- 型号: 298D336X06R3M2T

- 制造商: Vishay

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

298D336X06R3M2T产品简介:

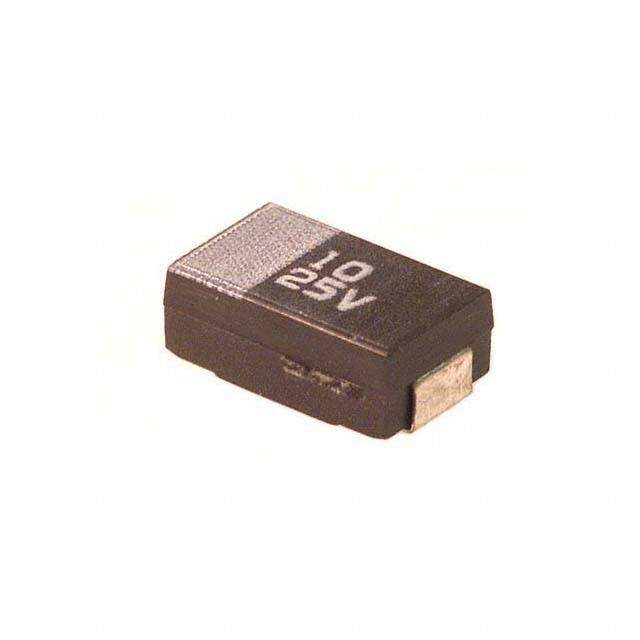

ICGOO电子元器件商城为您提供298D336X06R3M2T由Vishay设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 298D336X06R3M2T价格参考。Vishay298D336X06R3M2T封装/规格:钽电容器, 33µF 模制 钽电容器 6.3V 0603(1608 公制) 7.5 欧姆。您可以下载298D336X06R3M2T参考资料、Datasheet数据手册功能说明书,资料中有298D336X06R3M2T 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | CAP TANT 33UF 6.3V 20% 0603钽质电容器-固体SMD 33uF 6.3volts 20% M case MAP |

| ESR(等效串联电阻) | 7.5 欧姆 |

| 产品分类 | |

| 品牌 | Vishay / SpragueVishay Sprague |

| 产品手册 | |

| 产品图片 |

|

| rohs | 符合RoHS无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 钽电容器,钽质电容器-固体SMD,Vishay / Sprague 298D336X06R3M2TMICROTAN® 298D |

| 数据手册 | |

| 产品型号 | 298D336X06R3M2T298D336X06R3M2T |

| 不同温度时的使用寿命 | - |

| 产品 | Tantalum Solid Standard Grade - Other Various |

| 产品目录绘图 |

|

| 产品目录页面 | |

| 产品种类 | 钽质电容器-固体SMD |

| 其它名称 | 718-1611-1 |

| 制造商尺寸代码 | M |

| 制造商库存号 | M Case |

| 包装 | 剪切带 (CT) |

| 商标 | Vishay / Sprague |

| 商标名 | MICROTAN |

| 外壳代码-in | 0603 |

| 外壳代码-mm | 1608 |

| 外壳宽度 | 0.85 mm |

| 外壳长度 | 1.6 mm |

| 大小/尺寸 | 0.063" 长 x 0.033" 宽(1.60mm x 0.85mm) |

| 安装类型 | 表面贴装 |

| 容差 | ±20%20 % |

| 封装 | Reel |

| 封装/外壳 | 0603(1608 公制) |

| 封装/箱体 | 0603 (1608 metric) |

| 工作温度 | -55°C ~ 125°C |

| 工作温度范围 | - 55 C to + 85 C |

| 工厂包装数量 | 4000 |

| 引线间距 | - |

| 标准包装 | 1 |

| 特性 | 通用 |

| 特色产品 | http://www.digikey.com/cn/zh/ph/Vishay/298D.html |

| 电压-额定 | 6.3V |

| 电压额定值 | 6.3 V |

| 电容 | 33 uF33µF |

| 端接类型 | SMD/SMT |

| 类型 | 模制 |

| 系列 | 298x |

| 高度 | 0.9 mm |

| 高度-安装(最大值) | 0.035"(0.89mm) |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

298D, 298W www.vishay.com Vishay Sprague Solid Tantalum Chip Capacitors 298D MICROTAN®, 298W Extended Range MICROTAN®, Leadframeless Molded FEATURES • Small sizes include 0603 and 0402 footprint • Lead (Pb)-free L-shaped face-down terminations • 8 mm tape and reel packaging available pe r EIA-481 and reeling per IEC 60286-3 7" [178 mm] standard • Mounting: surface mount • Moisture sensitivity level 1 (for exceptions refe r to “Standard Ratings” table) • Material categorization: for definitions of compliance please see www.vishay.com/doc?99912 PERFORMANCE CHARACTERISTICS www.vishay.com/doc?40169 Capacitance Range: Operating Temperature: 298D: 0.33 μF to 220 μF 298D: -55 °C to +125 °C 298W: 2.2 μF to 220 μF (above 85 °C, voltage derating is required) Capacitance Tolerance: ± 20 % standard, ± 10 % available 298W: -55 °C to +125 °C Voltage Range: 2.5 V to 50 V DC DC (above 40 °C, voltage derating is required) ORDERING INFORMATION 298D 335 X0 010 M 2 T TYPE CAPACITANCE CAPACITANCE DC VOLTAGE RATING CASE CODE TERMINATION REEL SIZE AND TOLERANCE PACKAGING 298D This is expressed X0 = ± 20 % This is expressed in See Ratings 2 = 100 % tin T = tape and reel 298W in picofarads. The X9 = ± 10 % volts. To complete the and Case 4 = gold plated 7" [178 mm] reel first two digits are three-digit block, Codes table D = tape and reel the significant zeros precede the 7" [178 mm] reel, figures. The third voltage rating. A decimal is the number of point is indicated by an dry pack zeros to follow. “R” (6R3 = 6.3 V). Notes • Preferred tolerance and reel sizes are in bold. We reserve the right to supply higher voltage ratings and tighter capacitance tolerance capacitors in the same case size. Voltage substitutions will be marked with the higher voltage rating • Dry pack as specified in J-STD-033 for MSL 3 DIMENSIONS in inches [millimeters] Anode Termination Anode Polarity Bar Cathode Termination C W H P1 P2 P1 L CASE CODE L W H (MAX.) P1 P2 (REF.) C 0.039 + 0.008 0.020 + 0.008 0.024 0.01 ± 0.004 0.02 0.015 ± 0.004 K [1.0 + 0.2] [0.5 + 0.2] [0.6] [0.25 ± 0.1] [0.5] [0.38 ± 0.1] 0.063 ± 0.008 0.033 ± 0.008 0.035 0.020 ± 0.004 0.024 0.024 ± 0.004 M [1.60 ± 0.2] [0.85 ± 0.2] [0.9] [0.50 ± 0.1] [0.60] [0.60 ± 0.1] 0.079 ± 0.008 0.050 ± 0.008 0.035 0.020 ± 0.004 0.040 0.035 ± 0.004] S [2.00 ± 0.20] [1.25 ± 0.20] [0.9] [0.50 ± 0.10] [1.00] [0.90 ± 0.10] 0.081 ± 0.006 0.053 ± 0.006 0.062 0.020 ± 0.004 0.043 0.035 ± 0.004 R [2.06 ± 0.15] [1.35 ± 0.15] [1.57] [0.51 ± 0.1] [1.1] [0.90 ± 0.1] 0.094 ± 0.004 0.057 ± 0.004 0.047 0.020 ± 0.004 0.057 0.035 ± 0.004 P [2.4 ± 0.1] [1.45 ± 0.1] [1.2] [0.50 ± 0.1] [1.40] [0.90 ± 0.1] 0.126 ± 0.008 0.063 ± 0.008 0.039 0.031 ± 0.004 0.063 0.047 ± 0.004 Q [3.2 ± 0.2] [1.6 ± 0.2] [1.0] [0.80 ± 0.1] [1.60] [1.20 ± 0.1] 0.126 ± 0.008 0.063 ± 0.008 0.071 0.031 ± 0.004 0.063 0.047 ± 0.004 A [3.2 ± 0.2] [1.6 ± 0.2] [1.8] [0.80 ± 0.1] [1.60] [1.20 ± 0.1] Revision: 22-Jul-2019 1 Document Number: 40065 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

