ICGOO在线商城 > 0638019200

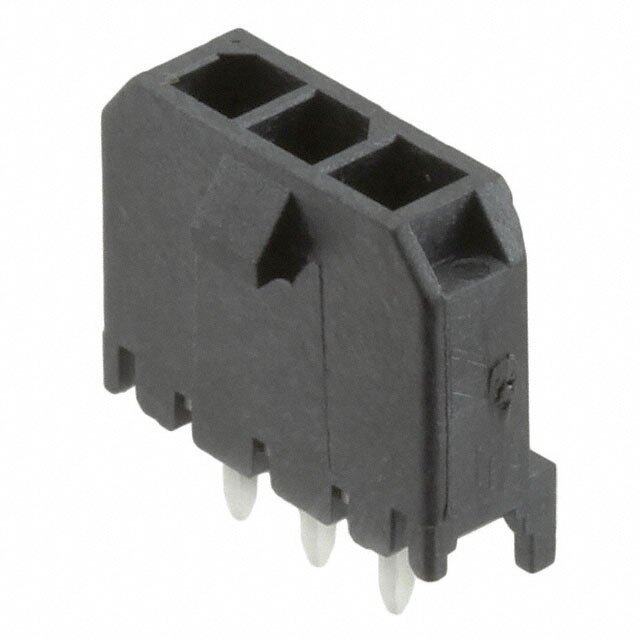

- 型号: 0638019200

- 制造商: Molex

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

0638019200产品简介:

ICGOO电子元器件商城为您提供0638019200由Molex设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 提供0638019200价格参考以及Molex0638019200封装/规格参数等产品信息。 你可以下载0638019200参考资料、Datasheet数据手册功能说明书, 资料中有0638019200详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | TOOL WIRE STRIPPER 10AWG-32AWG |

| 产品分类 | |

| 品牌 | Molex Inc |

| 数据手册 | |

| 产品图片 |

|

| 产品型号 | 0638019200 |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | WS-1000 |

| 其它名称 | 063801-9200 |

| 标准包装 | 1 |

| 特性 | 可调带长 |

| 特色产品 | http://www.digikey.cn/product-highlights/cn/zh/molex-application-tooling/4157 |

