ICGOO在线商城 > 集成电路(IC) > 嵌入式 - 微控制器 > ATSAM4LC8CA-AU

- 型号: ATSAM4LC8CA-AU

- 制造商: Atmel

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

ATSAM4LC8CA-AU产品简介:

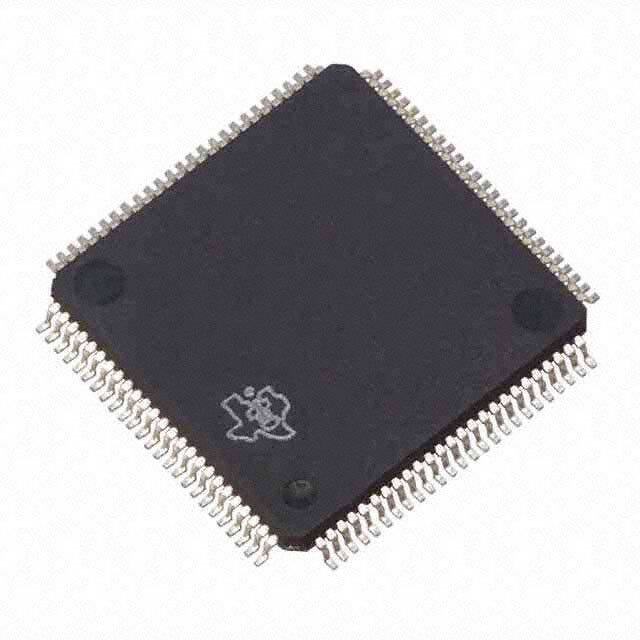

ICGOO电子元器件商城为您提供ATSAM4LC8CA-AU由Atmel设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 ATSAM4LC8CA-AU价格参考。AtmelATSAM4LC8CA-AU封装/规格:嵌入式 - 微控制器, ARM® Cortex®-M4 微控制器 IC SAM4L 32-位 48MHz 512KB(512K x 8) 闪存 100-TQFP(14x14)。您可以下载ATSAM4LC8CA-AU参考资料、Datasheet数据手册功能说明书,资料中有ATSAM4LC8CA-AU 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | 集成电路 (IC) |

| 描述 | IC MCU 32BIT 512KB FLASH 100TQFP |

| EEPROM容量 | - |

| 产品分类 | |

| I/O数 | 75 |

| 品牌 | Atmel |

| 数据手册 | |

| 产品图片 |

|

| 产品型号 | ATSAM4LC8CA-AU |

| RAM容量 | 64K x 8 |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | SAM4L |

| 产品培训模块 | http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=26162http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=26159http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=26180 |

| 供应商器件封装 | 100-TQFP(14x14) |

| 包装 | 托盘 |

| 外设 | 欠压检测/复位,DMA,I²S,LCD,POR,PWM,WDT |

| 封装/外壳 | 100-TQFP |

| 工作温度 | -40°C ~ 85°C |

| 应用说明 | |

| 振荡器类型 | 内部 |

| 数据转换器 | A/D 15x12b, D/A 1x10b |

| 标准包装 | 450 |

| 核心处理器 | ARM® Cortex™-M4 |

| 核心尺寸 | 32-位 |

| 电压-电源(Vcc/Vdd) | 1.68 V ~ 3.6 V |

| 程序存储器类型 | 闪存 |

| 程序存储容量 | 512KB(512K x 8) |

| 视频文件 | http://www.digikey.cn/classic/video.aspx?PlayerID=1364138032001&width=640&height=505&videoID=2620963593001 |

| 连接性 | I²C, IrDA, LIN, SPI, UART/USART, USB |

| 速度 | 48MHz |

| 配用 | /product-detail/zh/AT91SAM-ICE/AT91SAM-ICE-ND/1008639 |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

Summary Atmel's SAM4L series is a member of a family of Flash microcontrollers based on the high performance 32-bit ARM Cortex-M4 RISC processor running at fre- quencies up to 48MHz. The SAM4L series embeds state-of-the-art picoPower technology for ultra-low power consumption. Combined power control techniques are used to bring active current consumption down to 90μA/MHz. The device allows a wide range of options between functionality and power consumption, giving the user the ATSAM---e ability to reach the lowest possible power consumption with the feature set required for the application. The WAIT and RETENTION modes provide full logic ARM-based and RAM retention, associated with fast wake-up capability (<1.5μs) and a very low consumption of, respectively, 3 μA and 1.5 μA. In addition, WAIT mode sup- Flash MCU ports SleepWalking features. In BACKUP mode, CPU, peripherals and RAM are powered off and, while consuming less than 0.9μA with external interrupt wake- up supported. SAM4L Series The SAM4L series offers a wide range of peripherals such as segment LCD con- troller, embedded hardware capacitive touch (QTouch), USB device & embedded host, 128-bit AES and audio interfaces in addition to high speed serial peripherals such as USART, SPI and I2C. Additionally the Peripheral Event System and SleepWalking allows the peripherals to communicate directly with each other and make intelligent decisions and decide to wake-up the system on a qualified events on a peripheral level; such as I2C address match or and ADC threshold. Features • Core Summary – ARM® CortexTM-M4 running at up to 48MHz – Memory Protection Unit (MPU) – Thumb®-2 instruction set • picoPower® Technology for Ultra-low Power Consumption – Active mode downto 90µA/MHz with configurable voltage scaling – High performance and efficiency: 28 coremark/mA – Wait mode downto 3µA with fast wake-up time (<1.5µs) supporting SleepWalking – Full RAM and Logic Retention mode downto 1.5µA with fast wake-up time (<1.5µs) – Ultra low power Backup mode with/without RTC downto 1,5/0.9µA • Memories – From 128 to 512Kbytes embedded Flash, 64-bit wide access, • 0 wait-state capability up to 24MHz – up to 64Kbytes embedded SRAM • System Functions – Embedded voltage linear and switching regulator for single supply operation – Two Power-on-Reset and Two Brown-out Detectors (BOD) – Quartz or ceramic resonator oscillators: 0.6 to 30MHz main power with Failure Detection and low power 32.768 kHz for RTC or device clock – High precision 4/8/12MHz factory trimmed internal RC oscillator – Slow Clock Internal RC oscillator as permanent low-power mode device clock – High speed 80MHz internal RC oscillator – Low power 32kHz internal RC oscillator 42023HS–11/2016

