ICGOO在线商城 > 连接器,互连器件 > 端子 - PC 引脚插座,插座连接器 > 0342-0-15-15-42-27-10-0

- 型号: 0342-0-15-15-42-27-10-0

- 制造商: Mill-Max

- 库位|库存: xxxx|xxxx

- 要求:

| 数量阶梯 | 香港交货 | 国内含税 |

| +xxxx | $xxxx | ¥xxxx |

查看当月历史价格

查看今年历史价格

0342-0-15-15-42-27-10-0产品简介:

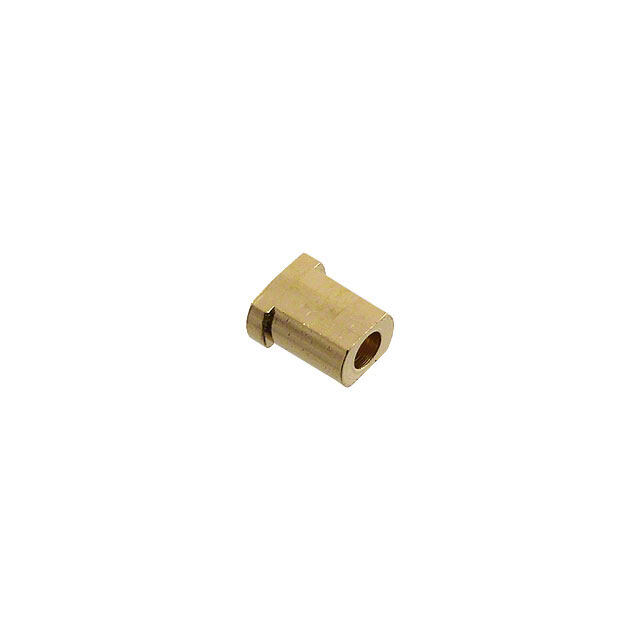

ICGOO电子元器件商城为您提供0342-0-15-15-42-27-10-0由Mill-Max设计生产,在icgoo商城现货销售,并且可以通过原厂、代理商等渠道进行代购。 0342-0-15-15-42-27-10-0价格参考¥2.74-¥5.76。Mill-Max0342-0-15-15-42-27-10-0封装/规格:端子 - PC 引脚插座,插座连接器, Pin Receptacle Connector 0.059" ~ 0.063" (1.50mm ~ 1.60mm) No Tail Press-Fit, Hex。您可以下载0342-0-15-15-42-27-10-0参考资料、Datasheet数据手册功能说明书,资料中有0342-0-15-15-42-27-10-0 详细功能的应用电路图电压和使用方法及教程。

| 参数 | 数值 |

| 产品目录 | |

| 描述 | CONN PRESS-FIT RECEPTACLE 6.1MM |

| 产品分类 | |

| 品牌 | Mill-Max Manufacturing Corp. |

| 数据手册 | |

| 产品图片 | |

| 产品型号 | 0342-0-15-15-42-27-10-0 |

| rohs | 无铅 / 符合限制有害物质指令(RoHS)规范要求 |

| 产品系列 | 342 |

| 产品培训模块 | http://www.digikey.cn/PTM/IndividualPTM.page?site=cn&lang=zhs&ptm=22027 |