| 电缆类型 | 10~32 AWG |

| 类型 | 气动式剥线机 |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

Pneumatic Bench Top Wire Stripping Machine WS-1000 Pneumatic Bench Top Wire Stripping Machine Operation Manual Order No. 63801-9200 (AWG wire) Order No. 63801-9250 (Metric wire) (cid:1) Description (cid:1) Operation (cid:1) Maintenance Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 1 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine Safety Warnings and Information Read and understand all of the instructions and safety information in this manual before operating or servicing this tool. Keep this manual available when using this tool. Replacement manuals are available at www.molex.com. SAFETY ALERT SYMBOL This symbol is used to call your attention to hazards or unsafe practices which could result in an injury or property damage. The signal word, defined below, indicates the severity of the hazard. The message after the signal word provides information for preventing or avoiding the hazard. DANGER: Indicates an imminently hazardous situation which, if not avoided, could result in death or serious injury. DANGER WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury. WARNING CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. CAUTION may also be used to alert against unsafe practices associated with events that could lead CAUTION to personal injury. WARNING WARNING Never use this machine without safety devices Always wear proper eye protection when that are intended to prevent hands from remaining Operating or servicing this tool. in the tool. Failure to wear eye protection could result Failure to observe this warning could in serious eye injury from flying debris during test. result in severe injury or death. WARNING WARNING Do not use compressed air to clean Never operate, service, install, or adjust this the equipment. The forces created by equipement without proper instruction and without compressed air can force debris into the tool. first reading and understanding the instructions in this manual and all applicable press and/or Failure to observe these precautions may wire processing machine manuals. result in injury or property damage. CAUTION Never perform any service or maintenance other than as described in this manual. Never modify, alter or misuse the equipment Molex crimp specifications are valid only when used with Molex terminals and tooling. Failure to observe this precaution may result in injury and / or property damage. Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 2 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine WARNING THE PNEUMATIC BENCH TOP WIRE STRIPPING MACHINE IS NOT INTENDED FOR THE PROCESSING OF MATERIALS OTHER THAN THOSE NORMALLY USED IN INSULATION AND JACKET MATERIALS FOR WIRES AND ELECTRICAL CONDUCTORS. THE PNEUMATIC BENCH TOP WIRE STRIPPING MACHINE IS ALSO NOT INTENDED FOR THE PROCESSING OF MASSIVE SHIELDS MADE OF COPPER OR HARDER MATERIALS, STEEL WIRE NETWORKS ETC. Tooling Technical Assistance Molex offers tooling technical assistance for customers who may need some guidance for tooling adjustments. This support can be obtained by calling either of the two numbers listed below and asking for the Molex Tooling Group. Call Toll Free 1-800-786-6539 (US) 1-630-969-4550 (Global). This assistance is limited to the operation and set-up of a customer’s Molex tool. Questions with regard to Molex connector products or how to identify the proper tooling and/ or tooling documentation should be directed to your local Molex personnel or Customer Service Representative. When calling for service on the Pneumatic Bench Top Stripping Machine it is recommended to have the following: a copy of the Operation Manual and a person familiar with the press should be present. The following information is also recommended to supply: 1. Customer name 2. Customer address 3. Person to contact such as (name, title, e-mail, and telephone number) 4. Urgency of request 5. Nature of problem Molex Application Tooling Group 2200 Wellington Court Lisle, IL 60532, USA Tel: +1 (630) 969-4550 Fax:+1 (630) 505-0049 Visit our Web site at http://www.molex.com Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 3 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine Table of Contents WS-1000 ............................................................................................................................................................................... 1 Pneumatic Bench Top Wire Stripping Machine ..................................................................................................................... 1 Safety Warnings and Information .......................................................................................................................................... 2 Tooling Technical Assistance ............................................................................................................................................ 3 Section 1 ............................................................................................................................................................................... 5 General Description .......................................................................................................................................................... 5 Principal Mechanical Parts of the WS-1000 (63801-9200 / 63801-9250) .......................................................................... 6 General Description .......................................................................................................................................................... 7 1.1 Description (See Figure 1-1).................................................................................................................................. 7 1.2 Features ................................................................................................................................................................ 7 1.3 Technical Specification .......................................................................................................................................... 7 1.4 Delivery Check ...................................................................................................................................................... 7 1.5 Tools ...................................................................................................................................................................... 7 Section 2 ............................................................................................................................................................................... 8 Set-Up and Adjustments ................................................................................................................................................... 8 2.1 Set-up .................................................................................................................................................................... 9 Air Supply Hook-Up ...................................................................................................................................................... 9 Safety Devices .............................................................................................................................................................. 9 2.2. Operation ............................................................................................................................................................. 10 2.3. Adjustments ............................................................................................................................................................. 10 2.4. Installing and Replacing Blades ........................................................................................................................... 11 2.5 Adjustment of the Brakes .................................................................................................................................... 