ICGOO在线商城 > 传感器,变送器 > 运动传感器 - 加速计 > ADXL337BCPZ-RL7

- 型号: ADXL337BCPZ-RL7

- 制造商: Analog

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

ADXL337BCPZ-RL7产品简介:

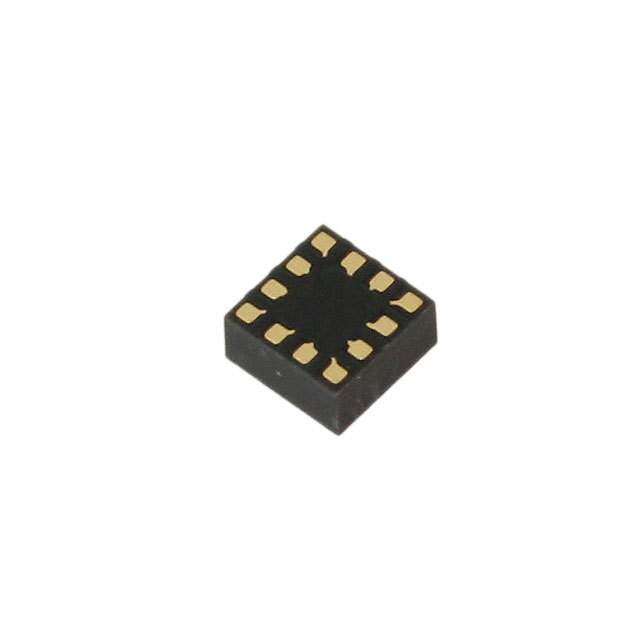

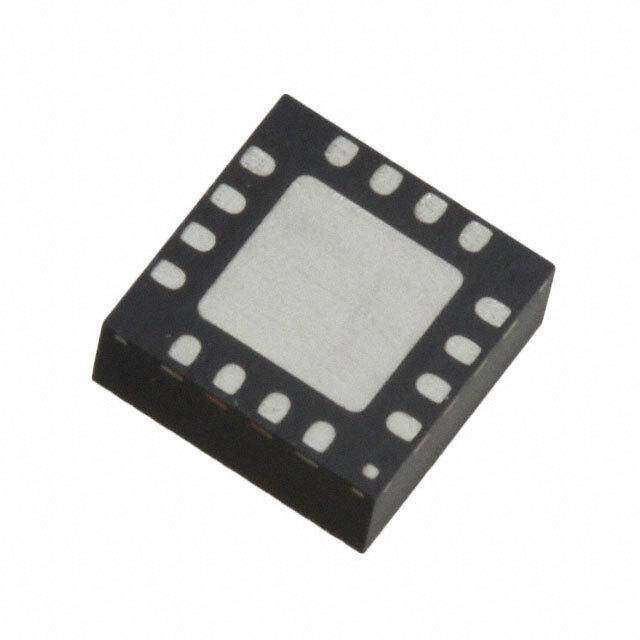

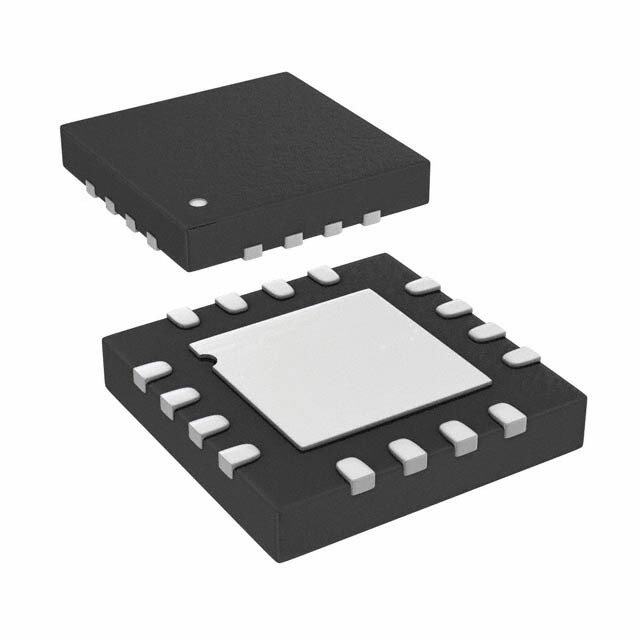

ICGOO电子元器件商城为您提供ADXL337BCPZ-RL7由Analog设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 ADXL337BCPZ-RL7价格参考。AnalogADXL337BCPZ-RL7封装/规格:运动传感器 - 加速计, Accelerometer X, Y, Z Axis ±3g 1.6kHz (X,Y), 550Hz (Z) 16-LFCSP-LQ (3x3)。您可以下载ADXL337BCPZ-RL7参考资料、Datasheet数据手册功能说明书,资料中有ADXL337BCPZ-RL7 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | IC ACCELEROMETER 3AXL 3G 16LFCSP加速计 Small 3-Axis +/-3 g Low Power |

