2C) and 0x01 (SPI) / 0x02 (I2C). Chip ID Revision ID 0xDD 0x00 Table 8: Chip and revision ID Rev. 1.10 Page 14 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 4.4 Interrupt control registers The BMA220 features a programmable interrupt controller that directly supports common mobile applications like tap sensing detection, orientation recognition and any-motion detection. Supported types of interrupts: Any-motion (slope) detection Tap/double-tap sensing Orientation recognition Low-g detection High-g detection Data-ready interrupt The configuration and status register bits of all interrupt engines and the exact interrupt functionality are given in chapter 5. Rev. 1.10 Page 15 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 5 Interrupt controller The BMA220 integrates a programmable interrupt controller. It can be configured via SPI/I2C to monitor individual axes (X-, Y- and Z-axis) and check whether certain conditions apply (e.g. the acceleration on one axis exceeds a certain threshold). The interrupt controller of the BMA220 is capable of checking for certain conditions simultaneously. If at least one of the configured conditions applies, an interrupt (logic ‘1’) is issued through the INT pin of the sensor. More details about the triggering condition (e.g. the type of the interrupt or the axis that triggered the interrupt) are saved in internal status registers and can be read out through the digital interface. It is recommended to reset the interrupt controller by setting reset_int to '1' when the interrupt settings has been set or changed. 5.1 Latched vs. non-latched modes The interrupt controller can be used in two modes Latched mode: Once one of the configured interrupt conditions applies, the INT pin is asserted and must be reset by the external master through the digital interface. Non-Latched mode: The interrupt controller clears the INT signal once the interrupt condition no longer applies. The interrupt output can be programmed by lat_int[2:0] to be either unlatched (‘000’) or latched permanently (‘111’) or have the latch time of 0.25s(‘001’)/0.5s(‘010’)/1s(‘011’)/2s(‘100’)/4s (‘101’)/8s(‘110’). The setting of these bits applies to all types of interrupts. Interrupt int from interrupt enigne interrupt output unlatched latch time latched for certain time latched permanently Figure 5: Interrupt output Rev. 1.10 Page 16 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 5.2 Supported types of interrupts The following interrupt modes are provided by the BMA220. Any-motion (slope) detection Tap/double-tap sensing Orientation recognition Low-g detection High-g detection Data-ready interrupt 5.3 Power-saving modes In order to reduce power consumption of the sensor itself, the BMA220 supports a low-power mode in which the ASIC wakes up periodically, checks whether any of the configured interrupt conditions apply and then either goes back to sleep (no interrupt) or stays awake (interrupt). The BMA220’s PMU (power management unit) controls the transitions from the ‘awake state’ into the ‘sleep state’ and vice versa. In normal mode, the interrupt controller is permanently turned on to continuously process the incoming data. In low-power mode, the interrupt controller will be turned on by the PMU once the chip has fully woken up. The time it takes before the sensor can go back to sleep is determined by the active interrupt engines. Once all active engines indicate that no interrupt condition applies, the PMU will switch the sensor back into sleep state (please refer to section 0 for more details). Furthermore the applied interrupt condition can be used not only to enable the low-power mode of the sensor itself but for the whole system. This enables a dramatically reduced power consumption of the whole system. The result is an extended operation and stand-by time e.g. of mobile devices in an order of magnitude. Rev. 1.10 Page 17 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 5.4 Any-motion (slope) detection The any-motion detection uses the slope between two successive acceleration signals to detect changes in motion. It generates an interrupt when a preset threshold slope_th is exceeded. The threshold can be configured between 0 and the maximum acceleration value corresponding to the selected measurement range. The time difference between the successive acceleration signals depends on the bandwidth of the configurable low pass filter and corresponds roughly to 1/(2*bandwidth) (Δt=1/(2*bw)). In order to suppress failure signals, the interrupt is only generated if a certain number slope_dur of consecutive slope data points is above the slope threshold slope_th. If the same number of data points falls below the threshold, the interrupt is reset. The criteria for any-motion detection are fulfilled and the slope interrupt is generated