| 其它名称 | 3.42015E+14 |

| 包装 | 散装 |

| 可接受的引脚直径 | 0.059" ~ 0.063"(1.50mm ~ 1.60mm) |

| 安装孔直径 | 0.090"(2.29mm) |

| 工作温度 | -55°C ~ 125°C |

| 引脚孔直径 | - |

| 插入力 | 20.0Nm |

| 插座深度 | 0.210"(5.33mm) |

| 板厚度 | - |

| 标准包装 | 500 |

| 法兰直径 | 0.106"(2.69mm) |

| 焊尾直径 | - |

| 焊尾类型 | 无尾 |

| 特性 | - |

| 端接 | 压配式、 六角形 |

| 触头材料 | 铜铍 |

| 触头镀层 | 金 |

| 触头镀层厚度 | 30µin (0.76µm) |

| 长度-总 | 0.240"(6.10mm) |

- 商务部:美国ITC正式对集成电路等产品启动337调查

- 曝三星4nm工艺存在良率问题 高通将骁龙8 Gen1或转产台积电

- 太阳诱电将投资9.5亿元在常州建新厂生产MLCC 预计2023年完工

- 英特尔发布欧洲新工厂建设计划 深化IDM 2.0 战略

- 台积电先进制程称霸业界 有大客户加持明年业绩稳了

- 达到5530亿美元!SIA预计今年全球半导体销售额将创下新高

- 英特尔拟将自动驾驶子公司Mobileye上市 估值或超500亿美元

- 三星加码芯片和SET,合并消费电子和移动部门,撤换高东真等 CEO

- 三星电子宣布重大人事变动 还合并消费电子和移动部门

- 海关总署:前11个月进口集成电路产品价值2.52万亿元 增长14.8%

PDF Datasheet 数据手册内容提取

Product Number: 0342-0-15-15-42-27-10-0 Description: 0342 - Press-Fit Receptacle for Plated Through Hole (PTH) Accepts .059" (1.50mm) - .063" (1.60mm) diameter leads. Packaging: Packaged in Bulk Mill-Max Shell Plating Contact Plating RoHS Part Compliant Number 0342-0-15-15-42-27-10-0 10 μ" Gold over Nickel 30 μ" Gold over Nickel CONTACT: Contact Used: #42, Power Contact Current Rating = 20 Amps BERYLLIUM COPPER ALLOY 172 (UNS C17200) per ASTM B 194 Properties of BERYLLIUM COPPER: Chemical composition: Cu 98.1%, Be 1.9% Temper as stamped: TD01 Properties after heat treatment (TH01): Hardness: 36-43 Rockwell C Mechanical Life: 1000 Cycles Min. Density: .298 lbs/in3 Electrical Conductivity: 22% IACS* Resistance: 10 miliohms Max Operating Temperature: -55°C/+125°C Melting point: 980°C/865°C (liquidus/solidus) Stress Relaxation†: 96% of stress remains after 1,000 hours @ 100 °C; 70% of stress remains after 1,000 hours @ 200 °C *International Annealed Copper Standard, i.e. as a % of pure copper. †Since BeCu loses its spring properties over time at high temperatures; it is rated for continuous use up to 150°C. For applications up to 300°C, Mill-Max offers many contacts in Beryllium Nickel. Contact Tech Support for more info. Mill-Max Mfg. Corp. Datasheet — Last Modified 12/12/2018 Page 1 of 3