| 产品分类 | 加速计运动与定位传感器 |

| 品牌 | Analog Devices |

| 产品手册 | |

| 产品图片 |

|

| rohs | RoHS 合规性豁免无铅 / 不受限制有害物质指令(RoHS)规范要求限制 |

| 产品系列 | 加速计,Analog Devices ADXL337BCPZ-RL7- |

| 数据手册 | |

| 产品型号 | ADXL337BCPZ-RL7 |

| PCN组件/产地 | |

| PCN设计/规格 | |

| 产品种类 | 加速计 |

| 传感轴 | Triple |

| 供应商器件封装 | 16-LFCSP-LQ(3x3) |

| 其它名称 | ADXL337BCPZ-RL7CT |

| 分辨率 | - |

| 加速 | 3 g |

| 加速度范围 | ±3.6g |

| 商标 | Analog Devices |

| 安装类型 | 表面贴装 |

| 安装风格 | SMD/SMT |

| 封装 | Reel |

| 封装/外壳 | 16-LFQFN 裸露焊盘,CSP |

| 封装/箱体 | LFCSP-16 |

| 工厂包装数量 | 1000 |

| 带宽 | 1600Hz |

| 接口 | - |

| 最大工作温度 | + 85 C |

| 最小工作温度 | - 40 C |

| 标准包装 | 1 |

| 灵敏度 | 300 mV/g |

| 电压-电源 | 1.8 V ~ 3.6 V |

| 电源电压-最大 | 3.6 V |

| 电源电压-最小 | 1.8 V |

| 电源电流 | 350 uA |

| 系列 | ADXL337 |

| 视频文件 | http://www.digikey.cn/classic/video.aspx?PlayerID=1364138032001&width=640&height=505&videoID=2245193160001http://www.digikey.cn/classic/video.aspx?PlayerID=1364138032001&width=640&height=505&videoID=2245193171001http://www.digikey.cn/classic/video.aspx?PlayerID=1364138032001&width=640&height=505&videoID=2245193170001http://www.digikey.cn/classic/video.aspx?PlayerID=1364138032001&width=640&height=505&videoID=2245193161001http://www.digikey.cn/classic/video.aspx?PlayerID=1364138032001&width=640&height=505&videoID=2245193172001 |

| 轴 | X,Y,Z |

| 输出类型 | Analog |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

Small, Low Power, 3-Axis ±3 g Accelerometer ADXL337 FEATURES GENERAL DESCRIPTION 3-axis sensing The ADXL337 is a small, thin, low power, complete 3-axis Small, low profile package accelerometer with signal conditioned voltage outputs. The 3 mm × 3 mm × 1.45 mm LFCSP product measures acceleration with a minimum full-scale range Low power: 300 μA (typical) of ±3 g. It can measure the static acceleration of gravity in tilt- Single-supply operation: 1.8 V to 3.6 V sensing applications, as well as dynamic acceleration resulting 10,000 g shock survival from motion, shock, or vibration. Excellent temperature stability The user selects the bandwidth of the accelerometer using the Bandwidth adjustment with a single capacitor per axis C , C , and C capacitors at the X , Y , and Z pins. X Y Z OUT OUT OUT RoHS/WEEE and lead-free compliant Bandwidths can be selected to suit the application, with a range of 0.5 Hz to 1600 Hz for X and Y axes and a range of 0.5 Hz to APPLICATIONS 550 Hz for the Z axis. Cost-sensitive, low power, motion- and tilt-sensing applications The ADXL337 is available in a small, low profile, 3 mm × 3 mm × Mobile devices 1.45 mm, 16-lead, lead frame chip scale package (LFCSP_LQ). Gaming systems Disk drive protection Image stabilization Sports and health devices FUNCTIONAL BLOCK DIAGRAM +3V VS ADXL337 OUTPUT ~32kΩ XOUT AC AMPLIFIERS AMPLIFIER CX CDC ~32kΩ YOUT DEMODULATOR 3-AXIS CY SENSOR ~32kΩ ZOUT CZ GND ST 09358-001 Figure 1. Rev. 0 Information furnished by Analog Devices is believed to be accurate and reliable. However, no responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A. rights of third parties that may result from its use. Specifications subject to change without notice. No license is granted by implication or otherwise under any patent or patent rights of Analog Devices. Tel: 781.329.4700 www.analog.com Trademarks and registered trademarks are the property of their respective owners. Fax: 781.461.3113 ©2010 Analog Devices, Inc. All rights reserved.

