ICGOO在线商城 > 连接器,互连器件 > USB,DVI,HDMI 连接器 > 651305142821

- 型号: 651305142821

- 制造商: Würth Electronics, Inc.

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

651305142821产品简介:

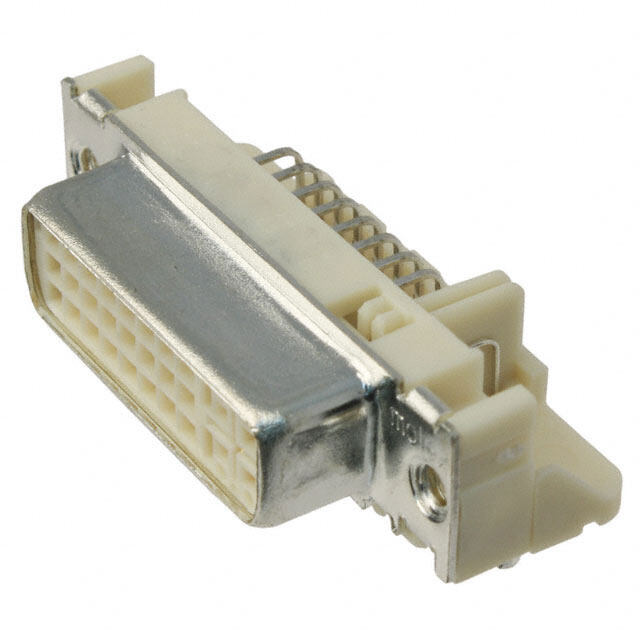

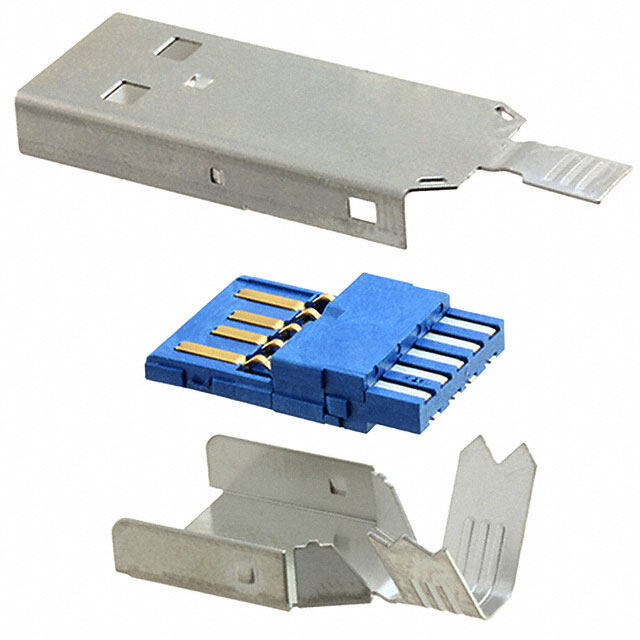

ICGOO电子元器件商城为您提供651305142821由Würth Electronics, Inc.设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 651305142821价格参考。Würth Electronics, Inc.651305142821封装/规格:USB,DVI,HDMI 连接器, USB - mini AB USB 2.0 插座 连接器 5 位 表面贴装,直角。您可以下载651305142821参考资料、Datasheet数据手册功能说明书,资料中有651305142821 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 3D型号 | http://katalog.we-online.de/em/download/651305142821.igshttp://katalog.we-online.de/em/download/651305142821.stphttp://katalog.we-online.de/em/download/651305142821.wrl |

| 产品目录 | |

| 描述 | CONN RCPT USB MINI AB R/A SMT |

| 产品分类 | |

| 品牌 | Wurth Electronics Inc |

| 数据手册 | |

| 产品图片 | |

| 产品型号 | 651305142821 |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | WR-COM |

