- 型号: 531202B02500G

- 制造商: Aavid Thermalloy

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

531202B02500G产品简介:

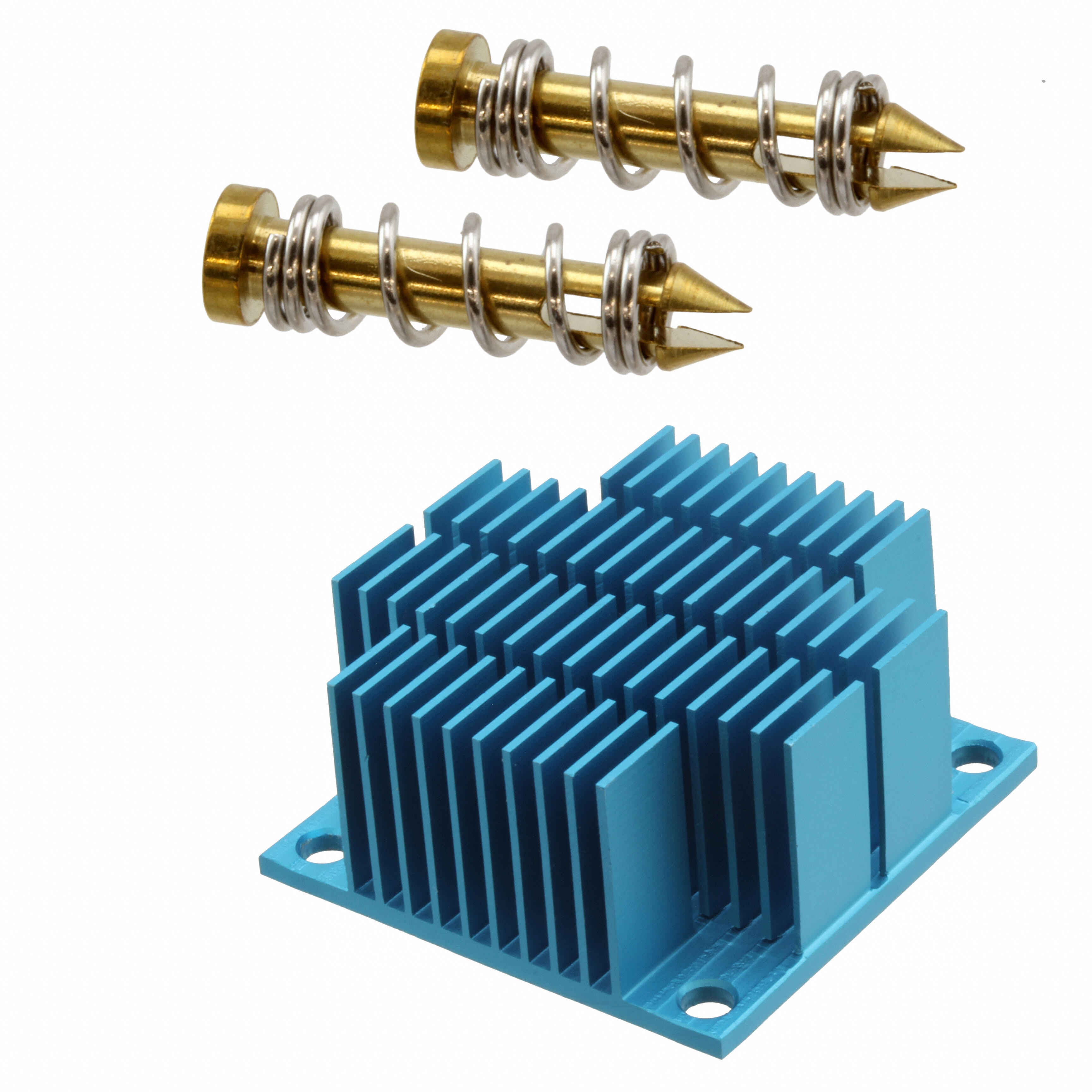

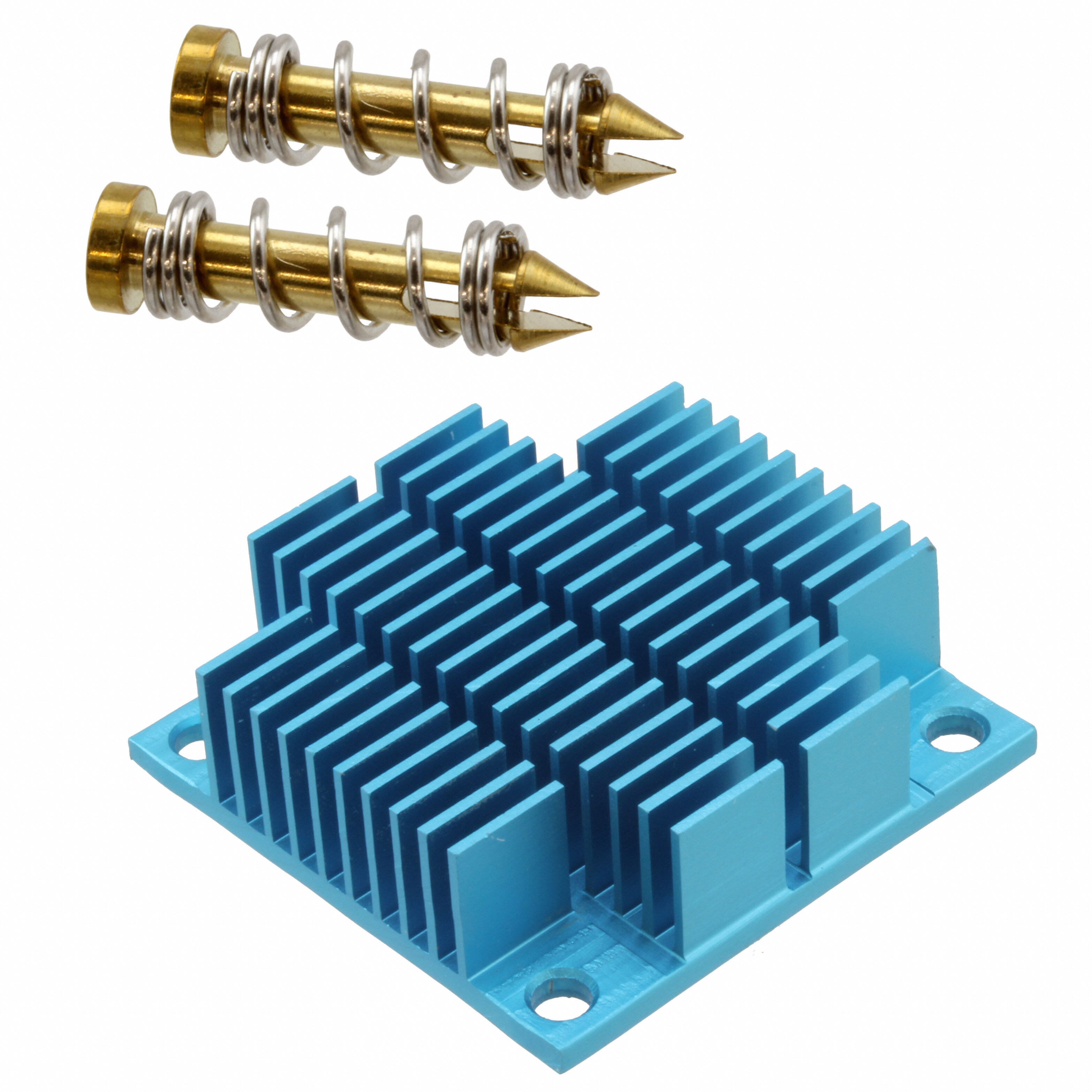

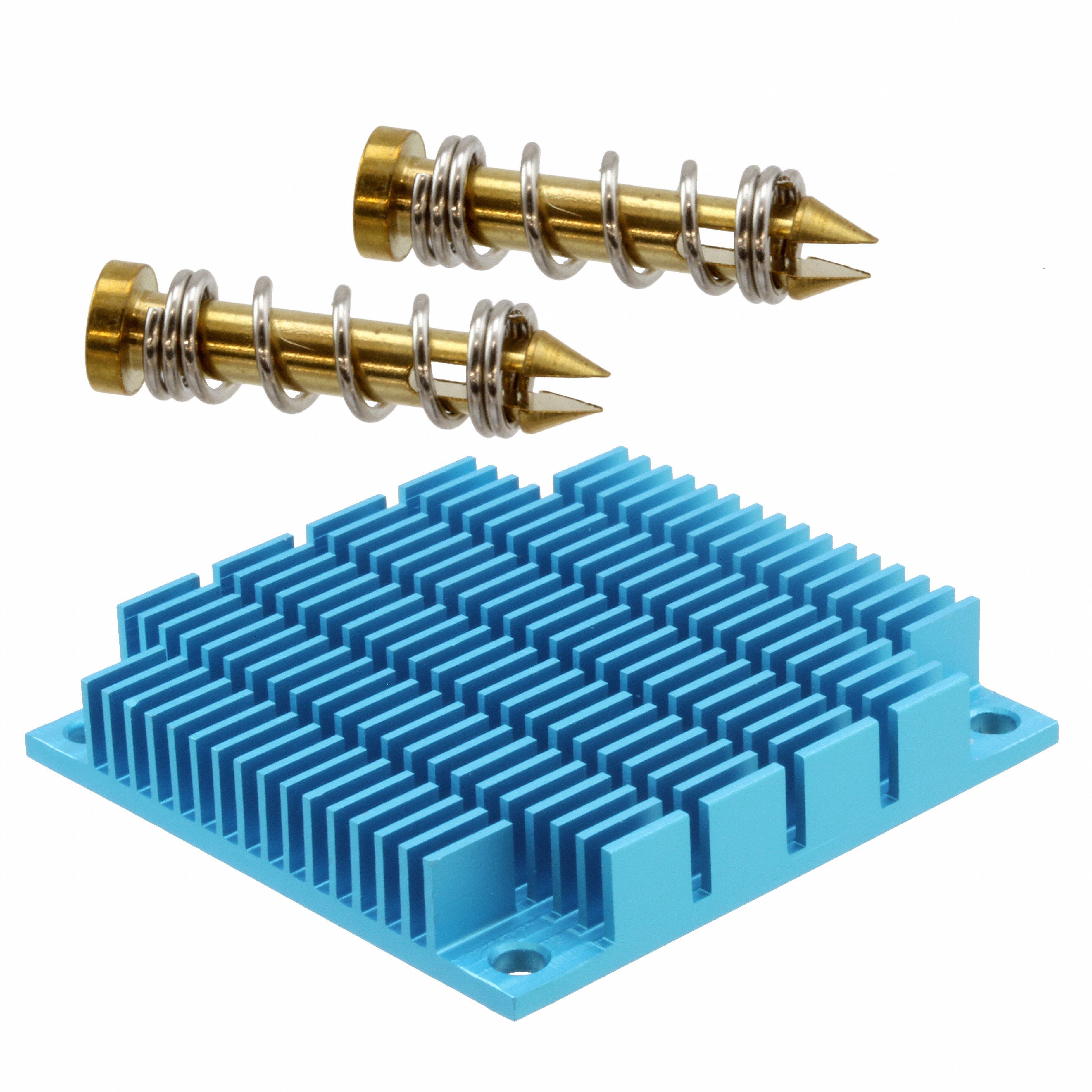

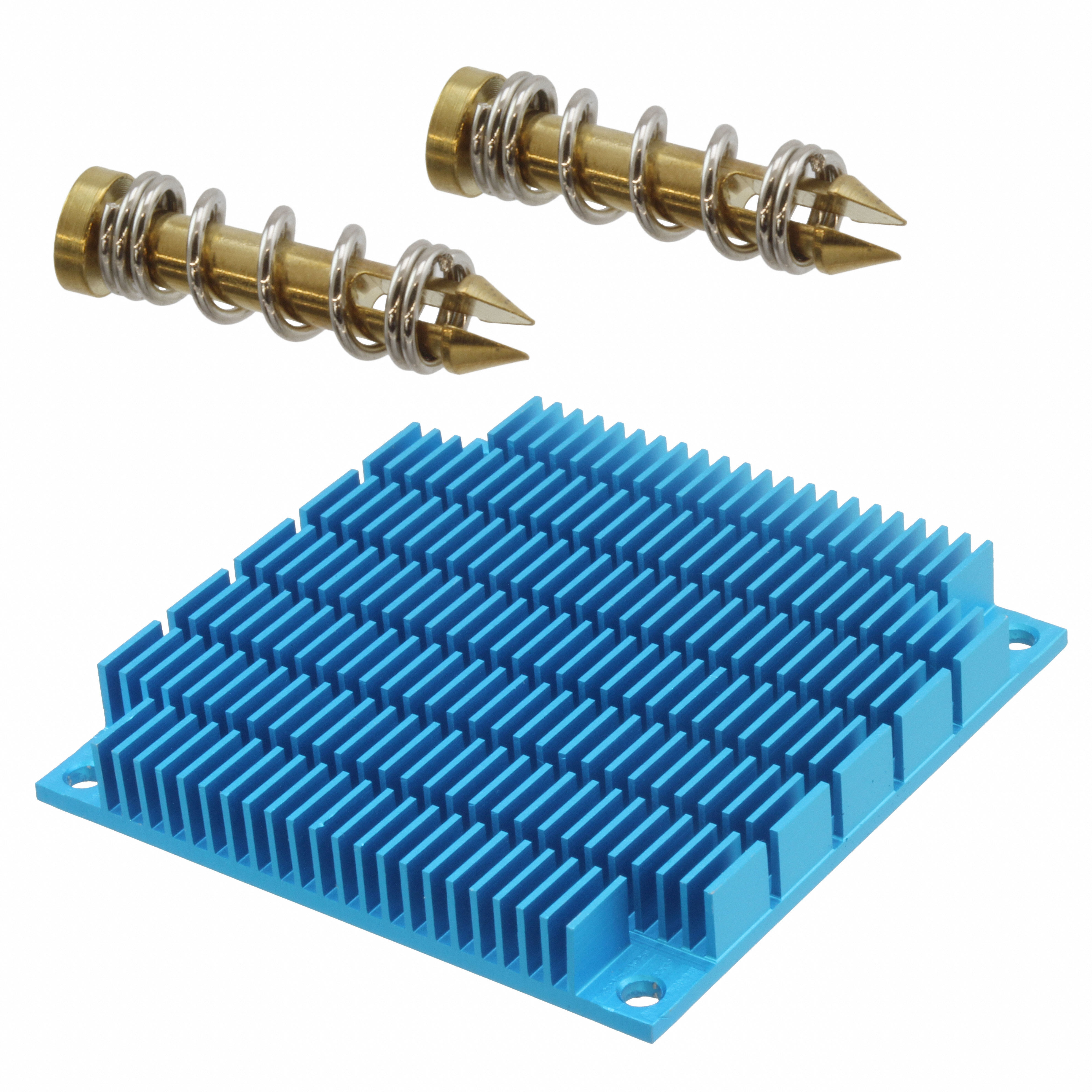

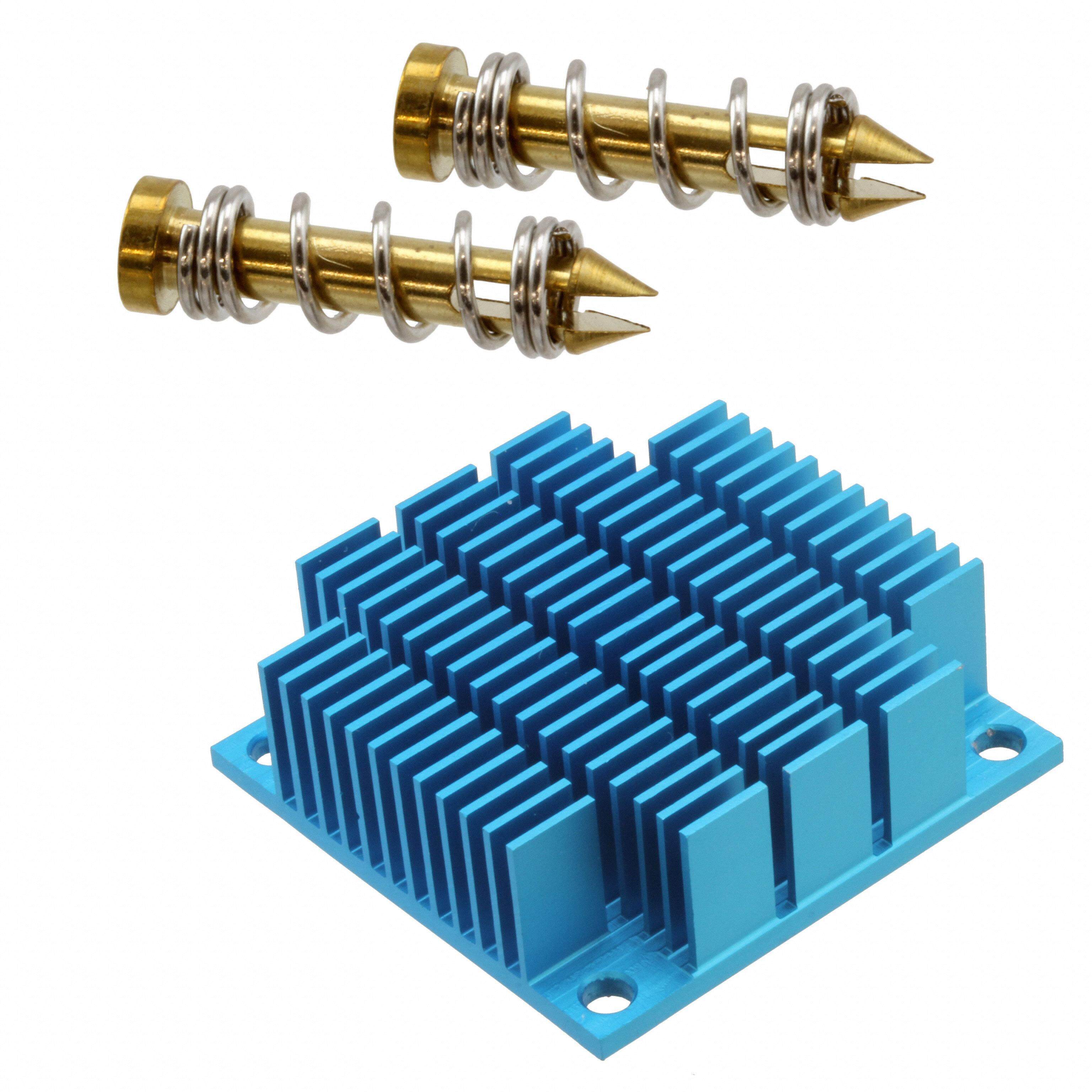

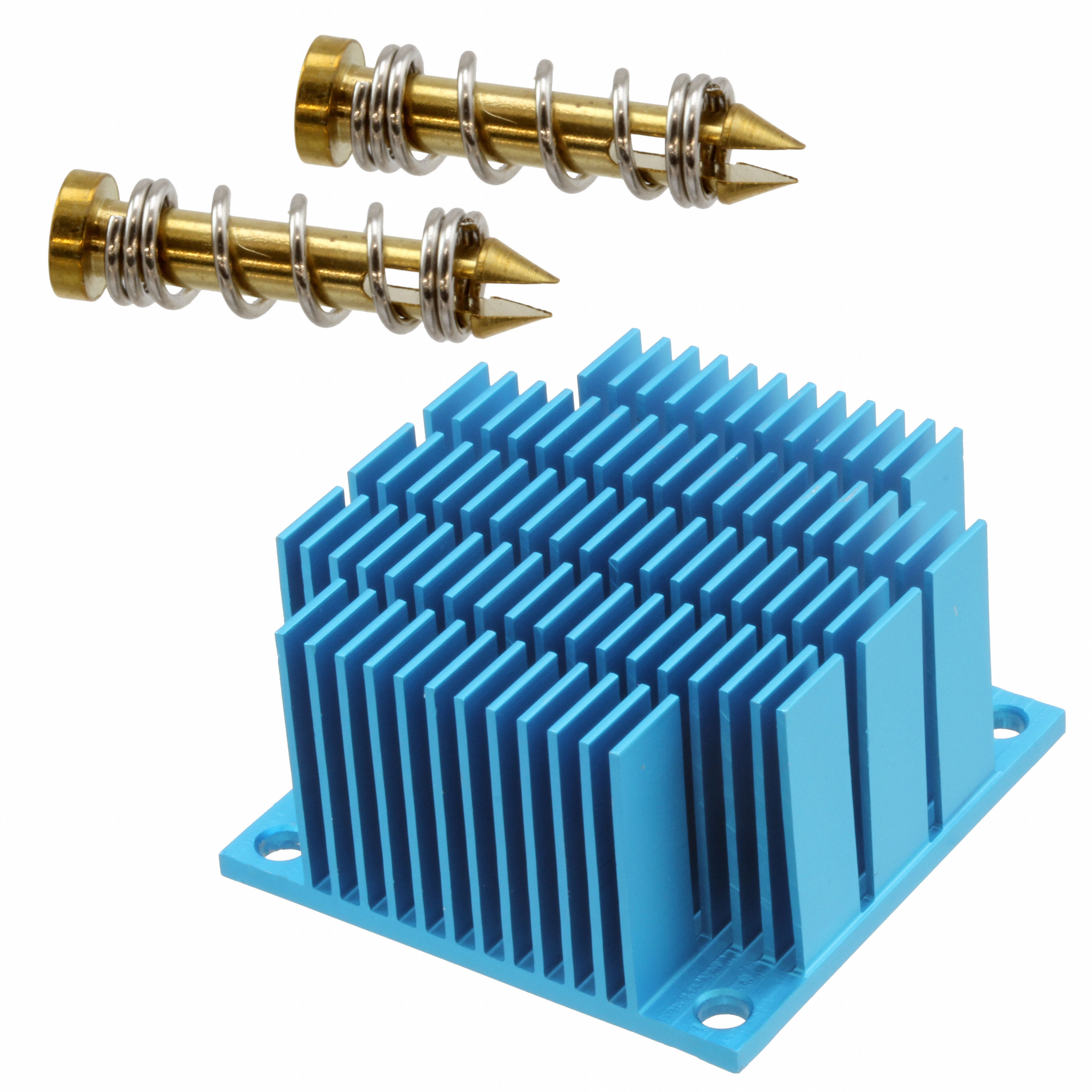

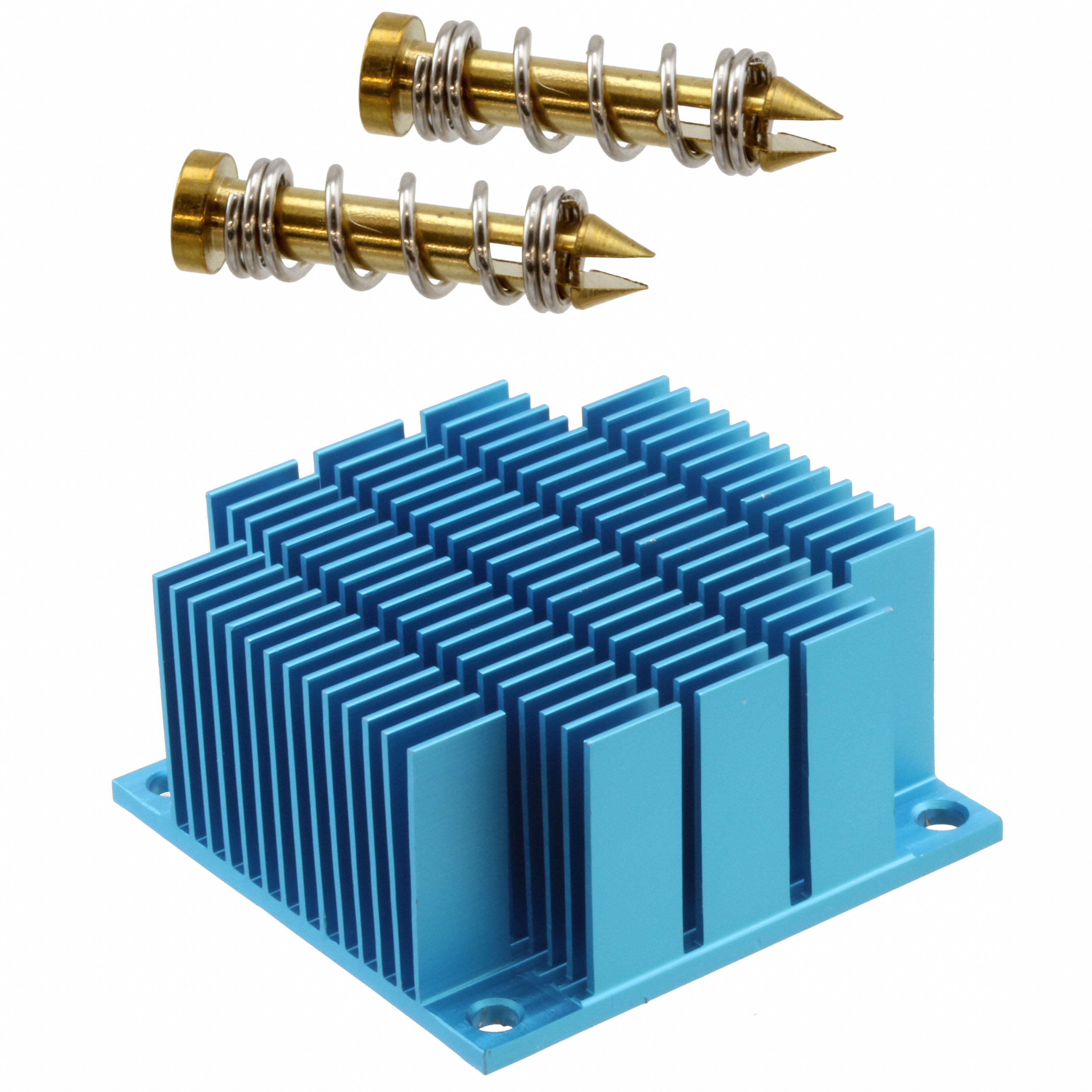

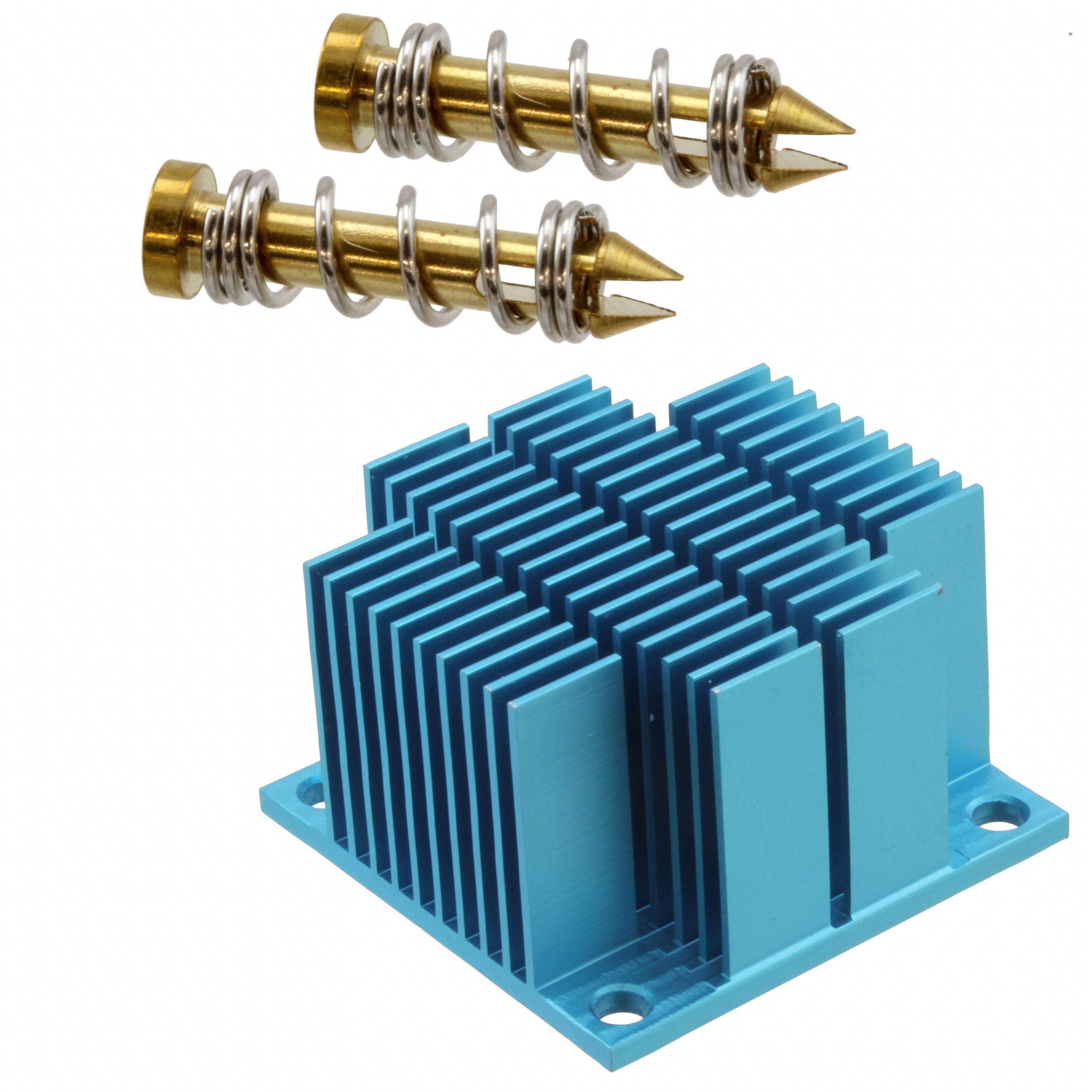

ICGOO电子元器件商城为您提供531202B02500G由Aavid Thermalloy设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 531202B02500G价格参考¥7.51-¥11.23。Aavid Thermalloy531202B02500G封装/规格:热敏 - 散热器, Heat Sink TO-220, TO-202 Aluminum 5.0W @ 40°C Board Level, Vertical。您可以下载531202B02500G参考资料、Datasheet数据手册功能说明书,资料中有531202B02500G 详细功能的应用电路图电压和使用方法及教程。