ADXL337 TABLE OF CONTENTS Features .............................................................................................. 1 Applications Information .............................................................. 11 Applications ....................................................................................... 1 Power Supply Decoupling ......................................................... 11 General Description ......................................................................... 1 Setting the Bandwidth Using C , C , and C .......................... 11 X Y Z Functional Block Diagram .............................................................. 1 Self Test ........................................................................................ 11 Revision History ............................................................................... 2 Design Trade-Offs for Selecting Filter Characteristics: The Specifications ..................................................................................... 3 Noise/BW Trade-Off .................................................................. 11 Absolute Maximum Ratings ............................................................ 4 Use with Operating Voltages Other than 3 V ............................ 12 ESD Caution .................................................................................. 4 Axes of Acceleration Sensitivity ............................................... 12 Pin Configuration and Function Descriptions ............................. 5 Layout and Design Recommendations ................................... 13 Typical Performance Characteristics ............................................. 6 Outline Dimensions ....................................................................... 14 Theory of Operation ...................................................................... 10 Ordering Guide .......................................................................... 14 Mechanical Sensor ...................................................................... 10 Performance ................................................................................ 10 REVISION HISTORY 10/10—Revision 0: Initial Version Rev. 0 | Page 2 of 16

ADXL337 SPECIFICATIONS T = 25°C, V = 3 V, C = C = C = 0.1 μF, acceleration = 0 g, unless otherwise noted. All minimum and maximum specifications are A S X Y Z guaranteed. Typical specifications are not guaranteed. Table 1. Parameter Test Conditions/Comments Min Typ Max Unit SENSOR INPUT Each axis Measurement Range ±3 ±3.6 g Nonlinearity % of full scale ±0.3 % Package Alignment Error ±1 Degrees Interaxis Alignment Error ±0.1 Degrees Cross-Axis Sensitivity1 ±1 % SENSITIVITY (RATIOMETRIC)2 Each axis Sensitivity at X , Y , Z V = 3 V 270 300 330 mV/g OUT OUT OUT S Sensitivity Change Due to Temperature3 V = 3 V ±0.01 %/°C S 0 g BIAS LEVEL (RATIOMETRIC) 0 g Voltage at X , Y V = 3 V 1.35 1.5 1.65 V OUT OUT S 0 g Voltage at Z V = 3 V 1.2 1.5 1.8 V OUT S 0 g Offset vs. Temperature X , Y ±1.1 mg/°C OUT OUT 0 g Offset vs. Temperature Z ±1.6 mg/°C OUT NOISE PERFORMANCE Noise Density X , Y 175 μg/√Hz rms OUT OUT Noise Density Z 300 μg/√Hz rms OUT FREQUENCY RESPONSE4 Bandwidth X , Y 5 No external filter 1600 Hz OUT OUT Bandwidth Z 5 No external filter 550 Hz OUT R Tolerance 32 ± 15% kΩ FILT Sensor Resonant Frequency 5.5 kHz SELF TEST6 Logic Input Low 0.6 V Logic Input High 2.4 V ST Actuation Current 60 μA Output Change at X Self test 0 to 1 −150 −325 −600 mV OUT Output Change at Y Self test 0 to 1 +150 +325 +600 mV OUT Output Change at Z Self test 0 to 1 +150 +550 +1000 mV OUT OUTPUT AMPLIFIER Output Swing Low No load 0.1 V Output Swing High No load 2.8 V POWER SUPPLY Operating Voltage Range7 1.8 3.0 3.6 V Supply Current V = 3 V 300 μA S Turn-On Time8 No external filter 1 ms TEMPERATURE Operating Temperature Range −40 +85 °C 1 Defined as coupling between any two axes. 2 Sensitivity is essentially ratiometric to VS. 3 Defined as the output change from ambient-to-maximum temperature or ambient-to-minimum temperature. 4 Actual frequency response controlled by user-supplied external filter capacitors (CX, CY, CZ). 5 Bandwidth with external capacitors = 1/(2 × π × 32 kΩ × C). For CX, CY = 0.003 μF, bandwidth = 1.6 kHz. For CZ = 0.01 μF, bandwidth = 500 Hz. For CX, CY, CZ = 10 μF, bandwidth = 0.5 Hz. 6 Self test response changes cubically with VS. 7 Tested at 3.0 V and guaranteed by design only (not tested) to work over the full range from 1.8 V to 3.6 V. 8 Turn-on time is dependent on CX, CY, CZ and is approximately 160 × (CX or CY or CZ) + 1, where CX, CY, and CZ are in μF and the resulting turn-on time is in ms. Rev. 0 | Page 3 of 16