298D, 298W www.vishay.com Vishay Sprague RATINGS AND CASE CODES (298D, 298W Extended Range) 2.5 V 4 V 6.3 V 10 V 16 V 20 V 25 V 35 V 50 V μF 298D 298D 298W 298D 298W 298D 298W 298D 298W 298D 298D 298D 298D 0.33 K 0.68 M M 1.0 K K / M K / M S M / R / S P 1.5 M 2.2 K / M K / M M K P 3.3 M M 4.7 K M M / P K M / P P P 10 K / M M / S K M R A 15 K M M 22 K K / M M M 33 M M P M 47 M M R / P / A M P 100 P M P / Q / A Q 220 P P / Q Q MARKING VOLTAGE CODE CAPACITANCE CODE V CODE CAP, μF CODE 2.5 e 0.68 w P, R, S-Case M-Case 4.0 G 1.0 A Polarity bar Vcoodlteage Ccoadpeacitance Polarity bar Voltage code 6.3 J 2.2 J 10 A 3.3 N G J A 16 C 4.7 S 20 D 6.8 W 25 E 10 K-Case 35 V 15 e A, Q-Case Polarity bar Voltage EIA capacitance 50 T 22 j Polarity bar code code (pF) 33 n 47 s J107 68 w 100 A 150 E 220 J Revision: 22-Jul-2019 2 Document Number: 40065 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

298D, 298W www.vishay.com Vishay Sprague STANDARD RATINGS (298D, 298W Extended Range) MAX. ESR MAX. RIPPLE MAX. DCL MAX. DF CAPACITANCE CASE AT +25 °C 100 kHz PART NUMBER AT +25 °C AT +25 °C (μF) CODE 100 kHz I (μA) (%) RMS () (A) 2.5 V AT +85 °C; 1.6 V AT +125 °C DC DC 22 K 298D226X02R5K(2)T 10 40 20.00 0.027 47 M 298D476X02R5M(2)T 2.4 20 4.00 0.080 220 P 298D227X02R5P(2)T 11 30 3.00 0.122 4 V AT +85 °C; 2.7 V AT +125 °C - 298D DC DC 4 V AT +40 °C; 2.5 V AT +85 °C; 1.6 V AT +125 °C - 298W DC DC DC 4.7 K 298D475X0004K(2)T 0.5 15 20.00 0.027 10 K 298D106X0004K(2)T 4.0 50 20.00 0.027 10 M 298D106(1)004M(2)T 0.5 8 5.00 0.071 15 K 298D156X0004K(2)T 10 50 20.00 0.027 22 K 298D226X0004K(2)T 25 40 20.00 0.027 22 M 298D226X0004M(2)T 0.9 15 4.00 0.080 33 M 298D336X0004M(2)T 2.6 30 4.00 0.080 47 M 298D476X0004M(2)T 3.8 40 7.50 0.080 100 P 298D107X0004P(2)T 4.0 30 2.00 0.100 100 M 298W107X0004M(2)T 110 60 15.00 0.041 220 P 298D227(1)004P(2)T 17.6 30 3.00 0.122 220 Q 298D227X0004Q(2)T 88 80 15.00 0.061 220 Q 298W227X0004Q(2)T 88 80 15.00 0.061 6.3 V AT +85 °C; 4 V AT +125 °C - 298D DC DC 6.3 V AT +40 °C; 4.0 V AT +85 °C; 2.5 V AT +125 °C - 298W DC DC DC 1.0 K 298D105X06R3K(2)T 0.5 6 20.00 0.027 2.2 K 298D225X06R3K(2)T 0.5 8 20.00 0.027 2.2 M 298D225(1)6R3M(2)T 0.5 10 5.00 0.070 3.3 M 298D335(1)6R3M(2)T 0.5 8 6.00 0.090 4.7 M 298D475(1)6R3M(2)T 0.5 8 3.00 0.090 10 M 298D106X06R3M(2)T 0.6 8 5.00 0.071 10 S 298D106X06R3S(2)T 0.6 8 5.00 0.084 10 K 298W106X06R3K(2)T 10 30 15.00 0.032 15 M 298D156X06R3M(2)T 1.0 20 7.00 0.060 22 M 298D226X06R3M(2)T 2.8 20 5.50 0.067 33 M 298D336X06R3M(2)T 4.2 30 7.50 0.058 47 M 298W476X06R3M(2)T 29.6 45 10.00 0.050 47 R 298D476X06R3R(2)T 3.0 25 3.00 0.122 47 P 298D476X06R3P(2)T 3.0 22 3.00 0.122 47 A 298D476X06R3A(2)T 3.0 10 2.00 0.150 100 P 298D107(1)6R3P(2)T 6.3 30 2.00 0.150 100 Q 298D107X06R3Q(2)T 10 30 1.10 0.220 100 A 298D107X06R3A(2)T 6.3 20 1.00 0.270 Notes • Part number definitions: (1) Tolerance: for 10 % tolerance, specify “X9”; for 20 % tolerance, change to “X0” (2) Termination: for 100 % tin specify “2”, for gold plated specify “4” (1) Rating is MSL 3 Revision: 22-Jul-2019 3 Document Number: 40065 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

