- 型号: AD5560JSVUZ

- 制造商: Analog

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

AD5560JSVUZ产品简介:

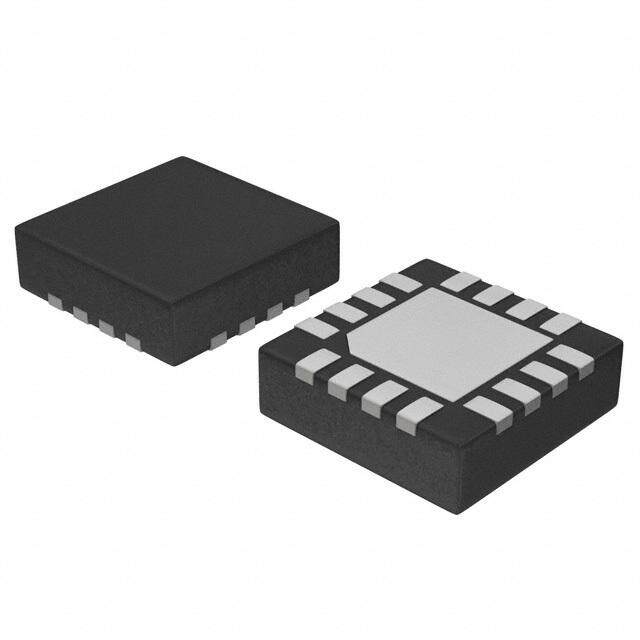

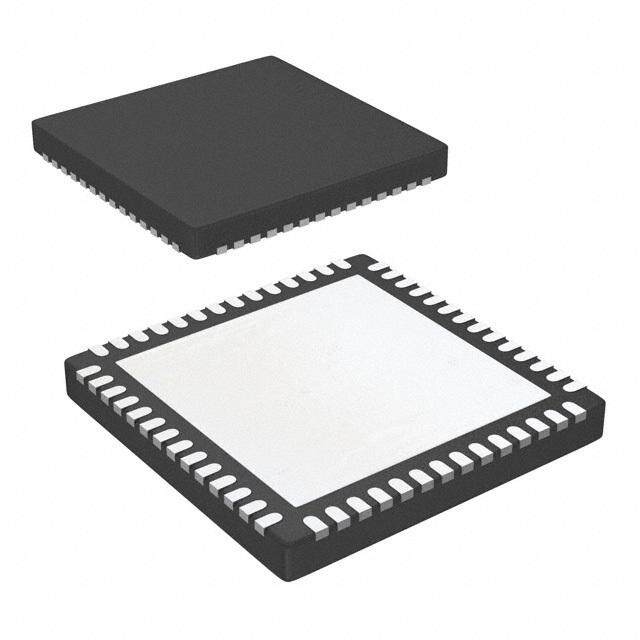

ICGOO电子元器件商城为您提供AD5560JSVUZ由Analog设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 AD5560JSVUZ价格参考。AnalogAD5560JSVUZ封装/规格:专用 IC, Power Supply IC Automatic Test Equipment 64-TQFP-EP (10x10)。您可以下载AD5560JSVUZ参考资料、Datasheet数据手册功能说明书,资料中有AD5560JSVUZ 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | 集成电路 (IC)半导体 |

| 描述 | 1.2A PROGRAMMABLE DPS专业电源管理 IC 12A programmable DPS w/s |

| DevelopmentKit | EVAL-AD5560EBUZ |

| 产品分类 | |

| 品牌 | Analog Devices Inc |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 电源管理 IC,专业电源管理,Analog Devices AD5560JSVUZ- |

| 数据手册 | |

| 产品型号 | AD5560JSVUZ |

| 产品种类 | 专业电源管理 |

| 供应商器件封装 | 64-TQFP-EP(10x10) |

| 其它名称 | Q4429347 |

| 包装 | 托盘 |

| 商标 | Analog Devices |

| 安装类型 | 表面贴装 |

| 安装风格 | SMD/SMT |

| 封装 | Tray |

| 封装/外壳 | 64-TQFP 裸露焊盘 |

| 封装/箱体 | TQFP-64 EP |

| 工作温度范围 | + 25 C to + 90 C |

| 工厂包装数量 | 160 |

| 应用 | 自动测试设备 |

| 标准包装 | 1 |

| 电源电压 | 25 V |

| 类型 | |

| 系列 | AD5560 |

| 设计资源 | |

| 输入电压范围 | - 22 V to 25 V |

| 输出电压范围 | 0 V to 25 V |

| 输出电流 | 5 uA to 25 mA |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

1.2 A Programmable Device Power Supply with Integrated 16-Bit Level Setting DACs Data Sheet AD5560 FEATURES On-chip comparators Gangable for higher current Programmable device power supply (DPS) Guard amplifier FV, MI, MV, FNMV functions System PMU connections 5 internal current ranges (on-chip R ) SENSE Current clamps ±5 µA, ±25 µA, ±250 µA, ±2.5 mA, ±25 mA Die temperature sensor and shutdown feature 2 external high current ranges (external R ) SENSE On-chip diode thermal array EXTFORCE1: ±1.2 A maximum Diagnostic register allows access to internal nodes EXTFORCE2: ±500 mA maximum Open-drain alarm flags (temperature, current clamp, Kelvin Integrated programmable levels alarm) All 16-bit DACs: force DAC, comparator DACs, clamp DACs, SPI-/MICROWIRE-/DSP-compatible interface offset DAC, OSD DAC, DGS DAC 64-lead (10 mm × 10 mm) TQFP with exposed pad (on top) Programmable Kelvin clamp and alarm 72-ball (8 mm × 8 mm) flip-chip BGA Offset and gain correction registers on-chip Ramp mode on force DAC for power supply slewing APPLICATIONS Programmable slew rate feature, 1 V/μs to 0.3 V/μs Automatic test equipment (ATE) DUTGND Kelvin sense and alarm Device power supply 25 V FV span with asymmetrical operation within −22 V/+25 V GENERAL DESCRIPTION The AD5560 is a high performance, highly integrated device dissipation. Current ranges in excess of ±1.2 A or at high power supply consisting of programmable force voltages and current and high voltage combinations can be achieved by measure ranges. This part includes the required DAC levels to paralleling or ganging multiple DPS devices. Open-drain set the programmable inputs for the drive amplifier, as well as alarm outputs are provided in the event of overcurrent, clamping and comparator circuitry. Offset and gain correction overtemperature, or Kelvin alarm on either the SENSE or is included on-chip for DAC functions. A number of program- DUTGND line. mable measure current ranges are available: five internal fixed The DPS functions are controlled via a simple 3-wire serial ranges and two external customer-selectable ranges (EXTFORCE1 interface compatible with SPI, QSPI™, MICROWIRE™, and DSP and EXTFORCE2) that can supply currents up to ±1.2 A and interface standards running at clock speeds of up to 50 MHz. ±500 mA, respectively. The voltage range possible at this high current level is limited by headroom and the maximum power Rev. E Document Feedback Information furnished by Analog Devices is believed to be accurate and reliable. However, no responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A. rights of third parties that may result from its use. Specifications subject to change without notice. No license is granted by implication or otherwise under any patent or patent rights of Analog Devices. Tel: 781.329.4700 ©2008–2016 Analog Devices, Inc. All rights reserved. Trademarks and registered trademarks are the property of their respective owners. Technical Support www.analog.com

AD5560 Data Sheet TABLE OF CONTENTS Features .............................................................................................. 1 Adjusting the Autocompensation Mode ................................. 39 Applications ....................................................................................... 1 Dealing with Parallel Load Capacitors .................................... 39 General Description ......................................................................... 1 DAC Levels .................................................................................. 39 Revision History ............................................................................... 3 Force and Comparator DACs ................................................... 39 Functional Block Diagram .............................................................. 4 Clamp DACs ............................................................................... 39 Specifications ..................................................................................... 5 OSD DAC .................................................................................... 40 Timing Characteristics .............................................................. 13 DUTGND DAC .......................................................................... 40 Timing Diagrams ........................................................................ 13 Offset DAC .................................................................................. 40 Absolute Maximum Ratings .......................................................... 15 Offset and Gain Registers .......................................................... 40 ESD Caution ................................................................................ 15 Reference Selection .................................................................... 41 Pin Configurations and Function Descriptions ......................... 16 Calibration................................................................................... 41 Typical Performance Characteristics ........................................... 20 Additional Calibration ............................................................... 41 Terminology .................................................................................... 28 System Level Calibration ........................................................... 41 Theory of Operation ...................................................................... 29 Choosing AV /AV Power Supply Rails ............................... 42 DD SS Force Amplifier ........................................................................... 29 Choosing HCAV x and HCAV x Supply Rails ................... 42 SS DD DAC Reference Voltage (VREF) ............................................... 29 Power Dissipation....................................................................... 42 Open-Sense Detect (OSD) Alarm and Clamp ....................... 29 Package Composition and Maximum Vertical Force ............ 43 Device Under Test Ground (DUTGND)................................. 29 Slew Rate Control ....................................................................... 43 GPO .............................................................................................. 29 Serial Interface ................................................................................ 45 Comparators ................................................................................ 30 SPI Interface ................................................................................ 45 Current Clamps .......................................................................... 30 SPI Write Mode .......................................................................... 45 Short-Circuit Protection ............................................................ 30 SDO Output ................................................................................ 45 Guard Amplifier ......................................................................... 30 RESET Function ......................................................................... 45 Compensation Capacitors ......................................................... 30 BUSY Function ........................................................................... 45 Current Range Selection ............................................................ 31 LOAD Function .......................................................................... 45 High Current Ranges ................................................................. 31 Register Update Rates ................................................................ 46 Ideal Sequence for Gang Mode ................................................. 32 Control Registers ............................................................................ 47 Compensation for Gang Mode ................................................. 32 DPS and DAC Addressing ........................................................ 47 System Force/Sense Switches .................................................... 32 Readback Mode .......................................................................... 58 Die Temperature Sensor and Thermal Shutdown.................. 33 DAC Readback............................................................................ 58 Measure Output (MEASOUT) ................................................. 33 Power-On Default ...................................................................... 58 VMID Voltage ................................................................................ 33 Using the HCAVDDx and HCAVSSx Supplies .......................... 60 Force Amplifier Stability............................................................ 36 Power Supply Sequencing ......................................................... 60 Poles and Zeros in a Typical System ........................................ 37 Required External Components ............................................... 61 Minimizing the Number of External Compensation Power Supply Decoupling ......................................................... 62 Components ................................................................................ 37 Applications Information .............................................................. 63 Extra Poles and Zeros in the AD5560 ...................................... 37 Thermal Considerations ............................................................ 63 Compensation Strategies ........................................................... 38 Temperature Contour Map on the Top of the Package ......... 64 Optimizing Performance for a Known Capacitor Using Outline Dimensions ....................................................................... 65 Autocompensation Mode .......................................................... 38 Ordering Guide .......................................................................... 66 Rev. E | Page 2 of 66

Data Sheet AD5560 REVISION HISTORY 5/2016—Rev. D to Rev. E 9/2009—Rev. A to Rev. B Changes to Figure 1........................................................................... 4 Changes to Table 1, Measure Current and Measure Voltage Changes to High Current Ranges Section ................................... 31 Parameters .......................................................................................... 6 Added Calibration Section, Reducing Zero-Scale Error Section, Changes to Die Temperature Sensor and Thermal Reducing Gain Error Section, Calibration Example Section, Shutdown Section ........................................................................... 31 Additional Calibration Section, and System Level Calibration Changes to Table 10 and Table 11 ................................................. 32 Section .............................................................................................. 41 Changes to Table 18, Bit 15 ............................................................ 45 Added Figure 58; Renumbered Sequentially ............................... 42 Changes to Table 23, Bits[15:12] ................................................... 50 Changes to Table 25 ........................................................................ 57 Changes to Table 25 ........................................................................ 54 8/2012—Rev. C to Rev. D 12/2008—Rev. 0 to Rev. A Added 72-Ball Flip-Chip BGA (Throughout) ............................... 1 Changes to Figure 1 .......................................................................... 4 Added Figure 7 and Table 5 (Renumbered Sequentially) .......... 18 Changes to Table 1 ............................................................................ 4 Added Applications Information Section .................................... 62 Changes to Table 2 .......................................................................... 13 Updated Outline Dimensions ........................................................ 64 Changes to Table 3 .......................................................................... 15 Changes to Ordering Guide ........................................................... 65 Changes to Open-Sense Detect (OSD) Alarm and Clamp ....... 27 Changes to Figure 53 ...................................................................... 30 10/2010—Rev. B to Rev. C Change to g Maximum Rating, Table 13 ................................... 34 m Changes to Force Output Voltage Parameter and Load Transient Changes to Table 19 ........................................................................ 46 Response Parameter, Table 1 ............................................................ 5 Changes to Bit 7, Bit 8 Functions, Table 21 ................................. 48 Changes to Figure 52 ...................................................................... 29 Changes to Power Supply Decoupling Section ........................... 59 Changes to Table 9 .......................................................................... 32 11/2008—Revision 0: Initial Version Rev. E | Page 3 of 66

