- 型号: AC05000003000JAC00

- 制造商: Vishay

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

AC05000003000JAC00产品简介:

ICGOO电子元器件商城为您提供AC05000003000JAC00由Vishay设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 AC05000003000JAC00价格参考。VishayAC05000003000JAC00封装/规格:通孔电阻器, 300 Ohms ±5% 5W Through Hole Resistor Axial Flame Retardant Coating, Pulse Withstanding, Safety Wirewound。您可以下载AC05000003000JAC00参考资料、Datasheet数据手册功能说明书,资料中有AC05000003000JAC00 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

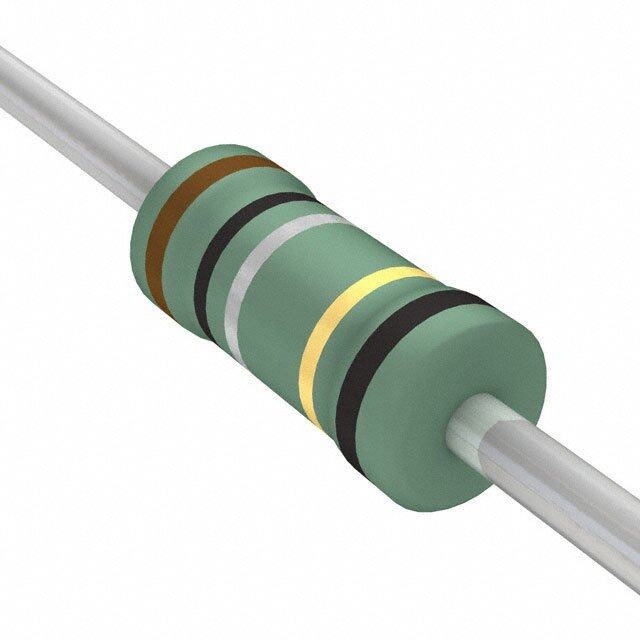

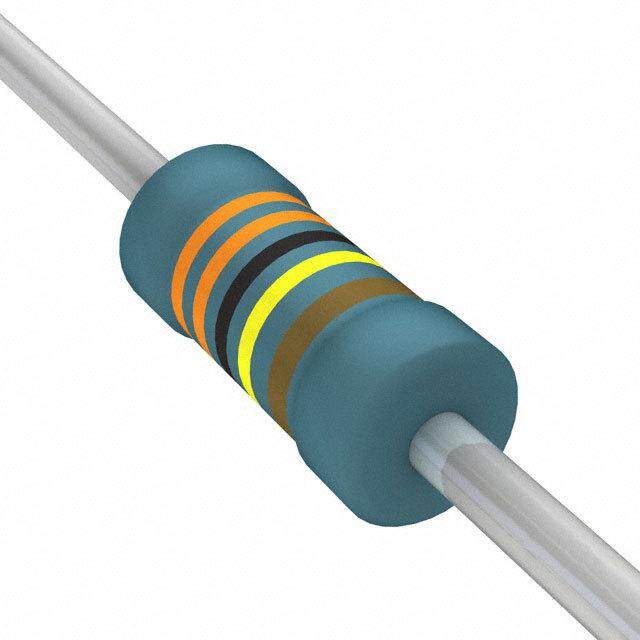

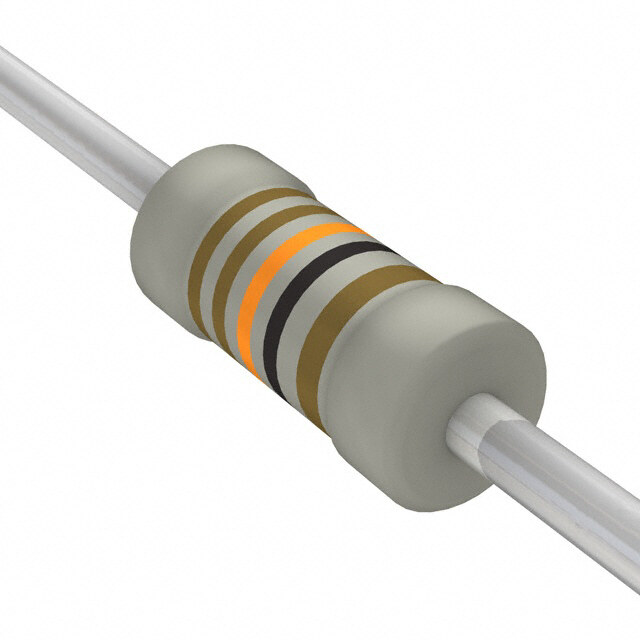

| 描述 | RES 300 OHM 5W 5% AXIAL线绕电阻器 - 透孔 5watts 300ohms 5% |

| 产品分类 | |

| 品牌 | Vishay BC ComponentsVishay / Draloric |

| 产品手册 | http://www.vishay.com/doc?28730 |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 线绕电阻器,线绕电阻器 - 透孔,Vishay / Draloric AC05000003000JAC00AC |