if any of the enabled channels exceeds the threshold slope_th for slope_dur consecutive times. As soon as all the enabled channels fall or stay below this threshold for slope_dur consecutive times the interrupt is reset unless interrupt signal is latched. The any-motion interrupt logic sends out the signals of the axis that has triggered the interrupt (slope_first_x, slope_first_y, slope_first_z) and the signal of motion direction (slope_sign). When serial interface is active, any-motion detection logic is enabled if any of the any-motion enable register bits is set. To disable the any-motion interrupt, clear all the axis enable bits. In the dedicated wake-up mode ( 0), all three axes are enabled for any-motion detection whether the individual axis enable bits are set or not. Rev. 1.10 Page 18 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet Figure 6: Any-motion (slope) interrupt detection acceleration acc(t ) 0 acc(t −1/(2*bw)) 0 time slope(t )=acc(t )−acc(t −1/(2*bw)) 0 0 0 slope slope_th time slope_dur slope_dur INT time The following table shows the signals used in any-motion detection. After reset, a default value will be assigned to each register. Rev. 1.10 Page 19 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet Name Register Description Number of Reset-value Address bits (SPI) * en_slope_x 0x0D.5 enable slope detection on x-axis 3 “000” en_slope_y 0x0D.4 enable slope detection on y-axis en_slope_z 0x0D.3 enable slope detection on z-axis slope_th 0x09[5:2] define the threshold level of the slope SLOPE_TH_N SLOPE_TH_INIT 1 LSB threshold is 1 LSB of acc_data UM (“0001”) 4 slope_dur 0x09[1:0] define the number of consecutive slope SLOPE_DUR_ SLOPE_DUR_INI data points above slope_th which are NUM T (“01”) required to set the interrupt 2 (“00” = 1,”01” = 2,”10” = 3, “11” = 4) slope_filt 0x09.6 defines whether filtered or unfiltered 1 ‘1’ acceleration data should be used (evaluated) (‘0’=unfiltered, ‘1’=filtered) slope_int 0x0C.0 whether slope interrupt has been triggered 1 ‘0’ slope_first_x whether x-axis has triggered the interrupt 3 “000” slope_first_y (0=no, 1=yes) slope_first_z whether y-axis has triggered the interrupt (0=no, 1=yes) whether z-axis has triggered the interrupt (0=no, 1=yes) slope_sign global register bit for all interrupts 1 ‘0’ define the slope sign of the triggering signal (0=positive slope, 1=negative slope) * For determining the corresponding I2C register address, please refer to figure 2 in chapter 4 (memory map) Table 9: Control and status register for any motion detection Rev. 1.10 Page 20 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 5.5 Tap sensing Tap sensing has the same functionality as a common laptop touch-pad. If 2 taps occur within a short time, a pre-defined action will be performed by the system. If time between 2 taps is too long or too short no action happens. When the serial interface is activated, tap sensing is enabled if any of the tap sensing enable register bits are set (en_tt_x, en_tt_y, en_tt_z). To disable the tap sensing interrupt, clear all the axis enable bits. When the preset threshold tt_th is exceeded, a tap-shock is detected. The tap sensing interrupt is generated only when a second tap is detected within a specified period of time. The slope between two successive acceleration data has to exceed tt_th to detect a tap-shock. The time difference between the two successive acceleration values depends on the bandwidth of the low pass filter. It roughly corresponds to 1/(2*bandwidth). The time delay tt_dur between two taps is typically between 12,5ms and 500ms. The threshold is typically between 0.7g and 1.5g in 2g measurement range. Due to different coupling between sensor and device shell (housing) and different measurement ranges of the sensor these parameters are configurable. The criteria for tap sensing are fulfilled and the interrupt is generated if the second tap occurs after tap_quiet and within tt_dur. The tap sensing direction is determined by the 1st tap. During tt_quiet period (30ms) no taps should occur. If a tap occurs during tap_quiet period it will be connoted as new tap. The slope detection interrupt logic stores the direction of the (first) tap-shock in a status register. This register will be locked for tap_shock=50ms in order to prevent other slopes to overwrite this information. When a tap sensing interrupt is triggered, the signals of the axis that has triggered the interrupt (tt_first_x, tt_first_y, tt_first_z) and the signal of motion direction (tt_sign) are stored in the corresponding registers. The axis on which the biggest slope occurs will trigger the first tap. The second tap will be triggered by any axis (not necessarily same as the first tap). The register tap_en defines whether single tap or double tap shall be detected. In dedicated tap