Aavid,作为Boyd Corporation的热管理解决方案部门,其型号为531202B02500G的散热器属于高性能热敏散热器系列。这类散热器广泛应用于需要高效散热的各种电子设备中,尤其适用于高功率密度和高可靠性要求的场景。 应用场景: 1. 通信设备: - 该型号散热器常用于基站、路由器、交换机等通信设备中,确保信号处理芯片在高温环境下稳定工作。例如,在5G基站中,由于功耗较高,散热性能直接影响到系统的稳定性和寿命。 2. 工业自动化: - 在工业控制柜、变频器、伺服驱动器等设备中,散热器能够有效降低电力电子元件的工作温度,提高系统的可靠性和效率。特别是在恶劣的工业环境中,良好的散热设计可以延长设备的使用寿命。 3. 服务器与数据中心: - 数据中心的服务器和存储设备通常需要高效的散热解决方案来维持长时间稳定运行。这款散热器可以安装在CPU、GPU和其他高发热组件上,帮助维持适宜的工作温度,减少过热导致的故障。 4. 汽车电子: - 随着电动汽车和自动驾驶技术的发展,车载电子系统对散热的要求越来越高。该型号散热器可用于逆变器、DC-DC转换器、电池管理系统等关键部件,确保这些组件在高温条件下正常工作。 5. 医疗设备: - 医疗成像设备(如CT扫描仪、MRI)和手术机器人等高端医疗器械中,散热器能保证内部精密电子元件的温度控制,从而提高设备的精度和安全性。 6. 消费电子产品: - 虽然消费级产品对散热的要求相对较低,但在一些高性能笔记本电脑、游戏主机等设备中,此类散热器也能发挥重要作用,提升用户体验并延长设备寿命。 总之,Aavid的531202B02500G散热器凭借其卓越的散热性能和可靠性,广泛应用于多个领域,为各种高要求的应用场景提供有效的热管理解决方案。