ADXL337 ABSOLUTE MAXIMUM RATINGS Stresses above those listed under Absolute Maximum Ratings Table 2. may cause permanent damage to the device. This is a stress Parameter Rating rating only; functional operation of the device at these or any Acceleration (Any Axis, Unpowered) 10,000 g other conditions above those indicated in the operational Acceleration (Any Axis, Powered) 10,000 g section of this specification is not implied. Exposure to absolute V −0.3 V to +3.6 V S maximum rating conditions for extended periods may affect All Other Pins (GND − 0.3 V) to (V + 0.3 V) S device reliability. Output Short-Circuit Duration Indefinite (Any Pin to Common) Temperature Range (Powered) −55°C to +125°C ESD CAUTION Temperature Range (Storage) −65°C to +150°C Rev. 0 | Page 4 of 16

ADXL337 PIN CONFIGURATION AND FUNCTION DESCRIPTIONS OUT S S C Z V V N 16 15 14 13 ADXL337 RES 1 12 NC TOP VIEW ST 2 (Not to Scale) 11 NC +Y RES 3 +Z 10 NC YOUT 4 +X 9 NC 5 6 7 8 NOTES XOUT GND GND NC 09358-003 1. NC = NO CONNECT. 2. EXPOSED PAD IS NOT INTERNALLY CONNECTED BUT SHOULD BE SOLDERED FOR MECHANICAL INTEGRITY. Figure 2. Pin Configuration Table 3. Pin Function Descriptions Pin No. Mnemonic Description 1, 3 RES Reserved. This pin must be connected to GND or left open. 2 ST Self Test. 4 Y Y Channel Output. OUT 5 X X Channel Output. OUT 6, 7 GND Must be connected to ground. 8 to 13 NC Not internally connected. 14 V Supply Voltage (3.0 V typical). S 15 V Supply Voltage (3.0 V typical). S 16 Z Z Channel Output. OUT EPAD Exposed Pad. Not internally connected but should be soldered for mechanical integrity. Rev. 0 | Page 5 of 16

ADXL337 TYPICAL PERFORMANCE CHARACTERISTICS N > 250 for all typical performance plots, unless otherwise noted. (N is the number of parts tested and used to produce the histograms.) 25 45 40 20 N N 35 O O ATI ATI 30 UL 15 UL P P O O 25 P P F F O O 20 T 10 T N N CE CE 15 R R E E P 5 P 10 5 0 0 1.401.411.421.431.441.451.461.471.48OU1.49TP1.50UT1.51 (V1.52) 1.531.541.551.561.571.581.591.60 09358-005 –0.35 –0.34OU–0.33TPUT –0.32CHAN–0.31GE D–0.30UET–0.29O SEL–0.28F TES–0.27T (V)–0.26 –0.25 09358-008 Figure 3. X-Axis Zero g Bias at 25°C, VS = 3 V Figure 6. X-Axis Self-Test Response at 25°C, VS = 3 V 25 45 40 20 N N 35 O O ATI ATI 30 L L U 15 U P P O O 25 P P F F O O 20 T 10 T N N CE CE 15 R R E E P 5 P 10 5 0 0 1.401.411.421.431.441.451.461.471.48OU1.49TP1.50UT1.51 (V1.52) 1.531.541.551.561.571.581.591.60 09358-006 0.180.190.200.21OU0.22TP0.23UT0.24 CH0.25AN0.26GE0.27 D0.28UE0.29TO0.30 SE0.31LF0.32 TE0.33ST0.34 (V0.35) 0.360.370.38 09358-009 Figure 4. Y-Axis Zero g Bias at 25°C, VS = 3 V Figure 7. Y-Axis Self-Test Response at 25°C, VS = 3 V 18 60 16 50 N14 N O O ATI12 ATI 40 UL UL P P O10 O OF P 8 OF P 30 NT NT CE 6 CE 20 R R E E P 4 P 10 2 0 1.401.411.421.431.441.451.461.471.48OU1.49TP1.50UT1.51 (V1.52) 1.531.541.551.561.571.581.591.60 09358-007 0 0.44 0.46OU0.T4P8UT0 .C50HA0N.5G2E D0.U54ET0O.5 S6EL0.F5 8TE0S.T6 0(V)0.62 0.64 09358-010 Figure 5. Z-Axis Zero g Bias at 25°C, VS = 3 V Figure 8. Z-Axis Self-Test Response at 25°C, VS = 3 V Rev. 0 | Page 6 of 16