298D, 298W www.vishay.com Vishay Sprague STANDARD RATINGS (298D, 298W Extended Range) MAX. ESR MAX. RIPPLE MAX. DCL MAX. DF CAPACITANCE CASE AT +25 °C 100 kHz PART NUMBER AT +25 °C AT +25 °C (μF) CODE 100 kHz I (μA) (%) RMS () (A) 10 V AT +85 °C; 7 V AT +125 °C - 298D DC DC 10 V AT +40 °C; 6.3 V AT +85 °C; 4.0 V AT +125 °C - 298W DC DC DC 1.0 K 298D105X0010K(2)T 0.5 6 20.00 0.027 1.0 M 298D105(1)010M(2)T 0.5 6 12.00 0.045 1.5 M 298D155(1)010M(2)T 0.5 6 14.00 0.040 2.2 K 298D225X0010K(2)T 2.2 8 15.00 0.027 2.2 M 298D225X0010M(2)T 0.5 10 10.00 0.050 3.3 M 298D335(1)010M(2)T 0.5 8 6.00 0.090 4.7 K 298W475X0010K(2)T 10 50 50.00 0.017 4.7 M 298D475(1)010M(2)T 0.5 6 5.00 0.071 4.7 P 298D475(1)010P(2)T 0.5 6 4.00 0.106 10 M 298D106X0010M(2)T 1.0 20 7.50 0.058 15 M 298D156X0010M(2)T 1.5 30 7.50 0.058 22 M 298D226X0010M(2)T 22 40 10.00 0.050 33 M 298W336X0010M(2)T 66 75 21.00 0.035 33 P 298D336X0010P(2)T 3.3 20 4.00 0.150 47 P 298D476X0010P(2)T 4.7 22 3.00 0.122 100 Q 298W107X0010Q(2)D (1) 100 50 15.00 0.060 16 V AT +85 °C; 10 V AT +125 °C - 298D DC DC 16 V AT +40 °C; 10 V AT +85 °C; 6.3 V AT +125 °C - 298W DC DC DC 1.0 K 298D105X0016K(2)T 1.6 10 20.00 0.027 1.0 M 298D105(1)016M(2)T 0.5 6 12.00 0.045 2.2 K 298W225(1)016K(2)T 10 50 50.00 0.017 2.2 M 298D225(1)016M(2)T 0.5 10 12.00 0.045 4.7 M 298D475X0016M(2)T 0.8 12 12.00 0.046 4.7 P 298D475(1)016P(2)T 0.8 6 4.00 0.106 10 R 298D106(1)016R(2)T 1.6 8 8.00 0.075 20 V AT +85 °C; 13 V AT +125 °C DC DC 0.33 K 298D334(1)020K(2)T 0.5 6 n/a n/a 0.68 M 298D684(1)020M(2)T 0.5 6 20.00 0.042 1.0 S 298D105X0020S(2)T 0.5 6 10.00 0.059 4.7 P 298D475(1)020P(2)T 1.0 6 4.00 0.106 25 V AT +85 °C; 17 V AT +125 °C DC DC 0.68 M 298D684(1)025M(2)T 0.5 6 20.00 0.042 1.0 M 298D105(1)025M(2)T 0.5 6 10.00 0.050 1.0 S 298D105X0025S(2)T 0.5 6 10.00 0.059 1.0 R 298D105(1)025R(2)T 0.5 6 10.00 0.067 4.7 P 298D475(1)025P(2)T 1.2 6 4.00 0.106 10 A 298D106(1)025A(2)T 2.5 10 3.50 0.146 35 V AT +85 °C; 23 V AT +125 °C DC DC 2.2 P 298D225X0035P(2)T 0.8 8 8.00 0.075 50 V AT +85 °C; 33 V AT +125 °C DC DC 1.0 P 298D105X0050P(2)T 0.5 8 8.00 0.075 Notes • Part number definitions: (1) Tolerance: for 10 % tolerance, specify “X9”; for 20 % tolerance, change to “X0” (2) Termination: for 100 % tin specify “2”, for gold plated specify “4” (1) Rating is MSL 3 Revision: 22-Jul-2019 4 Document Number: 40065 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

298D, 298W www.vishay.com Vishay Sprague RECOMMENDED VOLTAGE DERATING (298D) +85 °C RATING +125 °C RATING WORKING VOLTAGE WORKING VOLTAGE (V) (V) 2 1.3 4 2.7 6.3 4 10 7 15 10 16 10 20 13 25 17 35 23 50 33 RECOMMENDED VOLTAGE DERATING (298W) -55 °C/+40 °C RATING +40 °C/+85 °C RATING +85 °C/+125 °C RATING RATED VOLTAGE CATEGORY VOLTAGE CATEGORY VOLTAGE (V) (V) (V) 4 2.5 1.6 6.3 4 2.5 10 6.3 4 16 10 6.3 20 13 8 25 17 10 35 23 14 298W VOLTAGE VS. TEMPERATURE RATING Axis Title 120 10000 100 % 100 % 100 % 100 Rated range %) 80 1000 2nd lined Voltage ( 60 8800 %% 8800 %% 8800 %% 63 %40 % 1st line2nd line e 5500 %% at 40 100 R 298W recommended derating 3333 %% 20 0 10 -55 0 +40 +85 +125 Temperature (°C) Revision: 22-Jul-2019 5 Document Number: 40065 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