ATSAM4L8/L4/L2 – PLL up to 240MHz for device clock and for USB – Digital Frequency Locked Loop (DFLL) with wide input range – Up to 16 peripheral DMA (PDCA) channels • Peripherals – USB 2.0 Device and Embedded Host: 12 Mbps, up to 8 bidirectional Endpoints and Multi-packet Ping-pong Mode. On- Chip Transceiver – Liquid Crystal Display (LCD) Module with Capacity up to 40 Segments and up to 4 Common Terminals – One USART with ISO7816, IrDA®, RS-485, SPI, Manchester and LIN Mode – Three USART with SPI Mode – One PicoUART for extended UART wake-up capabilities in all sleep modes – Windowed Watchdog Timer (WDT) – Asynchronous Timer (AST) with Real-time Clock Capability, Counter or Calendar Mode Supported – Frequency Meter (FREQM) for Accurate Measuring of Clock Frequency – Six 16-bit Timer/Counter (TC) Channels with capture, waveform, compare and PWM mode – One Master/Slave Serial Peripheral Interface (SPI) with Chip Select Signals – Four Master and Two Slave Two-wire Interfaces (TWI), up to 3.4Mbit/s I2C-compatible – One Advanced Encryption System (AES) with 128-bit key length – One 16-channel ADC 300Ksps (ADC) with up to 12 Bits Resolution – One DAC 500Ksps (DACC) with up to 10 Bits Resolution – Four Analog Comparators (ACIFC) with Optional Window Detection – Capacitive Touch Module (CATB) supporting up to 32 buttons – Audio Bitstream DAC (ABDACB) Suitable for Stereo Audio – Inter-IC Sound (IISC) Controller, Compliant with Inter-IC Sound (I2S) Specification – Peripheral Event System for Direct Peripheral to Peripheral Communication – 32-bit Cyclic Redundancy Check Calculation Unit (CRCCU) – Random generator (TRNG) – Parallel Capture Module (PARC) – Glue Logic Controller (GLOC) • I/O – Up to 75 I/O lines with external interrupt capability (edge or level sensitivity), debouncing, glitch filtering and slew-rate control – Up to Six High-drive I/O Pins • Single 1.68-3.6V Power Supply • Packages – 100-lead LQFP, 14 x 14 mm, pitch 0.5 mm/100-ball VFBGA, 7x7 mm, pitch 0.65 mm – 64-lead LQFP, 10 x 10 mm, pitch 0.5 mm/64-pad QFN 9x9 mm, pitch 0.5 mm – 64-ball WLCSP, 4,314x4,434 mm, pitch 0.5 mm for SAM4LC4/2 and SAM4LS4/2 series – 64-ball WLCSP, 5,270x5,194 mm, pitch 0.5 mm for SAM4LC8 and SAM4LS8 series – 48-lead LQFP, 7 x 7 mm, pitch 0.5 mm/48-pad QFN 7x7 mm, pitch 0.5 mm 2 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 1. Description Atmel's SAM4L series is a member of a family of Flash microcontrollers based on the high per- formance 32-bit ARM Cortex-M4 RISC processor running at frequencies up to 48MHz. The processor implements a Memory Protection Unit (MPU) and a fast and flexible interrupt con- troller for supporting modern and real-time operating systems. The ATSAM4L8/L4/L2 embeds state-of-the-art picoPower technology for ultra-low power con- sumption. Combined power control techniques are used to bring active current consumption down to 90µA/MHz. The device allows a wide range of options between functionality and power consumption, giving the user the ability to reach the lowest possible power consumption with the feature set required for the application. On-chip regulator improves power efficiency when used in swichting mode with an external inductor or can be used in linear mode if application is noise sensitive. The ATSAM4L8/L4/L2 supports 4 power saving strategies. The SLEEP mode put the CPU in idle mode and offers different sub-modes which automatically switch off/on bus clocks, PLL, oscillators. The WAIT and RETENTION modes provide full logic and RAM retention, associated with fast wake-up capability (<1.5µs) and a very low consumption of, respectively, 3 µA and 1.5 µA. In addition, WAIT mode supports SleepWalking features. In BACKUP mode, CPU, peripher- als and RAM are powered off and, while consuming less than 0.5µA, the device is able to wake- up from external interrupts. The ATSAM4L8/L4/L2 incorporates on-chip Flash tightly coupled to a low power cache (LPCACHE) for active consumption optimization and SRAM memories for fast access. The LCD controller is intended for monochrome passive liquid crystal display (LCD) with up to 4 Common terminals and up to 40 Segments terminals. Dedicated Low Power Waveform, Con- trast Control, Extended Interrupt Mode, Selectable Frame Frequency and Blink functionality are supported to offload the CPU, reduce interrupts and reduce power consumption. The controller includes integrated LCD buffers and integrated power supply voltage. The low-power and high performance capacitive touch module (CATB) is introduced to meet the demand for a low power capacitive touch solution that could be used to handle buttons, sliders and wheels. The CATB provides excellent signal performance, as well as autonomous touch and proximity detection for up to 32 sensors. This solution includes an advanced sequencer in addition to an hardware filtering unit. The Advanced Encryption Standard module (AESA) is compliant with the FIPS (Federal Infor- mation Processing Standard) Publication 197, Advanced Encryption Standard (AES), which specifies a symmetric block cipher that is used to encrypt and decrypt electronic data. Encryp- tion is the transformation of a usable message, called the plaintext, into an unreadable form, called the ciphertext. On the other hand, decryption is the transformation that recovers the plain- text from the ciphertext. AESA supports 128 bits cryptographic key sizes. The Peripheral Direct Memory Access (DMA) controller enables data transfers between periph- erals and memories without processor involvement. The Peripheral DMA controller drastically reduces processing overhead when transferring continuous and large data streams. The Peripheral Event System (PES) allows peripherals to receive, react to, and send peripheral events without CPU intervention. Asynchronous interrupts allow advanced peripheral operation in low power modes. The Power Manager (PM) improves design flexibility and security. The Power Manager supports SleepWalking functionality, by which a module can be selectively activated based on peripheral 3 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 events, even in sleep modes where the module clock is stopped. Power monitoring is supported by on-chip Power-on Reset (POR18, POR33), Brown-out Detectors (BOD18, BOD33). The device features several oscillators, such as Phase Locked Loop (PLL), Digital Frequency Locked Loop (DFLL), Oscillator 0 (OSC0), Internal RC 4,8,12MHz oscillator (RCFAST), system RC oscillator (RCSYS), Internal RC 80MHz, Internal 32kHz RC and 32kHz Crystal Oscillator. Either of these oscillators can be used as source for the system clock. The DFLL is a program- mable internal oscillator from 40 to 150MHz. It can be tuned to a high accuracy if an accurate reference clock is running, e.g. the 32kHz crystal oscillator. The Watchdog Timer (WDT) will reset the device unless it is periodically serviced by the soft- ware. This allows the device to recover from a condition that has caused the system to be unstable. The Asynchronous Timer (AST) combined with the 32kHz crystal oscillator supports powerful real-time clock capabilities, with a maximum timeout of up to 136 years. The AST can operate in counter or calendar mode. The Frequency Meter (FREQM) allows accurate measuring of a clock frequency by comparing it to a known reference clock. The Full-speed USB 2.0 device and embedded host interface (USBC) supports several USB classes at the same time utilizing the rich end-point configuration. The device includes six identical 16-bit Timer/Counter (TC) channels. Each channel can be inde- pendently programmed to perform frequency measurement, event counting, interval measurement, pulse generation, delay timing, and pulse width modulation. The ATSAM4L8/L4/L2 also features many communication interfaces, like USART, SPI, or TWI, for communication intensive applications. The USART supports different communication modes, like SPI Mode and LIN Mode. A general purpose 16-channel ADC is provided, as well as four analog comparators (ACIFC). The ADC can operate in 12-bit mode at full speed. The analog comparators can be paired to detect when the sensing voltage is within or outside the defined reference window. Atmel offers the QTouch Library for embedding capacitive touch buttons, sliders, and wheels functionality. The patented charge-transfer signal acquisition offers robust sensing and includes fully debounced reporting of touch keys as well as Adjacent Key Suppression® (AKS®) technol- ogy for unambiguous detection of key events. The easy-to-use QTouch Suite toolchain allows you to explore, develop, and debug your own touch applications. The Audio Bitstream DAC (ABDACB) converts a 16-bit sample value to a digital bitstream with an average value proportional to the sample value. Two channels are supported, making the ABDAC particularly suitable for stereo audio. The Inter-IC Sound Controller (IISC) provides a 5-bit wide, bidirectional, synchronous, digital audio link with external audio devices. The controller is compliant with the Inter-IC Sound (I2S) bus specification. 4 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 2. Overview 2.1 Block Diagram Figure 2-1. Block Diagram System TAP TTDCOK JTAG & IEnm-Cuilractuoirt ARM CFomrtaexx -4M84 M PHrozcessor NVIC TDI Serial Wire TMS System Management MEMORY PROTECTION UNIT Access Port Instruction/ System Data M M M S HRAM 64/32 KB CONTROLLER RAM 1A28E-Sbit DMA S HBUIGSH M SAPTEREIDX S FLASH 512/256/128 KB CONTROLLER FLASH DP USBC S LOW POWER CACHE DM 8EndPoints S S S S M CONFIGURATION REGISTERS BUS VVDVDDDDCDOOIRPOSE I/Os UNRTE XXOIRNUST3EW23G2ILTUDCLOORAH/CTSINOC3G2R3K2POWBEBBARHARCI CSINMCDKBSBKTOAGUAY-UEPNNEPCSPRBAT TKBFGREUAOEMPCRL E BHRSIDBG-PEB D BHRSIDBG-PEB C BHRSIDBG-PEB A DMADMADMA CPTTTOEWWWNRIIIUUUUT IDMMMPSSSSRMSHAAAAAAAOPAESSSRRRRLI RTTTTTTTLEEEAE0123RRRLR 012 MNRIPSTTTCOSRTCSWWSCX,X,L CM[CDKKDD3KTO..S0S]I PPAB LPU REGISTERS TWI MASTER 3 PC GENERA EXTRINNXMTDI[8..1] EXTAESCRWYOPNNANICACTTTTLIIOHCMMR URIHONEEAODRRTLRNOLETEORGRURSU PT ONTROLLER DMADMADMA INCCTTTOOEWWNNRII TT-LSSIRRCCLLOO DAASLLVVOLLEEUEE 01NRRD SCEOTIIIGTIISSMWMSWW[CDC3D[BCCS3DKO9KIIK.AA...00SP]]LH,,BCIAAPSLH NERAL PURPOSE I/Os PPPCAB BACKUP DOMAIN ENT C DMA AUDIO BDIATCSTREAM AABBDDACACLCNK[1[1...0.0]] GE POWER MANAGER V RESETN CONCTLROOCLKLER PHERAL E DMA 1IN61-2TC-EbHRiAt FANADNCCEE L ATADRDVI[G1R4GE.E.F0RP] RESET SLEEP RI CONTROLLER CONTROLLER PE DMA IN10T-EbRit FDAACCE DACOUT GCLK_IN[1:0] GCL KR[3C:0S]YS DMA CAPACMIOTIDVUEL TEOUCH SENSDEIS[69..0] RCFAST RC80M SYSITNETMER CFOANCTEROL DMA PARCAOLNLETRL OCLALPETRURE PPCCEDNPAC1T,CPAKC[7E..N0]2 XXOIUN0T0 OSC0 GENERIC GLUE LOGIC IN[7..0] DFLL CLOCK CONTROLLER OUT[1..0] PLL CLK[2..0] TIMER/COUNTER 0 B[2..0] FREQUENCY METER TIMER/COUNTER 1 A[2..0] ACAP[3..0] AC INTERFACE ACAN[3..0] ACREFN PAD_EVT[3..0] TRUE RANDOM 32-BIT CRC GENERATOR CALCULATION UNIT 5 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 2.2 Configuration Summary Table 2-1. Sub Series Summary Feature ATSAM4LC ATSAM4LS SEGMENT LCD Yes No AESA Yes No USB Device + Host Device Only Table 2-2. ATSAM4LC Configuration Summary Feature ATSAM4LC8/4/2C ATSAM4LC8/4/2B ATSAM4LC8/4/2A Number of Pins 100 64 48 Max Frequency 48MHz Flash 512/256/128KB SRAM 64/32/32KB SEGMENT LCD 4x40 4x23 4x13 GPIO 75 43 27 High-drive pins 6 3 1 External Interrupts 8 + 1 NMI 1 Master + 1 TWI 2 Masters + 2 Masters/Slaves Master/Slave 3 in LC sub series USART 4 4 in LS sub series PICOUART 1 0 Peripheral DMA Channels 16 AESA 1 Peripheral Event System 1 SPI 1 Asynchronous Timers 1 Timer/Counter Channels 6 3 Parallel Capture Inputs 8 Frequency Meter 1 Watchdog Timer 1 Power Manager 1 Glue Logic LUT 2 1 6 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 2-2. ATSAM4LC Configuration Summary Feature ATSAM4LC8/4/2C ATSAM4LC8/4/2B ATSAM4LC8/4/2A Digital Frequency Locked Loop 20-150MHz (DFLL) Phase Locked Loop 48-240MHz (PLL) Crystal Oscillator 0.6-30MHz (OSC0) Crystal Oscillator 32kHz (OSC32K) Oscillators RC Oscillator 80MHz (RC80M) RC Oscillator 4,8,12MHz (RCFAST) RC Oscillator 115kHz (RCSYS) RC Oscillator 32kHz (RC32K) ADC 15-channel 7-channel 3-channel DAC 1-channel Analog Comparators 4 2 1 CATB Sensors 32 32 26 USB 1 Audio Bitstream DAC 1 IIS Controller 1 TQFP/QFN/ Packages TQFP/VFBGA TQFP/QFN WLCSP . Table 2-3. ATSAM4LS Configuration Summary Feature ATSAM4LS8/4/2C ATSAM4LS8/4/2B ATSAM4LS8/4/2A Number of Pins 100 64 48 Max Frequency 48MHz Flash 512/256/128KB SRAM 64/32/32KB SEGMENT LCD NA GPIO 80 48 32 High-drive pins 6 3 1 External Interrupts 8 + 1 NMI 1 Master + 1 TWI 2 Masters + 2 Masters/Slaves Master/Slave 3 in LC sub series USART 4 4 in LS sub series PICOUART 1 0 Peripheral DMA Channels 16 AESA NA Peripheral Event System 1 SPI 1 Asynchronous Timers 1 7 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 2-3. ATSAM4LS Configuration Summary Feature ATSAM4LS8/4/2C ATSAM4LS8/4/2B ATSAM4LS8/4/2A Timer/Counter Channels 6 3 Parallel Capture Inputs 8 Frequency Meter 1 Watchdog Timer 1 Power Manager 1 Glue Logic LUT 2 1 Digital Frequency Locked Loop 20-150MHz (DFLL) Phase Locked Loop 48-240MHz (PLL) Crystal Oscillator 0.6-30MHz (OSC0) Crystal Oscillator 32kHz (OSC32K) Oscillators RC Oscillator 80MHz (RC80M) RC Oscillator 4,8,12MHz (RCFAST) RC Oscillator 115kHz (RCSYS) RC Oscillator 32kHz (RC32K) ADC 15-channel 7-channel 3-channel DAC 1-channel Analog Comparators 4 2 1 CATB Sensors 32 32 26 USB 1 Audio Bitstream DAC 1 IIS Controller 1 TQFP/QFN/ Packages TQFP/VFBGA TQFP/QFN WLCSP 8 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 3. Package and Pinout 3.1 Package The device pins are multiplexed with peripheral functions as described in Section 3.2 ”Peripheral Multiplexing on I/O lines” on page 19. 