| 数据手册 | |

| 产品型号 | AC05000003000JAC00AC05000003000JAC00 |

| 产品 | Power Resistors Wirewound Cement Filled Ceramic |

| 产品目录绘图 |

|

| 产品种类 | 线绕电阻器 - 透孔 |

| 供应商器件封装 | 轴向 |

| 其它名称 | AC5W300CT |

| 功率(W) | 5W |

| 功率额定值 | 5 W |

| 包装 | 剪切带 (CT) |

| 商标 | Vishay / Draloric |

| 外壳直径 | 7.5 mm |

| 外壳长度 | 18 mm |

| 大小/尺寸 | 0.295" 直径 x 0.709" 长(7.50mm x 18.00mm) |

| 容差 | 5 %±5% |

| 封装 | Ammo Pack |

| 封装/外壳 | 轴向 |

| 工作温度范围 | 0 C to + 275 C |

| 工厂包装数量 | 500 |

| 引线直径 | 0.8 mm |

| 成分 | 绕线 |

| 标准包装 | 1 |

| 温度系数 | - 80 PPM / K, - 10 PPM / K-10/ -80ppm/°C |

| 特性 | 耐燃, 脉冲耐受 |

| 电阻 | 300 Ohms |

| 电阻(Ω) | 300 |

| 端子数 | 2 |

| 端接类型 | Axial |

| 类型 | Cemented Wirewound Resistor |

| 系列 | AC05 |

| 高度 | - |

PDF Datasheet 数据手册内容提取

AC, AC-AT www.vishay.com Vishay Draloric Cemented Leaded Wirewound Resistors FEATURES • AEC-Q200 qualified AC-AT series • High power dissipation in small design • Non-flammable coating conforming t o UL 94 V-0 • Excellent pulse load capability • Non-inductive (NI) version available • WSZ-form lead bending available for SM D mounting • Material categorization: for definitions of complianc e LINKS TO ADDITIONAL RESOURCES please see www.vishay.com/doc?99912 3DDD 333D 3D Models APPLICATIONS The AC series is the perfect choice for general purpose • Automotive electronics power applications. The AEC-Q200 qualified AC-AT serie s • Industrial electronics is best suited for automotive applications. The robus t silicone cement coating can handle challenging ambient • Power supplies and operating conditions. Typical applications include but • White goods are not limited to energy meters, power supplies an d • Pre-charging / discharging applications automotive electronics. For a given application, requirements of ohmic value, rated power, peak voltage , pulse shape, pulse duration, lead bending, and environmental conditions may be submitted to recommend the most suitable product. Various lead forms are available such as RT (radial taped), WSZ (Z-form), DK (double kink), EK (single kink) with define d mounting pitch. STANDARD ELECTRICAL SPECIFICATIONS RESISTANCE RESISTANCE RESISTANCE RATED RATED LIMITING RANGE (1) RANGE (1) RANGE (1) RESISTANCE TYPE DISSIPATION DISSIPATION VOLTAGE TCR = TCR = TCR = P P U -10 ppm/K to +100 ppm/K to ± 100 ppm/K TOLERANCE 40 70 max. -80 ppm/K +180 ppm/K AC01 1 W 0.9 W P x R 0.10 Ω to 33 Ω 36 Ω to 2.4 kΩ - ± 5 % AC01-AT 1 W 0.9 W P x R 0.39 Ω to 33 Ω 36 Ω to 2.4 kΩ - ± 5 % AC03 3 W 2.5 W P x R 0.10 Ω to 390 Ω 430 Ω to 3.3 kΩ 3.6 kΩ to 5.1 kΩ ± 5 % AC03-AT 3 W 2.5 W P x R 0.27 Ω to 390 Ω 430 Ω to 3.3 kΩ - ± 5 % AC04 4 W 3.5 W P x R 0.10 Ω to 620 Ω 680 Ω to 6.8 kΩ - ± 5 % AC04-AT 4 W 3.5 W P x R 0.22 Ω to 620 Ω 680 Ω to 6.8 kΩ - ± 5 % AC05 5 W 4.7 W P x R 0.10 Ω to 910 Ω 1.0 kΩ to 10 kΩ - ± 5 % AC05-AT 5 W 4.7 W P x R 0.62 Ω to 910 Ω 1.0 kΩ to 10 kΩ - ± 5 % AC07 7 W 5.8 W P x R 0.10 Ω to 820 Ω 910 Ω to 15 kΩ - ± 5 % AC07-AT 7 W 5.8 W P x R 1.0 Ω to 820 Ω 910 Ω to 15 kΩ - ± 5 % AC10 10 W 8.4 W P x R 0.22 Ω to 560 Ω 620 Ω to 27 kΩ - ± 5 % AC10-AT 10 W 8.4 W P x R 2.0 Ω to 560 Ω 620 Ω to 27 kΩ - ± 5 % Notes • The operating temperature range for these resistors is from -55 °C up to 250 °C (1) Resistance value to be selected from E24 series Revision: 07-Dec-2020 1 Document Number: 28730 For technical questions, contact: ww1resistors@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