sensing mode, all three axes are enabled for double tap sensing detection. Rev. 1.10 Page 21 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet Figure 7: Tap sensing interrupt detection slope 1stTAP 2nd TAP tt_th time tap shock=50ms tap quiet = 30ms tt_dur= 12.5 ÷ 500 ms tap shock=50ms tap quiet = 30ms single tap detection ( time double tap detection timee When a tap-sensing interrupt is triggered, the following details can be read from the corresponding registers: the axis that has triggered the interrupt (tt_first_x, tt_first_y, tt_first_z) and the motion direction of the triggering acceleration signal (tt_sign). Rev. 1.10 Page 22 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet Name Register Description Number of bits Reset-value Address (SPI) * en_tt_x 0x0D.2 enable tap sensing detection on x-axis 3 “000” en_tt_y 0x0D.1 enable tap sensing detection on y-axis en_tt_z 0x0D.0 enable tap sensing detection on z-axis tt_th 0x08[6:3] define the threshold level of the tap sensing TT_TH_NUM TT_TH_INIT slope 4 “0110” 1 LSB is 2*(LSB of acc_data) tt_dur 0x08[2:0] define the maximum delay of the second TT_DUR_NUM TT_DUR_INIT tap after the shock suppression (50, 105, 3 “101” 150, 219, 250, 375, 500, 700)ms tt_filt 0x08.7 defines whether filtered or unfiltered 1 ‘1’ acceleration data should be used (evaluated) (‘0’=unfiltered, ‘1’=filtered) tip_en 0x0A.4 whether tap or double-tap shall be detected 1 ‘0’ (0= double tap, 1=tap) tt_int 0x0C.4 whether tap sensing interrupt has been 1 ‘0’ triggered (0=no, 1=yes) tt_samp 0x0A[1:0] number of data to be sampled after wake- 2 ‘00’ up ‘00’ => 2 data ‘01’ => 4 data ‘10’ => 8 data ‘11’ => 16 data tt_first_x whether x-axis has triggered the interrupt 3 “000” tt_first_y (0=no, 1=yes) tt_first_z whether y-axis has triggered the interrupt (0=no, 1=yes) whether z-axis has triggered the interrupt (0=no, 1=yes) tt_sign give the slope sign of the triggering signal 1 ‘0’ (0=positive, 1=negative) * For determining the corresponding I2C register address, please refer to figure 2 in chapter 4 (memory map) Table 10: Control and status register for tap sensing Rev. 1.10 Page 23 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 5.6 Orientation recognition The orientation recognition feature informs on an orientation change of the sensor with respect to the gravitational field vector g. The measured acceleration vector components with respect to the gravitational field look as follows. Figure 8: Definition of acceleration-vector components z x y g [with respect to graviational field vector g (black dot = pin 1 identifier) ] acc_x = 1g·sin·cos acc_y = −1g·sin·sin acc_z = 1g·cos → acc_y/acc_x = −tan The output register is called orient and defined in the following way: ‘0xx’ upward looking (z>0): ‘000’ portrait upright (315°<<45°) → |acc_y/acc_x|<1 && acc_x>0 ‘001’ portrait upside down (135°<<225°) → |acc_y/acc_x|<1 && acc_x<0 ‘010’ landscape left (45°<<135°) → |acc_y/acc_x|>1 && acc_y<0 ‘011’ landscape right (225°<<315°) → |acc_y/acc_x|>1 && acc_y>0 ‘1xx’ downward looking (z<0), xx as before Rev. 1.10 Page 24 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet Figure 9: Orientation definition and interrupt thresholds with respect to the angle phi ppoorrttrraaiitt uupprriigghhtt llaannddssccaappee lleefftt ppoorrttrraaiitt uuppssiiddee llaannddssccaappee rriigghhtt ppoorrttrraaiitt uupprriigghhtt ddoowwnn 22 11..55 11 00..55 00 00 4455 9900 113355 118800 222255 227700 331155 336600 --00..55 --11 aacccc__yy//aacccc__xx aacccc__xx//ssiinn((tthheettaa)) --11..55 aacccc__yy//ssiinn((tthheettaa)) --22 pphhii The criteria for portrait/landscape switching is fulfilled and the interrupt is generated when the threshold |acc_y/acc_x|=1 is crossed (i.e. 45°, 135°, 225°, 315°). As soon as the interrupt is set, no new interrupt is generated within the hysteresis level of 0.66<|acc_y/acc_x|<1.66 corresponding to a hysteresis interval of 13% around the threshold. It is possible to block the orientation detection depending on certain conditions (no orientation interrupt will be triggered). This orientation interrupt blocking feature is configurable via the orient_blocking[1:0] bits in the following manner: ‘00’ interrupt blocking is completely disabled ‘01’ no interrupt is generated, when |z|>0.9g OR |x|+|y| < 0.4g OR when the slopes of the acceleration data exceeds 0.2g (sample-to-sample). ‘10’ no interrupt is generated, when |z|>0.9g OR |x|+|y| < 0.4g OR while the slopes of the acceleration data exceeds 0.3g (sample-to-sample). ‘11’ no interrupt is generated, when |z|>0.9g OR |x|+|y| < 0.4g OR while the slopes of the acceleration data exceeds 0.4g (sample-to-sample). For all states where interrupt blocking through slope detection is used, the interrupt should be re-enabled after the slope has been below the threshold for 3 times