| 参数 | 数值 |

| 产品目录 | |

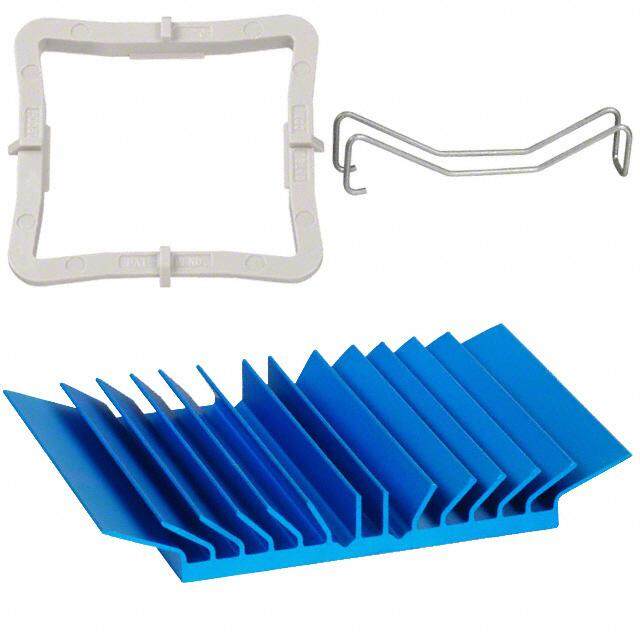

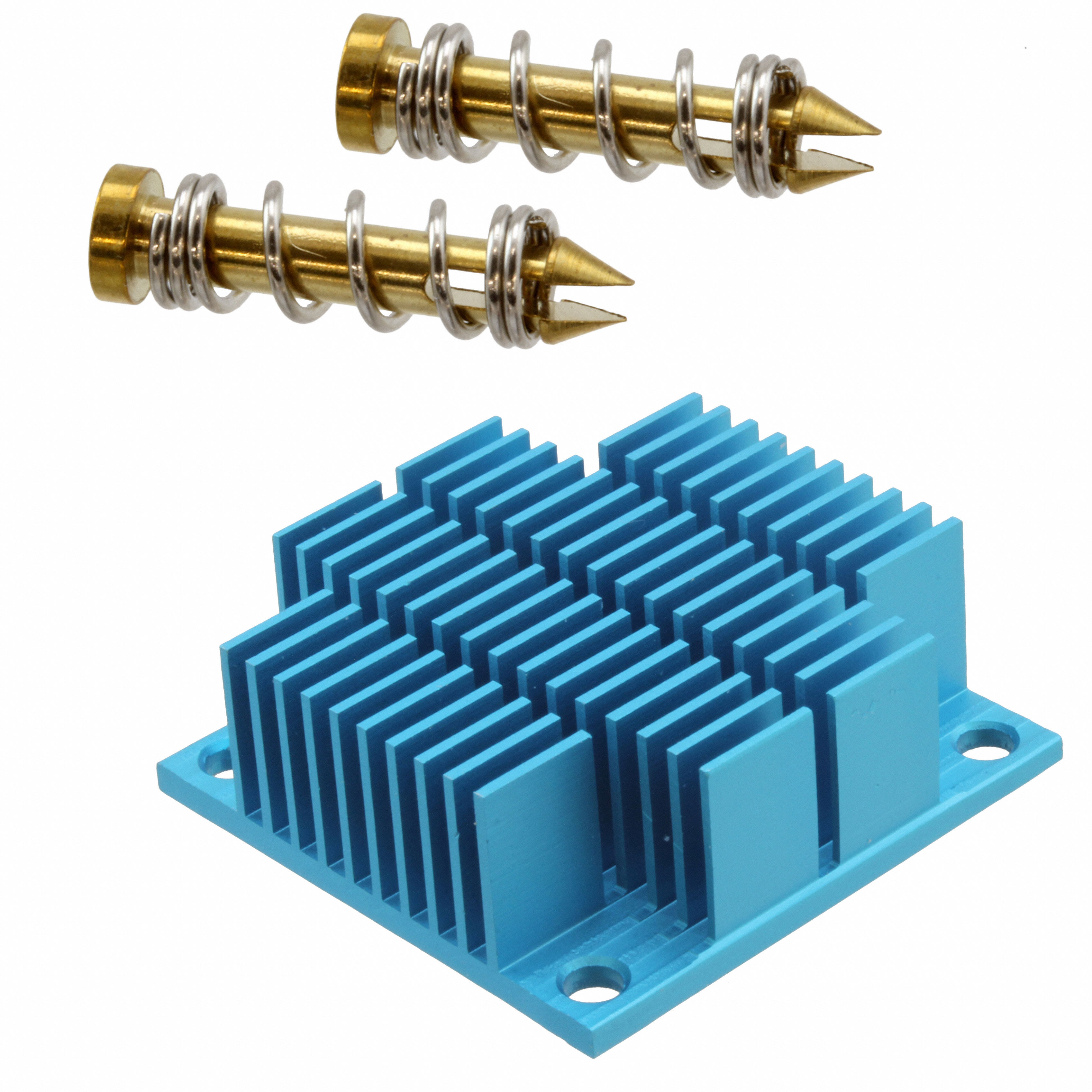

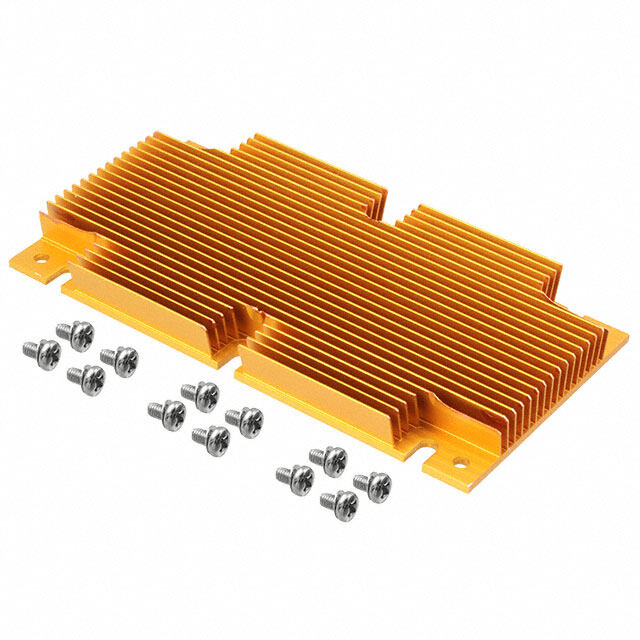

| 描述 | HEATSINK TO-220 POWER W/PINS BK散热片 TO-220 VERT 7.5 TR |

| 产品分类 | |

| 品牌 | Aavid Thermalloy |

| 产品手册 | http://www.aavid.com/products/standard/531202b02500g |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | Aavid Thermalloy 531202B02500G- |

| mouser_ship_limit | 该产品可能需要其他文件才能进口到中国。 |

| 数据手册 | http://www.aavid.com/sites/default/files/literature/Aavid-Board-Level-Heatsinks-Catalog.pdf#page=59 |

| 产品型号 | 531202B02500G |

| 不同强制气流时的热阻 | 4°C/W @ 600 LFM |

| 不同温升时功率耗散 | 5W @ 40°C |

| 产品 | Heat Sinks |

| 产品培训模块 | http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=25887 |

| 产品目录绘图 |

|

| 产品目录页面 | |

| 产品种类 | 散热片 |

| 其它名称 | HS382 |

| 冷却封装 | TO-220, TO-202 |

| 商标 | Aavid Thermalloy |

| 安装风格 | Through Hole |

| 宽度 | 1.375 in |

| 工厂包装数量 | 500 |

| 形状 | 矩形,鳍片 |

| 接合方法 | 螺栓固定和 PC 引脚 |

| 散热片材料 | Aluminum |

| 散热片样式 | Radial |

| 材料 | 铝 |

| 材料镀层 | 黑色阳极化处理 |

| 标准包装 | 500 |

| 热阻 | 7.5 C/W |

| 直径 | - |

| 相关产品 | /product-detail/zh/4880G/HS417-ND/1625654 |

| 离基底高度(鳍片高度) | 0.500"(12.70mm) |

| 类型 | 插件板级,垂直 |

| 自然条件下热阻 | 7.5°C/W |

| 设计目的 | TO-220 |

| 长度 | 2 in |

| 零件号别名 | 041634 |

| 颜色 | Black |

| 高度 | 0.5 in |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

Table of Contents General Information How to Use This Standard Part Catalog....................................................................................................................................................................................................................2 Index by Part Number.....................................................................................................................................................................................................................................................3 Index by Device and Thermal Resistance............................................................................................................................................................................................................4–5 Index by Style and Thermal Resistance................................................................................................................................................................................................................6–8 How to Select a Heat Sink......................................................................................................................................................................................................................................9–10 How to Read a Thermal Graph...................................................................................................................................................................................................................................11 S Board Mounted Heat Sinks T N Heat Sinks for IC Packages E T BGA.........................................................................................................................................................................................................................................................12–19 N DIP...........................................................................................................................................................................................................................................................21–23 O C Surface Mount Discrete Semiconductor Packages F D-PAK.....................................................................................................................................................................................................................................................24–25 O SO...................................................................................................................................................................................................................................................................24 E L SMT Footprints..........................................................................................................................................................................................................................................26 B Thru-Hole Discrete Semiconductor Packages A T TO-220..................................................................................................................................................................................................................................................27–50 TO-220 and TO-262..........................................................................................................................................................................................................................51–53 TO-220,TO-218,and TO-247.........................................................................................................................................................................................................53–58 TO-220 and TO-202..................................................................................................................................................................................................................................59 TO-220,TO-218,TO-247,and Multiwatt....................................................................................................................................................................................60–61 TO-218..........................................................................................................................................................................................................................................................62 TO-202...................................................................................................................................................................................................................................................63–64 TO-126..........................................................................................................................................................................................................................................................65 SIP............................................................................................................................................................................................................................................................66–67 TO-92.............................................................................................................................................................................................................................................................68 TO-3........................................................................................................................................................................................................................................................69–73 TO-66.............................................................................................................................................................................................................................................................74 TO-5........................................................................................................................................................................................................................................................75–76 Axial Lead Devices....................................................................................................................................................................................................................................77 Bridge Rectifiers........................................................................................................................................................................................................................................77 Options Table of Contents....................................................................................................................................................................................................................................................78–79 How to Decipher an Aavid 13 Digit Part Number..............................................................................................................................................................................................80 How to Decipher a "Thermalloy" Origin Part Number......................................................................................................................................................................................81 Index A,B,C = Aavid Standard Parts w/Options..........................................................................................................................................................................................82–84 Index D = "Thermalloy" Origin Parts w/Options.................................................................................................................................................................................................85 Interface Materials In-Sil™,Kondux™,Grafoil® Pads.............................................................................................................................................................................................................................. 86 Hi-Flow®,Alignment Pads.......................................................................................................................................................................................................................................... 87 Double Sided Tape Options (Factory Applied)....................................................................................................................................................................................................88 Labor Saving Heat Sink to Board and Semiconductor Mounts Wave-On™ Mounts,Semiconductor Mounts,Shur-Lock™ Tabs,Solderable Tabs,Solderable Pins.........................................................................................89–94 Solderable Nuts,Clinch Nuts,Solderable Studs,Device Mounting Studs..........................................................................................................................................94–96 Clips Kool-Klips™.......................................................................................................................................................................................................................................................................97 Thermal Clips....................................................................................................................................................................................................................................................................98 Accessories Mounting Kits........................................................................................................................................................................................................................................................................................99 Insulating Shoulder Washers.........................................................................................................................................................................................................................................................100 Insulators–Thermalfilm™ and Thermalfilm™ MT.........................................................................................................................................................................................................101–102 Insulators–Mica and Thermasil™ III.............................................................................................................................................................................................................................................103 Insulating Washers/Aluminum Oxide.........................................................................................................................................................................................................................................104 Insulating Stanchion Pads..............................................................................................................................................................................................................................................................105 Insulating Covers................................................................................................................................................................................................................................................................................106 Mounting Pads..........................................................................................................................................................................................................................................................................107–109 Finishes..................................................................................................................................................................................................................................................................................................110 Card Ejectors & Guides....................................................................................................................................................................................................................................................................111 Thermal Greases and Epoxies..............................................................................................................................................................................................................................................112–115 1 sales.na@aavid.com www.shopaavid.com

How to Use This Catalog Icons indicate that Base part Semiconductor Style description a mounting kit,grease number device for heat sink or epoxy can be used with the heat sink TO-220 Heat Sinks Grease Mounting 7022 Channel style heat sink with folded back fins Epo&xy Kits page112 page 99 N O Semiconductor devices Thermal graphs show natural and forced Mechanical drawing TI have been included in photos to convection based on black anodize finish. dimensions as shown A assist in determining mounting For information on how to use a thermal graph, are mm (inches) M position. please refer to page 11. R O F N 9.52 LI Air Velocity—Feet Per Minute (0.375) (203.9.0016) A 0 200 400 600 800 1000 50.44 GENER illuDsettraaitleesd t dhees hceriaptt sioinnk’s Mounting Surface TempRise Above Ambient—C°108246000000 503214 Thermal Resistance From MTGSurface to Ambient—C/Watt° (201.8.0238)2xø(03.1.8510) (1.98"6X)" (419.9.9698) differentiating features. 0 4 8 12 16 20 Heat Dissipated—Watts (04.1.8930) 2x 3.81 (104.5.4780) (0.150) 2.02 TAB (0.080) 3.18 2.67 Channel style heat sink with (0.125) (0.105) 2x2.03 folded back finsfor increased 2.29 (0.080) cooling surface area.Available 4.44 (0.090) 24.16 with tin plated solderable tabs (0.175) (0.951) for easy attachment to the Ordering information will Material and finish Material:1.27 (0.050) Thick Aluminum printed circuit card. specify the base heat sink with information is shown Finish:See Table available accessories. for each part ORDERINGINFORMATION Dia of PCB Plated Thru Part Number Description Finish Hole for Tabs 7022BG Channel heat sink with folded back fins Black anodize 7022PBG Channel heat sink with folded back fins Pre-black anodize* 7022B-MTG With solderable tabs Black anodize 2.90 (0.114) 7022PB-MTG With solderable tabs Pre-black anodize* 2.90 (0.114) * Edges cut during the manufacturing process will be unfinished. See page XX for more information Aavid has a large selection of popular POPULAR OPTIONS: 7022B- G options to enhance your heat sink selection. This section will indicate the most popular Base part no. A RoHS Compliant options available. Position Code Description Location Details A TC11-MT Insulated device mounting clip for T0-220 and solderable tabs Hole X Page Detailed indexes are available For additional options see page xx to select additional options. 2 sales.na@aavid.com www.shopaavid.com

