ICGOO在线商城 > 929941-1

- 型号: 929941-1

- 制造商: CORCOM/TYCO ELECTRONICS

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

929941-1产品简介:

ICGOO电子元器件商城为您提供929941-1由CORCOM/TYCO ELECTRONICS设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 提供929941-1价格参考以及CORCOM/TYCO ELECTRONICS929941-1封装/规格参数等产品信息。 你可以下载929941-1参考资料、Datasheet数据手册功能说明书, 资料中有929941-1详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 3D型号 | http://www.te.com/commerce/DocumentDelivery/DDEController?Action=srchrtrv&DocNm=929941-1&DocType=Customer+View+Model&DocLang=English |

| 产品目录 | |

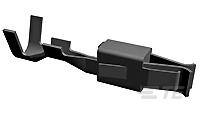

| 描述 | CONN CONTACT TIMER 24-20AWG汽车连接器 JUN POW-TIM REC CONT Reel of 3750 |

| 产品分类 | |

| 品牌 | TE Connectivity / AMP |

| 产品手册 | http://www.te.com/catalog/pn/en/929941-1?RQPN=929941-1 |

| 产品图片 | |

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | TE Connectivity / AMP 929941-1Junior Power Timer,AMP |

| 数据手册 | http://www.te.com/commerce/DocumentDelivery/DDEController?Action=srchrtrv&DocNm=1355046&DocType=Customer+Drawing&DocLang=English |

| 产品型号 | 929941-1 |

| RoHS指令信息 | http://www.te.com/commerce/alt/SinglePartSearch.do?PN=929941-1&dest=stmt点击此处下载产品Datasheet |

| 产品 | Terminals |

| 产品种类 | 汽车连接器 |

| 包装 | 带卷 (TR) |

| 商标 | TE Connectivity / AMP |

| 型式 | Female |

| 封装 | Reel |

| 工作温度范围 | - 40 C to + 130 C |

| 工厂包装数量 | 3750 |

| 引脚或插座 | 插口 |

| 标准包装 | 3,750 |

| 相关产品 | /product-detail/zh/539737-2/539737-2-ND/2040931 |

| 端接类型 | Crimp |

| 类型 | 功率 |

| 系列 | Junior Power Timer |

| 线规 | 20-24 AWG |

| 线规量程 | 28-20, 24-20 |

| 触头端接 | 压接 |

| 触头镀层 | 金 |

| 触头镀层厚度 | 31.5µin (0.80µm) |

| 触点材料 | Copper |

| 触点电镀 | Tin |

| 配用 | /product-detail/zh/1-967239-1/1-967239-1-ND/2187878 |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