in a row. For all states where interrupt blocking is enabled, in order to trigger the interrupt, the orientation should remain the same (stable) until the timer runs out (for ~100ms). The timer starts to count when orientation changes between two consecutive samples. If the orientation changes while timer is still counting, the timer is restarted. The criteria for switching from upward to downward looking fulfilled and the interrupt is generated when the threshold z=0g is crossed. As soon as the interrupt is set, no new interrupt is generated within the hysteresis level of -0.4g<z<0.4g (i.e. 25° tilt around vertical position). Rev. 1.10 Page 25 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet The given specification is valid for an upright mounted PCB. In order to enable also horizontal mounting, x and z axis can be exchanged via the register orient_ex. The x-, y-, z-axis will keep right-hand principle after the exchange. When serial interface is active, orientation detection is enabled if the enable bit en_orient is set. To disable the orientation interrupt, clear the enable bit. When the dedicated orientation mode is active, the orientation is given by certain output pins corresponding to the above-given definition of the orient register. For details on the output pins see section 6.1. In case the orientation interrupt condition has been satisfied and interrupt is not latched, int signal is asserted for one data sampling period unless no-reset condition applies. Name Register Description Number Reset-value Address of bits (SPI) * orient_ex 0x09.7 exchange x- and z-axis in algorithm, i.e x or z 1 ‘0’ is relevant axis for upward/downward looking recognition (0=z, 1=x) Orient 0x0B[6:4] give the orientation of the sensor with 3 ORIENT_INIT respect to the gravitational force ‘000’ orient_int 0x0B.7 whether orientation interrupt has been 1 ‘0’ triggered (0=no, 1=yes) en_orient 0x0D.6 enable signal for orientation detection 1 ‘0’ orient_blockin 0x0A Enable/configure orientation interrupt disable 2 ‘10’ g criteria. ‘00’ -> no slope, no wait ‘01’ -> no slope, wait-only (~100ms) ‘10’ -> wait 100ms + |z|-criteria, |x|+|y|-criteria and <0.2g slope ‘11’ -> wait 100ms + |z|-criteria, |x|+|y|- criteria and <0.4g slope * For determining the corresponding I2C register address, please refer to figure 2 in chapter 4 (memory map) Table 11: Control and status register for orientation recognition Rev. 1.10 Page 26 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 5.7 Low-g detection For freefall detection, the absolute values of the acceleration data of all axes are observed (global criteria). A low-g situation is likely to occur when all axes fall below a lower threshold low_th. The interrupt will be generated if the measured acceleration falls below the threshold and stays below the hysteresis level low_th+low_hy for a minimum number of data points (low_dur). Thus, the duration of a released interrupt is depending on the data sampling rate which is related to the bandwidth. Figure 10: Low-g interrupt detection acceleration low_th + low_hy low_th time counter value low_dur time INT (not latched) latched not latched time Rev. 1.10 Page 27 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet Name Register Description Number of bits Reset-value Address (SPI) * Low_th 0x06[7:4] define the low-g threshold level LOW_TH_NUM LOW_TH_INIT 1 LSB is 2*(LSB of acc_data) 4 “0100” Low_hy 0x07[7:6] define the low-g hysteresis level LOW_HY_NUM LOW_HY_INIT 1 LSB is 2*(LSB of acc_data) 2 “01” low_dur 0x07[5:0] define the number of measured data LOW_DUR_NUM LOW_DUR_INIT which has to be lower than 6 “111111” (3F) low_th+low_hy to set the interrupt (max. 64) en_low 0x0E.3 enable signal for low-g detection 1 ‘0’ low_int 0x0C.3 whether low-g interrupt has been 1 ‘0’ triggered (0=no, 1=yes) * For determining the corresponding I2C register address, please refer to figure 2 in chapter 4 (memory map) Table 12: Control and status register for low g detection Rev. 1.10 Page 28 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 5.8 High-g detection For indicating high-g events, an upper threshold can be programmed. The threshold high_th, the hysteresis high_hy and the duration high_dur are defined analogously to the low-g interrupt. The interrupt is generated if one of the three channels exceeds the threshold hight_th and does not fall below hysteresis level high_th-high_hy for minimum number of data points (high_dur). When the high-g interrupt is triggered, the signals of the axis that has triggered the interrupt (high_first_x, high_first_y, high_first_z) and the signal of motion direction (high_sign) will be stored in the corresponding status registers. Name Register Description Number of bits Reset-value address (SPI) * high_th 0x06[3:0] define the high-g threshold level