298D, 298W www.vishay.com Vishay Sprague STANDARD PACKAGING QUANTITY QUANTITY (pcs/reel) CASE CODE 7" REEL K 5000 M 4000 S 3000 R 2500 P 3000 Q 2500 A 2000 POWER DISSIPATION MAXIMUM PERMISSIBLE CASE CODE POWER DISSIPATION AT +25 °C (W) IN FREE AIR K 0.015 M 0.025 S 0.035 R 0.045 P 0.045 Q 0.055 A 0.075 PRODUCT INFORMATION Micro Guide Pad Dimensions www.vishay.com/doc?40115 Packaging Dimensions Moisture Sensitivity www.vishay.com/doc?40135 Typical Performance Characteristics www.vishay.com/doc?40169 SELECTOR GUIDES Solid Tantalum Selector Guide www.vishay.com/doc?49053 Solid Tantalum Chip Capacitors www.vishay.com/doc?40091 FAQ Frequently Asked Questions www.vishay.com/doc?40110 Revision: 22-Jul-2019 6 Document Number: 40065 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Micro Guide www.vishay.com Vishay Sprague Guide for Leadframeless Molded Tantalum Capacitors INTRODUCTION Rating for rating, tantalum capacitors tend to have as much as three times better capacitance / volume efficiency than Tantalum electrolytic capacitors are the preferred choice in aluminum electrolytic capacitors. An approximation of the applications where volumetric efficiency, stable electrical capacitance / volume efficiency of other types of capacitor s parameters, high reliability, and long service life are primary may be inferred from the following table, which shows the considerations. The stability and resistance to elevated dielectric constant ranges of the various materials used i n temperatures of the tantalum / tantalum oxide / manganes e each type. Note that tantalum pentoxide has a dielectri c dioxide system make solid tantalum capacitors an constant of 26, some three times greater than that of appropriate choice for today’s surface mount assembly aluminum oxide. This, in addition to the fact that extremel y technology. thin films can be deposited during the electrolytic proces s Vishay Sprague has been a pioneer and leader in this field, mentioned earlier, makes the tantalum capacitor extremely producing a large variety of tantalum capacitor types for efficient with respect to the number of microfarads available consumer, industrial, automotive, military, and aerospac e per unit volume. The capacitance of any capacitor i s electronic applications. determined by the surface area of the two conducting Tantalum is not found in its pure state. Rather, it is plates, the distance between the plates, and the dielectric commonly found in a number of oxide minerals, often in constant of the insulating material between the plates. combination with Columbium ore. This combination is known as “tantalite” when its contents are more than one-half tantalum. Important sources of tantalite include COMPARISON OF CAPACITOR DIELECTRIC Australia, Brazil, Canada, China, and several African CONSTANTS countries. Synthetic tantalite concentrates produced from e tin slags in Thailand, Malaysia, and Brazil are also a DIELECTRIC DIELECTRIC CONSTANT significant raw material for tantalum production. Air or Vacuum 1.0 Electronic applications, and particularly capacitors , consume the largest share of world tantalum production . Paper 2.0 to 6.0 Other important applications for tantalum include cuttin g Plastic 2.1 to 6.0 tools (tantalum carbide), high temperature super alloys , Mineral Oil 2.2 to 2.3 chemical processing equipment, medical implants, and Silicone Oil 2.7 to 2.8 military ordnance. Quartz 3.8 to 4.4 Vishay Sprague is a major user of tantalum materials in the Glass 4.8 to 8.0 form of powder and wire for capacitor elements and rod an d sheet for high temperature vacuum processing. Porcelain 5.1 to 5.9 Mica 5.4 to 8.7 THE BASICS OF TANTALUM CAPACITORS Aluminum Oxide 8.4 Most metals form crystalline oxides which are Tantalum Pentoxide 26 non-protecting, such as rust on iron or black oxide on Ceramic 12 to 400K copper. A few metals form dense, stable, tightly adhering, electrically insulating oxides. These are the so-called “valve” In the tantalum electrolytic capacitor, the distance betwee n metals and include titanium, zirconium, niobium, tantalum, the plates is very small since it is only the thickness of the hafnium, and aluminum. Only a few of these permit the tantalum pentoxide film. As the dielectric constant of th e accurate control of oxide thickness by electrochemical tantalum pentoxide is high, the capacitance of a tantalu m means. Of these, the most valuable for the electronic s capacitor is high if the area of the plates is large: industry are aluminum and tantalum. eA C = ------- Capacitors are basic to all kinds of electrical equipment, t from radios and television sets to missile controls and where automobile ignitions. Their function is to store an electrical charge for later use. C= capacitance Capacitors consist of two conducting surfaces, usually e = dielectric constant metal plates, whose function is to conduct electricity. They A= surface area of the dielectric are separated by an insulating material or dielectric. The dielectric used in all tantalum electrolytic capacitors is t = thickness of the dielectric tantalum pentoxide. Tantalum capacitors contain either liquid or solid Tantalum pentoxide compound possesses high-dielectri c electrolytes. In solid electrolyte capacitors, a dry material strength and a high-dielectric constant. As capacitors are (manganese dioxide) forms the cathode plate. A tantalum being manufactured, a film of tantalum pentoxide is applied lead is embedded in or welded to the pellet, which is in turn to their electrodes by means of an electrolytic process. Th e connected to a termination or lead wire. The drawings sho w film is applied in various thicknesses and at various voltage s the construction details of the surface mount types o f and although transparent to begin with, it takes on differen t tantalum capacitors shown in this catalog. colors as light refracts through it. This coloring occurs on the tantalum electrodes of all types of tantalum capacitors. Revision: 10-Mar-2020 1 Document Number: 40115 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Micro Guide www.vishay.com Vishay Sprague SOLID ELECTROLYTE TANTALUM CAPACITORS TANTALUM CAPACITORS FOR ALL DESIGN CONSIDERATIONS Solid electrolyte capacitors contain manganese dioxide , which is formed on the tantalum pentoxide dielectric laye r Solid electrolyte designs are the least expensive for a given by impregnating the pellet with a solution of manganous rating and are used in many applications where their very nitrate. The pellet is then heated in an oven, and the small size for a given unit of capacitance is of importance. manganous nitrate is converted to manganese dioxide. They will typically withstand up to about 10 % of the rated The pellet is next coated with graphite, followed by a laye r DC working voltage in a reverse direction. Also importan t are their good low temperature performance characteristics of metallic silver, which provides a conductive surface between the pellet and the leadframe. and freedom from corrosive electrolytes. Vishay Sprague patented the original solid electrolyt e Molded chip tantalum capacitor encases the element in plastic resins, such as epoxy materials. After assembly, th e capacitors and was the first to market them in 1956. Vishay capacitors are tested and inspected to assure long life an d Sprague has the broadest line of tantalum capacitors an d reliability. It offers excellent reliability and high stability fo r has continued its position of leadership in this field. Data sheets covering the various types and styles of Visha y consumer and commercial electronics with the added feature of low cost. Sprague capacitors for consumer and entertainment electronics, industry, and military applications are availabl e Surface mount designs of “Solid Tantalum” capacitors us e where detailed performance characteristics must be lead frames or lead frameless designs as shown in the specified. accompanying drawings. Side Cathode Termination (-) Epoxy Resin Voltage Code Encapsulation Excluding 0402 (1005 metric) case size Polarity Bar Marking Sintered Tantalum Pellet Side Anode Termination (+) MnO2/Carbon/ Silver Coating Bottom Cathode Termination (-) Silver Adhesive Epoxy Glass Reinforced Bottom Anode Epoxy Resin Termination (+) Fig. 1 - Leadframeless Molded Capacitors, All Types Revision: 10-Mar-2020 2 Document Number: 40115 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