AC, AC-AT www.vishay.com Vishay Draloric PART NUMBER AND PRODUCT DESCRIPTION Part Number: AC03000001509JAC00 AC03AT0001509JAC00 A C 0 3 0 0 0 0 0 1 5 0 9 J A C 0 0 A C 0 3 A T 0 0 0 1 5 0 9 J A C 0 0 TCR / TOLERANCE PACKAGING MODEL VARIANT (1) VALUE SPECIAL MATERIAL CODE CODE AC01000 = AC01 0 = neutral 0 = standard 3 digit value J = ± 5.0 % (see 00 = standard AC03000 = AC03 1 = RT 1 digit Packaging 2 digit code = AC04000 = AC04 2 = SWI multiplier table) customized AC05000 = AC05 3 = DK SP 20 mm MULTIPLIER version (2) AC07000 = AC07 4 = DK LP 33 mm 7 = *10-3 AC10000 = AC10 5 = DK LP 17.8 mm 8 = *10-2 6 = NI Non inductive 9 = *10-1 AC01AT0 = AC01-AT 7 = DK LP 25.4 mm 0 = *100 AC03AT0 = AC03-AT 8 = DK SP 25.4 mm 1 = *101 AC04AT0 = AC04-AT 9 = AC03/AC03AT-WSZ 2 = *102 AC05AT0 = AC05-AT A = EK 22.5 mm AC07AT0 = AC07-AT B = EK 17.8 mm AC10AT0 = AC10-AT C = EK 25.4 mm D = Cu wire 0.8 mm E = EK 33 mm G = DK SP 33 mm H = EK 20 mm I = DK SP 17.8 mm K = AC05/AC05AT-WSZ Product Description: AC03 15R 5 % AC AC03AT 15R 5 % AC AC03 15R 5 % AC AC03-AT 15R 5 % AC TYPE RESISTANCE TOLERANCE PACKAGING AC01 AC01-AT R10 = 0.1 Ω 5 % AC LB AC03 AC03-AT 75R = 75 Ω A1 LC AC04 AC04-AT 27K = 27 kΩ AB LK AC05 AC05-AT AE BM AC07 AC07-AT AC10 AC10-AT Notes • AC-AT: it is currently available only for standard axial taped parts and for AC03AT-WSZ, AC05AT-WSZ. Contact us for the availability of AC-AT in other lead termination bending forms (1) RT = radial taped lead bending (refer page 11) SWI = special winding EK = single kink lead bending (refer page 10) DK LP= double kink large pitch lead bending (refer page 10) DK SP= double kink small pitch lead bending (refer page 10) WSZ = “Z” form leads (refer page 11) (2) For special windings or the non-inductive versions, please contact: ww1resistors@vishay.com Revision: 07-Dec-2020 2 Document Number: 28730 For technical questions, contact: ww1resistors@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