HIGH_TH_NUM HIGH_TH_INIT 1 LSB is 2*(LSB of acc_data) 4 “1110” high_hy 0x05[7:6] define the high-g hysteresis level HIGH_HY_NUM HIGH_HY_INIT 1 LSB is 2*(LSB of acc_data) 2 “01” high_dur 0x05[5:0] define the number of measured signals HIGH_DUR_NUM HIGH_DUR_INIT which has to be higher than 6 “011111” (3F) high_th+high_hy to set the interrupt (max. 64) en_high_x 0x0E.2 enable high-g detection on x-axis 3 “000” (0=disabled, 1=enabled) en_high_y 0x0E.1 enable high-g detection on x-axis (0=disabled, 1=enabled) en_high_z 0x0E.0 enable high-g detection on x-axis (0=disabled, 1=enabled) high_int 0x0C.2 whether high-g interrupt has been 1 ‘0’ triggered (0=no, 1=yes) high_first_ whether x-axis has triggered the 3 “000” x interrupt (0=no, 1=yes) whether y-axis has triggered the high_first_ interrupt (0=no, 1=yes) y whether z-axis has triggered the interrupt (0=no, 1=yes) high_first_ z high_sign give the slope sign of the triggering 1 ‘0’ signal (0=positive, 1=negative) * For determining the corresponding I2C register address, please refer to figure 2 in chapter 4 (memory map) Table 13: Control and status register for high g detection Rev. 1.10 Page 29 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 5.9 Data ready detection This interrupt provides the possibility of synchronously reading out data from the BMA220 without missing a single data point. The data update detection monitors the data_update signals for all axes. It generates an interrupt as soon as the acceleration values for all enabled axes have been updated. The signal en_x_channel, en_y_channel and en_z_channel are the enable signals for the data conversion from each axis accordingly. The three enable signals can be configured by users (see section 0). For example, if all three axes are enabled, the interrupt is generated after updated signals for x-, y-, and z-axes have been detected. When data ready detection is activated, all other interrupts are not propagated to the INT pin. However their status can still be obtained from the appropriate registers. When the data-ready interrupt is not latched, the interrupt is cleared automatically after ~150μs. Name Description Number of bits Reset-value en_data enable signal for data-ready detection 1 ‘0’ data_int whether data-ready interrupt has been triggered 1 ‘0’ (0=no, 1=yes) Table 14: Control and status register for low g detection Rev. 1.10 Page 30 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 6 Operation modes Depending on the configuration the BMA220 is able to operate in two different types of modes General mode: A serial interface is active (SPI or I2C). Several interrupt engines may be activated in parallel. Through the serial interface, the external master (e.g. μC) can configure the interrupts of the BMA220 and read-out information about the current interrupt status. Dedicated mode: No serial interface is present. Internal default settings for all interrupt engines must be used. In these modes, only one interrupt engine can be active at a time. Currently, dedicated modes exist for the orientation interrupt, the tap sensing interrupt and the any-motion interrupt. The dedicated mode allows the sensor to be operated as a stand alone device, e.g. without any μC and without dealing with any acceleration data. So, in a very user friendly and convenient way taps/double-taps, orientation changes and wake-ups can be processed by a simple μC-less system. A flow chart of the different modes is depicted in figure 11: General mode with I2C reset One or more interrupts can be configured via I2C no Any of the no yes General mode with dedicated PS = ´0´? SPI mode invoked? One or more yes interrupts can be configured via SPI Tip-tap mode Orientation mode Wake-up mode Tip-tap orientation Any-motion interrupt is interrupt is interrupt is enabled enabled enabled Figure 11: Interrupt modes Rev. 1.10 Page 31 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet Mode PS SCK INT SPI 0 I²C 1 Dedicated orientation Z 0 Dedicated tap Z 1 0 sensing Dedicated wake-up Z 1 1 Table 15: Mode selection Please note that the PS must be connected to the appropriate supply (or left floating) at start-up (reset). The “Z-detection” circuit will be turned off when a stable value at the PS pin has been detected. Thus, the dedicated modes can be only activated after reset. Switching from one interface mode to another during operation may work but can not be guaranteed by the ASIC. The reason for this limitation is that the circuitry for z-detection consumes several μA. For debugging/test purposes, turning-off the z-detection circuitry can be suppressed by setting the comp_always_on bit within the OTP memory range. Pin # 2 1 10 12 5 11 6 3 4 7 8, 9 Mode SDI SDO CSB SCK INT PS CAP0 VDDIO VDDD VDDA GND SPI 4 wire SDI SDO CSB SCK INT GND NC VDDIO VDDD VDDA GND SPI 3 wire SDA NC