| 侵入防护 | - |

| 公母 | 插座 |

| 其它名称 | 732-3154-6 |

| 包装 | Digi-Reel® |

| 安装类型 | 表面贴装,直角,水平 |

| 标准包装 | 1 |

| 特性 | 屏蔽式,固定焊尾 |

| 相关产品 | /product-detail/zh/726141005/732-3828-ND/3124569 |

| 规格 | - |

| 触头数 | 5 |

| 连接器类型 | USB - mini AB |

PDF Datasheet 数据手册内容提取

Dimensions: [mm] Recommended Land Pattern: [mm] 8,90±0,15 3,20±0,15 0,80±0,15 0,50±0,15 2,00±0,15 1 5 0,40±0,15 0,80±0,15 1 5 3,20±0,15 1,60±0,15 76,,7900±±00,,1155 4,60±0,15 3,90±0,15 4,00±0,15 2,25±0,15 2,50±0,15 5,50±0,15 5 1 0, ± 1 5 0 0 1, 5,25±0,15 9,90±0,15 Scale - 6:1 5 15 0,1 50±0, 2,95± ±0,15 5, 20 9, Scale - 3:1 Article Properties: CHECKED REVISION DATE (YYYY-MM-DD) GENERAL TOLERANCE PROJECTION METHOD FPe 002.000 2019-08-22 DIN ISO 2768-1m Properties Value Unit PCB Thickness 1) 1.6 mm DESCRIPTION WR-COM Mini USB 2.0 Horizontal Pins 5 1) Note: This PCB thickness is recommended for optimal use. Processing temperature has to be WEMMaüxCrt- hE& yE tIlnhed-kSutrtcor.tn iv1ike eSioSlousti oGnmsbH & Co. KG 5 Contacts SMT O6RD5ER C1OD3E 05142821 adapted to respect JEDEC requirements if using other panel thicknesses. 74638 Waldenburg Germany Tel. +49 (0) 79 42 945 - 0 SIZE/TYPE BUSINESS UNIT STATUS PAGE www.we-online.com eiSos@we-online.com Type AB with Pads eiCan Valid 1/7 This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH & Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

Pin Assignment: Electrical Properties: Pin Number Signal Name Properties Value Unit Tol. 1 VBUS Rated Current I 1 A max. R 2 D- Working Voltage 30 V (AC) 3 D+ Withstanding Voltage 750 V (AC) 4 ID Contact Resistance R 20 mΩ max. 5 GND Insulation Resistance R 1000 MΩ min. ISO Shell Shield Certification: Kind Properties: RoHS Approval Compliant [ 2011/65/EU&2015/863 ] Durability 1 500 Mating cycles REACh Approval Conform or declared [ (EC)1907/2006 ] Connector Type Mini USB Halogen Free Conform [ IEC 61249-2-21 ] Gender Receptacle Halogen Free Conform [ JEDEC JS709B ] Type Horizontal UL Approval E323964 Material Properties: Packaging Properties: Insulator Material LCP Packaging Tape and Reel Insulator Flammability Rating UL94 V-0 Insulator Color Black Contact Material Copper Alloy Contact Plating 1) Selective Gold Shielding Material Brass Shielding Plating Nickel Contact Type Stamped 1) Mating side / Solder side General Information: Operating Temperature -40 up to +105 °C CHECKED REVISION DATE (YYYY-MM-DD) GENERAL TOLERANCE PROJECTION METHOD FPe 002.000 2019-08-22 DIN ISO 2768-1m DESCRIPTION WR-COM Mini USB 2.0 Horizontal WEMüCrt h& E Ilnedkutrcotnivike eSioSlousti oGnmsbH & Co. KG 5 Contacts SMT ORDER CODE Max-Eyth-Str. 1 651305142821 74638 Waldenburg Germany Tel. +49 (0) 79 42 945 - 0 SIZE/TYPE BUSINESS UNIT STATUS PAGE www.we-online.com eiSos@we-online.com Type AB with Pads eiCan Valid 2/7 This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH & Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