ADXL337 45 1.60 40 1.58 1.56 35 N O ATI 30 1.54 L F POPU 25 PUT (V)11..5502 NT O 20 OUT1.48 RCE 15 1.46 E P 10 1.44 5 1.42 0 1.40 –2.50 –2.25 –2.00T–1.75EMP–1.50ERA–1.25TUR–1.00E CO–0.75EFF–0.50ICIE–0.25NT 0(mg/0.25°C)0.50 0.75 1.00 09358-011 –40 –20 0 TEMP20ERATUR4E0 (°C) 60 80 10009358-014 Figure 9. X-Axis Zero g Bias Temperature Coefficient, VS = 3 V Figure 12. X-Axis Zero g Bias vs. Temperature—Eight Parts Soldered to PCB 35 1.60 1.58 30 1.56 N TIO 25 1.54 A L F POPU 20 PUT (V)11..5502 NT O 15 OUT1.48 E C R 10 1.46 E P 1.44 5 1.42 0 1.40 –2.50 –2.25 –2.00T–1.75EMP–1.50ERA–1.25TUR–1.00E CO–0.75EFF–0.50ICIE–0.25NT 0(mg/0.25°C)0.50 0.75 1.00 09358-012 –40 –20 0 TEMP20ERATUR4E0 (°C) 60 80 100 09358-015 Figure 10. Y-Axis Zero g Bias Temperature Coefficient, VS = 3 V Figure 13. Y-Axis Zero g Bias vs. Temperature—Eight Parts Soldered to PCB 30 1.60 1.58 25 1.56 N O ATI 20 1.54 L F POPU 15 PUT (V) 11..5502 O T NT OU 1.48 RCE 10 1.46 E P 1.44 5 1.42 0 1.40 –3.0 –2.5 –2.0TEM–1.5PER–1.0ATUR–0.5E CO0EFF0.5ICIEN1.0T (m1.5g/°C2.0) 2.5 3.0 09358-013 –60 –40 –20 TE0MPERA20TURE (4°0C) 60 80 100 09358-016 Figure 11. Z-Axis Zero g Bias Temperature Coefficient, VS = 3 V Figure 14. Z-Axis Zero g Bias vs. Temperature—Eight Parts Soldered to PCB Rev. 0 | Page 7 of 16

ADXL337 50 0.33 45 0.32 40 N O TI 35 OPULA 30 Y (V/g) 0.31 F P 25 VIT 0.30 O TI T 20 SI N N E E RC 15 S 0.29 E P 10 0.28 5 0 0.27 0.290 0.293 0.296 0.299SENS0.302ITIVIT0.305Y (V/g0.308) 0.311 0.314 0.317 09358-017 –40 –20 0 TEM2P0ERATUR4E0 (°C) 60 80 100 09358-020 Figure 15. X-Axis Sensitivity at 25°C, VS = 3 V Figure 18. X-Axis Sensitivity vs. Temperature, Eight Parts Soldered to PCB, VS = 3 V 60 0.33 50 0.32 N O ATIUL 40 V/g) 0.31 OF POP 30 TIVITY ( 0.30 NT NSI CE 20 SE 0.29 R E P 10 0.28 0 0.27 0.290 0.293 0.296 0.299 SE0.302NSITI0.305VITY (0.308V/g) 0.311 0.314 0.317 0.320 09358-018 –40 –20 0 TEM2P0ERATUR4E0 (°C) 60 80 100 09358-021 Figure 16. Y-Axis Sensitivity at 25°C, VS = 3 V Figure 19. Y-Axis Sensitivity vs. Temperature, Eight Parts Soldered to PCB, VS = 3 V 50 0.33 45 0.32 40 N O OF POPULATI 233505 TIVITY (V/g) 00..3301 CENT 20 SENSI 0.29 R 15 E P 10 0.28 5 0 0.27 0.290 0.293 0.296 0.299 SE0.302NSITI0.305VITY (0.308V/g) 0.311 0.314 0.317 0.320 09358-019 –40 –20 0 TEMP20ERATUR4E0 (°C) 60 80 100 09358-022 Figure 17. Z-Axis Sensitivity at 25°C, VS = 3 V Figure 20. Z-Axis Sensitivity vs. Temperature, Eight Parts Soldered to PCB, VS = 3 V Rev. 0 | Page 8 of 16

ADXL337 400 CX = CY = CZ = 0.001µF 350 300 ZOUT, A) 250 500mV/DIV µ T ( N 200 RE YOUT, R 500mV/DIV CU 150 XOUT, 100 500mV/DIV 5001.5 2.0 SUP2P.5LY VOLTAG3.E0 (V) 3.5 4.0 09358-023 P1OVW/DEIVR, OTUITMPEU (T1SmAs/RDEIV O)FFSET FOR CLARITY 09358-024 Figure 21. Typical Current Consumption vs. Supply Voltage Figure 22. Typical Turn-On Time, VS = 3 V Rev. 0 | Page 9 of 16