AC, AC-AT www.vishay.com Vishay Draloric PACKAGING TYPE / SIZE CODE DESCRIPTION QUANTITY PACKAGING STYLE WIDTH PITCH DIMENSIONS AC01 Taped acc. to IEC 60286-1 A1 A1 1000 63 mm 10 mm 260 mm x 85 mm x 70 mm AC01-AT fan-folded in a box AC01 DK/EK LC LC 500 Bulk packaging - - 260 mm x 80 mm x 55 mm Taped acc. to IEC 60286-2 AC01 RT AE AE 2500 - 12.7 mm 200 mm x 46 mm x 334 mm fan-folded in a box AC03 Taped acc. to IEC 60286-1 AC AC 500 63 mm 10 mm 260 mm x 85 mm x 58 mm AC03-AT fan-folded in a box AC03 DK/EK LC LC 500 Bulk packaging - - 224 mm x 82 mm x 54 mm Taped acc. to IEC 60286-2 AC03 RT AQ AQ 1800 - 12.7 mm 200 mm x 46 mm x 334 mm fan-folded in a box AC03 WSZ Blister taped acc. to BM BM 1250 - 8 mm 350 mm x 350 mm x 55 mm AC03-AT WSZ IEC 60286-3 on reel AC04 (1) Taped acc. to IEC 60286-1 260 mm x 85 mm x 70 mm AC AC 500 63 mm 10 mm AC04-AT (1) fan-folded in a box 260 mm x 85 mm x 58 mm AC04 DK/EK LC LC 500 Bulk packaging - - 224 mm x 82 mm x 54 mm AC05 Taped acc. to IEC 60286-1 AC AC 500 63 mm 10 mm 270 mm x 86 mm x 118 mm AC05-AT fan-folded in a box AC05 DK/EK LC LC 500 Bulk packaging - - 224 mm x 82 mm x 54 mm AC05 WSZ Blister taped acc. to BW BW 350 - 16 mm 350 mm x 335 mm x 60 mm AC05-AT WSZ IEC 60286-3 on reel AC07 Taped acc. to IEC 60286-1 AC AC 500 73 mm 10 mm 265 mm x 90 mm x 118 mm AC07-AT fan-folded in a box AC07 DK/EK LB LB 250 Bulk packaging - - 224 mm x 82 mm x 54 mm AC10 Taped acc. to IEC 60286-1 AB AB 250 88 mm 10 mm 265 mm x 105 mm x 105 mm AC10-AT fan-folded in a box Note (1) Manufacturing at different production locations may involve use of differently sized box Revision: 07-Dec-2020 3 Document Number: 28730 For technical questions, contact: ww1resistors@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

AC, AC-AT www.vishay.com Vishay Draloric DESCRIPTION ASSEMBLY Wirewound resistors are best suited for use in high power , The resistors are axial leaded for soldering. The terminals of high current applications. The silicone cement lacquer the resistors are completely lead (Pb)-free, the special tin coating enables AC series to withstand challenging plating provides compatibility with lead (Pb)-free and operating and environmental conditions. The coating is lead-containing soldering processes. resistant to cleaning solvents specified in IEC 60115-1 (1). Special lead forms may be available on request, please Production is strictly controlled and follows an extensive se t inquire at ww1resistors@vishay.com. As these components of instructions established for reproducibility. are high power dissipation resistors, customers are advised The winding is done with a specific material on a speciall y to use a high melting point solder. developed fine ceramic body (Al O ). The ceramic meets th e 2 3 APPLICATION INFORMATION highest requirements against mechanical resistance, thermal shocks, dielectric strength, and insulation The power dissipation of the resistor generates a resistance at high temperatures. With different diameters temperature rise with respect to the ambient. The and turn spacings of resistive wire, a large ohmic value permissible dissipation is derated for temperatures above range can be covered. 40 °C, as shown in the derating diagram, in order to avoid The resistors are marked with resistance, rated dissipation overheating of the resistor. The heat dissipated from the (P ) and tolerance. Product quality is verified by testing resistor may affect adjacent components, hence prope r 40 procedures, performed on all individual resistors. clearance will be required in order to avoid overheating. The Resistance is measured on the lead wires at a distance o f resistive wire is encapsulated by a protective lacquer 6 mm from the resistor body. If a greater length of lead wire coating. is used in the application, the user may need to consider the All materials used are non-flammable and inorganic. additional wire resistance, particularly with low resistance These resistors do not feature a limited lifetime whe n products. operated within the permissible limits. However, resistance MATERIALS value drift increasing over operating time may result i n exceeding a limit acceptable to the specific application, Vishay acknowledges the following systems for the thereby establishing a functional lifetime. regulation of hazardous substances: APPROVALS • IEC 62474, Material Declaration for Products of and for the Electrotechnical Industry, with the list of declarable AC-AT series is AEC-Q200 qualified, specifically for the use substances given therein (2) in automotive applications. It is currently available only for • The Global Automotive Declarable Substance List standard axial taped parts and for AC03AT-WSZ , (GADSL) (3) AC05AT-WSZ. • The REACH regulation (1907/2006/EC) and the related lis t Contact us for the availability of AC-AT in other lea d of substances with very high concern (SVHC) (4) for it s termination bending forms. supply chain RELATED PRODUCTS The products do not contain any of the banned substances as per IEC 62474, GADSL, or the SVHC list, see UL approved, special cement coated fusible resistor is als o www.vishay.com/how/leadfree. Hence the products fully available. For details please see the datasheet: comply with the following directives: “AC01-CS, AC03-CS, AC05-CS - Axial Cemented Fusibl e • 2000/53/EC End-of-Life Vehicle Directive (ELV) and Wirewound Safety Resistors” www.vishay.com/doc?28909 Annex II (ELV II) For high surge wirewound products, silicone cement coated • 2011/65/EU Restriction of the Use of Hazardous Z300-Cxx series is available, see the datasheet: Substances Directive (RoHS) with amendment “Z300-Cxx - High Surge Axial Cemented Wirewound 2015/863/EU Resistors” www.vishay.com/doc?21027 • 2012/19/EU Waste Electrical and Electronic Equipment For precision applications, cement coated PAC series is Directive (WEEE) available, see the datasheet: Vishay pursues the elimination of conflict minerals from “PAC Series - Cemented Wirewound Precision Resistors ” its supply chain, see the Conflict Minerals Policy at www.vishay.com/doc?28731 www.vishay.com/doc?49037 Notes (1) Other cleaning solvents with aggressive chemicals should be evaluated in actual cleaning process for their suitability (2) The IEC 62474 list of declarable substances is maintained in a dedicated database, which is available at http://std.iec.ch/iec62474 (3) The Global Automotive Declarable Substance List (GADSL) is maintained by the American Chemistry Council and available at www.gadsl.org (4) The SVHC list is maintained by the European Chemical Agency (ECHA) and available at http://echa.europa.eu/candidate-list-table Revision: 07-Dec-2020 4 Document Number: 28730 For technical questions, contact: ww1resistors@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