8 7 6 5 4 3 2 1 THIS DRAWING IS UNPUBLISHED. RELEASED FOR PUBLICATION 2014 REVISIONS C COPYRIGHT2014 Tyco Electronics AMP GmbH ALL RIGHTS RESERVED. P LTR DESCRIPTION DATE DWN APVD DESIGN 1 Ausfuehrung 1 A13 Part status changed 13NOV13 Ho. Eder D(cid:1)#(cid:2)0.5 DESIGN 5 A14 New Creo drawing created 25APR2014 Ho. Eder SECTION C-C SECTION D-D C Ausfuehrung 5 X10CrNi18-8 A15 Material of PN 928810-1 corrected 26MAY2014 GilchEder Schnitt Schnitt 7 B A16 Add PN´s in the Table 25NOV2014 Ho. Eder H(cid:1)#(cid:2)0.3 5 E(cid:1)#(cid:2)0.3 A 3 3 . . 0 05 0 (cid:2) . (cid:2) # .2 .3 0 # (cid:1) 0 0 2 (cid:1) K 5- 8- 3 1 G . . . 2 0 4 D D(cid:1)#(cid:2)0.2 Dr E E = 2.6 965901-1 PRETINNED H = 3.6 D 0.5-1.0 G = 2.8 0.5 max. D A 1 CuSn4 vorverzinnt 1.4-2.3 K = 3.9 3 4 5.5 18.8 0.4 FLR 12 min.0.8µm D = 1.1 D = 1.8 Dr 0 E = 3.6 . 965899-1 PRETINNED H = 4.7 2 >1.0-2.5 A 1 CuSn4 vorverzinnt 2.1-3.1 G = 3.8 K = 4.9 3.3 4.3 5.8 18.8 0.4 0. FLR 0 12 min.0.8µm D = 1.8 D = 2.6 3 Dr 8 7 E = 2.6 H = 3.9 3.6 PLAIN 0.5-1.0 G = 2.8 928876-1 A 1 CuSn4 2.0-2.7 K = 4.1 3 4 5.5 18.8 0.4 BLANK FLK D = 1.1 D = 2.4 Dr PRETINNED 0520 .3 .. 0 927775-7 M CuNi12ZN24 vorverzinnt 00 - +1- 2 . . min.0.8µm 3 2 927775-6 M CuSn4 1 E = 2.6 H = 3.9 0.5-1.0 G = 2.8 1 PRETINNED 2.0-2.7 K = 4.1 3 4 5.5 18.8 0.4 FLK D = 1.1 927775-3 M CuSn4 vorverzinnt D = 2.4 Dr min. 0.8µm 4.9 4.5 0.2 2 . 0 PRETINNED + 6 927775-1 M CuFe2 vorverzinnt . 0 min. 0.8µm 928810-1 PRETINNED E = 2.6 H = 3.6 DESIGN 6 0.5-1.0 A15 A 1 CuFe2 vorverzinnt 1.4-2.3 G = 2.8 K = 3.9 3.0 4.0 5.5 18.8 0.4 Ausfuehrung 6 FLR 9 min. 1µm D = 1.1 D = 1.8 Dr E = 3.6 963884-1 PRETINNED H = 4.7 >1.0-2.5 DESIGN 2 G = 3.8 A 1 CuSn4 vorverzinnt 2.1-3.1 K = 4.9 3.3 4.3 5.8 18.8 0.4 FLR Ausfuehrung 2 9 min. 1µm D = 1.8 D = 2.6 Dr E = 3.6 927773-3 N CuSn4 PRETINNED H = 5.5 >1.0-2.5 G = 3.8 1 vorverzinnt 2.7-4.1 K = 5.8 3.3 4.3 5.8 18.8 0.4 FLK 927773-1 N CuFe2 min. 1µm D = 1.8 D = 3.6 Dr 2-927768-1 R CuSn4 2 1-927768-1 R CuFe2 t e 927768-9 P t 3 4 E = 3.6 h 1 >1.0-2.5 H = 4.7 c 927768-6 P CuSn4 2.1-3.1 G = 3.8 K = 4.9 3.3 4.3 5.8 18.8 0.4 i 1 FLR d D = 1.8 D = 2.6 C e Dr C g 927768-3 P n PRETINNED u 927768-1 P vorverzinnt / D CuFe2 min. 1µm E A 1 L 1719810-110 A E 2-927771-2 N S 3 6 N CuSn4 DESIGN 3 U 2-927771-1 N Ausfuehrung 3 2 1-927771-1 N CuFe2 E = 2.6 927771-9 M H = 3.6 3 4 0.5-1.0 G = 2.8 1 1.4-2.3 K = 3.9 3 4 5.5 18.8 0.4 FLR 927771-8 N 3 5 DDr = 1.1 D = 1.8 CuSn4 NOTES 927771-6 M 1 Bemerkungen 927771-3 M PRETINNED vorverzinnt n 927771-1 M CuFe2 min. 1µm ONo 1 CONTACT BODY PRE-SILVER PLATED MIN. 0.8µm i I t Kontaktkoerper vorversilbert min. 0,8µm T 2-927774-1 C CuSn4 Aa k CONTACT ZONE SELECTIVE PRE-SILVER PLATED MIN. 3µm C i 2 If Kontaktzone selektiv vorversilbert min. 