SHELL MATERIAL: BRASS ALLOY 360 per ASTM B 16, or 385 per ASTM B455 Properties of BRASS ALLOY 360 ASTM B 16: Chemical composition: Cu 63% (max), Pb 3.7% (max)†, Fe .35% (max), Zn remainder Temper as machined: H02/H04 Yield Strength: 25-45 ksi Tensile strength: 57-80 ksi Hardness as machined: 80-90 Rockwell B Electrical conductivity: 26% IACS* Melting point: 1000°C/840°C (liquidus/solidus) Properties of BRASS ALLOY 385 ASTM B 455: Chemical composition: Cu 60% (max), Pb 3.5% (max)†, Fe .35% (max), Zn remainder Temper as machined: H02/H04 Yield Strength: 16 ksi(min) Tensile strength: 48 ksi(min) Hardness as machined: 80-90 Rockwell B Electrical conductivity: 28% IACS* Melting point: 1000°C/840°C (liquidus/solidus) After machining, brass parts are often annealed (softened) for subsequent bending, swaging or crimping. A partial anneal down to 60±10 RB is recommended for 90° bends, a full anneal down to 35±15 RB is recommended for pins or terminals that are swaged (riveted) to a circuit board or crimped to a wire. †RoHS-2 directive 2011/65/EU, exemption 6c allows up to 4% lead as an alloy agent in copper. *International Annealed Copper Standard, i.e. as a % of pure copper. Certificate of Compliance: This is to Certify that the product described above is manufactured to Mill-Max quality standards in accordance with all applicable specifications and drawing. Mill-Max certifies this product to be free from defects of materials and workmanship. This Certificate of Compliance covers the following requirements: Dimensional (all features verified to be within tolerances described on the applicable drawing). Raw Material (materials and properties verified to be as described on the applicable drawing). Plating (platings as required, thickness verified, and performance including solderability per mil-standard). Performance (insertion extraction or other force requirements as described on the applicable drawing). Compliance Statement for RoHS and RoHS-2, on the restriction of the use of certain hazardous substances in electrical and electronic equipment, for Mill-Max products. 1. Directive 2015/863/EU of 31 March 2015 amending Annex II to Directive 2011/65/EU of the European Parliament and of the Council as regards the list of restricted substances. 2. Directive 2011/65/EU of the European Parliament and of the Council of 8 June 2011 on the restriction of the use of certain hazardous substances in electrical and electronic equipment (recast) 3. Directive 2002/95/EC of the European Parliament and of the Council of January 27 2003 on the restriction of the use of certain hazardous substances in electrical and electronic equipment. In reference to the directives described above, Mill-Max Mfg.Corp. certifies that its product labeled as RoHS and RoHS-2 are compliant to the above directives with exemption 6c, (copper alloy containing up to 4 % lead by weight). No warranty or liability of indemnification is expressed or implied with this information. Compliance Statement for Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) Reference: 1. Regulation EC No 1907/2006 of the European Parliament and of the Council of 18 December 2006, concerning the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) 2. ECHA, Candidate list of Substances of Very High Concern (SVHC) http://echa.europa.eu/reach_en.asp Mill-Max is aware of the regulation and the SVHC list the EU published (referenced above). Mill-Max does not produce or sell any of the listed substances in their homogeneous form. These substances are not intentionally added during the manufacturing of any Mill-Max products. To our knowledge, our products do not contain the substances described on the ECHA SVHC list. Testing is not performed for materials and substances that were not intentionally added. No warranty, liability of indemnification is expressed or implied with this information. Mill-Max maintains surveillance of the ECHA website to obtain the latest information and periodically reviews the SVHC list for changes and additions. Compliance Statement for DRC Conflict Free products. Reference: Dodd-Frank Wall Street Reform and Consumer Protection Act, Section 1502, reporting requirements for users of conflict minerals. �Conflict minerals,� are Columbite-tantalite (coltan), cassiterite, gold, wolframite, or their derivatives; or any other mineral or its derivatives determined by the Secretary of State to be financing conflict in the Democratic Republic of the Congo (DRC) or an adjoining country. Metals derived from these minerals are tin, tantalum, tungsten, and gold. By this definition, Mill-Max Mfg. Corp. Datasheet — Last Modified 12/12/2018 Page 2 of 3

(DRC) or an adjoining country. Metals derived from these minerals are tin, tantalum, tungsten, and gold. By this definition, the only minerals of concern that may be found in Mill-Max products are tin and gold. Mill-Max Mfg.Corp. hereby certifies that its products are manufactured with tin and gold that is derived from material that is considered DRC Conflict Free. Mill-Max provides this assurance as a result of a due diligence process that includes traceability to the source and in some cases the identification of recycled and scrap materials included in the subject material. Mill-Max Mfg. Corp. Datasheet — Last Modified 12/12/2018 Page 3 of 3

Mouser Electronics Authorized Distributor Click to View Pricing, Inventory, Delivery & Lifecycle Information: M ill-Max: 0342-0-15-15-42-27-10-0 0342-0-15-01-42-01-10-0 0342-0-15-80-42-27-10-0

Datasheet下载

Datasheet下载