CSB SCK INT GND NC VDDIO VDDD VDDA GND I2C SDA NC I2C lsb_invert SCL INT VDDIO NC VDDIO VDDD VDDA GND Dedicated Orientation ORIENT_0 ORIENT_1 sleep_time GND ORIENT_2 NC NC VDDIO VDDD VDDA GND (wm/oo dμeC); Tap sensing SINGLE_TAP DOUBLE_TAP sleep on VDDIO GND NC NC VDDIO VDDD VDDA GND stand-alone Wake-up WAKE_UP_INT NC sleep_time VDDIO VDDIO NC NC VDDIO VDDD VDDA GND Table 16: Pin assignments for all operation modes 6.1 Dedicated Modes (μC-less / stand alone) After reset (POR, soft-reset or reset pin) the system monitors the pin PS (Protocol Select). If the pin is unconnected, an internal module detects the floating state and enables one of the dedicated modes depending on the other select pins (SCK, INT). There are three different dedicated modes: Orientation detection mode: only orientation interrupt detection is enabled. Tap/double-tap detection mode: only tap sensing interrupt detection is enabled. Wake-up detection mode: only wake-up interrupt detection is enabled In dedicated mode, the interrupt engine uses default settings for all configuration registers. Those default settings are loaded after reset and are listed in section 0. Changing the default Rev. 1.10 Page 32 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet configuration of the registers is not possible while the chip is in the dedicated mode. Currently, in orientation and wake-up mode, the user can select between two different sleep durations via the CSB pin: Dedicated Mode CSB Sleep duration 0 100ms Dedicated orientation 1 1s 0 10ms Dedicated wake-up 1 500ms 0 No sleep Dedicated tap-sensing 1 2ms Table 17: Sleep durations for dedicated modes Dedicated Mode Bandwidth Dedicated orientation 32Hz Dedicated wake-up 16Hz Dedicated tap-sensing 1kHz Table 18: Filter bandwidths for dedicated modes 6.2 Digital interface modes The BMA220 supports two different digital interfaces (SPI and I²C). The currently active general interface is determined by the primary input PS. The configuration of interrupt engines is fully customizable via the defined digital interface. SPI Active Mode: The SPI interface is enabled while PS is externally connected to GND (logic ‘0’ detected). I2C Active Mode: The I²C interface is enabled while PS is externally connected to V DDIO (logic ‘1’ detected). Rev. 1.10 Page 33 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 6.3 Low-power mode and suspend mode The BMA220 is optimized for low power consumption. Note: Simply switching-off of the power supplies (V and/or V ) is not a defined low-power mode. DDD DDA The deactivation of V while V is active (or vice versa) is not recommended for permanent DDD DDA operation. With respect to the application it might be useful to switch-off V while V and DDIO DDD V are active. This condition is supported and will lead to a reduction of current consumption. DDA The sensor register map will be reset. To reduce current consumption in a defined way, the BMA220 supports two energy saving modes: a suspend mode and a low-power mode. During normal mode operation, all analog modules are held powered-up and the clock for all digital modules is active. During low-power mode, the analog modules in the rate channel are held powered down and the clock of the digital rate, filter and trimming modules is gated. The average typical current consumption during sleep phase (i ) can be estimated by the low_power_mode following equation: First approximation: i = i sleep suspend t i t i Ø typ. i sleep suspend active active low_power_mode t t sleep awake For sleep phase time setting (t ) refer to chapter 4.1.2 table 3. sleep For approximate awake phase time (t ) refer to chapter 4.1.3 table 4. awake For current consumption in normal mode (i ) refer to chapter 1. active For current consumption in suspend mode (i ) refer to chapter 1. suspend Example: Bandwidth (BW) = 1kHz, nominal supplies resulting awake phase for 1st data sample (t ) = 1190μs = 1.190ms awake resulting sleep time (t ) = 50 ms sleep t i t i 50ms1µA1,190ms250µA Ø typ. i sleep suspend active active 6,8µA low_power_mode t t 50ms1,190ms sleep awake Rev. 1.10 Page 34 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 6.4 Mode transition via interface While the SPI or the I²C interfaces are active, transitions between the individual modes can be triggered via register accesses. 1. Low power: The BMA220 switches into low-power mode after setting the sleep_en register depicted in the memory map. While the BAA220 is in low-power mode, a period wake-up is performed (please refer to section 0). Normal mode operation is resumed after writing a ‘0’ to the sleep_en register. The sleep register is user accessible. 