AC, AC-AT www.vishay.com Vishay Draloric PULSE DIAGRAMS (t = pulse duration; t = repetition time) i p 10 000 10 000 W) W) tp/ti = 1000 R10 ˆP (max.1000 tp/ti = 1000 1RR100 ˆP (max.1000 tp/ti = 200 11R0R0 110R tp/ti = 200 11000RR tp/ti = 50 4K7 100 t/t = 50 2K0 100 p i t/t = 10 p i t/t = 10 10 p i 10 t/t = 2 p i t/t = 2 p i 1 1 10-6 10-5 10-4 10-3 1 0-2 10 -1 1 10-6 10-5 10-4 10-3 10-2 10-1 1 t (s) t (s) i i AC01 and AC01-AT Pulse on a regular basis; max. permissible AC03 and AC03-AT Pulse on a regular basis; max. permissible ˆ ˆ peak pulse power (Pmax.) as a function of pulse duration (ti) peak pulse power (Pmax.) as a function of pulse duration (ti) 10 000 10 000 t/t = 1000 W) p i R10 W) t/t = 1000 (max.1000 tp/ti = 200 11R0R0 (max.1000 tpp/tii = 200 1R1 ˆP 100R ˆP R10 tp/ti = 50 6K8 tp/ti = 50 11R 100R 100 100 8K2 tp/ti = 10 tp/ti = 10 t/t = 2 10 tp/ti = 2 10 p i 1 1 10-6 10-5 10-4 10-3 10-2 10 -1 1 10-6 10-5 10-4 10-3 1 0-2 1 0-1 1 10 t (s) t (s) i i AC04 and AC04-AT Pulse on a regular basis; max. permissible AC05 and AC05-AT Pulse on a regular basis; max. permissible ˆ ˆ peak pulse power (Pmax.) as a function of pulse duration (t) peak pulse power (Pmax.) as a function of pulse duration (t) i i 10 000 10 000 W) tp/ti = 1000 1R1 W) ttp//tti == 2100000 R2R682 ˆP (max.1000 ttpp//ttii == 2500 0 R110110R0R ˆP (max.1000 tpp/tii = 50 321453K0RR 15K t/t = 10 100 t/t = 10 100 p i p i t/t = 2 t/t = 2 p i p i 10 10 1 1 10-6 10-5 10-4 10-3 10-2 1 0-1 1 10 10-6 10-5 10-4 10-3 10-2 1 0-1 1 10 t (s) t (s) i i AC07 and AC07-AT Pulse on a regular basis; max. permissible AC10 and AC10-AT Pulse on a regular basis; max. permissible ˆ ˆ peak pulse power (Pmax.) as a function of pulse duration (t) peak pulse power (Pmax.) as a function of pulse duration (t) i i Revision: 07-Dec-2020 5 Document Number: 28730 For technical questions, contact: ww1resistors@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