Packaging Specification - Tape and Reel: [mm] P0 K0 A D0 P2 1 T W3 E W1 close to center F B D A N B0 E2 W C Top Cover Tape T1 W2 A D1 T2 A0 P1 detail B Carrier Tape End Feeding direction Start B Cover Tape Cover Tape Chip Cavity Sprocket Hole Embossment No Component Components No Component min. 160mm min. 100mm Cover Tape min. 400mm NB: Actual packaging may slightly differ from datasheet Packaging is referred to the international standard IEC 60286-3:2013 A (mm) B (mm) C (mm) D (mm) N (mm) W (m1m) W (m2m) W (m3m) W (m3m) Material ± 2,0 min. min. min. min. + 2,0 max. min. max. A0 B0 W T T1 T2 K0 P0 P1 P2 D0 D1 E1 E2 F Tape Type 2a VPE / packaging unit 330,00 1,50 12,80 20,20 60,00 24,40 30,40 23,90 27,40 Polystyrene typ. typ. +0,3/-0,1 max. max. max. typ. ±0,1 ±0,1 ±0,1 +0,1/ -0,0 min. ±0,1 min. ±0,1 pcs. 11,6 10,32 24,0 0,4 0,1 6,1 5,7 4,0 16,0 2,0 1,5 1,5 1,75 22,25 11,5 Polystyrene 700 CHECKED REVISION DATE (YYYY-MM-DD) GENERAL TOLERANCE PROJECTION METHOD FPe 002.000 2019-08-22 DIN ISO 2768-1m 165° - 180° DESCRIPTION WR-COM Mini USB 2.0 Horizontal WEMüCrt h& E Ilnedkutrcotnivike eSioSlousti oGnmsbH & Co. KG 5 Contacts SMT ORDER CODE Max-Eyth-Str. 1 651305142821 74638 Waldenburg Germany Pull-of force Tel. +49 (0) 79 42 945 - 0 SIZE/TYPE BUSINESS UNIT STATUS PAGE www.we-online.com Tape width 24 mm 0,1 N - 1,3 N eiSos@we-online.com Type AB with Pads eiCan Valid 3/7 This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH & Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

Packaging Specification - Reel in Carton: [mm] C H W L C C NB: Actual packaging may slightly differ from datasheet LC (mm) WC (mm) HC (mm) Nouot.e or fp raeceklaging PUancitkaging Material typ. typ. typ. reel. pcs. 350 350 296 9 6300 Paper CHECKED REVISION DATE (YYYY-MM-DD) GENERAL TOLERANCE PROJECTION METHOD FPe 002.000 2019-08-22 DIN ISO 2768-1m DESCRIPTION WR-COM Mini USB 2.0 Horizontal WEMüCrt h& E Ilnedkutrcotnivike eSioSlousti oGnmsbH & Co. KG 5 Contacts SMT ORDER CODE Max-Eyth-Str. 1 651305142821 74638 Waldenburg Germany Tel. +49 (0) 79 42 945 - 0 SIZE/TYPE BUSINESS UNIT STATUS PAGE www.we-online.com eiSos@we-online.com Type AB with Pads eiCan Valid 4/7 This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH & Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

Classification Reflow Profile for SMT components: Classification Reflow Soldering Profile: Profile Feature Value Preheat Temperature Min 1) T 150 °C s min Preheat Temperature Max T 200 °C s max T p t TC –5°C Preheat Time ts from Ts min to Ts max ts 60 - 120 seconds Max. Ramp Up Rate p Ramp-up Rate (T to T ) 3 °C/ second max. L P Max. Ramp Down Rate Liquidous Temperature T 217 °C L TL Time tL maintained above TL tL 60 - 150 seconds t Ts max Preheat Area L Peak package body temperature Tp see table e Time within 5°C of actual peak temperaure t 20 - 30 seconds r p u at Ramp-down Rate (TL to TP) 6 °C/ second max. er T Time 25°C to peak temperature 8 minutes max. p s min m 1) refer to IPC/JEDEC J-STD-020D e refer to IPC/ JEDEC J-STD-020E T t S Package Classification Reflow Temperature: Volume mm³ Volume mm³ Volume mm³ Properties <350 350-2000 >2000 25 PB-Free Assembly | Package Thickness < 1.6 mm 1) 260 °C 260 °C 260 °C Time 25°C to Peak PB-Free Assembly | Package Thickness 1.6 mm - 2.5 mm 260 °C 250 °C 245 °C Time PB-Free Assembly | Package Thickness ≥ 2.5 mm 250 °C 245 °C 245 °C 1) refer to IPC/JEDEC J-STD-020D refer to IPC/ JEDEC J-STD-020E CHECKED REVISION DATE (YYYY-MM-DD) GENERAL TOLERANCE PROJECTION METHOD FPe 002.000 2019-08-22 DIN ISO 2768-1m DESCRIPTION WR-COM Mini USB 2.0 Horizontal WEMüCrt h& E Ilnedkutrcotnivike eSioSlousti oGnmsbH & Co. KG 5 Contacts SMT ORDER CODE Max-Eyth-Str. 1 651305142821 74638 Waldenburg Germany Tel. +49 (0) 79 42 945 - 0 SIZE/TYPE BUSINESS UNIT STATUS PAGE www.we-online.com eiSos@we-online.com Type AB with Pads eiCan Valid 5/7 This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH & Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