AD5560 Data Sheet FUNCTIONAL BLOCK DIAGRAM EXTR1SENSE 100-97770 EXT2RSENSE UT D SLAVE_IN MASTER_OUT CTO CF0F4 EXTFORCE1 EXTFORCE2 CTO CF0F4 SYS_FORCE FORCE SYS_SENSE EXTMEASIH1 EXTMEASIH2 EXTMEASIL SENSE GUARD/SYS_DUTGNDDUTGND SW6 MUX UPTO ±1.2A UPTO ±500mA SW8 SW11 10kΩ SW9 SW18 HCAV2xCAV2xDDSS SW5b SW5a 25mA 20Ω2.5mA 200Ω250µA 2kΩ25µA 20kΩ5µA 100kΩ SW7 SW13 SW14 SW15 GUARDSW17AMP AD5560 HCAV1xHAV1xSSDD RSENSE NHIBIT SW4 DUTGND SENSEANDALARM ALARM BLOCKKSENSEDUTGND SENSEGUARD KELALM HC 8pFI OPENSENSEDETECT +– +– +– +– CC2C3 ΩΩkk50201 R: 200ΩPTO 1MΩ DGSDAC CCCC0C1 ΩR: 500ΩkZ6TO 1.6MΩ 40µA/V80µA/V300µA/V900µA/V gm SLEW RATECONTROL LOCAL FEEDBACKEXTFORCE1EXTFORCE2 DAC MID CODEVOLTAGETOCENTER IRANGECABISENSE+×10OR ×20–SW2 AGNDV+SENSE×1– VREFOSD16DAC 16 VREF C W1 S A B CLEN/LOADDGNDCLALMDVAVAVAGNDCCSSDD CLH16-BIT1616DAC×2 REG×1 REG16CLAMPM REG16OFFSET CONTROLC REG×1CLL16-BIT1616DAC×2 REG×1 REG16M REG16OFFSETC REG×1 RAMP REG1616×2 REG×1 REG16-BIT16FINDACM REG16C REGB×1R3R4AOFFSET DACCLH16-BIT16CLH DAC OFFSETR1R2AGNDS/W INH THERMAL SHUTDOWN161616-BIT16DAC16×2 REG×1 REGM REGC REGOFFSET×8161616-BIT16DAC16×2 REG×1 REGM REGC REGOFFSET×8 CPHSW3 CPL ISENSEVSENSESW16MUXKSENSEANDTSENSEGAINDUTGND SENSEDIE TEMP×1/×0.2DIAGNOSTIC ASENSORANDDIAGNOSTIC BTHERMALSHUTDOWN 16SERIAL SPI INTERFACE OWER-ONRESET SDISCLKSYNCBUSYSDOGPORESETTMPALM P VREF REFGND RCLK W_INH/LOAD CPOH/CPO CPOL MEASOUT H Figure 1. Rev. E | Page 4 of 66

Data Sheet AD5560 SPECIFICATIONS HCAV x ≤ (AV + 33 V), HCAV x ≤ AV , HCAV x ≥ AV , AV ≥ 8 V, AV ≤ −5 V, |AV − AV | ≥ 16 V and ≤ 33 V, DV = DD SS DD DD SS SS DD SS DD SS CC 2.3 V to 5.5 V, V = 5 V, gain (m), offset (c), and DAC offset registers are at default values; AGND = DGND = 0 V; T = 25°C to 90°C, REF J maximum specifications, unless otherwise noted. FSV is full-scale voltage, FSVR is full-scale voltage range, FSC is full-scale current, FSCR is full-scale current range. Table 1. Parameter Min Typ Max Unit Test Conditions/Comments FORCE VOLTAGE Force Output Voltage1 EXTFORCE1 AV + 2.25 AV − 2.25 V Allow ±500 mV for external R voltage drop SS DD SENSE HCAV 1x + 1.75 HCAV 1x − 1.75 V Allow ±500 mV for external R voltage drop SS SS SENSE HCAV 1x + 1.25 HCAV 1x − 1.25 V Allow ±500 mV for external R voltage drop; SS DD SENSE reduced headroom/footroom, clamps must be enabled2 EXTFORCE2 AV + 2.25 AV − 2.25 V Allow ±500 mV for external R voltage drop SS DD SENSE HCAV 2x + 1.75 HCAV 2x − 1.75 V Allow ±500 mV for external R voltage drop SS DD SENSE HCAV 2x + 1.25 HCAV 2x − 1.25 V Allow ±500 mV for external R voltage drop; SS DD SENSE reduced headroom/footroom, clamps must be enabled2 FORCE AV + 2.75 AV − 2.75 V Internal current ranges, includes ±500 mV for SS DD internal R voltage drop SENSE Headroom/Footroom1 −2.75 +2.75 V Internal current ranges to AV /AV , includes DD SS ±500 mV for internal R voltage drop. SENSE Headroom/Footroom1 −2.25 +2.25 V External current ranges, EXTFORCE1/ EXTFORCE2 to HCAV x and HCAV x supplies; DD SS includes ±500 mV for external R voltage drop.\ SENSE Force Output Voltage Span −22 +25 V May be a skewed range but within headroom requirements and maximum power dissipation for current range Forced Voltage Linearity Error −2 +2 mV Forced Voltage Offset Error −50 +50 mV Uncalibrated, use c register to calibrate, meas- ured at midscale Forced Voltage Offset Error Tempco1 27 μV/°C Standard deviation = 23 μV/°C Forced Voltage Gain Error −25 +25 mV Uncalibrated, use m register to calibrate Forced Voltage Gain Error Tempco1 4 ppm/°C Standard deviation = 3 ppm/°C Short-Circuit Current Limit3 Clamps off EXTFORCE1 −3.5 ±2.7 +3.5 A Positive and negative dc short-circuit current EXTFORCE2 −1.25 ±0.9 +1.25 A Positive and negative dc short-circuit current FORCE −75 ±50 +75 mA ±25 mA range, positive and negative dc short- circuit current −20 ±10 +20 mA All other ranges, positive and negative dc short- circuit current Active C Buffer −64 +64 mA Fx DC Load Regulation1 −1 +1 mV EXTFORCE1 range, ±1 A load current change −0.4 +0.4 mV EXTFORCE2 range, ±0.5 A load current change Load Transient Response1 70 mV 1.2 A load step into 100 μF DUT capacitance (10 mΩ ESR), autocompensation mode 140 mV 1.2 A load step into 30 µF DUT capacitance (10 mΩ ESR), autocompensation mode NSD1 350 nV/√Hz Measured at 1 kHz, at output of FORCE MEASURE CURRENT RANGES Sense resistors are trimmed to within 1%, nominal ±500 mV V RSENSE Internal Sense Resistors1 100 kΩ ±5 µA current range 20 kΩ ±25 µA current range 2 kΩ ±250 µA current range 200 Ω ±2.5 mA current range 20 Ω ±25 mA current range Rev. E | Page 5 of 66

AD5560 Data Sheet Parameter Min Typ Max Unit Test Conditions/Comments Measure Current Ranges Specified current ranges with V = 5 V and MI REF gain = 20, or with V = 2.5 V and MI gain = 5 REF ±5 µA Set using internal sense resistor ±25 µA Set using internal sense resistor ±250 µA Set using internal sense resistor ±2.5 mA Set using internal sense resistor ±25 mA Set using internal sense resistor ±500 mA EXTFORCE2, set by user with external sense resistor, limited by headroom requirements and maximum power dissipation ±1200 mA EXTFORCE1, set by user with external sense resistor, limited by headroom requirements and maximum power dissipation MEASURE CURRENT All offset DAC/supply combinations settings, all gain settings are measure current = (I × DUT R × MI gain), unless otherwise noted SENSE Differential Input Voltage Range1 −0.64 +0.64 V Maximum voltage across R , MI gain = 20 SENSE −0.7 +0.7 V Maximum voltage across R , MI gain = 10 SENSE Output Voltage Span1 25 V Measure current block alone (internal node) Offset Error −1 +1 % FSC At 0 A, MI gain = 20, MEASOUT gain = 1 Offset Error Tempco1 −1 ppm of FSC/°C Standard deviation = 13 ppm/°C Offset Error −1.5 +1.5 % FSC At 0 A, MI gain = 10, MEASOUT gain = 1 Offset Error Tempco1 −1 ppm of FSC/°C Standard deviation = 13 ppm/°C Offset Error −1.5 +1.5 % FSC At 0 A, MI gain = 20, MEASOUT gain = 0.2 Offset Error Tempco1 3 ppm of FSC/°C Standard deviation = 13 ppm/°C Offset Error −3 +3 % FSC At 0 A, MI gain = 10, MEASOUT gain = 0.2 Offset Error Tempco1 8 ppm of FSC/°C Standard deviation = 15 ppm/°C Gain Error −2 +2 % FSC Internal current ranges, all gain settings Gain Error1 −1 +1 % FSC External current ranges, excluding R SENSE Gain Error Tempco1 20 ppm/°C Standard deviation = 5 ppm/°C MEASOUT Gain = 1 All supply conditions Linearity Error −0.01 +0.01 % FSCR MI gain = 20 and 10 MEASOUT Gain = 0.2 Nominal supply (±16.5 V, 0x8000 offset DAC) Linearity Error −0.06 +0.06 % FSCR MI gain = 20 Linearity Error −0.05 +0.05 % FSCR MI gain = 10 MEASOUT Gain = 0.2 Low supply (−25 V/+8 V, 0xD4EB offset DAC) Linearity Error −0.125 +0.125 % FSCR MI gain = 20 Linearity Error −0.175 +0.175 % FSCR MI gain = 10 MEASOUT Gain = 0.2 High supply (−5 V/+28 V, 0xD1D offset DAC) Linearity Error −0.0875 +0.0875 % FSCR MI gain = 20 Linearity Error −0.1 +0.1 % FSCR MI gain = 10 Common-Mode Error −0.005 +0.005 %FSVR/V % of FS change at measure output per volts change in DUT voltage NSD1 900 nV/√Hz MI gain = 20, MEASOUT gain = 1, measured at MEASOUT at 1 kHz, inputs grounded 550 nV/√Hz MI gain = 10, MEASOUT gain = 1, measured at MEASOUT at 1 kHz, inputs grounded 170 nV/√Hz MI gain = 20, MEASOUT gain = 0.2, measured at MEASOUT at 1 kHz, inputs grounded 110 nV/√Hz MI gain = 10, MEASOUT gain = 0.2, measured at MEASOUT at 1 kHz, inputs grounded MEASURE VOLTAGE MEASOUT Gain 1 and MEASOUT Gain 0.2 Measure Voltage Range1 AV + 2.75 AV − 2.75 V All voltage ranges SS DD Gain Error −0.1 +0.1 % FS Gain Error Tempco1 3 ppm/°C Standard deviation = 2 ppm/°C MEASOUT Gain = 1 Linearity Error −2 +2 mV Offset Error −12 +12 mV Offset Error Tempco1 2 µV/°C Standard deviation = 12 µV/°C NSD1 100 nV/√Hz At 1 kHz, at MEASOUT, inputs grounded Rev. E | Page 6 of 66