3.1.1 ATSAM4LCx Pinout Figure 3-1. ATSAM4LC TQFP100 Pinout N PB11PB10PB09PB08PC23PC22PC21PC20PA17PA16PA15PA14PA13PC19PC18PC17PC16PC15VLCDIGNDBIASLBIASHVLCDCAPLCAPH 5432109876543210987654321 7777776666666666555555555 PA18 76 50 PA12 PA19 77 49 PA11 PA20 78 48 PA10 PC24 79 47 PA09 PC25 80 46 PB07 PC26 81 45 PB06 PC27 82 44 PA08 PC28 83 43 PC14 PC29 84 42 PC13 PC30 85 41 PC12 PC31 86 40 PC11 VDDIO 87 39 PC10 VDDIO 88 38 PC09 PB12 89 37 PC08 PB13 90 36 PC07 PA21 91 35 VDDANA PA22 92 34 ADVREFP PB14 93 33 GNDANA PB15 94 32 ADVREFN PA23 95 31 PA07 PA24 96 30 PA06 VDDIO 97 29 PB05 PA25 98 28 PB04 PA26 99 27 XOUT32 GND 100 26 XIN32 1111111111222222 1234567890123456789012345 PPPPPPGVPPPPRVGVVTPPPPPPP CCCCAANDCCCAEDNDDCABBBBAA 000000DD0000SDDDDK0000000 012301 IO4562ETCO OUIN 3012345 _NR T E 9 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Figure 3-2. ATSAM4LC VFBGA100 Pinout 1 2 3 4 5 6 7 8 9 10 A VDD PA05 PA04 GND VDDIN VDDOUT PA02 VDDIO GND PC00 CORE B PB05 XIN32 PA03 TCK RESET_N PC06 PC03 PA01 PA00 GND C PB04 XOUT32 PA06 PB03 PC04 PC05 PC02 PC01 PA26 VDDIO D AD GNDANA PA07 PC10 PB01 PA23 PB14 PB15 PA25 PA24 VREFN E AD VDDANA PC08 PC11 PB02 VDDIO PB12 PB13 PA21 PA22 VREFP F PC09 PC07 PC12 PC13 PA09 PC27 PC29 PC30 PC31 VDDIO G PC14 PA08 PB06 PC19 PA15 PB08 PB09 PB10 PC26 PC28 H PB07 PA10 PA11 PC17 PA13 PA17 PC20 PC23 PC25 PA20 J CAPL PA12 PB00 BIASL PC15 PC16 PA16 PC22 PC24 PA19 K CAPH VLCD BIASH GND VLCDIN PC18 PA14 PC21 PB11 PA18 10 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Figure 3-3. ATSAM4LC WLCSP64 Pinout 1 2 3 4 5 6 7 8 A AD PB04 GNDANA VDDANA PA09 CAPL CAPH PA12 VREFP B PB03 XIN32 XOUT32 PA08 PB06 PA10 PA11 VLCD C VDDIN PB01 PA05 PA06 PA07 PB07 PA13 BIASH D VDDOUT PB00 PA04 PB05 PB12 PB08 PA14 BIASL E GND PA03 PB02 RESET_N PB13 PB09 PA15 GND F VDD TCK PA02 PB14 PA22 PB10 PA16 VLCDIN CORE G GND PA26 PA24 PA00 PA01 PA19 PA18 PA17 H VDDIO PA25 PA23 PB15 PA21 VDDIO PA20 PB11 11 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Figure 3-4. ATSAM4LC TQFP64/QFN64 Pinout N PB11PB10PB09PB08PA17PA16PA15PA14PA13VLCDIGNDBIASLBIASHVLCDCAPLCAPH 8765432109876543 4444444443333333 PA18 49 32 PA12 PA19 50 31 PA11 PA20 51 30 PA10 VDDIO 52 29 PA09 PB12 53 28 PB07 PB13 54 27 PB06 PA21 55 26 PA08 PA22 56 25 VDDANA PB14 57 24 ADVREFP PB15 58 23 GNDANA PA23 59 22 PA07 PA24 60 21 PA06 VDDIO 61 20 PB05 PA25 62 19 PB04 PA26 63 18 XOUT32 GND 64 17 XIN32 1111111 1234567890123456 PPPRVGVVTPPPPPPP AAAEDNDDCABBBBAA 000SDDDDK0000000 012EC OIN 3012345 TO U _NR T E 12 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Figure 3-5. ATSAM4LC TQFP48/QFN48 Pinout N 1716151413CDIDSLSHCDPLPH AAAAALNAALAA PPPPPVGBIBIVCC 654321098765 333333322222 PA18 37 24 PA12 PA19 38 23 PA11 PA20 39 22 PA10 VDDIO 40 21 PA09 PA21 41 20 PA08 PA22 42 19 VDDANA PA23 43 18 ADVREFP PA24 44 17 GNDANA VDDIO 45 16 PA07 PA25 46 15 PA06 PA26 47 14 XOUT32 GND 48 13 XIN32 111 123456789012 PPPRVGVVTPPP AAAEDNDDCAAA 000SDDDDK000 012EC OI 345 N TO U _R T N E 13 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 3.1.2 ATSAM4LSx Pinout Figure 3-6. ATSAM4LS TQFP100 Pinout O 1110090823222120171615141319181716153130DID292827 BBBBCCCCAAAAACCCCCAADNAAA PPPPPPPPPPPPPPPPPPPPVGPPP 5432109876543210987654321 7777776666666666555555555 PA18 76 50 PA12 PA19 77 49 PA11 PA20 78 48 PA10 PC24 79 47 PA09 PC25 80 46 PB07 PC26 81 45 PB06 PC27 82 44 PA08 PC28 83 43 PC14 PC29 84 42 PC13 PC30 85 41 PC12 PC31 86 40 PC11 VDDIO 87 39 PC10 VDDIO 88 38 PC09 PB12 89 37 PC08 PB13 90 36 PC07 PA21 91 35 VDDANA PA22 92 34 ADVREFP PB14 93 33 GNDANA PB15 94 32 ADVREFN PA23 95 31 PA07 PA24 96 30 PA06 VDDIO 97 29 PB05 PA25 98 28 PB04 PA26 99 27 XOUT32 GND 100 26 XIN32 1111111111222222 1234567890123456789012345 PPPPPPGVPPPPRVGVVTPPPPPPP CCCCAANDCCCAEDNDDCABBBBAA 000000DD0000SDDDDK0000000 012301 IO4562ETCO OUIN 3012345 _NR T E 14 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Figure 3-7. ATSAM4LS VFBGA100 Pinout 1 2 3 4 5 6 7 8 9 10 A VDD PA05 PA04 GND VDDIN VDDOUT PA02 VDDIO GND PC00 CORE B PB05 XIN32 PA03 TCK RESET_N PC06 PC03 PA01 PA00 GND C PB04 XOUT32 PA06 PB03 PC04 PC05 PC02 PC01 PA26 VDDIO D AD GNDANA PA07 PC10 PB01 PA23 PB14 PB15 PA25 PA24 VREFN E AD VDDANA PC08 PC11 PB02 VDDIO PB12 PB13 PA21 PA22 VREFP F PC09 PC07 PC12 PC13 PA09 PC27 PC29 PC30 PC31 VDDIO G PC14 PA08 PB06 PC19 PA15 PB08 PB09 PB10 PC26 PC28 H PB07 PA10 PA11 PC17 PA13 PA17 PC20 PC23 PC25 PA20 J PA28 PA12 PB00 VDDIO PC15 PC16 PA16 PC22 PC24 PA19 K PA27 PA29 GND PA30 PA31 PC18 PA14 PC21 PB11 PA18 15 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Figure 3-8. ATSAM4LS WLCSP64 Pinout 1 2 3 4 5 6 7 8 A AD PB04 GNDANA VDDANA PA09 PA28 PA27 PA12 VREFP B PB03 XIN32 XOUT32 PA08 PB06 PA10 PA11 PA29 C VDDIN PB01 PA05 PA06 PA07 PB07 PA13 GND D VDDOUT PB00 PA04 PB05 PB12 PB08 PA14 VDDIO E GND PA03 PB02 RESET_N PB13 PB09 PA15 PA30 F VDD TCK PA02 PB14 PA22 PB10 PA16 PA31 CORE G GND PA26 PA24 PA00 PA01 PA19 PA18 PA17 H VDDIO PA25 PA23 PB15 PA21 VDDIO PA20 PB11 16 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Figure 3-9. ATSAM4LS TQFP64/QFN64 Pinout O 1110090817161514133130DID292827 BBBBAAAAAAADNAAA PPPPPPPPPPPVGPPP 8765432109876543 4444444443333333 PA18 49 32 PA12 PA19 50 31 PA11 PA20 51 30 PA10 VDDIO 52 29 PA09 PB12 53 28 PB07 PB13 54 27 PB06 PA21 55 26 PA08 PA22 56 25 VDDANA PB14 57 24 ADVREFP PB15 58 23 GNDANA PA23 59 22 PA07 PA24 60 21 PA06 VDDIO 61 20 PB05 PA25 62 19 PB04 PA26 63 18 XOUT32 GND 64 17 XIN32 1111111 1234567890123456 PPPRVGVVTPPPPPPP AAAEDNDDCABBBBAA 000SDDDDK0000000 012ETCO OUIN 3012345 _NR T E 17 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Figure 3-10. ATSAM4LS TQFP48/QFN48 Pinout O 17161514133130DID292827 AAAAAAADNAAA PPPPPPPVGPPP 654321098765 333333322222 PA18 37 24 PA12 PA19 38 23 PA11 PA20 39 22 PA10 VDDIO 40 21 PA09 PA21 41 20 PA08 PA22 42 19 VDDANA PA23 43 18 ADVREFP PA24 44 17 GNDANA VDDIO 45 16 PA07 PA25 46 15 PA06 PA26 47 14 XOUT32 GND 48 13 XIN32 111 123456789012 PPPRVGVVTPPP AAAEDNDDCAAA 000SDDDDK000 012EC OIN 345 TO U _NR T E See Section 3.3 ”Signals Description” on page 31 for a description of the various peripheral signals. Refer to ”Electrical Characteristics” on page 99 for a description of the electrical properties of the pin types used. 18 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 3.2 Peripheral Multiplexing on I/O lines 3.2.1 Multiplexed Signals Each GPIO line can be assigned to one of the peripheral functions. The following tables (Section 3-1 ”100-pin GPIO Controller Function Multiplexing” on page 19 to Section 3-4 ”48-pin GPIO Controller Function Multiplexing” on page 28) describes the peripheral signals multiplexed to the GPIO lines. Peripheral functions that are not relevant in some parts of the family are grey-shaded. For description of differents Supply voltage source, refer to the Section 6. ”Power and Startup Considerations” on page 46. Table 3-1. 100-pin GPIO Controller Function Multiplexing (Sheet 1 of 4) C S L L 4 4 M M y ATSA ATSA Pin GPIO Suppl GPIO Functions QFN VFBGA QFN VFBGA A B C D E F G 5 B9 5 B9 PA00 0 VDDIO 6 B8 6 B8 PA01 1 VDDIO SCIF SPI CATB 12 A7 12 A7 PA02 2 VDDIN GCLK0 NPCS0 DIS SPI 19 B3 19 B3 PA03 3 VDDIN MISO ADCIFE USART0 EIC GLOC CATB 24 A2 24 A2 PA04 4 VDDANA AD0 CLK EXTINT2 IN1 SENSE0 ADCIFE USART0 EIC GLOC ADCIFE CATB 25 A1 25 A1 PA05 5 VDDANA AD1 RXD EXTINT3 IN2 TRIGGER SENSE1 DACC USART0 EIC GLOC ACIFC CATB 30 C3 30 C3 PA06 6 VDDANA VOUT RTS EXTINT1 IN0 ACAN0 SENSE2 ADCIFE USART0 EIC GLOC ACIFC CATB 31 D3 31 D3 PA07 7 VDDANA AD2 TXD EXTINT4 IN3 ACAP0 SENSE3 USART0 TC0 PEVC GLOC LCDCA CATB 44 G2 44 G2 PA08 8 LCDA RTS A0 PAD EVT0 OUT0 SEG23 SENSE4 USART0 TC0 PEVC PARC LCDCA CATB 47 F5 47 F5 PA09 9 LCDA CTS B0 PAD EVT1 PCDATA0 COM3 SENSE5 USART0 TC0 PEVC PARC LCDCA CATB 48 H2 48 H2 PA10 10 LCDA CLK A1 PAD EVT2 PCDATA1 COM2 SENSE6 USART0 TC0 PEVC PARC LCDCA CATB 49 H3 49 H3 PA11 11 LCDA RXD B1 PAD EVT3 PCDATA2 COM1 SENSE7 USART0 TC0 PARC LCDCA CATB 50 J2 50 J2 PA12 12 LCDA TXD A2 PCDATA3 COM0 DIS USART1 TC0 SPI PARC LCDCA CATB 63 H5 63 H5 PA13 13 LCDA RTS B2 NPCS1 PCDATA4 SEG5 SENSE8 USART1 TC0 SPI PARC LCDCA CATB 64 K7 64 K7 PA14 14 LCDA CLK CLK0 NPCS2 PCDATA5 SEG6 SENSE9 USART1 TC0 SPI PARC LCDCA CATB 65 G5 65 G5 PA15 15 LCDA RXD CLK1 NPCS3 PCDATA6 SEG7 SENSE10 19 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 3-1. 100-pin GPIO Controller Function Multiplexing (Sheet 2 of 4) C S L L 4 4 M M y ATSA ATSA Pin GPIO Suppl GPIO Functions QFN VFBGA QFN VFBGA A B C D E F G USART1 TC0 EIC PARC LCDCA CATB 66 J7 66 J7 PA16 16 LCDA TXD CLK2 EXTINT1 PCDATA7 SEG8 SENSE11 USART2 ABDACB EIC PARC LCDCA CATB 67 H6 67 H6 PA17 17 LCDA RTS DAC0 EXTINT2 PCCK SEG9 SENSE12 USART2 ABDACB EIC PARC LCDCA CATB 76 K10 76 K10 PA18 18 LCDA CLK DACN0 EXTINT3 PCEN1 SEG18 SENSE13 USART2 ABDACB EIC PARC SCIF LCDCA CATB 77 J10 77 J10 PA19 19 LCDA RXD DAC1 EXTINT4 PCEN2 GCLK0 SEG19 SENSE14 USART2 ABDACB EIC GLOC SCIF LCDCA CATB 78 H10 78 H10 PA20 20 LCDA TXD DACN1 EXTINT5 IN0 GCLK1 SEG20 SENSE15 SPI USART1 EIC GLOC TWIM2 LCDCA CATB 91 E9 91 E9 PA21 21 LCDC MISO CTS EXTINT6 IN1 TWD SEG34 SENSE16 SPI USART2 EIC GLOC TWIM2 LCDCA CATB 92 E10 92 E10 PA22 22 LCDC MOSI CTS EXTINT7 IN2 TWCK SEG35 SENSE17 SPI TWIMS0 EIC GLOC SCIF LCDCA CATB 95 D6 95 D6 PA23 23 LCDC SCK TWD EXTINT8 IN3 GCLK IN0 SEG38 DIS SPI TWIMS0 GLOC SCIF LCDCA CATB 96 D10 96 D10 PA24 24 LCDC NPCS0 TWCK OUT0 GCLK IN1 SEG39 SENSE18 USBC USART2 CATB 98 D9 98 D9 PA25 25 VDDIO DM RXD SENSE19 USBC USART2 CATB 99 C9 99 C9 PA26 26 VDDIO DP TXD SENSE20 SPI IISC ABDACB GLOC USART3 CATB 51 K1 PA27 27 LCDA MISO ISCK DAC0 IN4 RTS SENSE0 SPI IISC ABDACB GLOC USART3 CATB 52 J1 PA28 28 LCDA MOSI ISDI DACN0 IN5 CTS SENSE1 SPI IISC ABDACB GLOC USART3 CATB 53 K2 PA29 29 LCDA SCK IWS DAC1 IN6 CLK SENSE2 SPI IISC ABDACB GLOC USART3 CATB 56 K4 PA30 30 LCDA NPCS0 ISDO DACN1 IN7 RXD SENSE3 SPI IISC ABDACB GLOC USART3 CATB 57 K5 PA31 31 LCDA NPCS1 IMCK CLK OUT1 TXD DIS TWIMS1 USART0 CATB 20 J3 20 J3 PB00 32 VDDIN TWD RXD SENSE21 TWIMS1 USART0 EIC CATB 21 D5 21 D5 PB01 33 VDDIN TWCK TXD EXTINT0 SENSE22 ADCIFE USART1 ABDACB IISC ACIFC CATB 22 E5 22 E5 PB02 34 VDDANA AD3 RTS DAC0 ISCK ACBN0 SENSE23 ADCIFE USART1 ABDACB IISC ACIFC CATB 23 C4 23 C4 PB03 35 VDDANA AD4 CLK DACN0 ISDI ACBP0 DIS ADCIFE USART1 ABDACB IISC DACC CATB 28 C1 28 C1 PB04 36 VDDANA AD5 RXD DAC1 ISDO EXT TRIG0 SENSE24 ADCIFE USART1 ABDACB IISC CATB 29 B1 29 B1 PB05 37 VDDANA AD6 TXD DACN1 IMCK SENSE25 USART3 GLOC IISC LCDCA CATB 45 G3 45 G3 PB06 38 LCDA RTS IN4 IWS SEG22 SENSE26 USART3 GLOC TC0 LCDCA CATB 46 H1 46 H1 PB07 39 LCDA CTS IN5 A0 SEG21 SENSE27 20 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 3-1. 