Index by Part Number Part Number Page Part Number Page Part Number Page Part Number Page Part Number Page Part Number Page 10-5597-02G 14 374424B00032G 17 530101B00150G 54 574102B00000G 45 581002B02500G 61 7022PB-MTG 29 10-5597-22G 14 374424B00035G 16 530102B00100G 54 574102B03300G 45 581101B02500G 61 7023BG 28 10-5597-33G 14 374424B60023G 12 530102B00150G 54 574204B00000G 63 581102B02500G 61 7023B-MTG 28 10-5607-04G 14 374524B00032G 17 530161B00162G 54 574204B03300G 63 581201B02500G 61 7025BG 27 10-5607-05G 14 374524B00035G 16 530162B00162G 54 574402B00000G 45 581202B02500G 61 7025B-MTG 27 10-5634-01G 12 374524B60023G 12 530401B00100G 55 574402B03200G 45 584000B00000G 67 7038BG 67 10-6326-27G 14 374624B00032G 17 530401B00150G 55 574502B00000G 45 584000B03500G 67 709203B00400G 19 10-6326-28G 14 374624B00035G 16 530402B00100G 55 574502B03300G 45 5900PBG 32 7106DG 24 10-6327-01G 14 374624B60024G 12 530402B00150G 55 574602B00000G 45 590102B03600G 34 7106D/TRG 24 10-BRD1-01G 12 374724B00032G 17 530510B00000G 66 574602B03300G 45 590302B03600G 34 7109DG 25 10-BRD1-03G 12 374724B00035G 16 530510U00000G 66 574802B00000G 43 591202B00000G 51 7109D/TRG 25 10-BRD1-04G 12 374724B60024G 12 530613B00000G 40 574802B03300G 43 591202B03100G 51 7128DG 36 10-BRD1-05G 12 374824B00032G 17 530614B00000G 40 574902B00000G 45 591202B04000G 51 7130DG 62 10-BRD1-07G 12 374824B00035G 16 530714B00000G 40 574902B03300G 45 591302B00000G 51 7136DG 35 10-BRD2-01G 12 374824B60024G 12 530801B05100G 54 575002B00000G 33 591302B02800G 51 7137DG 42 10-CLS1-01G 12 374924B00032G 17 530801B05150G 54 575002D00000G 33 591302B04000G 51 7139DG 35 X 10-CLS2-01G 12 374924B00035G 16 530802B05100G 54 575102B00000G 46 592201B03400G 62 7140DG 42 E 10-L4LB-03G 14 374924B60024G 12 530802B05150G 54 575200B00000G 68 592502B03400G 49 7141DG 38 D 10-L4LB-05G 14 375024B00032G 17 530861B05162G 54 575300B00000G 68 592502U03400G 49 7142DG 36 N 10-L4LB-11G 14 375024B00035G 16 530862B05162G 54 575400B00000G 68 592902B03400G 33 7148DG 67 I 10-THMA-01G 12 375024B60024G 12 531002B02500G 59 575603B00000G 70 593002B03400G 33 7173DG 39 10-TNT2-01G 14 375124B00032G 17 531002V02500G 59 575703B00000G 70 593101B03600G 62 7178DG 35 2317B-EP11-BGS1G 18 375124B00035G 16 531102B02500G 59 575803B00000G 70 593202B03500G 48 799403B01500G 19 2319B-TACHG 17 375124B60024G 12 531102V02500G 59 575903B00000G 70 5FG 75 92FG 68 2321B-TACHG 17 375224B00032G 17 531202B02500G 59 576012B00000G 40 6000DG 77 BW38-2G 58 2327B-CP50G 16 375324B00035G 16 531202V02500G 59 576014B00000G 40 6000UG 77 BW38-4G 58 2327B-TACHG 16 375424B00034G 16 531302B02500G 59 576103B00000G 73 6021BG 30 BW50-2G 58 2332B-TACHG 17 500103B00000G 72 531302V02500G 59 576203B00000G 73 6021PBG 30 BW50-4G 58 2338B-TACHG 17 500203B00000G 72 532602B02500G 50 576303B00000G 73 6022BG 47 BW63-2G 58 2342B-TACHG 17 500303B00000G 72 532702B02500G 50 576403B00000G 73 6022PBG 47 BW63-4G 58 2518B-EP11-BGS2G 18 500403B00000G 72 532802B02500G 50 576602B00000G 33 6025DG 48 ML26AAG 50 2519B-EP11-BGS5G 18 501000B00000G 20 533001B02551G 55 576602D00000G 33 6032DG 47 PF432G 52 2520B-EP04-BGS5G 18 501000J00000G 20 533002B02551G 55 576802B00000G 52 6038BG 36 PF433G 52 2522B-EP04-BGS5G 18 501100B00000G 23 533101B02551G 55 576802B03100G 52 6043PBG 43 PF434G 52 320105B00000G 76 501200B00000G 23 533102B02551G 55 576802B04000G 52 6046PBG 64 PF435G 52 320205B00000G 76 501303B00000G 70 533201B02551G 55 576802V00000G 52 6047PBG 64 PF436G 52 323005B00000G 76 501403B00000G 70 533202B02551G 55 576802V03100G 52 6049PBG 43 PF523G 73 325705B00000G 76 501503B00000G 70 533301B02551G 55 576802V04000G 52 6094PBG 43 PF526G 73 326005B00000G 76 501603B00000G 70 533302B02551G 55 576802U00000G 52 6109PBG 35 PF527G 73 335114B00032G 19 501706B00000G 74 533401B02552G 57 576802U03100G 52 6110PBG 35 PF720G 44 335211B00000G 19 501806B00000G 74 533402B02552G 57 576802U04000G 52 615653B00250G 19 PF723G 44 335211B00032G 19 501906B00000G 74 533421B02552G 57 576904B00000G 64 6201PBG 75 PF730G 65 335214B00000G 19 502006B00000G 74 533422B02552G 57 577002B00000G 34 6202PBG 75 PF732G 65 335214B00032G 19 504102B00000G 38 533501B02552G 57 577002B04000G 34 6203PBG 75 PF750G 44 335214B00034G 19 504222B00000G 38 533502B02552G 57 577102B00000G 34 6221PBG 30 PF752G 44 335224B00032G 17 505103B00000G 72 533521B02552G 57 577102B04000G 34 6222BG 77 PF758G 44 335224B00034G 16 505303B00000G 72 533522B02552G 57 577202B00000G 34 6223BG 77 SW25-2G 56 335314B00000G 19 505403B00000G 72 533601B02552G 57 577202B04000G 34 6224BG 77 SW25-4G 56 335314B00032G 19 506003B00000G 69 533602B02552G 57 577304B00000G 64 6225B-MTG 47 SW25-6G 59 335314B00035G 19 506304B00000G 63 533621B02552G 57 577404B00000G 64 6230DG 30 SW38-2G 56 335324B00032G 16 506902B00000G 41 533622B02552G 57 577500B00000G 65 6232B-MTG 48 SW38-4G 56 335714B00000G 19 507002B00000G 41 533701B02552G 57 577500U00000G 65 6232PB-MTG 48 SW38-6G 59 335714B00032G 19 507102B00000G 41 533702B02552G 57 577922B00000G 40 6236BG 39 SW50-2G 56 335724B00032G 17 507222B00000G 41 533721B02552G 57 578105B00000G 75 6236PBG 39 SW50-4G 56 335814B00000G 19 507302B00000G 38 533722B02552G 57 578205B00000G 75 6237BG 42 SW63-2G 56 335814B00032G 19 507302J00000G 38 533802B02554G 50 578305B00000G 75 6237PBG 42 SW63-4G 56 335824B00032G 17 508500B00000G 23 533902B02554G 50 578405B00000G 75 6238BG 37 TV1500G 32 335824B00034G 16 508600B00000G 23 534002B02554G 50 578505B00000G 75 6238B-MTG 37 TV1505G 32 336314B00000G 19 508700B00000G 23 534202B02853G 37 578622B03200G 40 6239B-MTG 37 TV265G 32 336624B00032G 17 513001B02500G 58 534202B03453G 37 579003B00000G 71 6284BG 23 TV35G 31 364424B00032G 17 513002B02500G 58 542502B00000G 49 579103B00000G 69 6374BG 61 TV4G 65 364424B00034G 16 513101B02500G 58 542502D00000G 49 579103V00000G 69 6380BG 60 TV40G 39 371824B00032G 17 513102B02500G 58 551002B00000G 29 579206B00000G 74 6381BG 60 TV46G 31 371824B00034G 16 513201B02500G 58 560200B00000G 20 579206V00000G 74 6382BG 60 TV47G 31 372024B00032G 17 513202B02500G 58 560200W00000G 20 579302B00000G 46 6396BG 60 TV58G 31 372024B00034G 16 513301B02500G 58 563002B00000G 33 579402B00000G 46 6396B-P2G 60 TV96G 53 372924M02000G 14 513302B02500G 58 563002D00000G 33 579604B00000G 63 6398BG 60 TV97G 53 373024B00032G 17 519703B00000G 71 566010B00000G 66 579604B03300G 63 6398B-P2G 60 YB32-4G 61 373024B00034G 16 519803B00000G 71 566010B03100G 66 579704B00000G 63 6399BG 60 373224M00032G 17 519903B00000G 71 566010B03400G 66 579704B03300G 63 6399B-P2G 60 373324M00032G 17 520103B00000G 71 566902B00000G 53 579802B00000G 43 6400BG 60 374024B00032G 17 520327B00000G 69 566902B03100G 53 579802B03300G 43 6400B-P2G 60 374024B00035G 16 520328B00000G 69 566902B04000G 53 579902B00000G 43 700353U01100G 19 374024B60023G 12 520329B00000G 69 569003B00000G 71 579902B03300G 43 7019BG 27 374124B00032G 17 529701B02500G 56 569022B00000G 42 580100B00000G 20 7019B-MTG 27 374124B00035G 16 529702B02500G 56 573100D00000G 24 580100W00000G 20 7019PBG 27 374124B60023G 12 529801B02500G 56 573100D00010G 24 580200B00000G 20 7020BG 27 374224B00032G 17 529802B02500G 56 573300D00000G 24 580200W00000G 20 7020B-MTG 27 374224B00035G 16 529901B02500G 56 573300D00010G 24 580300B00000G 21 7021BG 28 374224B60023G 12 529902B02500G 56 573400D00000G 25 580400B00000G 22 7021B-MTG 28 374324B00032G 17 530001B02500G 56 573400D00010G 25 580500B00000G 22 7022BG 29 374324B00035G 16 530002B02500G 56 574004B00000G 63 580600B00000G 21 7022B-MTG 29 374324B60023G 12 530101B00100G 54 574004U00000G 63 581001B02500G 61 7022PBG 29 3 sales.na@aavid.com www.shopaavid.com

Index by Device Cooled and Thermal Resistance Board Board Board Board Part Number θn Mounting Page Part Number θn Mounting Page Part Number θn Mounting Page Part Number θn Mounting Page AXIAL LEAD D2PAK TO-263 TO-66 533101B02551G 11.0 V 55 573300D00010G 16.0 H 24 513101B02500G 11.0 V 58 6000UG 15.0 V 77 573300D00000G 16.0 H 24 579206B00000G 22.0 H 74 SW38-2G 10.2 V 56 6000DG 15.0 V 77 7109D/TRG 9.0 H 25 579206V00000G 22.0 H 74 SW38-4G 10.2 V 56 7109DG 9.0 H 25 501706B00000G 12.0 H 74 533201B02551G 9.0 V 55 D2PAK TO-263 SO-10 501806B00000G 9.6 H 74 513201B02500G 9.0 V 58 BRIDGE RECTIFIERS 7106D/TRG 14.0 H 24 501906B00000G 8.0 H 74 SW50-2G 8.8 V 56 7106DG 14.0 H 24 502006B00000G 8.0 H 74 SW50-4G 8.8 V 56 6222BG 9.4 V 77 D3PAK TO-268 593101B03600G 8.6 V 62 6223BG 9.4 V 77 573400D00010G 11.0 H 25 YB32-4G 8.4 V 61 6224BG 9.4 V 77 573400D00000G 11.0 H 25 TO-92 513301B02500G 8.0 V 58 533301B02551G 8.0 V 55 X DIPS TO-3 575200B00000G 60.0 V 68 530001B02500G 8.0 V 56 575300B00000G 50.0 V 68 BW63-4G 7.4 V 58 E D 501200B00000G 68.0 H 23 575603B00000G 15.6 H 70 575400B00000G 40.0 V 68 BW38-2G 7.2 V 58 N 501100B00000G 67.0 H 23 575703B00000G 13.4 H 70 92FG 36.1 V 68 BW38-4G 7.2 V 58 I 501000J00000G 60.0 H 20 579103B00000G 12.5 H 69 SW63-2G 7.0 V 56 501000B00000G 60.0 H 20 579103V00000G 12.5 H 69 SW63-4G 7.0 V 56 580300B00000G 39.0 H 21 501303B00000G 12.0 H 70 TO-126 6380BG 6.8 V 60 580400B00000G 39.0 H 22 519803B00000G 11.4 H 71 592201B03400G 6.8 V 62 508500B00000G 34.0 H 23 575803B00000G 11.0 H 70 530101B00100G 6.3 V 54 508600B00000G 32.0 H 23 PF523G 10.1 H 73 PF730G 35.8 H-V 65 530101B00150G 6.3 V 54 580100B00000G 30.0 H 20 501403B00000G 10.0 H 70 PF732G 35.8 H-V 65 530801B05100G 6.3 V 54 580100W00000G 30.0 H 20 505103B00000G 10.0 H 72 577500B00000G 26.0 V 65 530801B05150G 6.3 V 54 508700B00000G 27.2 H 23 575903B00000G 9.8 H 70 577500U00000G 26.0 V 65 530401B00100G 6.3 V 55 6284BG 25.0 H 23 PF526G 8.9 H 73 TV4G 21.6 H 65 530401B00150G 6.3 V 55 560200B00000G 20.0 H 20 6381BG 5.8 V 60 560200W00000G 20.0 H 20 BW50-2G 5.8 V 58 KEY 580200B00000G 20.0 H 20 BW50-4G 5.8 V 58 580200W00000G 20.0 H 20 H = Horizontal mount 533701B02552G 5.7 V 57 580500B00000G 20.0 H 22 533721B02552G 5.7 V 57 580600B00000G 20.0 H 21 V = Vertical mount 6396BG 5.6 V 60 6396B-P2G 5.6 V 60 IC PACKAGES,BGA,PGA,QFP,LCC H–V = Either horizontal or vertical 529701B02500G 5.5 V 56 6374BG 5.0 V 61 Bi Directional Air Flow H 19 depending on device leads 533401B02552G 5.0 V 57 Solder Anchor H 12 533421B02552G 5.0 V 57 Push Pin H 14 θn = Natural convection thermal resistance 529801B02500G 5.0 V 56 Clip Attachment H 18 based on a 75°C heat sink temperature rise BW63-2G 4.7 V 58 Tape Attachment H 16 529901B02500G 4.5 V 56 533501B02552G 4.5 V 57 533521B02552G 4.5 V 57 MULTIWATT 501503B00000G 8.4 H 70 TO-202 530161B00162G 4.4 V 54 501603B00000G 7.8 H 70 530861B05162G 4.4 V 54 YB32-4G 8.4 V 61 505303B00000G 7.8 H 72 576904B00000G 32.0 H–V 64 6398BG 4.4 V 60 6380BG 6.8 V 60 PF527G 7.4 H 73 574004B00000G 28.0 V 63 6398B-P2G 4.4 V 60 6381BG 5.8 V 60 500103B00000G 7.2 H 72 574004U00000G 28.0 V 63 6382BG 4.2 V 60 6396BG 5.6 V 60 576103B00000G 7.2 H 73 577304B00000G 27.2 H–V 64 533601B02552G 3.8 V 57 6396B-P2G 5.6 V 60 506003B00000G 7.0 H 69 6046PBG 25.0 V 64 533621B02552G 3.8 V 57 6374BG 5.0 V 61 500203B00000G 6.2 H 72 6047PBG 25.0 V 64 6399BG 3.3 V 60 6398BG 4.4 V 60 576203B00000G 6.2 H 73 579604B00000G 24.0 V 63 6399B-P2G 3.3 V 60 6398B-P2G 4.4 V 60 579003B00000G 6.0 H 71 579604B03300G 24.0 V 63 6400BG 2.7 V 60 6382BG 4.2 V 60 505403B00000G 6.0 H 72 579704B00000G 24.0 V 63 6400B-P2G 2.7 V 60 6399BG 3.3 V 60 576303B00000G 6.0 H 73 579704B03300G 24.0 V 63 6399B-P2G 3.3 V 60 500303B00000G 5.8 H 72 577404B00000G 24.0 H–V 64 6400BG 2.7 V 60 569003B00000G 5.5 H 71 574204B00000G 16.8 V 63 TO-220 6400B-P2G 2.7 V 60 520103B00000G 5.4 H 71 574204B03300G 16.8 V 63 576403B00000G 5.1 H 73 506304B00000G 14.4 H–V 63 6094PBG 40.5 H 43 500403B00000G 5.0 H 72 531002B02500G 13.4 V 59 PF730G 35.8 V 65 SIPS 519703B00000G 4.8 H 71 531002V02500G 13.4 V 59 PF732G 35.8 V 65 520329B00000G 4.7 H 69 SW25-6G 13.0 V 59 7178DG 35.7 V 35 530510U00000G 20.6 V 66 520328B00000G 4.7 H 69 531102B02500G 10.4 V 59 6049PBG 34.1 V 43 530510B00000G 20.6 V 66 520327B00000G 4.7 H 69 531102V02500G 10.4 V 59 576802V00000G 32.6 V 52 7038BG 16.0 V 67 519903B00000G 4.2 H 71 SW38-6G 10.0 V 59 576802U00000G 32.6 V 52 7148DG 16.0 V 67 531302B02500G 8.0 V 59 576802V03100G 32.6 H 52 566010B00000G 11.5 H-V 66 TO-5 531302V02500G 8.0 V 59 576802U03100G 32.6 H 52 566010B03400G 11.5 V 66 531202V02500G 7.5 V 59 576802V04000G 32.6 V 52 566010B03100G 11.5 H 66 320105B00000G 63.0 V 76 531202B02500G 7.5 V 59 576802U04000G 32.6 V 52 584000B00000G 10.0 V 67 320205B00000G 63.0 V 76 577002B00000G 32.0 H–V 34 584000B03500G 10.0 V 67 325705B00000G 60.0 V 76 TO-218 577002B04000G 32.0 V 34 6380BG 6.8 V 60 326005B00000G 57.0 V 76 TV58G 29.9 H–V 31 6381BG 5.8 V 60 323005B00000G 56.0 V 76 TV96G 24.0 H 53 PF720G 28.9 V 44 6382BG 4.2 V 60 6201PBG 54.0 V 75 7130DG 23.1 V 62 PF723G 28.9 V 44 5FG 45.2 V 75 TV97G 20.0 H 53 7139DG 28.3 H 35 6202PBG 43.0 V 75 581001B02500G 19.6 V 61 576802B00000G 27.3 V 52 SMT 578105B00000G 40.0 V 75 581101B02500G 16.8 V 61 576802B03100G 27.3 H 52 578205B00000G 38.0 V 75 581201B02500G 12.8 V 61 576802B04000G 27.3 V 52 D-PAK TO-252 6203PBG 38.0 V 75 513001B02500G 13.4 V 58 TV46G 27.1 H–V 31 573100D00010G 25.0 H 24 578305B00000G 35.0 V 75 533001B02551G 13.0 V 55 TV47G 27.1 H–V 31 573100D00000G 25.0 H 24 578405B00000G 31.0 V 75 SW25-2G 11.4 V 56 591202B00000G 26.8 H–V 51 578505B00000G 28.0 V 75 SW25-4G 11.4 V 56 591202B03100G 26.8 H 51 4 sales.na@aavid.com www.shopaavid.com