Data Sheet AD5560 Parameter Min Typ Max Unit Test Conditions/Comments MEASOUT Gain = 0.2 Linearity Error −5.5 +5.5 mV Referred to MV input, nominal supply (±16.5 V, 0x8000 offset DAC) −9 +24 mV Referred to MV input, low supply (−25 V/+8 V, 0xD4EB offset DAC) −4 +13 mV Referred to MV input, high supply (−5 V/+28 V, 0xD1D offset DAC) Offset Error −30 +20 mV Referred to MV output Offset Error Tempco1 10 µV/°C Standard deviation = 12 µV/°C, referred to MV output NSD1 50 nV/√Hz At 1 kHz, at MEASOUT, inputs grounded COMBINED LEAKAGE Includes SYS_SENSE, SYS_FORCE, EXTFORCE1, EXTFORCE2, EXTMEASIH1, EXTMEASIH2, EXTMEASIL, FORCE, and SENSE; measured with PD = 1, SW-INH = 0 (power up and tristate) Leakage Current −37.5 +37.5 nA −30 +30 nA T = 25°C to 70°C J Leakage Current Tempco1 ±0.1 ±0.4 nA/°C SENSE INPUT Leakage Current −2.5 +2.5 nA Measured with PD = 1, SW-INH = 0 (power-up and tristate) Leakage Current Tempco1 ±0.01 nA/°C Pin Capacitance1 10 pF EXTMEASIH1, EXTMEASIH2, EXTMEASIL Leakage Current −2.5 +2.5 nA Measured with PD = 1, SW-INH = 0 (power-up and tristate) Leakage Current Tempco1 ±0.01 nA/°C Pin Capacitance1 5 pF FORCE OUTPUT, FORCE Maximum Current Drive1 −30 +30 mA Leakage Current −10 +10 nA Measured with PD = 1, SW-INH = 0 (power-up and tristate) Leakage Current Tempco1 ±0.03 nA/°C Pin Capacitance1 120 pF EXTFORCE1 OUTPUTS Maximum Current Drive1 −1200 +1200 mA Set with external sense resistor, limited by headroom and power dissipation Leakage Current −7.5 +7.5 nA Measured with PD = 1, SW-INH = 0 (power-up and tristate) Leakage Current Tempco1 ±0.03 ±0.06 nA/°C Pin Capacitance1 275 pF EXTFORCE2 OUTPUTS Maximum Current Drive1 −500 +500 mA Set with external sense resistor, limited by headroom and power dissipation Leakage Current −5 +5 nA Measured with PD = 1, SW-INH = 0 (power-up and tristate) Leakage Current Tempco1 ±0.02 ±0.05 nA/°C Pin Capacitance1 100 pF SYS_SENSE Voltage Range AV AV V SS DD Leakage Current −2.5 +2.5 nA SYS_SENSE high-Z, force amplifier inhibited Leakage Current Tempco1 ±0.005 ±0.025 nA/°C Path On Resistance 280 Ω AV = 16.5 V, AV = −16.5 V DD SS Pin Capacitance1 5 pF Rev. E | Page 7 of 66

AD5560 Data Sheet Parameter Min Typ Max Unit Test Conditions/Comments SYS_FORCE Voltage Range AV AV V SS DD Current Carrying Capability1 −25 +25 mA Leakage Current −2.5 +2.5 nA SYS_FORCE high-Z, force amplifier inhibited Leakage Current Tempco1 ±0.005 ±0.025 nA/°C Path On Resistance 35 Ω AV = 16.5 V, AV = −16.5 V DD SS Pin Capacitance1 5 pF SYS_DUTGND Voltage Range AV AV V SS DD Path On Resistance 300 400 Ω AV = 16.5 V, AV = −16.5 V DD SS CURRENT CLAMP Clamp Accuracy Programmed Programmed % of FS MI gain = 20, with clamp separation of 2 V, and clamp value clamp value + 10 1 V separation from AGND/0 A Programmed Programmed % of FS MI gain = 10, with clamp separation of 2 V, and clamp value clamp value + 20 1 V separation from AGND/0 A VCLL to VCLH1 2 V 10% of FSCR (MI gain = 20), 20% of FSCR (MI gain = 10), restriction to prevent both clamps activating together VCLL to 0 A1 1 V 5% of FSCR (MI gain = 20), 10% of FSCR (MI gain = 10), restriction to avoid impinging on FV before programmed level VCLH to 0 A1 1 V 5% of FSCR (MI gain 20), 10% of FSCR (MI gain = 10), restriction to avoid impinging on FV before programmed level Clamp Activation Response Time1 20 100 μs Measured from BUSY going low to visible clamping Clamp Recovery1 2 5 μs Measured from BUSY going low to visible recovery Alarm Delay 1 50 μs Time for CLALM to flag FORCE AMPLIFER Slew Rate1 1 V/µs Fastest slew rate, controlled via serial interface 0.312 V/µs Slowest slew rate, controlled via serial interface Maximum Stable Load Capacitance1 160 µF Voltage Overshoot/Undershoot1 5 % Of programmed value (≥1 V) SETTLING TIME (FORCE AMPLIFER) Compensation Register 1 = 0x4880 (229 nF to To within 10 mV of programmed value 380 nF, ESR 74 to 140 mΩ) FV (1200 mA EXTFORCE1 Range)1 16 25 µs 3.7 V step, R = 2.4 Ω, C = 0.22 µF, full dc load DUT DUT FV (900 mA EXTFORCE1 Range)1 18 30 µs 8 V step, R = 8.8 Ω, C = 0.22 µF, full dc load DUT DUT FV (500 mA EXTFORCE2 Range)1 34 53 µs 15 V step, R = 30 Ω, C = 0.22 µF, full dc load DUT DUT FV (300 mA EXTFORCE2 Range)1 25 50 µs 10 V step, R = 33.3 Ω, C = 0.22 µF, full dc load DUT DUT FV (25 mA Range)1, 3 125 180 µs 20 V step, R = 800 Ω, C = 0.22 µF, full dc load DUT DUT FV (2.5 mA Range)1, 3 300 500 µs 10 V step, R = 4 kΩ, C = 0.22 µF, full dc load DUT DUT FV (250 µA Range)1, 3 300 500 µs 10 V step, R = 40 kΩ, C = 0.22 µF, full dc load DUT DUT FV (25 µA Range)1, 3 400 600 µs 10 V step, R = 400 kΩ, C = 0.22 µF, full dc load DUT DUT FV (5 µA Range)1, 3 20 40 µs 1 V step, R = 200 kΩ, C = 0.22 µF, full dc load DUT DUT Compensation Register 1 = 0x8880 (1.7 μF to 2.9 μF, ESR 74 to 140 mΩ) FV (180 mA EXTFORCE1 Range)1 16 25 µs 3 V step, C = 2.2 µF, full dc load DUT FV (100 mA EXTFORCE2 Range)1 60 80 µs 8 V step, C = 2.2 µF, full dc load DUT Compensation Register 1 = 0xB880 (7.9μF to 13 μF, ESR 74 to 140 mΩ) FV (180 mA EXTFORCE1 Range)1 55 70 µs 3 V step, C = 10 µF, full dc load DUT FV (100 mA EXTFORCE2 Range)1 210 260 µs 8 V step, C = 10 µF, full dc load DUT Compensation Register 1 = 0xC880 (13 μF to 22 μF, ESR 74 to 140 mΩ) FV (180 mA EXTFORCE1 Range)1 65 80 µs 3 V step, C = 20 µF, full dc load DUT FV (100 mA EXTFORCE2 Range)1 310 370 µs 8 V step, C = 20 µF, full dc load DUT Rev. E | Page 8 of 66

Data Sheet AD5560 Parameter Min Typ Max Unit Test Conditions/Comments SETTLING TIME (FV, MEASURE Compensation Register 1 = 0x4880 (229 nF to To within 10 mV of programmed value CURRENT) 380 nF, ESR 74 to 140 mΩ) MI (1200 mA EXTFORCE1 Range)1 30 40 µs 3.7 V step, R = 2.4 Ω, C = 0.22 µF, full dc load DUT DUT MI (900 mA EXTFORCE1 Range)1 32 42 µs 8 V step, R = 8.8 Ω, C = 0.22 µF, full dc load DUT DUT MI (500 mA EXTFORCE2 Range)1 69 95 µs 15 V step, R = 30 Ω, C = 0.22 µF, full dc load DUT DUT MI (300 mA EXTFORCE2 Range)1 70 100 µs 10 V step, R = 33.3 Ω, C = 0.22 µF, full dc load DUT DUT MI (25 mA Range)1, 3 650 µs 20 V step, R = 800 Ω, C = 0.22 µF, full dc load DUT DUT MI (2.5 mA Range)1, 3 6400 µs 10 V step, R = 4 kΩ, C = 0.22 µF, full dc load DUT DUT MI Buffer Alone1 10 15 µs 0.5 V step using MEASOUT high-Z to within 10 mV of final value SETTLING TIME (FV, MEASURE Compensation Register 1 = 0x4880 (229 nF to To within 10 mV of programmed value VOLTAGE) 380 nF, ESR 74 to 140 mΩ) MV (1200 mA Range)1 16 µs 3.7 V step, R = 2.4 Ω, C = 0.22 µF, full dc load DUT DUT MV (900 mA Range)1 20 µs 8 V step, R = 8.8 Ω, C = 0.22 µF, full dc load DUT DUT MV (500 mA Range)1 34 µs 15 V step, R = 30 Ω, C = 0.22 µF, full dc load DUT DUT MV (300 mA Range)1 25 µs 10 V step, R = 33.3 Ω, C = 0.22 µF, full dc load DUT DUT MV (25 mA Range)1, 3 125 180 µs 20 V step, R = 800 Ω, C = 0.22 µF, full dc load DUT DUT MV (2.5 mA Range)1, 3 300 500 µs 10 V step, R = 4 kΩ, C = 0.22 µF, full dc load DUT DUT MV (250 µA Range)1, 3 300 500 µs 10 V step, R = 40 kΩ, C = 0.22 µF, full dc load DUT DUT MV Buffer Alone1 2 5 µs 10 V step using MEASOUT high-Z to within 10 mV of final value SETTLING TIME (FV) SAFE MODE To within 100 mV of programmed value FV (1200 mA EXTFORCE1 Range1 25 µs 3.7 V step, R = 3.1 Ω, C = 0.22 µF, full dc load DUT DUT FV (180 mA EXTFORCE1 Range)1 303 µs 3 V step, R = 16 Ω, C = 0. 22 µF to 20 μF, full DUT DUT dc load FV (100 mA EXTFORCE2 Range)1 660 µs 8 V step, R = 33.3 Ω, C = 0. 22 µF to 20 μF, DUT DUT full dc load FV (25 mA Range)1, 3 760 1000 µs 20 V step, R = 400 Ω, C = 0.22 µF, full dc load DUT DUT SWITCHING TRANSIENTS Range Change Transient1 0.5 % of FV C = 10 μF, changing from higher to adjacent DUT lower ranges (except EXTFORCE1 to EXTFORCE2) 20 mV C = 10 μF, changing from lower (5 µA) to DUT higher range (EXTFORCE1) 0.5 % of FV C = 100 μF, changing between all ranges DUT DAC SPECIFICATIONS Force/Comparator/Offset DACs Resolution 16 Bits Voltage Output Span −22 +25 V V = 5 V, minimum and maximum values set REF by offset DAC Differential Nonlinearity1 −1 +1 LSB Guaranteed monotonic Offset DAC Gain Error −20 +20 mV Clamp DAC CLL < CLH Resolution 16 Bits Voltage Output Span −22 +25 V V = 5 V, minimum and maximum values set REF by offset DAC Differential Nonlinearity1 −1 +1 LSB Guaranteed monotonic OSD DAC Resolution 16 Bits Voltage Output Span 0.62 5 V V = 5 V REF Differential Nonlinearity1 −2 +2 LSB DGS DAC Resolution 16 Bits Voltage Output Span 0 5 V V = 5 V REF Differential Nonlinearity1 −2 +2 LSB Comparator DAC Dynamic Output Voltage Settling Time1 3.5 6 µs 1 V change to 1 LSB Slew Rate1 1 V/µs Digital-to-Analog Glitch 10 nV-s Energy1 Glitch Impulse Peak Amplitude1 40 mV Rev. E | Page 9 of 66