12 Section 3 ............................................................................................................................................................................. 13 Maintenance ................................................................................................................................................................... 14 3.1 Cleaning .............................................................................................................................................................. 14 3.2 Lubrication ........................................................................................................................................................... 14 3.3 Perishable Parts .................................................................................................................................................. 15 3.4 Spare Parts ......................................................................................................................................................... 15 3.5 Storage ................................................................................................................................................................ 15 Section 4 ............................................................................................................................................................................. 16 4.1 Main Parts List ..................................................................................................................................................... 17 Assembly Drawing .......................................................................................................................................................... 19 4.2.1 Troubleshooting ............................................................................................................................................... 20 Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 4 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine Section 1 General Description 1.1 Description 1.2 Features 1.3 Technical Specifications 1.4 Delivery Check 1.5 Tools Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 5 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine Principal Mechanical Parts of the WS-1000 (63801-9200 / 63801-9250) FILTER REGULATOR GAUGE HOOK UP ADJUSTING WHEEL FOR CABLE CROSS SECTION SAFETY COVER WIRE / CABLE ADJUSTING WHEEL FOR BLADES STRIP LENGTH ADJUSTING SCREW FOR Figure 1-1 STRIP AND RETAIN Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 6 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine General Description Operating Parameters Cycle Time 0.5 seconds 1.1 Description (See Figure 1-1) Operating Air Pressure 3 to 6 bar (43 to 87psi ) The WS-1000 Pneumatic Bench Top Wire Stripping maximum 6 bar (87psi) Machine, Order no. 63801-9200 for AWG wire and Air Consumption per cycle 63801-9250 for metric wire, is a semi-automatic, 0.15l (0.005 cubic feet) pneumatic table instrument for the stripping of Sound Level cables and wires with insulations of different natural < 70 dB(A) and synthetic materials, such as; rubber, PUR, Cable Teflon etc. Round cables up to 5.0mm (.196") O.D. Cross section from 0.15 - 4mm² (26 - 12 AWG) The use of special blades, adapted to the cable to Flat cables up to 8mm wide (.315") be processed, allows the processing of nearly all Partial stroke from 1.0 – 15.0mm (0.04 – 0.59") common round and flat cables. Stripping length of 1.5-15.0mm (.06 - .59”) (total stripping) The Pneumatic Bench Top Wire Stripping Machine Removal length of 0 – 15.0mm (0 - .59”) can handle extremely short wire leads, less than 9mm in length. It can adjust to change wire strip Safety covers Order No. diameter settings, easily without tools, to process a Standard. 63801-9228 full range of wire sizes. The V-shaped blades can 4.0mm (.157”) maximum insulation diameter be adjusted for the full range of wire sizes, quickly in seconds, without tools, for quick production run Cover with safety collar (optional) changeouts. Self-centering clamping jaws and 63801-9229 release sensors ensure high quality strips, safely 8.0mm (.315”) maximum insulation diameter and efficiently. 1.4 Delivery Check 1.2 Features Carefully remove Wire Stripping Machine from (cid:1) Extremely short stranded wire ends can be its shipping container and determine that the processed (distance cover to stripping blades following items are included in the package. <= 9 mm) (cid:1) Exact parallel guide of the blade heads Description Quantity (cid:1) Processing with die-blades, prismatic blades 63801-92*0 Pneumatic Bench Top Wire and flat stripping blades Stripping Machine 1 (cid:1) Blade change within seconds and without tools 63801-9243 Hex Wrench 5mm 1 (cid:1) Sensor release of the stripping process 63801-9271 pair of prismatic blades (cid:1) Self-centering clamping jaws (installed at the factory) 1 (cid:1) Air blow-out 63801-9230 pair of rubber pads (cid:1) Guard cover for safety for clamping jaws 1 (cid:1) Putting in the cable from above 63801-9201 Air regulator & shut-off assy 1 TM-638019200 Instruction Manual 1 1.3 Technical Specification 1.5 Tools Dimensions The following tools are recommended for setup Width 95.0mm (3.74”) and adjustments. Depth 280.0mm (11.02“) (cid:2) Metric standard hex wrench set Height 165.0mm (6.50”) (cid:2) Adjustable wrench Weight 4.3kg (9.5lbs) (cid:2) Wire stripper / cutter Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 7 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine Section 2 Set-Up and Adjustments 2.1 Setup 2.2 Operation 2.3 Adjustments 2.4 Installing and Replacing Blades 2.5 Adjustment of the Brakes Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 8 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine 2.1 Set-up Caution: Always disconnect the air pressure until the system is ready to operate. Note: Detail nos. in parenthesis ( ) are shown on the Assembly Drawing in Section 5. These are not order nos. Air Supply Hook-Up 1. Read the following instructions before attempting to operate the tool. 2. An Air Regulator assembly, order no. 63801-9201, is included with this tool. It includes a filter / regulator unit with air shut-off and supply hose. Connect the assembly to the back panel of the machine, with the two included cap screws. See Figure 2-1. 3. Adjust the regulator to an operating pressure of 3 - 6 bar (43 – 87 PSI). The maximum operating pressure is 6 bar (87 PSI). Operating the tool above the maximum pressure may cause injury or damage to the tool. 4. Before using the machine, make sure the clear plastic safety cover is installed. Figure 2-1 Safety Devices The WS-1000 Bench Top Wire Stripping Machine is equipped with all necessary safety devices. However, no system can be completely protected against misuse. All changes and amendments not made by the manufacturer, or other modifications that are not granted in writing by the manufacturer, will void all guarantees and liability claims. When the safety cover is removed a safety switch will prevent the machine from operating. The clear plastic safety cover supplied with the unit, order no. 63801-9228 (028.0071), is for cable or wire insulation outer diameters up to 4.0mm. In addition to the standard safety cover, an optional safety cover, order no. 63801-9229 (028.0072), is available for cable or wire insulation outer diameters over 4.0mm. The safety cover protects the operator from the hazardous area of the Wire Stripping Machine. Please check regularly that the safety cover functions correctly by unscrewing the safety cover's two knurled screws, and sliding the cover forward (towards the operator) Note: If the machine works correctly, the safety switch will interrupt the air supply and the machine will not function. If the safety device does not function properly, operation of the machine should be avoided until the safety switch is repaired. Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 9 of 21 Revision: C Revision Date: 07-12-16