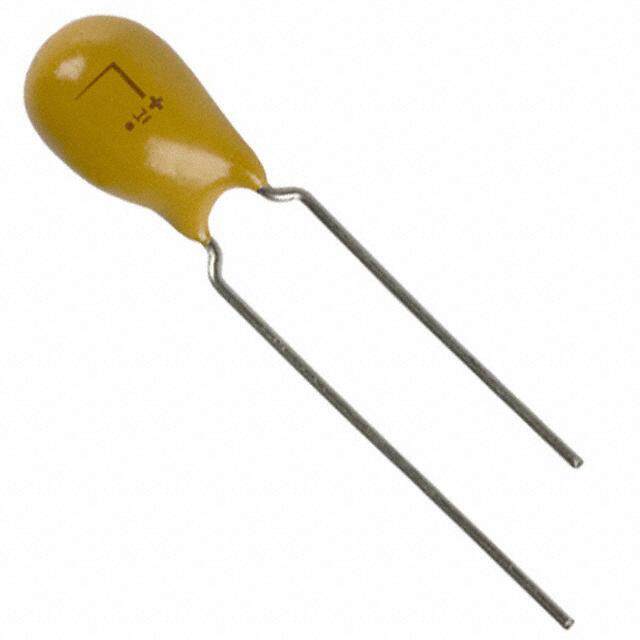

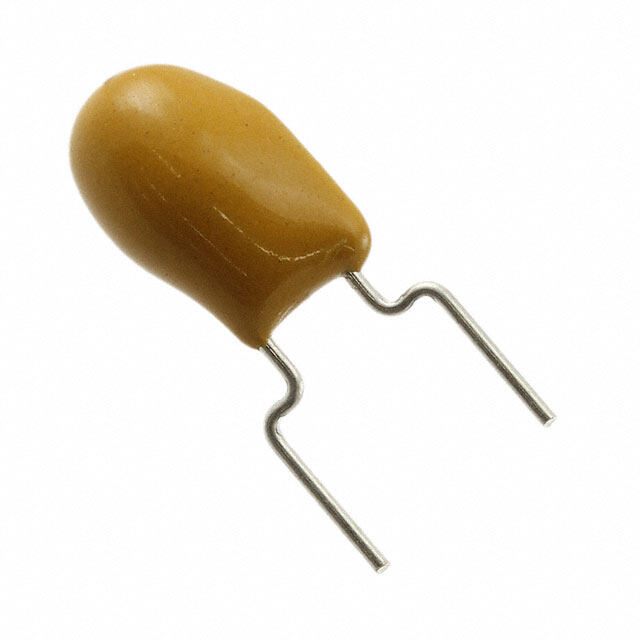

Micro Guide www.vishay.com Vishay Sprague SOLID TANTALUM CAPACITORS - LEADFRAMELESS MOLDED SERIES TL8 298D 298W TR8 PRODUCT IMAGE TYPE Solid tantalum leadframeless molded chip capacitors Small size including 0603 and 0402 foot print FEATURES Industrial grade, Ultra low profile Industrial grade Low ESR extended range Operating Temperature: Operating Temperature: Operating Temperature: Operating Temperature: -55 °C to +125 °C -55 °C to +125 °C -55 °C to +125 °C -55 °C to +125 °C TEMPERATURE RANGE (above 40 °C, voltage (above 85 °C, voltage (above 40 °C, voltage (above 85 °C, voltage derating is required) derating is required) derating is required) derating is required) CAPACITANCE RANGE 0.68 μF to 220 μF 0.33 μF to 220 μF 2.2 μF to 220 μF 1 μF to 220 μF VOLTAGE RANGE 4 V to 25 V 2.5 V to 50 V 4 V to 16 V 2.5 V to 25 V CAPACITANCE TOLERANCE ± 20 %, ± 10 % DISSIPATION FACTOR 6 % to 80 % 6 % to 80 % 30 % to 80 % 6 % to 80 % CASE CODES W9, A0, B0 K, M, R, P, Q, A, S, B K, M, Q M, R, P, Q, A, B TERMINATION 100 % tin 100 % tin or gold plated SOLID TANTALUM CAPACITORS - LEADFRAMELESS MOLDED SERIES TP8 TM8 DLA 11020 T42 PRODUCT IMAGE TYPE Solid tantalum leadframeless molded chip capacitors Built in fuse, Small size including 0603 and 0402 foot print double-stacked FEATURES High performance, High reliability, High reliability, High reliability automotive grade DLA approved ultra-low ESR Operating Temperature: TEMPERATURE RANGE -55 °C to +125 °C (above 85 °C, voltage derating is required) CAPACITANCE RANGE 1 μF to 100 μF 0.68 μF to 47 μF 1 μF to 47 μF 10 μF to 470 μF VOLTAGE RANGE 6.3 V to 40 V 2 V to 40 V 6.3 V to 40 V 16 V to 75 V CAPACITANCE TOLERANCE ± 20 %, ± 10 % DISSIPATION FACTOR 6 % to 30 % 6 % to 20 % 6 % to 8 % 6 % to 15 % CASE CODES M, W, R, P, A, N, T, B K, M, G, W, R, P, A, N, T M, W, R, P, A, N, T M2 Tin / lead solder plated, Tin / lead solder plated Tin / lead solder plated TERMINATION 100 % tin 100 % tin and gold plated or gold plated or 100 % tin Revision: 10-Mar-2020 3 Document Number: 40115 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Micro Guide www.vishay.com Vishay Sprague PLASTIC TAPE AND REEL PACKAGING in inches [millimeters] 0.157 ± 0.004 10 pitches cumulative [4.0 ± 0.10] Tape thickness toler ance on tape Deformation 0.059 + 0.004 - 0.0 ± 0.008 [0.200] between [1.5 + 0.10 - 0.0] Embossment 0.014 embossments 0.079 ± 0.002 0.069 ± 0.004 [0.35] [2.0 ± 0.05] [1.75 ± 0.10] max. Top ctaopveer A0 0.0m30in .[0 (3.7)5] F W 20° B1 (max.) (6) K0 B0 0.030 [0.75] Mcoamxipmounment Top cover min. (4) rotation tape (Side or front sectional view) Center lines P Freofre rteanpcee f eoendlyer 0 . 0 0m4a [x0..10] of cavity 1 D0.10 (7m9i nx. )0 f.o0r4 7c o[2m.0p oxn 1e.n2t]s and l.arger (5) including draft. USER DIRECTION Concentric around B0 (5) OF FEED Mcaavxitimy suimze (1) Cathode (-) Anode (+) DIRECTION OF FEED 3.937 [100.0] 20° maximum component rotation 0.039 [1.0] max. Typical component Tape Tape and Reel Specifications: all case sizes ar e cavity 0.039 [1.0] B0 center line max. available on plastic embossed tape per EIA-481 . 0.9843 [250.0] Standard reel diameter is 7" [178 mm]. Typical Camber component (Top view) A0 center line Allowable camber to be 0.039/3.937 [1/100] (Top view) Non-cumulative over 9.843 [250.0] Notes • Metric dimensions will govern. Dimensions in inches are rounded and for reference only (1) A , B , K , are determined by the maximum dimensions to the ends of the terminals extending from the component body and / or the bod y 0 0 0 dimensions of the component. The clearance between the ends of the terminals or body of the component to the sides and depth of the cavity (A , B , K ) must be within 0.002" (0.05 mm) minimum and 0.020" (0.50 mm) maximum. The clearance allowed must also prevent 0 0 0 rotation of the component within the cavity of not more than 20° (2) Tape with components shall pass around radius “R” without damage. The minimum trailer length may require additional length to provide “R” minimum for 12 mm embossed tape for reels with hub diameters approaching N minimum (3) This dimension is the flat area from the edge of the sprocket hole to either outward deformation of the carrier tape between the embosse d cavities or to the edge of the cavity whichever is less (4) This dimension is the flat area from the edge of the carrier tape opposite the sprocket holes to either the outward deformation of the carrier tape between the embossed cavity or to the edge of the cavity whichever is less (5) The embossed hole location shall be measured from the sprocket hole controlling the location of the embossment. Dimensions of embossment location shall be applied independent of each other (6) B dimension is a reference dimension tape feeder clearance only 1 CARRIER TAPE DIMENSIONS in inches [millimeters] FOR 298D, 298W, TR8, TP8, TL8 CASE CODE TAPE SIZE B (MAX.) (1) D (MIN.) F K (MAX.) P W 1 1 0 1 M (2) 8 mm 0.075 [1.91] 0.02 [0.5] 0.138 [3.5] 0.043 [1.10] 0.157 [4.0] 0.315 [8.0] W 8 mm 0.112 [2.85] 0.039 [1.0] 0.138 [3.5] 0.053 [1.35] 0.157 [4.0] 0.315 [8.0] R 8 mm 0.098 [2.46] 0.039 [1.0] 0.138 [3.5] 0.066 [1.71] 0.157 [4.0] 0.315 [8.0] P 8 mm 0.108 [2.75] 0.02 [0.5] 0.138 [3.5] 0.054 [1.37] 0.157 [4.0] 0.315 [8.0] A 8 mm 0.153 [3.90] 0.039 [1.0] 0.138 [3.5] 0.078 [2.00] 0.157 [4.0] 0.315 [8.0] A0, Q 8 mm - 0.02 [0.5] 0.138 [3.5] 0.049 [1.25] 0.157 [4.0] 0.315 [8.0] B 8 mm 0.157 [4.0] 0.039 [1.0] 0.138 [3.5] 0.087[2.22] 0.157 [4.0] 0.315 [8.0] W9, S 8 mm 0.126 [3.20] 0.029 [0.75] 0.138 [3.5] 0.045 [1.15] 0.157 [4.0] 0.315 [8.0] B0 12 mm 0.181 [4.61] 0.059 [1.5] 0.217 [5.5] 0.049 [1.25] 0.157 [4.0] 0.472 [12.0] Notes (1) For reference only (2) Packaging of M case in plastic tape is available per request Revision: 10-Mar-2020 4 Document Number: 40115 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Micro Guide www.vishay.com Vishay Sprague CARRIER TAPE DIMENSIONS in inches [millimeters] FOR TM8 