Index by Device Cooled and Thermal Resistance Board Board Board Board Part Number θn Mounting Page Part Number θn Mounting Page Part Number θn Mounting Page Part Number θn Mounting Page 591202B04000G 26.8 V 51 507102B00000G 15.6 H–V 41 TV35G 7.2 H 31 SW25-2G 11.4 V 56 591302B00000G 26.8 H–V 51 6225B-MTG 15.0 V 47 BW38-2G 7.2 V 58 SW25-4G 11.4 V 56 591302B02800G 26.8 V 51 TV1500G 14.2 V 32 BW38-4G 7.2 V 58 533101B02551G 11.0 V 55 591302B04000G 26.8 H 51 575002B00000G 13.6 V 33 SW63-2G 7.0 V 56 513101B02500G 11.0 V 58 579802B00000G 26.4 V 43 575002D00000G 13.6 V 33 SW63-4G 7.0 V 56 SW38-2G 10.2 V 56 579802B03300G 26.4 V 43 6238BG 13.6 H–V 37 7025BG 6.8 V 27 SW38-4G 10.2 V 56 579902B00000G 26.4 V 43 6238B-MTG 13.6 V 37 7025B-MTG 6.8 V 27 533201B02551G 9.0 V 55 579902B03300G 26.4 V 43 6239B-MTG 13.6 V 37 7021BG 6.8 V 28 513201B02500G 9.0 V 58 577102B00000G 25.9 H–V 34 593002B03400G 13.4 V 33 7021B-MTG 6.8 V 28 SW50-2G 8.8 V 56 577102B04000G 25.9 V 34 534202B02853G 13.4 V 37 6380BG 6.8 V 60 SW50-4G 8.8 V 56 7173DG 25.8 V 39 534202B03453G 13.4 V 37 7022BG 6.5 V 29 YB32-4G 8.4 V 61 6236BG 25.0 V 39 513002B02500G 13.4 V 58 7022PBG 6.5 V 29 533301B02551G 8.0 V 55 6236PBG 25.0 V 39 531002B02500G 13.4 V 59 7022B-MTG 6.5 V 29 530001B02500G 2.6 V 56 X 6237BG 25.0 H 42 531002V02500G 13.4 V 59 7022PB-MTG 6.5 V 29 513301B02500G 8.0 V 58 E 6237PBG 25.0 H 42 577922B00000G 13.2 V 40 504222B00000G 6.4 H 38 BW38-2G 7.2 V 58 D 577202B00000G 24.4 H–V 34 578622B03200G 13.2 V 40 530102B00100G 6.3 V 54 BW38-4G 7.2 V 58 N 577202B04000G 24.4 V 34 TV265G 13.0 V 32 530102B00150G 6.3 V 54 SW63-2G 7.0 V 56 I 507302B00000G 24.0 H–V 38 5900PBG 13.0 V 32 530802B05100G 6.3 V 54 SW63-4G 7.0 V 56 507302J00000G 24.0 H–V 38 563002B00000G 13.0 V 33 530802B05150G 6.3 V 54 6380BG 6.8 V 60 542502B00000G 24.0 H 49 563002D00000G 13.0 V 33 530402B00100G 6.3 V 55 530101B00100G 6.3 V 54 542502D00000G 24.0 H 49 533802B02554G 13.0 V 50 530402B00150G 6.3 V 55 530101B00150G 6.3 V 54 TV96G 24.0 H 53 533002B02551G 13.0 V 55 6381BG 5.8 V 60 530801B05100G 6.3 V 54 PF752G 23.7 V 44 SW25-6G 13.0 V 59 BW50-2G 5.8 V 58 530801B05150G 6.3 V 54 576014B00000G 23.2 H–V 40 581202B02500G 12.8 V 61 BW50-4G 5.8 V 58 530401B00100G 6.3 V 55 574402B00000G 23.2 H–V 45 6021BG 12.5 V 30 533702B02552G 5.7 V 57 530401B00150G 6.3 V 55 574402B03200G 23.2 H 45 6021PBG 12.5 V 30 533722B02552G 5.7 V 57 6381BG 5.8 V 60 574102B00000G 23.2 H–V 45 BW50-2G 5.8 V 58 574102B03300G 23.2 V 45 BW50-4G 5.8 V 58 6043PBG 23.0 V 43 NEED HIGHER PERFORMANCE? 533701B02552G 5.7 V 57 592502B03400G 22.0 V 49 533721B02552G 5.7 V 57 592502U03400G 22.0 V 49 Aavid also offers the Max Clip SystemTM 6396BBG 5.6 V 60 574602B00000G 21.6 H–V 45 6396B-P2G 5.6 V 60 574602B03300G 21.6 V 45 for discrete power semiconductors 529701B02500G 5.5 V 56 574502B00000G 21.2 H–V 45 6374BG 5.0 V 61 574502B03300G 21.2 V 45 featuring simple assembly and high 533401B02552G 5.0 V 57 6110PBG 21.0 H–V 35 533421B02552G 5.0 V 57 reliability. 576012B00000G 20.8 H–V 40 529801B02500G 5.0 V 56 7137DG 20.8 V 42 BW63-2G 4.7 V 58 7140DG 20.8 H 42 BW63-4G 4.7 V 58 574802B00000G 20.4 H–V 43 529901B02500G 4.5 V 56 574802B03300G 20.4 V 43 533501B02552G 4.5 V 57 PF750G 20.3 V 44 533521B02552G 4.5 V 57 7142DG 20.3 H 36 6221PBG 12.5 V 30 6396BG 5.6 V 60 6398BG 4.4 V 60 7141DG 20.3 V 38 6230DG 12.5 V 30 6396B-P2G 5.6 V 60 6398B-P2G 4.4 V 60 530714B00000G 20.3 H–V 40 551002B00000G 12.4 H 29 569022B00000G 5.5 H 42 530161B00162G 4.4 V 54 PF432G 20.3 V 52 SW25-2G 11.4 V 56 532602B02500G 5.5 V 50 530861B05162G 4.4 V 54 PF433G 20.3 V 52 SW25-4G 11.4 V 56 529702B02500G 5.5 V 56 6382BG 4.2 V 60 PF434G 20.3 H 52 590302B03600G 11.2 V 34 6374BG 5.0 V 61 533601B02552G 3.8 V 57 PF435G 20.3 V 52 7019BG 11.0 V 27 533402B02552G 5.0 V 57 533621B02552G 3.8 V 57 PF436G 20.3 H 52 7019PBG 11.0 V 27 533422B02552G 5.0 V 57 6399BG 3.3 V 60 506902B00000G 20.0 V 41 7019B-MTG 11.0 V 27 532702B02500G 4.8 V 50 6399B-P2G 3.3 V 60 TV97G 20.0 H–V 53 533902B02554G 11.0 V 50 BW63-2G 4.7 V 58 6400BG 2.7 V 60 7136DG 19.7 V 35 513102B02500G 11.0 V 58 BW63-4G 4.7 V 58 6400B-P2G 2.7 V 60 7128DG 19.2 V 36 533102B02551G 11.0 V 55 529902B02500G 4.5 V 56 566902B00000G 18.8 H-V 53 593202B03500G 10.4 V 48 533502B02552G 4.5 V 57 566902B03100G 18.8 H 53 531102B02500G 10.4 V 59 7023BG 4.4 V 28 TO-262 566902B04000G 18.8 V 53 531102V02500G 10.4 V 59 7023B-MTG 4.4 V 28 6038BG 18.0 V 36 SW38-2G 10.2 V 56 530162B00162G 4.4 V 54 576802B00000G 27.3 H–V 52 592902B03400G 17.9 V 33 SW38-4G 10.2 V 56 530862B05162G 4.4 V 54 576802V00000G 32.6 H–V 52 6025DG 17.9 V 48 590102B03600G 10.0 V 34 6398BG 4.4 V 60 576802U00000G 32.6 H–V 52 6025B-TTG 17.9 V 48 6232B-MTG 10.0 V 48 6398B-P2G 4.4 V 60 576802B03100G 27.3 H 52 ML26AAG 17.9 H 50 6232PB-MTG 10.0 V 48 532802B02500G 4.2 V 50 576802V03100G 32.6 H 52 581002B02500G 17.4 V 61 SW38-6G 10.0 V 59 6382BG 4.2 V 60 576802U03100G 32.6 H 52 PF758G 17.3 V 44 TV40G 9.9 H 39 533602B02552G 3.8 V 57 576802B04000G 27.3 V 52 TV1505G 17.0 V 32 507222B00000G 9.6 H 41 533622B02552G 5.0 V 57 576802V04000G 32.6 V 52 6109PBG 17.0 H–V 35 534002B02554G 9.0 V 50 6399BG 5.0 V 60 576802U04000G 32.6 V 52 575102B00000G 16.8 H–V 46 533202B02551G 9.0 V 55 529802B02500G 3.7 V 56 591202B00000G 26.8 H-V 51 579302B00000G 16.8 V 46 513202B02500G 9.0 V 58 6399B-P2G 3.3 V 60 591202B03100G 26.8 H 51 579402B00000G 16.8 V 46 SW50-2G 8.8 V 56 6400BG 2.7 V 60 591202B04000G 26.8 V 51 581102B02500G 16.8 V 61 SW50-4G 8.8 V 56 6400B-P2G 2.7 V 60 591302B00000G 26.8 H-V 51 530614B00000G 16.7 H–V 40 7020BG 8.7 V 27 533522B02552G 2.7 V 57 591302B02800G 26.8 V 51 530613B00000G 16.7 H–V 40 7020B-MTG 8.7 V 27 530002B02500G 2.6 V 56 591302B04000G 26.8 H 51 6022PBG 16.7 V 47 YB32-4G 8.4 V 61 PF432G 20.3 V 52 6022BG 16.7 V 47 6032DG 8.3 V 47 PF433G 20.3 V 52 576602B00000G 16.6 V 33 533302B02551G 8.0 V 55 TO-247 PF434G 20.3 H 52 576602D00000G 16.6 V 33 513302B02500G 8.0 V 58 PF435G 20.3 V 52 574902B00000G 16.0 H–V 45 531302B02500G 8.0 V 59 TV96G 24.0 H 53 PF436G 20.3 H 52 574902B03300G 16.0 V 45 531302V02500G 8.0 V 59 TV97G 20.0 H–V 53 566902B00000G 18.8 H-V 53 504102B00000G 15.6 H–V 38 531202V02500G 7.5 V 59 513001B02500G 13.4 V 58 566902B03100G 18.8 H 53 507002B00000G 15.6 H–V 41 531202B02500G 7.5 V 59 533001B02551G 13.0 V 55 566902B04000G 18.8 V 53 5 sales.na@aavid.com www.shopaavid.com

Index by Device Cooled,Heat Sink Style,and Thermal Resistance Board Board Board Part Number θn Mounting Page Part Number θn MountingPage Part Number θn Mounting Page AXIAL LEAD SMT TO-5 6000UG 15.0 V 77 D-Pak TO-252 Extruded Collar Heat Sinks 6000DG 15.0 V 77 573100D00010G 15.0 H 24 320105B00000G 63.0 V 76 573100D00000G 15.0 H 24 320205B00000G 63.0 V 76 BRIDGE RECTIFIERS D2Pak TO-263 325705B00000G 60.0 V 76 573300D00010G 18.0 H 24 326005B00000G 57.0 V 76 6222BG 9.4 V 77 573300D00000G 18.0 H 24 323005B00000G 56.0 V 76 6223BG 9.4 V 77 7109D/TRG 11.0 H 25 Low Cost Push On Heat Sink 6224BG 9.4 V 77 7109DG 11.0 H 25 5FG 45.2 V 75 D2Pak TO-263 SO10 (MO-184) Snap On Cooler Heat Sinks DIPS X 7106D/TRG 15.0 H 24 578105B00000G 40.0 V 75 E Extruded Heat Sinks 7106DG 15.0 H 24 578205B00000G 38.0 V 75 D 501200B00000G 68.0 H 23 D3Pak TO-268 578305B00000G 35.0 V 75 N I 501100B00000G 67.0 H 23 573400D00010G 14.0 H 25 578405B00000G 31.0 V 75 508700B00000G 27.2 H 23 573400D00000G 14.0 H 25 578505B00000G 28.0 V 75 6284BG 25.0 H 23 Space Saving Collar Heat Sinks 580500B00000G 20.0 H 22 TO-3 6201PBG 54.0 V 75 580600B00000G 20.0 H 21 6202PBG 43.0 V 75 Slide On Heat Sinks Diamond Shaped Basket Heat Sinks 6203PBG 38.0 V 75 501000J00000G 60.0 H 20 575603B00000G 15.6 H 70 501000B00000G 60.0 H 20 575703B00000G 13.4 H 70 TO-66 580300B00000G 39.0 H 21 501303B00000G 12.0 H 70 580400B00000G 39.0 H 22 Diamond Shaped Basket Heat Sinks 508500B00000G 34.0 H 23 501706B00000G 12.0 H 74 508600B00000G 32.0 H 23 KEY 501806B00000G 9.6 H 74 580100B00000G 30.0 H 20 501906B00000G 8.0 H 74 H = Horizontal mount 580100W00000G 30.0 H 20 502006B00000G 8.0 H 74 560200B00000G 20.0 H 20 Space Saving Collar Heat Sinks V = Vertical mount 560200W00000G 20.0 H 20 579206B00000G 22.0 H 74 580200B00000G 20.0 H 20 H–V = Either horizontal or vertical 579206V00000G 22.0 H 74 580200W00000G 20.0 H 20 depending on device leads TO-92 IC PACKAGES,BGA,PGA,QFP,LCC θn = Natural convection thermal resistance Bi Directional Air Flow H 19 Clip On Style Heat Sink based on a 75°C heat sink temperature rise Solder Anchor H 12 92FG 36.1 V 68 Push Pin H 14 Slip On Style Heat Sinks Clip Attachment H 18 575200B00000G 60.0 V 68 Tape Attachment H 16 575300B00000G 50.0 V 68 575803B00000G 11.0 H 70 575400B00000G 40.0 V 68 MULTI-WATT PF523G 10.1 H 73 Extruded Heat Sinks 501403B00000G 10.0 H 70 TO-126 YB32-4G 8.4 V 61 575903B00000G 9.8 H 70 6380BG 6.8 V 60 PF526G 8.9 H 73 Channel Style Heat Sink 6381BG 5.8 V 60 501503B00000G 8.4 H 70 TV4G 21.6 H 65 6396BG 5.6 V 60 501603B00000G 7.8 H 70 Slip On Style Heat Sinks 6396B-P2G 5.6 V 60 PF527G 7.4 H 73 PF730G 35.8 H-V 65 6374BG 5.0 V 61 Hat Section Heat Sink PF732G 35.8 H-V 65 6398BG 4.4 V 60 506003B00000G 7.0 H 69 577500B00000G 26.0 V 65 6398B-P2G 4.4 V 60 Space Saving Collar Heat Sinks 577500U00000G 26.0 V 65 6382BG 4.2 V 60 579103B00000G 12.5 H 69 6399BG 3.3 V 60 579103V00000G 12.5 H 69 TO-202 6399B-P2G 3.3 V 60 Square Basket Heat Sinks 6400BG 2.7 V 60 519803B00000G 11.4 H 71 Channel Style Heat Sinks 6400B-P2G 2.7 V 60 505103B00000G 10.0 H 72 576904B00000G 32.0 H–V 64 505303B00000G 7.8 H 72 577304B00000G 27.2 H–V 64 SIPS 500103B00000G 7.2 H 72 577404B00000G 24.0 H–V 64 Channel Style Heat Sinks 576103B00000G 7.2 H 73 Compact Slide On Heat Sinks 530510U00000G 20.6 V 66 500203B00000G 6.2 H 72 6046PBG 25.0 V 64 530510B00000G 20.6 V 66 576203B00000G 6.2 H 73 6047PBG 25.0 V 64 Clip On Style Heat Sinks 579003B00000G 6.0 H 71 Extruded Heat Sinks 584000B00000G 10.0 V 67 505403B00000G 6.0 H 72 531002B02500G 13.4 V 59 584000B03500G 10.0 V 67 576303B00000G 6.0 H 73 531002V02500G 13.4 V 59 Extruded Heat Sinks 500303B00000G 5.8 H 72 SW25-6G 13.0 V 59 6380BG 6.8 V 60 569003B00000G 5.5 H 71 531102B02500G 10.4 V 59 6381BG 5.8 V 60 520103B00000G 5.4 H 71 531102V02500G 10.4 V 59 6382BG 4.2 V 60 576403B00000G 5.1 H 73 SW38-6G 10.0 V 59 Plug In Style Heat Sinks 500403B00000G 5.0 H 72 531302B02500G 8.0 V 59 566010B00000G 11.5 H–V 66 519703B00000G 4.8 H 71 531302V02500G 8.0 V 59 566010B03400G 11.5 V 66 519903B00000G 4.2 H 71 531202V02500G 7.5 V 59 566010B03100G 11.5 H 66 Two Piece Heat Sinks 531202B02500G 7.5 V 59 Slide On Style Heat Sinks 520329B00000G 4.7 H 69 Low Cost Slide On Heat Sinks 7038BG 16.0 V 67 520328B00000G 4.7 H 69 574004B00000G 28.0 V 63 7148DG 16.0 V 67 520327B00000G 4.7 H 69 574004U00000G 28.0 V 63 6 sales.na@aavid.com www.shopaavid.com