ADJUSTING WHEEL Figure 2-3

Pneumatic Bench Top Wire Stripping Machine 2. Stripping length (See Figure 2-4) The desired stripping length 1.5 – 15.0mm (.059” to .590”) is adjusted with the adjusting wheel (028.0046) on the right side of the machine in increments of 0.5mm. Note: The middle scale line is valid when using the Prismatic Blades. The front and rear scale lines are used when using the Flat Blades; The front line is used when the draft angle of the flat blade is facing out and the rear scale line is used when the draft angle of the Flat Blade is facing in (not visible) 3. Removal length / Partial stroke (See Figure 1-1) The removal length also can be adjusted as required, (from 0 – ADJUSTING 15.0mm). This is done by using a 5mm hex wrench to adjust the WHEEL screw (028.0041), located through the hole on the lower left side of Figure 2-4 the front plate. 2.4. Installing and Replacing Blades This machine will accomadate 2 different interchangable blade sets. The 63801-9200 includes the standard prismatic blades, order no. 63801-9271. There are also optional flat stripping bades available, order no. 63801- 9272. Follow the steps below to install and replace them. Figure 2-5 63801-9271 PRISMATIC BLADES 63801-9272 FLAT STRIPPING BLADES 1. Remove the safety cover. This is done by loosening (2) knurled screws on each side of the cover and then sliding the cover forward, up and off the machine. 2. Push back the guide pin on the swing lever that is located behind each blade holder, (one side at a time) and pull out the blade from the side. See Figure 2.6. 3. Make sure that the guide slots are clean and free of debris. 4. To Install new blades, push back the guide pin and slide in the blade until the blade clicks onto the guide pin. Make sure that the guide pins catch in the corresponding holes of the blades. See Figure 2-7. GUIDE PINS PUSH BACK GUIDE PIN PUSH IN THE BLADE Figure 2-7 Figure 2-6 Note: The prismatic blades must be installed so they overlap when closed. Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 11 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine 2.5 Adjustment of the Brakes The correct function of this machine is dependent on two adjustable brakes. Improper adjustment or wear of the brakes can influence the function of the machine and cause faulty stripping results. The following two malfunctions are possible, due to improperly adjusted brakes: 1. The blades move together before the clamp jaws close - this means that the cable is not sufficiently clamped and centered. Correction: The brake, below the cylinder (028.6001), requires readjustment: 1. Unscrew the button head screw (028.8033) on the side plate (028.0002). 2. Turn the screw, located behind the side plate (028.0002), with a 3mm hex wrench, approximately 1 to 3 turns clockwise (CW). 3. This tightens the brake and increases the brake power. 2. The slide blade head (028.0014) with blade holder and blade moves back before the blades have moved together – this means that the insulation is removed too late or not at all. Caution: Before re-adjusting the brake always disconnect the compressed air from the machine. Correction: The brake (028.0040) requires readjustment. 1. Remove the compressed air supply from the machine. 2. Unscrew the cover (028.5001). 3. Turn the screw (009.8050) with a 3mm hex wrench approximately 1 to 3 turns clockwise (CW). 4. Check the correct brake adjustment by pushing back (machine should have no compressed air) the cylinder (028.6001) manually on the unscrewed carrier . The blades will first move together. Then, the cone (028.0053) must move with its binding face against the adjusting screw (028.0036). Finally, it pulls back the complete slide (blade head 028.0014) with blade holders and the blades. 5. In an opposite movement, the slide (blade head 028.0014) is pulled towards the front plate (028.0001). The blades first have to open before the slide (028.0014) moves. Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 12 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine Section 3 Maintenance 3.1 Cleaning 3.2 Lubrication 3.3 Perishable Parts 3.4 Spare Parts 3.5 Storage Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 13 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine Maintenance CAUTION: Always disconnect the compressed air supply before all maintenance In order to insure the best operating condition and machine safety, a regular inspection of all relevant parts and functions should be done, appropriate to the frequency of their use. 3.1 Cleaning See Chart for recommended Preventive Maintenance Schedule. An example of a maintenance chart is shown below. Copy and use this chart to track the maintenance of your machine or use this as a template to create you own schedule or use your company’s standard chart, if applicable. The following applies to this machine with tooling installed. 1. For efficient operation, the tooling should be cleaned daily with a soft bristle brush to remove any debris from the tooling area. 2. All hose connections must be free of grit and grime. 3. Machine interior: From time to time, the working area of the machine should be cleaned with a soft brush. An intermediate cleaning is recommended in case of considerable dirt due to talcum and stripping scrap. Make sure that there are no foreign parts or liquids getting into the case openings. 4. When it is necessary to change the tooling, care should be taken to remove any debris from tapped holes or mounting surfaces. Debris can prevent tooling from being properly locked into position. 5. All rotating and other movable elements are equipped with antifriction bearings or maintenance-free slide bearings. These parts are adequately lubricated and do not require any further maintenance. CAUTION: Using compressed air to clean tooling is not recommended. Chips can wedge in the tooling and/or fly at an operator. 3.2 Lubrication Pneumatics All control valves and cylinders have been adequately lubricated with pneumatic oil, and therefore, do not require any further maintenance. Filter-Regulator It will be necessary to check the filter bowl at least once a month, depending on how dirty the air supply is, and empty as required. Preventive Maintenance Chart Daily: Clean. See Section 4.1. Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 14 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine CHECK SHEET MONTH YEAR _________ Days of the Week Week Daily Use Solution MON TUE WED THU FRI SAT SUN 1 2 3 4 Bleeding Air From Run the system thru After prolong use the System several cycles. Hose connections free of grit Cleaning Use soft cloth and dirt. Schedule should be adjusted up or down depending on usage. Molex recommends that a log of preventive maintenance be kept with the tool. 3.3 Perishable Parts Customers are responsible for maintaining the Pneumatic Bench Top Wire Stripping Machine. Perishable parts are those parts that come in contact with the product and will wear out over time. Molex recommends that all customers keep at least one set of the perishable parts in stock at all times. This will reduce the amount of production down time. 3.4 Spare Parts Customers are responsible for maintaining the The Pneumatic Bench Top Wire Stripping Machine. Spare parts are available. Moving and functioning parts can be damaged or wear out over time and will require replacement. Molex recommends that the customer keep some or all of them in stock to reduce production down time. These parts are identified in the Parts List. See Section 5. 3.5 Storage When storing the WS-1000 Pneumatic Bench Top Wire Stripping Machine, disconnect the air supply and store in a dry location. Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 15 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine Section 4 Parts List, Assembly Drawings and Troubleshooting 4.1. Parts Lists and Assembly Drawings 4.2. Troubleshooting Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 16 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine 4.1 Main Parts List WS-1000 Pneumatic Bench Top Wire Stripping Machine (63801-9200 or 36801-9250) RSP / PP Parts Order No Detail No Description Quantity and Notes 63801-9201 Not shown Filter Regulator and shut-off valve assy Pneumatic parts 1 63801-9202 003.6027 Micro Ram Valve Pneumatic parts 1 63801-9203 009.8050 Screw 3 63801-9204 028.0001 Front Plate 1 63801-9205 028.0002 Side Plate (Right) 1 63801-9206 028.0003 Side Plate (Left) 1 63801-9207 028.0004 Back Plate 1 63801-9208 028.0005 Bottom Plate 1 63801-9209 028.0010 Clamp Jaw, Right 