AD5560 Data Sheet Parameter Min Typ Max Unit Test Conditions/Comments REFERENCE INPUT VREF DC Input Impedance 1 MΩ Typically 100 MΩ VREF Input Current −10 +10 µA Per input; typically ±30 nA VREF Range1 2 5 V COMPARATOR Measured directly at comparator; does not include measure block errors Error −7 +7 mV Uncalibrated VOLTAGE COMPARATOR With respect to the measured voltage Propagation Delay1 0.25 µs Error1 −12 +12 mV Uncalibrated CURRENT COMPARATOR Propagation Delay1 0.25 1 µs Error1 −1.5 +1.5 % Of programmed current range, uncalibrated MEASURE OUTPUT, MEASOUT Measure Output Voltage Span1 −12.81 +12.81 V MEASOUT gain = 1, V = 5 V, offset DAC = REF 0x8000 Measure Output Voltage Span1 −6.405 +6.405 V MEASOUT gain = 1, V = 2.5 V REF Measure Output Voltage Span1 0 5.125 V MEASOUT gain = 0.2, V = 5 V, offset DAC = REF 0x8000 Measure Output Voltage Span1 0 2.56 V MEASOUT gain = 0.2, V = 2.5 V REF Measure Pin Output Impedance 115 Ω Output Leakage Current −100 +100 nA When HW_INH is low Output Capacitance1 5 pF Short-Circuit Current1 −10 +10 mA OPEN-SENSE DETECT/CLAMP/ALARM Measurement Accuracy −200 +200 mV Clamp Accuracy 600 900 mV Alarm Delay1 50 μs DUTGND Voltage Range1 −1 +1 V Pull-Up Current +50 +70 μA Pull-up for purpose of detecting open circuit on DUTGND, can be disabled Leakage Current −1 +1 μA When pull-up disabled, DGS DAC = 0x3333 (1 V with V = 5 V); if DUTGND voltage is far away REF from one of comparator thresholds, more leakage may be present Trip Point Accuracy −30 +10 mV Alarm Delay1 50 μs GUARD AMPLIFIER Voltage Range1 AV + 2.25 AV − 2.25 V SS DD Voltage Span1 25 V Output Offset −10 +10 mV Short-Circuit Current1 −20 +20 mA Load Capacitance1 100 nF Output Impedance 100 Ω Alarm Delay1 200 μs If it moves 100 mV away from input level DIE TEMPERATURE SENSOR Accuracy1 −10 +10 % Relative to a temperature change Output Voltage at 25°C 1.54 V Output Scale Factor1 4.7 mV/°C Output Voltage Range1 1 2 V Rev. E | Page 10 of 66

Data Sheet AD5560 Parameter Min Typ Max Unit Test Conditions/Comments SPI INTERFACE LOGIC Logic Inputs Input High Voltage, V 1.7/2.0 V (2.3 V to 2.7 V)/(2.7 V to 5.5 V) JEDEC-compliant IH input levels Input Low Voltage, V 0.7/0.8 V (2.3 V to 2.7 V)/(2.7 V to 5.5 V) JEDEC-compliant IL input levels Input Current, I , I −1 +1 µA INH INL Input Capacitance, C 1 10 pF IN CMOS Logic Outputs SDO, CPOL, CPOH, GPO, CPO Output High Voltage, V DV − 0.4 V OH CC Output Low Voltage, V 0.4 V I = 500 µA OL OL Tristate Leakage Current −1 +1 μA SDO, CPOL, CPOH, CPO Output Capacitance1 10 10 10 pF SDO, CPOL, CPOH, CPO Open-Drain Logic Outputs BUSY, TMPALM, CLALM, KELALM Output Low Voltage, V 0.4 V I = 500 µA, C = 50 pF, R = 1 kΩ OL OL L PULLUP Output Capacitance1 10 pF POWER SUPPLIES HCAV 1x 4 28 V |HCAV x – HCAV x| < 33 V, HCAV x ≥ AV , DD DD SS SS SS HCAV x ≤ AV DD DD HCAV 1x −25 −5 V SS HCAV 2x 4 28 V |HCAV x – HCAV x| < 33 V, HCAV x ≥ AV , DD DD SS SS SS HCAV x ≤ AV DD DD HCAV 2x −25 −5 V SS AV 8 28 V |AV – AV | < 33 V DD DD SS AV −25 −5 V SS DV 2.3 5.5 V CC AI 4 30 mA All ranges DD AI 4 −30 mA All ranges SS DI 3 mA CC AI 4 27 mA Channel inhibited/tristate, HW_INH or SW-INH low DD AI 4 −27 mA Channel inhibited/tristate, HW_INH or SW-INH low SS HCAV x and HCAV x supply currents shown DD SS are excluding load currents; however, for power budget calculations, the supply currents here are consumed by the load HCAI 1 20 mA When enabled, excluding load conditions DD HCAI 1 0.5 mA When disabled DD HCAI 1 −20 mA When enabled, excluding load condition SS HCAI 1 −0.5 mA When disabled SS HCAI 2 15 mA When enabled, excluding load conditions DD HCAI 2 0.25 mA When disabled DD HCAI 2 −15 mA When enabled, excluding load conditions SS HCAI 2 −0.25 mA When disabled SS POWER-DOWN CURRENTS Supply currents on power-up or during a power-down condition HCAI 250 μA DD HCAI −250 μA SS HCAI 250 μA DD HCAI −250 μA SS AI 5 mA DD AI −5 mA SS DI 3 mA CC Maximum Power Dissipation EXTFORCE1 10 W EXTFORCE2 5 W Power-Up Overshoot1 5 % Of programmed value Rev. E | Page 11 of 66

AD5560 Data Sheet Parameter Min Typ Max Unit Test Conditions/Comments Power Supply Sensitivity1 DC to 1 kHz ΔForced Voltage/ΔAV −65 dB −30 dB at 100 kHz DD ΔForced Voltage/ΔAV −65 dB −25 dB at 100 kHz SS ΔForced Voltage/ΔHCAV x −90 dB −60 dB at 100 kHz DD ΔForced Voltage/ΔHCAV x −90 dB −62 dB at 100 kHz SS ΔMeasured Current/ΔAV −50 dB −25 dB at 100 kHz DD ΔMeasured Current/ΔAV −43 dB −20 dB at 100 kHz SS ΔMeasured Current/ΔHCAV x −90 dB −60 dB at 100 kHz DD ΔMeasured Current/ΔHCAV x −90 dB −60 dB at 100 kHz SS ΔMeasured Voltage/ΔAV −65 dB −30 dB at 100 kHz DD ΔMeasured Voltage/ΔAV −65 dB −25 dB at 100 kHz SS ΔMeasured Voltage/ΔHCAV x −90 dB −60 dB at 100 kHz DD ΔMeasured Voltage/ΔHCAV x −90 dB −65 dB at 100 kHz SS ΔForced Voltage/ΔDV −80 dB −46 dB at 100 kHz CC ΔMeasured Current/ΔDV −80 dB −36 dB at 100 kHz CC ΔMeasured Voltage/ΔDV −80 dB −46 dB at 100 kHz CC 1 Guaranteed by design and characterization, not subject to production test. 2 Programmable clamps must be enabled if taking advantage of reduced headroom/footroom. 3 Clamps disabled. 4 Not including internal pull-up current between AVDD/AVSS and HCAVDDx/HCAVSSx pins. Rev. E | Page 12 of 66

Data Sheet AD5560 TIMING CHARACTERISTICS HCAV x ≤ AV + 33 V, HCAV x ≥ AV , AV ≥ 8 V, AV ≤ −5 V, |AV − AV | ≥ 16 V and ≤ 33 V, V = 5 V (T = 25°C to 90°C, DD SS SS SS DD SS DD SS REF J maximum specifications, unless otherwise noted). Table 2. SPI Interface DV = 2.3 V DV = 2.7 V DV = 4.5 V CC CC CC Parameter1, 2, 3 to 2.7 V to 3.3 V to 5.5 V Unit Description t 600 600 600 ns max Channel update cycle time UPDATE t 25 20 20 ns min SCLK cycle time; 60/40 duty cycle 1 t 10 8 8 ns min SCLK high time 2 t 10 8 8 ns min SCLK low time 3 t 10 10 10 ns min SYNC falling edge to SCLK falling edge setup time 4 t 15 15 15 ns min Minimum SYNC high time 5 t 5 5 5 ns min 24th SCLK falling edge to SYNC rising edge 6 t 5 5 5 ns min Data setup time 7 t 4.5 4.5 4.5 ns min Data hold time 8 t4 40 35 30 ns max SYNC rising edge to BUSY falling edge 9 t 1.5 1.5 1.5 μs max BUSY pulse width low for DAC x1 write 10 280 280 280 ns max BUSY pulse width low for other register write t 25 20 10 ns min RESET pulse width low 11 t 400 400 400 µs max RESET time indicated by BUSY low 12 t 250 250 250 ns min Minimum SYNC high time in readback mode 13 t 5, 6 45 35 25 ns max SCLK rising edge to SDO valid 14 t 30 30 30 ns max SYNC rising edge to SDO high-Z 15 LOAD TIMING t 20 20 20 ns min LOAD pulse width low 16 t 150 150 150 ns min BUSY rising edge to force output response time 17 t 0 0 0 ns min BUSY rising edge to LOAD falling edge 18 t 150 150 150 ns min LOAD rising edge to FORCE output response time 19 150 150 150 ns min LOAD rising edge to current range response 1 Guaranteed by design and characterization, not production tested. 2 All input signals are specified with t = t = 2 ns (10% to 90% of DV ) and timed from a voltage level of 1.2 V. R F CC 3 See Figure 4 and Figure 5. 4 This is measured with the load circuit shown in Figure 2. 5 This is measured with the load circuit shown in Figure 3. 6 Longer SCLK cycle time is required for correct operation of readback mode; consult timing diagrams and timing specifications. TIMING DIAGRAMS DVCC 200µA IOL RLOAD 2.2kΩ TO OUTPUT VOH (MIN) – VOL (MAX) PIN 2 CLOAD TO OUTPUT 50pF PIN CL5O0pAFD VOL 07779-002 200µA IOL 07779-003 Figure 2. Load Circuit for Open Drain Figure 3. Load Circuit for CMOS Rev. E | Page 13 of 66

AD5560 Data Sheet t1 SCLK 1 2 24 t3 t2 t4 t6 SYNC t5 t7 t8 SDI DB23 DB0 t9 t10 BUSY t16 LOAD1,3 EXTFFOORRCCEE1 t17 EXTFORCE21 t18 t16 LOAD2,3 FORCE EXETXFTOFROCREC2E2,13 t19 t11 RESET BUSY t12 123LLLOOOAAADDD AAFCCUTTNIICVVTEEIOADFNUT RIESINR AGBVUBAUSILYSA.YB.LE VIA CLEN OR HW_INH AS DETERMINED BY DPS REGISTER 2. 07779-004 Figure 4. SPI Write Timing SCLK 24 48 t14 t13 SYNC t15 SDI DB23 D0B DB23 DB0 INPUT WORD SPECIFIES NOP CONDITION REGISTER TO BE READ SDO DB23 DB0 SELECCTLEOD CRKEEGDIS OTUETR DATA 07779-005 Figure 5. SPI Read Timing Rev. E | Page 14 of 66

