ICGOO在线商城 > ASMT-QAB2-FDE0E

- 型号: ASMT-QAB2-FDE0E

- 制造商: Avago Technologies

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

ASMT-QAB2-FDE0E产品简介:

ICGOO电子元器件商城为您提供ASMT-QAB2-FDE0E由Avago Technologies设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 提供ASMT-QAB2-FDE0E价格参考以及Avago TechnologiesASMT-QAB2-FDE0E封装/规格参数等产品信息。 你可以下载ASMT-QAB2-FDE0E参考资料、Datasheet数据手册功能说明书, 资料中有ASMT-QAB2-FDE0E详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 25°C时通量,电流-测试 | 11 lm (9 lm ~ 15 lm) |

| 85°C时通量,电流-测试 | 4 lm |

| 产品目录 | |

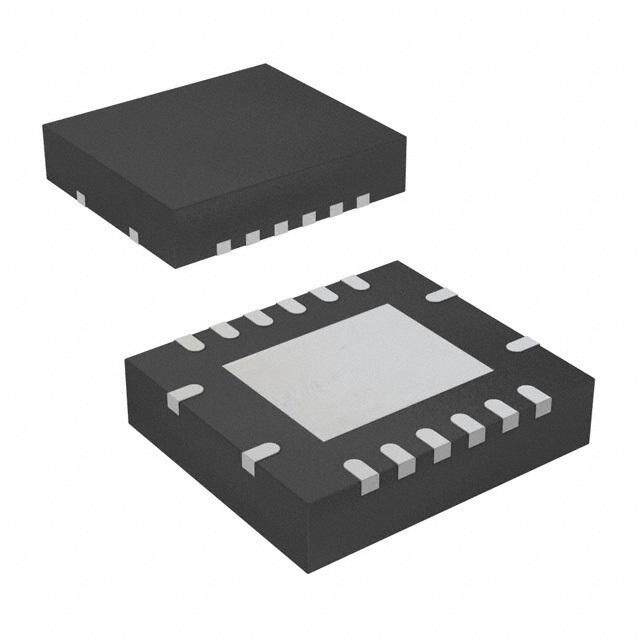

| 描述 | LED INDICATOR 0.5W AMBER 4PLCC大功率LED - 单色 0.5 Watt Amber |

| 产品分类 | |

| 品牌 | Avago Technologies |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | LED发射器,大功率LED - 单色,Avago Technologies ASMT-QAB2-FDE0E- |