2. Suspend: The BMA220 is put into suspend mode by reading from the suspend address. A subsequent read switches back to the previous state. Concluding, a read from the suspend address toggles the suspend register. Figure 12: Energy saving mode transitions Rev. 1.10 Page 35 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 6.5 Self test mode The sensor features an on-chip self-test mode. The self test is realized by a physical deflection of the seismic mass due to an applied electrostatic force. Thus, it provides full testing of the complete signal evaluation path including the micromachined sensor structure and the evaluation ASIC. The self test mode can be activated individually for each axis by setting the the sbist register to the corresponding value (‘01’=x-axis, ‘10’=y-axis, ‘11’=z-axis). The self test works in all acceleration ranges. By setting the sbist_sign register to ‘1’, the polarity of the self test signal can be changed from positive to negative. The self test response remains as a static offset on the output as long as the sbist register is not set back to ‘00’. While the self test is activated, any acceleration or gravitational force applied to the sensor will be observed in the output signal as a superposition of both acceleration and self test signal. Figure 13: Self-test mode output signal [LSB] self test response sbist register 01 00 sbist_sign register 1 0 Rev. 1.10 Page 36 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 7 Interfaces The BMA220 can connect to the host system via three interfaces: SPI (3-wire, 4-wire) I²C Dedicated mode pins (for μC-less- or stand-alone operation, see section 0) In SPI and I²C mode, the BMA220 supports two commands: read and write. The ASIC can be entirely controlled through those commands. A detailed register to address mapping can be found in section 0. It should be noted that there is no way to access internal control or configuration registers while the BMA220 is in one of its dedicated modes. In I²C and SPI mode, the internal registers can be accessed via a 7-bit address. Each read- and write-cycle accesses 8 bits only. BusAdapter BusSlave0 BusSlave1 BusGateway SPI I/O Bus I2C BusSlave2 Figure 14: BMA220 I/O bus concept The SPI and I²C interfaces are connected to the internal bus gateway which activates either one of the two interfaces according to the current mode. All internal digital modules accessible via the serial interfaces are called bus slave. Each slave is connected to the internal bus through a bus adapter. Rev. 1.10 Page 37 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 7.1 General digital interface description In general there are two common digital protocols selectable, the serial interfaces I²C and SPI. By default, SPI is used in the standard 4-wire configuration. The SPI interface may be configured by SW to operate in 3-wire interface mode, instead of standard 4-wire mode. The two serial interfaces are mapped onto the same pads. An external pin is needed to switch between the interfaces. When this protocol select pin (PS) is connected to VSS, SPI is selected as the current interface; when the select pin is connected to V , I²C is used as the interface. DDIO When select pin is left floating, one of the dedicated modes is selected. The BMA220 doesn’t provide a functional analog output of the three axes since there is just CAP0 available in the package. PIN Name PIN description CSB SPI serial enable bar SCK/SCL SPI serial clock (SCK) I²C serial clock (SCL) SDI/SDO/SDA SPI serial data input (SDI) SPI serial data output in 3-wire SPI mode (SDO) I²C serial data (SDA) SDO SPI serial data output Table 19: Interface pin name 7.2 SPI interface The SPI interface integrated in BMA220 is a slave SPI. 16-bit protocols are used for single byte reading and writing. Multiple bytes read-out is also possible. However, multiple bytes write is not supported. 4-wire SPI and 3-wire SPI are using same protocols. The communication starts with a read/write control bit followed by 7 bits address and at least 8 bits data. In case of reading out of acceleration data from all axes the chip provides the option to use an automatic incremented read command to read more than one byte (multiple read). This is activated when the SPI serial enable pin CSB is held low during the data readout. Thus data from next address will be automatically read out if the CSB are kept low for another 8 SPI clock cycles. 