Data Sheet AD5560 ABSOLUTE MAXIMUM RATINGS Table 3. Stresses at or above those listed under Absolute Maximum Parameter Rating Ratings may cause permanent damage to the product. This is a AV to AV 34 V stress rating only; functional operation of the product at these DD SS AVDD to AGND −0.3 V to +34 V or any other conditions above those indicated in the operational AVSS to AGND −34 V to +0.3 V section of this specification is not implied. Operation beyond HCAV x to HCAV x 34 V DD SS the maximum operating conditions for extended periods may HCAV x to AGND −0.3 V to +34 V DD affect product reliability. HCAV x to AGND −34 V to +0.3 V SS HCAV x to AV −0.3 V to AV + 34 V DD SS SS HCAV x to AV −0.3 V to AV + 0.3 V DD DD DD ESD CAUTION HCAV x to AV +0.3 V to AV − 0.3 V SS SS SS DV to DGND −0.3 V to +7 V CC AGND to DGND −0.3 V to +0.3 V REFGND to AGND −0.3 V to +0.3 V Digital Inputs to DGND −0.3 V to DV + 0.3 V CC Analog Inputs to AGND AV − 0.3 V to AV + 0.3 V SS DD EXTFORCE1 and EXTFORCE2 to AGND1 AV − 28 V DD Storage Temperature −65°C to +125°C Operating Junction Temperature 25°C to 90°C Reflow Profile J-STD 20 (JEDEC) Junction Temperature 150°C max Power Dissipation 10 W max (EXTFORCE1 stage) 5 W max (EXTFORCE2 stage) ESD HBM 1500 V FICDM 500 V 1 When an EXTFORCE1 or EXTFORCE2 stage is enabled and the supply differ- ential |AV − AV | > 28 V, take care to ensure that these pins are not directly DD SS shorted to AV voltage at any time because this can cause damage to the device. SS Rev. E | Page 15 of 66

AD5560 Data Sheet PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS C B B A A 1 2 1 2 1 PO C_V1CSS XTFORCE CAV1CDD CAV2BDD XTFORCE CAV2BSS CAV1BSS XTFORCE CAV1BDD CAV2ADD XTFORCE CAV2ASS CAV1ASS XTFORCE CAV1ADD G H E H H E H H E H H E H H E H 64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 CLALM 1 48 EXTMEASIH2 KELALM 2 PIN 1 47 EXTMEASIH1 TMPALM 3 46 AVDD CPOH/CPO 4 45 AVSS CPOL 5 44 AGND BUSY 6 43 GUARD/SYS_DUTGND SDO 7 AD5560 42 EXTMEASIL DVCC 8 TOP VIEW 41 SENSE DGND 9 (Not to Scale) 40 DUTGND SCLK 10 EXPOSED PAD ON TOP 39 CF0 SDI 11 38 CF1 SYNC 12 37 CF2 RCLK 13 36 CF3 RESET 14 35 CF4 CLEN/LOAD 15 34 NC HW_INH/LOAD 16 33 AVDD 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 REFGND VREF AGND AVSS AVDD MEASOUT CC3 CC0 CC1 CC2 SLAVE_IN STER_OUT YS_SENSE AVSS YS_FORCE FORCE A S S M N12 .. O NEMTXCOEP SS=O TNS NOEE DCG OPAANTDNIV EOECN PT .TOOINPT O, AFV PSAS.CKAGE. EXPOSED PAD IS INTERNALLY CONNECTED TO 07779-006 Figure 6. TQFP_EP Pin Configuration Table 4. TQFP_EP Pin Function Descriptions Pin No. Mnemonic Description 1 CLALM Clamp Alarm Output. Open-drain output, active low; this pin can be programmed to be either latched or unlatched. 2 KELALM Kelvin Alarm Pin for SENSE and DUTGND, Open-Drain Active Low. This pin can be programmed to be either latched or unlatched. 3 TMPALM Temperature Alarm Flag. Open-drain output, active low; this pin can be programmed to be either latched or unlatched. 4 CPOH/CPO Comparator High Output (CPOH) or Window Comparator Output (CPO). 5 CPOL Comparator Low Output. 6 BUSY Open-Drain Active Low Output. This pin indicates the status of the calibration engine for the DAC channels. 7 SDO Serial Data Output. This pin is used for reading back DAC and DPS register information for diagnostic purposes. 8 DV Digital Supply Voltage. CC 9 DGND Digital Ground Reference Point. 10 SCLK Clock Input, Active Falling Edge. 11 SDI Serial Data Input. 12 SYNC Frame Sync, Active Low. 13 RCLK Ramp Clock Logic Input. If the ramp function is used, a clock signal of 833 kHz maximum should be applied to this input to drive the ramp circuitry. Tie RCLK low if it is unused. 14 RESET Logic Input. This pin is used to reset all internal nodes on the device to their power-on reset value. 15 CLEN/LOAD Clamp Enable. This input allows the user to enable or disable the clamp circuitry. This pin can be configured as a LOAD function to allow synchronization of multiple devices. Either CLEN or HW_INH can be chosen as LOAD input (see the system control register, Address 0x1). 16 HW_INH/LOAD Hardware Inhibit Input to Disable Force Amplifier. This pin can be configured as a LOAD function to allow synchronization of multiple devices. Either CLEN or HW_INH can be chosen as a LOAD input (see the system control register, Address 0x1). 17 REFGND Accurate Ground Reference for Applied Voltage Reference. Rev. E | Page 16 of 66

Data Sheet AD5560 Pin No. Mnemonic Description 18 VREF Reference Input for DAC Channels, Input Range 2 V to 5 V. 19, 44 AGND Analog Ground. 20, 30, 45 AV Negative Analog Supply Voltage. These pins supply DACs and other high voltage circuitry, such as SS measure blocks. 21, 33, 46 AV Positive Analog Supply Voltage. These pins supply DACs and other high voltage circuitry, such as DD measure blocks. 22 MEASOUT Multiplexed DUT voltage sense, DUT current sense, Kelvin sense, or temperature output; refer to AGND. 23 C Compensation Capacitor Input 3. C3 24 C Compensation Capacitor Input 0. C0 25 C Compensation Capacitor Input 1. C1 26 C Compensation Capacitor Input 2. C2 27 SLAVE_IN Slave Input When Ganging Multiple DPS Devices. 28 MASTER_OUT Master Output When Ganging Multiple DPS Devices. 29 SYS_SENSE External Sense Signal Output. 31 SYS_FORCE External Force Signal Input. 32 FORCE Output Force Pin for Internal Current Ranges. 34 NC No Connect. 35 C Feedforward Capacitor 4. F4 36 C Feedforward Capacitor 3. F3 37 C Feedforward Capacitor 2. F2 38 C Feedforward Capacitor 1. F1 39 C Feedforward Capacitor 0. F0 40 DUTGND Device Under Test Ground. 41 SENSE Input Sense Line. 42 EXTMEASIL Low Side Measure Current Line for External High Current Ranges. 43 GUARD/SYS_DUTGND Guard Amplifier Output Pin or System Device Under Test Ground Pin. See the DPS Register 2 in Table 19 for addressing details. 47 EXTMEASIH1 Input High Measure Line for External High Current Range 1. 48 EXTMEASIH2 Input High Measure Line for External High Current Range 2. 49, 55, 61 HCAV 1A, High Current Positive Analog Supply Voltage, for EXTFORCE1 Range. DD HCAV 1B, DD HCAV 1C DD 50, 56, 62 EXTFORCE1A, Output Force. This pin is used for high Current Range 1, up to a maximum of ±1.2 A. EXTFORCE1B, EXTFORCE1C 51, 57, 63 HCAV 1A, High Current Negative Analog Supply Voltage, for EXTFORCE1 Range. SS HCAV 1B, SS HCAV 1C SS 52, 58 HCAV 2A, HCAV 2B High Current Negative Analog Supply Voltage, for EXTFORCE2 Range. SS SS 53, 59 EXTFORCE2A, Output Force. This pin is used for high Current Range 2, up to a maximum of ±500 mA. EXTFORCE2B 54, 60 HCAV 2A, High Current Positive Analog Supply Voltage, for EXTFORCE2 Range. DD HCAV 2B DD 64 GPO Extra Logic Output Bit. Ideal for external functions such as switching out a decoupling capacitor at DUT. 65 EP The exposed pad is internally connected to AV . SS Rev. E | Page 17 of 66

AD5560 Data Sheet 9 8 7 6 5 4 3 2 1 A EXTFORCE1A EXTFORCE1A EXTFORCE2A EXTFORCE1B EXTFORCE1B EXTFORCE2B EXTFORCE1C EXTFORCE1C GPO B HCAVDD1A HCAVSS1A HCAVDD2A HCAVDD1B HCAVSS1B HCAVDD2B HCAVDD1C HCAVSS1C CLALM C HCAVDD1A HCAVSS1A HCAVSS2A HCAVDD1B HCAVSS1B HCAVSS2B HCAVDD1C HCAVSS1C KELALM D AVDD EXTMEASIH1 EXTMEASIH2 CPOL CPOH/CPO TMPALM E AVSS AGND SYSG_UDAURTDG/ND 3 × 3 ARRAY IS VOID OF BALLS DVCC SDO BUSY F DUTGND EXTMEASIL SENSE SDI SCLK DGND G CF0 CF2 SYS_FORCE SYS_SENSE CC0 AVSS RESET RCLK SYNC CLEN/ H CF1 CF3 SLAVE_IN MASTER_OUT CC1 MEASOUT AVDD VREF LOAD HW_INH/ J CF4 AVDD FORCE CC2 CC3 AVSS AGND REFGND LOAD 07779-062 Figure 7. Flip-Chip BGA Pin Configuration, Bottom Side (BGA Balls Are Visible) Table 5. Flip-Chip BGA Pin Function Descriptions Pin No. Mnemonic Description A1 GPO Extra Logic Output Bit. Ideal for external functions such as switching out a decoupling capacitor at DUT. A2, A3 EXTFORCE1C Output Force. These pins are used for high Current Range 1, up to a maximum of ±1.2 A. A4 EXTFORCE2B Output Force. This pin is used for high Current Range 2, up to a maximum of ±500 mA. A5, A6 EXTFORCE1B Output Force. These pins are used for high Current Range 1, up to a maximum of ±1.2 A. A7 EXTFORCE2A Output Force. This pin is used for high Current Range 2, up to a maximum of ±500 mA. A8, A9 EXTFORCE1A Output Force. These pins are used for high Current Range 1, up to a maximum of ±1.2 A. B1 CLALM Clamp Alarm Output. Open-drain output, active low; this pin can be programmed to be either latched or unlatched. B2, C2 HCAV 1C High Current Negative Analog Supply Voltage for EXTFORCE1 Range. SS B3, C3 HCAV 1C High Current Positive Analog Supply Voltage for EXTFORCE1 Range. DD B4 HCAV 2B High Current Positive Analog Supply Voltage for EXTFORCE2 Range. DD B5, C5 HCAV 1B High Current Negative Analog Supply Voltage for EXTFORCE1 Range. SS B6, C6 HCAV 1B High Current Positive Analog Supply Voltage for EXTFORCE1 Range. DD B7 HCAV 2A High Current Positive Analog Supply Voltage for EXTFORCE2 Range. DD B8, C8 HCAV 1A High Current Negative Analog Supply Voltage for EXTFORCE1 Range. SS B9, C9 HCAV 1A High Current Positive Analog Supply Voltage for EXTFORCE1 Range. DD C1 KELALM Kelvin Alarm Pin for SENSE and DUTGND, Open-Drain Active Low. This pin can be programmed to be either latched or unlatched. C4 HCAV 2B High Current Negative Analog Supply Voltage for EXTFORCE2 Range. SS C7 HCAV 2A High Current Negative Analog Supply Voltage for EXTFORCE2 Range. SS Rev. E | Page 18 of 66