AC, AC-AT www.vishay.com Vishay Draloric PULSE DIAGRAMS Pulse energy in joules or wattseconds is calculated with the help of the R-value to be used in the application. Choose the R value on X axis and look for the corresponding E (Ws/Ω) value on Y axis. Multiplying both the R (Ω) to corresponding E (Ws/Ω), will be resultant total pulse Energy (Ws or J) for adiabatic conditions. 100 1000 Ω) Ω) Ws/ 10 Ws/ 100 y ( y ( 10 g g ner 1 ner 1 E E se 0.1 se 0.1 ul ul P P 0.01 0.01 0.001 0.001 0.0001 0.0001 0.00001 0.1 1 10 100 1000 10 000 0.1 1 10 100 1000 10 000 R (Ω) R (Ω) AC01 and AC01-AT Pulse capability; E (Ws) as a function of R (Ω) AC03 and AC03-AT Pulse capability; E (Ws) as a function of R (Ω) 1000 1000 Ω) Ω) s/ 100 s/ 100 W W gy ( 10 gy ( 10 er er n n E 1 E 1 e e s s Pul 0.1 Pul 0.1 0.01 0.01 0.001 0.001 0.0001 0.0001 0.1 1 10 100 1000 10 000 0.1 1 10 100 1000 10 000 R (Ω) R (Ω) AC04 and AC04-AT Pulse capability; E (Ws) as a function of R (Ω) AC05 and AC05-AT Pulse capability; E (Ws) as a function of R (Ω) 1000 1000 Ω) Ws/ 100 Ω s/) 100 W gy ( 10 y ( 10 ner erg E 1 n 1 se e E Pul 0.1 uls 0.1 P 0.01 0.01 0.001 0.001 0.0001 0.0001 0.1 1 10 100 1000 10 000 0.1 1 10 100 1000 10 000 100 000 R (Ω) R (Ω) AC07 and AC07-AT Pulse capability; E (Ws) as a function of R (Ω) AC10 and AC10-AT Pulse capability; E (Ws) as a function of R (Ω) Revision: 07-Dec-2020 6 Document Number: 28730 For technical questions, contact: ww1resistors@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

AC, AC-AT www.vishay.com Vishay Draloric 1500 2000 V) V) (x. (x. a a m m 1500 ˆV ˆV 1000 1000 500 500 0 0 10-6 10-5 10-4 10-3 10-2 10-1 1 10-6 10-5 10-4 10-3 10-2 10-1 1 t (s) t (s) i i AC01 and AC01-AT Pulse on a regular basis; max. permissible AC03 and AC03-AT Pulse on a regular basis; max. permissible ˆ ˆ peak pulse voltage (Vmax.) as a function of pulse duration (ti) peak pulse voltage (Vmax.) as a function of pulse duration (ti) 2500 2500 V) V) (max. 2000 (max. 2000 ˆV ˆV 1500 1500 1000 1000 500 500 0 0 10-6 10-5 10-4 10-3 10-2 10-1 1 10-6 10-5 10-4 10-3 10-2 10-1 1 t (s) t (s) i i AC04 and AC04-AT Pulse on a regular basis; max. permissible AC05 and AC05-AT Pulse on a regular basis; max. permissible ˆ ˆ peak pulse voltage (Vmax.) as a function of pulse duration (ti) peak pulse voltage (Vmax.) as a function of pulse duration (ti) 5000 5000 V) V) (max. 4000 (max.4000 ˆV ˆV 3000 3000 2000 2000 1000 1000 0 0 10-6 10-5 10-4 10-3 10-2 10-1 1 10-6 10-5 10-4 10-3 10-2 10-1 1 t (s) t (s) i i AC07 and AC07-AT Pulse on a regular basis; max. permissible AC10 and AC10-AT Pulse on a regular basis; max. permissible ˆ ˆ peak pulse voltage (Vmax.) as a function of pulse duration (ti) peak pulse voltage (Vmax.) as a function of pulse duration (ti) Revision: 07-Dec-2020 7 Document Number: 28730 For technical questions, contact: ww1resistors@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

AC, AC-AT www.vishay.com Vishay Draloric FUNCTIONAL PERFORMANCE 120 % n er i100 w o P d 80 e at R 60 40 20 0 -55 0 50 100 150 200 250 300 350 40 Ambient Temperature in °C Derating 350 K n AC10, e i 300 AC10-AT s Ri e 250 AC07, atur AC07-AT er 200 AC05, p m AC05-AT Te 150 AC04, AC04-AT 100 AC03, AC03-AT 50 AC01, AC01-AT 0 0 5 10 15 Temperature Rise Power in W Revision: 07-Dec-2020 8 Document Number: 28730 For technical questions, contact: ww1resistors@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