100-pin GPIO Controller Function Multiplexing (Sheet 3 of 4) C S L L 4 4 M M y ATSA ATSA Pin GPIO Suppl GPIO Functions QFN VFBGA QFN VFBGA A B C D E F G USART3 GLOC TC0 LCDCA CATB 72 G6 72 G6 PB08 40 LCDA CLK IN6 B0 SEG14 SENSE28 USART3 PEVC GLOC TC0 LCDCA CATB 73 G7 73 G7 PB09 41 LCDA RXD PAD EVT2 IN7 A1 SEG15 SENSE29 USART3 PEVC GLOC TC0 SCIF LCDCA CATB 74 G8 74 G8 PB10 42 LCDA TXD PAD EVT3 OUT1 B1 GCLK0 SEG16 SENSE30 USART0 SPI TC0 SCIF LCDCA CATB 75 K9 75 K9 PB11 43 LCDA CTS NPCS2 A2 GCLK1 SEG17 SENSE31 USART0 SPI PEVC TC0 SCIF LCDCA CATB 89 E7 89 E7 PB12 44 LCDC RTS NPCS3 PAD EVT0 B2 GCLK2 SEG32 DIS USART0 SPI PEVC TC0 SCIF LCDCA CATB 90 E8 90 E8 PB13 45 LCDC CLK NPCS1 PAD EVT1 CLK0 GCLK3 SEG33 SENSE0 USART0 SPI TWIM3 TC0 SCIF LCDCA CATB 93 D7 93 D7 PB14 46 LCDC RXD MISO TWD CLK1 GCLK IN0 SEG36 SENSE1 USART0 SPI TWIM3 TC0 SCIF LCDCA CATB 94 D8 94 D8 PB15 47 LCDC TXD MOSI TWCK CLK2 GCLK IN1 SEG37 SENSE2 SPI USART0 TC1 CATB 1 A10 1 A10 PC00 64 VDDIO NPCS2 CLK A0 SENSE3 SPI USART0 TC1 CATB 2 C8 2 C8 PC01 65 VDDIO NPCS3 RTS B0 SENSE4 SPI USART0 USART0 TC1 CATB 3 C7 3 C7 PC02 66 VDDIO NPCS1 CTS RXD A1 SENSE5 SPI EIC USART0 TC1 CATB 4 B7 4 B7 PC03 67 VDDIO NPCS0 EXTINT5 TXD B1 SENSE6 SPI EIC TC1 CATB 9 C5 9 C5 PC04 68 VDDIO MISO EXTINT6 A2 SENSE7 SPI EIC TC1 CATB 10 C6 10 C6 PC05 69 VDDIO MOSI EXTINT7 B2 DIS SPI EIC TC1 CATB 11 B6 11 B6 PC06 70 VDDIO SCK EXTINT8 CLK0 SENSE8 ADCIFE USART2 PEVC TC1 CATB 36 F2 36 F2 PC07 71 VDDANA AD7 RTS PAD EVT0 CLK1 SENSE9 ADCIFE USART2 PEVC TC1 USART2 CATB 37 E3 37 E3 PC08 72 VDDANA AD8 CLK PAD EVT1 CLK2 CTS SENSE10 ADCIFE USART3 ABDACB IISC ACIFC CATB 38 F1 38 F1 PC09 73 VDDANA AD9 RXD DAC0 ISCK ACAN1 SENSE11 ADCIFE USART3 ABDACB IISC ACIFC CATB 39 D4 39 D4 PC10 74 VDDANA AD10 TXD DACN0 ISDI ACAP1 SENSE12 ADCIFE USART2 PEVC CATB 40 E4 40 E4 PC11 75 VDDANA AD11 RXD PAD EVT2 SENSE13 ADCIFE USART2 ABDACB IISC CATB 41 F3 41 F3 PC12 76 VDDANA AD12 TXD CLK IWS SENSE14 ADCIFE USART3 ABDACB IISC ACIFC CATB 42 F4 42 F4 PC13 77 VDDANA AD13 RTS DAC1 ISDO ACBN1 SENSE15 ADCIFE USART3 ABDACB IISC ACIFC CATB 43 G1 43 G1 PC14 78 VDDANA AD14 CLK DACN1 IMCK ACBP1 DIS TC1 GLOC LCDCA CATB 58 J5 58 J5 PC15 79 LCDA A0 IN4 SEG0 SENSE16 21 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 3-1. 100-pin GPIO Controller Function Multiplexing (Sheet 4 of 4) C S L L 4 4 M M y ATSA ATSA Pin GPIO Suppl GPIO Functions QFN VFBGA QFN VFBGA A B C D E F G TC1 GLOC LCDCA CATB 59 J6 59 J6 PC16 80 LCDA B0 IN5 SEG1 SENSE17 TC1 GLOC LCDCA CATB 60 H4 60 H4 PC17 81 LCDA A1 IN6 SEG2 SENSE18 TC1 GLOC LCDCA CATB 61 K6 61 K6 PC18 82 LCDA B1 IN7 SEG3 SENSE19 TC1 GLOC LCDCA CATB 62 G4 62 G4 PC19 83 LCDA A2 OUT1 SEG4 SENSE20 TC1 LCDCA CATB 68 H7 68 H7 PC20 84 LCDA B2 SEG10 SENSE21 TC1 PARC LCDCA CATB 69 K8 69 K8 PC21 85 LCDA CLK0 PCCK SEG11 SENSE22 TC1 PARC LCDCA CATB 70 J8 70 J8 PC22 86 LCDA CLK1 PCEN1 SEG12 SENSE23 TC1 PARC LCDCA CATB 71 H8 71 H8 PC23 87 LCDA CLK2 PCEN2 SEG13 DIS USART1 EIC PEVC PARC LCDCA CATB 79 J9 79 J9 PC24 88 LCDB RTS EXTINT1 PAD EVT0 PCDATA0 SEG24 SENSE24 USART1 EIC PEVC PARC LCDCA CATB 80 H9 80 H9 PC25 89 LCDB CLK EXTINT2 PAD EVT1 PCDATA1 SEG25 SENSE25 USART1 EIC PEVC PARC SCIF LCDCA CATB 81 G9 81 G9 PC26 90 LCDB RXD EXTINT3 PAD EVT2 PCDATA2 GCLK0 SEG26 SENSE26 USART1 EIC PEVC PARC SCIF LCDCA CATB 82 F6 82 F6 PC27 91 LCDB TXD EXTINT4 PAD EVT3 PCDATA3 GCLK1 SEG27 SENSE27 USART3 SPI GLOC PARC SCIF LCDCA CATB 83 G10 83 G10 PC28 92 LCDB RXD MISO IN4 PCDATA4 GCLK2 SEG28 SENSE28 USART3 SPI GLOC PARC SCIF LCDCA CATB 84 F7 84 F7 PC29 93 LCDB TXD MOSI IN5 PCDATA5 GCLK3 SEG29 SENSE29 USART3 SPI GLOC PARC SCIF LCDCA CATB 85 F8 85 F8 PC30 94 LCDB RTS SCK IN6 PCDATA6 GCLK IN0 SEG30 SENSE30 USART3 SPI GLOC PARC SCIF LCDCA CATB 86 F9 86 F9 PC31 95 LCDB CLK NPCS0 OUT1 PCDATA7 GCLK IN1 SEG31 SENSE31 Table 3-2. 64-pin GPIO Controller Function Multiplexing (Sheet 1 of 3) C S L L 4 4 M M ATSA ATSA Pin GPIO upply GPIO Functions S QFP QFP QFN QFN A B C D E F G 1 1 PA00 0 VDDIO 2 2 PA01 1 VDDIO SCIF SPI CATB 3 3 PA02 2 VDDIN GCLK0 NPCS0 DIS SPI 10 10 PA03 3 VDDIN MISO 22 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 3-2. 64-pin GPIO Controller Function Multiplexing (Sheet 2 of 3) C S L L 4 4 M M ATSA ATSA Pin GPIO upply GPIO Functions S QFP QFP QFN QFN A B C D E F G ADCIFE USART0 EIC GLOC CATB 15 15 PA04 4 VDDANA AD0 CLK EXTINT2 IN1 SENSE0 ADCIFE USART0 EIC GLOC ADCIFE CATB 16 16 PA05 5 VDDANA AD1 RXD EXTINT3 IN2 TRIGGER SENSE1 DACC USART0 EIC GLOC ACIFC CATB 21 21 PA06 6 VDDANA VOUT RTS EXTINT1 IN0 ACAN0 SENSE2 ADCIFE USART0 EIC GLOC ACIFC CATB 22 22 PA07 7 VDDANA AD2 TXD EXTINT4 IN3 ACAP0 SENSE3 USART0 TC0 PEVC GLOC LCDCA CATB 26 26 PA08 8 LCDA RTS A0 PAD EVT0 OUT0 SEG23 SENSE4 USART0 TC0 PEVC PARC LCDCA CATB 29 29 PA09 9 LCDA CTS B0 PAD EVT1 PCDATA0 COM3 SENSE5 USART0 TC0 PEVC PARC LCDCA CATB 30 30 PA10 10 LCDA CLK A1 PAD EVT2 PCDATA1 COM2 SENSE6 USART0 TC0 PEVC PARC LCDCA CATB 31 31 PA11 11 LCDA RXD B1 PAD EVT3 PCDATA2 COM1 SENSE7 USART0 TC0 PARC LCDCA CATB 32 32 PA12 12 LCDA TXD A2 PCDATA3 COM0 DIS USART1 TC0 SPI PARC LCDCA CATB 40 40 PA13 13 LCDA RTS B2 NPCS1 PCDATA4 SEG5 SENSE8 USART1 TC0 SPI PARC LCDCA CATB 41 41 PA14 14 LCDA CLK CLK0 NPCS2 PCDATA5 SEG6 SENSE9 USART1 TC0 SPI PARC LCDCA CATB 42 42 PA15 15 LCDA RXD CLK1 NPCS3 PCDATA6 SEG7 SENSE10 USART1 TC0 EIC PARC LCDCA CATB 43 43 PA16 16 LCDA TXD CLK2 EXTINT1 PCDATA7 SEG8 SENSE11 USART2 ABDACB EIC PARC LCDCA CATB 44 44 PA17 17 LCDA RTS DAC0 EXTINT2 PCCK SEG9 SENSE12 USART2 ABDACB EIC PARC LCDCA CATB 49 49 PA18 18 LCDA CLK DACN0 EXTINT3 PCEN1 SEG18 SENSE13 USART2 ABDACB EIC PARC SCIF LCDCA CATB 50 50 PA19 19 LCDA RXD DAC1 EXTINT4 PCEN2 GCLK0 SEG19 SENSE14 USART2 ABDACB EIC GLOC SCIF LCDCA CATB 51 51 PA20 20 LCDA TXD DACN1 EXTINT5 IN0 GCLK1 SEG20 SENSE15 SPI USART1 EIC GLOC TWIM2 LCDCA CATB 55 55 PA21 21 LCDC MISO CTS EXTINT6 IN1 TWD SEG34 SENSE16 SPI USART2 EIC GLOC TWIM2 LCDCA CATB 56 56 PA22 22 LCDC MOSI CTS EXTINT7 IN2 TWCK SEG35 SENSE17 SPI TWIMS0 EIC GLOC SCIF LCDCA CATB 59 59 PA23 23 LCDC SCK TWD EXTINT8 IN3 GCLK IN0 SEG38 DIS SPI TWIMS0 GLOC SCIF LCDCA CATB 60 60 PA24 24 LCDC NPCS0 TWCK OUT0 GCLK IN1 SEG39 SENSE18 USBC USART2 CATB 62 62 PA25 25 VDDIO DM RXD SENSE19 USBC USART2 CATB 63 63 PA26 26 VDDIO DP TXD SENSE20 23 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 3-2. 64-pin GPIO Controller Function Multiplexing (Sheet 3 of 3) C S L L 4 4 M M ATSA ATSA Pin GPIO upply GPIO Functions S QFP QFP QFN QFN A B C D E F G SPI IISC ABDACB GLOC USART3 CATB 33 PA27 27 LCDA MISO ISCK DAC0 IN4 RTS SENSE0 SPI IISC ABDACB GLOC USART3 CATB 34 PA28 28 LCDA MOSI ISDI DACN0 IN5 CTS SENSE1 SPI IISC ABDACB GLOC USART3 CATB 35 PA29 29 LCDA SCK IWS DAC1 IN6 CLK SENSE2 SPI IISC ABDACB GLOC USART3 CATB 38 PA30 30 LCDA NPCS0 ISDO DACN1 IN7 RXD SENSE3 SPI IISC ABDACB GLOC USART3 CATB 39 PA31 31 LCDA NPCS1 IMCK CLK OUT1 TXD DIS TWIMS1 USART0 CATB 11 11 PB00 32 VDDIN TWD RXD SENSE21 TWIMS1 USART0 EIC CATB 12 12 PB01 33 VDDIN TWCK TXD EXTINT0 SENSE22 ADCIFE USART1 ABDACB IISC ACIFC CATB 13 13 PB02 34 VDDANA AD3 RTS DAC0 ISCK ACBN0 SENSE23 ADCIFE USART1 ABDACB IISC ACIFC CATB 14 14 PB03 35 VDDANA AD4 CLK DACN0 ISDI ACBP0 DIS ADCIFE USART1 ABDACB IISC DACC CATB 19 19 PB04 36 VDDANA AD5 RXD DAC1 ISDO EXT TRIG0 SENSE24 ADCIFE USART1 ABDACB IISC CATB 20 20 PB05 37 VDDANA AD6 TXD DACN1 IMCK SENSE25 USART3 GLOC IISC LCDCA CATB 27 27 PB06 38 LCDA RTS IN4 IWS SEG22 SENSE26 USART3 GLOC TC0 LCDCA CATB 28 28 PB07 39 LCDA CTS IN5 A0 SEG21 SENSE27 USART3 GLOC TC0 LCDCA CATB 45 45 PB08 40 LCDA CLK IN6 B0 SEG14 SENSE28 USART3 PEVC GLOC TC0 LCDCA CATB 46 46 PB09 41 LCDA RXD PAD EVT2 IN7 A1 SEG15 SENSE29 USART3 PEVC GLOC TC0 SCIF LCDCA CATB 47 47 PB10 42 LCDA TXD PAD EVT3 OUT1 B1 GCLK0 SEG16 SENSE30 USART0 SPI TC0 SCIF LCDCA CATB 48 48 PB11 43 LCDA CTS NPCS2 A2 GCLK1 SEG17 SENSE31 USART0 SPI PEVC TC0 SCIF LCDCA CATB 53 53 PB12 44 LCDC RTS NPCS3 PAD EVT0 B2 GCLK2 SEG32 DIS USART0 SPI PEVC TC0 SCIF LCDCA CATB 54 54 PB13 45 LCDC CLK NPCS1 PAD EVT1 CLK0 GCLK3 SEG33 SENSE0 USART0 SPI TWIM3 TC0 SCIF LCDCA CATB 57 57 PB14 46 LCDC RXD MISO TWD CLK1 GCLK IN0 SEG36 SENSE1 USART0 SPI TWIM3 TC0 SCIF LCDCA CATB 58 58 PB15 47 LCDC TXD MOSI TWCK CLK2 GCLK IN1 SEG37 SENSE2 24 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 3-3. 64-pin GPIO Controller Function Multiplexing for WLCSP package (Sheet 1 of 3) C S L L 4 4 M M y TSA TSA Pin GPIO uppl GPIO Functions A A S WLCSP WLCSP A B C D E F G G4 G4 PA00 0 VDDIO G5 G5 PA01 1 VDDIO SCIF SPI CATB F3 F3 PA02 2 VDDIN GCLK0 NPCS0 DIS SPI E2 E2 PA03 3 VDDIN MISO ADCIFE USART0 EIC GLOC CATB D3 D3 PA04 4 VDDANA AD0 CLK EXTINT2 IN1 SENSE0 ADCIFE USART0 EIC GLOC ADCIFE CATB C3 C3 PA05 5 VDDANA AD1 RXD EXTINT3 IN2 TRIGGER SENSE1 DACC USART0 EIC GLOC ACIFC CATB C4 C4 PA06 6 VDDANA VOUT RTS EXTINT1 IN0 ACAN0 SENSE2 ADCIFE USART0 EIC GLOC ACIFC CATB C5 C5 PA07 7 VDDANA AD2 TXD EXTINT4 IN3 ACAP0 SENSE3 USART0 TC0 PEVC GLOC LCDCA CATB B4 B4 PA08 8 LCDA RTS A0 PAD EVT0 OUT0 SEG23 SENSE4 USART0 TC0 PEVC PARC LCDCA CATB A5 A5 PA09 9 LCDA CTS B0 PAD EVT1 PCDATA0 COM3 SENSE5 USART0 TC0 PEVC PARC LCDCA CATB B6 B6 PA10 10 LCDA CLK A1 PAD EVT2 PCDATA1 COM2 SENSE6 USART0 TC0 PEVC PARC LCDCA CATB B7 B7 PA11 11 LCDA RXD B1 PAD EVT3 PCDATA2 COM1 SENSE7 USART0 TC0 PARC LCDCA CATB A8 A8 PA12 12 LCDA TXD A2 PCDATA3 COM0 DIS USART1 TC0 SPI PARC LCDCA CATB C7 C7 PA13 13 LCDA RTS B2 NPCS1 PCDATA4 SEG5 SENSE8 USART1 TC0 SPI PARC LCDCA CATB D7 D7 PA14 14 LCDA CLK CLK0 NPCS2 PCDATA5 SEG6 SENSE9 USART1 TC0 SPI PARC LCDCA CATB E7 E7 PA15 15 LCDA RXD CLK1 NPCS3 PCDATA6 SEG7 SENSE10 USART1 TC0 EIC PARC LCDCA CATB F7 F7 PA16 16 LCDA TXD CLK2 EXTINT1 PCDATA7 SEG8 SENSE11 USART2 ABDACB EIC PARC LCDCA CATB G8 G8 PA17 17 LCDA RTS DAC0 EXTINT2 PCCK SEG9 SENSE12 USART2 ABDACB EIC PARC LCDCA CATB G7 G7 PA18 18 LCDA CLK DACN0 EXTINT3 PCEN1 SEG18 SENSE13 USART2 ABDACB EIC PARC SCIF LCDCA CATB G6 G6 PA19 19 LCDA RXD DAC1 EXTINT4 PCEN2 GCLK0 SEG19 SENSE14 USART2 ABDACB EIC GLOC SCIF LCDCA CATB H7 H7 PA20 20 LCDA TXD DACN1 EXTINT5 IN0 GCLK1 SEG20 SENSE15 SPI USART1 EIC GLOC TWIM2 LCDCA CATB H5 H5 PA21 21 LCDC MISO CTS EXTINT6 IN1 TWD SEG34 SENSE16 SPI USART2 EIC GLOC TWIM2 LCDCA CATB F5 F5 PA22 22 LCDC MOSI CTS EXTINT7 IN2 TWCK SEG35 SENSE17 25 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 3-3. 64-pin GPIO Controller Function Multiplexing for WLCSP package (Sheet 2 of 3) C S L L 4 4 M M y TSA TSA Pin GPIO uppl GPIO Functions A A S WLCSP WLCSP A B C D E F G SPI TWIMS0 EIC GLOC SCIF LCDCA CATB H3 H3 PA23 23 LCDC SCK TWD EXTINT8 IN3 GCLK IN0 SEG38 DIS SPI TWIMS0 GLOC SCIF LCDCA CATB G3 G3 PA24 24 LCDC NPCS0 TWCK OUT0 GCLK IN1 SEG39 SENSE18 USBC USART2 CATB H2 H2 PA25 25 VDDIO DM RXD SENSE19 USBC USART2 CATB G2 G2 PA26 26 VDDIO DP TXD SENSE20 SPI IISC ABDACB GLOC USART3 CATB A7 PA27 27 LCDA MISO ISCK DAC0 IN4 RTS SENSE0 SPI IISC ABDACB GLOC USART3 CATB A6 PA28 28 LCDA MOSI ISDI DACN0 IN5 CTS SENSE1 SPI IISC ABDACB GLOC USART3 CATB B8 PA29 29 LCDA SCK IWS DAC1 IN6 CLK SENSE2 SPI IISC ABDACB GLOC USART3 CATB E8 PA30 30 LCDA NPCS0 ISDO DACN1 IN7 RXD SENSE3 SPI IISC ABDACB GLOC USART3 CATB F8 PA31 31 LCDA NPCS1 IMCK CLK OUT1 TXD DIS TWIMS1 USART0 CATB D2 D2 PB00 32 VDDIN TWD RXD SENSE21 TWIMS1 USART0 EIC CATB C2 C2 PB01 33 VDDIN TWCK TXD EXTINT0 SENSE22 ADCIFE USART1 ABDACB IISC ACIFC CATB E3 E3 PB02 34 VDDANA AD3 RTS DAC0 ISCK ACBN0 SENSE23 ADCIFE USART1 ABDACB IISC ACIFC CATB B1 B1 PB03 35 VDDANA AD4 CLK DACN0 ISDI ACBP0 DIS ADCIFE USART1 ABDACB IISC DACC CATB A1 A1 PB04 36 VDDANA AD5 RXD DAC1 ISDO EXT TRIG0 SENSE24 ADCIFE USART1 ABDACB IISC CATB D4 D4 PB05 37 VDDANA AD6 TXD DACN1 IMCK SENSE25 USART3 GLOC IISC LCDCA CATB B5 B5 PB06 38 LCDA RTS IN4 IWS SEG22 SENSE26 USART3 GLOC TC0 LCDCA CATB C6 C6 PB07 39 LCDA CTS IN5 A0 SEG21 SENSE27 USART3 GLOC TC0 LCDCA CATB D6 D6 PB08 40 LCDA CLK IN6 B0 SEG14 SENSE28 USART3 PEVC GLOC TC0 LCDCA CATB E6 E6 PB09 41 LCDA RXD PAD EVT2 IN7 A1 SEG15 SENSE29 USART3 PEVC GLOC TC0 SCIF LCDCA CATB F6 F6 PB10 42 LCDA TXD PAD EVT3 OUT1 B1 GCLK0 SEG16 SENSE30 USART0 SPI TC0 SCIF LCDCA CATB H8 H8 PB11 43 LCDA CTS NPCS2 A2 GCLK1 SEG17 SENSE31 USART0 SPI PEVC TC0 SCIF LCDCA CATB D5 D5 PB12 44 LCDC RTS NPCS3 PAD EVT0 B2 GCLK2 SEG32 DIS 26 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 3-3. 