1 63801-9210 028.0011 Clamp Jaw, Left 1 63801-9211 028.0014 Blade Head 1 63801-9212 028.0015 Adjusting Wheel (metric wire sizes) On 63801-9250 1 63801-9213 028.0017 Sleeve 1 63801-9214 028.0025 Sensor Fork 1 63801-9215 028.0028 Waste Shaft 1 63801-9216 028.0034 Pipe For Sensor 1 63801-9217 028.0035 Sensor 1 63801-9218 028.0036 Adjusting Screw 1 63801-9219 028.0037 Rubber For Ram 1 63801-9220 028.0038 Swing Pin 2 63801-9221 028.0040 Brake 1 63801-9222 028.0041 Screw 1 63801-9223 028.0046 Adjusting Wheel 1 63801-9224 028.0053 Cone 1 63801-9225 028.0054 Pedestal 2 63801-9226 028.0055 Conus Guide 1 63801-9271 028.0060 Prismatic Blades, Pair PP 1 63801-9272 028.0063 Flat Stripping Blades, Pair PP Optional part 0 63801-9227 028.0064 Centering Piece 1 63801-9228 028.0071 Safety Cover, Standard RSP 1 63801-9229 028.0072 Safety Cover 8mm Optional part 1 63801-9230 028.0075 Pair Of Rubber Pads For Clamping Jaws RSP Accessories REF 1 63801-9231 028-0083 Adjusting Wheel (AWG) On 63801-9200 1 63801-9232 028.5001 Cover 1 63801-9233 028.6001 Short Stroke Cylinder Pneumatic parts 1 63801-9234 028.6002 5/2 Sliding Valve Pneumatic parts 1 63801-9235 028.6034 Throttle Return Stroke Valve Pneumatic parts 1 63801-9236 028.8004 Grooved Ball Bearing 2 63801-9237 028.8005 Grooved Ball Bearing 2 63801-9238 028.8007 DU-Sleeves 4 63801-9239 028.8008 Sleeve (Sinter Bronze) 1 Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 17 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine WS-1000 Pneumatic Bench Top Wire Stripping Machine (63801-9200 or 36801-9250) RSP / PP Parts Order No Detail No Description Quantity and Notes 63801-9240 028.8012 Guide Pins 2 63801-9241 028.8013 Swing Levers 2 63801-9242 028.8023 Sleeve (Sinter Bronze) 2 63801-9243 028.8025 Hexagon Socket Wrench 5mm Accessories REF 1 63801-9244 028.8033 Button Head Screw 1 63801-9245 028.8034 High-Grade Steel Strand 1 63801-9246 001.8010 Rubber Foot 4 63801-9247 028.5002 Lower Cover 1 63801-9248 028.8031 Compression Spring 2 63801-9249 028.8017 Extension Spring 2 63801-9253 028.8018 Extension Spring 1 63801-9251 028.8016 Compression Spring 2 63801-9252 028.8049 Compression Spring 1 RSP - Part is a Molex Recommended Spare Part. PP - Part is a Perishable Part. Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 18 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine Assembly Drawing Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 19 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine 4.2.1 Troubleshooting Symptom (cid:1) Cause Solution Blades do not open. (cid:1) Blade guide is dirty. Clean blade head. Insulation is cut improperly. (cid:1) Dull blades. Install new blades Machine has excessive air leaking (cid:1) Safety switch is not pressed in far Push safety cover around the safety cover. enough by the safety cover. towards the front plate The cable is not sufficiently See Section 3.5 (cid:1) Worn or improperly adjusted brakes. clamped and centered. Adjustment of the Brakes The insulation is removed too late See Section 3.5 (cid:1) Worn or improperly adjusted brakes or not at all. Adjustment of the Brakes (cid:1) Cable scrap between clamp jaws Clamp jaws do not open. Remove cable scrap. and safety cover. CAUTION: Molex tooling crimp specifications are valid only when used with Molex terminals and tooling manufactured by Molex and sold by Molex or authorized distributors ("Molex Tooling"). When using tooling other than Molex Tooling with Molex specific connector systems listed in our ATS documents, the Molex tooling qualification does not apply and the responsibility for full CAUTION qualification of the connector system is that of the customer. Molex accepts no liability for connector performance or tooling support where tooling other than Molex Tooling is used or where Molex Tooling is modified. Application Tooling Support 2200 Wellington Court Lisle, IL 60532 USA Phone: +1-402-458-TOOL (8665) E-mail: applicationtooling@molex.com Visit our Website at www.molex.com/applicationtooling Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 20 of 21 Revision: C Revision Date: 07-12-16

Pneumatic Bench Top Wire Stripping Machine Order No: TM-638019200 Release Date: 10-01-09 UNCONTROLLED COPY Page 21 of 21 Revision: C Revision Date: 07-12-16

Datasheet下载

Datasheet下载