AC, AC-AT www.vishay.com Vishay Draloric TEST PROCEDURES AND REQUIREMENTS All tests are carried out in accordance with the following Unless otherwise specified the following values apply: specifications: • Temperature: 15 °C to 35 °C • IEC 60115-1, generic specification (includes tests) • Relative humidity: 45 % to 75 % The test and requirements table contains only the mos t • Air pressure: 86 kPa to 106 kPa (860 mbar to 1060 mbar) important tests. For the full test schedule refer to the For performing some of the tests, the components ar e documents above. mounted on a test board in accordance with IEC 60115-1, The tests are carried out in accordance with IEC 60068-2-xx 4.31. test method and under standard atmospheric conditions i n In test procedures and requirements table, only the test s accordance with IEC 60068-1, 4.3. and requirements are listed with reference to the relevant Climatic category -55 / 200 / 56 (rated temperature range: clauses of IEC 60115-1 and IEC 60068-2-xx test methods . lower category temperature, upper category temperature ; A short description of the test procedure is also given. damp heat, steady state, test duration: 56 days) is valid. TEST PROCEDURES AND REQUIREMENTS IEC 60068-2 IEC 60115-1 REQUIREMENTS CLAUSE TEST TEST PROCEDURE PERMISSIBLE CHANGE (ΔR ) METHOD MAX. Room temperature; 4.13 - Short time overload 10x rated power P ; ± (2 % R + 0.1 Ω) 40 5 s 21 (Ua ) 1 Robustness of No damage 4.16 21 (Ub) terminations Tensile, bending and torsion ± (0.5 % R + 0.05 Ω) 21 (Uc) 4.18 20 (Tb) Resistance to Unmounted components ± (0.5 % R + 0.05 Ω) soldering heat (260 ± 5) °C; (10 ± 1) s 30 min at -55 °C and Rapid change 4.19 - 30 min at +200 °C; ± (1.5 % R + 0.05 Ω) of temperature 5 cycles 4.23 Climatic sequence: 4.23.2 2 (Ba) Dry heat 16 h; 200 °C Damp heat 24 h; 55 °C; 4.23.3 30 (Db) (accelerated) 90 % to 100 % RH 1st cycle 4.23.4 1 (Aa) Cold 2 h; -55 °C ± (1 % R + 0.05 Ω) 2 h; 8.5 kPa; 4.23.5 13 (M) Low air pressure 15 °C to 35 °C Damp heat 5 days; 55 °C; 4.23.6 30 (Db) remaining cyclic 95 % to 100 % RH; 5 cycles 4.24 78 (Cab) Damp heat, 56 days; (40 ± 2) °C; ± (5 % R + 0.1 Ω) (steady state) (93 ± 5) % RH 1000 h; 4.25.2 - (at rooEmnd tuermanpceerature) loaded with 116 % of P70 ± (5 % R + 0.1 Ω) 1.5 h ON and 0.5 h OFF Endurance at 4.25.3 - upper category 200 °C; 30 % of P ; 1000 h ± (5 % R + 0.1 Ω) 70 temperature IEC 60695-11-5 4.35 - Flammability No burning after 30 s needle flame test; 10 s (85 ± 2) °C; RH (85 ± 3) %; 4.37 67 C(y) Damp haecacte,l esrtaetaeddy state, 10 % of ope1r0a0ti0o nh ;power (P ) ± (5 % R + 0.1 Ω) 70 U ≤ 0.3 x U max. 4.38 - Electrostatic discharge test 2 discharges, 8 kV ± (5 % R + 0.1 Ω) (1 positive, 1 negative) Revision: 07-Dec-2020 9 Document Number: 28730 For technical questions, contact: ww1resistors@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