Data Sheet AD5560 Pin No. Mnemonic Description D1 TMPALM Temperature Alarm Flag. Open-drain output, active low; this pin can be programmed to be either latched or unlatched. D2 CPOH/CPO Comparator High Output (CPOH) or Window Comparator Output (CPO). D3 CPOL Comparator Low Output. D7 EXTMEASIH2 Input High Measure Line for External High Current Range 2. D8 EXTMEASIH1 Input High Measure Line for External High Current Range 1. D9,H3, J8 AV Positive Analog Supply Voltage. These pins supply DACs and other high voltage circuitry, such as DD measure blocks. E1 BUSY Open-Drain Active Low Output. This pin indicates the status of the calibration engine for the DAC channels. E2 SDO Serial Data Output. This pin is used for reading back DAC and DPS register information for diagnostic purposes. E3 DV Digital Supply Voltage. CC E7 GUARD/SYS_DUTGND Guard Amplifier Output Pin or System Device Under Test Ground Pin. See the DPS Register 2 in Table 19 for addressing details. E8 AGND Analog Ground. E9, G4, J4 AV Negative Analog Supply Voltage. These pins supply DACs and other high voltage circuitry, such as SS measure blocks. F1 DGND Digital Ground Reference Point. F2 SCLK Clock Input, Active Falling Edge. F3 SDI Serial Data Input. F7 SENSE Input Sense Line. F8 EXTMEASIL Low Side Measure Current Line for External High Current Ranges. F9 DUTGND Device Under Test Ground. G1 SYNC Frame Sync, Active Low. G2 RCLK Ramp Clock Logic Input. If the ramp function is used, a clock signal of 833 kHz maximum should be applied to this input to drive the ramp circuitry. Tie RCLK low if it is unused. G3 RESET Logic Input. This pin is used to reset all internal nodes on the device to their power-on reset value. G5 C Compensation Capacitor Input 0. C0 G6 SYS_SENSE External Sense Signal Output. G7 SYS_FORCE External Force Signal Input. G8 C Feedforward Capacitor 2. F2 G9 C Feedforward Capacitor 0. F0 H1 CLEN/LOAD Clamp Enable. This input allows the user to enable or disable the clamp circuitry. This pin can be configured as a LOAD function to allow synchronization of multiple devices. Either CLEN or HW_INH can be chosen as LOAD input (see the system control register, Address 0x1). H2 VREF Reference Input for DAC Channels, Input Range is 2 V to 5 V. H4 MEASOUT Multiplexed DUT voltage sense, DUT current sense, Kelvin sense, or temperature output; refer to AGND. H5 C Compensation Capacitor Input 1. C1 H6 MASTER_OUT Master Output When Ganging Multiple DPS Devices. H7 SLAVE_IN Slave Input When Ganging Multiple DPS Devices. H8 C Feedforward Capacitor 3. F3 H9 C Feedforward Capacitor 1. F1 J1 HW_INH/LOAD Hardware Inhibit Input to Disable Force Amplifier. This pin can be configured as a LOAD function to allow synchronization of multiple devices. Either CLEN or HW_INH can be chosen as a LOAD input (see the system control register, Address 0x1). J2 REFGND Accurate Ground Reference for Applied Voltage Reference. J3 AGND Analog Ground. J5 C Compensation Capacitor Input 3. C3 J6 C Compensation Capacitor Input 2. C2 J7 FORCE Output Force Pin for Internal Current Ranges. J9 C Feedforward Capacitor 4. F4 Rev. E | Page 19 of 66

AD5560 Data Sheet TYPICAL PERFORMANCE CHARACTERISTICS 1.2 12 TJ = 25°C 1.0 10 AAVVDSSD == –82V5V VREF = 5V 8 OFFSET DAC = 0xD4EB 0.8 V) RITY (mV) 0.6 ARITY (m 46 MEASOUT GAIN = 0.2 LINEA 0.4 V LINE 2 M 0.2 0 0 –2 MEASOUT GAIN = 1 –0.20 10,000 20,000 30,0C0O0DE40,000 50,000 60,000 07779-026 –40 10,000 20,000 30,0C0O0DE40,000 50,000 60,000 07779-034 Figure 8. Force Voltage Linearity vs. Code, V = 5 V, No Load Figure 11. Measure Voltage Linearity vs. Code (MEASOUT Gain 1, REF MEASOUT Gain = 0.2, Negative Skew Supply) 2.0 0.0100 TJ = 25°C HIGH: AVDD = 28V, AVSS = –5V, OFFSET DAC = 0xD1D 1.5 AAVVDSSD == –1166.2.255VV 0.0075 LNOOWM:: AAVVDDDD /=A V5SVS, A= V±S1S6 .=2 5–V2,5 OV FOFFSFESTE DT ADCA C= 0=x 08x0D004EB VREF = 5V VREF = 5V V) 1.0 0.0050 m R ( RITY ERRO 0.50 MEASOUT GAIN = 0.2 EARITY (%) 0.00250 LOW SUPPLIES A N NE–0.5 LI–0.0025 LI MV –1.0 –0.0050 –1.5 –0.0075 NOMINAL SUPPLIES MEASOUT GAIN = 1 HIGH SUPPLIES –2.00 10,000 20,000 30,0C0O0DE40,000 50,000 60,000 07779-027 –0.01000 10,000 20,000 30,00C0OD4E0,000 50,000 60,000 70,000 07779-035 Figure 9. Measure Voltage Linearity vs. Code (MEASOUT Gain = 1, Figure 12. Measure Current Linearity vs. Code (MEASOUT Gain = 1, MEASOUT Gain = 0.2, Nominal Supplies) MI Gain = 20), T = 25°C J 5 0.010 TJ = 25°C HIGH: AVDD = 28V, AVSS = –5V, OFFSET DAC = 0xD1D AVDD = 28V LOW: AVDD = 5V, AVSS = –25V OFFSET DAC = 0xD4EB 4 AVSS= –5V NOM: AVDD/AVSS = ±16.25V, OFFSET DAC = 0x8000 VREF = 5V VREF = 5V OFFSET DAC = 0xD1D 0.005 3 mV) %) ARITY ( 2 MEASOUT GAIN = 0.2 ARITY ( 0 LOW SUPPLIES NE 1 NE V LI MI LI M 0 –0.005 –1 MEASOUT GAIN = 1 NOMINAL SUPPLIES HIGH SUPPLIES –20 10,000 20,000 30,0C0O0DE40,000 50,000 60,000 07779-033 –0.0100 10,000 20,000 30,00C0OD4E0,000 50,000 60,000 70,000 07779-036 Figure 10. Measure Voltage Linearity vs. Code (MEASOUT Gain = 1, Figure 13. Measure Current Linearity vs. Code (MEASOUT Gain = 1, MEASOUT Gain = 0.2, Positive Skew Supply) MI Gain = 10) Rev. E | Page 20 of 66

Data Sheet AD5560 0.0500 0.0500 0.0375 HLNV±2ORIOG5EWMmHF :::A= AAA 5RVVVVADDDDDND / G=A= EV 52SV8S,V A=, VA±SV1SS6. S2= 5 =–V 2–, 55OVVF ,O FOSFFFEFSTSE DETAT D CDA A=C C0 = x= 80 00x0xD0D41EDB 0.0375 AOAVRVVFEDSFFSDS =E== T 5–+ V1D166A..2C255 V=V 0x8000 0.0250 0.0250 MI GAIN = 20 MEASOUT GAIN = 0.2 25µA RANGE %) 0.0125 NOMINAL SUPPLIES %) 0.0125 Y ( Y ( RIT 0 LOW SUPPLIES RIT 0 A A E E N N LI–0.0125 LI–0.0125 –0.0250 –0.0250 2.5mA –0.0375 –0.0375 25mA RANGE HIGH SUPPLIES –0.05000 10,000 20,000 30,00C0OD4E0,000 50,000 60,000 70,000 07779-037 –0.05000 10,000 20,000 30,0C0O0DE40,000 50,000 60,000 07779-040 Figure 14. Measure Current Linearity vs. Code (MEASOUT Gain = 0.2, Figure 17. Measure Current Linearity vs. I (MEASOUT Gain = 0.2, RANGE MI Gain = 20) MI Gain = 20) 0.100 1.5 HLOIGWH :: AAVVDDDD == 258VV, ,A AVVSSSS = = – –255VV, OOFFFFSSEETT DDAACC == 00xxDD41EDB TJ = 25°C 0.075 NOM : AVDD/AVSS = ±16.25V, OFFSET DAC = 0x8000 1.0 VREF = 5V±25mA RANGE 0.5 0.050 A) %) 0.025 HIGH SUPPLIES NT (n 0 Y ( RE–0.5 EXTFORCE1A EARIT 0 E CUR–1.0 EFEOXXTTRFFCOOERRCCEE21BB LIN–0.025 NOMINAL SUPPLIES KAG–1.5 ESXETNMSEEASIH1 A EXTFORCE1C E –0.050 LOW SUPPLIES L–2.0 ESYXSTM_FEOARSCIHE2 EXTFORCE2A –0.075 –2.5 EXTMEASIL SYS_SENSE COMBINED LEAKAGE –0.1000 10,000 20,000 30,00C0OD4E0,000 50,000 60,000 70,000 07779-038 –3.0–10 5 STRESS VO0LTAGE (V) 5 10 07779-030 Figure 15. Measure Current Linearity vs. Code (MEASOUT Gain = 0.2, Figure 18. Leakage Current vs. Stress Voltage (Force and Combined Leakage) MI Gain = 10) 0.0100 7 AAVVDSSD == –+1166..2255VV VSTRESS = 9V 0.0075 VREF = 5V 6 OFFSET DAC = 0x8000 0.0050 MMIE GASAOINU =T 2G0AIN = 1 25µA RANGE nA) 5 %) 0.0025 NT ( EEXXTTFFOORRCCEE12BA Y ( RE 4 FORCE ARIT 0 CUR EEXXTTFMOERACSEIH11B LINE–0.0025 2.5mA KAGE 3 SEEXEXTTNFMSOEERACSEIH12C A SYS_FORCE –0.0050 LE 2 EXTFORCE2A EXTMEASIL SYS_SENSE –0.0075 25mA RANGE 1 COMBINED LEAKAGE –0.01000 10,000 20,000 30,0C0O0DE40,000 50,000 60,000 07779-039 025 35 45 TEM5P5ERATUR6E5(°C) 75 85 95 07779-031 Figure 16. Measure Current Linearity vs. I (MEASOUT Gain = 1, Figure 19. Leakage Current vs. Temperature (Force and Combined Leakage), RANGE MI Gain = 20) V = 9 V STRESS Rev. E | Page 21 of 66

AD5560 Data Sheet 0 0.15 EXTFORCE1A EXTFORCE2B TJ = 25°C 0.10 EEXXTTFMOERACSEIH11B –0.02 SENSE NT (nA) 0.05 EESEXYXXTSTTFFM_FOOEORRARCCSCEEIHE122CA R (%)–0.04 NOMINAL HIGH RRE 0 ESXYTSM_SEEANSSILE RRO–0.06 U E AGE C–0.05 GAIN –0.08 LOW K A E–0.10 L –0.10 –0.15 –0.12 –0.20–10 5 STRESS VO0LTAGE (V) 5 10 07779-032 25 35 45TEMPER55ATURE6(°5C) 75 85 07779-48 Figure 20. Leakage Current vs. Stress Voltage Figure 23. MI Positive Gain Error vs. Temperature, MI Gain = 20, MEASOUT Gain = 1 0.8 1.8 0 0.7 VSTRESS=9V 1.6 AAVVVREDSFSD === 5–±V1166..2255VV A) 0.6 mV) 1.4 OFFSET DAC = 0x8000 –0.5 mV) E CURRENT (n 00..45 EEEESEXXXXEXTTTTNTMFFFFSOOOOEERRRRACCCCSEEEEIH11121CABB GAIN ERROR ( 011...802 –1.0 GAIN ERROR ( LEAKAG 00..23 ESEESXYXXYTTTSSMMF__SFOEEOERAANRCSSSCEIIHLEE22A POSITIVE 00..46 ––21..05 NEGATIVE 0.1 0.2 025 35 45 TEM5P5ERATUR6E5(°C) 75 85 95 07779-061 025 35 45TEMPE5R5ATURE 6(5°C) 75 85 –2.5 07779-043 Figure 21. Leakage Current vs. Temperature, VSTRESS = 9 V Figure 24. FV Gain Error vs. Temperature 0.10 23.0 HIGH 0.2 LOW 0.05 22.5 NOMINAL OR (%) 0 NOMINAL 0.2 R (mV)22.0 R HIGH O ER–0.05 RR21.5 ET T E S E F S OF–0.10 FF21.0 LOW 0.2 O –0.15 HLOIGWH :: AAVVDDDD == 258VV, ,A AVVSSSS = = – –255VV, OOFFFFSSEETT DDAACC == 00xxDD41EDB 20.5 NOM : AVDD/AVSS = ±16.25V, OFFSET DAC = 0x8000 VREF = 5V LOW0.2/HIGH0.2/NOM0.2 MEAN FOR MEASOUT GAIN = 0.2 –0.2025 35 45TEMPER55ATURE6(°5C) 75 85 07779-047 20.025 35 45TEMPE5R5ATURE6(5°C) 75 85 07779-041 Figure 22. MI Offset Error vs. Temperature, MI Gain = 20, Figure 25. FV Offset Error vs. Temperature MEASOUT Gain = 1 and 0.2 Rev. E | Page 22 of 66