Cautions and Warnings: Potting and Coating: • If the product is potted in the customer application, the potting material might shrink or expand during and after hardening. Shrinking The following conditions apply to all goods within the product series of the Connectors of could lead to an incomplete seal, allowing contaminants into the components. Expansion could damage the components. We Würth Elektronik eiSos GmbH & Co. KG: recommend a manual inspection after potting or coating to avoid these effects. General: Storage Conditions: • This mechanical component is designed and manufactured for use in general electronic equipment. • A storage of Würth Elektronik products for longer than 12 months is not recommended. Within other effects, the terminals may suffer • Würth Elektronik must be asked for written approval (following the PPAP procedure) before incorporating the components into any degradation, resulting in bad solderability. Therefore, all products shall be used within the period of 12 months based on the day of equipment in fields such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, shipment. ship control), transportation signal, disaster prevention, medical, public information network, etc. where higher safety and reliability are • Do not expose the components to direct sunlight. especially required and/or if there is the possibility of direct damage or human injury. • The storage conditions in the original packaging are defined according to DIN EN 61760-2. • Mechanical components that will be used in safety-critical or high-reliability applications, should be pre-evaluated by the customer. • The mechanical component is designed and manufactured to be used within the datasheet specified values. If the usage and operation Handling: conditions specified in the datasheet are not met, the component may be damaged or dissolved. • Do not drop or impact the components, the component may be damaged. • Do not repeatedly operate the component with excessive force. It may damage or deform the component resulting in malfunction. • Prevent any damage or scratches on the component, especially on the actuator. • In the case a product requires particular handling precautions, in addition to the general recommendations mentioned here before, these • Direct mechanical impact to the product shall be prevented (e.g overlapping of the PCB´s). will appear on the product datasheet. • Würth Elektronik products are qualified according to international standards, which are listed in each product reliability report. Würth Elektronik does not warrant any customer qualified product characteristics beyond Würth Elektroniks’ specifications, for its validity and These cautions and warnings comply with the state of the scientific and technical knowledge and are believed to be accurate and reliable. sustainability over time. However, no responsibility is assumed for inaccuracies or incompleteness. • The responsibility for the applicability of the customer specific products and use in a particular customer design is always within the authority of the customer. All technical specifications for standard products do also apply to customer specific products. • The mechanical component is designed to be used along with Würth Elektronik counterparts and tools. Würth Elektronik cannot ensure the reliability of these components while being used with other products. Product Specific: Soldering: • The solder profile must comply with the technical product specifications. All other profiles will void the warranty. • All other soldering methods are at the customers’ own risk. Cleaning and Washing: • Washing agents used during the production to clean the customer application might damage or change the characteristics of the component, body, pins and termination. Washing agents may have a negative effect on the long-term functionality of the product. • Using a brush during the cleaning process may deform function relevant areas. Therefore, we do not recommend using a brush during the PCB cleaning process. CHECKED REVISION DATE (YYYY-MM-DD) GENERAL TOLERANCE PROJECTION METHOD FPe 002.000 2019-08-22 DIN ISO 2768-1m DESCRIPTION WR-COM Mini USB 2.0 Horizontal WEMüCrt h& E Ilnedkutrcotnivike eSioSlousti oGnmsbH & Co. KG 5 Contacts SMT ORDER CODE Max-Eyth-Str. 1 651305142821 74638 Waldenburg Germany Tel. +49 (0) 79 42 945 - 0 SIZE/TYPE BUSINESS UNIT STATUS PAGE www.we-online.com eiSos@we-online.com Type AB with Pads eiCan Valid 6/7 This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH & Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