64-pin GPIO Controller Function Multiplexing for WLCSP package (Sheet 3 of 3) C S L L 4 4 M M y TSA TSA Pin GPIO uppl GPIO Functions A A S WLCSP WLCSP A B C D E F G USART0 SPI PEVC TC0 SCIF LCDCA CATB E5 E5 PB13 45 LCDC CLK NPCS1 PAD EVT1 CLK0 GCLK3 SEG33 SENSE0 USART0 SPI TWIM3 TC0 SCIF LCDCA CATB F4 F4 PB14 46 LCDC RXD MISO TWD CLK1 GCLK IN0 SEG36 SENSE1 USART0 SPI TWIM3 TC0 SCIF LCDCA CATB H4 H4 PB15 47 LCDC TXD MOSI TWCK CLK2 GCLK IN1 SEG37 SENSE2 27 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 3-4. 48-pin GPIO Controller Function Multiplexing (Sheet 1 of 2) TSAM4LC TSAM4LS Pin GPIO Supply A B C GPIO FuDnctions E F G A A 1 1 PA00 0 VDDIO 2 2 PA01 1 VDDIO SCIF SPI CATB 3 3 PA02 2 VDDIN GCLK0 NPCS0 DIS SPI 10 10 PA03 3 VDDIN MISO ADCIFE USART0 EIC GLOC CATB 11 11 PA04 4 VDDANA AD0 CLK EXTINT2 IN1 SENSE0 ADCIFE USART0 EIC GLOC ADCIFE CATB 12 12 PA05 5 VDDANA AD1 RXD EXTINT3 IN2 TRIGGER SENSE1 DACC USART0 EIC GLOC ACIFC CATB 15 15 PA06 6 VDDANA VOUT RTS EXTINT1 IN0 ACAN0 SENSE2 ADCIFE USART0 EIC GLOC ACIFC CATB 16 16 PA07 7 VDDANA AD2 TXD EXTINT4 IN3 ACAP0 SENSE3 USART0 TC0 PEVC GLOC LCDCA CATB 20 20 PA08 8 LCDA RTS A0 PAD EVT0 OUT0 SEG23 SENSE4 USART0 TC0 PEVC PARC LCDCA CATB 21 21 PA09 9 LCDA CTS B0 PAD EVT1 PCDATA0 COM3 SENSE5 USART0 TC0 PEVC PARC LCDCA CATB 22 22 PA10 10 LCDA CLK A1 PAD EVT2 PCDATA1 COM2 SENSE6 USART0 TC0 PEVC PARC LCDCA CATB 23 23 PA11 11 LCDA RXD B1 PAD EVT3 PCDATA2 COM1 SENSE7 USART0 TC0 PARC LCDCA CATB 24 24 PA12 12 LCDA TXD A2 PCDATA3 COM0 DIS USART1 TC0 SPI PARC LCDCA CATB 32 32 PA13 13 LCDA RTS B2 NPCS1 PCDATA4 SEG5 SENSE8 USART1 TC0 SPI PARC LCDCA CATB 33 33 PA14 14 LCDA CLK CLK0 NPCS2 PCDATA5 SEG6 SENSE9 USART1 TC0 SPI PARC LCDCA CATB 34 34 PA15 15 LCDA RXD CLK1 NPCS3 PCDATA6 SEG7 SENSE10 USART1 TC0 EIC PARC LCDCA CATB 35 35 PA16 16 LCDA TXD CLK2 EXTINT1 PCDATA7 SEG8 SENSE11 USART2 ABDACB EIC PARC LCDCA CATB 36 36 PA17 17 LCDA RTS DAC0 EXTINT2 PCCK SEG9 SENSE12 USART2 ABDACB EIC PARC LCDCA CATB 37 37 PA18 18 LCDA CLK DACN0 EXTINT3 PCEN1 SEG18 SENSE13 USART2 ABDACB EIC PARC SCIF LCDCA CATB 38 38 PA19 19 LCDA RXD DAC1 EXTINT4 PCEN2 GCLK0 SEG19 SENSE14 USART2 ABDACB EIC GLOC SCIF LCDCA CATB 39 39 PA20 20 LCDA TXD DACN1 EXTINT5 IN0 GCLK1 SEG20 SENSE15 SPI USART1 EIC GLOC TWIM2 LCDCA CATB 41 41 PA21 21 LCDC MISO CTS EXTINT6 IN1 TWD SEG34 SENSE16 SPI USART2 EIC GLOC TWIM2 LCDCA CATB 42 42 PA22 22 LCDC MOSI CTS EXTINT7 IN2 TWCK SEG35 SENSE17 SPI TWIMS0 EIC GLOC SCIF LCDCA CATB 43 43 PA23 23 LCDC SCK TWD EXTINT8 IN3 GCLK IN0 SEG38 DIS 28 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 3-4. 48-pin GPIO Controller Function Multiplexing (Sheet 2 of 2) TSAM4LC TSAM4LS Pin GPIO Supply A B C GPIO FuDnctions E F G A A SPI TWIMS0 GLOC SCIF LCDCA CATB 44 44 PA24 24 LCDC NPCS0 TWCK OUT0 GCLK IN1 SEG39 SENSE18 USBC USART2 CATB 46 46 PA25 25 VDDIO DM RXD SENSE19 USBC USART2 CATB 47 47 PA26 26 VDDIO DP TXD SENSE20 SPI IISC ABDACB GLOC USART3 CATB 25 PA27 27 LCDA MISO ISCK DAC0 IN4 RTS SENSE0 SPI IISC ABDACB GLOC USART3 CATB 26 PA28 28 LCDA MOSI ISDI DACN0 IN5 CTS SENSE1 SPI IISC ABDACB GLOC USART3 CATB 27 PA29 29 LCDA SCK IWS DAC1 IN6 CLK SENSE2 SPI IISC ABDACB GLOC USART3 CATB 30 PA30 30 LCDA NPCS0 ISDO DACN1 IN7 RXD SENSE3 SPI IISC ABDACB GLOC USART3 CATB 31 PA31 31 LCDA NPCS1 IMCK CLK OUT1 TXD DIS 3.2.2 Peripheral Functions Each GPIO line can be assigned to one of several peripheral functions. The following table describes how the various peripheral functions are selected. The last listed function has priority in case multiple functions are enabled on the same pin. Table 3-5. Peripheral Functions Function Description GPIO Controller Function multiplexing GPIO and GPIO peripheral selection A to H JTAG port connections JTAG debug port Oscillators OSC0 3.2.3 JTAG Port Connections If the JTAG is enabled, the JTAG will take control over a number of pins, irrespectively of the I/O Controller configuration. Table 3-6. JTAG Pinout 48-pin 64-pin 64-pin 100-pin 100-ball Pin JTAG Packages QFP/QFN WLSCP QFN VFBGA Name Pin 10 10 E2 19 B3 PA03 TMS 43 59 H3 95 D6 PA23 TDO 44 60 G3 96 D10 PA24 TDI 9 9 F2 18 B4 TCK TCK 29 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 3.2.4 ITM Trace Connections If the ITM trace is enabled, the ITM will take control over the pin PA23, irrespectively of the I/O Controller configuration. The Serial Wire Trace signal is available on pin PA23 3.2.5 Oscillator Pinout The oscillators are not mapped to the normal GPIO functions and their muxings are controlled by registers in the System Control Interface (SCIF) or Backup System Control Interface (BSCIF). Refer to the Section 15. ”System Control Interface (SCIF)” on page 308 and Section 15. ”Backup System Control Interface (BSCIF)” on page 308 for more information about this. Table 3-7. Oscillator Pinout 48-pin Packages 64-pin QFN/QFP 64-pin WLCSP 100-pin Packages 100-ball VFBGA Pin Name Oscillator Pin 1 1 G4 5 B9 PA00 XIN0 13 17 B2 26 B2 XIN32 XIN32 2 2 G5 6 B8 PA01 XOUT0 14 18 B3 27 C2 XOUT32 XOUT32 30 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 3.3 Signals Description The following table gives details on signal names classified by peripheral. Table 3-8. Signal Descriptions List (Sheet 1 of 4) Active Signal Name Function Type Level Comments Audio Bitstream DAC - ABDACB CLK D/A clock output Output DAC1 - DAC0 D/A bitstream outputs Output DACN1 - DACN0 D/A inverted bitstream outputs Output Analog Comparator Interface - ACIFC ACAN1 - ACAN0 Analog Comparator A negative references Analog ACAP1 - ACAP0 Analog Comparator A positive references Analog ACBN1 - ACBN0 Analog Comparator B negative references Analog ACBP1 - ACBP0 Analog Comparator B positive references Analog ADC controller interface - ADCIFE AD14 - AD0 Analog inputs Analog ADVREFP Positive voltage reference Analog TRIGGER External trigger Input Backup System Control Interface - BSCIF Analog/ XIN32 32 kHz Crystal Oscillator Input Digital XOUT32 32 kHz Crystal Oscillator Output Analog Capacitive Touch Module B - CATB DIS Capacitive discharge line Output SENSE31 - SENSE0 Capacitive sense lines I/O DAC Controller - DACC DAC external trigger DAC external trigger Input DAC voltage output DAC voltage output Analog Enhanced Debug Port For ARM Products - EDP TCK/SWCLK JTAG / SW Debug Clock Input TDI JTAG Debug Data In Input TDO/TRACESWO JTAG Debug Data Out / SW Trace Out Output TMS/SWDIO JTAG Debug Mode Select / SW Data I/O External Interrupt Controller - EIC EXTINT8 - EXTINT0 External interrupts Input Glue Logic Controller - GLOC IN7 - IN0 Lookup Tables Inputs Input OUT1 - OUT0 Lookup Tables Outputs Output 31 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 3-8. Signal Descriptions List (Sheet 2 of 4) Active Signal Name Function Type Level Comments Inter-IC Sound (I2S) Controller - IISC IMCK I2S Master Clock Output ISCK I2S Serial Clock I/O ISDI I2S Serial Data In Input ISDO I2S Serial Data Out Output IWS I2S Word Select I/O LCD Controller - LCDCA BIASL Bias voltage (1/3 VLCD) Analog BIASH Bias voltage (2/3 VLCD) Analog CAPH High voltage end of flying capacitor Analog CAPL Low voltage end of flying capacitor Analog COM3 - COM0 Common terminals Analog SEG39 - SEG0 Segment terminals Analog VLCD Bias voltage Analog Parallel Capture - PARC PCCK Clock Input PCDATA7 - PCDATA0 Data lines Input PCEN1 Data enable 1 Input PCEN2 Data enable 2 Input Peripheral Event Controller - PEVC PAD_EVT3 - Event Inputs Input PAD_EVT0 Power Manager - PM RESET_N Reset Input Low System Control Interface - SCIF GCLK3 - GCLK0 Generic Clock Outputs Output GCLK_IN1 - GCLK_IN0 Generic Clock Inputs Input Analog/ XIN0 Crystal 0 Input Digital XOUT0 Crystal 0 Output Analog Serial Peripheral Interface - SPI MISO Master In Slave Out I/O MOSI Master Out Slave In I/O NPCS3 - NPCS0 SPI Peripheral Chip Selects I/O Low SCK Clock I/O Timer/Counter - TC0, TC1 32 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 3-8. Signal Descriptions List (Sheet 3 of 4) Active Signal Name Function Type Level Comments A0 Channel 0 Line A I/O A1 Channel 1 Line A I/O A2 Channel 2 Line A I/O B0 Channel 0 Line B I/O B1 Channel 1 Line B I/O B2 Channel 2 Line B I/O CLK0 Channel 0 External Clock Input Input CLK1 Channel 1 External Clock Input Input CLK2 Channel 2 External Clock Input Input Two-wire Interface - TWIMS0, TWIMS1, TWIM2, TWIM3 TWCK Two-wire Serial Clock I/O TWD Two-wire Serial Data I/O Universal Synchronous Asynchronous Receiver Transmitter - USART0, USART1, USART2, USART3 CLK Clock I/O CTS Clear To Send Input Low RTS Request To Send Output Low RXD Receive Data Input TXD Transmit Data Output USB 2.0 Interface - USBC DM USB Full Speed Interface Data - I/O DP USB Full Speed Interface Data + I/O Power GND Ground Ground GNDANA Analog Ground Ground Power VDDANA Analog Power Supply 1.68V to 3.6V Input Power VDDCORE Core Power Supply 1.68V to 1.98V Input Power VDDIN Voltage Regulator Input 1.68V to 3.6V Input 1.68V to 3.6V. VDDIO must Power VDDIO I/O Pads Power Supply always be equal to or lower than Input VDDIN. Power VDDOUT Voltage Regulator Output 1.08V to 1.98V Output General Purpose I/O 33 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 3-8. Signal Descriptions List (Sheet 4 of 4) Active Signal Name Function Type Level Comments PA31 - PA00 Parallel I/O Controller I/O Port A I/O PB15 - PB00 Parallel I/O Controller I/O Port B I/O PC31 - PC00 Parallel I/O Controller I/O Port C I/O Note: 1. See “Power and Startup Considerations” section. 3.4 I/O Line Considerations 3.4.1 SW/JTAG Pins The JTAG pins switch to the JTAG functions if a rising edge is detected on TCK low after the RESET_N pin has been released. The TMS, and TDI pins have pull-up resistors when used as JTAG pins. The TCK pin always has pull-up enabled during reset. The JTAG pins can be used as GPIO pins and multiplexed with peripherals when the JTAG is disabled. Refer to Section 3.2.3 ”JTAG Port Connections” on page 29 for the JTAG port connections. For more details, refer to Section 1.1 ”Enhanced Debug Port (EDP)” on page 3. 3.4.2 RESET_N Pin The RESET_N pin is a schmitt input and integrates a permanent pull-up resistor to VDDIN. As the product integrates a power-on reset detector, the RESET_N pin can be left unconnected in case no reset from the system needs to be applied to the product. 3.4.3 TWI Pins When these pins are used for TWI, the pins are open-drain outputs with slew-rate limitation and- inputs with inputs with spike-filtering. When used as GPIO-pins or used for other peripherals, the pins have the same characteristics as GPIO pins. 3.4.4 GPIO Pins All the I/O lines integrate a pull-up/pull-down resistor and slew rate controller. Programming these features is performed independently for each I/O line through the GPIO Controllers. After reset, I/O lines default as inputs with pull-up and pull-down resistors disabled and slew rate enabled. 3.4.5 High-drive Pins The six pins PA02, PB00, PB01, PC04, PC05 and PC06 have high-drive output capabilities. Refer to Section 9.6.2 ”High-drive I/O Pin : PA02, PC04, PC05, PC06” on page 115 for electrical characteristics. 3.4.6 USB Pins When these pins are used for USB, the pins are behaving according to the USB specification. When used as GPIO pins or used for other peripherals, the pins have the same behavior as other normal I/O pins, but the characteristics are different. Refer to Section 9.6.3 ”USB I/O Pin : PA25, PA26” on page 116 for electrical characteristics. These pins are compliant to USB standard only when VDDIO power supply is 3.3V nominal. 34 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 3.4.7 ADC Input Pins These pins are regular I/O pins powered from the VDDANA. 