Data Sheet AD5560 0 5 HIGH 4 –0.001 3 –0.002 V) 2 AIN ERROR (%)––00..000043 NOMINAL LOW SET ERROR (m –101 NOMINAL G–0.005 OFF –2 HIGH –3 LOW –0.006 –4 –0.00725 35 45TEMPER55ATURE6(°5C) 75 85 07779-045 –525 35 45TEMPER55ATURE6(°5C) 75 85 07779-044 Figure 26. MV Gain Error vs. Temperature, MEASOUT Gain = 1 Figure 29. MV Offset Error vs. Temperature, MEASOUT Gain = 0.2 1.0 CH1 p-p 0.9 27mV HIGH CH1AREA 0.8 10.92µVs NOMINAL V) 0.7 R (m 0.6 LOW O FORCE R R 0.5 1 E T E 0.4 S F OF 0.3 0.2 0.0125 35 45TEMPE5R5ATURE6(5°C) 75 85 07779-042 3 CCHH31 55V0mV BBWW SYMNT 2C 0100.µ4s% A CH3 1.5V 07779-015 Figure 27. MV Offset Error vs. Temperature, MEASOUT Gain = 1 Figure 30. Range Change 2.5 mA to 25 mA, Safe Mode, 2.5 mA ILOAD, 10 μF Load 0.030 NOMINAL CH1 p-p LOW 16mV CH1AREA 0.025 –5.336µVs R (%)0.020 HIGH O FORCE RR0.015 1 E N AI G0.010 0.005 025 35 45TEMPER55ATURE6(°5C) 75 85 07779-046 3 CCHH31 55V0mV BBWW SYMTN 2C 0100.µ4s% A CH3 1.5V 07779-016 Figure 28. MV Gain Error vs. Temperature, MEASOUT Gain = 0.2 Figure 31. Range Change 25 mA to 2.5 mA, Safe Mode, 2.5 mA ILOAD, 10 μF Load Rev. E | Page 23 of 66

AD5560 Data Sheet CH1 p-p CH1 p-p 159mV 84mV CH1AREA 14.31µVs TRIGGER 2 FORCE FORCE 1 1 3 SYNC 07779-017 07779-020 CH1 50mV BW M200µs A CH3 1.5V CH1 100mV BW CH2 5V M40µs A CH2 1.6V CH3 5V BW T 10.4% T 120.4µs Figure 32. Range Change 25 mA to EXTFORCE2, Safe Mode, Figure 35. Autocompensation Mode 90% to 10% ILOAD Change, 25 mA ILOAD, 10 μF Load EXTFORCE2 Range, 10 μF Load CH1 p-p CH1 p-p 36mV TRIGGER 86mV CH1AREA –9.738µVs 2 FORCE FORCE 1 1 3 SYNC 07779-018 07779-021 CH1 50mV M200µs A CH3 1.5V CH1 100mV BW CH2 5V M40µs A CH2 4V CH3 5V T 10.4% T 120.4µs Figure 33. Range Change EXTFORCE2 to 25 mA, Safe Mode, Figure 36. Autocompensation Mode 10% to 90% ILOAD Change, 25 mA ILOAD, 10 μF Load EXTFORCE2 Range, 10 μF Load 350 10µF LOAD 30µF LOAD CH1 p-p 300 100µF LOAD 172mV 250 TRIGGER V) 2 m AK ( 200 PE FORCE TO- 150 1 K- A E P 100 50 0 MSAOEFDXEET RANCAGOUEMT OP1 MSEAOXFDETE RANCGAOUEMT 2OP MS2AO5FmDEEA RANCAGOUMETOP 07779-019 CH1 100mV BW CH2 5V MT 4 012µ0s.4µs A CH2 1.6V 07779-022 Figure 34. Kick/Droop Response vs. IRANGE, Compensation, and CLOAD,, Figure 37. Safe Mode 80% to 10%, EXTFORCE2 Range, 10 μF Load 10% to 90% to 10% ILOAD Change Rev. E | Page 24 of 66

Data Sheet AD5560 CH1 p-p TRIGGER 174mV FORCE MEASOUT – MI 2 TA = 25°C AVDD = +16.25V 1 FORCE 1 AVRVESFS == 5–V16.25V OFFSET DAC = 0x8000 IRANGE/ILOAD = 25mA 0 TO 10V STEP RLOAD = 40kΩ CLOAD = 220nF 2 AUTOCOMP MODE 0x4480 MEASOUT GAIN 1, MI GAIN 20 07779-023 43 BUSY 07779-055 CH1 100mV BW CH2 5V M40µs A CH2 4.6V CH1 5V CH2 2V BW M20µs A CH3 2.9V T 120.4µs CH3 5V CH4 10V T 1.4% Figure 38. Safe Mode 10% to 90%, EXTFORCE2 Range, 10 μF Load Figure 41. Transient Response FVMI Mode, 25 mA Range, Autocompensation Mode 2.0 AVDD = +16.5V AVSS = –16.5V FORCE 1.9 MEASOUT – MI V) E ( 1.8 G TA TA = 25°C VOL 1.7 1 AAVVDSSD == –+1166..2255VV OUT VORFEFFS =E T5 VDAC = 0x8000 EAS 1.6 0IR TANOG 1E0/IVL OSATDE =P 250µA M RLOAD = 40kΩ 2 CLOAD = 220nF 1.5 SAFE MODE BUSY MEASOUT GAIN 1, MI GAIN 20 1.425 35 FO45RCED TE5M5PERATU65RE(°C)75 85 07779-024 43 CCHH31 55VV CCHH42 120VVBW MT 1 070.2µ%s A CH3 2.9V 07779-056 Figure 39. MEASOUT TSENSE Temperature Sensor vs. Temperature Figure 42. Transient Response FVMI Mode, 25mA Range, Safe Mode (Multiple Devices) FORCE MEASOUT – MI MEASOUT – MI FORCE TA = 25°C AVDD = +16.25V 1 V0AOIR RVFTAESFNOFSGS 1=EE=0 / T5IV–L V1 DOS6AAT.2DCE5 =PV= 205x08µ0A00 1 VTAOAARVVF EDSF=FSDS 2 =E==5 T° 5–+C V1D166A..2C255 V=V 0x8000 2 RCLLOOAADD == 4202k0nΩF 0IR TANOG 3E./7ILVO SATDE =P EXTFORCE1/1.2A AMUETAOSCOOUMT PG AMIOND 1E, M0xI 4G8A8I0N 20 2 ACULOTAODC =O 1M0Pµ FM COEDREA 0MxI9C680 43 BUSY 07779-054 43 MEASOUT GAIN 1, MI GAIN 20 BUSY 07779-057 CH1 5V CH2 2V BW M400µs A CH3 2.9V CH1 5V CH2 1V BW M4µs A CH3 2.9V CH3 5V CH4 10V T 10.2% CH3 5V CH4 10V T 3% Figure 40. Transient Response FVMI Mode, ±250 μA Range, Figure 43. Transient Response FVMI Mode, EXTFORCE1 Range, Autocompensation Mode Autocompensation Mode Rev. E | Page 25 of 66

AD5560 Data Sheet 1000 PART H1 900 PART H2 PART H3 800 700 MEASOUT – MI Hz) 600 √ nV/ 500 TA = 25°C SD ( 400 1 AVDD = +16.25V N AVRVESFS == 5–V16.25V 300 OFFSET DAC = 0x8000 I0R TANOG 3E./7ILVO SATDE =P EXTFORCE1/1.2A FORCE 200 2 CLOAD = 10µF CERAMIC 100 SAFE MODE 43 CCHH13 55VV MEACCSHHO42U T11 0VGVABIWN 1, MMTI G2 04A.µ6IsN% 20 A CH3B U S 2Y.9V 07779-058 0 FVMN GAIN = 00FVMVGAIN = 10 GAIN = 00FNMVGAIN = 10 GAIN = 00 GAIN = 01FVMIGAIN = 10 GAIN = 11 07779-025 Figure 44. Transient Response FVMI Mode, EXTFORCE1 Range, Safe Mode Figure 47. NSD vs. Amplifier Stage and Gain Setting at 1 kHz 20 DVCC = +5.25V, AVDD = +16.5V, AVSS = –16.5V 0 –20 1 TAVAARVV EDS=FSD 2 ===5 ° 5–+CV1166..2255VV MEASOUT – MI RR (dB) –40 OFFSET DAC = 0x8000 S I R A N G E / I L O A D = E 3X0T0FmOARCE2/ ACP FOH 0 TO 10V STEP FORCE –60 MV: GAIN 0 2 CLOAD = 220nF MMVV:: GGAAIINN 12 AUTOCOMP MODE 0x4880 MV: GAIN 3 43 MEASOUT GAIN 1, MI GAIN 20 BUSY 07779-059 –80 MMMMIIII::::G GGGAAAAIINIINNN 1 023 CCHH13 55VV CCHH42 120VVBW MT 1 09.µ8s% A CH3 2.9V –10010 100 1kFREQUE10NkCY (Hz)100k 1M 10M07779-049 Figure 45. Transient Response FVMI Mode, EXTFORCE2 Range, Figure 48. ACPSRR of AVDD vs. Frequency Autocompensation Mode 0 FORCE –20 MEASOUT – MI –40 1 TA0OIAVR ARVVFTA EDSFNO=FSDGS 2 1 =EE==50 / T° 5IV–+LC V1 DO1S66AAT..D2C2E5 5 =PV=V E0Xx8T0F0O0RCE2/300mA ACPSRR (dB) ––8600 FMMMOVVVH::: GGGAAAIIINNN 012 2 CLOAD = 220nF –100 MMVI: :G GAAININ 0 3 SAFE MODE MI:GAIN 1 43 BUSY MEASOUT GAIN 1, MI GAIN 20 07779-060 –120 DVCC = +5.25V, AVDD = +16.5V, AVSS = –16.5V MMII:: GGAAIINN 23 CCHH31 55VV CCHH42 120VVBW MT 1 090.8µ%s A CH3 2.9V –14010 100 1kFREQUE10NkCY (Hz)100k 1M 10M07779-050 Figure 46. Transient Response FVMI Mode, EXTFORCE2 Range, Safe Mode Figure 49. ACPSRR of AVSS vs. Frequency Rev. E | Page 26 of 66

Data Sheet AD5560 0 0 MI: GAIN 0 –20 –20 FOH MI: GAIN 0 –40 –40 B) B) d d –60 R ( R ( R –60 R S S ACP MV: GAIN 0 ACP –80 MV: GAIN 0 –80 –100 –100 –120 FOH DVCC = +5.25V, AVDD = +16.5V, AVSS = –16.5V DVCC = +5.25V, AVDD = +16.5V, AVSS = –16.5V –12010 100 1kFREQUE10NkCY (Hz)100k 1M 10M07779-051 –14010 100 1kFREQUE10NkCY (Hz)100k 1M 10M07779-053 Figure 50. ACPSRR of DV vs. Frequency Figure 52. ACPSRR of HCAV x vs. Frequency CC SS 0 1600 CABLE L = 2µH, CLAMP AT 1.2A MI: GAIN 0 CABLE L = 1µH, CLAMP AT 1.2A –20 1400 CCAABBLLEE LL == 00µ.2Hµ,H C, LCALMAPM PA TA T1. 21A.2A 1200 –40 A) CCAABBLLEE LL == 12µµHH,, CCLLAAMMPP AATT 880000mmAA R (dB) –60 MV: GAIN 0 LUE (m1000 CCAABBLLEE LL == 00µ.2Hµ,H C, LCALMAPM PA TA T80 800m0mAA R A 800 CPS –80 VMP CCAABBLLEE LL == 12µµHH,, CCLLAAMMPP AATT 440000mmAA A A600 CABLE L = 0.2µH, CLAMP AT 400mA CL CABLE L = 0µH, CLAMP AT 400mA I –100 400 CABLE L = 2µH, CLAMP AT 100mA –120 FOH 200 CCCAAABBBLLLEEE LLL === 001µ.µ2HHµ,,H CC, LLCAALMMAPMP PAA TTA T110 01000mm0mAAA DVCC = +5.25V, AVDD = +16.5V, AVSS = –16.5V –14010 100 1kFREQUE10NkCY (Hz)100k 1M 10M07779-052 00.001 0.01 RLO0A.D1 (Ω) 1 10 07779-063 Figure 51. ACPSRR of HCAVDDx vs. Frequency Figure 53. ICLAMP Value vs. RLOAD – Cal at 1Ohm Rev. E | Page 27 of 66