Important Notes 6. Product Life Cycle Due to technical progress and economical evaluation we also reserve the right to discontinue production and delivery of products. As a The following conditions apply to all goods within the product range of Würth Elektronik standard reporting procedure of the Product Termination Notification (PTN) according to the JEDEC-Standard we will inform at an early stage eiSos GmbH & Co. KG: about inevitable product discontinuance. According to this we cannot guarantee that all products within our product range will always be available. Therefore it needs to be verified with the field sales engineer or the internal sales person in charge about the current product 1. General Customer Responsibility availability expectancy before or when the product for application design-in disposal is considered. The approach named above does not apply in the case of individual agreements deviating from the foregoing for customer-specific products. Some goods within the product range of Würth Elektronik eiSos GmbH & Co. KG contain statements regarding general suitability for certain application areas. These statements about suitability are based on our knowledge and experience of typical requirements concerning the 7. Property Rights areas, serve as general guidance and cannot be estimated as binding statements about the suitability for a customer application. The responsibility for the applicability and use in a particular customer design is always solely within the authority of the customer. Due to this All the rights for contractual products produced by Würth Elektronik eiSos GmbH & Co. KG on the basis of ideas, development contracts as fact it is up to the customer to evaluate, where appropriate to investigate and decide whether the device with the specific product well as models or templates that are subject to copyright, patent or commercial protection supplied to the customer will remain with Würth characteristics described in the product specification is valid and suitable for the respective customer application or not. Elektronik eiSos GmbH & Co. KG. Würth Elektronik eiSos GmbH & Co. KG does not warrant or represent that any license, either expressed or implied, is granted under any patent right, copyright, mask work right, or other intellectual property right relating to any combination, 2. Customer Responsibility related to Specific, in particular Safety-Relevant Applications application, or process in which Würth Elektronik eiSos GmbH & Co. KG components or services are used. It has to be clearly pointed out that the possibility of a malfunction of electronic components or failure before the end of the usual lifetime 8. General Terms and Conditions cannot be completely eliminated in the current state of the art, even if the products are operated within the range of the specifications. In certain customer applications requiring a very high level of safety and especially in customer applications in which the malfunction or Unless otherwise agreed in individual contracts, all orders are subject to the current version of the “General Terms and Conditions of Würth failure of an electronic component could endanger human life or health it must be ensured by most advanced technological aid of suitable Elektronik eiSos Group”, last version available at www.we-online.com. design of the customer application that no injury or damage is caused to third parties in the event of malfunction or failure of an electronic component. Therefore, customer is cautioned to verify that data sheets are current before placing orders. The current data sheets can be downloaded at www.we-online.com. 3. Best Care and Attention Any product-specific notes, cautions and warnings must be strictly observed. Any disregard will result in the loss of warranty. 4. Customer Support for Product Specifications Some products within the product range may contain substances which are subject to restrictions in certain jurisdictions in order to serve specific technical requirements. Necessary information is available on request. In this case the field sales engineer or the internal sales person in charge should be contacted who will be happy to support in this matter. 5. Product R&D Due to constant product improvement product specifications may change from time to time. As a standard reporting procedure of the Product Change Notification (PCN) according to the JEDEC-Standard inform about minor and major changes. In case of further queries regarding the PCN, the field sales engineer or the internal sales person in charge should be contacted. The basic responsibility of the customer as per Section 1 and 2 remains unaffected. CHECKED REVISION DATE (YYYY-MM-DD) GENERAL TOLERANCE PROJECTION METHOD FPe 002.000 2019-08-22 DIN ISO 2768-1m DESCRIPTION WR-COM Mini USB 2.0 Horizontal WEMüCrt h& E Ilnedkutrcotnivike eSioSlousti oGnmsbH & Co. KG 5 Contacts SMT ORDER CODE Max-Eyth-Str. 1 651305142821 74638 Waldenburg Germany Tel. +49 (0) 79 42 945 - 0 SIZE/TYPE BUSINESS UNIT STATUS PAGE www.we-online.com eiSos@we-online.com Type AB with Pads eiCan Valid 7/7 This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH & Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

Datasheet下载

Datasheet下载

.jpg)