CASE CODE TAPE SIZE B (MAX.) (1) D (MIN.) F K (MAX.) P W 1 1 0 1 M 8 mm 0.075 [1.91] 0.02 [0.5] 0.138 [3.5] 0.043 [1.10] 0.157 [4.0] 0.315 [8.0] G 8 mm 0.077 [1.96] 0.02 [0.5] 0.138 [3.5] 0.051 [1.30] 0.157 [4.0] 0.315 [8.0] W 8 mm 0.112 [2.85] 0.039 [1.0] 0.138 [3.5] 0.053 [1.35] 0.157 [4.0] 0.315 [8.0] R 8 mm 0.098 [2.46] 0.039 [1.0] 0.138 [3.5] 0.066 [1.71] 0.157 [4.0] 0.315 [8.0] P 8 mm 0.108 [2.75] 0.02 [0.5] 0.138 [3.5] 0.054 [1.37] 0.157 [4.0] 0.315 [8.0] A 8 mm 0.153 [3.90] 0.039 [1.0] 0.138 [3.5] 0.078 [2.00] 0.157 [4.0] 0.315 [8.0] N 12 mm 0.154 [3.90] 0.059 [1.5] 0.216 [5.5] 0.051 [1.30] 0.157 [4.0] 0.472 [12.0] T 12 mm 0.154 [3.90] 0.059 [1.5] 0.216 [5.5] 0.067 [1.70] 0.157 [4.0] 0.472 [12.0] Notes (1) For reference only CARRIER TAPE DIMENSIONS in inches [millimeters] FOR T42 CASE CODE TAPE SIZE B (MAX.) (1) D (MIN.) F K (MAX.) P W 1 1 0 1 M2 16 mm 0.404 [10.3] 0.059 [1.5] 0.295 [7.5] 0.176 [4.5] 0.472 [12.0] 0.630 [16.0] Note (1) For reference only PAPER TAPE AND REEL PACKAGING in inches [millimeters] FOR 298D, 298W, TR8, TP8, TL8, TM8 (K case only) [10 pitches cumulative tolerance on tape ± 0.2 mm] T Ø D0 P2 P0 E1 A0 F Bottom cover W tape Top B0 E2 cover tape Anode P G Bottom cover tape Cavity center lines 1 Cavity size (1) USER FEED DIRECTION CASE TAPE A B D P P P E F W T SIZE SIZE 0 0 0 0 1 2 0.033 ± 0.002 0.053 ± 0.002 0.06 ± 0.004 0.157 ± 0.004 0.078 ± 0.004 0.079 ± 0.002 0.069 ± 0.004 0.0138 ± 0.002 0.315 ± 0.008 0.03 ± 0.002 K 8 mm [0.85 ± 0.05] [1.35 ± 0.05] [1.5 ± 0.1] [4.0 ± 0.1] [2.0 ± 0.1] [2.0 ± 0.05] [1.75 ± 0.1] [3.5 ± 0.05] [8.0 ± 0.2] [0.75 ± 0.05] 0.041 ± 0.002 0.071 ± 0.002 0.06 ± 0.004 0.157 ± 0.004 0.157 ± 0.004 0.079 ± 0.002 0.069 ± 0.004 0.0138 ± 0.002 0.315 ± 0.008 0.037 ± 0.002 M 8 mm [1.05 ± 0.05] [1.8 ± 0.05] [1.5 ± 0.1] [4.0 ± 0.1] [4.0 ± 0.1] [2.0 ± 0.05] [1.75 ± 0.1] [3.5 ± 0.05] [8.0 ± 0.2] [0.95 ± 0.05] Note (1) A , B are determined by the maximum dimensions to the ends of the terminals extending from the component body and / or the body 0 0 dimensions of the component. The clearance between the ends of the terminals or body of the component to the sides and depth of the cavity (A , B ) must be within 0.002" (0.05 mm) minimum and 0.020" (0.50 mm) maximum. The clearance allowed must also prevent rotation 0 0 of the component within the cavity of not more than 20° Revision: 10-Mar-2020 5 Document Number: 40115 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Micro Guide www.vishay.com Vishay Sprague RECOMMENDED REFLOW PROFILES Capacitors should withstand reflow profile as per J-STD-020 standard, three cycles. T P Max. Ramp Up Rate = 3 °C/s tp Max. Ramp Down Rate = 6 °C/s T L t ure TSmax. Preheat Area L at er mp TSmin. e T t S 25 Time 25 °C to Peak Time PROFILE FEATURE SnPb EUTECTIC ASSEMBLY LEAD (Pb)-FREE ASSEMBLY PREHEAT AND SOAK Temperature min. (T ) 100 °C 150 °C Smin. Temperature max. (T ) 150 °C 200 °C Smax. Time (t ) from (T to T ) 60 s to 90 s 60 s to 150 s S Smin. Smax. RAMP UP Ramp-up rate (T to T ) 3 °C/s maximum L p Liquidus temperature (T ) 183 °C 217 °C L Time (t ) maintained above T 60 s to 150 s L L Peak package body temperature (T ) max. 235 °C 260 °C p Time (t ) within 5 °C of the peak max. temperature 20 s 30 s p RAMP DOWN Ramp-down rate (T to T ) 6 °C/s maximum p L Time from 25 °C to peak temperature 6 min maximum 8 min maximum PAD DIMENSIONS in inches [millimeters] D B C A CASE CODE A (NOM.) B (MIN.) C (NOM.) D (MIN.) K 0.021 [0.53] 0.016 [0.41] 0.022 [0.55] 0.054 [1.37] M, G 0.024 [0.61] 0.027 [0.70] 0.025 [0.64] 0.080 [2.03] R, W9, S 0.035 [0.89] 0.029 [0.74] 0.041 [1.05] 0.099 [2.52] W 0.035 [0.89] 0.029 [0.74] 0.037 [0.95] 0.095 [2.41] P 0.035 [0.89] 0.029 [0.74] 0.054 [1.37] 0.112 [2.84] A, Q, A0 0.047 [1.19] 0.042 [1.06] 0.065 [1.65] 0.148 [3.76] B, B0 0.094 [2.39] 0.044 [1.11] 0.072 [1.82] 0.159 [4.03] N, T 0.094 [2.39] 0.044 [1.11] 0.065 [1.65] 0.152 [3.86] M2 0.315 [8.00] 0.098 [2.50] 0.197 [5.00] 0.394 [10.0] Revision: 10-Mar-2020 6 Document Number: 40115 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Micro Guide www.vishay.com Vishay Sprague TYPICAL LEAKAGE CURRENT FACTOR RANGE 100 R + 125 °C O T 10 + 85 °C C A + 55 °C F T + 25 °C N 1.0 RE 0 °C R U C 0.1 GE - 55 °C A K A 0.01 E L 0.001 0 10 20 30 40 50 60 70 80 90 100 PERCENT OF RATED VOLTAGE Notes • At +25 °C, the leakage current shall not exceed the value listed in the Standard Ratings table • At +85 °C, the leakage current shall not exceed 10 times the value listed in the Standard Ratings table • At +125 °C, the leakage current shall not exceed 12 times the value listed in the Standard Ratings table TYPICAL CURVES AT +25 °C, IMPEDANCE AND ESR VS. FREQUENCY “M” Case “M” Case 100 100 IMPEDANCE IMPEDANCE ESR ESR 10 Ω Ω R/Z, 10 R/Z, S S E E 47 μF - 4 V 1 22 μF - 4 V 1 0.1 0.1 1 10 100 1000 0.1 1 10 100 1000 FREQUENCY, kHz FREQUENCY, kHz “M” Case “M” Case 1000 1000 IMPEDANCE IMPEDANCE ESR ESR 100 100 Ω Ω R/Z, R/Z, 10 ES ES 4.7 μF - 10 V 10 1 10 μF - 6 V 1 0.1 0.1 1 10 100 1000 0.1 1 10 100 1000 FREQUENCY, kHz FREQUENCY, kHz Revision: 10-Mar-2020 7 Document Number: 40115 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Micro Guide www.vishay.com Vishay Sprague TYPICAL CURVES AT +25 °C, IMPEDANCE AND ESR VS. FREQUENCY “M” Case “M” Case 1000 10 000 IMPEDANCE IMPEDANCE ESR ESR 1000 100 Ω Ω R/Z, R/Z, 100 S S E E 10 1 μF - 16 V 10 10 μF - 10 V 1 1 0.1 1 10 100 1000 0.1 1 10 100 1000 FREQUENCY, kHz FREQUENCY, kHz “P” CASE “P” CASE 100.0 1000.0 IMPEDANCE IMPEDANCE ESR ESR 100.0 10.0 Ω Ω R/Z, R/Z, 10.0 S S E E 1.0 1.0 4.7 μF - 25 V 33 μF - 10 V 0.1 0.1 0.1 1 10 100 1000 0.1 1 10 100 1000 FREQUENCY, kHz FREQUENCY, kHz “P” CASE “P” CASE 100.0 10.0 IMPEDANCE IMPEDANCE ESR ESR 10.0 Ω Ω R/Z, R/Z, 1.0 S S E E 1.0 47 μF - 10 V 220 μF - 4 V 0.1 0.1 0.1 1 10 100 1000 0.1 1 10 100 1000 FREQUENCY, kHz FREQUENCY, kHz Revision: 10-Mar-2020 8 Document Number: 40115 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Micro Guide www.vishay.com Vishay Sprague GUIDE TO APPLICATION 1. AC Ripple Current: the maximum allowable rippl e 6. Printed Circuit Board Materials: molded capacitor s current shall be determined from the formula: are compatible with commonly used printed circuit board materials (alumina substrates, FR4, FR5, G10, P I = ------------ PTFE-fluorocarbon and porcelanized steel). RMS R ESR 7. Attachment: where, 7.1 Solder Paste: the recommended thickness of the solder paste after application is 0.007" ± 0.001" P = power dissipation in watts at +25 °C (see [0.178 mm ± 0.025 mm]. Care should be exercised i n paragraph number 5 and the table Powe r Dissipation as given in the tables in the selecting the solder paste. The metal purity should product datasheets) be as high as practical. The flux (in the paste) must be active enough to remove the oxides formed on the R = the capacitor equivalent series resistance at ESR metallization prior to the exposure to soldering heat. the specified frequency In practice this can be aided by extending the solder 2. AC Ripple Voltage: the maximum allowable ripple preheat time at temperatures below the liquidous voltage shall be determined from the formula: state of the solder. P 7.2 Soldering: capacitors can be attached b y V = Z ------------ RMS R conventional soldering techniques; vapor phase, ESR convection reflow, infrared reflow, wave soldering and hot plate methods. The Soldering Profile charts or, from the formula: show recommended time / temperature condition s VRMS = IRMS x Z for soldering. Preheating is recommended. The recommended maximum ramp rate is 2 °C per s . where, Attachment with a soldering iron is not recommended due to the difficulty of controllin g P = power dissipation in watts at +25 °C (see paragraph number 5 and the table Powe r temperature and time at temperature. The solderin g Dissipation as given in the tables in the iron must never come in contact with the capacitor . product datasheets) For details see www.vishay.com/doc?40214. R = the capacitor equivalent series resistance at 7.2.1 Backward and Forward Compatibility: capacitor s ESR the specified frequency with SnPb or 100 % tin termination finishes can be soldered using SnPb or lead (Pb)-free soldering Z = the capacitor impedance at the specified frequency processes. 2.1 The sum of the peak AC voltage plus the applied DC 8. Cleaning (Flux Removal) After Soldering: molded voltage shall not exceed the DC voltage rating of the capacitors are compatible with all commonly used capacitor. solvents such as TES, TMS, Prelete, Chlorethane, Terpene and aqueous cleaning media. However, 2.2 The sum of the negative peak AC voltage plus the CFC / ODS products are not used in the production applied DC voltage shall not allow a voltage reversal exceeding 10 % of the DC working voltage at of these devices and are not recommended. +25 °C. Solvents containing methylene chloride or othe r epoxy solvents should be avoided since these will 3. Reverse Voltage: these capacitors are capable of attack the epoxy encapsulation material. withstanding peak voltages in the reverse direction equal to 10 % of the DC rating at +25 °C, 5 % of the 8.1 When using ultrasonic cleaning, the board may DC rating at +25 °C, 5 % of the DC rating at +85 °C , resonate if the output power is too high. This and 1 % of the DC rating at +125 °C. vibration can cause cracking or a decrease in the 4. Temperature Derating: if these capacitors are to be adherence of the termination. DO NOT EXCEED 9W/l operated at temperatures above +25 °C, the at 40 kHz for 2 min. permissible RMS ripple current shall be calculated 9. Recommended Mounting Pad Geometries: proper using the derating factors as shown: mounting pad geometries are essential for successful solder connections. These dimensions TEMPERATURE DERATING FACTOR are highly process sensitive and should be designed +25 °C 1.0 to minimize component rework due to unacceptable +85 °C 0.9 solder joints. The dimensional configurations show n +125 °C 0.4 are the recommended pad geometries for both wav e and reflow soldering techniques. These dimensions 5. Power Dissipation: power dissipation will b e are intended to be a starting point for circuit board affected by the heat sinking capability of th e designers and may be fine tuned if necessary base d mounting surface. Non-sinusoidal ripple current ma y upon the peculiarities of the soldering process and / produce heating effects which differ from those or circuit board design. shown. It is important that the equivalent I value RMS be established when calculating permissible operating levels. (Power Dissipation calculated using +25 °C temperature rise.) Revision: 10-Mar-2020 9 Document Number: 40115 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Typical Performance Characteristics www.vishay.com Vishay Sprague Solid Tantalum Chip Capacitors MICROTAN® Leadframeless Molded Capacitors 298D, 298W, TR8 and TL8 ELECTRICAL PERFORMANCE CHARACTERISTICS ITEM PERFORMANCE CHARACTERISTICS Category temperature range -55 °C to +85 °C (to +125 °C with voltage derating) Capacitance tolerance ± 20 %, ± 10 %, tested via bridge method, at 25 °C, 120 Hz Dissipation factor Limits per Standard Ratings table. Tested via bridge method, at 25 °C, 120 Hz. ESR Limits per Standard Ratings table. Tested via bridge method, at 25 °C, 100 kHz. Leakage current After application of rated voltage applied to capacitors for 5 min using a steady source of power with 1 k resistor in series with the capacitor under test, leakage current at 25 °C is not more than described in Standard Ratings table. Note that the leakage current varies with temperature and applied voltage. See graph below for the appropriate adjustment factor. Reverse voltage Capacitors are capable of withstanding peak voltages in the reverse direction equal to: 10 % of the DC rating at +25 °C 5 % of the DC rating at +85 °C 1 % of the DC rating at +125 °C Vishay does not recommend intentional or repetitive application of reverse voltage. Ripple current and For maximum permissible ripple current (IRMS) or/and