ICGOO在线商城 > 电感器,线圈,扼流圈 > 固定值电感器 > 744314850

- 型号: 744314850

- 制造商: Würth Electronics, Inc.

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

744314850产品简介:

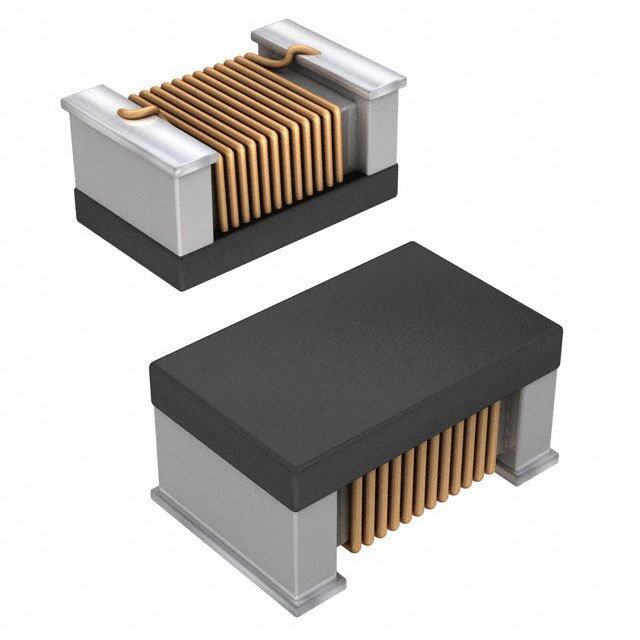

ICGOO电子元器件商城为您提供744314850由Würth Electronics, Inc.设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 744314850价格参考¥19.43-¥27.16。Würth Electronics, Inc.744314850封装/规格:固定值电感器, 8.5µH 屏蔽 绕线 电感器 4A 32.5 毫欧 非标准 。您可以下载744314850参考资料、Datasheet数据手册功能说明书,资料中有744314850 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 3D型号 | http://katalog.we-online.de/pbs/download/WE-HCI_7050_744314.igshttp://katalog.we-online.de/pbs/download/WE-HCI_7050_744314.stphttp://katalog.we-online.de/pbs/download/WE-HCI_7050_744314.wrl |

| 产品目录 | |

| DC电阻(DCR) | 32.5 毫欧 |

| 描述 | INDUCTOR POWER 8.5UH 4.0A SMD固定电感器 WE-HCI Flat 7050 8.5uH 4A 30.5mOhm |

| 产品分类 | |

| 品牌 | Wurth Electronics Inc |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 固定电感器,Wurth Electronics 744314850WE-HCI |

| 数据手册 | |

| 产品型号 | 744314850 |

| 不同频率时的Q值 | - |

| 产品 | High Current Inductors |

| 产品目录绘图 |

|

| 产品目录页面 | |

| 产品种类 | 固定电感器 |

| 供应商器件封装 | - |

| 其它名称 | 732-2182-6 |

| 包装 | Digi-Reel® |

| 商标 | Wurth Electronics |

| 外壳宽度 | 6.9 mm |

| 外壳长度 | 7 mm |

| 外壳高度 | 4.8 mm |

| 大小/尺寸 | 0.272" 长 x 0.272" 宽 (6.90mm x 6.90mm) |

| 安装类型 | 表面贴装 |

| 容差 | ±20% |

| 封装 | Reel |

| 封装/外壳 | 非标准 |

| 屏蔽 | 屏蔽 |

| 工作温度 | -40°C ~ 150°C |

| 工作温度范围 | - 40 C to + 150 C |

| 工厂包装数量 | 1000 |

| 最大直流电流 | 4 A |

| 最大直流电阻 | 32.5 mOhms |

| 材料-磁芯 | - |

| 标准包装 | 1 |

| 测试频率 | 100 kHz |

| 电感 | 8.5µH |

| 电流-饱和值 | 4.5A |

| 端接类型 | SMD/SMT |

| 类型 | 绕线 |

| 系列 | WE-HCI |

| 自谐振频率 | 44 MHz |

| 芯体材料 | Superflux |

| 频率-测试 | 100kHz |

| 频率-自谐振 | 44MHz |

| 额定电流 | 4A |

| 高度-安装(最大值) | 0.197"(5.00mm) |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