Index by Device Cooled,Heat Sink Style,and Thermal Resistance Board Board Board Part Number θn Mounting Page Part Number θn Mounting Page Part Number θn Mounting Page TO-202 CONTINUED Hat Section Heat Sinks 534202B02853G 13.4 V 38 TV96G 24.0 H 53 534202B03453G 13.4 V 38 Low Cost Slide On Cooler Heat Sinks TV97G 20.0 H–V 53 577922B00000G 13.2 V 41 579604B00000G 24.0 V 63 High Rise Style Heat Sinks 578622B03200G 13.2 V 41 579604B03300G 24.0 V 63 530101B00100G 6.3 V 54 563002B00000G 13.0 V 34 579704B00000G 24.0 V 63 530101B00150G 6.3 V 54 563002D00000G 13.0 V 34 579704B03300G 24.0 V 63 530801B05100G 6.3 V 54 TV265G 13.0 V 32 574204B00000G 16.8 V 63 530801B05150G 6.3 V 54 5900PBG 13.0 V 32 574204B03300G 16.8 V 63 530401B00100G 6.3 V 55 6021BG 12.5 V 30 Low Profile Hat Section Heat Sink 530401B00150G 6.3 V 55 6021PBG 12.5 V 30 506304B00000G 14.4 H–V 63 Plug In Style Heat Sink 6221PBG 12.5 V 30 Space Saving Staggered Heat Sink 592201B03400G 6.8 V 62 6230DG 12.5 V 30 X E 6034DG 8.3 V 64 Slide On Heat Sink 551002B00000G 12.4 H 30 D 7130DG 23.1 V 62 590302B03600G 11.2 V 34 N TO-218 7019BG 11.0 V 27 I TO-220 7019PBG 11.0 V 27 Channel Style Heat Sink 7019B-MTG 11.0 V 27 593101B03600G 8.6 V 62 Channel Style Heat Sinks 590102B03600G 10.0 V 34 Dual Extruded Heat Sinks 7178DG 35.7 V 35 TV40G 9.9 H 39 533721B02552G 5.7 V 57 577002B04000G 32.0 V 35 7020BG 8.7 V 27 533421B02552G 5.0 V 57 577002B00000G 32.0 H-V 35 7020B-MTG 8.7 V 27 533521B02552G 4.5 V 57 TV58G 29.9 H-V 31 TV35G 7.2 H 31 533621B02552G 3.8 V 57 7139DG 28.3 H 35 7025BG 6.8 V 27 Dual High Rise Style Heat Sinks 7025B-MTG 6.8 V 27 530161B00162G 4.4 V 54 7021BG 6.8 V 28 530861B05162G 4.4 V 54 NEED HIGHER PERFORMANCE? 7021B-MTG 6.8 V 28 Extruded Heat Sinks 7022BG 6.5 V 29 581001B02500G 19.6 V 61 Aavid also offers the Max Clip 7022PBG 6.5 V 29 581101B02500G 16.8 V 61 7022B-MTG 6.5 V 29 513001B02500G 13.4 V 58 SystemTM for discrete power 7022PB-MTG 6.5 V 29 533001B02551G 13.0 V 55 semiconductors featuring simple 504222B00000G 6.4 H 39 581201B02500G 12.8 V 61 7023BG 4.4 V 28 assembly and high reliability. SW25-2G 11.4 V 56 7023B-MTG 4.4 V 28 SW25-4G 11.4 V 56 Clip On Style Heat Sinks 533101B02551G 11.0 V 55 6094PBG 40.5 H 43 513101B02500G 11.0 V 58 6049PBG 34.1 V 43 SW38-2G 10.2 V 56 579802B00000G 26.4 V 44 SW38-4G 10.2 V 56 579802B03300G 26.4 V 44 533201B02551G 9.0 V 55 TV46G 27.1 H–V 31 579902B00000G 26.4 V 44 513201B02500G 9.0 V 58 TV47G 27.1 H–V 31 579902B03300G 26.4 V 44 SW50-2G 8.8 V 56 577102B00000G 25.9 H-V 35 6043PBG 23.0 V 43 SW50-4G 8.8 V 56 577102B04000G 25.9 V 35 574802B00000G 20.4 H–V 44 YB32-4G 8.4 V 61 7173DG 25.8 V 39 574802B03300G 20.4 V 44 533301B02551G 8.0 V 55 6236BG 25.0 V 39 Dual Extruded Heat Sinks 530001B02500G 8.0 V 56 6236PBG 25.0 V 39 6380BG 6.8 V 60 513301B02500G 8.0 V 58 577202B00000G 24.4 H-V 35 6381BG 5.8 V 60 BW63-4G 7.4 V 58 577202B04000G 24.4 V 35 533722B02552G 5.7 V 57 BW38-2G 7.2 V 58 507302B00000G 24.0 H-V 39 533422B02552G 5.0 V 57 BW38-4G 7.2 V 58 507302J00000G 24.0 H-V 39 6374BG 5.0 V 61 SW63-2G 7.0 V 56 576014B00000G 23.2 H-V 41 6382BG 4.2 V 60 SW63-4G 7.0 V 56 6110PBG 21.0 H-V 35 533622B02552G 3.8 V 57 6380BG 6.8 V 60 576012B00000G 20.8 H-V 41 533522B02552G 2.7 V 57 BW50-2G 5.8 V 58 7142DG 20.3 H 36 Dual High Rise Style Heat Sinks BW50-4G 5.8 V 58 7141DG 20.3 V 38 530162B00162G 4.4 V 54 6381BG 5.8 V 60 530714B00000G 20.3 H-V 41 530862B05162G 4.4 V 54 533701B02552G 5.7 V 57 7136DG 19.7 V 35 Extruded Heat Sinks 6396BG 5.6 V 60 7128DG 19.2 V 36 ML26AAG 17.9 H 50 6396B-P2G 5.6 V 60 6038BG 18.0 V 36 581002B02500G 17.4 V 61 529701B02500G 5.5 V 56 592902B03400G 17.9 V 33 581102B02500G 16.8 V 61 533401B02552G 5.0 V 57 6109PBG 17.0 H-V 35 513002B02500G 13.4 V 58 529801B02500G 5.0 V 56 TV1505G 17.0 V 32 531002B02500G 13.4 V 59 BW63-2G 4.7 V 58 530614B00000G 16.7 H-V 41 531002V02500G 13.4 V 59 529901B02500G 4.5 V 56 530613B00000G 16.7 H-V 41 533802B02554G 13.0 V 50 533501B02552G 4.5 V 57 576602B00000G 16.6 V 34 533002B02551G 13.0 V 55 6398BG 4.4 V 60 576602D00000G 16.6 V 34 SW25-6G 13.0 V 59 6398B-P2G 4.4 V 60 504102B00000G 15.6 H–V 39 581202B02500G 12.8 V 61 6382BG 4.2 V 60 TV1500G 14.2 V 32 SW25-2G 11.4 V 56 533601B02552G 3.8 V 57 575002B00000G 13.6 V 34 SW25-4G 11.4 V 56 6399BG 3.3 V 60 575002D00000G 13.6 V 34 533902B02554G 11.0 V 50 6399B-P2G 3.3 V 60 6238BG 13.6 H–V 37 533102B02551G 11.0 V 55 6400BG 2.7 V 60 6238B-MTG 13.6 V 37 513102B02500G 11.0 V 58 6400B-P2G 2.7 V 60 6239B-MTG 13.6 V 37 531102B02500G 10.4 V 59 6374BG 5.0 V 61 593002B03400G 13.4 V 33 531102V02500G 10.4 V 59 7 sales.na@aavid.com www.shopaavid.com

Index by Device Cooled,Heat Sink Style,and Thermal Resistance Board Board Board Part Number θn Mounting Page Part Number θn Mounting Page Part Number θn Mounting Page TO-220 CONTINUED 591302B04000G 26.8 H 51 533101B02551G 11.0 V 55 PF432G 20.3 V 52 513101B02500G 11.0 V 58 SW38-2G 10.2 V 56 PF433G 20.3 V 52 SW38-2G 10.2 V 56 SW38-4G 10.2 V 56 PF434G 20.3 H 52 SW38-4G 10.2 V 56 SW38-6G 10.0 V 59 PF435G 20.3 V 52 533201B02551G 9.0 V 55 534002B02554G 9.0 V 50 PF436G 20.3 H 52 513201B02500G 9.0 V 58 533202B02551G 9.0 V 55 566902B00000G 18.8 H-V 53 SW50-2G 8.8 V 56 513202B02500G 9.0 V 58 566902B03100G 18.8 H 53 SW50-4G 8.8 V 56 SW50-2G 8.8 V 56 566902B04000G 18.8 V 53 YB32-4G 8.4 V 61 SW50-4G 8.8 V 56 Slide On Heat Sinks 533301B02551G 8.0 V 55 YB32-4G 8.4 V 61 PF730G 35.8 V 65 530001B02500G 8.0 V 56 533302B02551G 8.0 V 55 PF732G 35.8 V 65 513301B02500G 8.0 V 58 530002B02500G 2.6 V 56 PF720G 28.9 V 44 BW38-2G 7.2 V 58 X 513302B02500G 8.0 V 58 PF723G 28.9 V 44 BW38-4G 7.2 V 58 E 531302B02500G 8.0 V 59 PF752G 23.7 V 44 SW63-2G 7.0 V 56 D 531302V02500G 8.0 V 59 N 531202V02500G 7.5 V 59 574402B00000G 23.2 H-V 45 SW63-4G 7.0 V 56 I 574402B03200G 23.2 H 45 6380BG 6.8 V 60 531202B02500G 7.5 V 59 574102B00000G 23.2 H–V 45 BW50-2G 5.8 V 58 BW38-2G 7.2 V 58 574102B03300G 23.2 V 45 BW50-4G 5.8 V 58 BW38-4G 7.2 V 58 574602B00000G 21.6 H-V 45 6381BG 5.8 V 60 SW63-2G 7.0 V 56 574602B03300G 21.6 V 45 533701B02552G 5.7 V 57 SW63-4G 7.0 V 56 574502B00000G 21.2 H-V 45 6396BG 5.6 V 60 BW50-2G 5.8 V 58 574502B03300G 21.2 V 45 6396B-P2G 5.6 V 60 BW50-4G 5.8 V 58 PF750G 20.3 V 44 529701B02500G 5.5 V 56 533702B02552G 5.7 V 57 PF758G 17.3 V 44 533401B02552G 5.0 V 57 6396BG 5.6 V 60 574902B00000G 16.0 H-V 45 6374BG 5.0 V 61 6396B-P2G 5.6 V 60 574902B03300G 16.0 V 45 529801B02500G 5.0 V 56 532602B02500G 5.5 V 50 BW63-2G 4.7 V 58 529702B02500G 5.5 V 56 KEY BW63-4G 4.7 V 58 533402B02552G 5.0 V 57 529901B02500G 4.5 V 56 532702B02500G 4.8 V 50 H = Horizontal mount 533501B02552G 4.5 V 57 BW63-2G 4.7 V 58 6398BG 4.4 V 60 BW63-4G 4.7 V 58 V = Vertical mount 6398B-P2G 4.4 V 60 529902B02500G 4.5 V 56 H–V = Either horizontal or vertical 6382BG 4.2 V 60 533502B02552G 4.5 V 57 533601B02552G 3.8 V 57 6398BG 4.4 V 60 depending on device leads 6399BG 3.3 V 60 6398B-P2G 4.4 V 60 532802B02500G 4.2 V 50 θn = Natural convection thermal resistance 6399B-P2G 3.3 V 60 6400BG 2.7 V 60 533602B02552G 3.8 V 57 based on a 75°C heat sink temperature rise 6400B-P2G 2.7 V 60 529802B02500G 3.7 V 56 Hat Section Heat Sinks 6399BG 3.3 V 60 Snap Down Style Heat Sinks TV96G 24.0 H 53 6399B-P2G 3.3 V 60 575102B00000G 16.8 H–V 46 TV97G 20.0 H–V 53 6400BG 2.7 V 60 579302B00000G 16.8 V 46 High Rise Style Heat Sinks 6400B-P2G 2.7 V 60 579402B00000G 16.8 V 46 530101B00100G 6.3 V 54 Hat Section Heat Sinks Space Saving Heat Sinks 530101B00150G 6.3 V 54 6237BG 25.0 H 42 542502B00000G 24.0 H 49 530801B05100G 6.3 V 54 6237PBG 25.0 H 42 542502D00000G 24.0 H 49 530801B05150G 6.3 V 54 TV96G 24.0 H 53 592502B03400G 22.0 V 49 530401B00100G 6.3 V 55 7137DG 20.8 V 42 592502U03400G 22.0 V 49 530401B00150G 6.3 V 55 7140DG 20.8 H 42 6025DG 17.9 V 48 506902B00000G 20.0 V 42 6022PBG 16.7 V 47 TO-262 TV97G 20.0 H–V 53 6022BG 16.7 V 47 507002B00000G 15.6 H–V 42 6225B-MTG 15.0 V 47 Plug In Style Heat Sinks 507102B00000G 15.6 H–V 42 593202B03500G 10.4 V 48 576802B00000G 27.3 H–V 52 507222B00000G 9.6 H 42 6232B-MTG 10.0 V 48 576802V00000G 32.6 H–V 52 High Rise Style Heat Sinks 6232PB-MTG 10.0 V 48 576802U00000G 32.6 H–V 52 530102B00100G 6.3 V 54 6032DG 8.3 V 47 576802B03100G 27.3 H 52 530102B00150G 6.3 V 54 Square Basket Heat Sink 576802V03100G 32.6 H 52 530802B05100G 6.3 V 54 569022B00000G 5.5 H 42 576802U03100G 32.6 H 52 530802B05150G 6.3 V 54 576802B04000G 27.3 V 52 530402B00100G 6.3 V 55 576802V04000G 32.6 V 52 530402B00150G 6.3 V 55 TO-247 576802U04000G 32.6 V 52 Plug In Style Heat Sinks 591202B00000G 26.8 H-V 51 576802B00000G 27.3 V 52 Dual Extruded Heat Sinks 591202B03100G 26.8 H 51 576802V00000G 32.6 V 52 533721B02552G 5.7 V 57 591202B04000G 26.8 V 51 576802U00000G 32.6 V 52 533421B02552G 5.0 V 57 591302B00000G 26.8 H-V 51 576802B03100G 27.3 H 52 533521B02552G 4.5 V 57 591302B02800G 26.8 V 51 576802V03100G 32.6 H 52 533621B02552G 3.8 V 57 591302B04000G 26.8 H 51 576802U03100G 32.6 H 52 Dual High Rise Style Heat Sinks 566902B00000G 18.8 H-V 53 576802B04000G 27.3 V 52 530161B00162G 4.4 V 54 566902B03100G 18.8 H 53 576802V04000G 32.6 V 52 530861B05162G 4.4 V 54 566902B04000G 18.8 V 53 576802U04000G 32.6 V 52 Extruded Heat Sinks PF432G 20.3 V 52 591202B00000G 26.8 H-V 51 513001B02500G 13.4 V 58 PF433G 20.3 V 52 591202B03100G 26.8 H 51 533001B02551G 13.0 V 55 PF434G 20.3 H 52 591202B04000G 26.8 V 51 SW25-2G 11.4 V 56 PF435G 20.3 V 52 591302B00000G 26.8 H-V 51 SW25-4G 11.4 V 56 PF436G 20.3 H 52 591302B02800G 26.8 V 51 8 sales.na@aavid.com www.shopaavid.com

How To Select a Heat Sink How to select a heat sink The basic equation for heat transfer or power dissipation may be stated as follows: ΔT P = D ΣR K θ N I S Where: T PD = the power dissipated by the semiconductor device in watts. A E H ΔT = the temperature difference of driving potential which causes the flow of heat. A ΣRθ = the sum of the thermal resistances of the heat flow path across which ΔT exists. T C The above relationship may be stated in the following forms: E L PD = TJ–TA PD = TC–TA PD = TS–TA SE RθJC + RθCS + RθSA RθCS + RθSA RθSA TO W Where: O H TJ =the junction temperature in °C (maximum is usually stated by the manufacturer of the semiconductor device). TC = case temperature of the semiconductor device in °C. TS = temperature of the heat sink mounting surface in thermal contact with the semiconductor device in °C. TA = ambient air temperature in °C. RθJC = thermal resistance from junction to case of the semiconductor device in °C per watt (usually stated by manufacturer of semiconductor device). RθCS = thermal resistance through the interface between the semiconductor device and the surface on which it is mounted in °C per watt. RθSA = thermal resistance from mounting surface to ambient or thermal resistance of heat sink in °C per watt. The above equations are generally used to determine the required thermal resistance of the heat sink (RθSA), since the heat dissipation,maximum junction and/or case temperature,and ambient temperature are known or set. Figure 1 indicates the location of the various heat The common practice is to represent the system with flow paths,temperatures and thermal resistances. a network of resistances in series as shown in Figure 2. FIGURE 1 FIGURE 2 Mounting surface Atmosphere (cooler/dissipator) or ambient Interface T Junction A (heat source) TJ TC TS TA PD PD Semiconductor case RθJC RθCS RθSA RθCS RθSA Heat flow path mounting surface to ambient, equation (3) T RθJC S Heat flow path case to ambient equation (2) T C Heat flow path junction to ambient, equation (1) TJ TA 9 sales.na@aavid.com www.shopaavid.com