ADXL337 THEORY OF OPERATION The ADXL337 is a complete 3-axis acceleration measurement MECHANICAL SENSOR system. The ADXL337 has a measurement range of ±3 g minimum. The ADXL337 uses a single structure for sensing the X, Y, and Z axes. It contains a polysilicon surface micromachined sensor and signal As a result, the three axes sense directions are highly orthogonal conditioning circuitry to implement an open-loop acceleration with little cross-axis sensitivity. Mechanical misalignment of the measurement architecture. The output signals are analog voltages sensor die to the package is the chief source of cross-axis sensitivity. that are proportional to acceleration. The accelerometer can Mechanical misalignment can be calibrated out at the system level. measure the static acceleration of gravity in tilt-sensing applications PERFORMANCE as well as dynamic acceleration resulting from motion, shock, or vibration. Rather than using additional temperature compensation circuitry, innovative design techniques ensure that high performance is built The sensor is a polysilicon surface micromachined structure into the ADXL337. As a result, there is neither quantization error built on top of a silicon wafer. Polysilicon springs suspend the nor nonmonotonic behavior, and temperature hysteresis is very structure over the surface of the wafer and provide a resistance low (typically less than 3 mg over the −25°C to +85°C temperature against acceleration forces. Deflection of the structure is measured range). using a differential capacitor that consists of independent fixed plates and plates attached to the moving mass. The fixed plates are driven by 180° out-of-phase square waves. Acceleration deflects the moving mass and unbalances the differential capacitor resulting in a sensor output whose amplitude is proportional to acceleration. Phase-sensitive demodulation techniques are then used to determine the magnitude and direction of the acceleration. The demodulator output is amplified and brought off chip through a 32 kΩ resistor. The user then sets the signal bandwidth (BW) of the device by adding a capacitor. This filtering improves measurement resolution and helps prevent aliasing. Rev. 0 | Page 10 of 16

ADXL337 APPLICATIONS INFORMATION POWER SUPPLY DECOUPLING DESIGN TRADE-OFFS FOR SELECTING FILTER CHARACTERISTICS: THE NOISE/BW TRADE-OFF For most applications, a single 0.1 μF capacitor, C , placed DC close to the ADXL337 supply pins adequately decouples the The selected accelerometer bandwidth ultimately determines accelerometer from noise on the power supply. However, in the measurement resolution (smallest detectable acceleration). applications where noise is present at the 50 kHz internal clock Filtering can be used to lower the noise floor to improve the frequency (or any harmonic thereof), additional care in power resolution of the accelerometer. Resolution is dependent on the supply bypassing is required because this noise can cause errors analog filter bandwidth at X , Y , and Z . OUT OUT OUT in acceleration measurement. If additional decoupling is needed, a The output of the ADXL337 has a typical bandwidth of greater 100 Ω (or smaller) resistor or ferrite bead can be inserted in the than 500 Hz. The user must filter the signal at this point to limit supply line. Additionally, a larger bulk bypass capacitor (1 μF or aliasing errors. The analog bandwidth must be no more than half greater) can be added in parallel to C . Ensure that the connection DC the analog-to-digital sampling frequency to minimize aliasing. from the ADXL337 ground to the power supply ground is low The analog bandwidth can be decreased further to reduce noise impedance because noise transmitted through ground has a and improve resolution. similar effect as noise transmitted through V. S The ADXL337 noise has the characteristics of white Gaussian SETTING THE BANDWIDTH USING C , C , AND C X Y Z noise, which contributes equally at all frequencies and is described The ADXL337 has provisions for band limiting the X , Y , in terms of μg/√Hz (the noise is proportional to the square root OUT OUT and Z pins. Capacitors must be added at these pins to implement of the accelerometer bandwidth). The user should limit bandwidth OUT low-pass filtering for antialiasing and noise reduction. The to the lowest frequency needed by the application to maximize equation for the 3 dB bandwidth is the resolution and dynamic range of the accelerometer. f = 1/(2π(32 kΩ) × C ) With the single-pole, roll-off characteristic, the typical noise of −3 dB (X, Y, Z) the ADXL337 is determined by or more simply f = 5 μF/C rms Noise = Noise Density × ( BW×1.6) –3 dB (X, Y, Z) The tolerance of the internal resistor (R ) typically varies as It is often useful to know the peak value of the noise. Peak-to-peak FILT much as ±15% of its nominal value (32 kΩ), and the bandwidth noise can only be estimated by statistical methods. Table 5 is useful varies accordingly. A minimum capacitance of 0.0047 μF for C , for estimating the probabilities of exceeding various peak values, X C , and C is recommended in all cases. given the rms value. Y Z Table 4. Filter Capacitor Selection, C , C , and C Table 5. Estimation of Peak-to-Peak Noise X Y Z Bandwidth (Hz) Capacitor (μF) Percent of Time that Noise Exceeds Peak-to-Peak Value Nominal Peak-to-Peak Value 1 4.7 2 × rms 32 10 0.47 4 × rms 4.6 50 0.10 6 × rms 0.27 100 0.05 8 × rms 0.006 200 0.027 500 0.01 SELF TEST The ST pin controls the self test feature. When this pin is set to V, an electrostatic force is exerted on the accelerometer beam. S The resulting movement of the beam allows the user to test if the accelerometer is functional. The typical change in output is −1.08 g (corresponding to −325 mV) in the X-axis, +1.08 g (or +325 mV) on the Y-axis, and +1.83 mg (or +550 mV) on the Z-axis. This ST pin can be left open circuit or connected to common (GND) in normal use. Never expose the ST pin to voltages greater than V + 0.3 V. If S this cannot be guaranteed due to the system design (for instance, if there are multiple supply voltages), then a low V clamping F diode between ST and V is recommended. S Rev. 0 | Page 11 of 16