Dimensions: [mm] Recommended Land Pattern: [mm] Electrical Properties: Properties Test conditions Value Unit Tol. Inductance L 100 kHz/ 100 mV 8.5 µH ±20% Rated Inductance L 100 kHz/ 100 mV/ 4.0 A 6.8 µH typ. 3 2,2 R ±0, 0,3 Rated Current IR ΔT = 50 K 4 A max. ± 1,8 7,0 2,7 SDaCt uRreastiisotna nCcuerrent RISAT |@ΔL 2/L0| °<C 30 % 340.5.5 mAΩ ±t1y0p.% DC 4 Self Resonant Frequency f 44 MHz typ. 3,45±0,3 2, res Certification: RoHS Approval Compliant [ 2011/65/EU&2015/863 ] REACh Approval Conform or declared [ (EC)1907/2006 ] 6,9±0,3 Halogen Free Conform [ JEDEC JS709B ] Scale - 3:1 Halogen Free Conform [ IEC 61249-2-21 ] +0,2-0,3 8 Schematic: 4, 1,2±0,3 General Information: It is recommended that the temperature of the component does not exceed +150°C under worst case conditions Ambient Temperature (referring 0,3 to IR) -40 up to +100 °C ± 9 Operating Temperature -40 up to +150 °C 6, Storage Conditions (in original < 40 °C ; < 75 % RH packaging) Moisture Sensitivity Level (MSL) 1 Scale - 3:1 Test conditions of Electrical Properties: +20 °C, 33 % RH if not specified differently Product Marking: Marking X YMDD X CHECKED REVISION DATE (YYYY-MM-DD) GENERAL TOLERANCE PROJECTION Marking X (may be changed) METHOD BD 002.006 2019-04-03 DIN ISO 2768-1m Marking - Date Code YMDD DESCRIPTION WE-HCI SMT High Current WEMüCrt h& E Ilnedkutrcotnivike eSioSlousti oGnmsbH & Co. KG Inductor ORDER CODE Max-Eyth-Str. 1 744314850 74638 Waldenburg Germany Tel. +49 (0) 79 42 945 - 0 SIZE/TYPE BUSINESS UNIT STATUS PAGE www.we-online.com eiSos@we-online.com 7050 eiSos Valid 1/6 This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH & Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

Typical Inductance vs. Current Characteristics: Typical Temperature Rise vs. Current Characteristics: 9.0 100.0 90.0 8.0 80.0 7.0 70.0 6.0 60.0 ] ] H K µ 5.0 [ [ e e s c Ri 50.0 n a e ct 4.0 ur u t d a n er 40.0 I p m 3.0 e T 30.0 2.0 20.0 1.0 10.0 0.0 0.0 0.0 2.0 4.0 6.0 8.0 10.0 12.0 0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 Current [A] Current [A] CHECKED REVISION DATE (YYYY-MM-DD) GENERAL TOLERANCE PROJECTION METHOD BD 002.006 2019-04-03 DIN ISO 2768-1m DESCRIPTION WE-HCI SMT High Current WEMüCrt h& E Ilnedkutrcotnivike eSioSlousti oGnmsbH & Co. KG Inductor ORDER CODE Max-Eyth-Str. 1 744314850 74638 Waldenburg Germany Tel. +49 (0) 79 42 945 - 0 SIZE/TYPE BUSINESS UNIT STATUS PAGE www.we-online.com eiSos@we-online.com 7050 eiSos Valid 2/6 This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH & Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