3µm 1-927774-1 C CuFe2 Fi E = 2.1 I H = 2.7 z C 0.2-0.5 e G = 2.1 E 927774-6 B 2 1.0-1.6 K = 2.8 2.5 3.5 5.6 18.8 0.4 p CuSn4 1 FLR DDr = 0.8 D = 1.4 SPss50 2 CONTACT ZONE GOLD PLATED MIN. 0.8µm OVER MIN. 1.3µm NICKEL-LAYER 927774-3 B PRETINNED -g0 Kontaktzone vergoldet min. 0,8µm ueber min. 1,3µm Nickel-Zwischenschicht n8 vorverzinnt u1 N CRIMP AREA MIN.1µm TIN PLATED OVER NICKEL-LAYER t- 927774-1 B CuFe2 min. 1µm Oi4 I Crimpbereich min. 1µm verzinnt ueber Nickel-Zwischenschicht e1 T PRETINNED E = 1.7 H = 3.1 Arb1 DESIGN 4 0.08-0.2 C G = 1.7 a 963708-1 B 2 CuFe2 vorverzinnt 1.5-1.8 K = 3.2 2.5 3.7 5.9 18.8 0.4 Ir Ausfuehrung 4 min. 1µm Sonderleitung D = 0.6 D = 1.6 PLe 3 CANTILEVER SPRING INSIDE AND OUTSIDE 0.4-1.2µm GOLD PLATED Dr V P Ueberfeder innen und aussen 0,4-1,2µm vergoldet 969137-1 PRETINNED E = 2.1 H = 3.5 Ae A 3 CuSn4 vorverzinnt 0.2-0.5 1.2-2.3 G = 2.1 K = 3.6 2.5 3.5 5 18.8 0.4 Eeh E FLR i 12 min.0.8µm DDr = 0.8 D = 2 Ss 4 CONTACT BODY, CONTACT SPRING INSIDE AND CRIMP AREA MIN. 1µm TIN PLATED OVER NICKEL-LAYER, TOUCHING AREA TO CANTILEVER SPRING AND CONTACT SPRING OUTSIDE 1-927778-1 D CuFe2 SELECTIVE 0.8µm GOLD OVER MIN. 1.3µm NICKEL-LAYER 2 E = 2.1 H = 3.5 Kontaktkoerper, Kontaktfeder innen und Crimpbereich min. 1.3µm verzinnt 0.2-0.5 G = 2.1 3 1.2-2.3 K = 3.6 2.5 3.5 5 18.8 0.4 ueber Nickel-Zwischenschicht, Anlageflaeche zur UeberfedeKro nutnadk tfeder aussen FLK 927778-3 C CuSn4 PRETINNED D = 0.8 D = 2.0 selektiv 0,8µm vergoldet ueber min. 1µm Nickel-Zwischenschicht B Dr B vorverzinnt 927778-1 C CuFe2 min.0.8µm E = 2.4 5 CONTACT ZONE AND TOUCHING AREA TO CANTILEVER SPRING MIN. 0.8µm 2112132-1 H = 2.9 PLAIN 0.2-0.5 G = 2.3 SELECTIVE GOLD PLATED OVER A 4 CuSn4 1.15-1.6 K = 2.9 2.5 3.5 5.6 18.8 0.2 13 BLANK FLR D = 1 D = 1.4 1.3µm NICKEL PLATED, CRIMP AREA MIN. 1µm TIN PLATED OVER NICKEL-LAYER Dr Kontaktzone und Anlageflaeche zur Ueberfeder min. 0,8µm vergoldet ueber 2-927766-1 E CuSn4 min. 1,3µm Nickel-Zwischenschicht Crimpbereich min. 1µm verzinntN iucekbeelr- Zwischenschicht 2 E = 3.6 1-927766-1 E CuFe2 H = 5.4 >1.0-2.5 G = 3.8 5 2.7-3.0 K = 4.6 3.5 5.9 7.5 18.8 0.4 FLK 6 CONTACT BODY AND CRIMP AREA MIN. 1µm TIN PLATED OVER NICKEL-LAYER, 927766-3 D CuSn4 PRETINNED D = 1.8 D = 3.2 Dr TOUCHING AREA TO CANTILEVER SPRING SELECTIVE 0.8µm GOLD OVER MIN. 1.3µmN ICKEL-LAYER vorverzinnt 927766-1 D CuFe2 min. 1µm Kontaktkoerper und Crimpbereich min. 1µm verzinnt uNeibcekre l-Zwischenschicht Anlageflaeche zur Ueberfeder selektiv 0,8µm vergoldet ueber min.N i1c,k3eµlm- Zwischenschicht 2-929937-1 E CuSn4 2 7 CONTACT OFF OPTIONAL 1-929937-1 E CuFe2 E = 3.6 Abschnitt\Freischnitt optional H = 5.4 >1.0-2.5 G = 3.8 929937-6 E 5 2.7-3.0 K = 4.6 3.5 5.9 7.5 21 0.4 1 FLR CuSn4 