4-wire SPI protocol and timing 4-wire SPI is the default serial interface. It interacts with the outside world using CSB (chip select low active), SCK (serial clock), SDI (serial data input) and SDO (serial data output). The communication starts when the CSB is pulled low by the SPI master and stops when CSB is pulled high. SCK is also controlled by SPI master. During the transitions on CSB, SCK must be high. SDI and SDO are driven at the falling edge of SCK and should be captured at the rising edge of SCK. Single byte write/read commands use 16-bits protocol. Bit0: Read/Write bit. When 0, the data SDI is written into the chip. When 1, the data SDO from the chip is read. Rev. 1.10 Page 38 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet Bit1-7: Address AD(6:0). Bit8-15: when in write mode, these are data SDI, which will be written into the address. When in read mode, these are the data SDO, which are read from the address. CSB SCK SDI R/W AD6 AD5 AD4 AD3 AD2 AD1 AD0 DI7 DI6 DI5 DI4 DI3 DI2 DI1 DI0 SDO Z tri-state Figure 15: 4-wire SPI write command Write command is completed in 16 clock cycles. During the entire write cycle SDO remains in high- impedance state. CSB SCK SDI R/W AD6 AD5 AD4 AD3 AD2 AD1 AD0 SDO DO7 DO6 DO5 DO4 DO3 DO2 DO1 DO0 tri-state Figure 16: 4-wire SPI read command Read command is completed in 16 clock cycles or in multiple of 8 in case of multiple byte read. In multiple-read cycle further blocks of 8 clock periods will be extended for each acknowledged data. Rev. 1.10 Page 39 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet T_setup_csb_4 T_hold_csb_4 CSB T_low_sck_4 T_high_sck_4 SCK SDI T_setup_sdi_4 T_hold_sdi_4 SDO T_delay_sdo_4 Figure 17: Timing diagram of 4-wire SPI cycle Parameter Symbol Condition Min Units CSB lead time T_setup_csb 10 CSB lag time T_hold_csb 10 SDI setup time T_setup_sdi 5 ns SDI hold time T_hold_sdi 5 SDO delay time T_delay_sdo C ≤ 50pF 30 (MAX) Load SCK period T_sck 100 Table 20: SPI Timing 3-wire SPI 3-wire SPI interface uses SDI pin for both data input and output. It can be invoked by setting the SPI3 register bit at address 0x0F. The write command for the 3-wire SPI is identical to the 4-wire SPI write command. When a read command is performed, output data are redirected to SDI pin after last address bit AD0 is latched. No extra clock cycle is needed for output redirection. Output data are synchronized at falling edge of SCK. Both input and output data shall be captured at rising edge of SCK. Rev. 1.10 Page 40 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet CSB SCK SDI R/W AD6 AD5 AD4 AD3 AD2 AD1 AD0 DO7 DO6 DO5 DO4 DO3 DO2 DO1 DO0 tri-state SDO Figure 18: 3-wire SPI read protocol Rev. 1.10 Page 41 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet 7.3 I²C interface The I²C interface on board is a slave bus. Two signal lines SCL and SDA are used for communication. SDA is a bidirectional line used for sending and receiving data to/from the interface. SCL is the serial clock line used to synchronize the data. Both lines are connected to VDD via pull-up resistors. So the lines are pulled high when the bus is free. The lines are low only when any of the transmitters drives ‘0’. The on-board I²C interface supports standard and fast-mode I²C. Important: The default slave address assigned to the BMA220 is 000 1011. When in I²C mode, the LSB can be inverted by tying the CSB pin to ‘1’. This allows resolving conflicts with existing devices. Also, the 4 LSB can be configured via OTP. I²C protocol: Start and stop conditions (see Figure 19): Data transmission on the bus begins with a HIGH to LOW transition on SDA line while SCK is held high (start condition (S) indicated by I²C bus master). Once the START signal is transferred by the master, the bus is considered busy. Each data transfer should be terminated by a Stop signal (P) generated by master. The STOP condition is a LOW to HIGH transition on SDA line while SCK is held high. SCK tHDSTA SDA tSUSTA tSUSTO Figure 19: Waveform diagram for I²C start and stop conditions Parameter Symbol Condition Min Units START hold time T 0.6 HDSTA START setup time T 0.6 SUSTA STOP setup time T 0.6 SUSTO t = 100 ns μs Internal hold time T f_SDA 0.3 (MAX) HOLD_INT t = 100 ns f_SCL t = 100 ns Clock to Data Out T f_SDA 0.08 VD_ACK t = 100 ns f_SCL Table 21: I²C start/stop timing Rev. 1.10 Page 42 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.

BMA220 Bosch Sensortec Data sheet Acknowledge: Each byte of data transferred must be acknowledged. It is indicated by an acknowledge bit sent by the receiver. The transmitter must release the SDA line (no pull down) during the acknowledge pulse while the receiver must then pull the SDA line low so that it remains stable low during the high period of the acknowledge clock cycle. SDA By transmitter Not Acknowledge SDA By receiver Acknowledge SCK 1 2 8 9 S Start condition Clock pulse for acknowledgement Figure 20: Waveform diagram for I²C acknowledgement on SDA Data Transfer: Each data bit transferred via SDA line must remain stable during high period of SCK pulse. Rev. 1.10 Page 43 13 April 2011 © Bosch Sensortec GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties. BOSCH and the symbol are registered trademarks of Robert Bosch GmbH, Germany. Note: Specifications within this document are subject to change without notice. Document is not intended for publication.