Packaging Specification - Tape and Reel: [mm] P0 K0 W3 D0 P2 T A W1 1 close to center E B D F A N C W B0 E2 Top Cover Tape W2 A D1 P1 T1 A0 T2 detail B End Feeding direction Start Carrier Tape B Cover Tape Cover Tape Chip Cavity Sprocket Hole No Component Components No Component min. 160mm min. 100mm Embossment Cover Tape min. 400mm Packaging is refered to the international standard IEC 60286-3:2013 A (mm) B (mm) C (mm) D (mm) N (mm) W (m1m) W (m2m) W (m3m) W (m3m) Material ± 2,0 min. min. min. min. + 2,0 max. min. max. Tape Type A (m0m) B (m0m) W (mm) T (mm) T (1mm) T (2mm) K (m0m) P (0mm) P (1mm) P (2mm) D (m0m) D (m1m) E (1mm) E (2mm) F (mm) Material Q (ptyc.s.) 330,00 1,50 12,80 20,20 60,00 16,40 22,40 15,90 19,40 Polystyrene/ Polyurethane typ. typ. +0,3/ -0,1 ref. ref. typ. typ. ±0,1 ±0,1 ±0,1 +0,1/ -0,0 min. ±0,1 min. ±0,1 2a 7,30 7,55 16,00 0,35 0,10 5,80 5,55 4,00 12,00 2,00 1,50 1,50 1,75 14,25 7,50 Polystyrene 1000 CHECKED REVISION DATE (YYYY-MM-DD) GENERAL TOLERANCE PROJECTION METHOD BD 002.006 2019-04-03 DIN ISO 2768-1m 165° - 180° DESCRIPTION WE-HCI SMT High Current WEMüCrt h& E Ilnedkutrcotnivike eSioSlousti oGnmsbH & Co. KG Inductor ORDER CODE Max-Eyth-Str. 1 744314850 74638 Waldenburg Germany Pull-of force Tel. +49 (0) 79 42 945 - 0 SIZE/TYPE BUSINESS UNIT STATUS PAGE www.we-online.com Tape width 16 mm 0,1 N - 1,3 N eiSos@we-online.com 7050 eiSos Valid 3/6 This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH & Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

Classification Reflow Profile for SMT components: Classification Reflow Soldering Profile: Profile Feature Value Preheat Temperature Min T 150 °C s min Preheat Temperature Max T 200 °C s max T p t TC –5°C Preheat Time ts from Ts min to Ts max ts 60 - 120 seconds Max. Ramp Up Rate p Ramp-up Rate (T to T ) 3 °C/ second max. L P Max. Ramp Down Rate Liquidous Temperature T 217 °C L TL Time tL maintained above TL tL 60 - 150 seconds t Ts max Preheat Area L Peak package body temperature Tp see table below e Time within 5°C of actual peak temperaure t 20 - 30 seconds r p u at Ramp-down Rate (TL to TP) 6 °C/ second max. er T Time 25°C to peak temperature 8 minutes max. p s min m refer to IPC/ JEDEC J-STD-020E e T tS Package Classification Reflow Temperature: Volume mm³ Volume mm³ Volume mm³ Properties <350 350-2000 >2000 PB-Free Assembly | Package Thickness < 1.6 mm 260 °C 260 °C 260 °C 25 Time 25°C to Peak PB-Free Assembly | Package Thickness 1.6 mm - 2.5 mm 260 °C 250 °C 245 °C PB-Free Assembly | Package Thickness ≥ 2.5 mm 250 °C 245 °C 245 °C Time refer to IPC/ JEDEC J-STD-020E CHECKED REVISION DATE (YYYY-MM-DD) GENERAL TOLERANCE PROJECTION METHOD BD 002.006 2019-04-03 DIN ISO 2768-1m DESCRIPTION WE-HCI SMT High Current WEMüCrt h& E Ilnedkutrcotnivike eSioSlousti oGnmsbH & Co. KG Inductor ORDER CODE Max-Eyth-Str. 1 744314850 74638 Waldenburg Germany Tel. +49 (0) 79 42 945 - 0 SIZE/TYPE BUSINESS UNIT STATUS PAGE www.we-online.com eiSos@we-online.com 7050 eiSos Valid 4/6 This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH & Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