AC, AC-AT www.vishay.com Vishay Draloric DIMENSION AND MASS L d x B D DIMENSIONS in millimeters TYPE L D d (1) x B MASS PER UNIT (g) max. max. max. AC01, AC01-AT 11.0 4.3 2 63 ± 1 0.52 AC03, AC03-AT 13.0 4.8 2 63 ± 1 0.75 AC04, AC04-AT 16.5 5.5 3 63 ± 1 1.10 0.8 ± 0.03 AC05, AC05-AT 18.0 7.5 3 63 ± 1 1.90 AC07, AC07-AT 26.0 7.5 3 73 ± 1 2.60 AC10, AC10-AT 44.0 8.0 3 88 ± 1 4.50 LEAD TERMINATION BENDING FORMS P P 1 1 L L L Ø D Ø d Ø d Ø d h h h P P2 P2 Ø B Ø B Ø B S MAX. LEAD BENDING STYLE LEAD BENDING STYLE = DK SP LEAD BENDING STYLE = DK LP = EK (Single Kink) (Double Kink Small Pitch) (Double Kink Large Pitch) DIMENSIONS - Single and double kink lead type outline TERMINATION PART Ø D L KINK h ± 1 P ± 0.5 P ± 0.5 P ± 3 S Ø B ± 0.1 MASS TYPE max. max. WIRE DIAMETER (1) 1 2 max. NUMBER (mm) (mm) TYPE (mm) (mm) (mm) (mm) (mm) (mm) (g) Ø d (mm) VARIANT EK 0.8 ± 0.03 8.0 17.8 - - 2 1.0 0.52 B AC01 4.3 11.0 DK SP 0.8 ± 0.03 8.0 - 19.8 17.8 2 1.0 0.52 I DK LP 0.8 ± 0.03 8.0 - 17.8 17.8 2 1.0 0.52 5 EK 0.8 ± 0.03 8.0 20.0 - - 2 1.0 0.75 H EK 0.8 ± 0.03 8.0 25.4 - - 2 1.0 0.75 C DK SP 0.8 ± 0.03 8.0 - 22.0 20.0 2 1.0 0.75 3 AC03 4.8 13.0 DK SP 0.8 ± 0.03 8.0 - 27.4 25.4 2 1.0 0.75 8 DK LP 0.8 ± 0.03 8.0 - 17.8 17.8 2 1.0 0.75 5 DK LP 0.8 ± 0.03 8.0 - 25.4 25.4 2 1.0 0.75 7 EK 0.8 ± 0.03 8.0 25.4 - - 2 1.0 1.10 C DK SP 0.8 ± 0.03 8.0 - 22.0 20.0 2 1.0 1.10 3 AC04 5.5 16.5 DK SP 0.8 ± 0.03 8.0 - 27.4 25.4 2 1.0 1.10 8 DK LP 0.8 ± 0.03 8.0 25.4 25.4 2 1.0 1.10 7 EK 0.8 ± 0.03 8.0 22.5 - - 2 1.0 1.90 A AC05 7.5 18.0 EK 0.8 ± 0.03 8.0 25.4 - - 2 1.0 1.90 C DK SP 0.8 ± 0.03 8.0 - 22.0 20.0 2 1.0 1.90 3 EK 0.8 ± 0.03 8.0 33.0 - - 2 1.0 2.60 E AC07 7.5 26.0 DK SP 0.8 ± 0.03 8.0 - 35.0 33.0 2 1.0 2.60 G DK LP 0.8 ± 0.03 8.0 - 33.0 33.0 2 1.0 2.60 4 Note (1) Terminal wire material is FeCu with Sn coating Revision: 07-Dec-2020 10 Document Number: 28730 For technical questions, contact: ww1resistors@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

AC, AC-AT www.vishay.com Vishay Draloric Z-FORM LEADS FOR SMD MOUNTING in millimeters A B Recommended solder pad dimensions Ø D l a LEAD BENDING STYLE = WSZ n b (Z-form) H m L F Ø d TYPE WSZ Ø d (1) Ø D A B F H L a b l m n max. AC03, AC03-AT 0.8 ± 0.03 4.8 17 ± 0.3 11 - 12 4.8 ± 0.3 3.6 ± 0.2 5.0 ± 0.5 4 8 12.2 25 2 AC05, AC05-AT 0.8 ± 0.03 7.5 23.5 ± 0.5 18 max. 7.7 ± 0.5 5.73 ± 0.5 7.9 ± 0.7 4 10 18.7 25 2 Notes (1) Terminal wire material is FeCu with Sn coating • Given solder pad dimension is a suggestion only, used for testing purposes at practicable conditions. Customer has to reconsider temperature restrictions due to solder type, PCB-material, etc. according to individual application AC01 WITH RADIAL TAPING LEAD BENDING STYLE = RT (Radial Taped) DIMENSIONS in millimeters P Pitch of components P 12.7 ± 1.0 Lead spacing F 5.0 + 0.6, - 0.1 Width of carrier tape W 18.0 ± 0.5 Height for cutting (max.) L 11 1 H1 Height for insertion (max.) H 32 1 L1 F W AC03 WITH RADIAL TAPING LEAD BENDING STYLE = RT (Radial Taped) DIMENSIONS in millimeters P Pitch of components P 12.7 ± 1.0 Lead spacing F 5.0 + 0.4, - 0.2 Width of carrier tape W 18.0 ± 0.5 Height for cutting (max.) L 11 1 H1 Height for insertion (max.) H 32 1 L1 F W Revision: 07-Dec-2020 11 Document Number: 28730 For technical questions, contact: ww1resistors@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice www.vishay.com Vishay Disclaimer ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROV E RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE. Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively, “Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other disclosure relating to any product. Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose o r the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special, consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular purpose, non-infringement and merchantability. Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of typical requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements about the suitability of products for a particular application. It is the customer’s responsibility to validate that a particular product with the properties described in the product specification is suitable for use in a particular application. Parameters provided in datasheets and / or specifications may vary in different applications and performance may vary over time. All operating parameters, including typical parameters, must be validated for each customer application by the customer’s technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase, including but not limited to the warranty expressed therein. Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustainin g applications or for any other application in which the failure of the Vishay product could result in personal injury or death. Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk . Please contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this documen t or by any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners. © 2019 VISHAY INTERTECHNOLOGY, INC. ALL RIGHTS RESERVED Revision: 01-Jan-2019 1 Document Number: 91000

Datasheet下载

Datasheet下载