ADXL337 USE WITH OPERATING VOLTAGES OTHER THAN 3 V At V = 2 V, the self test response is approximately −96 mV for S the X-axis, +96 mV for the Y-axis, and −163 mV for the Z-axis. The ADXL337 is tested and specified at V = 3 V; however, it S can be powered with V as low as 1.8 V or as high as 3.6 V. Note The supply current decreases as the supply voltage decreases. S that some performance parameters change as the supply voltage Typical current consumption at VS = 3.6 V is 375 μA, and is varied. typical current consumption at VS = 2 V is 200 μA. The ADXL337 output is ratiometric; therefore, the output AXES OF ACCELERATION SENSITIVITY sensitivity (or scale factor) varies proportionally to the supply The axes of sensitivity for the accelerometer are shown in Figure 23, voltage. At V = 3.6 V, the output sensitivity is typically 360 mV/g. S and Figure 24 shows the output response when the accelerometer is At V = 2 V, the output sensitivity is typically 195 mV/g. S oriented parallel to each of these axes. The zero g bias output is also ratiometric; therefore, the zero g AZ output is nominally equal to V/2 at all supply voltages. S The output noise is not ratiometric but is absolute in volts; therefore, the noise density decreases as the supply voltage increases. This is because the scale factor (mV/g) increases AY while the noise voltage remains constant. At V = 3.6 V, the X- S and Y-axis noise density is typically 120 μg/√Hz, and at V = S 2 V, the X- and Y-axis noise density is typically 270 μg/√Hz. Self test response in g is roughly proportional to the square of TOP the supply voltage. However, when ratiometricity of sensitivity is factored in with supply voltage, the self test response in volts iesx raomupglhel,y a tp rVop =o r3t.i6o nVa, lt htoe tsheelf ctuesbte r oesf pthone sseu pfoprl yth veo AltaDgXe.L F3o3r7 is AX 09358-030 S Figure 23. Axes of Acceleration Sensitivity, Corresponding Output Voltage approximately −560 mV for the X-axis, +560 mV for the Y-axis, Increases When Accelerated Along the Sensitive Axis and +950 mV for the Z-axis. XOUT = –1g YOUT = 0g ZOUT = 0g TOP GRAVITY XOUT = 0g XOUT = 0g YOUT = 1g TOP TOP YOUT = –1g ZOUT = 0g ZOUT = 0g TOP XOUT = 1g YOUT = 0g ZOUT = 0g TOP XYZOOOUUUTTT === 100ggg XYZOOOUUUTTT === –001ggg 09358-031 Figure 24. Output Response vs. Orientation to Gravity Rev. 0 | Page 12 of 16