How To Select a Heat Sink Example A Example B Find a space saving heat sink to keep a TO-220 device below the Find a heat sink to keep a TO-220 device below the maximum maximum 150°C junction temperature in natural convection.Device 150 °C junction temperature in forced convection at 400 ft/min. will be screw mounted with an electrically conductive interface. Device must be electrically insulated and mounted with a labor saving clip. Given: K N PD= 6 watts Given: I S RθJC= 3°C/W (from semiconductor manufacturer) PD= 12 watts T A TJmax = 150°C (from semiconductor manufacturer) RθJC= 2.5°C/W (from semiconductor manufacturer) HE TAmax = 65°C TJmax = 140°C (from semiconductor manufacturer) A TAmax = 50°C T A KonduxTMpad is a good choice for electrically conductive C applications.Thermal resistance for KonduxTMcan be determined A Hi-Flow® pad works great with clip mounting and provides the E L from the following graph. necessary electrical insulation.Thermal resistance for E S Hi-Flow® at low pressure is 1.15°C/W (from page 87). O T Typical TO-220 Performance Using equation 1,solve for RθSA 0.60 W 0.50 HO R (ºC/W)CS000...234000 RθSA= 1401 –2 50 - (2.5 + 1.15) = 3.85°C/W 0.10 Many styles are available.If board space is a concern, 0.00 533202B02551G (pg 55) meets the requirements. 0 1 2 3 4 5 6 Screw Torque (in-lb) Air Velocity—Feet Per Minute At 2 in-lb of torque the thermal resistance 0 200 400 600 800 1000 100 10 iURsθ saiSnpAgp =reo q1xu5ima0t a–iot e6nl5 y1 R, -sθ o(C l3vS e+= f 0o0.r5. 5R)° θ=CS/ WA10.7°C/W Mounting Surface TempRise Above Ambient—°C824600000 06428 Thermal Resistance From MTGSurface to Ambient—°C/Watt 6 0 2 4 6 8 10 53320X Heat Dissipated—Watts 53330X The Index by Heat Sink Style on page 8 lists space saving heat sinks. Several models are in the 10 °C/W range.Choose the one that best fits the application and verify thermal resistance from graph. According to the above graph,an airflow of 400 ft/min results in a thermal resistance of 3°C/W.This is less than the required Part number 593202B03500G shows thermal resistance of 3.85°C/W and is therefore acceptable a 60 °C temperature rise at 6 watts. under these airflow conditions. Air Velocity—Feet Per Minute If height is a concern,533702B02552G would meet the 0 200 400 600 800 1000 100 10 requirements and is only 1.0”tall Mounting Surface TempRise Above Ambient—°C824600000 06428 Thermal Resistance From MTGSurface to Ambient—°C/Watt Hi-Flow®is a trademark of the Bergquist Company 0 2 4 6 8 10 Heat Dissipated—Watts RθSA= 60 = 10.0°C/W 6 Which meets the above requirement in natural convection. 10 sales.na@aavid.com www.shopaavid.com

Reading a Thermal Performance Graph The performance graphs you will see in this 579802 CONVERTINGVOLUME H catalog (see graph 579802) are actually a TOVELOCITY Air Velocity—Feet Per Minute P composite of two separate graphs which 0 200 400 600 800 1000 Although most fans are normally rated and A 100 20 R hatpishrau rpevbo recwloi usbpshre evoeerendlny c e acomasorscormuheums bncpiuitnonerengvddde ta shtin.noeTdd hsd iatecehvarveemti e chsae ptel o atago ctwr easbh.pienTihc hkchs eoi sa aos rixmleneisdall Mounting Surface TempRise Above Ambient—C°824600000 1108426Thermal Resistance From MTGSurface to Ambient—C/Watt° cbaothopuaempct pkalpi ucnpaattrr itemeciosidpusn uaasstrtt. ei Fbot,hoentehr d oiiarsef c fribcrsaeu atrerecaa kdrace ipy6rly ,r0dte %theshels–ieuv 8v erco0era%l.ysu e amf toin ezr eomrfoost RMANCEG its recommended mounting position. 0 1 2 3 4 5 O Heat Dissipated—Watts F EXAMPLE:The output air volume R E of a fan is given as 80 CFM.The output area P GRAPHA GRAPHB is 6 inches by 6 inches or 36 in2or 25 ft2. L A To find velocity: M Air Velocity—Feet Per Minute 0 200 400 600 800 1000 Volume(CFM) R 100 20 Velocity(LFM) = E Mounting Surface TempRise Above Ambient—C°824600000 1108426Thermal Resistance From MTGSurface to Ambient—C/Watt° VdeelroacteitVsy e tiolso 32ci25t06y =LLFFMM08,.. 20wa5hreica=h ( f3at22t) 080%, ADINGATH 0 1 2 3 4 5 E Heat Dissipated—Watts R GRAPH A is used to show heat sink perform- GRAPH Bis used to show heat sink per- DESIGN ASSISTANCE ance when used in a natural convection envi- formance when used in a forced convec- Aavid can assist in the design of heat sinks ronment (i.e. without forced air). This graph tion environment (i.e.with forced air flow for both forced and natural convection starts in the lower left hand corner with the through the heat sink).This graph has its applications. Contact us for help with your horizontal axis representing the heat dissipa- origin in the top right hand corner with next thermal challenge. For more tion (watts) and the vertical left hand axis the horizontal axis representing air velocity information, visit our web site at: representing the rise in heat sink mounting over the heat sink LFM* and the vertical www.shopaavid.com surface temperature above ambient (°C). By axis representing the thermal resistance of knowing the power to be dissipated, the the heat sink (°C/W).Air velocity is calculat- temperature rise of the mounting surface ed by dividing the output volumetric flow can be predicted. Thermal resistance in natu- rate of the fan by the cross-sectional area ral convection is determined by dividing this of the outflow air passage. temperature rise by the power input (°C/W). Velocity (LFM)* = Volume(CFM)** area (ft2) EXAMPLE A: Aavid part number 579802 is to be used to dissipate 3 watts of power in EXAMPLE B: For the same application natural convection. Because we are dealing we add a fan which blows air over the heat with natural convection, we refer to graph sink at a velocity of 400 LFM. “A”. Knowing that 3 watts are to be dis- The addition of a fan indicates the use of sipated, follow the grid line to the curve and forced convection and therefore we refer find that at 3 watts there is a temperature to graph “B”. This resistance of 9.50°C/W is rise of 75°C. To get the thermal resistance, then multiplied by the power to be dissi- divide the temperature rise by the power pated,3 watts.This yields a temperature dissipated, which yields 25°C/W. rise of 28.5°C. * Linear feet per minute ** Cubic feet per minute 11 sales.na@aavid.com www.shopaavid.com

BGA–Solder Anchor Solder anchor attachment Aavid's unique Solder anchor attachment method uses two or four small Solder anchors attached to the circuit card and a wire spring clip to securely fasten the heat sink to the device.This method is S rugged,compact and allows for easy removal in E case of rework. G All products include a phase change pad suitable A K for most IC package styles to optimize thermal C performance.Models are available with a single A P or dual spring clips for additional thermal interface C pressure.Solder anchors are ordered separately. I R O F S K N I S T A E H ORDERINGINFORMATION IC Pkg Size (mm) IC Pkg Style Part Number “W”(mm) “L”(mm) “H”(mm) “A”(mm) θn1 θf2 Finish Fig.4 PCB Fig.4 #Anchors3 23 x 23 All 374024B60023G 23.00 23.00 10.00 49.70 40.00 11.69 Black anodize 1 A 2 23 x 23 All 374124B60023G 23.00 23.00 18.00 49.70 23.40 7.39 Black anodize 1 A 2 23 x 23 All 374224B60023G 23.00 23.00 25.00 49.70 19.70 6.37 Black anodize 1 A 2 27 x 27 All 374324B60023G 27.00 27.00 10.00 49.70 30.60 9.35 Black anodize 1 A 2 27 x 27 All 374424B60023G 27.00 27.00 18.00 49.70 20.30 6.46 Black anodize 1 A 2 27 x 27 All 374524B60023G 27.00 27.00 25.00 49.70 16.50 5.47 Black anodize 1 A 2 35 x 35 Flip chip 10-5634-01G 31.00 34.90 23.00 11.50 4.20 Black anodize 2 C 2 35 x 35 Flip chip 10-THMA-01G 31.00 34.90 35.00 10.70 3.95 Black anodize 2 C 2 35 x 35 All 374624B60024G 35.00 35.00 10.00 62.30 23.40 7.55 Black anodize 1 B 2 35 x 35 All 374724B60024G 35.00 35.00 18.00 62.30 15.30 5.15 Black anodize 1 B 2 35 x 35 All 374824B60024G 35.00 35.00 25.00 62.30 12.00 4.27 Black anodize 1 B 2 37.5 x 37.5 Flip chip 10-BRD2-01G 35.70 37.30 23.00 11.50 4.20 Clear anodize 2 B 2 37.5 x 37.5 Flip chip 10-BRD1-01G 37.50 37.50 23.00 10.10 3.83 Black anodize 2 B 2 37.5 x 37.5 Flip chip 10-BRD1-03G 37.50 37.50 23.00 10.10 3.83 Black anodize 3 D 4 37.5 x 37.5 Flip chip 10-BRD1-04G 37.50 37.50 23.00 10.10 3.83 Black anodize 2 B 2 37.5 x 37.5 Flip chip 10-BRD1-05G 37.50 37.50 23.00 10.10 3.83 Clear anodize 3 D 4 37.5 x 37.5 Flip chip 10-BRD1-07G 37.50 37.50 23.00 10.10 3.83 Clear anodize 2 B 2 40 x 40 All 374924B60024G 40.00 40.00 10.00 62.30 20.30 6.46 Black anodize 1 B 2 40 x 40 All 375024B60024G 40.00 40.00 18.00 62.30 12.20 4.34 Black anodize 1 B 2 42 x 40 All 375124B60024G 40.00 40.00 25.00 62.30 10.30 3.83 Black anodize 1 B 2 42.5 x 42.5 Flip chip 10-CLS1-01G 42.30 42.30 23.00 8.80 3.51 Black anodize 2 E 2 42.5 x 42.5 Flip chip 10-CLS2-01G 42.30 42.30 35.00 8.30 3.44 Black anodize 2 E 2 SOLDER ANCHOR 2.49 Part Number PCB Thickness (mm) “A”Dim (mm) 7.19 (0.098) (0.283) 125700D00000G 1.60 3.61 125800D00000G 2.54-2.79 4.70 "A" 0.64 (0.025) 5.08 (0.200) 7.62 (0.300) 1.Natural convection thermal resistance based on a 75º C heat sink temperature rise. 2.Force convection thermal resistance based on an entering 1.0 m/s (200LFM) airflow. 3.Solder anchors are sold separately refer to drawing above. 4.Solder anchor mechanical drawings and board mounting drawings see page 13. 12 sales.na@aavid.com www.shopaavid.com

BGA–Solder Anchor Solder anchor heat sinks mechanical drawings FIGURE 1 FIGURE 2 12.70 (0.500) "H" S "W" "L" 54.74 12.70 E (2.155) "W" (0.500) G A K C A "A" P C "L" "H" I R O F S K N I S T A FIGURE 3 E H (415.8.8086)"W" (105.5.0901) 15.00 (0.591) "H" "L" Board mounting pattern information for solder anchor heat sinks FIGURE A FIGURE B 35.56 48.26 (1.400) (1.900) ø0.97 ± 0.03 (0.038 ± 0.001) 26.67 (Ø0.00.3987 00..00031) PLATHEODL TEHS R4O XUGH (1.050) (25.31.0304) PLATHEOD LTEHSR 4OXUGH (26.66.0004) 33.02 (1.300) (107.7.7080) (05.2.0080)2X (02.49.5103) 5.08 (0.200)2x FIGURE C FIGURE D FIGURE E Ø 0.97 ± 0.03 45.72 PL(0A.0T3E8D ±T H0.R0O01U)GH (25.52.0808) (1.800) HOLES 2X Ø 0.97 0.03 (0.038 0.001) 48.26 Ø0.97 0.03 PLATED THROUGH (1.900) 2X (0.038 0.001) HOLES 4X 58.42 (02.49.5103) PLATHEODL TEHS R4OXUGH 66.04 (2.300) (2.600) 29.21 33.02 (1.150) (05.2.0080) 4X (1.300) 33.02 22.86 (1.300) (0.900) (05..20080)2X 66.04 (12.71.0904) 5.08 (2.600) 2X (0.200) 2X 13 sales.na@aavid.com www.shopaavid.com

BGA–Push Pin Attachment Push pin attachment Push pin heat sinks require two 3.10mm holes in the circuit card to quickly attach the heat sink over the device.The one piece design makes assembly a snap.Pressure is maintained by the tension of the push pin coil springs to ensure even pressure S E across the device.Push pins provide a greater margin of reliabil- G ity in applications where gravity or vibration may cause tapes or A adhesives to fail.The addition of a phase change pad optimizes K C thermal performance. A P C I R O F S K N I S T A E H ORDERINGINFORMATION IC Pkg.Size (mm) Part Number “W”(mm) “L”(mm) “H”(mm) “S”(mm) “T”(mm) θn2 θf3 Finish Fig. PCB Fig.1 Pin Style Pad 28 x 28 10-6326-27G 28.00 28.00 6.00 46.60 6.50 44.10 13.13 Black anodize 1 A Plastic Yes 28 x 28 10-6326-28G 28.00 28.00 6.00 46.60 6.50 44.10 13.13 Black anodize 1 A Brass Yes 28 x 28 10-6327-01G 28.50 28.50 10.00 46.60 7.00 30.60 9.26 Black anodize 2 A Plastic No 35 x 35 10-TNT2-01G 36.10 48.00 11.60 6.50 18.80 6.13 Black anodize 3 D Plastic No 37.5 x 37.5 10-5597-02G 37.40 37.40 6.00 59.00 6.50 33.30 9.91 Green anodize 5 B Plastic No 37.5 x 37.5 10-5597-22G 37.40 37.40 6.00 59.00 6.50 33.30 9.91 Gold anodize 5 B Plastic Yes 37.5 x 37.5 10-5597-33G 37.40 37.40 6.00 59.00 6.50 33.30 9.91 Gold anodize 5 B Brass Yes 37.5 x 37.5 10-5607-04G 37.40 37.40 10.00 59.00 7.00 22.10 6.99 Black anodize 5 B Plastic Yes 37.5 x 37.5 10-5607-05G 37.40 37.40 10.00 59.00 7.00 22.10 6.99 Black anodize 5 B Brass Yes 37.5 x 37.5 372924M02000G 37.40 37.40 6.00 59.00 6.50 32.60 9.91 Green anodize 5 B Plastic No 45 x 45 10-L4LB-03G 45.20 41.40 11.89 58.80 8.00 16.70 5.60 Black anodize 4 C Plastic Yes 45 x 45 10-L4LB-05G 45.20 41.40 11.89 58.80 8.00 16.70 5.60 Black anodize 4 C Brass Yes 45 x 45 10-L4LB-11G 45.20 41.40 11.70 58.80 8.00 14.20 4.91 Black anodize 4 C Plastic No 1.Push pin mechanical drawings and board mounting drawings see page 15 2.Natural convection thermal resistance based on a 75°C heat sink temperature rise. 3.Forced convection thermal resistance based on an entering 1.0 m/s (200LFM) airflow. 14 sales.na@aavid.com www.shopaavid.com

BGA–Push Pin Attachment Mechanical drawings FIGURE 1 FIGURE 2 FIGURE 3 41.70 "T" "H" "T" (416.8.6305) "H" (1.642) S "S" E G A "L" "L" "L" (411.6.5304) CK A P C I "W" "W" R "T" "W" "H" O F S K N I FIGURE 4 FIGURE 5 S T A "T" E "S" "H" H "S" "L" 20.02 "L" (0.788) "T" "W" 10.69 (0.421) "W" "H" Board mounting pattern information FIGURE A FIGURE B ø3.10 ± 0.030 (0.122 ± 0.001) THROUGH HOLES (UNPLATED) 2X 46.60 (1.830) REF 59.00 (2.320) REF 32.95 (1.297) Ø 3.10 0.03 41.74 (0.122 0.001) (1.643) THROUGH HOLES 16.48 16.48 (UNPLATED) 2X (02.08.2827) (0.649) (0.649) 32.95 20.87 (1.297) (0.822) 41.74 (1.643) FIGURE C FIGURE D Ø 3.10 ± 0.03 (Ø 0.122 ± 0.001) Ø 3.10 ± 0.03 THROUGH HOLES (Ø 0.122 ± 0.001) 20.02 (UNPLATED)2X THROUGH HOLES (0.788) (UNPLATED) 2X 41.50 (1.634) 20.85 (0.821) 10.01 25.40 20.75 (0.394) (1.000) (0.817) 41.70 50.80 (1.642) (2.000) 15 sales.na@aavid.com www.shopaavid.com