D = 1.8 D = 3.2 Dr 929937-3 E PRETINNED 8 SAWAG ONLY FOR PN 929937,929939, 929941 1 1 vorverzinnt Swage nur fuer PN 929937, 929939, 929941 929937-1 E CuFe2 min. 1µm 2-929939-1 E CuSn4 em 1-929939-1 E CuFe2 2 9 VARIANTS WITH GAP-SIZE 0.3mm (±0.1) E = 2.6 /t H = 5.4 Varianten mit Gap-Size 0.3mm (±0.1)1 Ls 0.5-1.0 G = 2.8 . Ay 929939-6 E 5 1.4-2.1 K = 4.6 3 5.4 7 21 0.6 0 SEss CuSn4 1 FLR DDr = 1.1 D = 3.2 .3 g 929939-3 E PRETINNED 0 En Ru vorverzinnt It 10 CONTACTS DIPPED IN OR SPRAYED WITH LUBRICANT BARRIERTA Wh 929939-1 E CuFe2 min. 1µm c Kontakte getaucht oder besprueht mit Lubricant Barrierta Ei Ld 2-927770-1 G CuSn4 Gl Ne 2 Iz 1-927770-1 G CuFe2 11 ACCORDING INSULATION DIA IS TO CHOOSE THE SINGLE WIRE SEAL Sn E = 2.6 H = 5.4 i E 0.5-1.0 G = 2.8 3 Entsprechend dem Isolationsdurchmesser ist die 927770-6 F 5 CuSn4 1 FLR 1.4-2.1 DDr = 1.1 KD == 43..62 3 5.4 7 18.8 0.6 0.3 0.4 828904 5:1 Einzel-Dichtung auszuwaehlen 0.1 927770-3 F PRETINNED 4 828905 . 5- . 3 6 vorverzinnt 3 . 927770-1 F CuFe2 min. 1µm SINGLE WIRE SEAL 11 0 Einzel-Dichtung 3 12 VARIANTS WITH GAP-SIZE 0.65mm (-0.1) A 2-929941-1 E CuSn4 blue .3 0. A 828904-1 1.2-2.1 0 6 Varianten mit Gap-Size 0.65mm (-0.1) blau 2 6 . 1-929941-1 E CuFe2 . 5 white E = 2.1 H = 5.4 828905-1 2.2-3.0 5 0.2-0.5 weiss G = 2.1 929941-6 D 6 1.15-1.6 K = 4.6 2.5 4.9 6.5 21 0.9 CuSn4 1 FLR D = 0.8 D = 3.2 ORDER No. INSULATION (cid:1)n(cid:2) COLOUR 13 VARIANTS WITH GAP-SIZE 0.15mm (-0.05) Dr Bestell-Nr. Isolations (cid:1)n(cid:2) Farbe 929941-3 D PRETINNED 0.8 0.3 4.3 0.3 Varianten mit Gap-Size 0.15mm (-0.05)05 vorverzinnt 0.8 0.3 4.3 0.3 . 0 929941-1 D CuFe2 min. 1µm 15- 7.8 0.3 . 7.8 0.3 0 1-927772-1 D CuFe2 2 E = 2.1 H = 5.4 0.2-0.5 DWN 09JUN99 927772-3 C 6 CuSn4 PRETINNED 1.15-1.6 G = 2.1 K = 4.6 2.5 4.9 6.5 18.8 0.9 THIS DRAWING IS A CONTROLLED DOCUMENT. K. Gerlach FLR TE Connectivity vorverzinnt D = 0.8 D = 3.2 CHK 09JUN99 Dr J. Has 927772-1 C CuFe2 min. 1µm DIMENSIONS: OTTHOELREWRIASNEC ESSP EUCNILFEISESD: APVD - NAME mm - PRODUCT GROUP DRAWING FOR TE STRIP FORM CRIMP DATA 0 PLC - PRODUCT SPEC JUNIOR POWER TIMER CONTACT 1 PLC - WIRE RANGE INSULATION WIRE CRIMP INSUL.-CRIMP 108-18013 ORDER NO. DESIGN MATERIAL SURFACE Drahtgroessen Isolations Drahtcrimp Iso.-Crimp AND 23 PPLLCC -- APPLICATION SPEC Produkt-Gruppen-Zeichnung fuer JPT REV. Bandware A B C D E CRIMP TOOL 4 PLC - SIZE CAGE CODE DRAWING NO RESTRICTED TO Ausfuehrung Werkstoff Oberflaeche Bereich ANGLES 1(cid:1)$(cid:2) 114-18050 STRIP FORM [mm²] [mm] CRIMP DIMENSION (mm) Crimpdaten u. MATERIAL FINISH WEIGHT - A0 00779 1355046 - SEE TABLE SEE TABLE Bandware Crimpwerkzeuge Crimpabmessungen (mm) SCALE SHEET OF REV - - Customer Drawing 5:1 1 1 A16 4806 (3/13)

Datasheet下载

Datasheet下载