ADXL337 LAYOUT AND DESIGN RECOMMENDATIONS The recommended soldering profile is shown in Figure 25 followed by a description of the profile features in Table 6. The recommended PCB layout or solder land drawing is shown in Figure 26. CRITICAL ZONE TP tP TL TO TP RAMP-UP URETL TSMAX tL T A ER TSMIN P M E T t PREHSEAT RAMP-DOWN t25°C TIME 09358-002 Figure 25. Recommended Soldering Profile Table 6. Recommended Soldering Profile Profile Feature Sn63/Pb37 Pb-Free Average Ramp Rate (T to T) 3°C/sec maximum 3°C/sec maximum L P Preheat Minimum Temperature (T ) 100°C 150°C SMIN Maximum Temperature (T ) 150°C 200°C SMAX Time (T to T ), t 60 sec to 120 sec 60 sec to 180 sec SMIN SMAX S T to T SMAX L Ramp-Up Rate 3°C/sec maximum 3°C/sec maximum Time Maintained Above Liquidous (T) L Liquidous Temperature (T) 183°C 217°C L Time (t) 60 sec to 150 sec 60 sec to 150 sec L Peak Temperature (T) 240°C + 0°C/−5°C 260°C + 0°C/−5°C P Time within 5°C of Actual Peak Temperature (t) 10 sec to 30 sec 20 sec to 40 sec P Ramp-Down Rate 6°C/sec maximum 6°C/sec maximum Time 25°C to Peak Temperature (t ) 6 minutes maximum 8 minutes maximum 25°C 0.40 3 MAX 0.50 0.25 0.25 MAX 0.50 3 1.60 0.25 CENTER PAD IS NOT INTERNALLY CONNECTED BUT SHOULD BE SOLDERED FOR MECHANICAL INTEGRITY 1.60 DIMENSIONS SHOWN IN MILLIMETERS 09358-004 Figure 26. Recommended PCB Layout Rev. 0 | Page 13 of 16

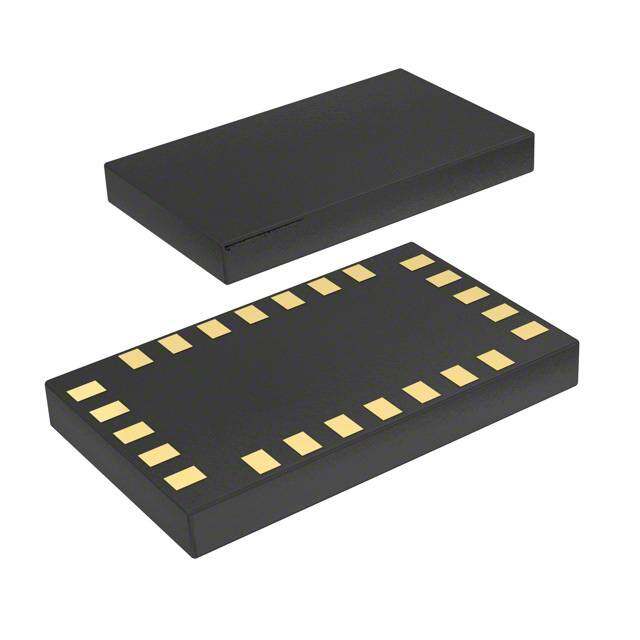

ADXL337 OUTLINE DIMENSIONS 3.10 0.30 3.00SQ 0.25 PIN1 2.90 0.18 INDICATOR PIN1 0.50 13 16 INDICATOR BSC 12 1 EXPOSED 1.70 PAD 1.60SQ 1.50 9 4 0.45 8 5 0.20MIN TOPVIEW 0.40 BOTTOMVIEW 1.50 0.35 1.45 FORPROPERCONNECTIONOF 1.40 THEEXPOSEDPAD,REFERTO THEPINCONFIGURATIONAND 0.05MAX FUNCTIONDESCRIPTIONS 0.02NOM SECTIONOFTHISDATASHEET. COPLANARITY SEATING 0.08 PLANE 0.152REF 04-27-2010-A Figure 27. 16-Lead Lead Frame Chip Scale Package [LFCSP_LQ] 3 mm × 3 mm Body, Thick Quad (CP-16-28) Dimensions shown in millimeters ORDERING GUIDE Model1 Measurement Range Specified Voltage Temperature Range Package Description Package Option ADXL337BCPZ–RL ±3 g 3 V −40°C to +85°C 16-Lead LFCSP_LQ CP-16-28 ADXL337BCPZ–RL7 ±3 g 3 V −40°C to +85°C 16-Lead LFCSP_LQ CP-16-28 EVAL-ADXL337Z Evaluation Board 1 Z = RoHS Compliant Part. Rev. 0 | Page 14 of 16

ADXL337 NOTES Rev. 0 | Page 15 of 16

ADXL337 NOTES ©2010 Analog Devices, Inc. All rights reserved. Trademarks and registered trademarks are the property of their respective owners. D09358-0-10/10(0) Rev. 0 | Page 16 of 16

Mouser Electronics Authorized Distributor Click to View Pricing, Inventory, Delivery & Lifecycle Information: A nalog Devices Inc.: ADXL337BCPZ-RL7 EVAL-ADXL337Z-S EVAL-ADXL337Z ADXL337BCPZ-RL

Datasheet下载

Datasheet下载