Cautions and Warnings: Potting: • If the product is potted in the customer application, the potting material might shrink or expand during and after hardening. Shrinking The following conditions apply to all goods within the product series of WE-HCI of Würth could lead to an incomplete seal, allowing contaminants into the core. Expansion could damage the core or wire contacts. We Elektronik eiSos GmbH & Co. KG: recommend a manual inspection after potting to avoid these effects. General: Storage Conditions: • This electronic component is designed and manufactured for use in general electronic equipment. • A storage of Würth Elektronik products for longer than 12 months is not recommended. Within other effects, the terminals may suffer • Würth Elektronik must be asked for written approval (following the PPAP procedure) before incorporating the components into any degradation, resulting in bad solderability. Therefore, all products shall be used within the period of 12 months based on the day of equipment in fields such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, shipment. ship control), transportation signal, disaster prevention, medical, public information network etc. where higher safety and reliability are • Do not expose the components to direct sunlight. especially required and/or if there is the possibility of direct damage or human injury. • The storage conditions in the original packaging are defined according to DIN EN 61760-2. • Electronic components that will be used in safety-critical or high-reliability applications, should be pre-evaluated by the customer. • The component is designed and manufactured to be were used within the datasheet specified values. If the usage and operation Handling: conditions specified in the datasheet are not met, the wire insulation may be damaged or dissolved. • Do not drop or impact the components, as the core may flake apart. • Violation of the technical product specifications such as exceeding the nominal rated current will void the warranty. • Würth Elektronik products are qualified according to international standards, which are listed in each product reliability report. Würth • Applying currents with audio-frequency signals may result in audible noise due to the magnetostrictive material properties. Elektronik does not warrant any customer qualified product characteristics beyond Würth Elektroniks’ specifications, for its validity and sustainability over time. These cautions and warnings comply with the state of the scientific and technical knowledge and are believed to be accurate and reliable. • The responsibility for the applicability of the customer specific products and use in a particular customer design is always within the However, no responsibility is assumed for inaccuracies or incompleteness. authority of the customer. All technical specifications for standard products also apply to customer specific products. Product specific: Soldering: • The solder profile must comply with the Würth Elektronik technical soldering specification. All other profiles will void the warranty • All other soldering methods are at the customers’ own risk. • Strong forces which may affect the coplanarity of the components’ electrical connection with the PCB (i.e. pins), can damage the part, resulting in avoid of the warranty. Cleaning and Washing: • Washing agents used during the production to clean the customer application might damage or change the characteristics of the wire insulation, marking or plating. Washing agents may have a negative effect on the long-term functionality of the product. • Using a brush during the cleaning process may break the wire due to its small diameter. Therefore, we do not recommend using a brush during the PCB cleaning process. CHECKED REVISION DATE (YYYY-MM-DD) GENERAL TOLERANCE PROJECTION METHOD BD 002.006 2019-04-03 DIN ISO 2768-1m DESCRIPTION WE-HCI SMT High Current WEMüCrt h& E Ilnedkutrcotnivike eSioSlousti oGnmsbH & Co. KG Inductor ORDER CODE Max-Eyth-Str. 1 744314850 74638 Waldenburg Germany Tel. +49 (0) 79 42 945 - 0 SIZE/TYPE BUSINESS UNIT STATUS PAGE www.we-online.com eiSos@we-online.com 7050 eiSos Valid 5/6 This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH & Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