voltage (VRMS) please refer to product datasheet Temperature derating and Guide to Application. If capacitors are to be used at temperatures above +25 °C, the permissible RMS ripple current or voltage shall be calculated using the derating factors: 1.0 at +25 °C 0.9 at +85 °C 0.4 at +125 °C Maximum operating voltage 298W AND TL8 CATEGORY VOLTAGE (V) RATED VOLTAGE AT TEMPERATURE RANGE (V) -55 °C to +40 °C +40 °C to +85 °C -85 °C to +125 °C 4.0 4.0 2.5 1.6 6.3 6.3 4.0 2.5 10 10 6.3 4.0 16 16 10 6.3 20 20 13 8 25 25 17 10 35 35 23 14 298D AND TR8 CATEGORY VOLTAGE (V) RATED VOLTAGE AT TEMPERATURE RANGE (V) -55 °C to +85 °C +85 °C to +125 °C 2.5 2.5 1.7 4.0 4.0 2.7 6.3 6.3 4.0 10 10 7.0 16 16 10 20 20 13 25 25 17 35 35 23 50 50 33 Revision: 20-Jan-14 1 Document Number: 40169 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Typical Performance Characteristics www.vishay.com Vishay Sprague TYPICAL LEAKAGE CURRENT FACTOR RANGE 100 +125 °C +85 °C ctor 10 +55 °C a nt F 1.0 +25 °C urre 0 °C C e 0.1 g a -55 °C k a e L 0.01 0.001 0 10 20 30 40 50 60 70 80 90 100 Percent of Rated Voltage Notes • At +25 °C, the leakage current shall not exceed the value listed in the Standard Ratings table. • At +85 °C, the leakage current shall not exceed 10 times the value listed in the Standard Ratings table. • At +125 °C, the leakage current shall not exceed 12 times the value listed in the Standard Ratings table. ENVIRONMENTAL PERFORMANCE CHARACTERISTICS ITEM CONDITION POST TEST PERFORMANCE Thermal shock At -55 °C/+125 °C, 30 min each, for 5 cycles. Capacitance change ± 30 % MIL-STD-202 method 107 Dissipation factor Not to exceed 150 % of initial Leakage current Not to exceed 200 % of initial Surge voltage 85 °C, 1000 successive test cycles at 1.3 of category Capacitance change ± 30 % voltage in series with a 1 k resistor at the rate of Dissipation factor Not to exceed 150 % of initial 30 s ON, 30 s OFF, MIL-PRF-55365 Leakage current Not to exceed 200 % of initial Life test at +85 °C 1000 h application of category voltage at 85 °C with Capacitance change ± 30 % a 3 series resistance, MIL-STD-202 method 108 Dissipation factor Not to exceed 150 % of initial Leakage current Not to exceed 200 % of initial Humidity test At 40 °C/90 % RH 500 h, no voltage applied. Capacitance change ± 30 % MIL-STD-202 method 103 Dissipation factor Not to exceed 150 % of initial Leakage current Not to exceed 200 % of initial MECHANICAL PERFORMANCE CHARACTERISTICS ITEM CONDITION POST TEST PERFORMANCE Terminal strength/ Apply a pressure load of 5 N for 10 s ± 1 s There shall be no visual damage when viewed at 20 x Shear stress test horizontally to the center of capacitor side body. magnification and the component shall meet the original AEC-Q200-006 electrical requirements. Vibration MIL-STD-202, method 204, condition D, There shall be no mechanical or visual damage to 10 Hz to 2000 Hz, 20 g peak capacitors post-conditioning. Shock MIL-STD-202, method 213, condition I, Capacitance change ± 30 % (specified pulse) 100 g peak Dissipation factor Initial specified value or less Leakage current Initial specified value or less There shall be no mechanical or visual damage to capacitors post-conditioning. Resistance MIL-STD-202, method 210, condition K Capacitance change ± 30 % to solder heat Dissipation factor Not to exceed 150 % of initial Leakage current Not to exceed 200 % of initial There shall be no mechanical or visual damage to capacitors post-conditioning. Solderability MIL-STD-202, method 208, ANSI/J-STD-002, test B. All terminations shall exhibit a continuous solder coating Applies only to solder and tin plated terminations. free from defects for a minimum of 95 % of the critical area Does not apply to gold terminations. of any individual lead. Resistance to solvents MIL-STD-202, method 215 Marking has to remain legible, no degradation of encapsulation material. Flammability Encapsulation materials meet UL 94 V-0 with an oxygen index of 32 % Note • All measurements to be performed after 24 h conditioning at room temperature. Revision: 20-Jan-14 2 Document Number: 40169 For technical questions, contact: tantalum@vishay.com THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice www.vishay.com Vishay Disclaimer ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROV E RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE. Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively, “Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other disclosure relating to any product. Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose o r the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special, consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular purpose, non-infringement and merchantability. Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of typical requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements about the suitability of products for a particular application. It is the customer’s responsibility to validate that a particular product with the properties described in the product specification is suitable for use in a particular application. Parameters provided in datasheets and / or specifications may vary in different applications and performance may vary over time. All operating parameters, including typical parameters, must be validated for each customer application by the customer’s technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase, including but not limited to the warranty expressed therein. Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustainin g applications or for any other application in which the failure of the Vishay product could result in personal injury or death. Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk . Please contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this documen t or by any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners. © 2019 VISHAY INTERTECHNOLOGY, INC. ALL RIGHTS RESERVED Revision: 01-Jan-2019 1 Document Number: 91000

Datasheet下载

Datasheet下载