| 数据手册 | http://www.avagotech.com/docs/AV02-0232EN |

| 产品型号 | ASMT-QAB2-FDE0E |

| PCN过时产品 | http://www.avagotech.com/docs/OBS072913OPD1 |

| 不同最大电流时的流明 | 11 lm |

| 不同测试电流时的流明/瓦 | 28 lm/W |

| 产品种类 | 大功率LED - 单色 |

| 光强度 | 3.3 cd |

| 光通量/辐射通量 | 11.4 lm |

| 其它名称 | 516-2468-6 |

| 功率额定值 | 500 mW |

| 包装 | 剪切带 (CT) |

| 商标 | Avago Technologies |

| 安装类型 | 表面贴装 |

| 安装风格 | SMD/SMT |

| 封装 | Reel |

| 封装/外壳 | 4-PLCC |

| 封装热阻 | 60°C/W |

| 工厂包装数量 | 2000 |

| 显示角 | 120 deg |

| 最大工作温度 | + 110 C |

| 最小工作温度 | - 40 C |

| 标准包装 | 1 |

| 正向电压 | 2.7 V |

| 正向电流 | 150 mA |

| 波长 | 594.5 nm |

| 照明颜色 | Amber |

| 电压-正向(Vf)(典型值) | 2.7V |

| 电压 -正向,最大电流时 | 2.7V |

| 电流-最大值 | 150mA |

| 电流-测试 | 150mA |

| 视角 | 120° |

| 透镜颜色/类型 | Clear |

| 颜色 | 琥珀 |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

ASMT-QxB2-Fxxxx Super 0.5 W Power PLCC-4 Surface Mount LED Indicator Data Sheet Description Features The Super 0.5 W Power PLCC-4 SMT LED is an extension • Industry Standard PLCC 4 platform (3.2 x 2.8 x 1.9 of Power PLCC-4 SMT LEDs. The package can be driven mm) at high current due to its superior package design. The • High reliability package with enhanced silicone resin product is able to dissipate the heat more effi ciently encapsulation compared to the Power PLCC-4 SMT LEDs. These LEDs • High intensity brightness with optimum fl ux produce higher light output with better fl ux perfor- performance using AllnGaP chip technologies mance compared to the Power PLCC-4 SMT LED. • Available in Red, Red Orange and Amber colors The Super 0.5 W Power PLCC-4 SMT LEDs are designed • High optical effi ciency for higher reliability, better performance, and operate • Available in 8 mm carrier tape and 7 inch reel under a wide range of environmental conditions. The performance characteristics of these new mid-power • Low thermal resistance LEDs make them uniquely suitable for use in harsh • Super wide viewing angle at 120 degrees conditions such as in automotive applications, and in • Longer life time with minimum degradation due to electronics signs and signals. enhanced Silicone resin material To facilitate easy pick and place assembly, the LEDs are • JEDEC MSL 2a packed in EIA-compliant tape and reel. Every reel is shipped in single intensity and color bin (except for red), Applications to provide close uniformity. • Exterior automotive Super 0.5 W Power PLCC-4 SMT LED is available in red, - Turn signals red orange and amber colors. - Side repeaters - CHSML - Rear combination lamp - Side markers - Truck clearance lamp • Electronic signs and signals - Channel lettering - Contour lighting - Indoor variable message sign • Offi ce automation, home appliances, industrial equipment - Front panel backlighting - Push button backlighting - Display backlighting CAUTION: ASMT-QxB2-Fxxxx LEDs are Class 2 ESD sensitive. Please observe appropriate precautions during handling and processing. Refer to Avago Application Note AN-1142 for additional details.

Package Drawing 1.9 0.2 2.8 0.2 0.8 0.1 2.2 0.2 0.15 (TYP.) 1.15 0.05 2.40 C C 0.41 (TYP.) 3.2 0.2 3.6 0.2 0.56 (TYP.) 0.8 0.3 A A 0.5 0.1 2.30 0.05 0.7 0.1 ANODE MARKING NOTES: 1. ALL DIMENSIONS IN MILLIMETERS. 2. LEAD POLARITY AS SHOWN IN FIGURE 13. 3. TERMINAL FINISH: Ag PLATING. 4. ENCAPSULATION MATERIAL: SILICONE RESIN. Figure 1. Package drawing Table 1. Device Selection Guide (T = 25 °C) J Luminous Flux, ΦV[1] (lm) Min. Flux Typ. Flux Max. Flux Test Current Color Part Number (lm) (lm) (lm) (mA) Dice Technology Amber ASMT-QAB2-FDE0E 9.0 11.4 15.0 150 AlInGaP Red Orange ASMT-QHB2-FEF0E 11.5 14.0 19.5 150 AlInGaP Red ASMT-QRB2-FCD0E 7.0 9.8 11.5 150 AlInGaP Notes: 1. ΦV is the total luminous fl ux output as measured with an integrating sphere at mono pulse conditions. 2. Tolerance = ±12%. Part Numbering System A S M T – Q X1 B 2 – F X2 X3 X4 X5 Packaging Option Color Bin Selection Max. Flux Bin Selection Min. Flux Bin Selection Color A - Amber H - Red Orange R - Red 2

Table 2. Absolute Maximum Ratings (T = 25°C) A Parameters ASMT-QxB2-Fxxxx DC Forward Current [1] 150 mA Peak Forward Current [2] 200 mA Power Dissipation 470 mW Reverse Voltage 5 V Junction Temperature 125°C Operating Temperature -40°C to +110°C Storage Temperature -40°C to +110°C Notes: 1. Derate l inearly as shown in Figure 6. 2. Duty Factor = 10%, Frequency = 1kHz. Table 3. Optical Characteristics (T = 25°C) J Dominant Viewing Luminous Total Flux / Wavelength Angle 2θ1/2[2] Effi ciency Luminous Intensity λD[1] (nm) (Degrees) ηe(lm/W) FV (lm) / IV (cd) Dice Color Part Number Technology Typ. Typ. Typ. Typ. Amber ASMT-QAB2-Fxxxx AlInGaP 594.5 120 28 3.3 Red Orange ASMT-QHB2-Fxxxx AlInGaP 617.0 120 35 3.3 Red ASMT-QRB2-Fxxxx AlInGaP 624.0 120 21 3.3 Notes: 1. The dominant wavelength, λD, is derived from the CIE Chromaticity diagram and represents the color of the device. 2. θ1/2 is the off -axis angle where the luminous intensity is 1/2 the peak intensity. Table 4. Electrical Characteristics (T = 25°C) J Forward Voltage VF Reverse Voltage Thermal Resistance (Volts) @ IF = 150 mA VR @ 100 μA RθJ-P (°C/W) Part Number Typ. Max. Min. ASMT-QAB2-Fxxxx 2.70 3.25 5 60 ASMT-QHB2-Fxxxx 2.70 3.25 5 60 ASMT-QRB2-Fxxxx 3.10 3.55 5 60 3