Important Notes 6. Product Life Cycle Due to technical progress and economical evaluation we also reserve the right to discontinue production and delivery of products. As a The following conditions apply to all goods within the product range of Würth Elektronik standard reporting procedure of the Product Termination Notification (PTN) according to the JEDEC-Standard we will inform at an early stage eiSos GmbH & Co. KG: about inevitable product discontinuance. According to this we cannot guarantee that all products within our product range will always be available. Therefore it needs to be verified with the field sales engineer or the internal sales person in charge about the current product 1. General Customer Responsibility availability expectancy before or when the product for application design-in disposal is considered. The approach named above does not apply in the case of individual agreements deviating from the foregoing for customer-specific products. Some goods within the product range of Würth Elektronik eiSos GmbH & Co. KG contain statements regarding general suitability for certain application areas. These statements about suitability are based on our knowledge and experience of typical requirements concerning the 7. Property Rights areas, serve as general guidance and cannot be estimated as binding statements about the suitability for a customer application. The responsibility for the applicability and use in a particular customer design is always solely within the authority of the customer. Due to this All the rights for contractual products produced by Würth Elektronik eiSos GmbH & Co. KG on the basis of ideas, development contracts as fact it is up to the customer to evaluate, where appropriate to investigate and decide whether the device with the specific product well as models or templates that are subject to copyright, patent or commercial protection supplied to the customer will remain with Würth characteristics described in the product specification is valid and suitable for the respective customer application or not. Elektronik eiSos GmbH & Co. KG. Würth Elektronik eiSos GmbH & Co. KG does not warrant or represent that any license, either expressed or implied, is granted under any patent right, copyright, mask work right, or other intellectual property right relating to any combination, 2. Customer Responsibility related to Specific, in particular Safety-Relevant Applications application, or process in which Würth Elektronik eiSos GmbH & Co. KG components or services are used. It has to be clearly pointed out that the possibility of a malfunction of electronic components or failure before the end of the usual lifetime 8. General Terms and Conditions cannot be completely eliminated in the current state of the art, even if the products are operated within the range of the specifications. In certain customer applications requiring a very high level of safety and especially in customer applications in which the malfunction or Unless otherwise agreed in individual contracts, all orders are subject to the current version of the “General Terms and Conditions of Würth failure of an electronic component could endanger human life or health it must be ensured by most advanced technological aid of suitable Elektronik eiSos Group”, last version available at www.we-online.com. design of the customer application that no injury or damage is caused to third parties in the event of malfunction or failure of an electronic component. Therefore, customer is cautioned to verify that data sheets are current before placing orders. The current data sheets can be downloaded at www.we-online.com. 3. Best Care and Attention Any product-specific notes, cautions and warnings must be strictly observed. Any disregard will result in the loss of warranty. 4. Customer Support for Product Specifications Some products within the product range may contain substances which are subject to restrictions in certain jurisdictions in order to serve specific technical requirements. Necessary information is available on request. In this case the field sales engineer or the internal sales person in charge should be contacted who will be happy to support in this matter. 5. Product R&D Due to constant product improvement product specifications may change from time to time. As a standard reporting procedure of the Product Change Notification (PCN) according to the JEDEC-Standard inform about minor and major changes. In case of further queries regarding the PCN, the field sales engineer or the internal sales person in charge should be contacted. The basic responsibility of the customer as per Section 1 and 2 remains unaffected. CHECKED REVISION DATE (YYYY-MM-DD) GENERAL TOLERANCE PROJECTION METHOD BD 002.006 2019-04-03 DIN ISO 2768-1m DESCRIPTION WE-HCI SMT High Current WEMüCrt h& E Ilnedkutrcotnivike eSioSlousti oGnmsbH & Co. KG Inductor ORDER CODE Max-Eyth-Str. 1 744314850 74638 Waldenburg Germany Tel. +49 (0) 79 42 945 - 0 SIZE/TYPE BUSINESS UNIT STATUS PAGE www.we-online.com eiSos@we-online.com 7050 eiSos Valid 6/6 This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH & Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

Datasheet下载

Datasheet下载