BGA–Tape Attachment Heat sinks for plastic BGA packages S E G A "L" "H" K C A P C I R O F S "W" K N SI Pressure sensitive,thermally conductive adhesive tape T easily and reliably bonds a heat sink to an integrated A circuit package.Tapes provide high thermal conductiv- E H ity and exceptional bonding properties.Adhesives are formulated for plastic and metal/ceramic packages. Material:Aluminum ORDERINGINFORMATION IC Pkg.Size (mm) IC Pkg.Style Part Number “W”(mm) “L”(mm) “H”(mm) θn2 θf3 Finish Tape code1 10 x 10 Plastic 375324B00035G 10.20 10.20 10.20 71.40 21.20 Black anodize 35 15 x 15 Plastic 375424B00034G 15.20 15.20 6.40 62.50 17.60 Black anodize 34 23 x 23 Plastic 374024B00035G 23.00 23.00 10.00 40.00 11.69 Black anodize 35 23 x 23 Plastic 374124B00035G 23.00 23.00 18.00 23.40 7.39 Black anodize 35 23 x 23 Plastic 374224B00035G 23.00 23.00 25.00 19.70 6.370 Black anodize 35 25 x 25 Plastic 335224B00034G 25.00 25.00 9.90 34.00 10.39 Black anodize 34 27 x 27 Plastic 374324B00035G 27.00 27.00 10.00 30.60 9.35 Black anodize 35 27 x 27 Plastic 374424B00035G 27.00 27.00 18.00 20.30 6.46 Black anodize 35 27 x 27 Plastic 374524B00035G 27.00 27.00 25.00 16.50 5.47 Black anodize 35 28 x 28 Plastic 373024B00034G 27.90 27.90 8.90 33.30 10.00 Black anodize 34 28 x 28 Plastic 2327B-CP50G 27.90 28.10 15.20 23.40 7.43 Black anodize 34 31 x 31 Plastic 335824B00034G 30.00 30.00 9.40 29.40 9.11 Black anodize 34 35 x 35 Plastic 371824B00034G 35.00 35.00 7.00 31.90 9.67 Black anodize 34 35 x 35 Plastic 374624B00035G 35.00 35.00 10.00 23.40 7.55 Black anodize 35 35 x 35 Plastic 374724B00035G 35.00 35.00 18.00 15.30 5.15 Black anodize 35 35 x 35 Plastic 374824B00035G 35.00 35.00 25.00 12.00 4.27 Black anodize 35 35 x 35 Plastic 372024B00034G 35.00 35.00 27.90 11.90 4.28 Black anodize 34 40 x 40 Plastic 374924B00035G 40.00 40.00 10.00 20.30 6.46 Black anodize 35 40 x 40 Plastic 364424B00034G 40.10 40.00 11.40 18.40 6.02 Black anodize 34 40 x 40 Plastic 375024B00035G 40.00 40.00 18.00 12.20 4.34 Black anodize 35 40 x 40 Plastic 375124B00035G 40.00 40.00 25.00 10.30 3.83 Black anodize 35 1.For tape specifications see page 88 2.Natural convection thermal resistance based on a 75°C heat sink temperature rise. 3.Forced convection thermal resistance based on an entering 1.0 m/s (200LFM) airflow. 16 sales.na@aavid.com www.shopaavid.com

BGA–Tape Attachment Heat sinks for metal/ceramic BGA packages S E G "L" "H" A K C A P C I R O F "W" S K N I S T A E H Material:Aluminum ORDERINGINFORMATION IC Pkg.Size (mm) IC Pkg.Style Part Number “W”(mm) “L”(mm) “H”(mm) θn2 θf3 Finish Tape Code1 10 x 10 Metal / Ceramic 375224B00032G 10.20 11.10 10.20 71.40 21.20 Black anodize 32 23 x 23 Metal / Ceramic 374024B00032G 23.00 23.00 10.00 40.00 11.69 Black anodize 32 23 x 23 Metal / Ceramic 374124B00032G 23.00 23.00 18.00 23.40 7.39 Black anodize 32 23 x 23 Metal / Ceramic 374224B00032G 23.00 23.00 25.00 19.70 6.370 Black anodize 32 25 x 25 Metal / Ceramic 335224B00032G 25.00 25.00 9.90 34.00 10.39 Black anodize 32 27 x 27 Metal / Ceramic 335324B00032G 26.90 26.90 11.40 27.70 8.71 Black anodize 32 27 x 27 Metal / Ceramic 374324B00032G 27.00 27.00 10.00 30.60 9.35 Black anodize 32 27 x 27 Metal / Ceramic 374424B00032G 27.00 27.00 18.00 20.30 6.46 Black anodize 32 27 x 27 Metal / Ceramic 374524B00032G 27.00 27.00 25.00 16.50 5.47 Black anodize 32 28 x 28 Metal / Ceramic 373024B00032G 27.90 27.90 8.89 33.30 10.00 Black anodize 32 28 x 28 Metal / Ceramic 373224M00032G 28.00 28.00 6.00 44.10 13.13 Green anodize 32 28 x 28 Metal / Ceramic 2327B-TACHG 27.90 28.10 15.20 23.40 7.43 Black anodize 32 31 x 31 Metal / Ceramic 335724B00032G 30.10 30.10 6.60 35.70 10.84 Black anodize 32 31 x 31 Metal / Ceramic 335824B00032G 30.00 30.00 9.40 29.40 9.11 Black anodize 32 32.5 x 32.5 Metal / Ceramic 2338B-TACHG 33.00 31.40 12.50 23.10 7.23 Black anodize 32 35 x 35 Metal / Ceramic 371824B00032G 35.00 35.00 7.00 31.90 9.67 Black anodize 32 35 x 35 Metal / Ceramic 374624B00032G 35.00 35.00 10.00 23.40 7.55 Black anodize 32 35 x 35 Metal / Ceramic 374724B00032G 35.00 35.00 18.00 15.30 5.15 Black anodize 32 35 x 35 Metal / Ceramic 374824B00032G 35.00 35.00 25.00 12.00 4.27 Black anodize 32 35 x 35 Metal / Ceramic 372024B00032G 35.00 35.00 27.90 11.90 4.28 Black anodize 32 37.5 x 37.5 Metal / Ceramic 373324M00032G 37.40 37.40 6.00 32.60 9.91 Green anodize 32 37.5 x 37.5 Metal / Ceramic 2319B-TACHG 38.10 38.10 10.16 12.50 3.50 Black anodize 32 37.5 x 37.5 Metal / Ceramic 336624B00032G 38.10 38.10 16.00 15.30 5.15 Black anodize 32 40 x 40 Metal / Ceramic 374924B00032G 40.00 40.00 10.00 20.30 6.46 Black anodize 32 40 x 40 Metal / Ceramic 364424B00032G 40.10 40.00 11.40 18.40 6.02 Black anodize 32 40 x 40 Metal / Ceramic 375024B00032G 40.00 40.00 18.00 12.20 4.34 Black anodize 32 40 x 40 Metal / Ceramic 375124B00032G 40.00 40.00 25.00 10.30 3.83 Black anodize 32 42.5 x 42.5 Metal / Ceramic 2321B-TACHG 43.20 41.30 8.90 22.10 6.93 Black anodize 32 42.5 x 42.5 Metal / Ceramic 2332B-TACHG 43.20 41.30 16.50 12.90 4.53 Black anodize 32 45 x 45 Metal / Ceramic 2342B-TACHG 45.70 44.60 7.00 23.10 7.26 Black anodize 32 50 + Metal / Ceramic 3334B-TACHG 50.50 50.20 16.50 6.0 3.3 Black anodize 32 1.For tape specifications see page 88 2.Natural convection thermal resistance based on a 75°C heat sink temperature rise. 3.Forced convection thermal resistance based on an entering 1.0 m/s (200LFM) airflow. 17 sales.na@aavid.com www.shopaavid.com

BGA–Clip Attachment Clip attachment S E G A K C A P C I R O F "L" "H" S K Aavid's BGS Clip heat sinks provide a mechanical N I attachment alternative to tape applications S where it is desirable to attach the heat sink T A directly to the device.The unique clip uses "W" E spring pressure to ensure even contact across H the device while the end plates firmly engage the edge of the package,locking the heat sink in place.Each heat sink uses pre-applied thermal grease for optimum thermal performance. Material: Aluminum Finish: Black Anodize ORDERINGINFORMATION IC Pkg.Size (mm) Part Number “W”(mm) “L”(mm) “H”(mm) IC Pkg.Style θn1 θf2 Interface Clip 27 x 27 2317B-EP11-BGS1G 26.14 20.47 15.24 All 32.60 9.94 EP11 BGS1 35 x 35 2518B-EP11-BGS2G 30.50 28.10 15.60 All 22.70 7.05 EP11 BGS2 42.5 x 42.5 2519B-EP11-BGS5G 34.50 31.40 15.60 All 19.70 6.30 EP11 BGS5 42.5 x 42.5 2520B-EP04-BGS5G 38.10 38.00 15.60 All 15.60 5.17 EP04 BGS5 42.5 x 42.5 2522B-EP04-BGS5G 38.10 38.00 10.16 All 22.10 6.94 EP04 BGS5 1.Natural convection thermal resistance based on a 75°C heat sink temperature rise. 2.Forced convection thermal resistance based on an entering 1.0 m/s (200LFM) airflow. THERMALCOTETM GREASE "E" PULL TAB "D" TAPE TYPE AND INTERFACE MATERIAL INFORMATION Material Description Adhesive Thermal Resistance Color Carrier “D”Dim “E”Dim EP11 ThermalcoteTMgrease with release liner None 0.18 White None 13.34 (0.525) 13.34 (0.525) EP04 ThermalcoteTMgrease with release liner None 0.03 White None 31.75 (1.250) 31.75 (1.250) For more information on ThermalcoteTMsee page 113. 18 sales.na@aavid.com www.shopaavid.com

BGA – Bi Directional Bi Directional S E G A "W" K C A P C I R O "L" "H" F S K Designed for applications with airflow traveling N I in a single direction,these heat sinks are suitable S for a variety of standard square IC packages. Material: Aluminum T A Models are available with pre-applied thermal E tape for easy attachment to the IC.Epoxy attach H models are also available. ORDERINGINFORMATION IC Pkg Size IC Pkg Style Part Number “W”(mm) “L”(mm) “H”(mm) θn3 θf4 Finish Attachment Tape Code 2 10 X 10 All 615653B00250G 6.00 6.00 5.00 142.58 76.26 Black anodize Epoxy1 N/A 10 X 10 All 709203B00400G 10.00 10.00 10.00 55.98 29.94 Black anodize Epoxy1 N/A 24 X 24 Metal 335114B00032G 24.00 24.00 24.00 13.60 7.27 Black anodize Tape 32 25 X 25 Metal 335214B00032G 25.00 25.00 10.00 10.00 5.35 Black anodize Tape 32 25 X 25 Metal 335211B00032G 25.00 25.00 10.00 10.00 5.35 Black anodize Tape 32 25 X 25 All 335214B00000G 25.00 25.00 10.00 10.00 5.35 Black anodize Epoxy1 N/A 25 X 25 All 335211B00000G 25.00 25.00 10.00 10.00 5.35 Black anodize Epoxy1 N/A 25 X 25 Plastic 335214B00034G 25.00 25.00 10.00 10.00 5.35 Black anodize Tape 34 27 X 27 Plastic 335314B00035G 27.00 27.00 11.00 10.00 5.35 Black anodize Tape 35 27 X 27 Metal 335314B00032G 27.00 27.00 11.00 10.00 5.35 Black anodize Tape 32 27 X 27 All 335314B00000G 27.00 27.00 11.00 10.00 5.35 Black anodize Epoxy1 N/A 28 X 28 All 700353U01100G 28.00 28.00 9.00 18.49 9.89 Unfinished Epoxy1 N/A 30 X 30 All 335814B00000G 30.00 30.00 9.00 10.50 5.61 Black anodize Epoxy1 N/A 30 X 30 All 335714B00000G 30.00 30.00 7.00 15.20 8.13 Black anodize Epoxy1 N/A 30 X 30 Metal 335814B00032G 30.00 30.00 9.00 9.20 4.92 Black anodize Tape 32 30 X 30 Metal 335714B00032G 30.00 30.00 7.00 15.20 8.13 Black anodize Tape 32 37.5 X 37.5 All 799403B01500G 38.00 38.00 10.00 12.21 6.53 Black anodize Epoxy1 N/A 37.5 X 37.5 All 336314B00000G 36.00 36.00 17.00 11.00 5.88 Black anodize Epoxy1 N/A 1.Epoxy ordered separately for information on Epoxy see page 114,115. 2.For tape specifications see page 88. 3.Natural convection thermal resistance based on a 75°C heat sink temperature rise. 4.Forced convection thermal resistance based on an entering 1.0 m/s (200LFM) airflow. 19 sales.na@aavid.com www.shopaavid.com

DIPS 5801 Slide on heat sink with staggered fins S E G A Air Velocity—Feet Per Minute K 0 200 400 600 800 1000 C 100 20 DUCTORPA Saetaltisdailceyh .oTenhs etho he 8ea atp tsi nsini nDkkI wP f eiptaahtcu skrteaasgg edgso equrubeildcek fsliypn rasinngd Mounting Surface TempRise Above Ambient—C°824600000 1108426Thermal Resistance From MTGSurface to Ambient—C/Watt° (104.5.2672) (105.6.2040) N action and locking catch to firmly attach 0 0.4 0.8 1.2 1.6 2.0 O Heat Dissipated—Watts the device creating a thermal conduction MIC pAavathil aobnl eb iont htw thoe f itnoisph aens.d bottom surfaces. (101.4.4530) E LOCKING S CATCH TE ORDERINGINFORMATION 10.54 (05.2.3130) RE Part Number Finish (0.415) (06.2.3550) C 580100B00000G Black anodize S 580100W00000G Black anodize with black paint on bottom side Material:0.63 (0.025) Thick Aluminum I Finish:See Table D LE 5010 Angle fin heat sink GEpreo&axsye O page112 H U R Air Velocity—Feet Per Minute H 0 200 400 600 800 1000 T 100 100 AcSounsigtta lsbeo lfelui nftoi ohr ne1 a4fot ars nicndok o1li6isn pag i snDi mpIPap dcleke avlogicweess. Mounting Surface TempRise Above Ambient—C°824600000 642800000Thermal Resistance From MTGSurface to Ambient—C/Watt° (109.7.0550) and available in two finish options. 0 0.4 0.8 1.2 1.6 2.0 Easily attaches using thermal epoxy. Heat Dissipated—Watts (105.6.3044) REF ORDERINGINFORMATION 5.39 (0.212) Part Number Finish 501000J00000G Pre black anodize* 6.35 (0.250) 501000B00000G Black anodize Material:1.27 (0.050) Thick Aluminum Finish:See Table * Edges cut during the manufacturing process will be unfinished. See page 110 for more information. 5602,5802 Slide on heat sink with angled fins Air Velocity—Feet Per Minute 0 200 400 600 800 1000 100 20 Saqtlutidiaccekh loye nsa nthode 1ae4ta ssaiinlnyd.kT 1wh6ei t phhien aa Dnt gIsPiln epkda fcfeikanatsgueress Mounting Surface TempRise Above Ambient—C°824600000 1108426Thermal Resistance From MTGSurface to Ambient—C/Watt° (202.8.6910) (105.6.2040) 0 0.4 0.8 1.2 1.6 2.0 double spring action and locking catch Heat Dissipated—Watts to firmly attach the device creating a 10.42 thermal conduction path on both the (0.410) top and bottom surfaces.Available in LOCKING two finishes. CATCH 5.08 21.34 (0.200) (0.840) "A" ORDERINGINFORMATION Part Number Device Pkg Style Finish “A”Dim 560200B00000G Ceramic Black anodize 7.87 (0.310) Material:0.63 (0.025) Thick Aluminum 560200W00000G Ceramic Black anodize with black paint on bottom side 7.87 (0.310) Finish:See Table 580200B00000G Plastic Black anodize 6.35 (0.250) 580200W00000G Plastic Black anodize with black paint on bottom side 6.35 (0.250) 20 sales.na@aavid.com www.shopaavid.com