35 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 4. Cortex-M4 processor and core peripherals 4.1 Cortex-M4 The Cortex-M4 processor is a high performance 32-bit processor designed for the microcon- troller market. It offers significant benefits to developers, including: • outstanding processing performance combined with fast interrupt handling • enhanced system debug with extensive breakpoint and trace capabilities • efficient processor core, system and memories • ultra-low power consumption with integrated sleep modes • platform security robustness, with integrated memory protection unit (MPU). Cortex-M4 processor NVIC Processor core Debug Serial Memory Access Wire protection unit Port viewer Flash Data patch watchpoints Bus matrix Code SRAM and interface peripheral interface The Cortex-M4 processor is built on a high-performance processor core, with a 3-stage pipeline Harvard architecture, making it ideal for demanding embedded applications. The processor delivers exceptional power efficiency through an efficient instruction set and extensively opti- mized design, providing high-end processing hardware including a range of single-cycle and SIMD multiplication and multiply-with-accumulate capabilities, saturating arithmetic and dedi- cated hardware division. To facilitate the design of cost-sensitive devices, the Cortex-M4 processor implements tightly- coupled system components that reduce processor area while significantly improving interrupt handling and system debug capabilities. The Cortex-M4 processor implements a version of the Thumb® instruction set based on Thumb-2 technology, ensuring high code density and reduced program memory requirements. The Cortex-M4 instruction set provides the exceptional perfor- mance expected of a modern 32-bit architecture, with the high code density of 8-bit and 16-bit microcontrollers. The Cortex-M4 processor closely integrates a configurable Nested Vectored Interrupt Controller (NVIC), to deliver industry-leading interrupt performance. The NVIC includes a non-maskable interrupt (NMI), and provides up to 80 interrupt priority levels. The tight integration of the proces- 36 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 sor core and NVIC provides fast execution of interrupt service routines (ISRs), dramatically reducing the interrupt latency. This is achieved through the hardware stacking of registers, and the ability to suspend load-multiple and store-multiple operations. Interrupt handlers do not require wrapping in assembler code, removing any code overhead from the ISRs. A tail-chain optimization also significantly reduces the overhead when switching from one ISR to another. To optimize low-power designs, the NVIC integrates with the sleep modes, that include a deep sleep function enabling the entire device to be rapidly powered down while still retaining pro- gram state. 4.2 System level interface The Cortex-M4 processor provides multiple interfaces using AMBA® technology to provide high speed, low latency memory accesses. It supports unaligned data accesses and implements atomic bit manipulation that enables faster peripheral controls, system spinlocks and thread-safe Boolean data handling. The Cortex-M4 processor has an memory protection unit (MPU) that provides fine grain memory control, enabling applications to utilize multiple privilege levels, separating and protecting code, data and stack on a task-by-task basis. Such requirements are becoming critical in many embedded applications such as automotive. 4.3 Integrated configurable debug The Cortex-M4 processor implements a complete hardware debug solution. This provides high system visibility of the processor and memory through either a traditional JTAG port or a 2-pin Serial Wire Debug (SWD) port that is ideal for microcontrollers and other small package devices. For system trace the processor integrates an Instrumentation Trace Macrocell (ITM) alongside data watchpoints and a profiling unit. To enable simple and cost-effective profiling of the system events these generate, a Serial Wire Viewer (SWV) can export a stream of software-generated messages, data trace, and profiling information through a single pin. The Flash Patch and Breakpoint Unit (FPB) provides 8 hardware breakpoint comparators that debuggers can use. The comparators in the FPB also provide remap functions of up to 8 words in the program code in the CODE memory region. This enables applications stored on a non- erasable, ROM-based microcontroller to be patched if a small programmable memory, for exam- ple flash, is available in the device. During initialization, the application in ROM detects, from the programmable memory, whether a patch is required. If a patch is required, the application pro- grams the FPB to remap a number of addresses. When those addresses are accessed, the accesses are redirected to a remap table specified in the FPB configuration, which means the program in the non-modifiable ROM can be patched. A specific Peripheral Debug (PDBG) register is implemented in the Private Peripheral Bus address map. This register allows the user to configure the behavior of some modules in debug mode. 37 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 4.4 Cortex-M4 processor features and benefits summary • tight integration of system peripherals reduces area and development costs • Thumb instruction set combines high code density with 32-bit performance • code-patch ability for ROM system updates • power control optimization of system components • integrated sleep modes for low power consumption • fast code execution permits slower processor clock or increases sleep mode time • hardware division and fast digital-signal-processing orientated multiply accumulate • saturating arithmetic for signal processing • deterministic, high-performance interrupt handling for time-critical applications • memory protection unit (MPU) for safety-critical applications • extensive debug and trace capabilities: – Serial Wire Debug and Serial Wire Trace reduce the number of pins required for debugging, tracing, and code profiling. 4.5 Cortex-M4 core peripherals These are: Nested Vectored Interrupt Controller The NVIC is an embedded interrupt controller that supports low latency interrupt processing. System control block The System control block (SCB) is the programmers model interface to the processor. It pro- vides system implementation information and system control, including configuration, control, and reporting of system exceptions. System timer The system timer, SysTick, is a 24-bit count-down timer. Use this as a Real Time Operating Sys- tem (RTOS) tick timer or as a simple counter. Memory protection unit The Memory protection unit (MPU) improves system reliability by defining the memory attributes for different memory regions. It provides up to eight different regions, and an optional predefined background region. The complete Cortex-M4 User Guide can be found on the ARM web site: http://infocenter.arm.com/help/topic/com.arm.doc.dui0553a/DUI0553A_cortex_m4_dgug.pdf 38 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 4.6 Cortex-M4 implementations options This table provides the specific configuration options implemented in the SAM4L series Option Implementation Inclusion of MPU yes Inclusion of FPU No Number of interrupts 80 Number of priority bits 4 Inclusion of the WIC No Embedded Trace Macrocell No Sleep mode instruction Only WFI supported Endianness Little Endian Bit-banding No SysTick timer Yes Register reset values No Table 4-1. Cortex-M4 implementation options 4.7 Cortex-M4 Interrupts map The table below shows how the interrupt request signals are connected to the NVIC. Table 4-2. Interrupt Request Signal Map (Sheet 1 of 3) Line Module Signal 0 Flash Controller HFLASHC 1 Peripheral DMA Controller PDCA 0 2 Peripheral DMA Controller PDCA 1 3 Peripheral DMA Controller PDCA 2 4 Peripheral DMA Controller PDCA 3 5 Peripheral DMA Controller PDCA 4 6 Peripheral DMA Controller PDCA 5 7 Peripheral DMA Controller PDCA 6 8 Peripheral DMA Controller PDCA 7 9 Peripheral DMA Controller PDCA 8 10 Peripheral DMA Controller PDCA 9 11 Peripheral DMA Controller PDCA 10 39 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 4-2. Interrupt Request Signal Map (Sheet 2 of 3) Line Module Signal 12 Peripheral DMA Controller PDCA 11 13 Peripheral DMA Controller PDCA 12 14 Peripheral DMA Controller PDCA 13 15 Peripheral DMA Controller PDCA 14 16 Peripheral DMA Controller PDCA 15 17 CRC Calculation Unit CRCCU 18 USB 2.0 Interface USBC 19 Peripheral Event Controller PEVC TR 20 Peripheral Event Controller PEVC OV 21 Advanced Encryption Standard AESA 22 Power Manager PM 23 System Control Interface SCIF 24 Frequency Meter FREQM 25 General-Purpose Input/Output Controller GPIO 0 26 General-Purpose Input/Output Controller GPIO 1 27 General-Purpose Input/Output Controller GPIO 2 28 General-Purpose Input/Output Controller GPIO 3 29 General-Purpose Input/Output Controller GPIO 4 30 General-Purpose Input/Output Controller GPIO 5 31 General-Purpose Input/Output Controller GPIO 6 32 General-Purpose Input/Output Controller GPIO 7 33 General-Purpose Input/Output Controller GPIO 8 34 General-Purpose Input/Output Controller GPIO 9 35 General-Purpose Input/Output Controller GPIO 10 36 General-Purpose Input/Output Controller GPIO 11 37 Backup Power Manager BPM 38 Backup System Control Interface BSCIF 39 Asynchronous Timer AST ALARM 40 Asynchronous Timer AST PER 41 Asynchronous Timer AST OVF 42 Asynchronous Timer AST READY 43 Asynchronous Timer AST CLKREADY 44 Watchdog Timer WDT 45 External Interrupt Controller EIC 1 46 External Interrupt Controller EIC 2 47 External Interrupt Controller EIC 3 40 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Table 4-2. Interrupt Request Signal Map (Sheet 3 of 3) Line Module Signal 48 External Interrupt Controller EIC 4 49 External Interrupt Controller EIC 5 50 External Interrupt Controller EIC 6 51 External Interrupt Controller EIC 7 52 External Interrupt Controller EIC 8 53 Inter-IC Sound (I2S) Controller IISC 54 Serial Peripheral Interface SPI 55 Timer/Counter TC00 56 Timer/Counter TC01 57 Timer/Counter TC02 58 Timer/Counter TC10 59 Timer/Counter TC11 60 Timer/Counter TC12 61 Two-wire Master Interface TWIM0 62 Two-wire Slave Interface TWIS0 63 Two-wire Master Interface TWIM1 64 Two-wire Slave Interface TWIS1 Universal Synchronous Asynchronous 65 USART0 Receiver Transmitter Universal Synchronous Asynchronous 66 USART1 Receiver Transmitter Universal Synchronous Asynchronous 67 USART2 Receiver Transmitter Universal Synchronous Asynchronous 68 USART3 Receiver Transmitter 69 ADC controller interface ADCIFE 70 DAC Controller DACC 71 Analog Comparator Interface ACIFC 72 Audio Bitstream DAC ABDACB 73 True Random Number Generator TRNG 74 Parallel Capture PARC 75 Capacitive Touch Module B CATB 77 Two-wire Master Interface TWIM2 78 Two-wire Master Interface TWIM3 79 LCD Controller A LCDCA 41 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 4.8 Peripheral Debug The PDBG register controls the behavior of asynchronous peripherals when the device is in debug mode.When the corresponding bit is set, that peripheral will be in a frozenstate in debug mode. 4.8.1 Peripheral Debug Name: PDBG Access Type: Read/Write Address: 0xE0042000 Reset Value: 0x00000000 31 30 29 28 27 26 25 24 - - - - - - - - 23 22 21 20 19 18 17 16 - - - - - - - - 15 14 13 12 11 10 9 8 - - - - - - - - 7 6 5 4 3 2 1 0 - - - - - PEVC AST WDT • WDT: Watchdog PDBG bit WDT = 0: The WDT counter is not frozen during debug operation. WDT = 1: The WDT counter is frozen during debug operation when Core is halted • AST: Asynchronous Timer PDBG bit AST = 0: The AST prescaler and counter is not frozen during debug operation. AST = 1: The AST prescaler and counter is frozen during debug operation when Core is halted. • PEVC: PEVC PDBG bit PEVC= 0: PEVC is not frozen during debug operation. PEVC= 1: PEVC is frozen during debug operation when Core is halted. 