1.0 200 AlInGaP AlInGaP AMBER 0.9 RED-ORANGE 180 AlInGaP AMBER 0.8 160 AlInGaP RED 0.7 mA 140 TY – SI 0.6 T 120 N N E E NT 0.5 RR 100 ELATIVE I 00..43 WARD CU 8600 R OR AlInGaP RED 0.2 F 40 AlInGaP 0.1 20 RED-ORANGE 0 0 380 430 480 530 580 630 680 730 780 0 1 2 3 4 WAVELENGTH – nm FORWARD VOLTAGE – V Figure 2. Relative intensity vs. wavelength Figure 3. Forward current vs. forward voltage 1.2 2.2 2.0 AMBER 1.0 1.8 ATIVE LUMINOUS INTENSITYNORMALIZED AT 150 mA) 000...864 AMBERRED/RED-ORANGE ATIVE LUMINOUS INTENSITY(NORMALIZED AT 25 C) 001111......860246 RED-ORANGE RED REL( 0.2 REL 0.4 0.2 0 0 0 50 100 150 200 -50 -25 0 25 50 75 100 125 JUNCTION TEMPERATURE – C DC FORWARD CURRENT – mA Figure 4. Relative intensity vs. forward current Figure 5. Relative intensity vs. temperature 160 160 140 RJA = 140 80 °C/W mA RJA = 100 °C/W AMBER / RED-ORANGE – 120 120 ENT RJA = 110 °C/W RED R 100 100 R A RWARD CU 6800 RJA = 130 °C/W RRENT – m 6800 O U M F C U 40 40 M XI MA 20 20 0 0 0 20 40 60 80 100 120 0 20 40 60 80 100 120 JUNCTION TEMPERATURE – °C TEMPERATURE – °C Figure 6a. Maximum forward current vs. ambient temperature. Derated Figure 6b. Maximum forward current vs. solder point temperature. based on TJMAX = 125°C, RθJ-A = 130°C/W, 110°C/W, 100°C/W and 80°C/W. Derated based on TJMAX = 125°C, RJP = 60°C/W. 4

0.30 0.30 t tp D0. =05 D = Tp T IF 0.10 0.20 0.25 0.20 D = 0.50 0.05 CURRENT - A 0.10 1 CURRENT - A 0.10 0001...125050 t tp D = Tp T IF 0.00 0.00 1.00E-05 1.00E-03 1.00E-01 1.00E+01 1.00E-05 1.00E-03 1.00E-01 1.00E+01 tp - Time - (S) tp - Time - (S) Figure 7a. Maximum pulse current vs. ambient temperature. Derated Figure 7b. Maximum pulse current vs. ambient temperature.Derated vased based on TA = 25°C, RθJ-A =110°C/W. on TA= 85°C, RθJ-P =110°C/W. 630 0.15 AlInGaP RED 0.10 620 m H – n AlInGaP RED-ORANGE FT (V) 0.05 WAVELENGT 660100 VOLTAGE SHI 0 NANT AlInGaP AMBER WARD -0.05 MI R DO 590 FO -0.10 580 -0.15 0 50 100 150 200 -50 -25 0 25 50 75 100 FORWARD CURRENT – mA TJ – JUNCTION TEMPERATURE – C Figure 8. Dominant wavelength vs. forward current – AlInGaP devices Figure 9. Forward voltage shift vs. temperature 1.0 0.9 0.8 TY 0.7 SI EN 0.6 T N D I 0.5 E LIZ 0.4 A M 0.3 R O N 0.2 0.1 0 -90 -60 -30 0 30 60 90 ANGULAR DISPLACEMENT – DEGREES Figure 10. Radiation pattern 5

10 - 30 SEC. 255 - 260 °C 217 °C 3 °C/SEC. MAX. ID RE 200 °C -6 °C/SEC. MAX. U Note: Diameter "ID" should AT R 150 °C be bigger than 2.3mm PE M 3 °C/SEC. MAX. E T 60 - 120 SEC. 100 SEC. MAX. TIME (Acc. to J-STD-020C) Figure11. Recommended pick and place nozzle size Figure 12. Recommended Pb-free refl ow soldering profi le Note: For detail information on refl ow soldering of Avago sur- face mount LEDs, do refer to Avago Application Note AN 1060 Surface Mounting SMT LED Indicator Components. 2.4 0.6 0.9 X 6 C C C C 1.3 x 6 A A 0.4 A A 1.1 A A ANODE 4.6 MARKING C CATHODE 0.3 A ANODE SOLDER MASK ANODE MARKING MINIMUM 55 mm2 OF ANODE PAD FOR IMPROVED HEAT DISSIPATION Figure 13. Recommended soldering pad pattern 6