AD5560 Data Sheet TERMINOLOGY Slew Rate Offset Error The slew rate is the rate of change of the output voltage Offset error is a measure of the difference between the actual expressed in volts per microsecond (V/μs). voltage and the ideal voltage at midscale or at zero current expressed in millivolts (mV) or percentage of full-scale range Differential Nonlinearity (DNL) (%FSR). DNL is the difference between the measured change and the ideal 1 LSB change between any two adjacent codes. A specified Gain Error DNL of ±1 LSB maximum ensures monotonicity. Gain error is the difference between full-scale error and zero- scale error. It is expressed in percentage of full-scale range Output Voltage Settling Time (%FSR). Output voltage settling time is the amount of time it takes for the output of a DAC to settle to a specified level for a full-scale Gain Error = Full-Scale Error − Zero-Scale Error input change. where: Digital-to-Analog Glitch Energy Full-Scale Error is the difference between the actual voltage and Digital-to-analog glitch energy is the amount of energy that is the ideal voltage at full scale. injected into the analog output at the major code transition. It Zero-Scale Error is the difference between the actual voltage and is specified as the area of the glitch in nanovolts per second the ideal voltage at zero scale. (nV-sec). It is measured by toggling the DAC register data Linearity Error between 0x7FFF and 0x8000. Linearity error, or endpoint linearity, is a measure of the AC Power Supply Rejection Ratio (ACPSRR) maximum deviation from a straight line passing through the ACPSRR is a measure of the part’s ability to avoid coupling endpoints of the full-scale range. It is measured after adjusting noise and spurious signals that appear on the supply voltage for offset error and gain error and is expressed in millivolts (mV). pin to the output of the switch. The dc voltage on the device Common-Mode (CM) Error is modulated by a sine wave of 0.2 V p-p. The ratio of the CM error is the error at the output of the amplifier due to the amplitude of the signal on the output to the amplitude of the common-mode input voltage. It is expressed in percentage of modulation is the ACPSRR. It is expressed in decibels (dB). full-scale voltage range per volt (%FSVR/V). V STRESS Clamp Limit V is the stress voltage applied to each pin during leakage STRESS Clamp limit is a measure of where the clamps begin to function testing. fully and limit the clamped voltage or current. Leakage Current Leakage current is the current measured at an output pin when the circuit connected to that pin is in high impedance state. Rev. E | Page 28 of 66

Data Sheet AD5560 THEORY OF OPERATION The AD5560 is a single-channel, device power supply for use level. This limits the maximum or minimum voltage that in semiconductor automatic test equipment. All the DAC levels can appear on the FORCE pin; it can be driven no higher required to operate the device are available on chip. than [V(F DAC) + threshold + V ] and no lower than IN BE [V(F DAC) − threshold − V ]. This device contains programmable modes to force a pin vol- IN BE • It triggers an alarm on KELALM if the force line goes more tage and measure the corresponding current (FVMI) covering a wide current measure range of up to ±1.2 A. A voltage sense than the threshold voltage away (OSD DAC level) from the amplifier allows measurement of the DUT voltage. Measured sense line. current or voltage is available on the MEASOUT pin. • It translates the V(force − sense) voltage to a level relative to AGND so that it can be measured through FORCE AMPLIFIER the MEASOUT pin. The force amplifier is a unity gain amplifier forcing voltage The open-sense detect level is programmable over the range directly to the device under test (DUT). This high bandwidth 0.62 V to 5 V (16-bit OSD DAC plus one diode drop). The 5 V amplifier allows suppression of load transient induced glitching OSD DAC can be accessed through the serial interface (see the on the amplifier output. Headroom and footroom requirements DAC register addressing portion of Table 24). There is a 10 kΩ for the amplifier are 2.25 V and an additional ±500 mV dropped resistor that can be connected between the FORCE and SENSE across the selected sense resistor with full-scale current flowing. pins by use of SW11. This 10 kΩ resistor is intended to The amplifier is designed to drive high currents up to ±1.2 A maintain a force/sense connection when a DUT is not in place. with the capability of ganging together outputs of multiple It is not intended to be connected when measurements are AD5560 devices for currents in excess of ±1.2 A. being made because this defeats the purpose of the OSD circuit The force amplifier can be compensated to ensure stability in identifying an open circuit between FORCE and SENSE. In when driving DUT capacitances of up to 160 μF. addition, the sense path has a 2.5 kΩ resistor in series; there- fore, if the 10 kΩ switch is closed, errors may become apparent The device is capable of supplying transient currents in excess when in high current ranges. of ±1.2 A when powering a DUT with a large decoupling capacitor. A clamp enable pin (CLEN) allows disabling of the DEVICE UNDER TEST GROUND (DUTGND) clamp circuitry to allow the amplifier to quickly charge this DUTGND is the ground level of the DUT. large capacitance. DUTGND Kelvin Sense An extra control bit (GPO) is available to switch out DUT KELALM flags when the voltage at the DUTGND pin moves decoupling when making low current measurements. too far away from the AGND line (>1 V default setting of the HW_INH Function DGS DAC). This alarm trigger is programmable via the serial A hardware inhibit pin (HW_INH/LOAD) allows disabling of interface. The threshold for the alarm function is program- the force amplifier, making the output high impedance. This mable using the DUTGND SENSE DAC (DGS DAC) (see function is also available through the serial interface (see the Table 24). SW-INH bit in the DPS Register 1, Address 0x2). The DUTGND pin has a 50 μA pull-up resistor that allows This pin can also be configured as a LOAD function to allow the alarm function to detect whether DUTGND is open. Setting multiple devices to be synchronized. Note that either CLEN the disable DUTALM bit high (Register 0x6, Bit 10) disables the or HW_INH can be chosen as a LOAD function. 50 μA pull-up resistor and also disables the alarm feature. The alarm feature can also be set to latched or unlatched (Register 0x6, DAC REFERENCE VOLTAGE (VREF) Bit 11). One analog reference input, VREF, supplies all DAC levels with Kelvin Alarm (KELALM) the necessary reference voltage to generate the required dc levels. The open-drain active low Kelvin alarm pin flags the user when OPEN-SENSE DETECT (OSD) ALARM AND CLAMP an open occurs in either the sense or DUTGND line; it can be The open-sense detect (OSD) circuitry protects the DUT from programmed to be either latched or unlatched (Register 0x6, overvoltage when the force and sense lines of the force Bit 13, Bit 11, Bit 7). The delay in the alarm flag is 50 μs. amplifier becoming disconnected from each other. GPO This block performs three functions related to the force and The GPO pin can be used as an extra control bit for external sense lines. switching functions, such as for switching out DUT decoupling • It clamps the sense line to within a programmable when making low current measurements. threshold level (plus a V ) of the force line, where the BE The GPO pin is also internally connected to an array of thermal programmable threshold is set by the OSD DAC voltage diodes scattered across the AD5560. The diagnostic register Rev. E | Page 29 of 66

AD5560 Data Sheet (Address 0x7) details the addressing and location of the diodes. The clamp register limits the CLL clamp to the range 0x0000 to These can be used for diagnostic purposes to determine the 0x7FFF; any code in excess of this is seen as 0x7FFF. Similarly, thermal gradients across the die and across a board containing the CLH clamp registers are limited to the range 0x8000 to many AD5560 devices. When selected, the anode of these 0xFFFF (see Table 24). diodes is connected to GPO and the cathode to AGND. The Clamp Alarm Function (CLALM) AD5560 evaluation board uses the ON Semiconductor® The CLALM open-drain output flags the user when a clamp ADT7461 temperature sensor for the purpose of analyzing the temperature at different points across the die. limit has been hit; it can be programmed to be either latched or unlatched. COMPARATORS Clamp Enable Function (CLEN/LOAD) The DUT measured value is monitored by two comparators Pin 15 (CLEN) allows the user to disable the clamping function (CPOL, CPOH). These comparators give the advantage of when powering a device with large DUT capacitance, thus allowing speed for go-no-go testing. increased current drive to the device and, therefore, speeding Table 6. Comparator Output Function up the charging time of the load capacitance. CLEN is active high. Test Condition CPOL CPOH This pin can also be configured as LOAD to allow multiple devices (V or I ) > CPH 0 DUT DUT to be synchronized. Note that either CLEN or HW_INH can be (V or I ) < CPH 1 DUT DUT chosen as a LOAD function. (V or I ) > CPL 1 DUT DUT (V or I ) < CPL 0 DUT DUT SHORT-CIRCUIT PROTECTION CPH > (V or I ) > CPL 1 1 DUT DUT The AD5560 force amplifier stage has built-in short-circuit To minimize the number of comparator output lines routed protection per stage as noted in the Specifications section. back to the controller, it is possible to change the comparator When the current clamps are disabled, the user must minimize function to a window comparator that outputs on one single the duration of time that the device is left in a short-circuit pin, CPO. This pin is shared with CPOH and, when configured condition (for all current ranges). through the serial interface, it provides information on whether GUARD AMPLIFIER the measured DUT current or voltage is inside or outside the A guard amplifier allows the user to force the shield of the window set by the CPL and CPH DAC levels (see Table 24). coaxial cable to be driven to the same forced voltage at the Table 7. Comparator Output Function in CPO Mode DUT, ensuring minimal voltage drops across the cable to Test Condition CPO Output minimize errors from cable insulation leakage. (VDUT or IDUT) > CPL and < CPH 1 The guard amplifier also has an alarm function that flags the (VDUT or IDUT) < CPL or > CPH 0 open-drain KELALM pin when the guard output is shorted. The delay in the alarm flag is 200 μs. CURRENT CLAMPS The guard amplifier output (GUARD/SYS_DUTGND, Pin 43) High and low current clamps are included on chip. These protect can also be configured to function as a SYS_DUTGND pin; to the DUT in the event of a short circuit. The CLH and CLL do this, the guard amplifier must be tristated via software (see levels are set by the 16-bit DAC levels. The clamp works to DPS Register 2, Table 19). limit the current supplied by the force amplifier to within the COMPENSATION CAPACITORS set levels. The clamp circuitry compares the voltage across the sense resistor (multiplied by an in-amp gain of 10 or 20) to The force amplifier is capable of driving DUT capacitances up compare to the programmed clamp limit and activates the to 160 μF. Four external compensation capacitor (CCx) inputs clamp circuit if either the high level or low level is exceeded, are provided to ensure stability into the maximum load capacit- thus ensuring that the DUT current can never exceed the ance while ensuring that settling time is optimized. In addition, programmed clamp limit + 10% of full-scale current. five CFx capacitor inputs are provided to switch across the sense resistors to further optimize stability and settling time perform- If a clamp level is exceeded, this is flagged via the latched open- ance. The AD5560 has three compensation modes: safe mode, drain CLALM pin, and the resulting alarm information can be autocompensation mode, and manual compensation mode, all read back via the SPI interface. of which are described in more detail in the Force Amplifier The clamp levels should not be set to the same level; instead, Stability section. they should be set a minimum of 2 V apart (irrespective of the The range of suggested compensation capacitors allows MI gain setting). This equates to 10% of FSCR (MI gain = 20) optimum performance for any capacitive load from 0 pF (20% of FSCR, MI gain of 10) apart. They should also be 1 V to 160 μF using one of the modes previously listed. away from the 0 A level. Rev. E | Page 30 of 66