42 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 5. Memories 5.1 Product Mapping Figure 5-1. ATSAM4L8/L4/L2 Product Mapping Global Memory Space Code 0x00000000 0x00000000 Code Internal Flash Peripheral Bridge A Peripheral Bridge B 0x20000000 0x00800000 0x40000000 0x400A0000 SRAM Reserved Reserved FLASHCALW 0x40004000 0x400A0400 0x22000000 0x1FFFFFFF I2SC PICOCACHE 0x40008000 0x400A1000 SPI HMATRIX Undefined SRAM 0x4000C000 0x400A2000 Reserved PDCA 0x20000000 0x40010000 0x400A3000 0x40000000 HRAMC0 TC0 SMAP 0x40014000 0x400A4000 Peripherals 0x20010000 TC1 CRCCU 0x40018000 0x400A5000 0x60000000 Reserved TWIMS0 USBC Reserved 0x21000000 0x4001C000 0x400A6000 TWIMS1 PEVC 0xE0000000 HRAMC1 0x40020000 0x400A6400 0x210007FF Reserved Reserved System 0x40024000 0x400AFFFF 0xFFFFFFFF Reserved USART0 0x40028000 0x21FFFFFF USART1 0x4002C000 USART2 Peripheral Bridge C System Peripherals 0x40030000 USART3 0x400E0000 0xE0000000 0x40000000 0x40034000 PM ITM Peripheral Reserved 0x400E0740 0xE0001000 Bridge A 0x40038000 CHIPID DWT ADCIFE 0x400E0800 0x400A0000 0xE0002000 Peripheral 0x4003C000 SCIF FPB DACC 0x400E0C00 0xE0003000 Bridge B 0x40040000 FREQM 0x400B0000 ACIFC 0x400E1000 Reserved AESA 0x40044000 GPIO 0xE000E000 Reserved 0x400E1800 SCS 0x400B0100 0x40060000 Reserved 0xE000F000 Reserved GLOC 0x400EFFFF 0x40064000 Reserved 0x400E0000 ABDACB Peripheral 0x40068000 Peripheral Bridge D 0xE0040000 TRNG Bridge C TPIU 0x4006C000 0x400F0000 0xE0041000 0x400F0000 PARC BPM Reserved Peripheral 0x40070000 0x400F0400 0xE0042000 Bridge D CATB BSCIF 0x40100000 0x40074000 0x400F0800 External PPB Reserved AST 0x40078000 0x400F0C00 0xE00FF000 TWIM2 WDT ROM Table 0x4007C000 0x400F1000 0xE0100000 Reserved TWIM3 EIC 0x40080000 0x400F1400 LCDCA PICOUART Reserved 0x40084000 0x400F1800 Reserved Reserved 0xFFFFFFFF 0x5FFFFFFF 0x4009FFFF 0x400FFFFF System Controller 43 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 5.2 Embedded Memories • Internal high-speed flash – 512Kbytes (ATSAM4Lx8) – 256Kbytes (ATSAM4Lx4) – 128Kbytes (ATSAM4Lx2) • Pipelined flash architecture, allowing burst reads from sequential flash locations, hiding penalty of 1 wait state access • Pipelined flash architecture typically reduces the cycle penalty of 1 wait state operation compared to 0 wait state operation • 100 000 write cycles, 15-year data retention capability • Sector lock capabilities, bootloader protection, security bit • 32 fuses, erased during chip erase • User page for data to be preserved during chip erase • Internal high-speed SRAM, single-cycle access at full speed – 64Kbytes (ATSAM4Lx8) – 32Kbytes (ATSAM4Lx4, ATSAM4Lx2) 5.3 Physical Memory Map The system bus is implemented as a bus matrix. All system bus addresses are fixed, and they are never remapped in any way, not even during boot. The 32-bit physical address space is mapped as follows: Table 5-1. ATSAM4L8/L4/L2 Physical Memory Map Start Address Size Size Memory ATSAM4Lx4 ATSAM4Lx2 Embedded Flash 0x00000000 256Kbytes 128Kbytes Embedded SRAM 0x20000000 32Kbytes 32Kbytes Cache SRAM 0x21000000 4Kbytes 4Kbytes Peripheral Bridge A 0x40000000 64Kbytes 64Kbytes Peripheral Bridge B 0x400A0000 64Kbytes 64Kbytes AESA 0x400B0000 256 bytes 256 bytes Peripheral Bridge C 0x400E0000 64Kbytes 64Kbytes Peripheral Bridge D 0x400F0000 64Kbytes 64Kbytes Start Address Size Memory ATSAM4Lx8 Embedded Flash 0x00000000 512Kbytes Embedded SRAM 0x20000000 64Kbytes Cache SRAM 0x21000000 4Kbytes Peripheral Bridge A 0x40000000 64Kbytes Peripheral Bridge B 0x400A0000 64Kbytes 44 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Start Address Size Memory ATSAM4Lx8 AESA 0x400B0000 256 bytes Peripheral Bridge C 0x400E0000 64Kbytes Peripheral Bridge D 0x400F0000 64Kbytes Table 5-2. Flash Memory Parameters Device Flash Size (FLASH_PW) Number of Pages (FLASH_P) Page Size (FLASH_W) ATSAM4Lx8 512Kbytes 1024 512 bytes ATSAM4Lx4 256Kbytes 512 512 bytes ATSAM4Lx2 128Kbytes 256 512 bytes 45 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 6. Power and Startup Considerations 6.1 Power Domain Overview Figure 6-1. ATSAM4LS Power Domain Diagram n O E D T R L U O BUCK/(PA02) VDDIN GND VDDO VDDC DUAL OUTPUT CORE DOMAIN TRIMMABLE CORTEX M4 PDCA USBC RAM FLASH VOLTAGE REGULATOR CPU BUS MATRIX VDDANA DOMAIN PERIPHERAL BRIDGE A PERIPHERAL BRIDGE B AD0-AD14 ADC PERIPHERALS AHB PERIPHERALS ADVREF AC0A-AC3A ANALOG PERIPHERAL BRIDGE C COMPARATORS AC0B-AC3B GPIO DACOUT DAC POWER MANAGER FREQUENCY METER STARTUP LOGIC PLL POR33 SYSTEM DFLL VDDIO DOMAIN BOD33 CONTROL INTERFACE RCSYS USB PADS BOD18 RCFAST MPOSC PERIPHERAL BRIDGE D GPIOs RC80M BACKUP RC32K POWER MANAGER BACKUP SYSTEM XIN32 CONTROL INTERFACE OSC32K POR18 VDDIO GND XOUT32 EXTERNAL INTERRUPT WATCHDOG EXTINT0-EXTINT8 CONTROLLER TIMER BACKUP ASYNCHRONOUS TIMER REGISTERS VDDANA GNDANA BACKUP DOMAIN 46 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Figure 6-2. ATSAM4LC Power Domain Diagram n O E D T R L U O BUCK/(PA02) VDDIN GND VDDO VDDC VLCDIN GND LCDA DOMAIN DUAL OUTPUT CORE DOMAIN CAPH RTEVRGOIMULMTLAAAGTBOLEER CORCTPEUX M4 PDCA USBC RAM FLASH VPLCUDMP BBCIIAAAPSSLHL VLCD BUS MATRIX GPIOs VDDANA DOMAIN PERIPHERAL BRIDGE A PERIPHERAL BRIDGE B AD0-AD14 ADC PERIPHERALS AHB PERIPHERALS LCDB DOMAIN ADVREF VDDIO AC0A-AC3A ANALOG GPIOs COMPARATORS PERIPHERAL BRIDGE C AC0B-AC3B GPIO DACOUT DAC LCDC DOMAIN POWER MANAGER FREQUENCY VDDIO METER STARTUP GPIOs LOGIC PLL POR33 SYSTEM DFLL VDDIO DOMAIN BOD33 CONTROL INTERFACE RCSYS USB PADS BOD18 RCFAST MPOSC PERIPHERAL BRIDGE D GPIOs RC80M BACKUP RC32K BACKUP SYSTEM POWER MANAGER XIN32 CONTROL INTERFACE OSC32K POR18 VDDIO GND XOUT32 EXTINT0-EXTINT8 EXTERNAL INTERRUPT WATCHDOG CONTROLLER TIMER BACKUP ASYNCHRONOUS TIMER REGISTERS VDDANA GNDANA BACKUP DOMAIN 47 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 6.2 Power Supplies The ATSAM4L8/L4/L2 has several types of power supply pins: • VDDIO: Powers I/O lines, the general purpose oscillator (OSC), the 80MHz integrated RC oscillator (RC80M) . Voltage is 1.68V to 3.6V. • VLCDIN: (ATSAM4LC only) Powers the LCD voltage pump. Voltage is 1.68V to 3.6V. • VDDIN: Powers the internal voltage regulator. Voltage is 1.68V to 3.6V. • VDDANA: Powers the ADC, the DAC, the Analog Comparators, the 32kHz oscillator (OSC32K), the 32kHz integrated RC oscillator (RC32K)and the Brown-out detectors (BOD18 and BOD33). Voltage is 1.68V to 3.6V nominal. • VDDCORE: Powers the core, memories, peripherals, the PLL, the DFLL, the 4MHz integrated RC oscillator (RCFAST) and the 115kHz integrated RC oscillator (RCSYS). – VDDOUT is the output voltage of the regulator and must be connected with or without an inductor to VDDCORE. The ground pins GND are common to VDDCORE, VDDIO, and VDDIN. The ground pin for VDDANA is GNDANA. For decoupling recommendations for the different power supplies, refer to the schematic document. 6.2.1 Voltage Regulator An embedded voltage regulator supplies all the digital logic in the Core and the Backup power domains. The regulator has two functionnal mode depending of BUCK/LDOn (PA02) pin value. When this pin is low, the regulator is in linear mode and VDDOUT must be connected to VDDCORE exter- nally. When this pin is high, it behaves as a switching regulator and an inductor must be placed between VDDOUT and VDDCORE. The value of this pin is sampled during the power-up phase when the Power On Reset 33 reaches V (Section 9.9 ”Analog Characteristics” on page 129) POT+ Its output voltages in the Core domain (V ) and in the Backup domain (V ) are always CORE BKUP equal except in Backup mode where the Core domain is not powered (V =0). The Backup CORE domain is always powered. The voltage regulator features three different modes: • Normal mode: the regulator is configured as linear or switching regulator. It can support all different Run and Sleep modes. • Low Power (LP) mode: the regulator consumes little static current. It can be used in Wait modes. • Ultra Low Power (ULP) mode: the regulator consumes very little static current . It is dedicated to Retention and Backup modes. In Backup mode, the regulator only supplies the backup domain. 48 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 6.2.2 Typical Powering Schematics The ATSAM4L8/L4/L2 supports the Single supply mode from 1.68V to 3.6V. Depending on the input voltage range and on the final application frequency, it is recommended to use the follow- ing table in order to choose the most efficient power strategy Figure 6-3. Efficient power strategy: VDDIN Voltage 1.68V 1.80V 2.00V 2.30V 3.60V Switching Mode Possible but (BUCK/LDOn N/A Optimal power efficiency not efficient (PA02) =1) Linear Mode (BUCK/LDOn Optimal power efficiency Possible but not efficient (PA02) =0) Up to 36MHz In PS0 F 12MHz Up to 12MHz in PS1 CPUMAX Up to 48MHz in PS2 PowerScaling PS1(1) ALL Typical power consumption in ℵ 212µA/MHz @ FCPU=12MHz(PS1) ℵ 100µA/MHz @ FCPU=12MHz(PS1) @ VVDDIN=3.3V RUN mode ℵ 306µA/MHz @ FCPU= 48MHz(PS2) ℵ 180µA/MHz @ FCPU=48MHz(PS2) @ VVDDIN=3.3V Typical power consumption in 1.5µA RET mode Note 1. The SAM4L boots in PS0 on RCSYS(115kHz), then the application must switch to PS1 before running on higher frequency (<12MHz) 49 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 The internal regulator is connected to the VDDIN pin and its output VDDOUT feeds VDDCORE in linear mode or through an inductor in switching mode. Figure 6-4 shows the power schematics to be used. All I/O lines will be powered by the same power (V =V =V ). VDDIN VDDIO VDDANA Figure 6-4. Single Supply Mode VLCDIN LCD VPUMP VDDIO Main Supply RC80M, OSC, (1.68V-3.6V) VDDANA ADC, DAC, AC0/1, RC32K, OSC32K, BOD18, BOD33 BUCK/LDOn (PA02) Core domain: CPU, Peripherals, RAM, Flash, VDDIN RCSYS, PLL, DFLL, REGULATOR VDDOUT RCFAST VDDCORE Backup domain: AST, WDT, EIC, BPM, BSCIF 6.2.3 LCD Power Modes 6.2.3.1 Principle LCD lines is powered using the device internal voltage sources provided by the LCDPWR block. When enabled, the LCDPWR blocks will generate the VLCD, BIASL, BIASH voltages. LCD pads are splitted into three clusters that can be powered independently namely clusters A, B and C. A cluster can either be in GPIO mode or in LCD mode. When a cluster is in GPIO mode, its VDDIO pin must be powered externally. None of its GPIO pin can be used as a LCD line When a cluster is in LCD mode, each clusters VDDIO pin can be either forced externally (1.8- 3.6V) or unconnected (nc). GPIOs in a cluster are not available when it is in LCD mode. A clus- ter is set in LCD mode by the LCDCA controller when it is enabled depending on the number of segments configured. The LCDPWR block is powered by the VLCDIN pin inside cluster A When LCD feature is not used, VLCDIN must be always powered (1.8-3.6V). VLCD, CAPH, CAPL, BIASH, BIASL can be left unconnected in this case 50 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 Figure 6-5. LCD clusters in the device R SEG17 SEG16 SEG15 SEG14 SEG13 SEG12 SEG11 SEG10 SEG9 SEG8 SEG7 SEG6 SEG5 SEG4 SEG3 SEG2 SEG1 SEG0 VLCDIN GND BIASL BIASH VLCD CAPL CAPH E T S U 5 4 3 2 1 0 9 8 7 6 5 4 3 2 1 0 9 8 7 6 5 4 3 2 1 L 7 7 7 7 7 7 6 6 6 6 6 6 6 6 6 6 5 5 5 5 5 5 5 5 5 C A D N LC SEG18 76 SEG8 SEG7 SEG6 SEG5 SEG4 SEG3 SEG2 SEG1 SEG0 VLCDI GND BIASL BIASH VLCD CAPL CAPH 50 COM0 SEG19 77 49 COM1 SEG20 78 48 COM2 8 7 6 5 4 3 2 1 0 9 8 7 6 5 4 3 4 4 4 4 4 4 4 4 4 3 3 3 3 3 3 3 SEG24 79 47 COM3 TER SSEEGG2256 8801 SEG9 49 SEG4SEG3SEG2SEG1SEG0VLCDINGNDBIASLBIASHVLCDCAPLCAPH 32 COM0 4456 SSEEGG2212 US SEG27 82 SEG10 50 31 COM1 44 SEG23 L SEG11 51 30 COM2 B C SSEEGG2289 8834 VDDIO 52 363534333231302928272625 29 COM3 4423 D SEG15 53 SEG5 37 24 COM0 28 SEG12 C SEG30 85 SEG6 38 23 COM1 41 L SEG16 54 SEG7 39 22 COM2 27 SEG13 SEG31 86 SEG17 55 VDDIO 40 21 COM3 26 SEG14 40 SEG9 41 20 SEG8 VDDIO 87 SEG18 56 SEG10 42 TQFP48/QFN48 19 VDDANA 25 VDDANA 39 VDDIO 88 SEG19 57 SSEEGG1112 4434 1178 GNDANA 24 38 SEG20 58 VDDIO 45 16 23 GNDANA ER SSEEGG3323 8990 SEG21 59 4467 1145 22 3367 T SEG22 60 GND 48 13 21 US SEG34 91 VDDIO 61 20 35 VDDANA CL SEG35 92 62 123456789101112 19 34 C SEG36 93 63 18 33 GNDANA CD SEG37 94 GND 64 VDGNVDVD 17 32 L SEG38 95 DCODDOUDIN TQFP64/QFN64 31 R T E SEG39 96 30 1 1 1 1 1 1 1 97 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 29 98 28 V G V V 99 D N D D 27 D D D D GND 100 CO OU IN 26 R T E TQFP100 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 G V V G V V N D D N D D D D D D D D IO CO OU IN R T E 6.2.3.2 Internal LCD Voltage In this mode the LCD voltages are internally generated. Depending of the number of segments required by the application, LCDB and LDCC clusters VDDIO pin must be unconnected (nc) or 51 42023HS–SAM–11/2016