TRAILER COMPONENT LEADER 200 mm MIN. FOR ∅180 REEL. 480 mm MIN. FOR ∅180 REEL. 200 mm MIN. FOR ∅330 REEL. 960 mm MIN. FOR ∅330 REEL. C A USER FEED DIRECTION Figure 14. Tape leader and trailer dimensions Ø1.5 +–00.1 4 ± 0.1 4 ± 0.1 2 ± 0.05 1.75 ± 0.1 2.29 ± 0.1 C C 3.5 ± 0.05 3.8 ± 0.1 8+0.3 –0.1 A A 3.05 ± 0.1 Ø1+–00.1 0.229 ± 0.01 8° ALL DIMENSIONS IN mm. Figure 15. Tape dimensions USER FEED DIRECTION CATHODE SIDE PRINTED LABEL Figure 16. Reeling orientation 7

Device Color (X ) Color Bin Select (X ) 1 4 Individual reel will contain parts from one full bin only. A Amber H Red Orange X4 0 Full Distribution R Red A 1 and 2 only B 2 and 3 only C 3 and 4 only Flux Bin Select (X X ) 2 3 D 4 and 5 only Individual reel will contain parts from one bin only. E 5 and 6 only X2 Min Flux Bin G 1, 2 and 3 only X3 Max Flux Bin H 2, 3 and 4 only J 3, 4 and 5 only K 4, 5 and 6 only Flux Bin Limits M 1, 2, 3 and 4 only N 2, 3, 4 and 5 only Bin ID Min. (lm) Max. (lm) P 3, 4, 5 and 6 only A 4.30 5.50 R 1, 2, 3, 4 and 5 only B 5.50 7.00 S 2, 3, 4, 5 and 6 only C 7.00 9.00 Z Special Color Bin D 9.00 11.50 E 11.50 15.00 F 15.00 19.50 G 19.50 25.50 Color Bin Limits H 25.50 33.00 J 33.00 43.00 Amber/Yellow Min. (nm) Max. (nm) K 43.00 56.00 2 583.0 586.0 L 56.00 73.00 3 586.0 589.0 4 589.0 592.0 Tolerance of each bin limit = ±12%. 5 592.0 595.0 6 595.0 598.0 Red Orange Min. (nm) Max. (nm) 1 611.0 616.0 2 616.0 620.0 3 620.0 625.0 Red Min. (nm) Max. (nm) Full Distribution 620.0 635.0 Tolerance of each bin limit = ±1 nm. 8

V Binning Moisture Sensitivity F Bin Min. Max. This product is qualifi ed as Moisture Sensitive Level 2a per Jedec J-STD-020. Precaution when handling this 2D 2.35 2.50 moisture sensitive product is important to ensure the 2E 2.50 2.65 reliability of the product. Do refer to Avago Application 2F 2.65 2.80 Note AN5305 Handling of Moisture Sensitive Surface Mount Devices for details. 2G 2.80 2.95 2H 2.95 3.10 A. Storage before use 2J 3.10 3.25 - Unopen moisture barrier bag (MBB) can be stored at <40°C/90%RH for 12 months. If the actual shelf 2K 3.25 3.40 life has exceeded 12 months and the HIC indicates 2L 3.40 3.55 that baking is not required, then it is safe to refl ow the LEDs per the original MSL rating. Tolerance of each bin = ±0.1 V. B. Control after opening the MBB - The humidity indicator card (HIC) shall be read im- Packaging Option (X5 ) mediately upon opening of MBB. - The LEDs must be kept at <30°C/60%RH at all times Option Test Current Package Type Reel Size and all high temperature related processes, includ- E 150 mA Top Mount 7 Inch ing soldering, curing or rework, need to be com- pleted within 672 hours. C. Control for unfi nished reel Handling Precaution - For any unused LEDs, they need to be stored in sealed MBB with desiccant or desiccator at <5%RH. The encapsulation of the product is made of silicone for better reliability of the product. As silicone is a soft D. Control of assembled boards material, please do not press on the silicone or poke a - If the PCB soldered with the LEDs is to be subjected sharp object onto the silicone. This might damage the to other high temperature processes, the PCB needs product and cause premature failure. During assembly to be stored in sealed MBB with desiccant or desic- or handling, the unit should be held on the body only. cator at <5% RH to ensure no LEDs have exceeded Please refer to Avago Application Note AN 5288 for their fl oor life of 672 hours. detailed information. E. Baking is required if: - “10%” is Not Green and “5%” HIC indicator is Azure. - The LEDs are exposed to condition of >30°C/60% RH at any time. - The LEDs fl oor life exceeded 672 hours. Recommended baking condition: 60 ± 5°C for 20 hours. For product information and a complete list of distributors, please go to our website: www.avagotech.com Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries. Data subject to change. Copyright © 2005-2011 Avago Technologies. All rights reserved. AV02-0232EN - September 30, 2011

Datasheet下载

Datasheet下载