ATSAM4L8/L4/L2 connected to an external voltage source (1.8-3.6V). LCDB cluster is not available in 64 and 48 pin packages Table 6-1. LCD powering when using the internal voltage pump Segments VDDIO VDDIO Package in use LCDB LCDC [1,24] 1.8-3.6V 1.8-3.6V 100-pin packages [1, 32] nc 1.8-3.6V [1, 40] nc nc [1,15] - 1.8-3.6V 64-pin packages [1, 23] - nc [1,9] - 1.8-3.6V 48-pin packages [1,13] - nc Up to 4x24 segments Up to 4x40 segments Up to 4x32 segments Up to 16 GPIOs in No GPIO in LCD Up to 8 GPIOs in LCDB & LCDC clusters LCDC clusters clusters 1.8–3.6V 1.8–3.6V 1.8–3.6V DIN GND DIN GND DIN GND C C C L L L V V V LCDA DOMAIN LCDA DOMAIN LCDA DOMAIN CAPH CAPH CAPH CAPL CAPL CAPL LCD BIASH LCD BIASH LCD BIASH VPUMP BIASL VPUMP BIASL VPUMP BIASL VLCD VLCD VLCD GPIOs GPIOs GPIOs h on LCDB DOMAIN h on LCDB DOMAIN h off LCDB DOMAIN 1.8–3.6V c c c wit VDDIO wit VDDIO wit VDDIO S nc S nc S GPIOs GPIOs GPIOs h on LCDC DOMAIN h off LCDC DOMAIN 1.8–3.6V h off LCDC DOMAIN c c c wit VDDIO wit VDDIO wit VDDIO S nc S S GPIOs GPIOs GPIOs 52 42023HS–SAM–11/2016